Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "Improve physical quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

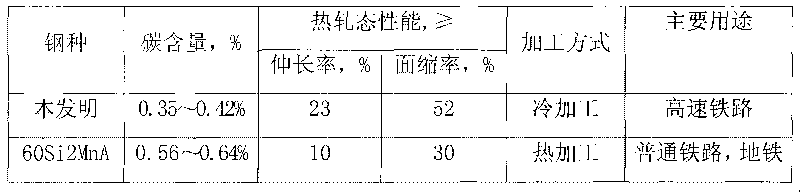

Manufacturing process of spring steel wire rod

InactiveCN101716721AReduce carbon contentLow physical qualityTemperature control deviceProcess efficiency improvementWire rodElectric arc furnace

The invention belongs to the field of metallurgy and discloses a manufacturing process of a spring steel wire rod, which comprises the following steps: preparing raw materials, smelting the raw materials in an EAF eccentric bottom tapping electric arc furnace, refining the raw materials outside an LF furnace, performing vacuum degassing (VD) treatment, performing CCM continuous casting, performing shot blasting on a continuous casting billet, performing flaw detection, polishing, heating and rolling to manufacture the steel wire rod by a high-speed wire-rod rolling mill. The manufacturing process of the invention has the advantages of simple process, low energy consumption, less investment equipment and high production efficiency; and compared with the spring steel wire rod used by the traditional domestic railway spring strip, the spring steel wire rod of the invention has the advantages of low carbon content, good plasticity and toughness, delivery in the form of the steel wire rod, high size precision and yield, and good quality of a real object, capacity of being machined into the steel wire rod, and low manufacturing cost.

Owner:NANJING IRON & STEEL CO LTD

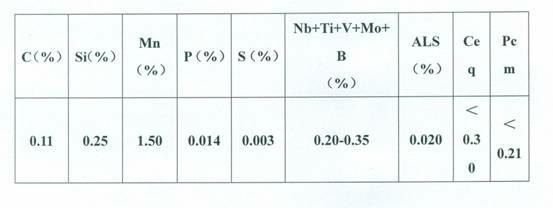

Steel plate made of bainite structure high-strength toughness structural steel Q550D(E) and production method thereof

InactiveCN102051522AImprove physical qualityLarge performance marginProcess efficiency improvementSheet steelChemical composition

The invention discloses a steel plate made of bainite structure high-strength toughness structural steel Q550D(E) and a production method thereof. The steel plate comprises the following chemical ingredients in percentage by mass: 0.05-0.15 percent of C, 0.10-0.40 percent of Si, 1.40-1.65 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.30 percent of micro alloying element (V+Nb+Ti+Mo+B), less than or equal to 0.050 percent of Als and the balance of Fe and residual elements. The production method comprises the following steps of: pretreating molten iron; smelting in a converter; refining in an LF (Ladle Furnace); carrying out VD (Vacuum Degassing); carrying out continuous steel casting; heating; carrying out TMCP (Thermo Mechanical Control Process) rolling; controlling cold; and stacking for slow cooling. In the invention, in the rectifying and reforming processes from molten steel treatment to steel plate stacking for slow cooling and rectification, a strict process point control standard is formulated and executed, thus the mass quality of a product is good, and the margin performance is larger, wherein the yield margin is 50-100MPa, the tensile margin is 30-60MPa, the elongation margin is 2-4 percent, and the impact property reaches the level of -60 DEG C; and the TMCP process is adopted for producing qualified products at a time without quenching and tempering, thus the production cost is greatly reduced.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Novel method for controlling casting blank pull rate of round continuous casting machine

ActiveCN103537642ALess attention should be paid to the straightening temperature of the slabOvercoming technical biasMechanical engineeringContinuous caster

The invention belongs to the technical field of alloy steel continuous casting and particularly relates to a novel method for controlling casting blank pull rate of a round continuous casting machine. The method for controlling the casting blank pull rate includes two stages. Stage one, before a continuous casting blank is released from a dummy bar head (about 10-30 minutes), the pull rate of the casting blank is set according to a traditional method that the pull rate is set according to actual degree of superheat of middle bag molten steel. Stage two, after the casting blank is released from the dummy bar head, the actual pull rate of the casting blank is determined according to the actual temperature of the casting blank surface of the casting blank in a straightening section, namely actual pull rate data of the casting blank is adjusted according to surface actual data of the casting blank at the straightening section position, the casting blank is released from a dangerous temperature range of 723-912 DEG C of a theoretical brittleness temperature range as soon as possible, possibility of cracks on the casting blank surface due to casting blank self texture phase change is greatly reduced, and the middle bag molten steel temperature is also considered. By means of the method, the phenomenon that cracks are prone to occur on a billet surface of an arc large round continuous casting machine is effectively reduced or basically avoided, under the premise that the casting blank quality is guaranteed, the whole production efficiency of the continuous casting machine is greatly improved, casting blank yield is further improved, and large round continuous casting blank surface quality is well improved.

Owner:SHANDONG XIWANG SPECIAL STEEL

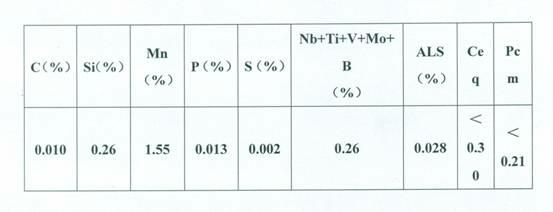

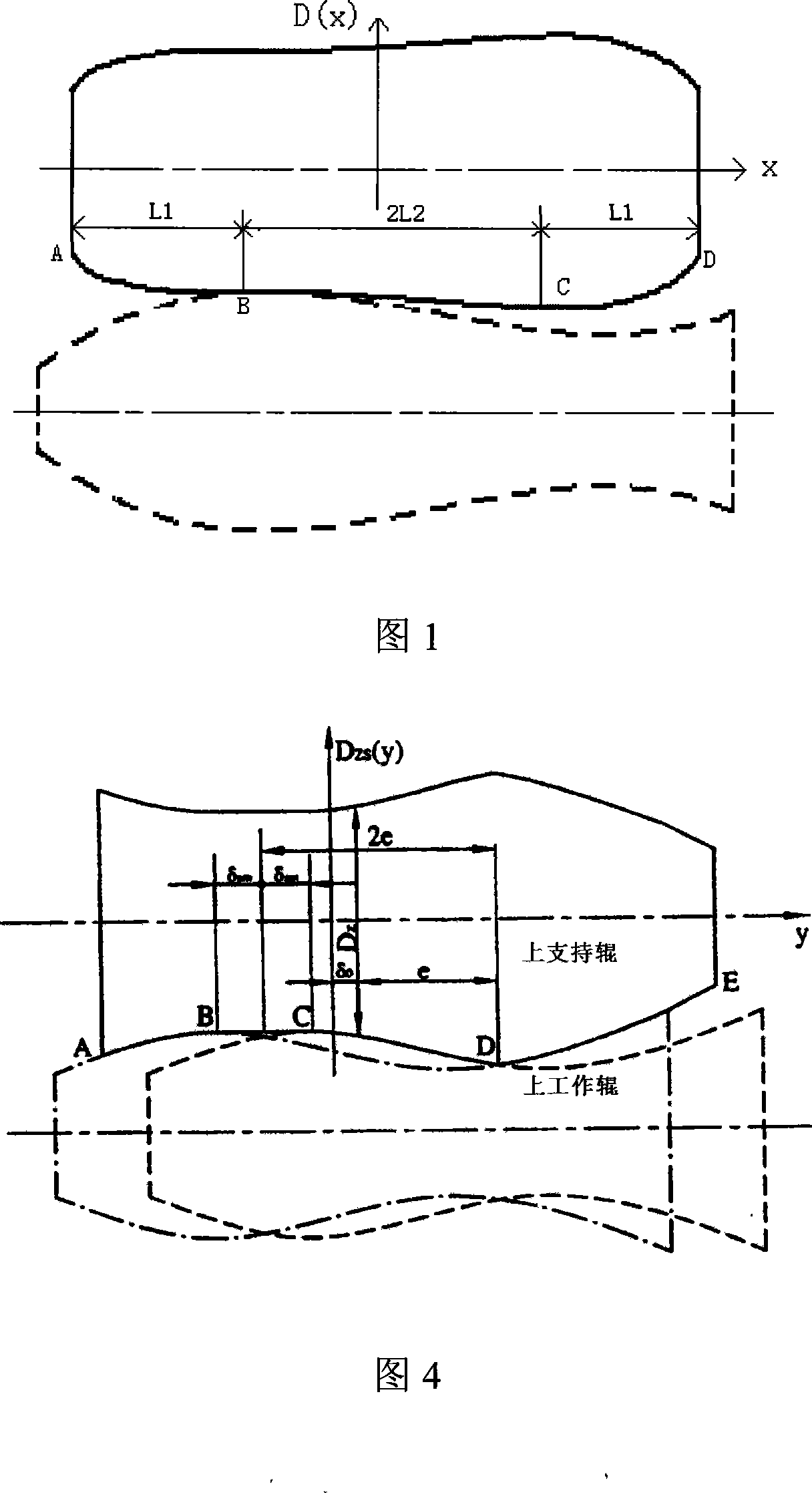

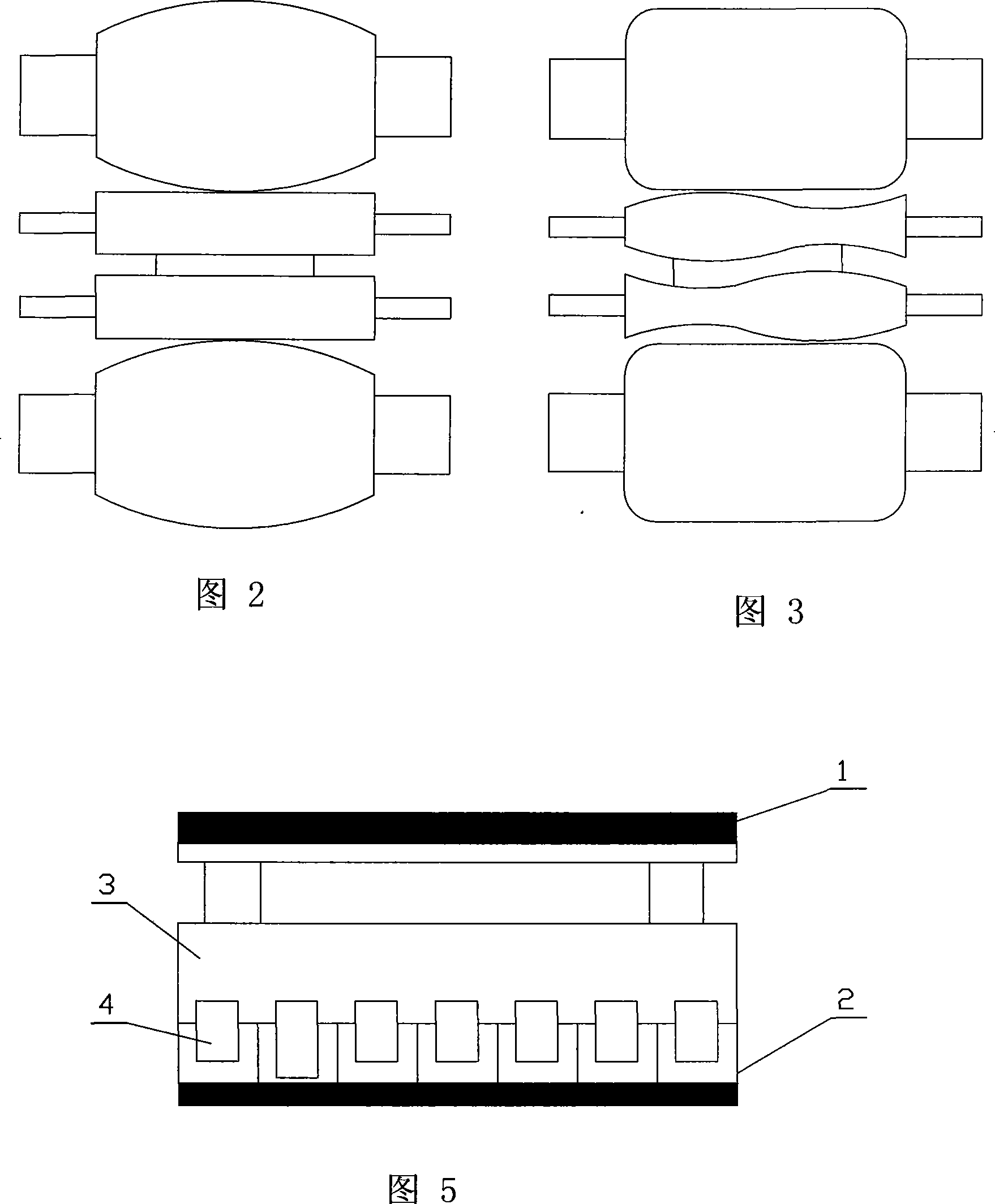

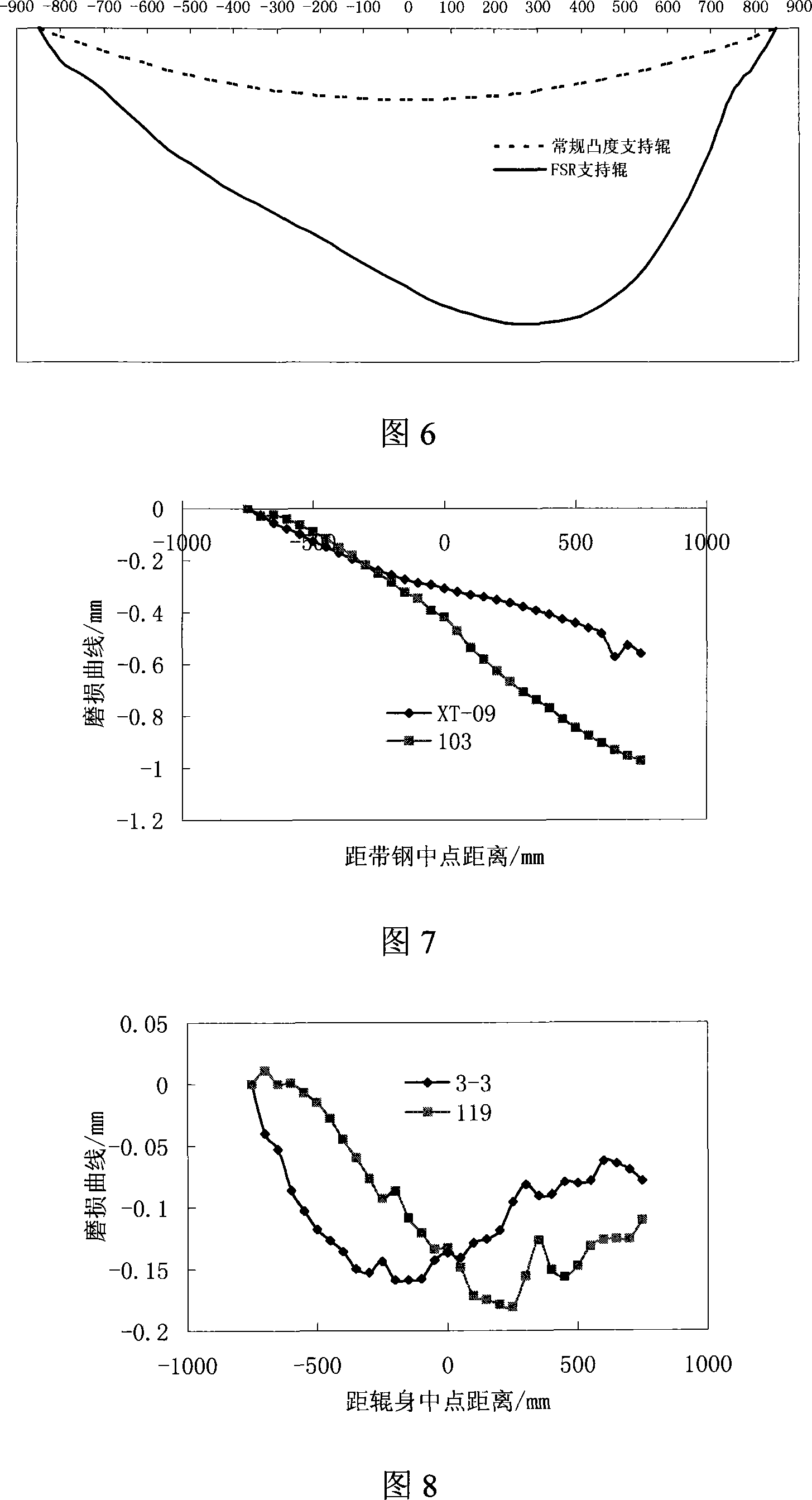

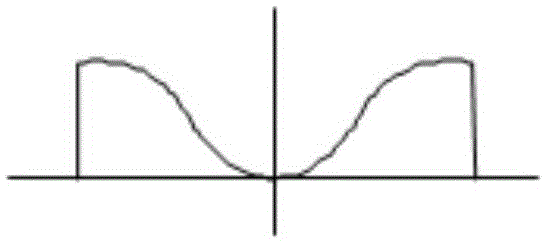

Continuous variational convexity degree rolling mill back-up shaft

InactiveCN101229560AExtended service periodImprove roll gap lateral stiffness characteristicsCounter-pressure devicesMetal rolling arrangementsContact pressureWork roll

The invention provides a continuously variable crown mill support roll to be matched with a roll curve of a continuously variable crown work roll. The roll shape is skew asymmetrical curve which essentially consists of a roll gap whole line contact curve section in the range of the strip width at the middle of the roll body and a contact line variable curve section at two ends of the roll; and the roll shape curves of an upper support roll and a lower support roll are the same but are arranged reversedly in an angle of 180 degrees The continuously variable crown mill support roll with the roll shape curve and the mill roll system with the continuously variable crown work roll can not only reduce uneven distribution and peak of the contact pressure between the roll, reduce or eliminate side spalling of the continuously variable crown mill support roll with normal crown, improve service cycle and service life of the support roll and reduce roll consumption of the support roll, but also overcomes harmful contact zone outside the rolled strip width and improves roll gap lateral rigidity of the mill and plate shape control efficiency of bending force, thereby improving plate shape quality of the rolling strip.

Owner:武汉钢铁有限公司 +1

Surface-treated pigments

InactiveUS20060042511A1Improve chemical qualityImprove physical qualityFatty acid chemical modificationSynthetic resin layered productsChemistrySaturated fatty acid

Inorganic pigments, having deposited on the pigment surface at least one ester or partial ester of an organic polyol and a hydroxy group-functionalized saturated fatty acid, possess improved processibility and dispersibility in thermoplastic materials, and impart improved properties to thermoplastic compositions containing said surface-treated pigments.

