Converter steelmaking method for replacing total scrap steel with slag iron

A converter steelmaking and iron slag technology, which is applied in the manufacture of converters, improvement of process efficiency, lime production, etc., can solve problems such as inability to recycle and reuse, fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

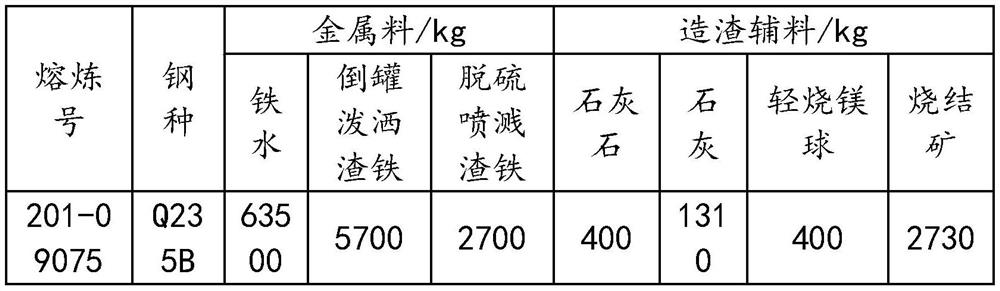

[0046] For smelting Q235B steel, the steel [P] and [S] require ≤0.035%, the molten iron [Si] content is 0.26%, the molten iron temperature is 1346°C, and the bottom height of the converter is "±0mm";

[0047] After tapping the furnace, half of the slag is turned over, and the amount of slag left is controlled at 2.7t, and then the slag is solidified by splashing and confirmed;

[0048] Load 63.5t of molten iron, 8.2t of iron slag, and shake the converter to zero;

