Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Improve cold working performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing ultralow-rigidity annealing-free cold forging steel

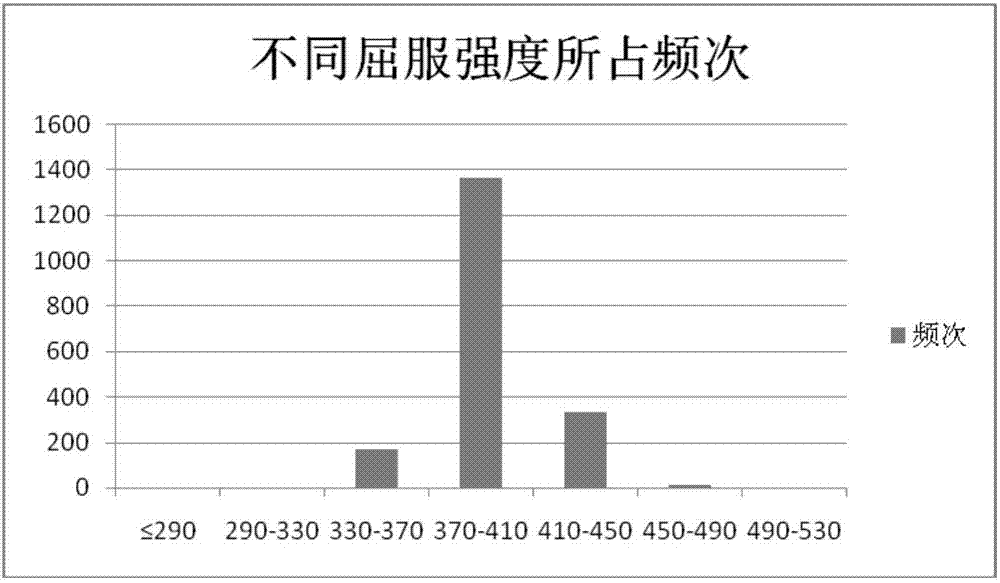

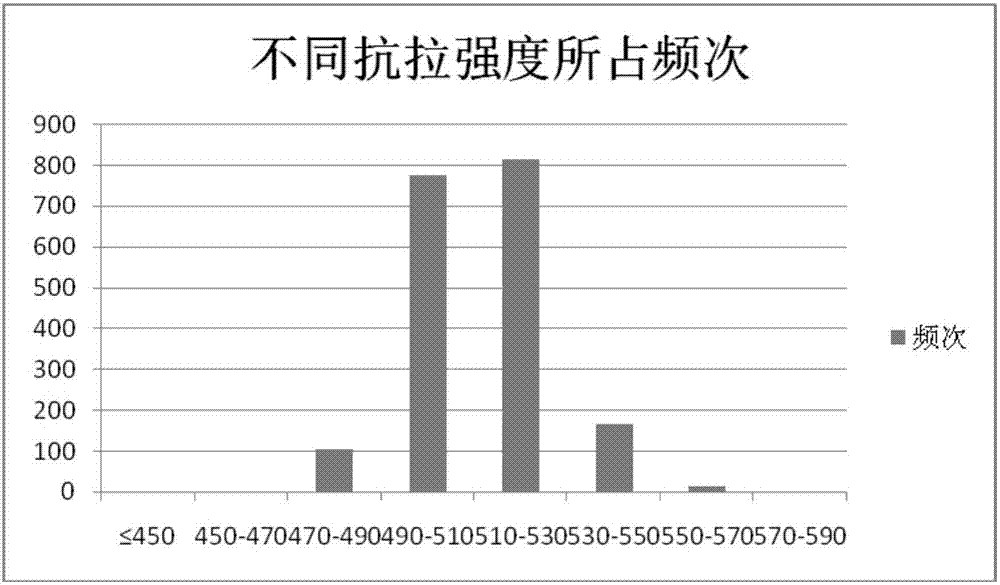

The invention relates to a method for producing ultralow-rigidity annealing-free cold forging steel. The ultralow-rigidity annealing-free cold forging steel comprises the following components in percentage by weight: 0.19%-0.22% of C, less than or equal to 0.08% of Si, 0.80%-1.00% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, more than or equal to 0.025% of Alt, 0.025%-0.050% of Ti, less than or equal to 0.035% of B and the balance of Fe and inevitable impurities. The production process comprises the following steps: smelting; continuously casting; heating; carrying out finish rolling; carrying out final rolling; slightly cooling; spinning into a ring; cooling a Stelmor roller way, wherein the heating temperature is 1090-1170 DEG C, the rolling starting temperature is 1000-1060 DEG C, the finish rolling temperature is 850-900 DEG C, the slight cooling temperature is 800-850 DEG C, the cooling speed of the Stelmor roller way is 0.10-0.40 m / s. The method disclosed by the invention can be used for reducing the usage amount of silicon and chromium, enhancing the plasticity of a product and reducing the rigidity of the steel.