Owner:KERR MCGEE CHEM CORP

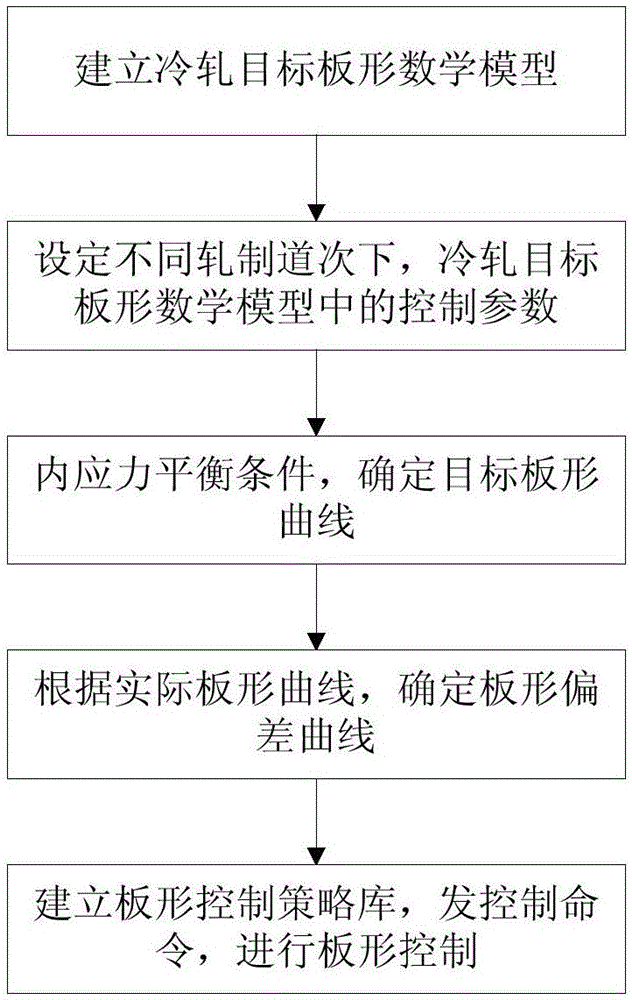

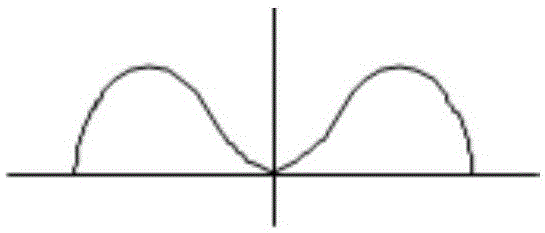

Strip shape control method based on target strip shape settings of cold-rolled strip steel

ActiveCN106475420AImprove calculation accuracyQuality is easy to controlProfile control deviceMathematical modelShape deviation

The invention discloses a strip shape control method based on target strip shape settings of cold-rolled strip steel. The control method includes the steps of establishing a mathematical model of cold rolling target strip shapes; setting control parameters of the mathematical model of the cold rolling target strip shapes in different rolling passes according to different rolling technology requirements of different rolling passes; determining a target strip shape curve; obtaining a strip shape deviation curve by measuring actual strip shape curves of each pass in real time; and establishing a strip shape control strategy database according to the strip shape deviation curve, sending control commands and carrying out strip shape control. According to the control method, the product quality can be improved, the production efficiency can be improved, the rolling stability can be improved, and the problems that existing control modes do not adapt to settings of high-temperature rolling target strip shapes of thin strip steel, fine setting and controlling cannot be realized according to target strip shapes of a machine frame or passes and the control quality of strip shapes of the thin strip steel is poor can be solved.

Owner:BAOSHAN IRON & STEEL CO LTD

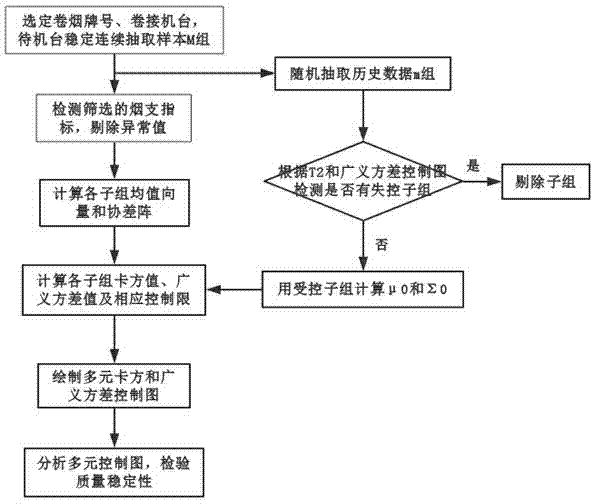

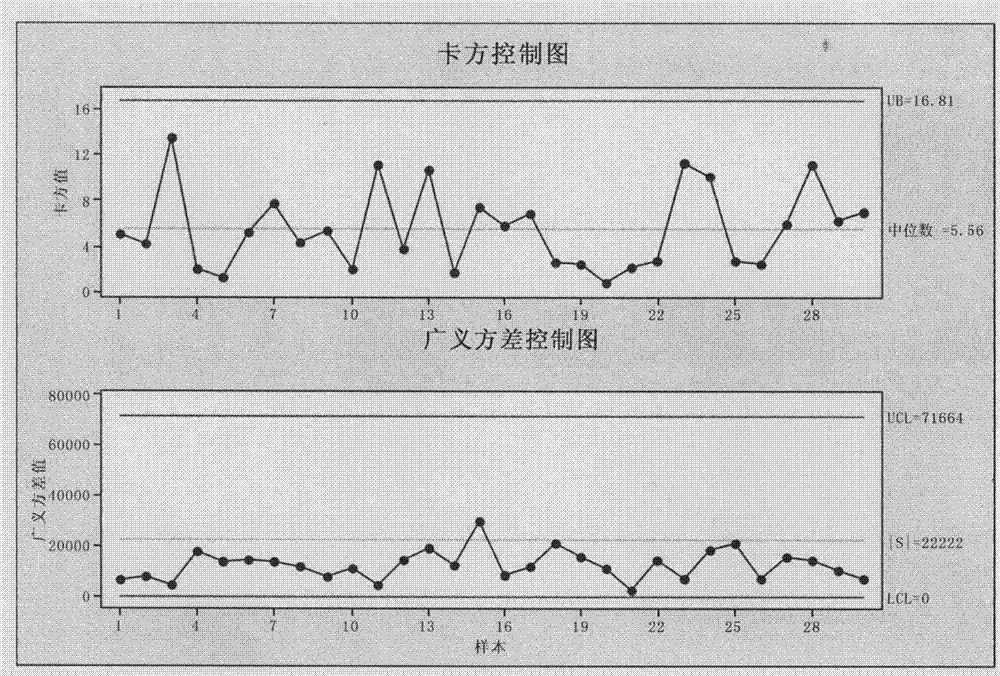

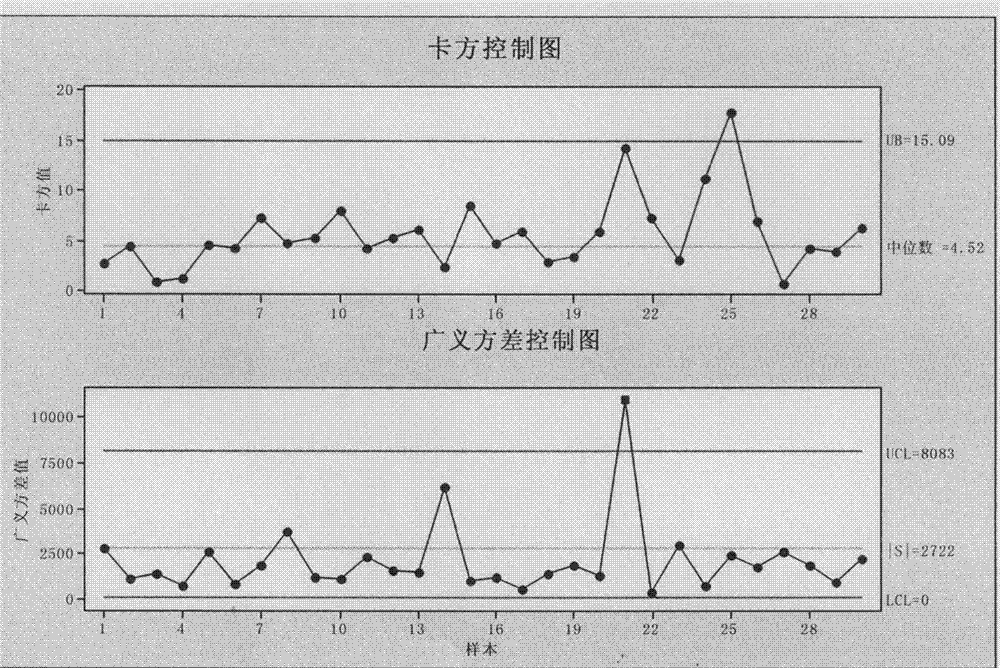

Method for inspecting cigarette rolling quality stability in cigarette processing

ActiveCN104503402AImprove stabilityImprove physical qualityTotal factory controlProgramme total factory controlMultivariate control chartsMultivariate statistical process control

The invention provides a method for inspecting the cigarette rolling quality stability in cigarette processing. The method is characterized in that a multivariate control chart tool in a statistical process control method is used for inspecting the integral rolling quality stability of a plurality of physical index expressions of the cigarettes. According to the method, the multivariate statistical process control theory is used, firstly, the controlled historical data estimation is carried out to obtain mu0 and Sigma0, then, x<2> and the absolute value of S statistical quantity for control are calculated according to the field collection data, and the deviation condition of the multi-index average value vector from the standard value and the sample in-group dispersing degree in the cigarette processing process can be controlled, so that the combined monitoring of a plurality of quality feature variables is realized, and the integral quality stability of the cigarette rolling integral process can be reasonably evaluated. The method has the important significance on improving the cigarette physical quality and improving the stability of the cigarette rolling process.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Green sanitary aquatic products produced by using marine lives as bioreactor and method

InactiveCN1759718AFast growthNo harmful drug residuesClimate change adaptationAnimal feeding stuffAquatic animalBioreactor

A method for producing the health-care aquatic products, such as fish, tortoise and trutle, by using said living aquatic animals as bioreactor is disclosed. Said health-care aquatic products contains the active components of one or more of 16 edible funguses including ganoderma, champignon, cordyceps, etc and / or the active components of one or more of 21 Chinese-medicinal materials including aloe, ginseng, astragalus root, wolfberry fruit, etc. Its advantages are sure heath-care function, no environmental pollution and special taste.

Owner:吴跃飞

Compound type yoghurt stabilizer and preparation method thereof

PendingCN105211674AImprove survival rateHigh content of live bacteriaMilk preparationFood preparationTremellaGlutaminase

The invention discloses a compound type yoghurt stabilizer and a preparation method thereof, which belong to the technical field of yoghurt stabilizer preparation. The compound type yoghurt stabilizer is prepared by taking modified dietary fibers with high water holding capacity, expansibility, thickening property and adsorptivity as well as abundant grid structure as main raw materials, scientifically compounding a plant extract and protein hydrolysate which contain high-content natural antifreeze peptides, Chinse herbal medicinal extracts with cold and heat stress resistance, sodium carboxymethylcellulose, pectin, tremella polysaccharide, transglutaminase and other food raw materials and refining; the prepared compound type yoghurt stabilizer has the advantages that the quality problems about low viscosity, rough texture, poor mouthfeel, whey separating and the like in the late-stage storage process of yoghurt are solved; in addition, the viable content of lactic acid bacteria in the yoghurt is obviously improved, and the shelf life is prolonged to over twenty-one days; besides, the yoghurt is good in solidifying state, and is suitable for long-distance transportation.

Owner:NINGXIA HAIDA BIOTECH DEV

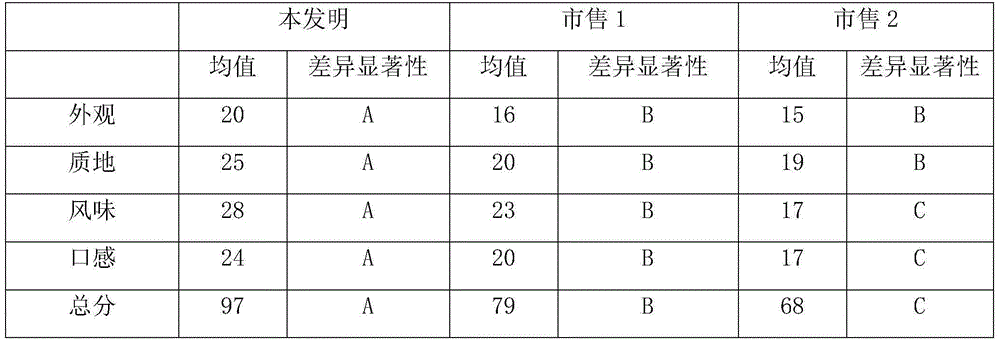

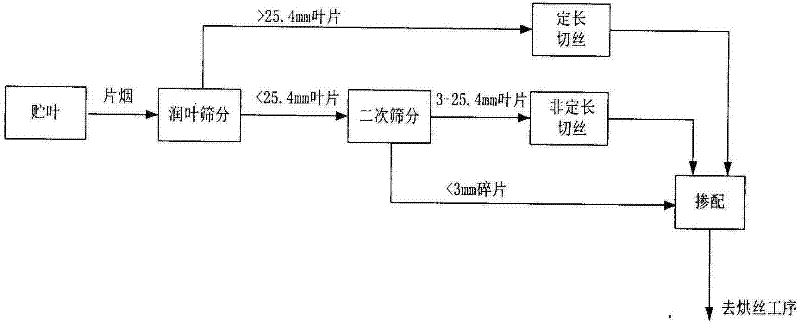

Tobacco flake sorting method based on flake-shaped structure grouping processing

InactiveCN102342580AImprove structural uniformityImprove physical qualityTobacco preparationMechanical engineeringMaterials science

The invention discloses a tobacco flake sorting method based on flake-shaped structure grouping processing, comprising the following concrete process flows of: outputting flaked tobacco by a leaf storage cabinet, then, enabling the flaked tobacco to enter into a conditioning and sieving unit, conditioning and loosing the flaked tobacco, and meanwhile, sieving to obtain tobacco flakes larger than and smaller than 25.4mm; feeding large tobacco flakes into a shredding unit with a length-limit shredding mode; further secondarily sieving small tobacco flakes to obtain tobacco flakes smaller than 3mm and tobacco flakes with the length of 3-25.4mm; feeding the secondarily sieved tobacco flakes with the length of 3-25.4mm into the other shredding unit with a non-length-limit shredding mode; and directly mixing the sieved tobacco flakes with the length of 3mm with cut tobacco obtained after the large tobacco flakes and the tobacco flakes with the length of 3-25.4mm are cut without shredding, and then entering a subsequent cut tobacco drying process. The tobacco flakes are subjected to multistage sorting by combining roller type conditioning and loosing sieving and orifice plate type vibrating sieving, thus, the grouping processing of a shredding process of different flaked raw materials can be realized, the stability of physical quality of cigarette products is improved, and the tobacco flake sorting method is easy to realize on the basis of the traditional cut tobacco preparing and processing equipment.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Finishing mill collar assembly and detection method

InactiveCN101704189ALow failure rateImprove assembly qualityMeasuring devicesMetal working apparatusRelative displacementWire rod

The invention relates to a finishing mill collar assembly and detection method, aiming to increase the assembly quality of the wire stock finishing mill collar and reduce the fault. The method of the invention comprises the following steps: sleeving a collar on an axle head through a taper sleeve, exerting an axial force to the taper sleeve to ensure that the taper sleeve generates elastic deformation and no relative displacement exists between the collar and the axle head; using a 0.05-0.10mm of filler gauge to detect whether the straight-line segment of the axle head and the taper sleeve has the clearance or not, wherein if part of the filler gauge can not be squeezed in, the grinding deformation point is needed to be removed for installing the filler gauge again; installing the standard taper sleeve without the collar on the axle head to be measured, pressurizing to 20MPa, and using an outside micrometer to separately measure the outside diameter of the deformed taper sleeve at a plurality of positions for comparison, wherein when the average difference reaches 0.04 mm, the axle head of the mill is needed to change.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