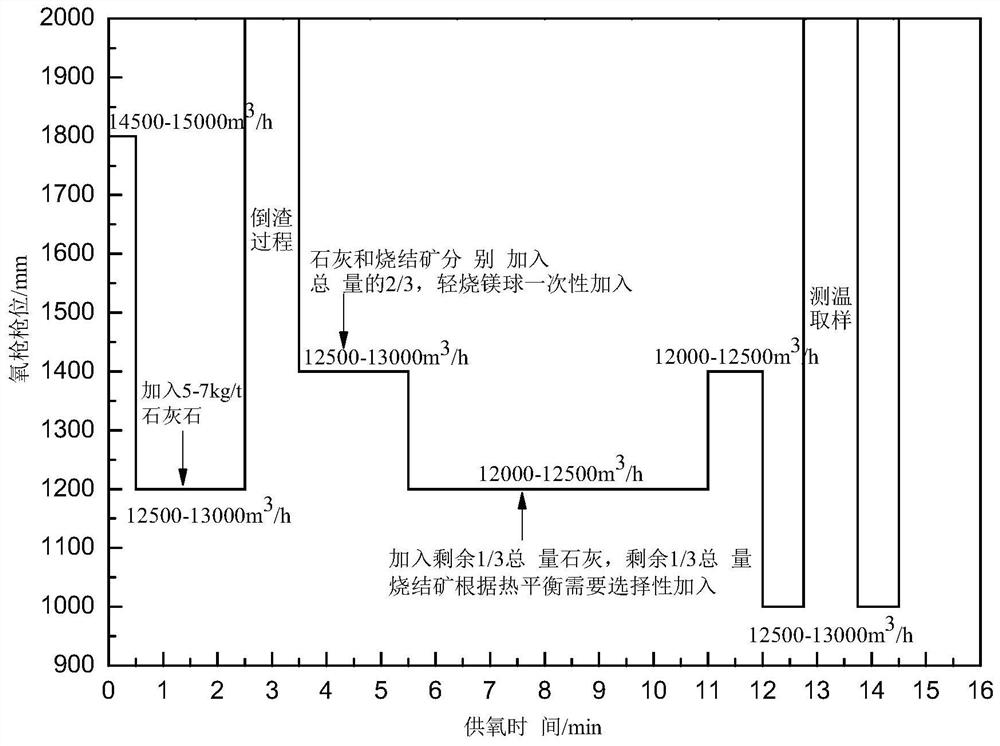

[0049] Set the oxygen pressure to 900kpa and the oxygen flow to 14800m 3 / h, the gun position is 1800mm to ignite, after blowing oxygen for 30s, the oxygen pressure is adjusted to 750kpa, and the oxygen flow rate is 12800m 3 / h, the position of the oxygen lance is lowered to 1200mm, blow oxygen for 1min, add 400kg of limestone, continue to blow oxygen for 1min, lift the gun and turn off the oxygen; switch the operation of the oxygen lance to "nitrogen manual", lower the oxygen lance to 4600mm, and turn on nitrogen ...

Embodiment 2

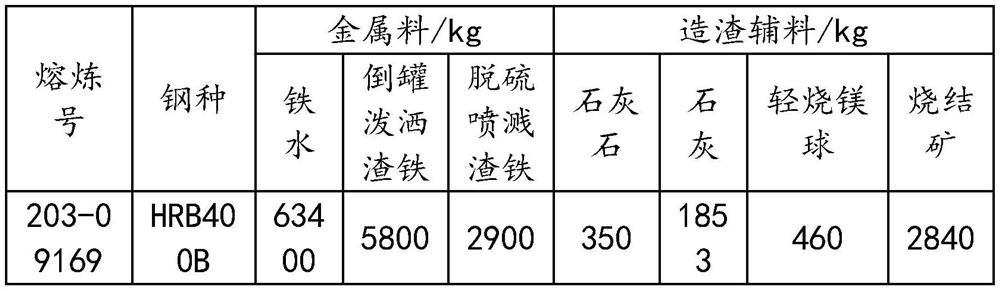

[0057] For smelting HRB400B steel, the steel [P] and [S] requirements are ≤0.045%, the molten iron [Si] content is 0.37%, the molten iron temperature is 1343°C, and the bottom height of the converter is "+100mm";

[0058] After tapping the steel in the upper furnace, half of the slag is turned over, and the amount of slag left is controlled at 3.2t, and then the slag is solidified by splashing and confirmed;

[0059] Load 63.4t of molten iron, 8.7t of iron slag, and shake the converter to zero;

[0060] Set oxygen pressure to 900kpa, oxygen flow rate to 14900m3 / h, lance position to ignite at 1900mm, after blowing oxygen for 41s, adjust oxygen pressure to 750kpa, oxygen flow rate to 12900m3 / h, oxygen lance position to 1320mm, blow oxygen for 1min, add 350kg of limestone, Continue to blow oxygen for 1 minute, lift the gun and turn off the oxygen; switch the operation of the oxygen gun to "nitrogen manual", lower the oxygen gun to 4800mm, turn on the nitrogen and purge for 43 sec...

Embodiment 3

[0068] For smelting Q355B steel, the steel [P] and [S] require ≤0.035%, the molten iron [Si] content is 0.41%, the molten iron temperature is 1336°C, and the bottom height of the converter is "-100mm";

[0069] After tapping the steel in the upper furnace, half of the slag is turned over, and the amount of slag left is controlled at 3.5t, and then the slag is solidified by splashing and confirmed;

[0070] Load 62.8t of molten iron, 8.6t of iron slag, and shake the converter to zero;

[0071] Set the oxygen pressure to 900kpa and the oxygen flow to 14600m 3 / h, the gun position is 1700mm to ignite, after blowing oxygen for 35s, the oxygen pressure is adjusted to 750kpa, and the oxygen flow rate is 12700m 3 / h, the position of the oxygen lance is lowered to 1100mm, blow oxygen for 1min, add 380kg of limestone, continue to blow oxygen for 1min, lift the gun and turn off the oxygen; switch the operation of the oxygen lance to "nitrogen manual", lower the oxygen lance to 4500mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com