Cut tobacco structure measuring method and its vibrating screen

A shredded tobacco structure and shredded tobacco technology, applied in the field of tobacco processing, can solve problems such as incomplete shredded tobacco structure, achieve accurate control, and achieve the effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with examples (accompanying drawings), but does not limit the present invention.

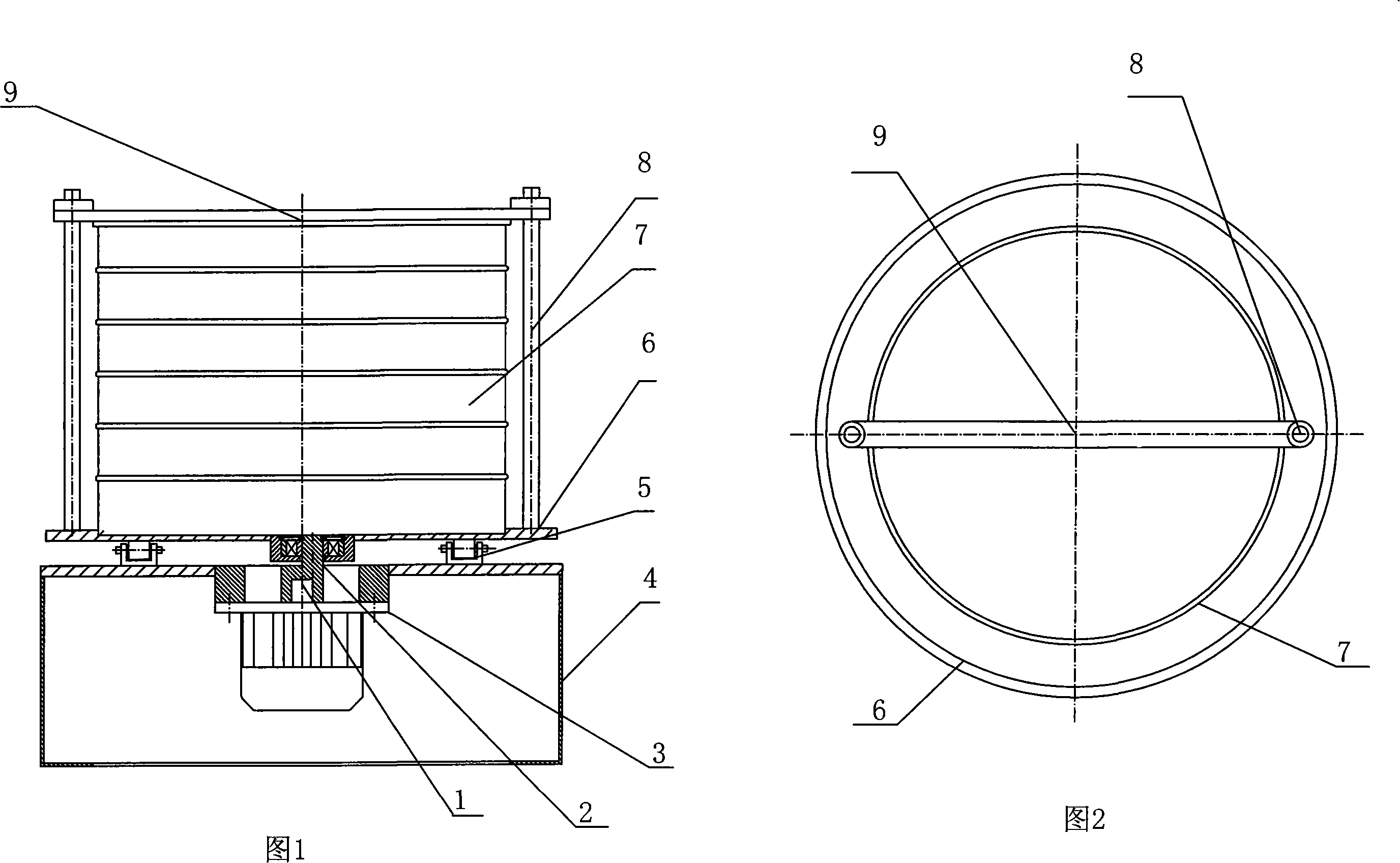

[0015] As shown in Figures 1 and 2, the detection vibrating sieve of the present invention includes a rotating frame 6 driven by an eccentric stepping drive device 3. Layer sieve body 7; the sieve body 7 is fixed as a whole by the column 8 arranged around the edge of the rotating frame and the pressure plate 9 located at the upper end of the column. This structural feature can make the amplitude and step angle and speed of all sieve bodies consistent. , and can be adjusted as required; the eccentric stepping drive device 3 is arranged in the chassis body 4 below the rotating frame, and its output shaft 1 is connected to the rotating frame 6 through the drive link sleeve 2; the rotating frame 6 The rollers 5 matched with its bottom surface are placed on the chassis body 4; in order to meet the needs of different detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com