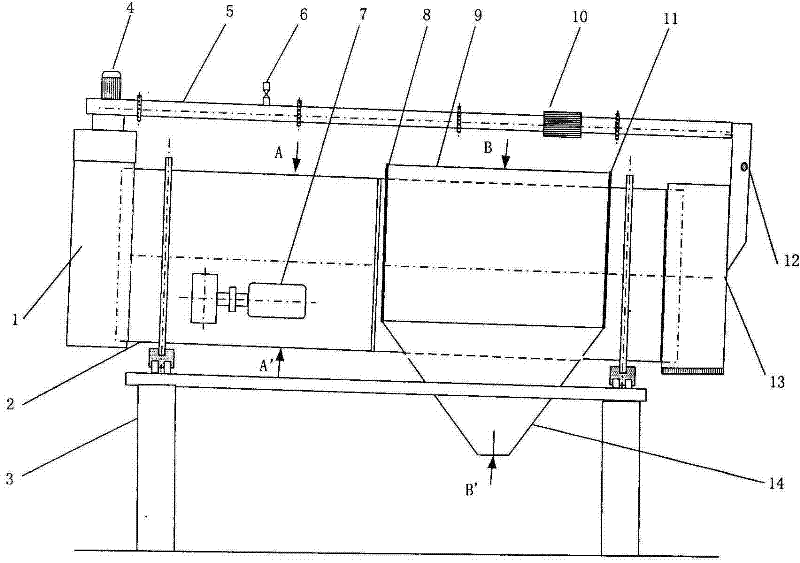

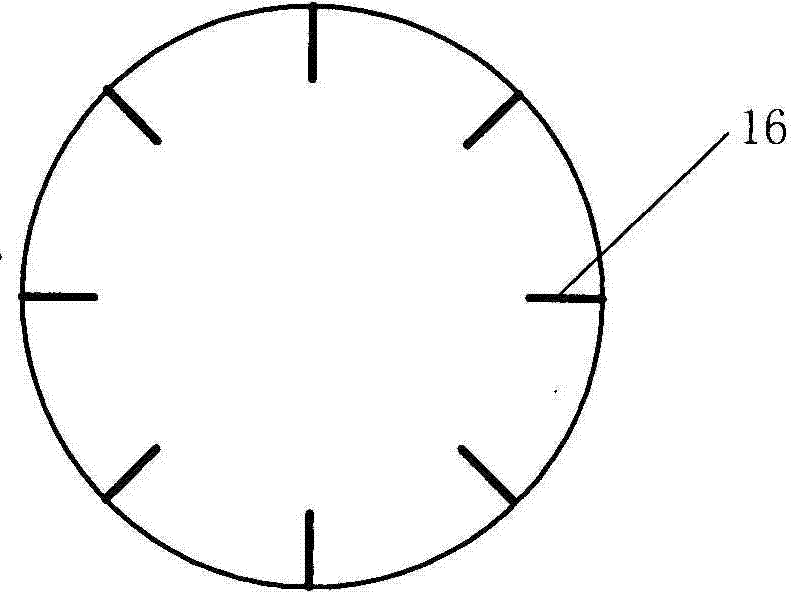

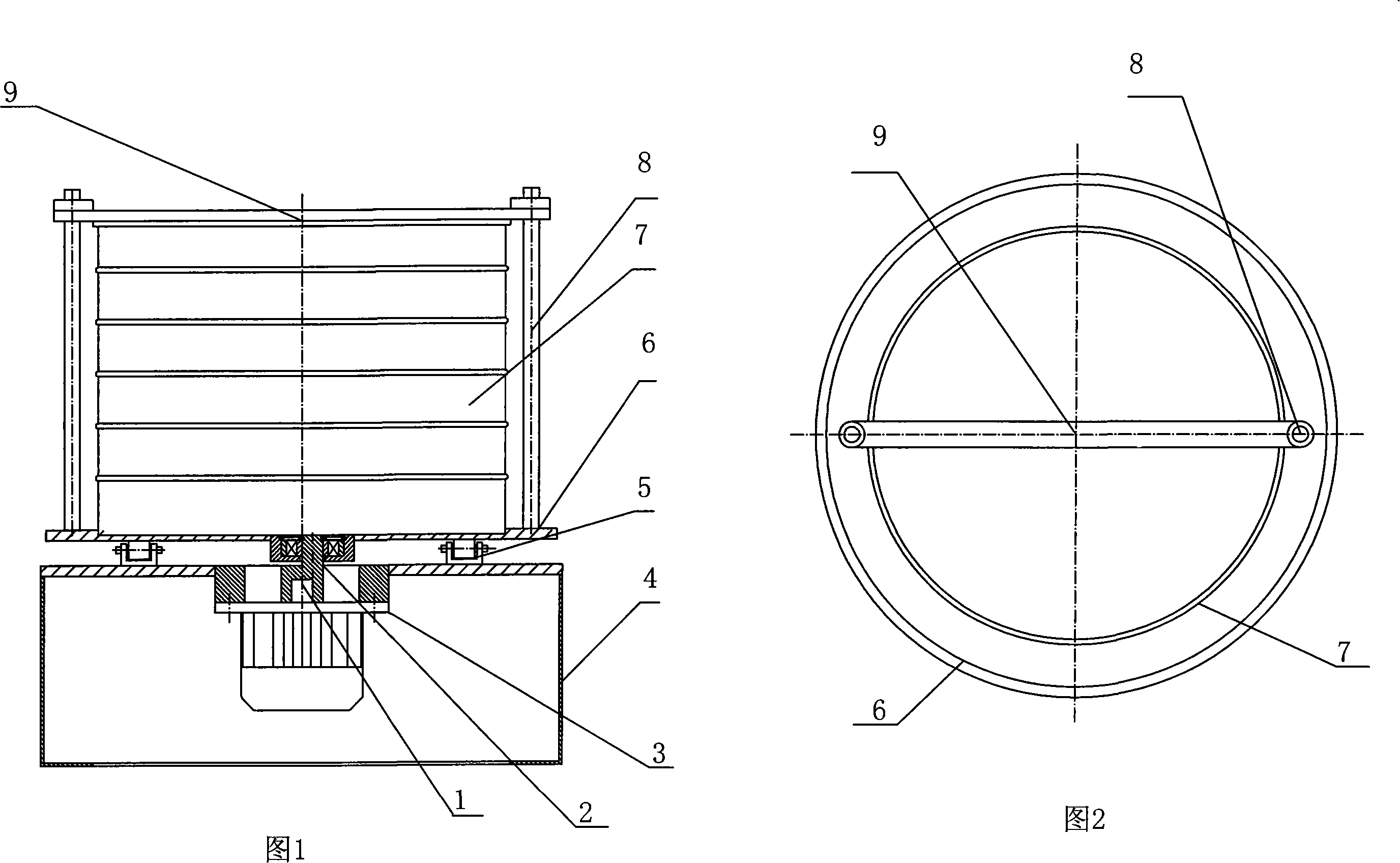

Cut tobacco structure measuring method and its vibrating screen

InactiveCN101109683AAvoid mistakesThe preventer is interceptedCigarette manufactureMaterial weighingEngineeringSieve

The invention relates to a method for determining the structure of cut tobacco and a testing vibration sieve for that, which is characterized in that, certain amount of cut tobacco sample to be tested is placed on a sieve mesh at the top layer of a testing sieve comprising a plurality layers of sieves that are placed layer by layer according to the sieve mesh sizes; all sieves moves horizontally in set frequency, so that all cut tobacco in size less than the mesh at the top layer will fall on the second layer of sieve, all cut tobacco in size less than the mesh at the second layer will fall on the third layer of sieve, and so on; in this way, the cut tobacco of different structural sizes can be separated; finally, by weighing, the masses of different cut tobaccos can be obtained; and the proportions of different cut tobaccos can be obtained through dividing the masses of different cut tobaccos by the total mass of the sample. The invention provides an integral and feasible way for rapidly determining the structure of cut tobaccos.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +3

Surface-treated pigments

ActiveUS20060042510A1Improve chemical qualityImprove physical qualityInorganic pigment treatmentPolyolInorganic pigments

Inorganic pigments, having deposited on the pigment surface at least one alkenyl- or alkyl-substituted succinic anhydride and at least one organic polyol, possess improved processibility and dispersibility in thermoplastic materials, and impart improved properties to thermoplastic compositions containing said surface-treated pigments.

Owner:TRONOX LLC

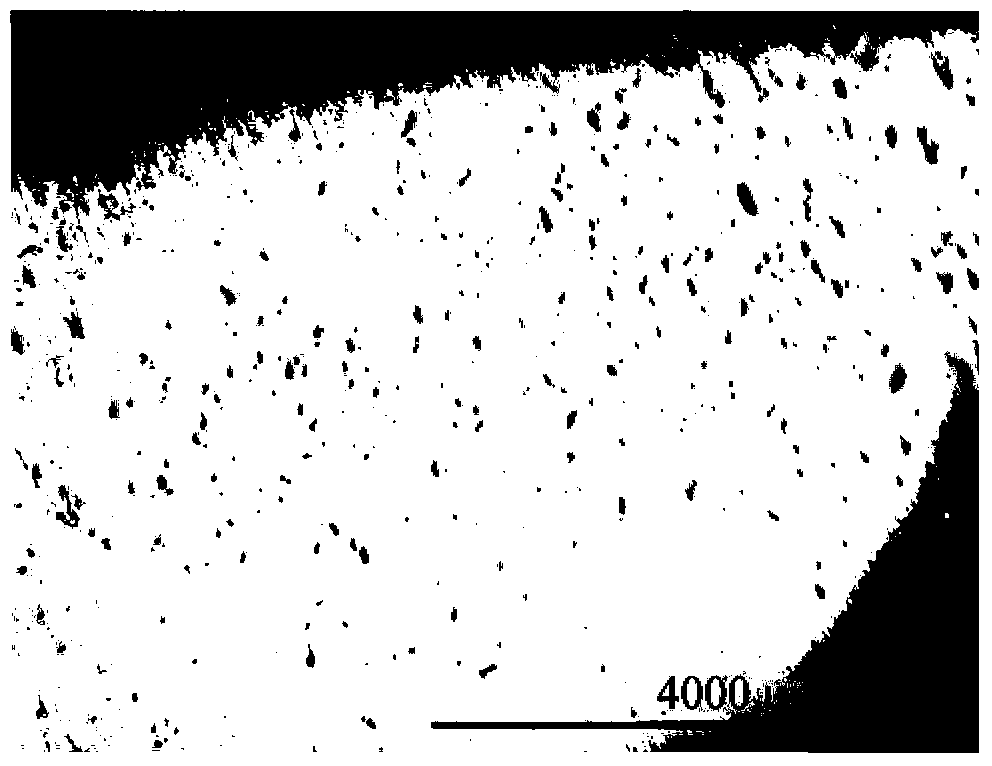

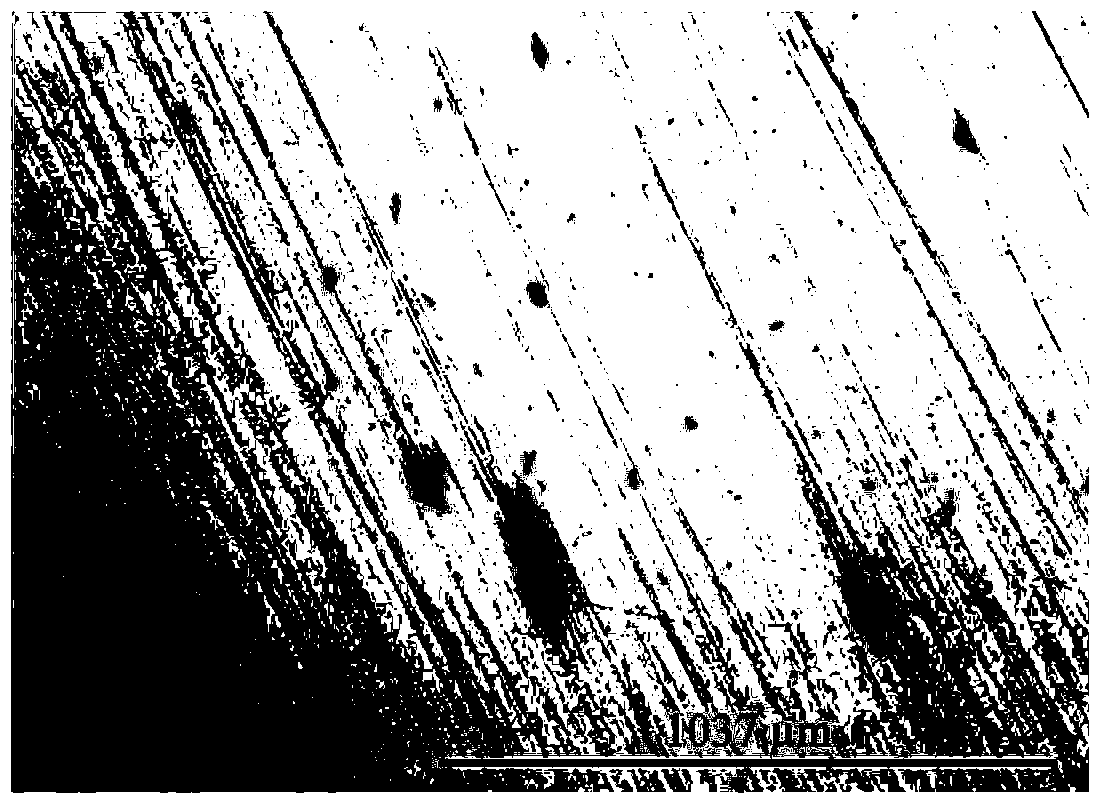

Method for detecting microporous defect at heart part of cold-drawn seamless steel tube

InactiveCN104007177AEasy to detectAccurate detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationEngineeringMechanical engineering

The invention provides a method for detecting the microporous defect at the heart part of a cold-drawn seamless steel tube. The method comprises the following steps: selecting sample pieces; performing ultrasonic flaw detection on the sample pieces; regulating a gain knob of an ultrasonic flow detector to ensure that the height of the bottom wave at the first time is A and fixing the gain knob to acquire the ultrasonic flow detector with determined detection sensitivity; scanning the cold-drawn seamless steel tube to be detected by using the ultrasonic flow detector with determined detection sensitivity along the axial direction, recording the height X of the bottom wave at the first time of all parts of the cold-drawn seamless steel tube to be detected, and representing whether the heart part of the cold-drawn seamless steel tube to be detected has the microporous defect or not by using decibel difference 201g(A / X) between the height A of the bottom wave at the first time and the height X of the bottom wave at the first time of a certain part of the cold-drawn seamless steel tube to be detected. According to the method, the microporous defect at the heart part of the cold-drawn seamless steel tube can be conveniently and accurately detected, and the method has the significant meaning on improvement of the quality of real objects of cold-drawn seamless steel tube products.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

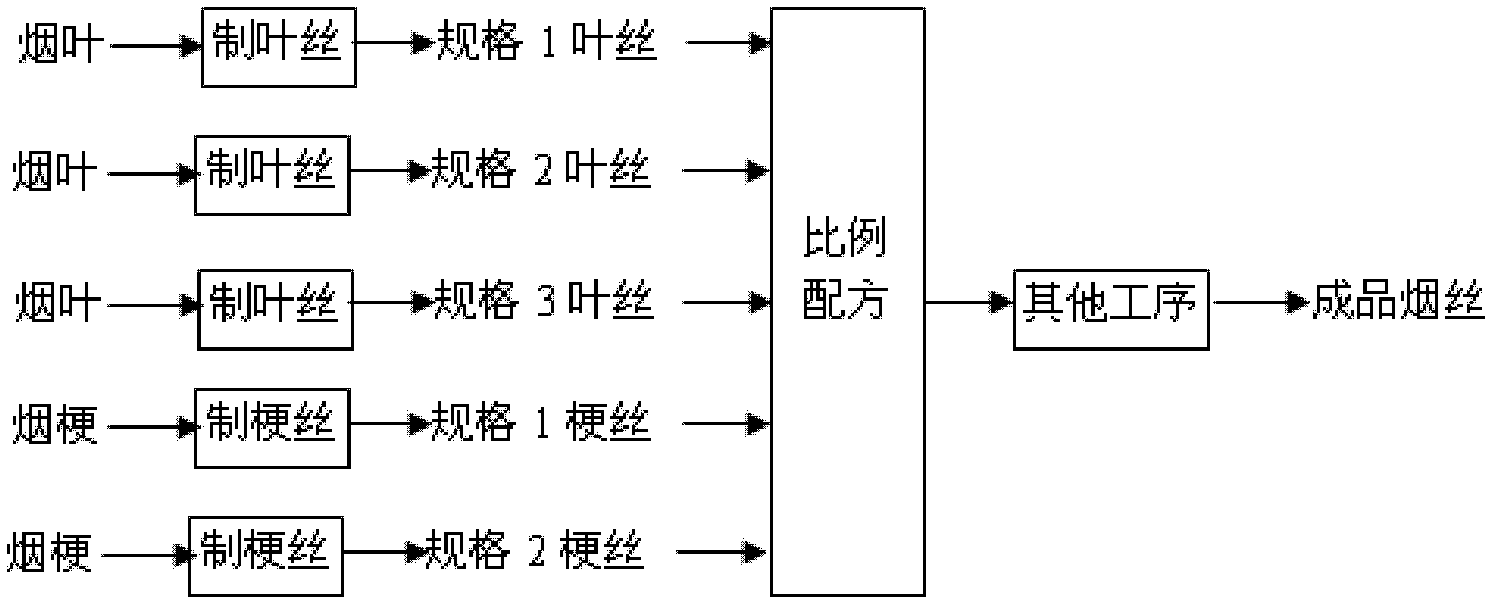

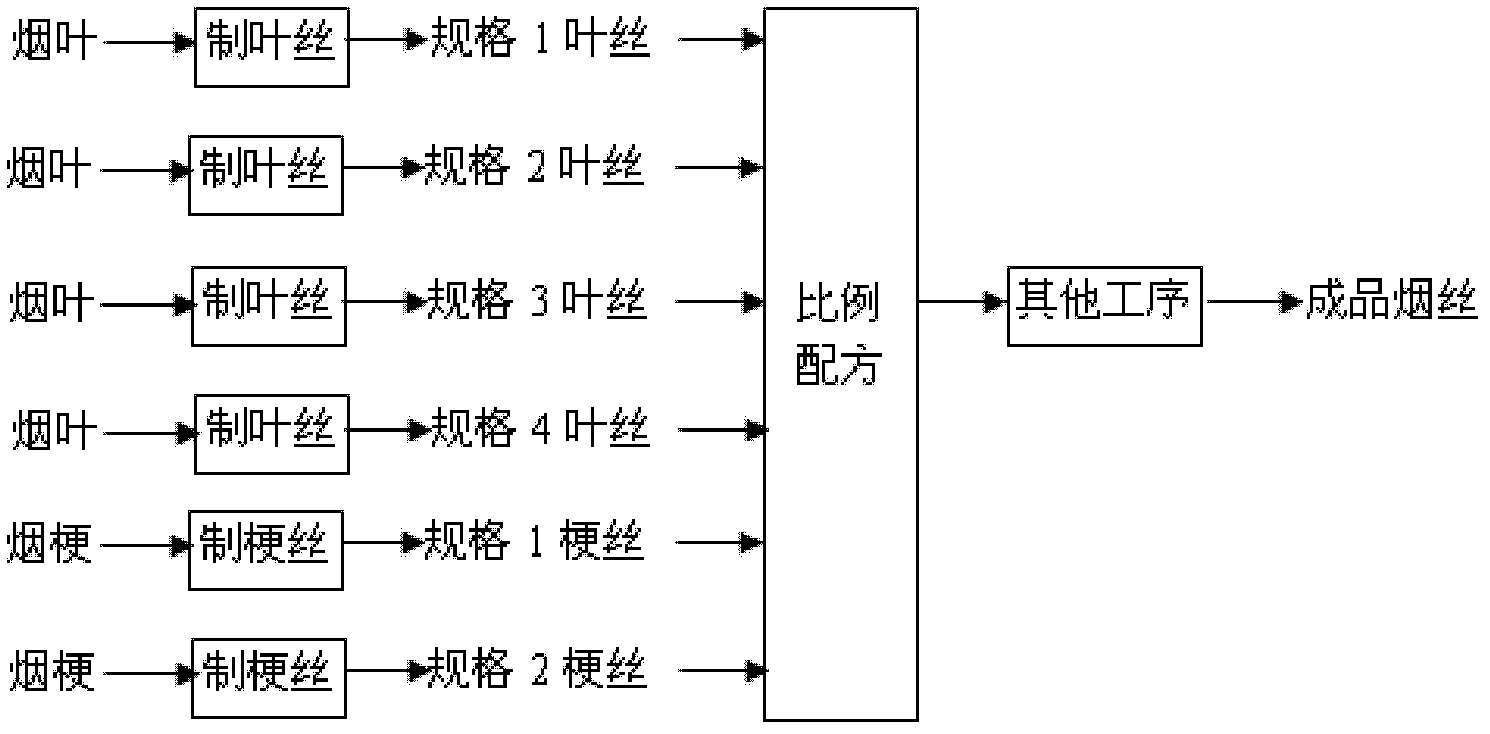

Matching method based on physical form of tobacco shred

InactiveCN102631018AQuality improvementImprove stabilityTobacco preparationDensity distributionEngineering

