Method for inspecting cigarette rolling quality stability in cigarette processing

A technology of quality stability and inspection method, which is applied in the field of inspection of quality stability of cigarette processing and rolling, and can solve problems such as the inability to jointly monitor the physical indicators of cigarettes and the inability to effectively test the comprehensive physical quality stability of cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

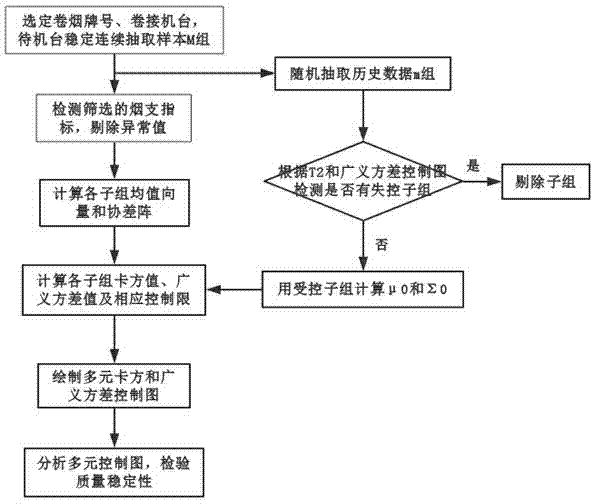

[0030] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

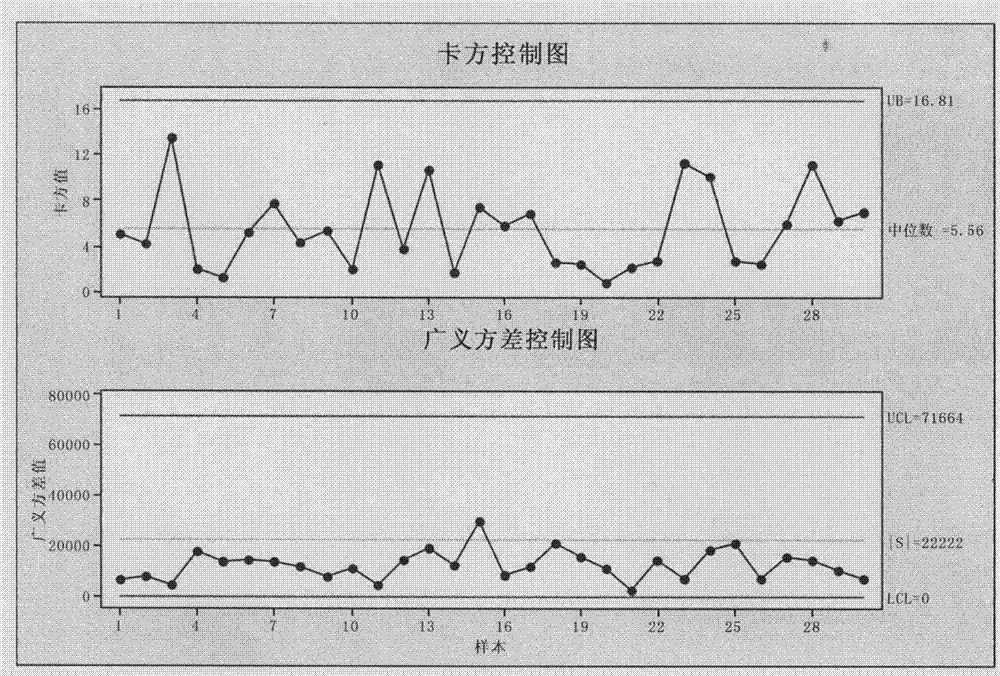

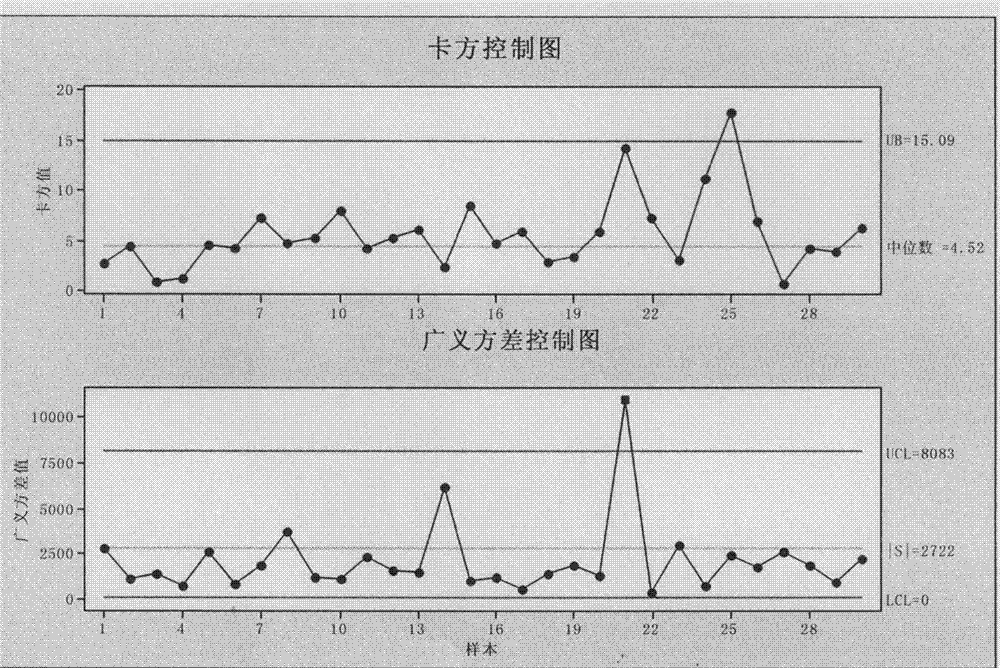

[0031] The present invention uses PROTOS-70 model B-J2 machine to produce low-focus brand cigarette A and common brand cigarette B, and PROTOS-M5 model F-J7 machine and PROTOS-70 model B-J1 machine. Brand B cigarettes are the inspection objects, and the monitoring indicators are quality, circumference, draw resistance, length, hardness, and total ventilation rate (low-focus cigarette indicators), and the method is as follows:

[0032] (1) After the crimping machine is stable, 30 groups of samples are continuously taken at the exit at intervals of 5 minutes, and each subgroup contains 30 cigarettes. In this way, the samples of each machine and brand are respectively extracted. Then send the samples to the quality inspection room to test the physical indicators of each cigarette and record the data.

[0033] (2) Data processing

[0034] (a) Taking the brand A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com