Owner:张家港联峰钢铁研究所有限公司

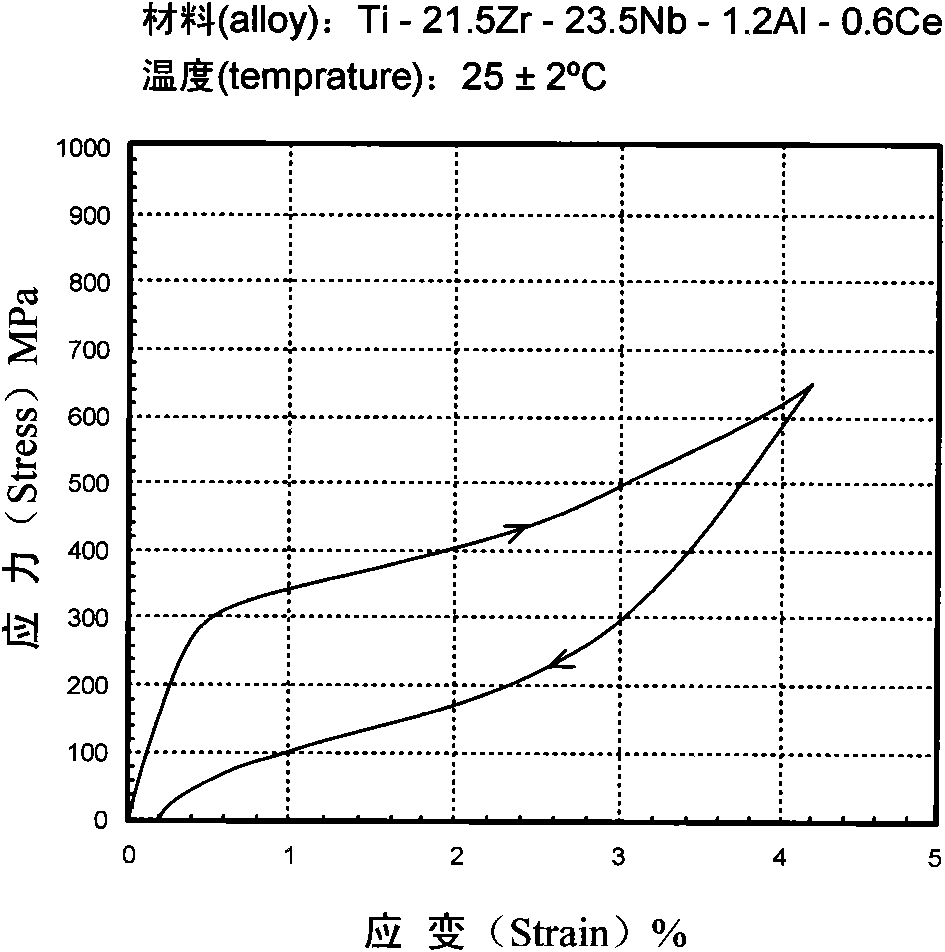

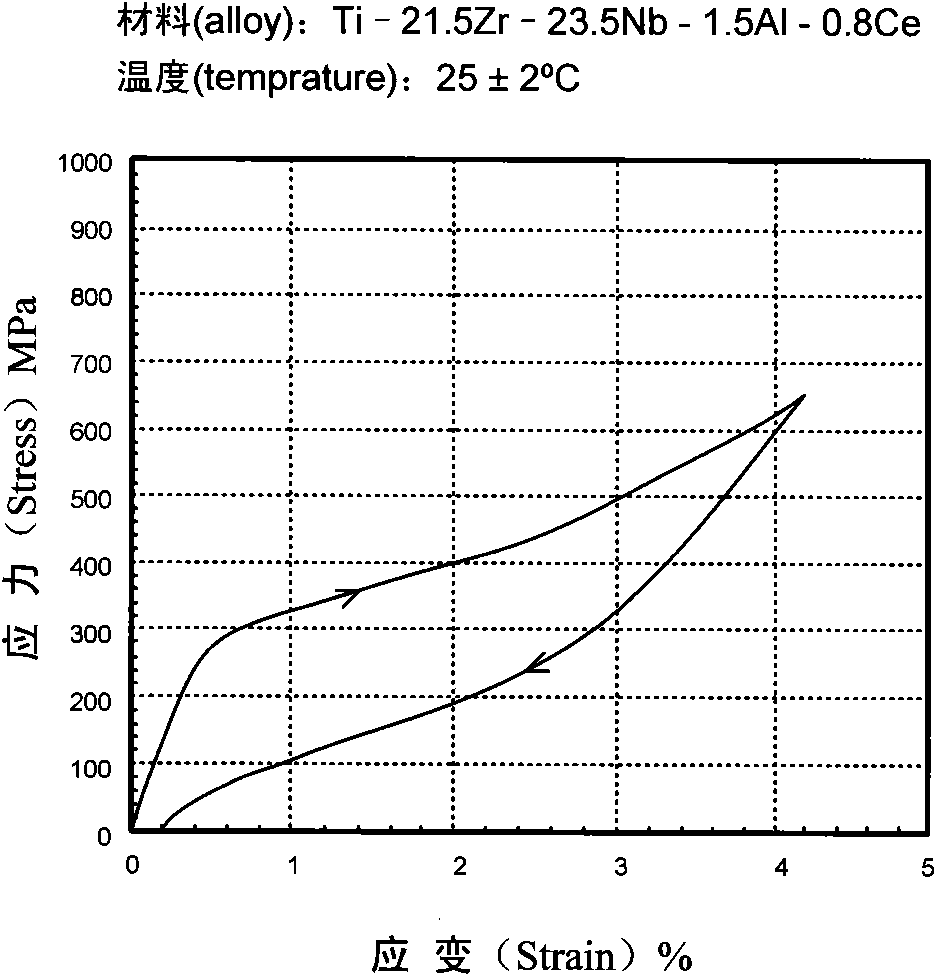

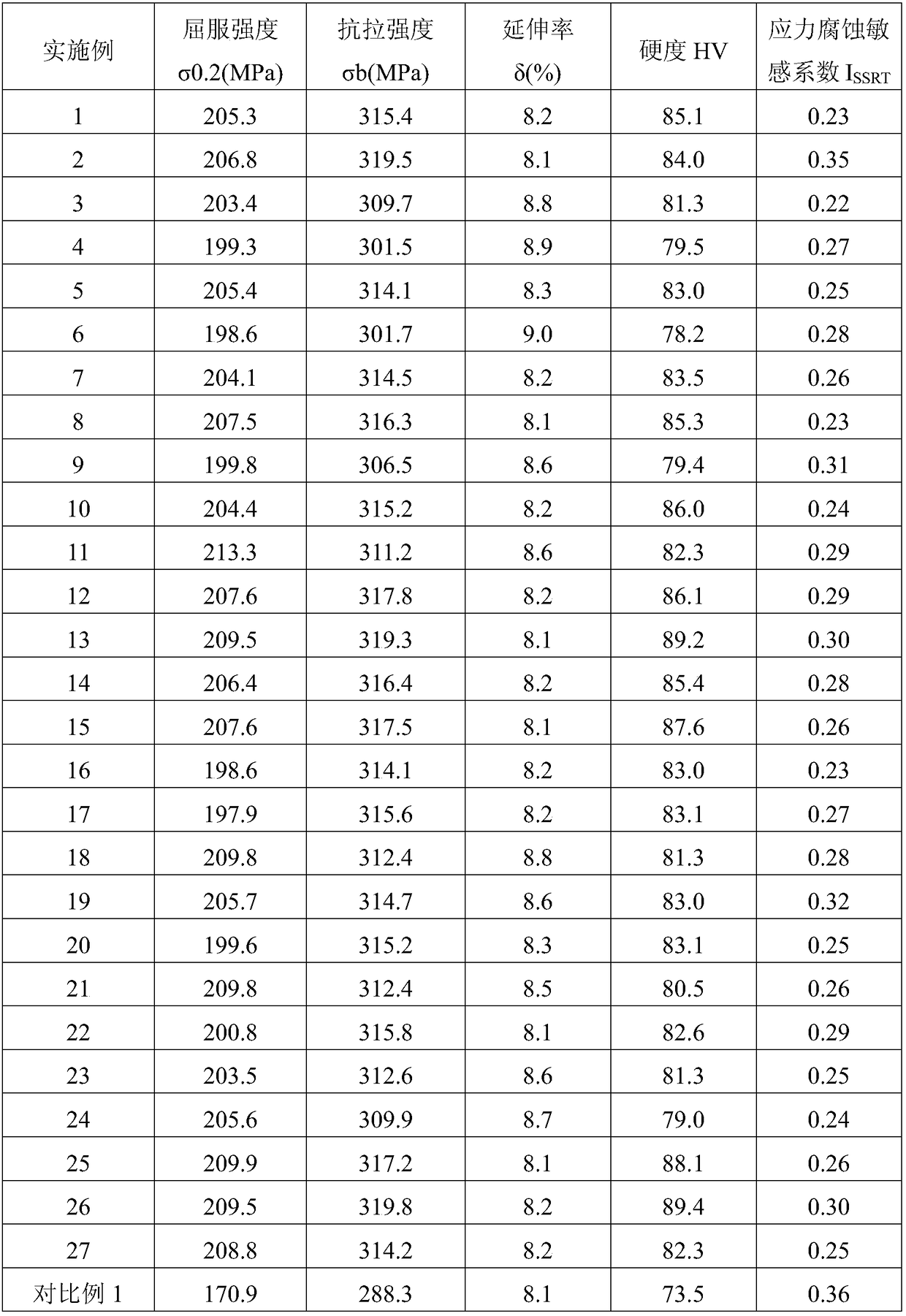

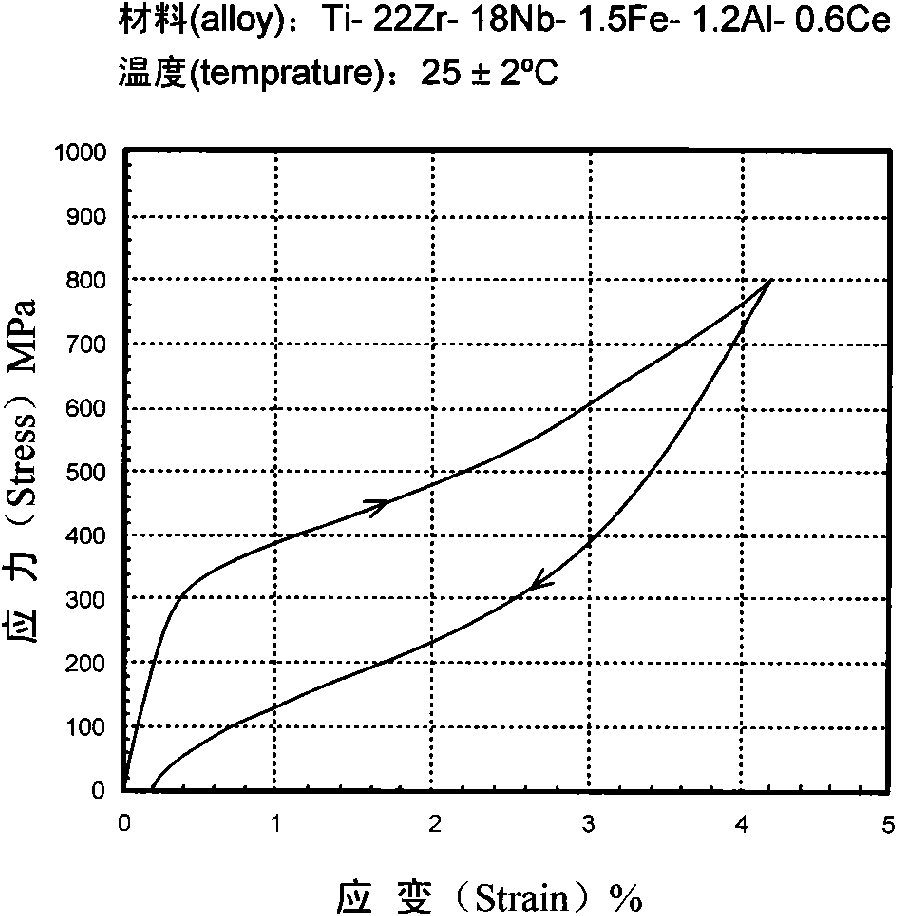

Ni-free super elastic Ti-based shape memory alloy and products thereof

InactiveCN101580907AImprove corrosion resistanceImprove high temperature oxidation resistanceImpression capsSurgeryDriven elementBiocompatibility Testing

The invention relates to a Ni-free super elastic Ti-based shape memory alloy and products thereof. Because of adding rare earths metal element Ce, the Ti-Zr-Nb-Fe-Al-Ce Ni-free super elastic Ti-based shape memory alloy has high erosion resistance and oxidation resistance as well as excellent welding performance, cold workability, phase-changing super elasticity, shape memory property and biocompatibility. The welding performance, the cold workability and the biocompatibility of the alloy are better than those of TiNi shape memory alloy, while the super elasticity and the shape memory property are equivalent to those of the TiNi shape memory alloy. The