The invention discloses a matching method based on the physical form of tobacco shred. The method comprises the following steps of: according to size, respectively preparing the tobacco into leaf shred and stalk shred which are different in length and width by using different tobacco shred preparing processes, mixing the leaf shred and the stalk shred which are different in length and width according to the formula proportion design of cigarette, and finally processing into the finished tobacco shred by follow-up processing steps. According to the method, the differential selection of the cigarette trade mark to the tobacco shred structure can be realized, so that the even distribution of the tobacco shred in the cigarette can be improved, the stability of the physical quality and the chemical constituents of the cigarette can be effectively improved, and the loss in the process of processing can be reduced. A tobacco shred classifying working procedure is performed after the tobacco shred is baked, so that the mixing evenness of the tobacco shred and the other components in the formula can be improved. The tobacco shred structure of the cigarette can be effectively improved, so that the evenness of the tobacco shred density distribution in the cigarette can be improved, and the physical quality of the cigarette can be improved. The method is convenient to operate, and good in application prospect.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Method for determining tobacco shred structure in cigarette

InactiveCN1885002AImprove splicing qualityReduce weightMaterial weighingVibration amplitudeEngineering

The invention relates to a method for testing the structure of thread tobacco of cigarette, which is characterized in that: a, arranging cigarette into the condition as temperature at 20+-2 Deg. C and humidity is 65+-5%, then taking out the cigarette, to be uniformly divided into two parts, and taking out the thread tobacco from the cigarette; b, inputting two sample thread tobaccos into seven-layer screener to be screened for two times, while the vibration amplitude is 55-70 and the time is 10-20 minutes; c, using laminated weighting, recording the weight of thread tobacco of each layer after each screening, to calculate out the total weight; d, comparing the weight of each layer with the total weight, to obtain the ratio of each layer; e, adding the ratios of same layer of two times of screening, to obtain the average value, to test the ratio of different thread tobacco in the cigarette.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

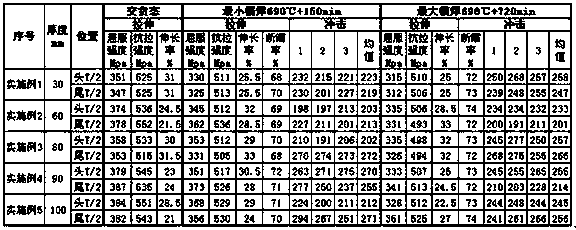

Production method of 15CrMoR steel plates for equipment in hydrogen service

InactiveCN109518079AImprove cleanlinessLarge amount of wealthProcess efficiency improvementSheet steelHydrogen

The invention discloses a production method of 15CrMoR steel plates for equipment in hydrogen service. Steel is prepared from chemical components including, by weight, 0.10%-0.15% of C, 0.16%-0.25% ofSi, 0.42%-0.52% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.020%-0.050% of Alt, 0.90%-1.10% of Cr, 0.46%-0.56% of Mo, less than or equal to 0.010% of Sn, less thanor equal to 0.012% of As, less than or equal to 0.003% of Sb and the balance Fe and residual elements; and the tempering embrittlement coefficient X is equal to (10P+5Sb+4Sn+As)*10<-2> and is less than or equal to 15 ppm. The production technology process includes smelting in a converter, refinement in an LF, VD vacuum treatment, continuous casting, slab heating, controlled rolling, online coolingand heat treatment. Various actual product quality properties of the products produced with the method are as follows: head and tail samples of the steel plates are subjected to maximum simulated postweld heat treatment, the yield margin at the 1 / 2-plate-thickness positions of the samples ranges from 40 MPa to 100 MPa, the tensile margin ranges from 50 MPa to 80 MPa, and the low-temperature impact property is stable and large in margin.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Cut tobacco structure measuring method and its vibrating screen

InactiveCN101109684AAvoid mistakesThe preventer is interceptedCigarette manufactureMaterial weighingEngineeringMechanical engineering

The invention relates to a method for determining the structure of cut tobacco and a testing vibration sieve for that, which is characterized in that, certain amount of cut tobacco sample to be tested is placed evenly on a conveying belt, and a sieve mesh at the top layer of a testing sieve comprising a plurality layers of sieves that are placed layer by layer according to the sieve mesh sizes is supplied with cut tobacco by the conveying belt at set speed; the cut tobacco in size bigger than the mesh at the top layer will go into a first cut-tobacco collecting and weighing container, the rest will go to the second layer; the cut tobacco in size bigger than the mesh at the second layer will go into a second cut-tobacco collecting and weighing container, the rest will go to the third layer, and so on; in this way, the cut tobacco of different structural sizes can be separated; finally, by weighing, the masses of different cut tobaccos can be obtained; and the proportions of different cut tobaccos can be obtained through dividing the masses of different cut tobaccos collected in each cut-tobacco collecting and weighing container by the total mass of the sample.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +3

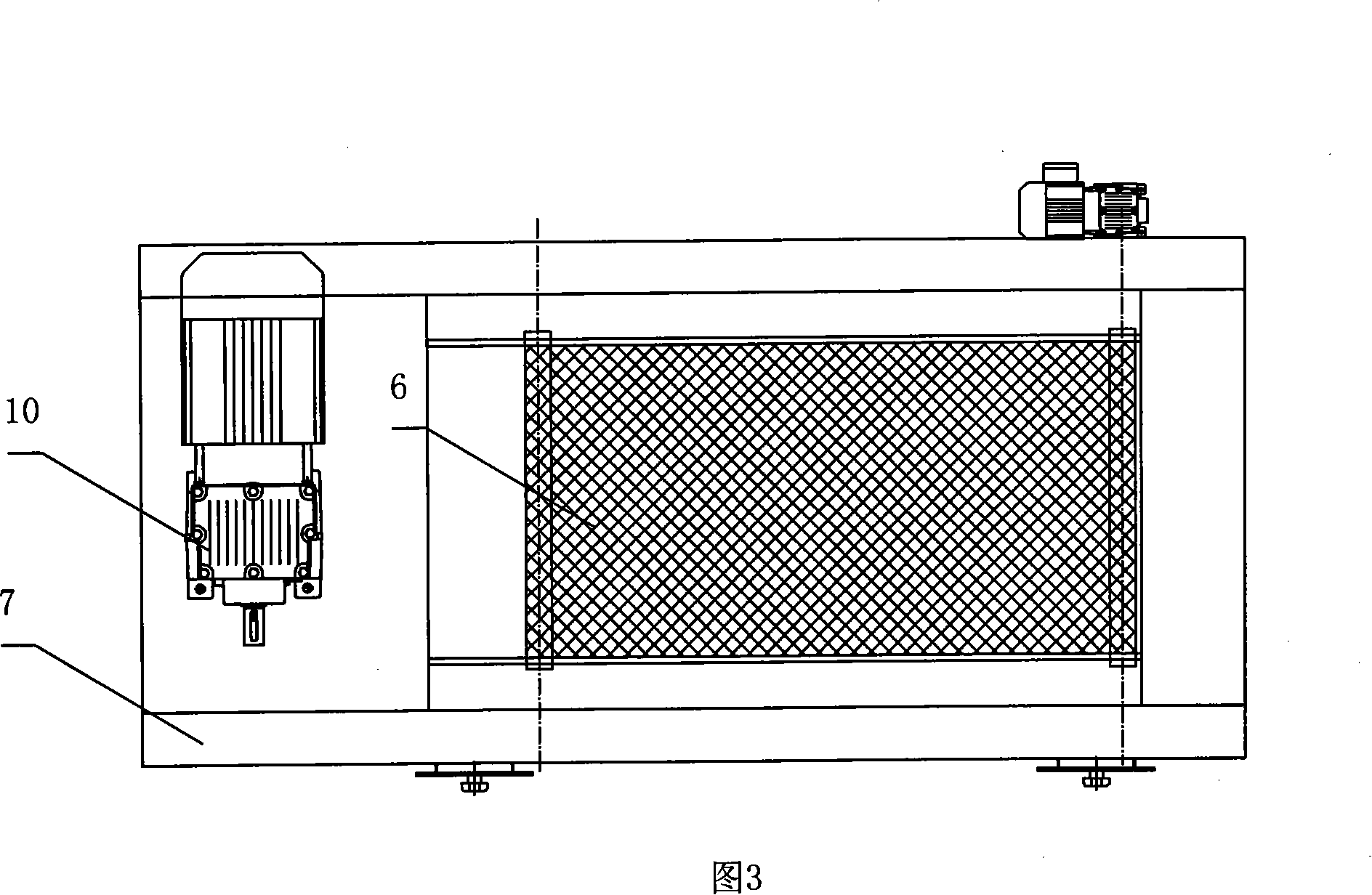

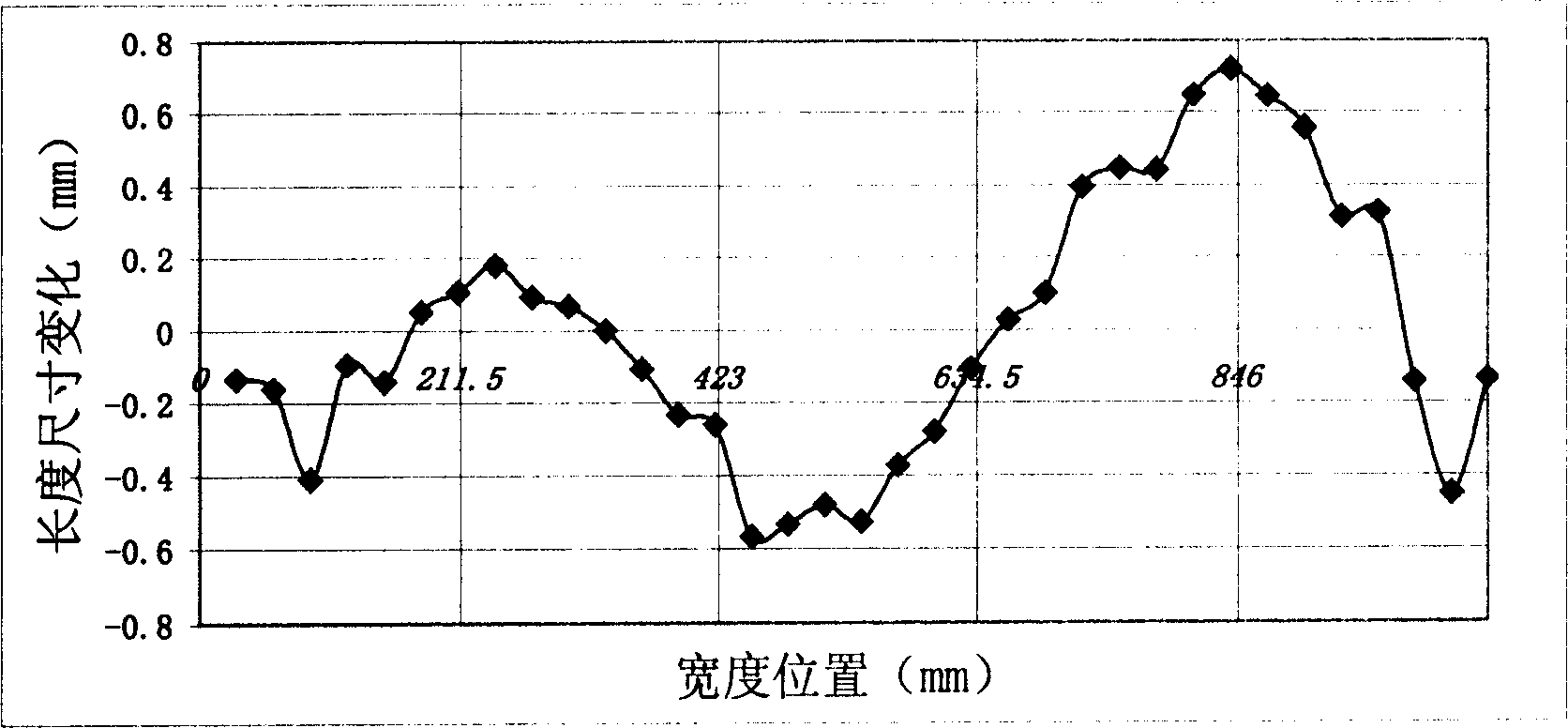

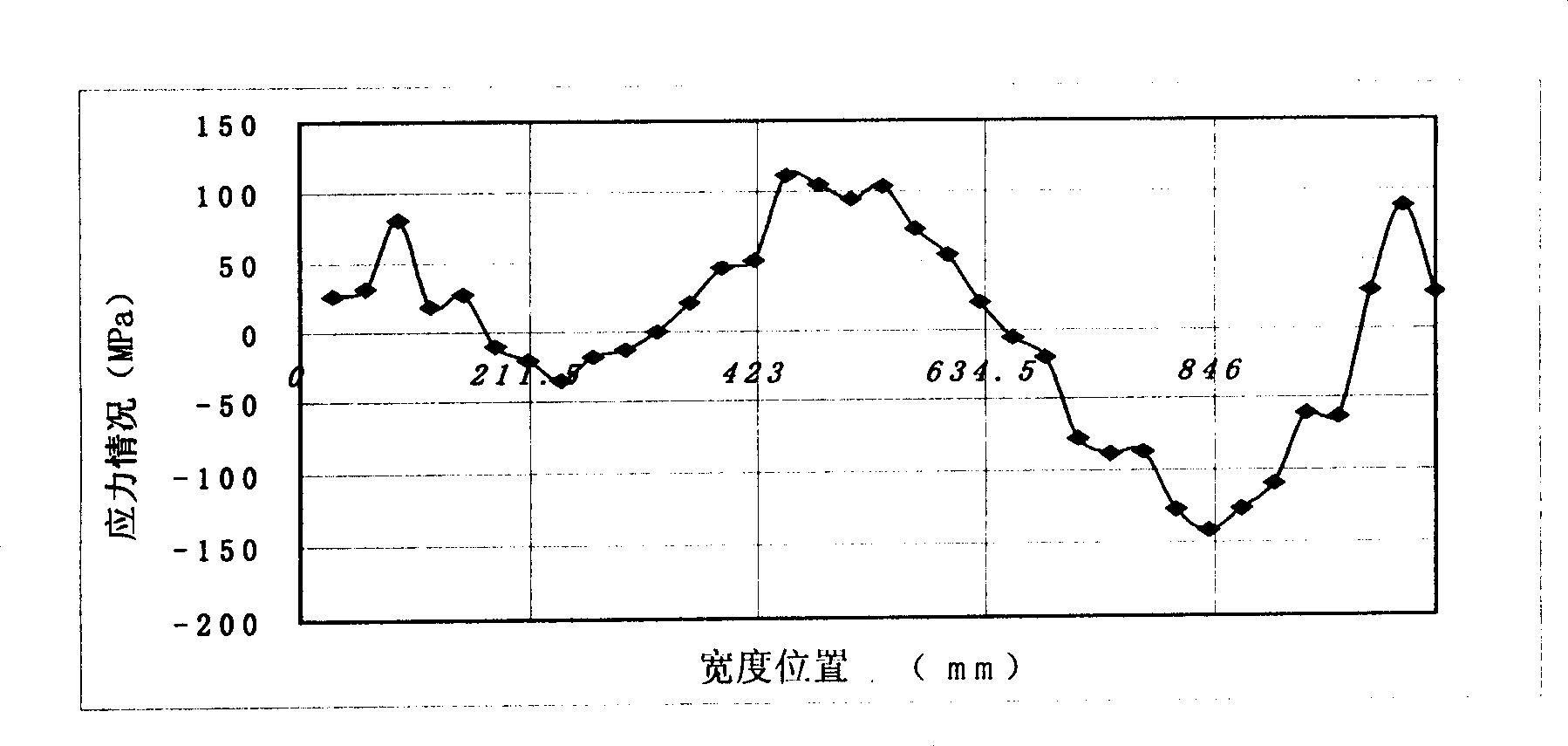

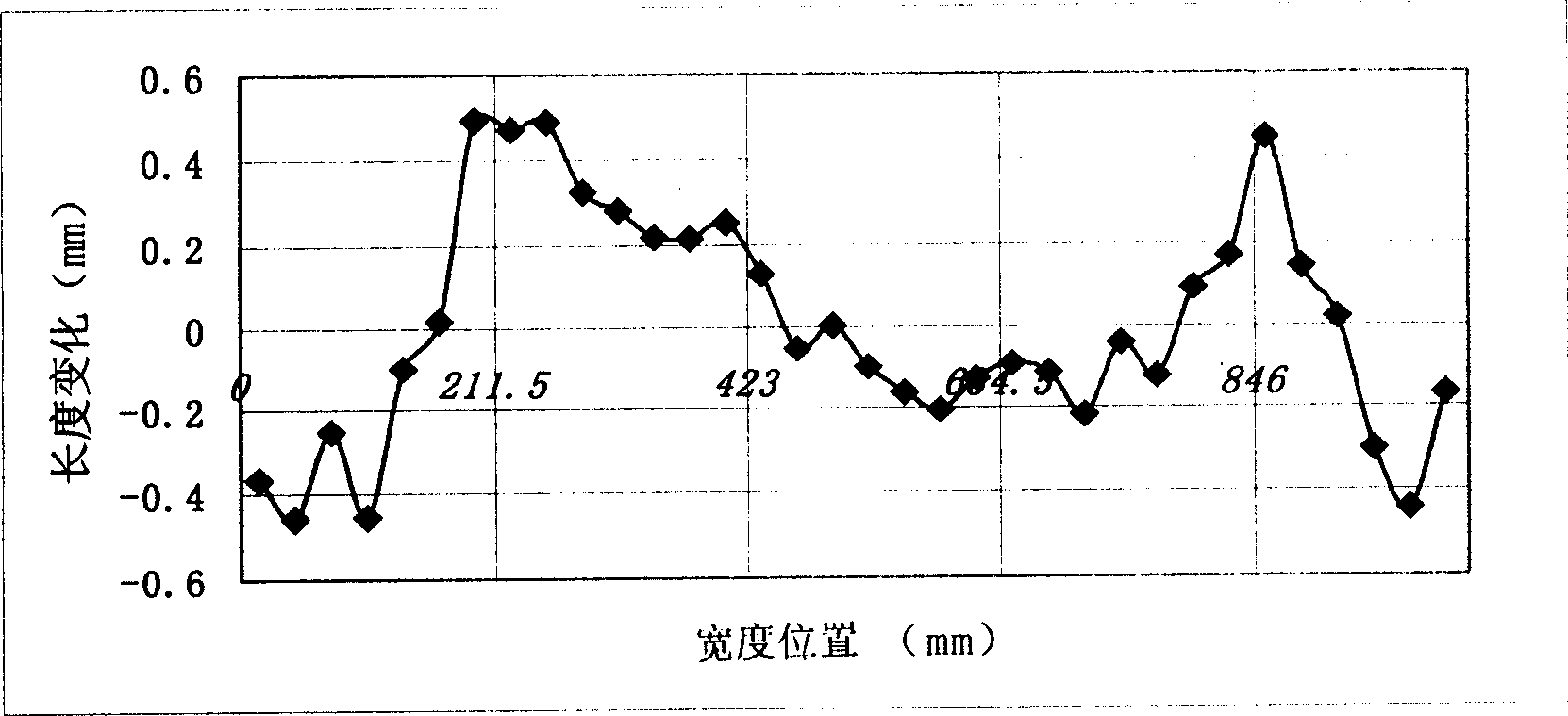

Detecting method for cold rolled steel strip inner stress

InactiveCN1474170AImprove sheet forming performanceEasy to operateForce measurementSteel platesSheet steel

