Compound type yoghurt stabilizer and preparation method thereof

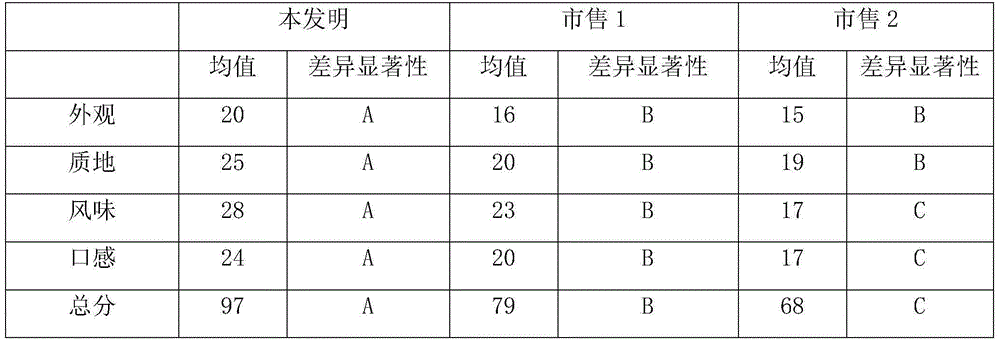

A stabilizer and yogurt technology, applied in food preparation, milk preparations, dairy products, etc., can solve the problems of poor taste, rough texture, low viscosity, etc., achieve long shelf life, increase the content of live bacteria, and improve the survival of lactic acid bacteria rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 raw material preparation

[0049] 1. Preparation of modified dietary fiber:

[0050] The preparation method of the modified dietary fiber comprises the following steps: uniformly mixing inulin, apple fiber, and oat fiber in a mass ratio of 4:3:2, adding water five times its mass, and ultrasonically extracting at room temperature 200W and 40KHz for 12min , and then under the conditions of electric field strength 30kV / cm, pulse time 400μs, and pulse frequency 300Hz, conduct high-voltage pulse electric field treatment for 12 minutes; use lactic acid to adjust the pH value to 5.5, add 0.2% biological enzyme in the mixture, and enzymolyze it at 50°C for 35 minutes; The solution solution is concentrated under reduced pressure, freeze-dried, and crushed at low temperature until the particle size is 0.2mm to obtain the modified dietary fiber;

[0051] The biological enzymes are cellulase, xylanase, laccase and pectinase, which are uniformly mixed in a mass ratio o...

Embodiment 2

[0064] A compound type yoghurt stabilizer is made from the following raw materials in parts by weight:

[0065] 35 parts of modified dietary fiber, 20 parts of sodium carboxymethylcellulose, 15 parts of plant extract, 10 parts of pectin, 6 parts of protein hydrolyzate, 5 parts of tremella polysaccharide, 5 parts of Chinese herbal medicine extract, 2.5 parts of transglutaminase share;

[0066] The preparation method comprises the steps of:

[0067] 1) According to the formula, take 82% (by weight) of modified dietary fiber, plant extract, protein hydrolyzate, tremella polysaccharide, and Chinese herbal medicine extract, grind them, pass through a 200-mesh sieve, and then mix them uniformly for 10 minutes to obtain a mixed powder;

[0068] 2) Mix sodium carboxymethylcellulose and pectin evenly, dissolve the mixture in water at 55°C, and process it ultrasonically at a power of 200W and a frequency of 40kHz for 12min to make a 10% (weight) aqueous solution;

[0069] 3) Add the a...

Embodiment 3

[0072] A compound type yoghurt stabilizer is made from the following raw materials in parts by weight:

[0073] 20 parts of modified dietary fiber, 10 parts of sodium carboxymethylcellulose, 10 parts of plant extract, 5 parts of pectin, 3 parts of protein hydrolyzate, 2 parts of tremella polysaccharide, 2 parts of Chinese herbal medicine extract, 1 part of transglutaminase share;

[0074] The preparation method comprises the steps of:

[0075] 1) According to the formula, take 75% (by weight) of modified dietary fiber, plant extract, protein hydrolyzate, tremella polysaccharide, and Chinese herbal medicine extract, grind them, pass through a 200-mesh sieve, and then mix them uniformly for 5 minutes to obtain a mixed powder;

[0076] 2) Mix sodium carboxymethylcellulose and pectin evenly, dissolve the mixture in water at 50°C, and process it ultrasonically at a power of 100W and a frequency of 35kHz for 10min to make an 8% (weight) aqueous solution;

[0077] 3) Add the aqueou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com