Ti-Zr-Nb-Fe-Al-Ce Ni-free super elastic Ti-based shape memory alloy not only can be used as biomaterial capable of being implanted in a human body for a long time, but also can be used as hyperelastic alloy manufacturing industrial products such as spectacle frame, bra support, golf club head, pipe joint, spring and drive element; moreover, the alloy has the advantages of easy processing, low cost and wide application range.

Owner:深圳市星河泉新材料有限公司

Al-Mg-Zn aluminum alloy welding wire and preparation method thereof

PendingCN108396206AImprove mechanical propertiesIncreased intensityWelding/cutting media/materialsSoldering mediaWeld seamUltimate tensile strength

The invention relates to an Al-Mg-Zn aluminum alloy welding wire and a preparation method thereof, and belongs to the technical field of aluminum alloy welding wires. The Al-Mg-Zn aluminum alloy welding wire is prepared from the components in percentage by mass: 0.5 to 3.0 percent of Zn, 4.5 to 5.5 percent of Mg, 0.05 to 0.20 percent of Mn, less than or equal to 0.15 percent of Ti, less than or equal to 0.15 percent of Cr, less than or equal to 0.25 percent of Fe, less than or equal to 0.25 percent of Si, less than or equal to 0.15 percent of the total amount of other impurity elements, less than or equal to 0.05 percent of the content of single impurity element, and the balance Al. The preparation method comprises the steps of smelting, casting, heating to 440 DEG C to 470 DEG C, keepingwarm for 3h to 6h, carrying out hot extrusion, heating to 480 DEG C to 550 DEG C, keeping arm for 3h to 6h, rolling, intermediate annealing, scaling, and multi-pass drawing. According to the method, high-temperature long-time homogenization treatment is not needed, so that the energy is saved, and the welding wire production process is shortened; and excess crystal phase particles in the welding wire are fine in size and uniform in dispersion and distribution, so that wire breakage caused by drawing is reduced, the welding wire yield is improved, the production cost is reduced, and a welding performance and the weld seam metal strength of the welding wire can be improved.