The method of detecting internal stress of cold rolled steel strip includes the following steps: cutting 500-1500 mm long detection sample in the stable rolled part of the steel strip; cutting two ends of the sample to ensure the effective length; cutting the sample into several sample pieces of specified size while maintaining the sample piece order; measuring the lengths of the sample pieces and describing the change of the sample pieces in coordinate curves; converting the length change of the sample pieces into the stress of the sample pieces based on Hooke's law; and drawing stress distribution curves in width of the rolled steel strip. The present invention can describe the internal stress distribution of steel strip and is significant in guiding the improvement of steel strip form.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

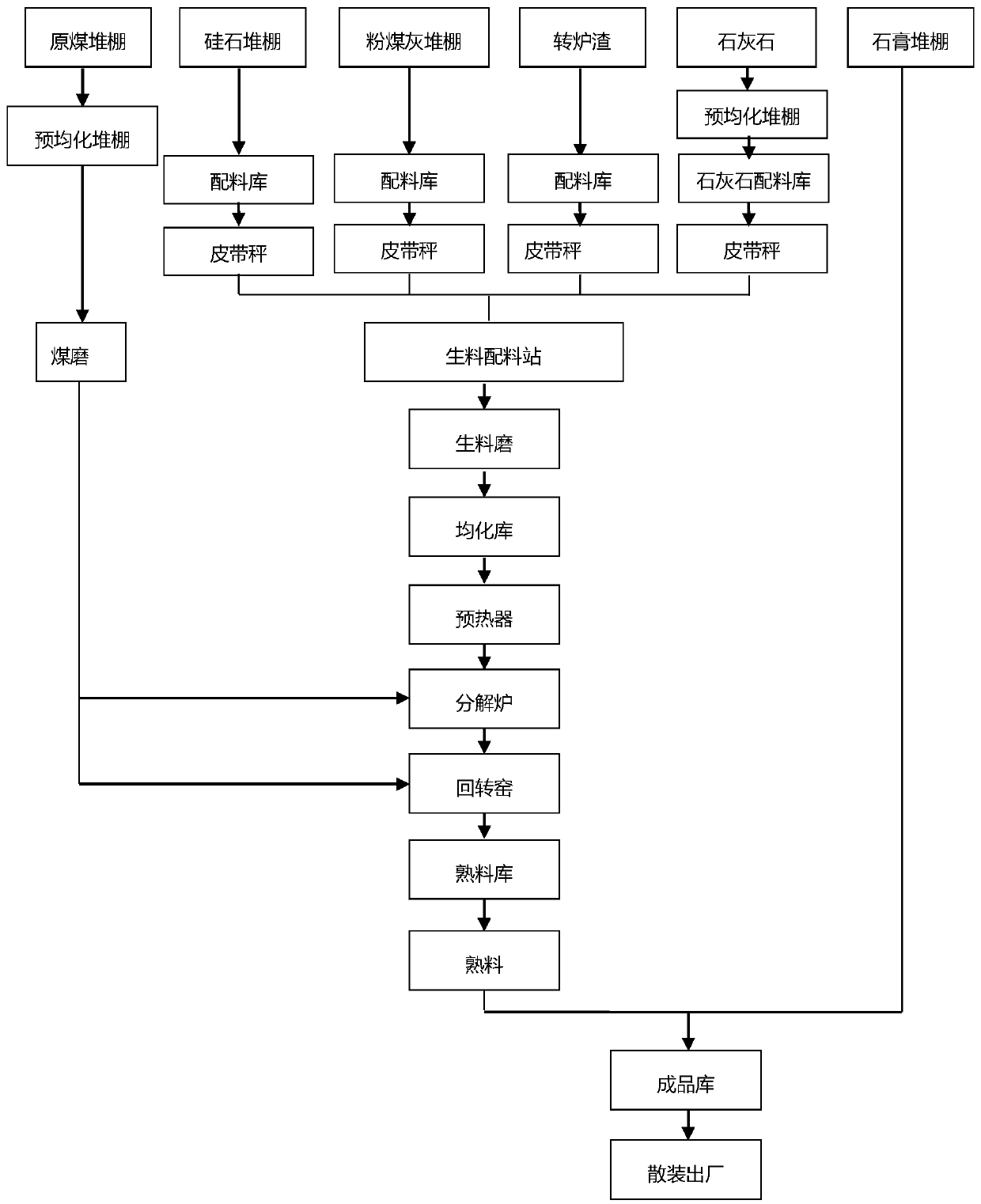

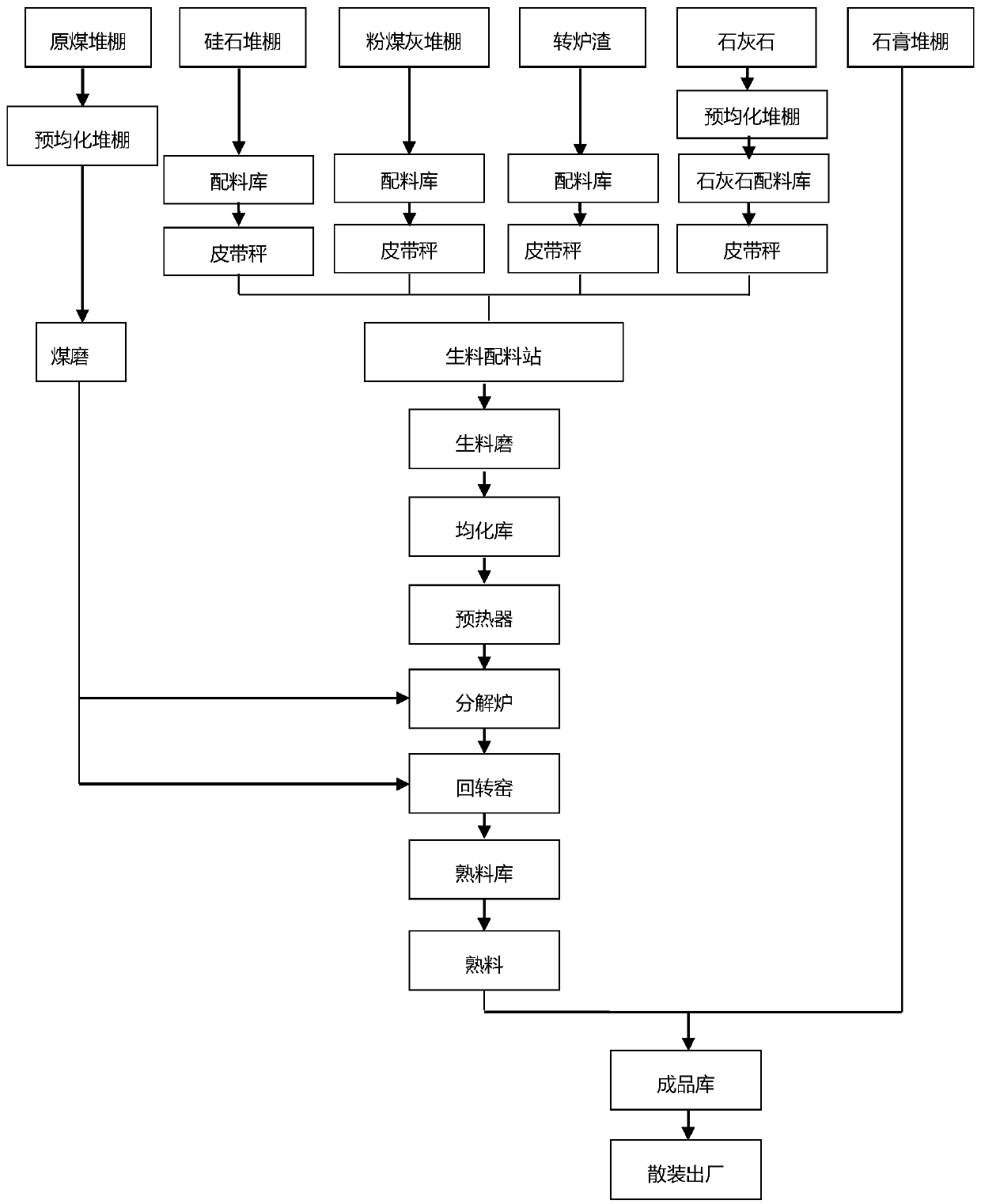

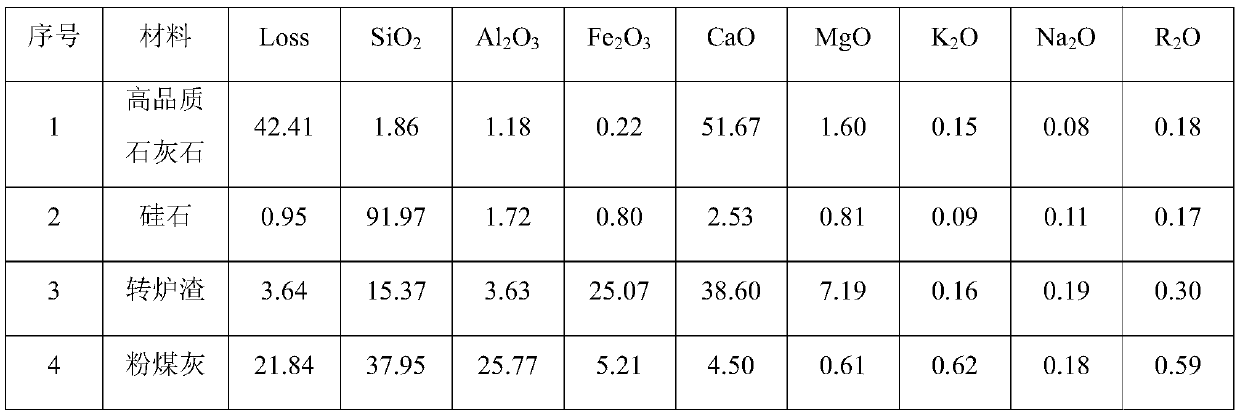

Airport road cement production process

ActiveCN111170664ALow alkali contentReduce heat of hydrationSolid waste managementSocial benefitsClinker (waste)

The invention discloses an airport road cement production process. A method mainly comprises the following steps: 1, proportioning four raw materials of high-quality limestone, fly ash, converter slagand silica to obtain a raw material; sequentially performing grinding, homogenization treatment, and high-solid-gas-ratio suspension preheating pre-decomposition, then firing the clinker in a novel dry-method rotary kiln, and carrying out cement milling on 96.0% of clinker, 4.0% of gypsum and 0.06% of grinding aid to prepare the cement. According to the invention, the alkali content in the cementis reduced, so that the physical quality of the cement is improvedand the hydration heat of the cement is reduced; therefore, the damage of alkali-aggregate reaction to concrete is prevented, the service life of the airfield pavement can be greatly prolonged, and the resource waste is reduced, so that huge economic and social benefits are generated.

Owner:陕西富平生态水泥有限公司

Rare earth Al-Ca-Fe alloy for rare earth micro-treated steel and preparation method thereof

The invention relates to a rare earth Al-Ca-Fe alloy for rare earth micro-treated steel and a preparation method thereof, and belongs to the technical field of ferroalloys. The rare earth Al-Ca-Fe alloy comprises, by weight, 28-65% of aluminum, 0.5-5% of calcium, 0.1-0.99% of rare earth, less than0.05% of impurity element carbon, less than0.4% of silicon, 0.02% of sulfur, less than0.02% of phosphor, less than1% of inevitable impurities and the balance ferrum. According to the preparation method, the finished alloy which meets requirements is prepared by utilizing pure aluminum ingots, rare earth, calcium metal and low-carbon high-quality scrap steel through a three-step method smelting process of an induction furnace. The rare earth Al-Ca-Fe alloy and the preparation method have the advantages that consumption of rare earth is reduced and the cost is reduced.

Owner:包头市北科创业高新材料有限责任公司

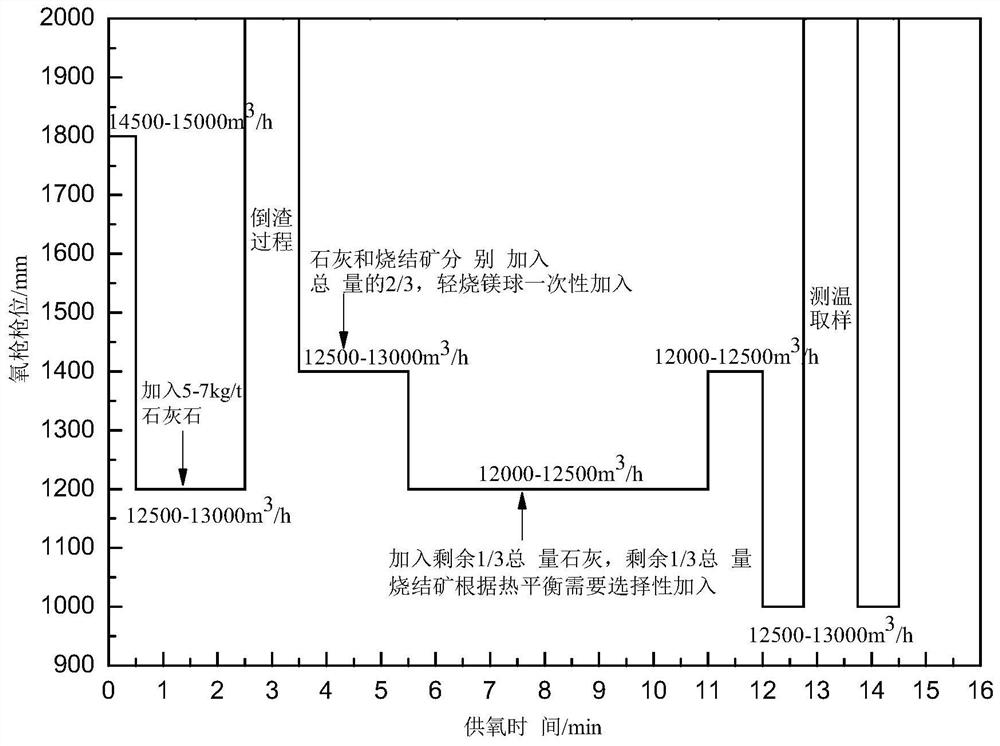

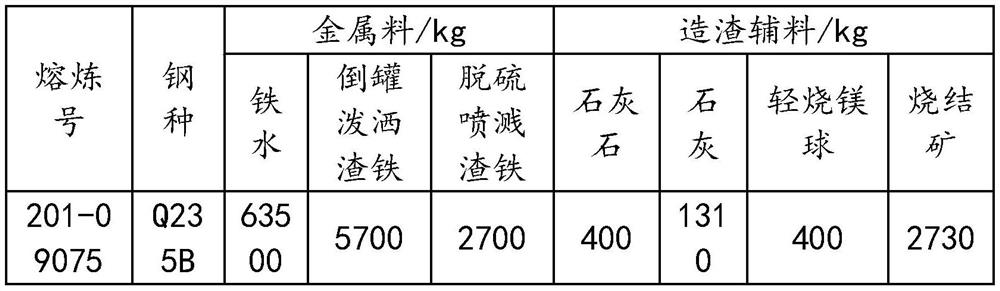

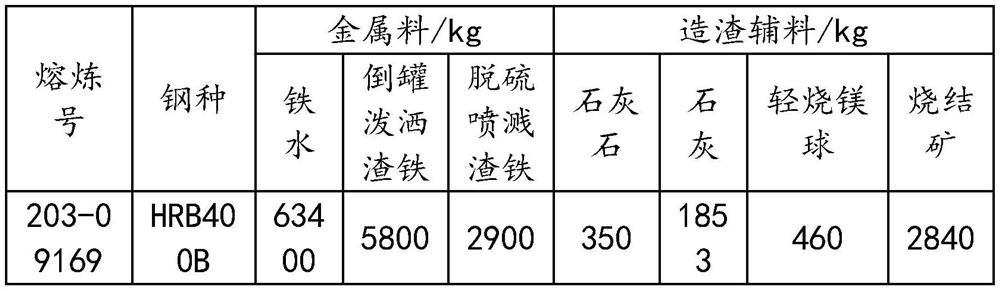

Converter steelmaking method for replacing total scrap steel with slag iron

ActiveCN112708719AEfficient recyclingReduce dosageManufacturing convertersProcess efficiency improvementSteelmakingMolten steel

The invention discloses a converter steelmaking method for replacing total scrap steel with slag iron. The converter steelmaking method comprises the following steps that converter slagging main raw materials comprise lime, light-burned magnesium balls and limestone, after converter tapping is completed, half of slag is turned over, the slag remaining amount is controlled to be 35-45 kg / t, then slag splashing solidification is conducted, confirmation is conducted, molten iron is 910-930 kg / t, slag iron is 110-130 kg / t, the converter smelting adopts an operation mode of ' remaining 1 / 2 slag and double slag ' and ' high catching and supplementary blowing', the total adding amount of lime, caustic-burned magnesia balls and limestone is controlled according to 40-50 kg / ( [Si]% * 100 ), 6.0-8 kg / t and 5-7 kg / t respectively, after the smelting is finished and the components and temperature of molten steel meet the technological requirements, the converter is tilted for normal tapping, and qualified molten steel is obtained through deoxidation alloying operation. According to the method, the operation method of remaining 1 / 2 slag and double slag is adopted, the sulfur and phosphorus bringing amount can be reduced to the maximum extent, the lime using amount is reduced, splashing caused by large-slag-amount operation and fluctuation of sulfur and phosphorus components of molten steel after smelting are avoided, and effective recycling of a large number of slag iron is achieved.

Owner:安徽长江钢铁股份有限公司

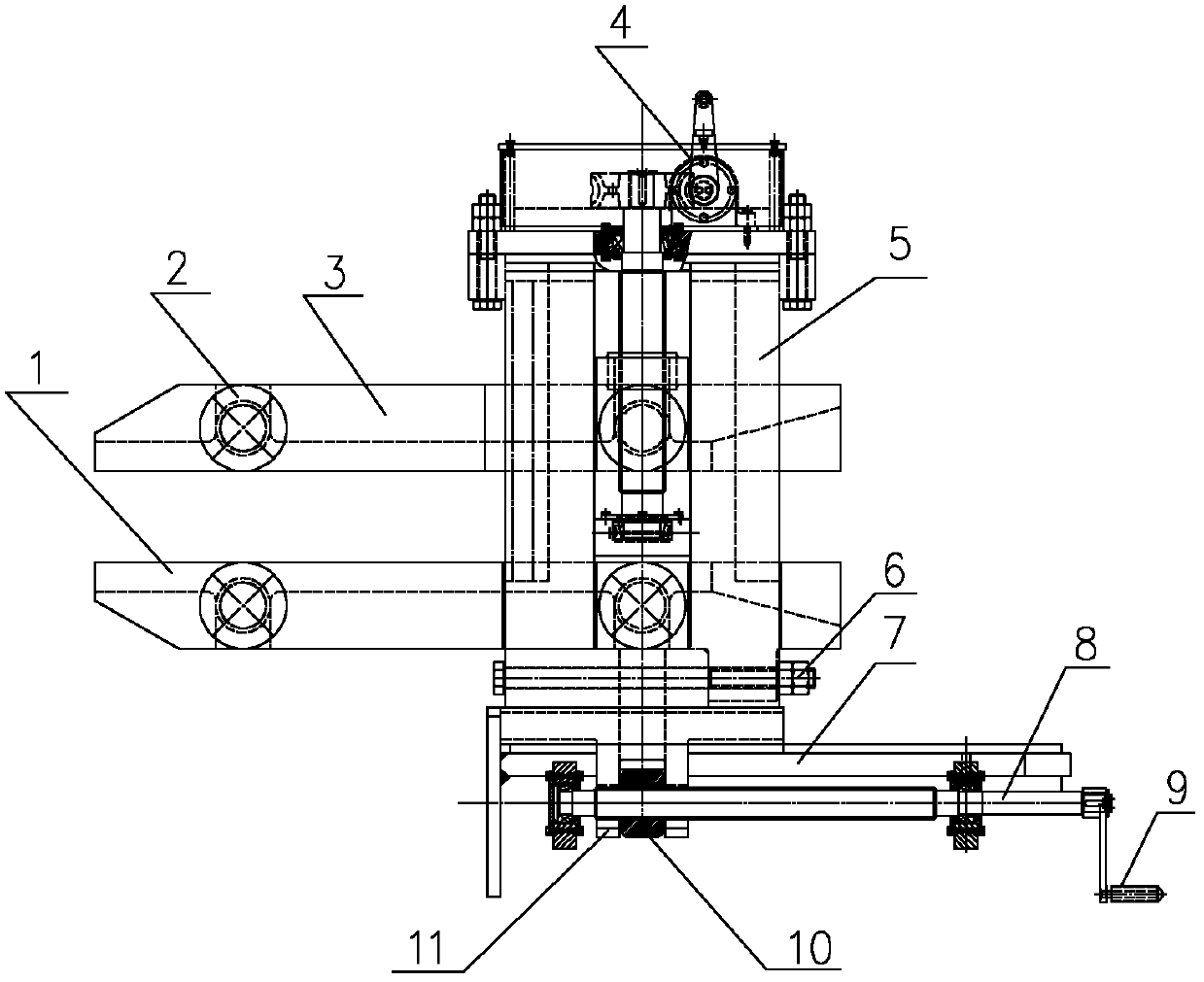

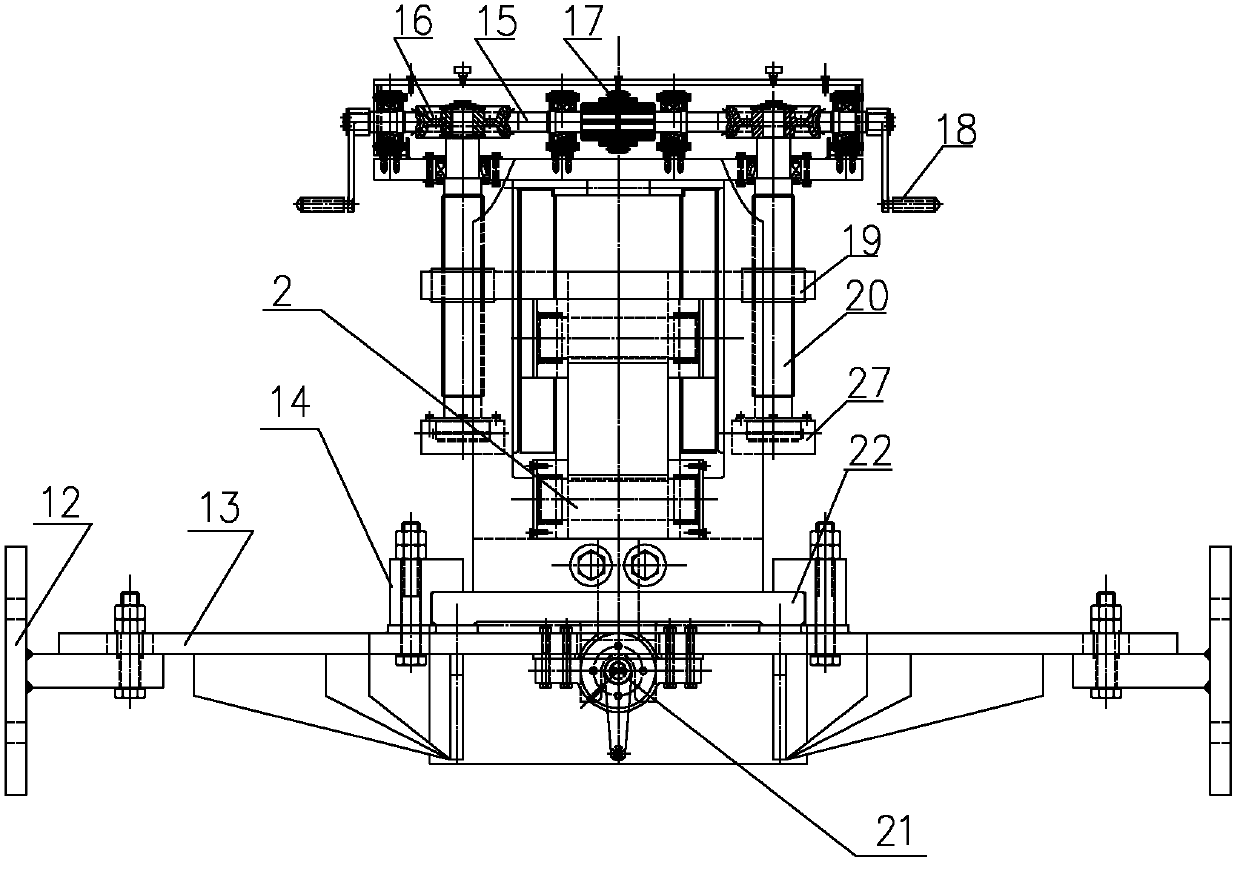

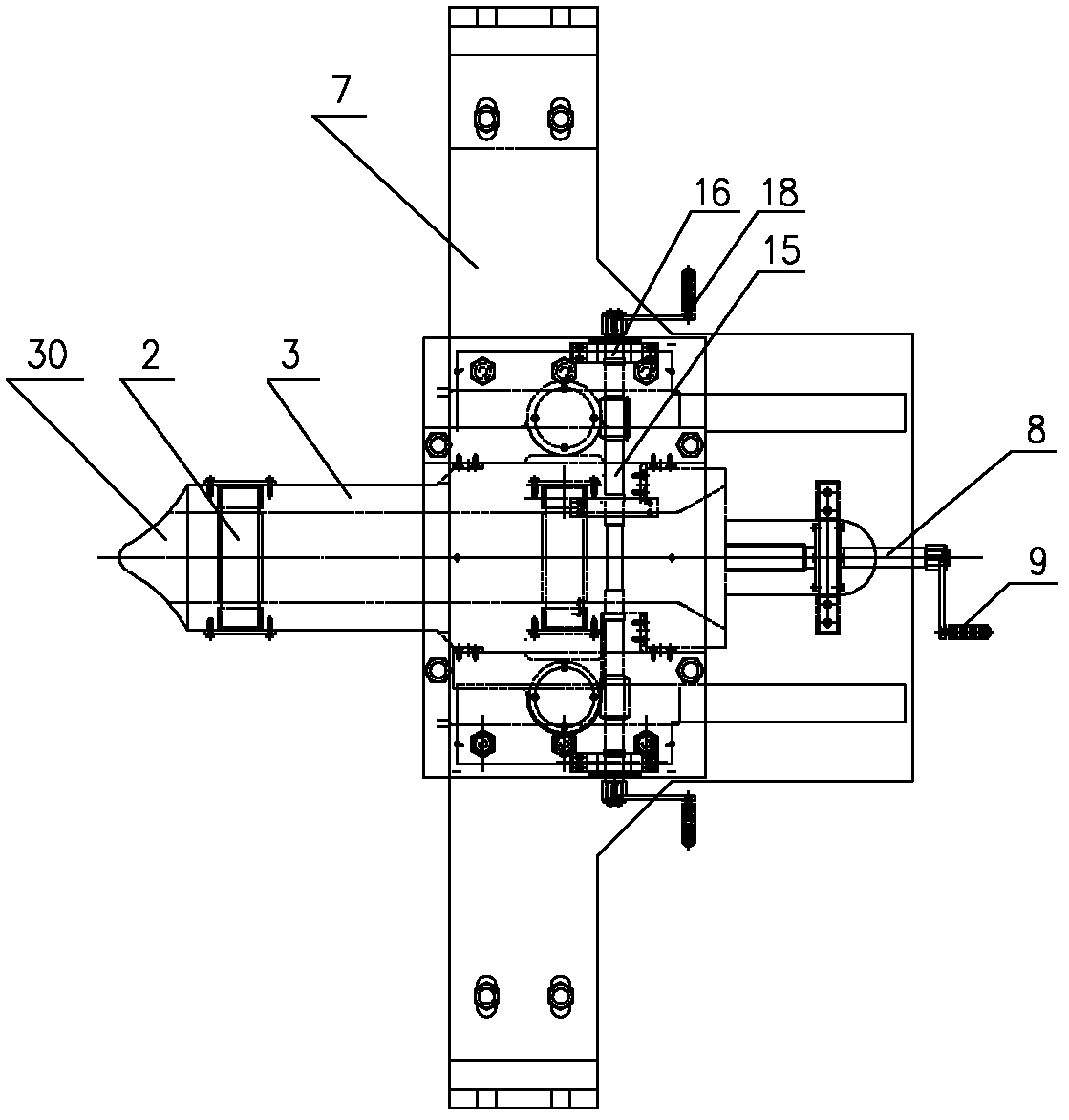

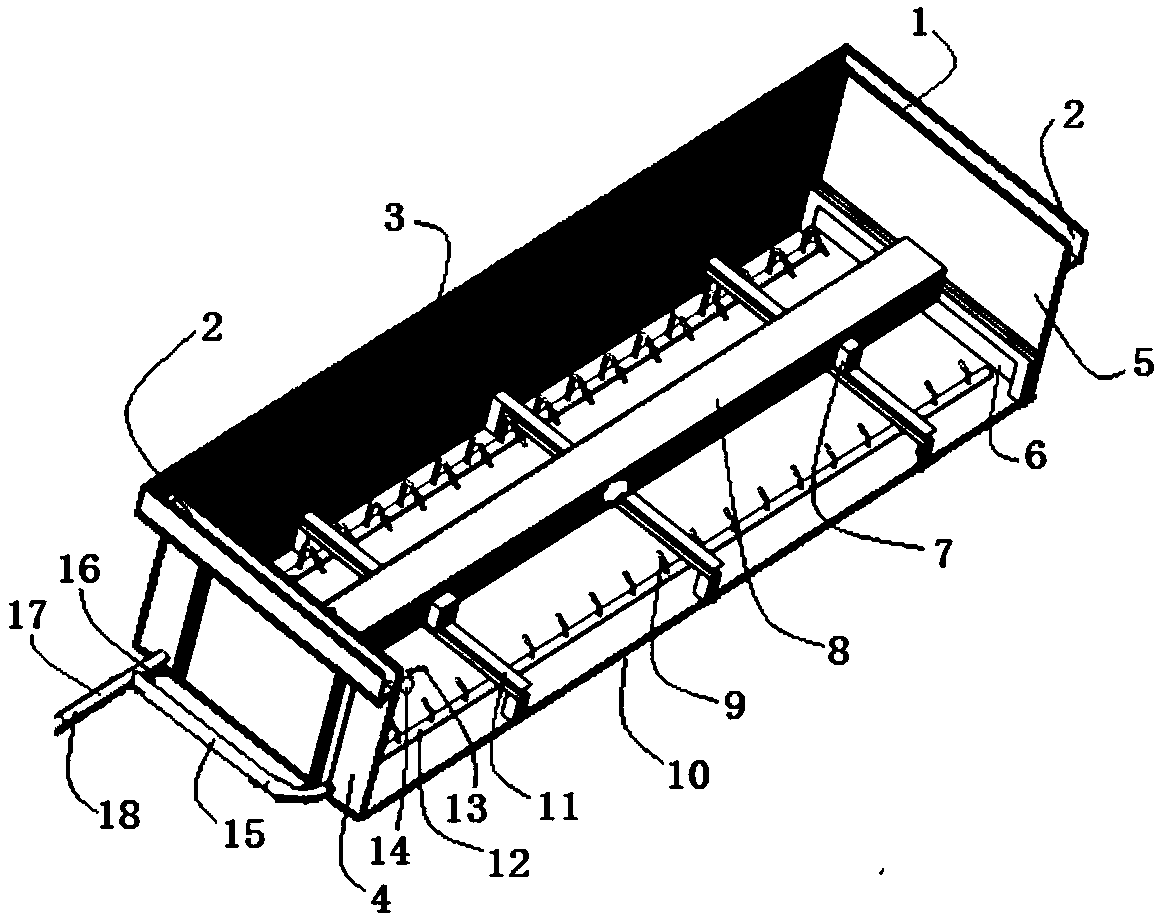

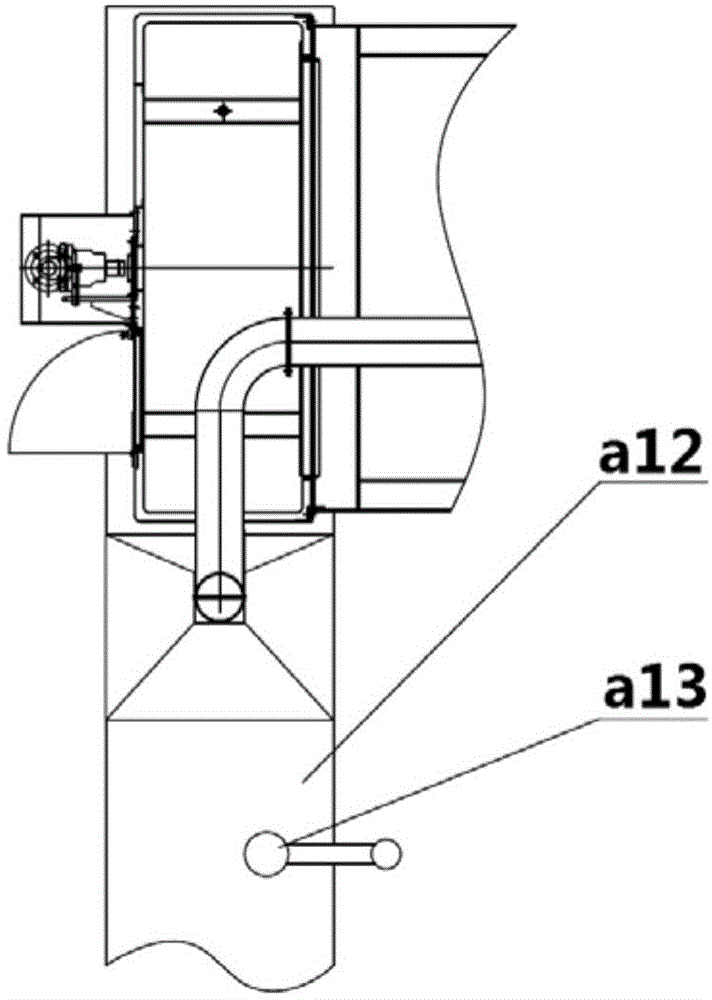

Vertical mill inlet shared induction device

ActiveCN102728628BExtended service lifeImprove physical qualityGuiding/positioning/aligning arrangementsRolling millSpare part

The invention provides a vertical mill inlet shared induction device, which consists of a fixing bracket, a guide body, an upper supporting arm, a lower supporting arm, a guide roller, a guide roller opening adjusting mechanism and a guide body horizontal movement mechanism, wherein the billet moves in a space formed by the upper and lower supporting arms and a side baffle, is guided by the guide roller and the side baffle and is correctly engaged with a rolling mill; when the milling specification is changed, an adjusting handle is rotated, the upper supporting arm drives the upper guide roller to lift to meet the novel specification requirement; the supporting arm stretches into two rollers on an inner frame, the guide plate body moves backwards in the process of replacing the rollers, and the supporting arms and the guide rollers retract the rollers and the arch of the inner frame; and therefore, the guide device is not required to be replaced in the process of replacing the rollers, the roller replacing time can be obviously shortened, the operate rate of the rolling mill is improved, the service life of the guide device is greatly prolonged, the storage and consumption of spare parts are reduced, and the production cost is reduced; and meanwhile, the scratch defect on the surface of a rolled piece can be overcome, and the quality of the finished rolled product is improved.