Owner:NORTHEASTERN UNIV

Mo-containing ferritic stainless steel and manufacturing method thereof

ActiveCN102206791AKeep N element contentGood formabilityTemperature control deviceChemical elementImpurity

The invention discloses Mo-containing ferritic stainless steel, which comprises the following chemical elements in percentage by mass: less than or equal to 0.025 percent of C, less than or equal to 0.025 percent of N, less than or equal to 1.0 percent of Si, less than or equal to 1.0 percent of Mn, less than or equal to 0.04 percent of P, less than or equal to 0.03 percent of S, more than 20.0 percent and less than or equal to 22.0 percent of Cr, more than 0 percent and less than or equal to 1.0 percent, less than or equal to 1.3 percent of (Ni+Cu), more than or equal to 0.5 percent and lessthan or equal to 1.2 percent of Mo, more than or equal to 10(C+N) and less than or equal to 0.8 percent of (Ti+Nb), less than or equal to 0.015 percent of O, and the balance of Fe and other inevitable impurities. Correspondingly, the invention also discloses a manufacturing method for the steel. Compared with the conventional SUS444 and SUS436L steel, the Mo-containing ferritic stainless steel has the advantages of greatly reducing manufacturing cost, maintaining pitting corrosion resistance and chlorine-ion stress corrosion resistance, and being suitable for water system medium environments.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

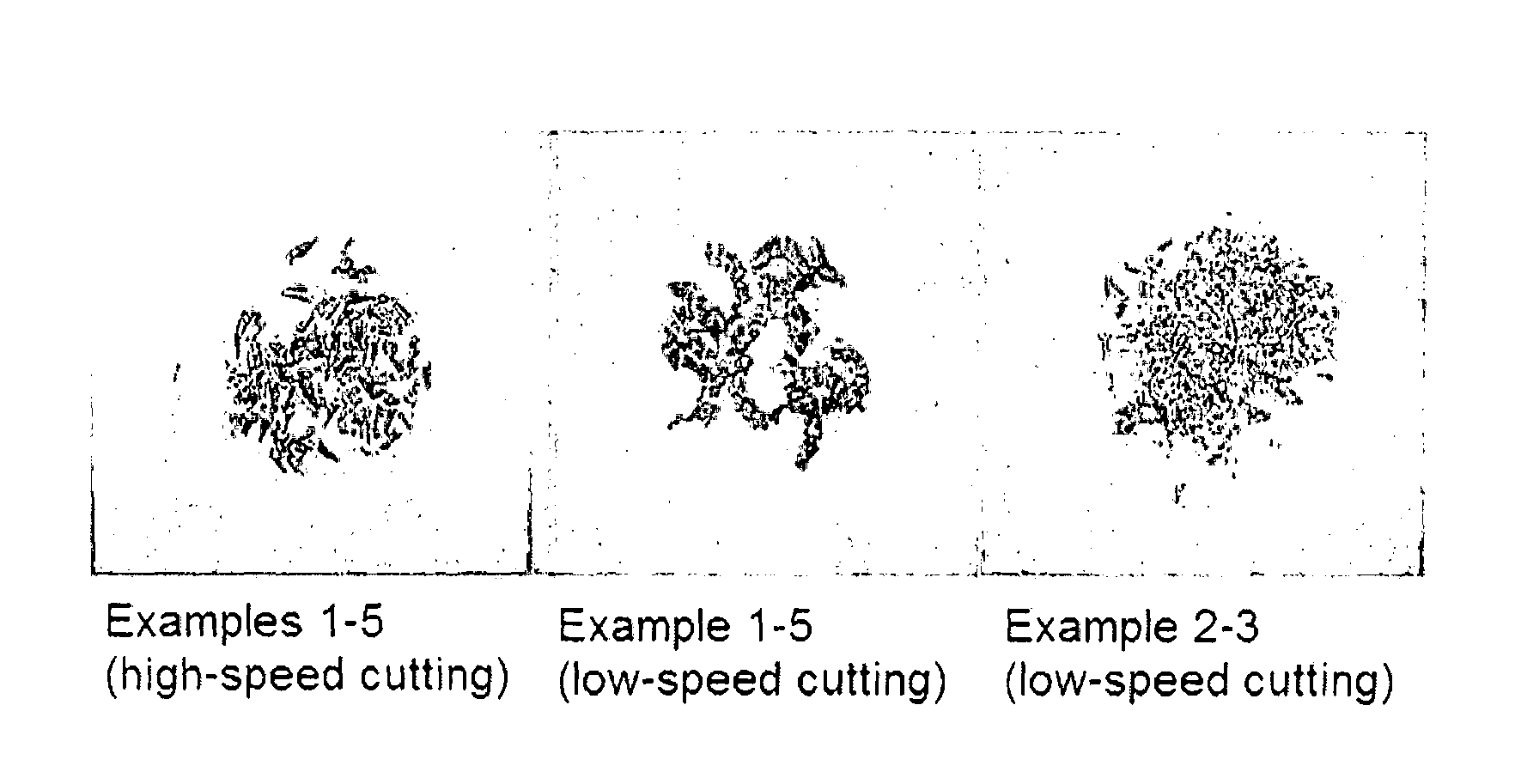

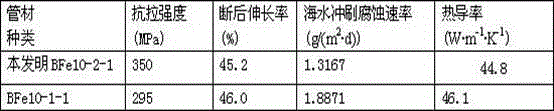

Leadless free-cutting copper alloy and method for producing the same

ActiveUS20140248175A1Improve machinabilityIncrease resistanceRollsMetal rolling arrangementsManganeseZinc