Owner:ANGANG STEEL CO LTD

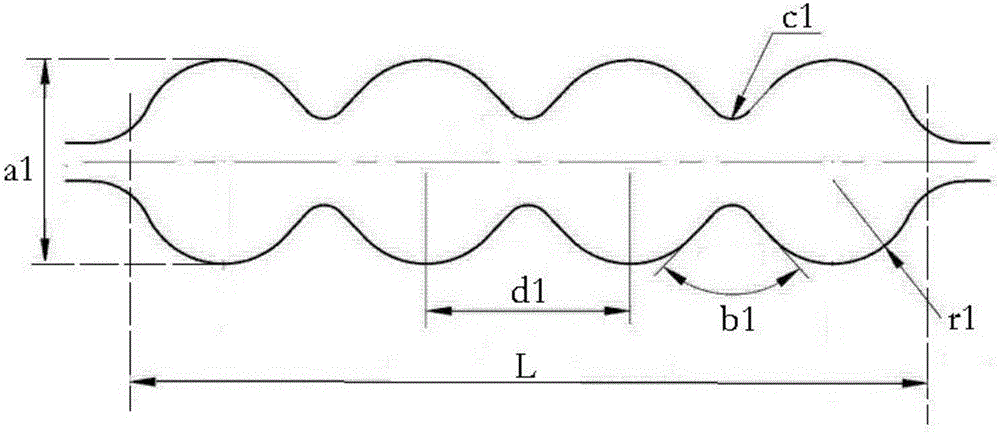

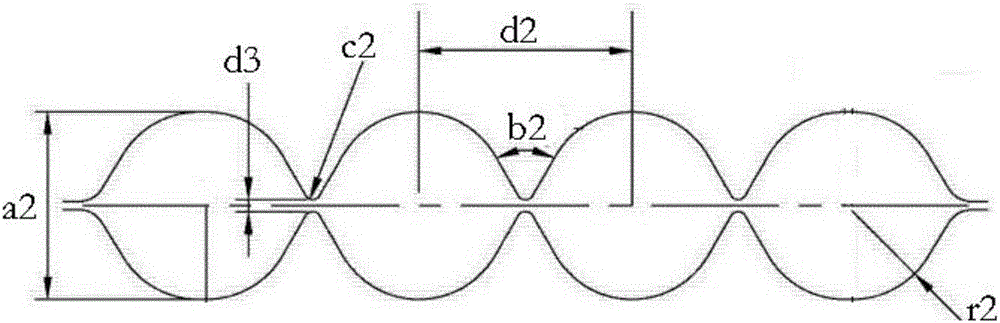

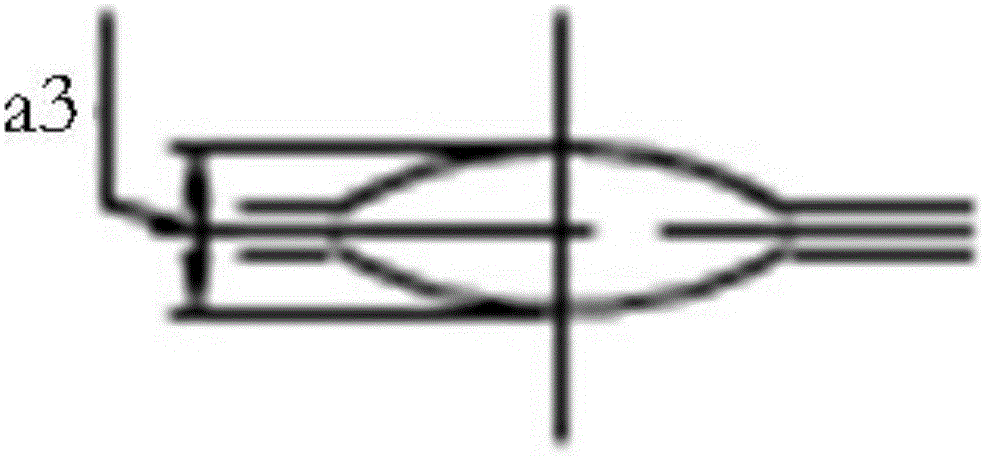

Slit-rolling groove

InactiveCN105080972AImprove mill productivityReduce material consumptionGuiding/positioning/aligning arrangementsRoll mill control devicesEllipseMiddle line

The invention discloses a slit-rolling groove. The slit-rolling groove comprises a pre-slitting groove K4, a slitting groove K3, an oval groove K2 and a final groove K1. The slit-rolling groove is characterized in that the height of the tank bottom of the pre-slitting groove K4 is 17.64mm, the roller wedge angle of the pre-slitting groove K4 is 88.5-89 degrees, and the circular arc radius of the wedge top of the pre-slitting groove K4 is 1.45-1.5mm; the height of the tank bottom of the slitting groove K3 is 14.5mm, the wedge angle of the slitting groove K3 is 50.5-51 degrees, and the circular arc radius of the wedge top of the slitting groove K3 is 0.6-0.9mm; the height of the tank bottom of the oval groove K2 is 8.5mm, and the height of the tank bottom of the final groove K1 is 11.2mm. Through the adoption of the slit-rolling groove disclosed by the invention, the good quality of products is guaranteed, the operation rate of a rolling machine is improved, the material consumption is reduced, the phenomenon of uneven slitting is avoided, midline folding is eliminated, the surface quality of finished products is improved, the size of finished products is stabilized, and the production efficiency is improved.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

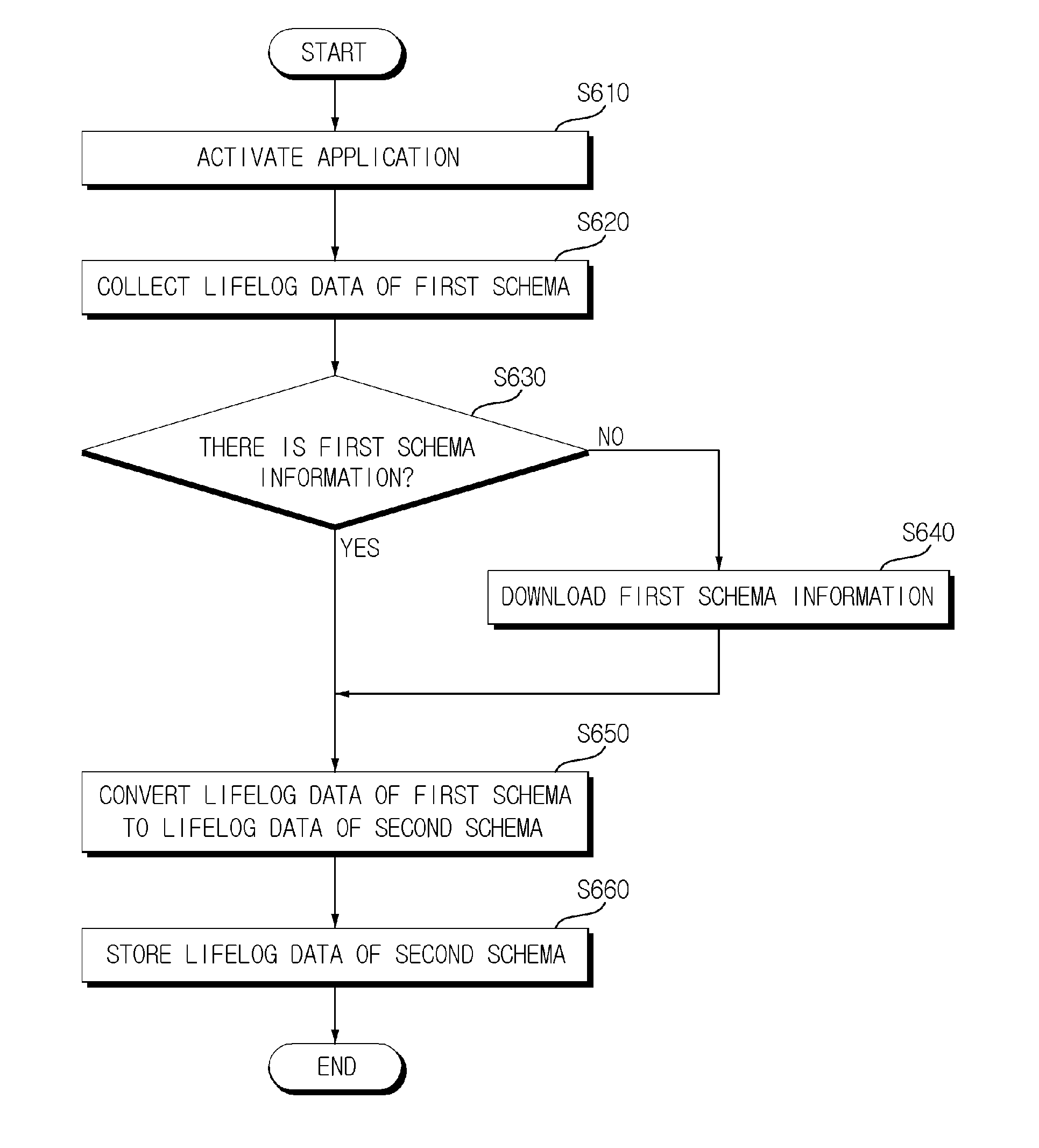

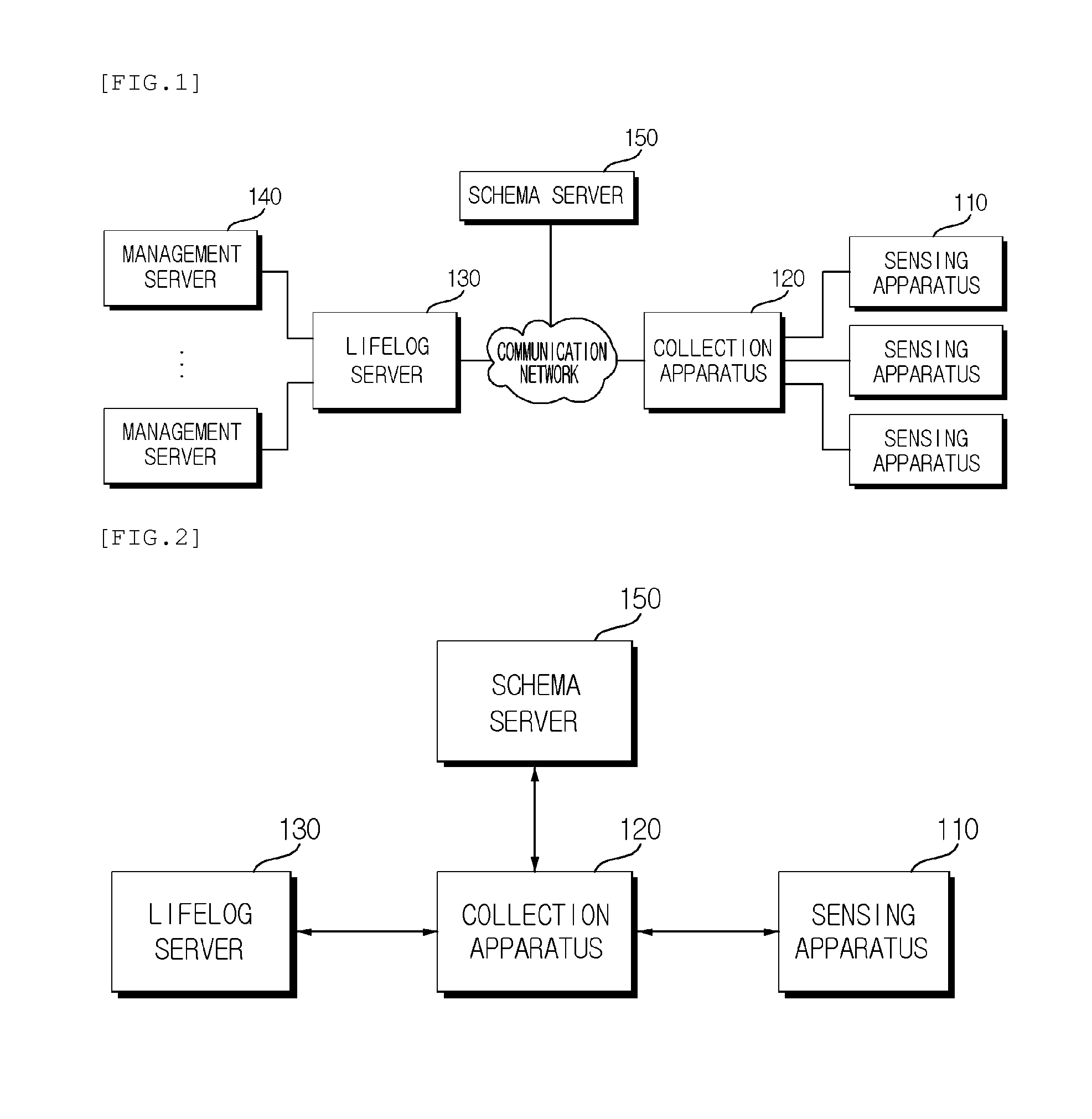

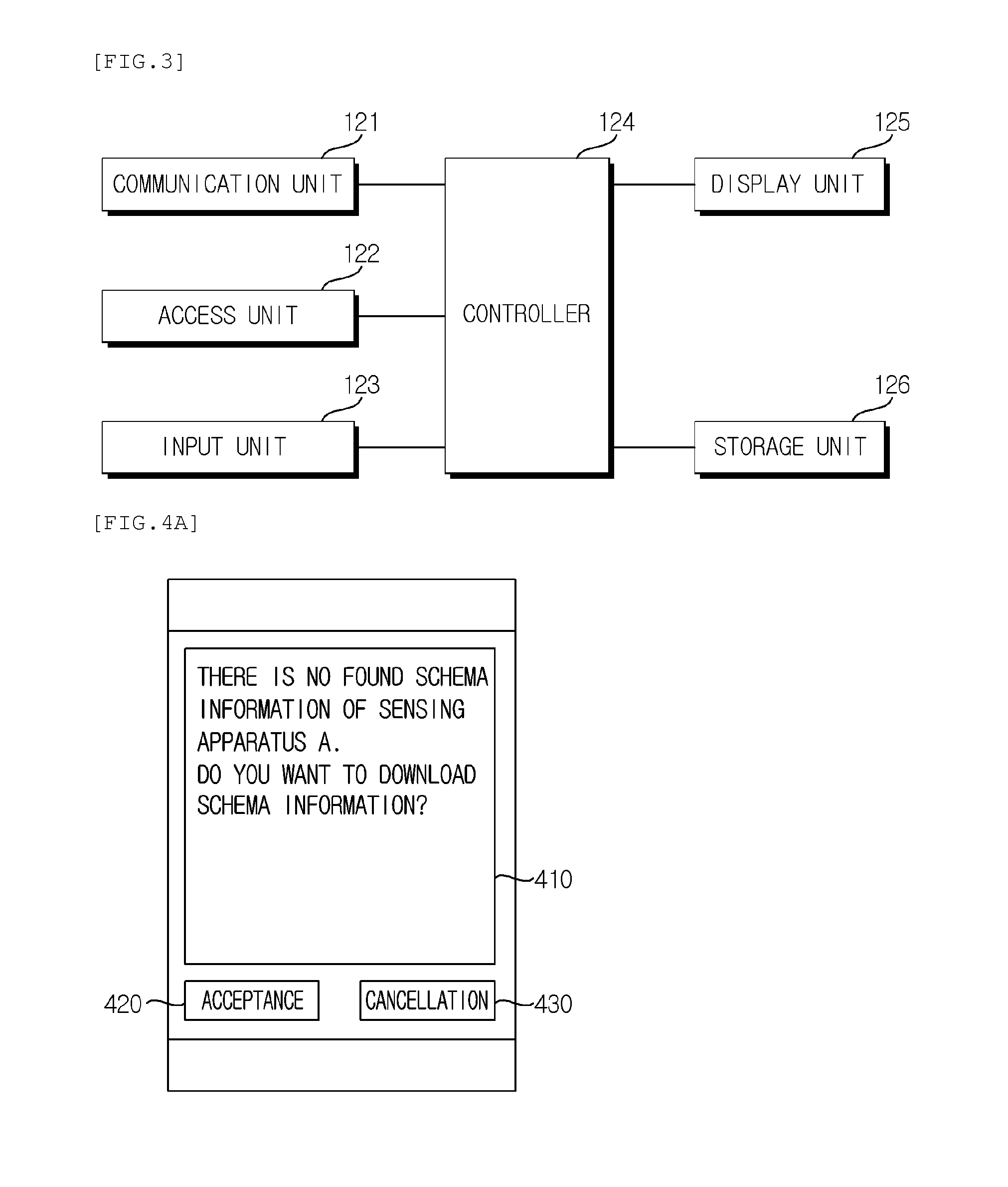

Apparatus for collecting lifelog data and method thereof

ActiveUS20140122541A1Improve physical qualityImprove medical qualityPhysical therapies and activitiesDigital data information retrievalWorld Wide WebLifelog

Owner:ELECTRONICS & TELECOMM RES INST

Straightening method for improving plate shape of thin controlled-cooling steel plate

The invention relates to a straightening method for improving the plate shape of a thin controlled-cooling steel plate, a hot straightening method is adopted, and the plate shape of the head part andthe tail part of a steel plate are controlled through a straightener. Adjusted straightening technological parameters comprise straightening pass, pass interval time, a straightener inlet roller gap set value, an outlet roller gap set value, a straightener leading-out roller set value, inlet roller and outlet roller tilting set values and a straightening speed. The method effectively improves theplate shape of the head part and the tail part of an 8-15mm thin controlled-cooling steel plate, so that the quality of the steel plate in kind is improved, the working process is shortened, the costis saved, and finally the user experience is improved.

Owner:ANGANG STEEL CO LTD

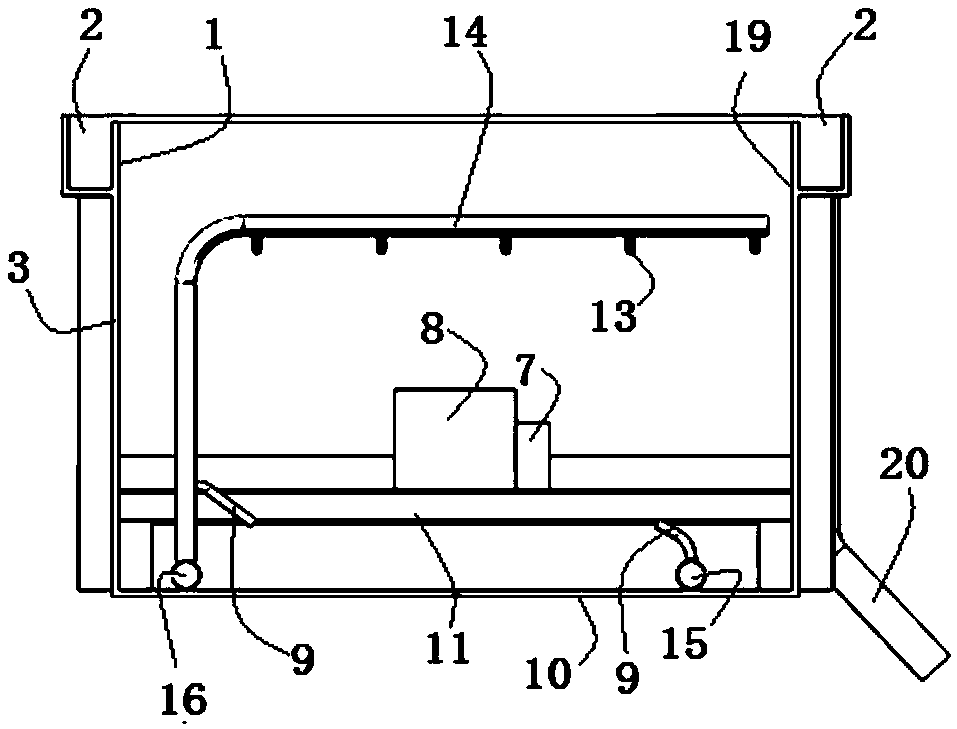

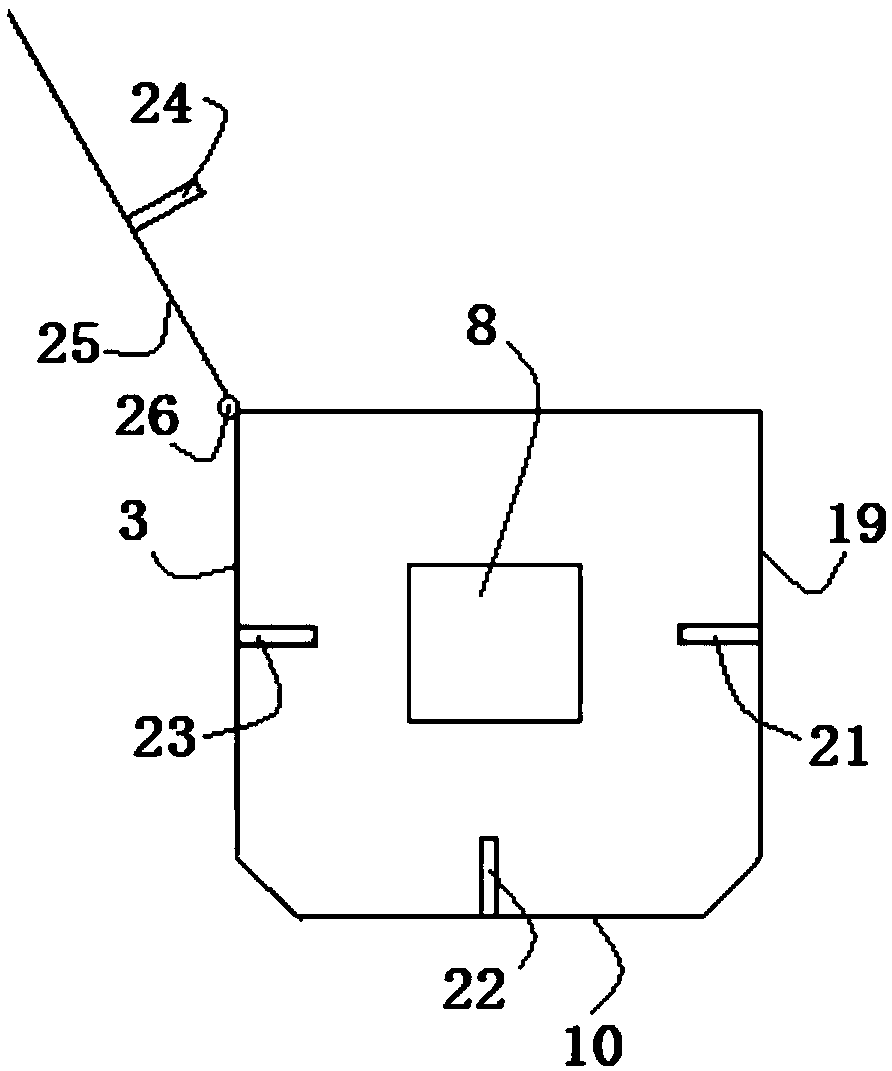

Online continuously cast billet surface strengthening quenching treatment equipment system and process

PendingCN109022717AImprove stabilityImprove surface qualityFurnace typesHeat treatment furnacesQuenchingSlow cooling

Provided are an online continuously cast billet surface strengthening quenching treatment equipment system and process. A quenching tank is arranged between a continuously cast billet roller bed of acontinuous casting production line and a heat conveying process or slow cooling heat preservation procedure to carry out online forced cooling on a continuously cast billet, the surface of the continuously cast billet can stride across the microalloy element carbo-nitride separation critical temperature area, separation and gathering of microalloy element carbo-nitride can be avoided, and therefore the continuously cast billet surface crack happening probability is effectively reduced, and the aim of improving the surface quality of the continuously cast billet and then increasing the yield afinished rolled piece is achieved.

Owner:SHIJIAZHUANG IRON & STEEL

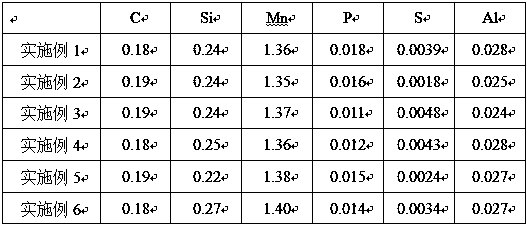

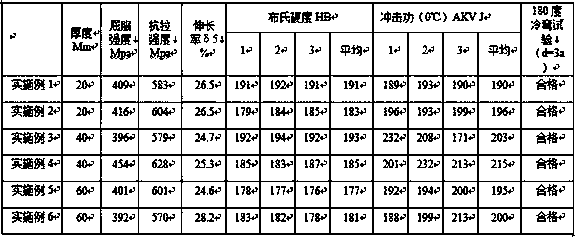

Production method of high-hardness steel sheet for rolling wheel of road roller

InactiveCN109112406AImprove cleanlinessLarge amount of wealthProcess efficiency improvementSheet steelChemical composition

The invention relates to a production method of a high-hardness and high-toughness steel sheet for a rolling wheel of a road roller. The steel comprises the following chemical components in percentageby mass: 0.16 to 0.20% of C (carbon), 0.20 to 0.50% of Si (silicon), 1.35 to 1.45% of Mn (manganese), 0.020% or less of P (phosphor), 0.010% or less of S (sulfur), 0.020 to 0.050% of Al (aluminum), and the balance of Fe (iron) and residue elements. The production method comprises the production process with the following steps of smelting by a converter, LF (ladle furnace) refining, VD (vacuum distillation) vacuum treatment, continuous casting, heating of sheet blanks, controlling of rolling, controlling of cooling, and finishing. The production method has the advantage that by implementing the whole process from pretreatment of hot metal through controlling of cooling of steel sheets to finishing, the quality properties of the physical product are excellent, namely that the yield marginof steel sheet is 50MPa or above, the tensile margin is 80 to 100MPa, and the Brinell hardness is 170HB or above; the low-temperature impact property is stable, and the margin is high.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

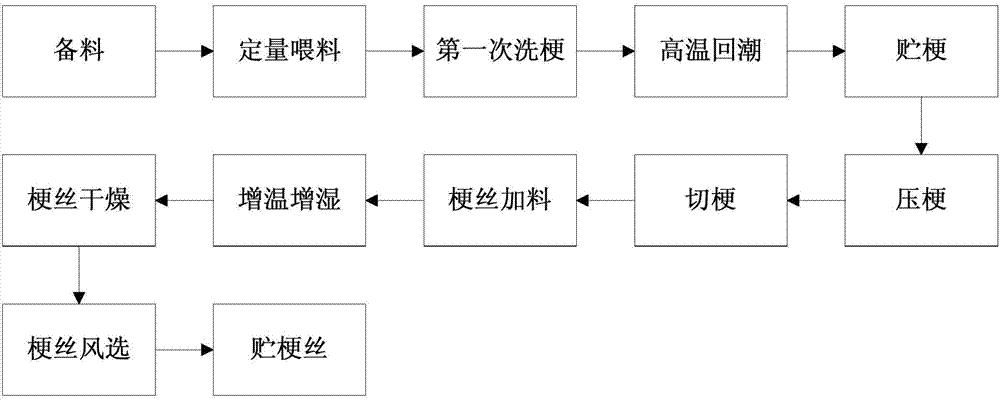

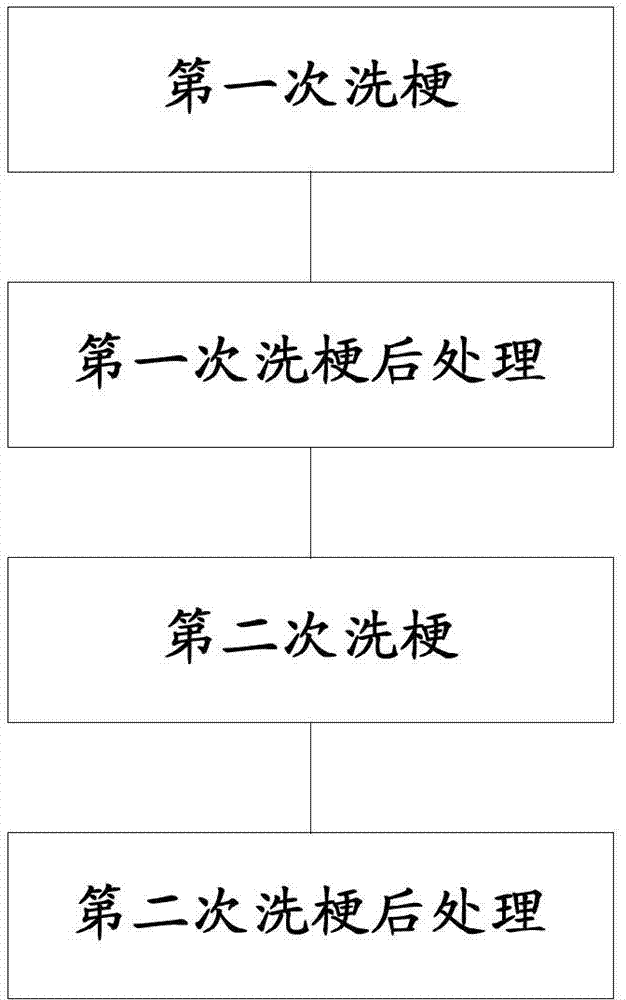

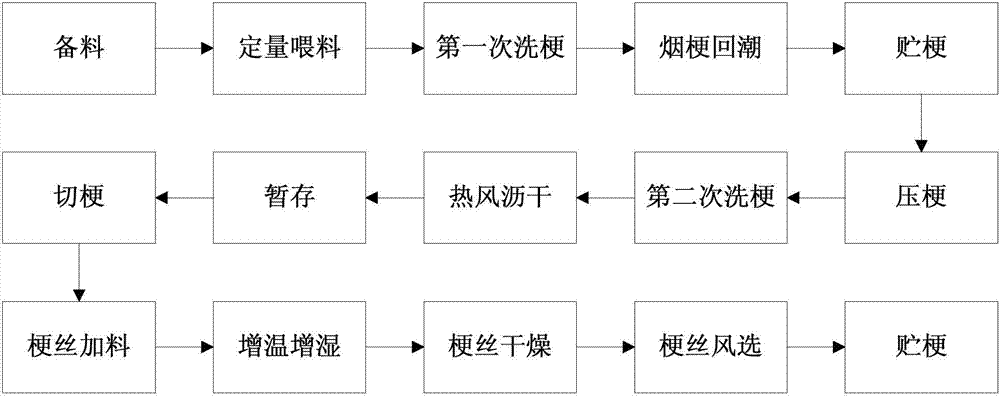

Two-time cleaning processing method for tobacco stems

ActiveCN103919260AImprove physical qualityGood removal effectTobacco preparationEngineeringWater soluble

The invention relates to a two-time cleaning processing method for tobacco stems. The method comprises the steps that the tobacco stems are cleaned for the first time, substances on the surfaces of the tobacco stems and substances influencing the physical quality and sensory quality are removed, and the moisture content of the tobacco stems is increased at the same time; the tobacco stems cleaned for the first time is postprocessed so as to meet the requirement of subsequent processing procedures; the tobacco stems which are cleaned for the first time and postprocessed are cleaned for the second time, and the substances on the surface of the tobacco stems and the substances influencing the physical quality and sensory quality are removed further, and the moisture content of the tobacco stems is further increased at the same time; the tobacco stems cleaned for the second time is postprocessed so as to meet the requirement of subsequent processing procedures. According to the two-time cleaning processing method for tobacco stems, due to the fact that the tobacco stems are cleaned twice, the tobacco stems are further humidified and expanded, moisture is sufficiently absorbed, harmful substances such as chloridion, phenolic substances and water soluble pectin on the surface of the tobacco stems and inside the tobacco stems are further removed, tobacco powder can be removed, and the physical quality and sensory quality of the stem silks are improved.

Owner:XIAMEN TOBACCO IND +1

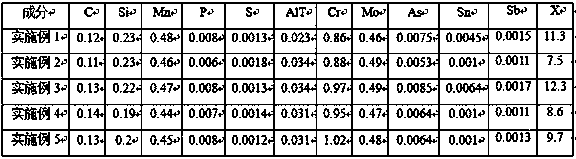

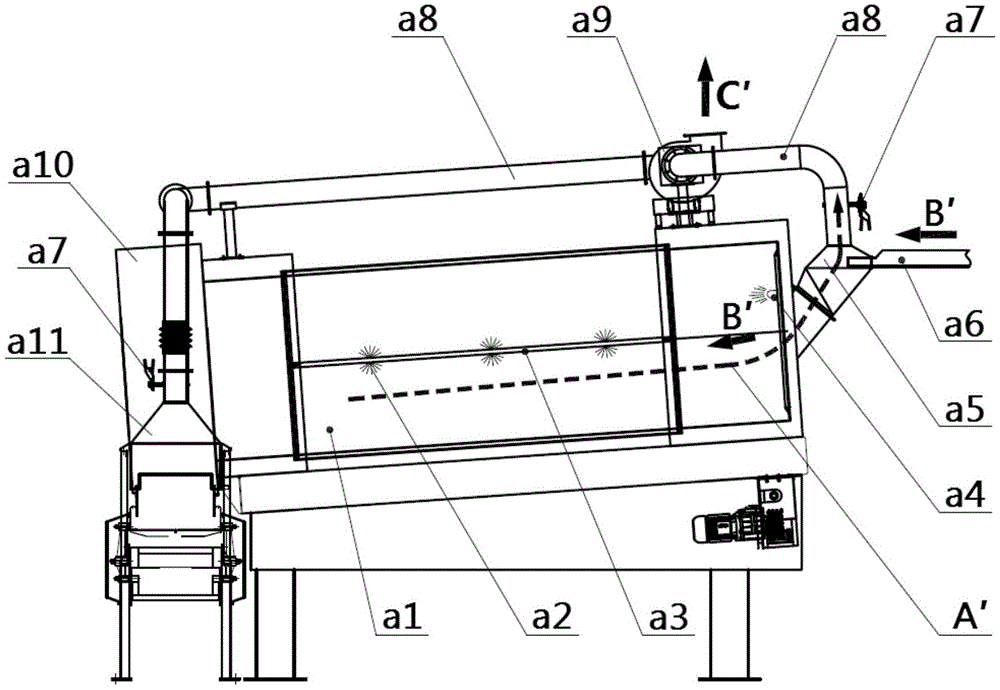

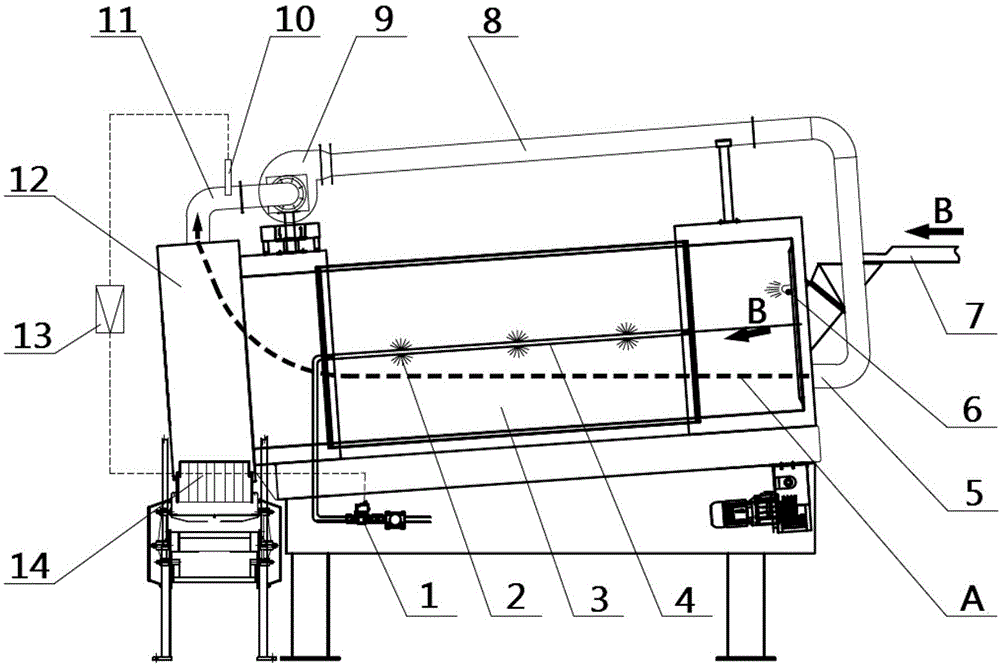

Cylindrical stalk moistening machine and stalk moistening method of cylindrical stalk moistening machine

The invention relates to a cylindrical stalk moistening machine and a stalk moistening method of the cylindrical stalk moistening machine. The cylindrical stalk moistening machine comprises a rotary drum, a steam and moisture spraying mechanism, a first air returning pipe and a circulating fan. The discharging end of the rotary drum is communicated with the circulating fan through the first air returning pipe, and under the effect of the circulating fan, the flow direction of technological hot air with steam and moisture in the rotary drum is coincident with the advancing direction of materials in the rotary drum. By means of the cylindrical stalk moistening machine and the stalk moistening method, the time spent when the materials absorb steam heat energy and atomized water is lengthened to the maximum degree, the time is enough for the steam and the moisture to seep into the materials, and the material moistening rate, the tobacco stalk processing resistance, the stalk converting rate and the finished-product physical quality are improved. Further, the technological hot air is fed into the rotary drum from the feeding end of the rotary drum through the circulating fan to be recycled, the use rate of the technological hot air is improved, a large amount of energy is prevented from being wasted, and meanwhile the environment pollution, caused by exhausting the technological hot air, to the external is avoided.

Owner:XIAMEN TOBACCO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com