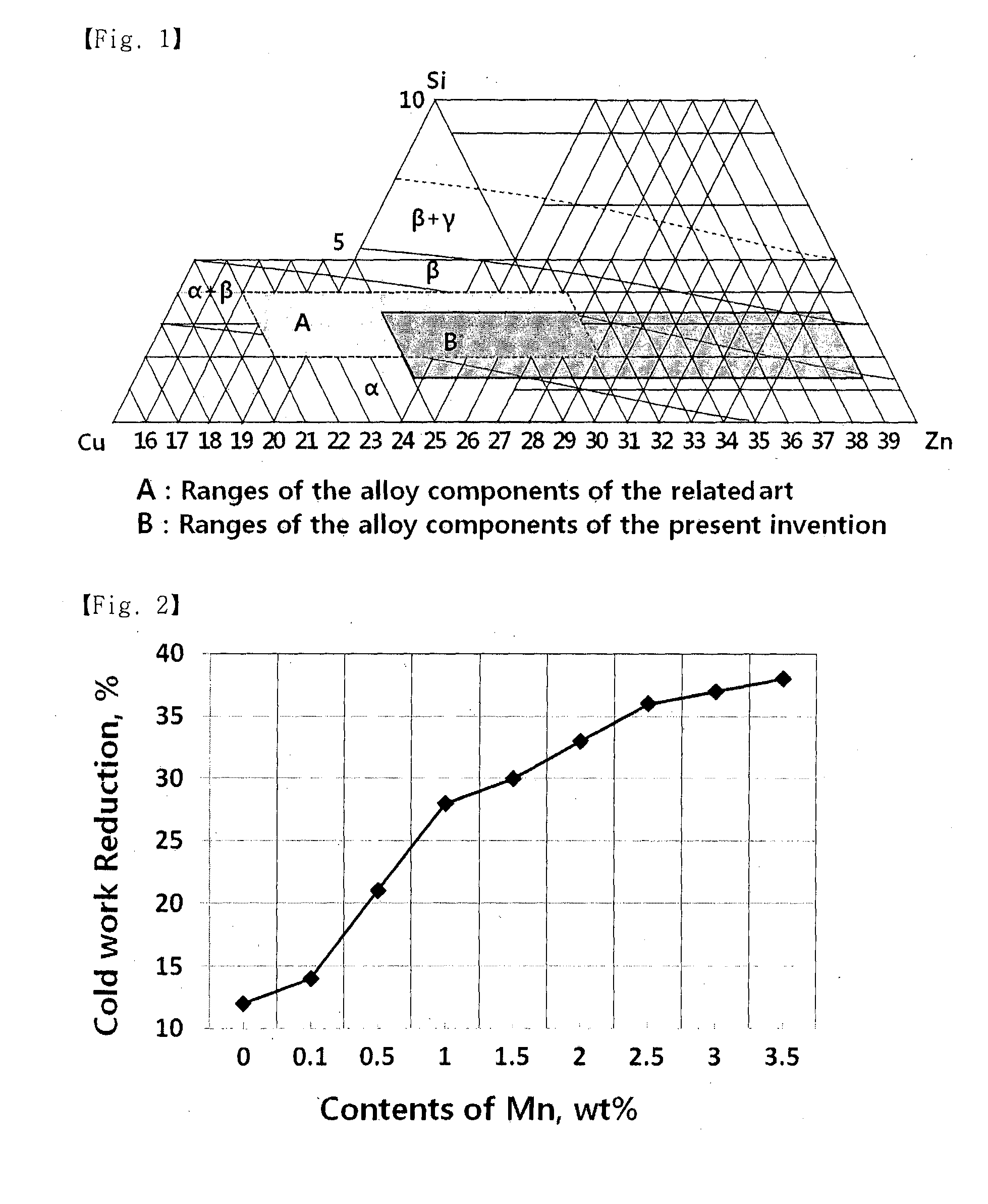

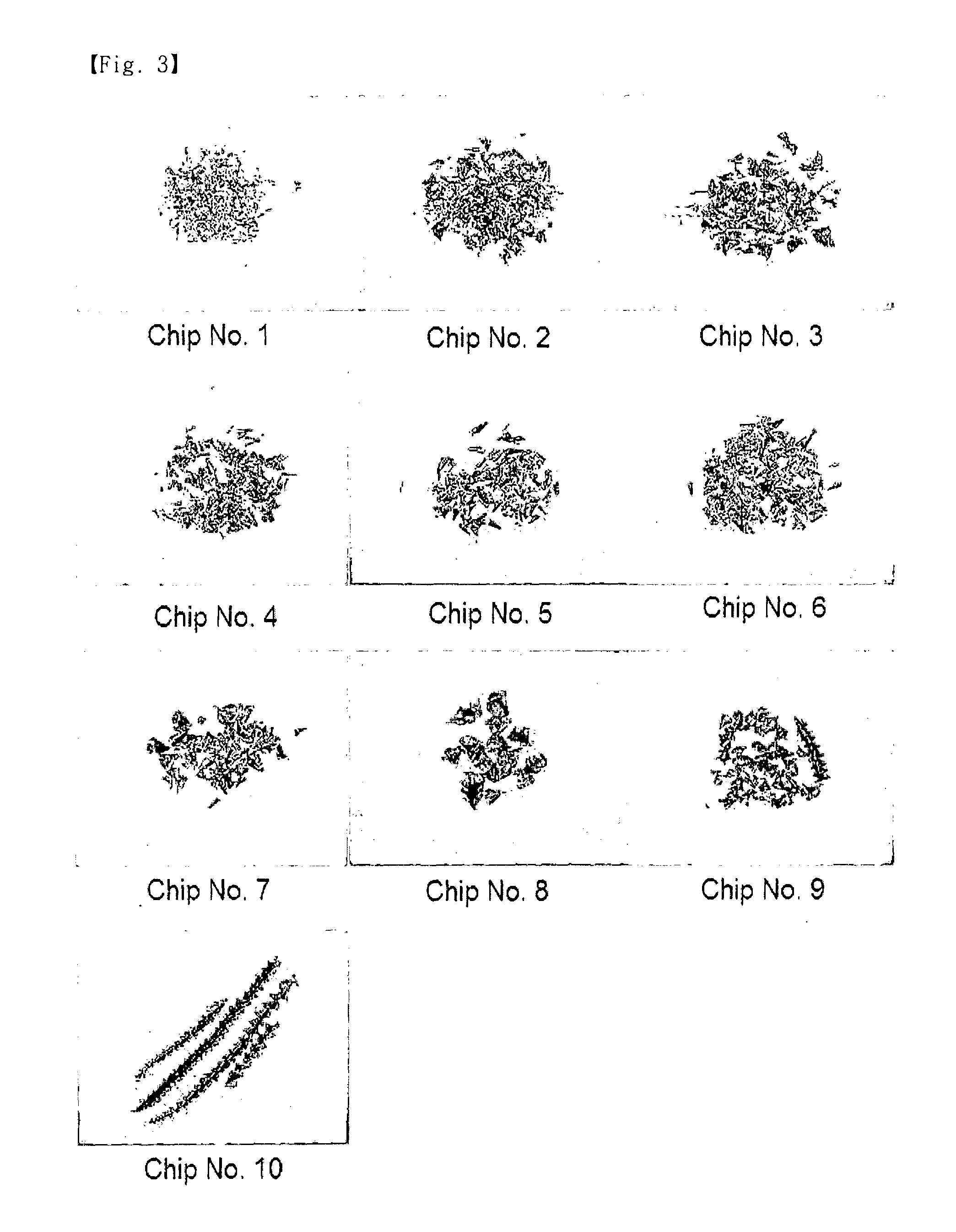

Disclosed is a leadless free-cutting copper alloy that exhibits superior machinability, cold workability and dezincification resistance and a method for producing the same. The leadless free-cutting copper alloy comprises 56 to 77% by weight of copper (Cu), 0.1 to 3.0% by weight of manganese (Mn), 1.5 to 3.5% by weight of silicon (Si), and the balance of zinc (Zn) and other inevitable impurities, thus exhibiting superior eco-friendliness, machinability, cold workability and dezincification resistance.

Owner:POONGSAN CO LTD

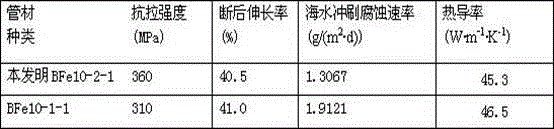

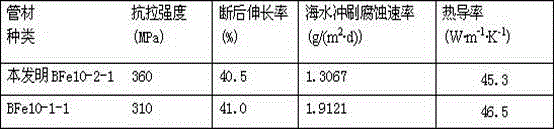

High-iron cupronickel alloy pipe and short-process production method thereof

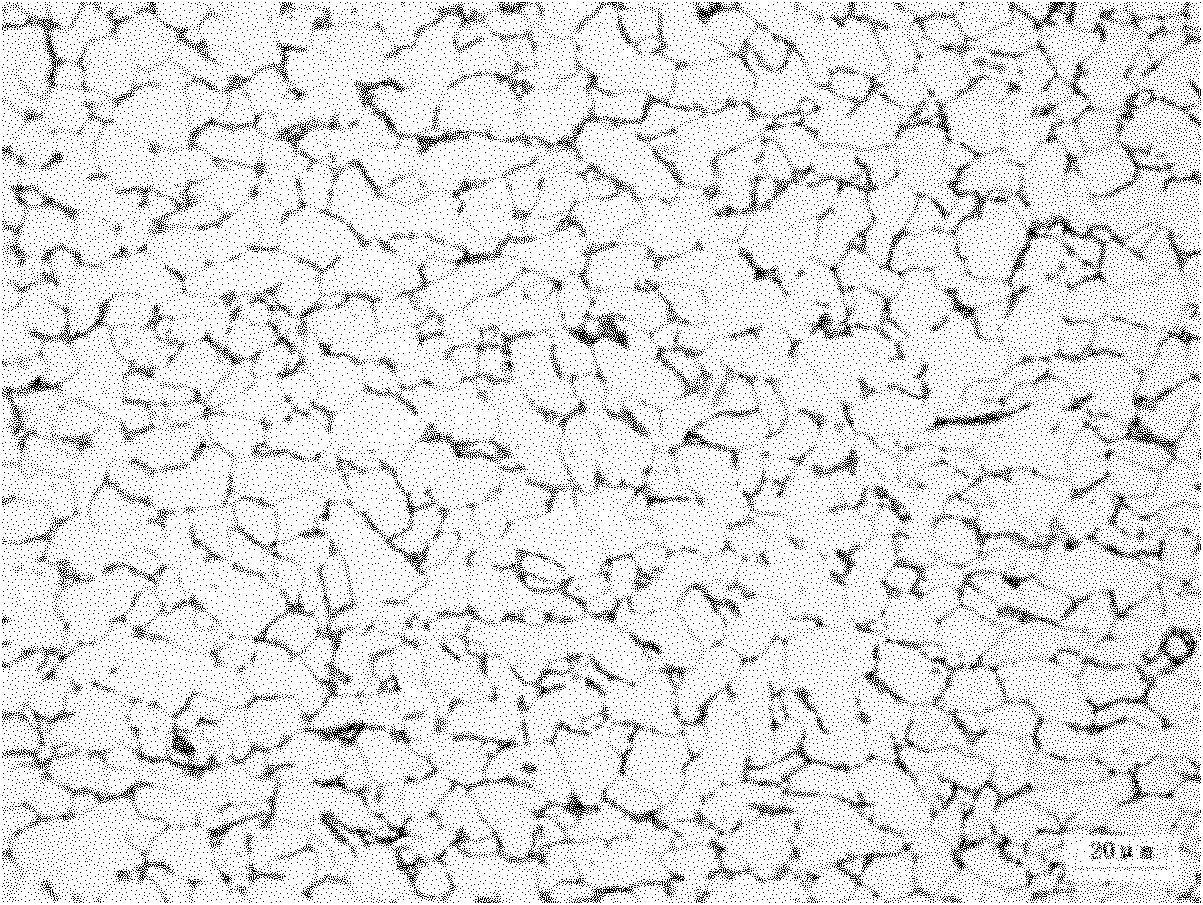

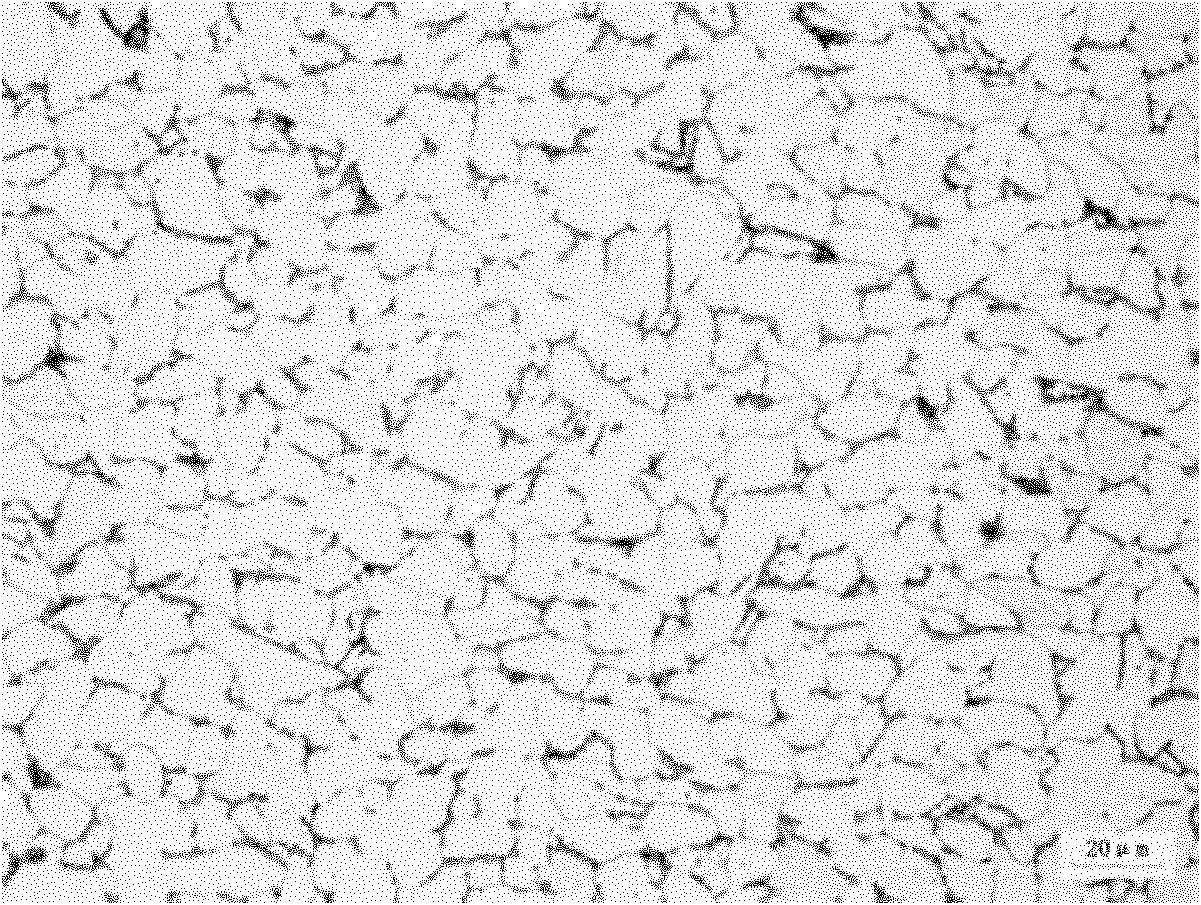

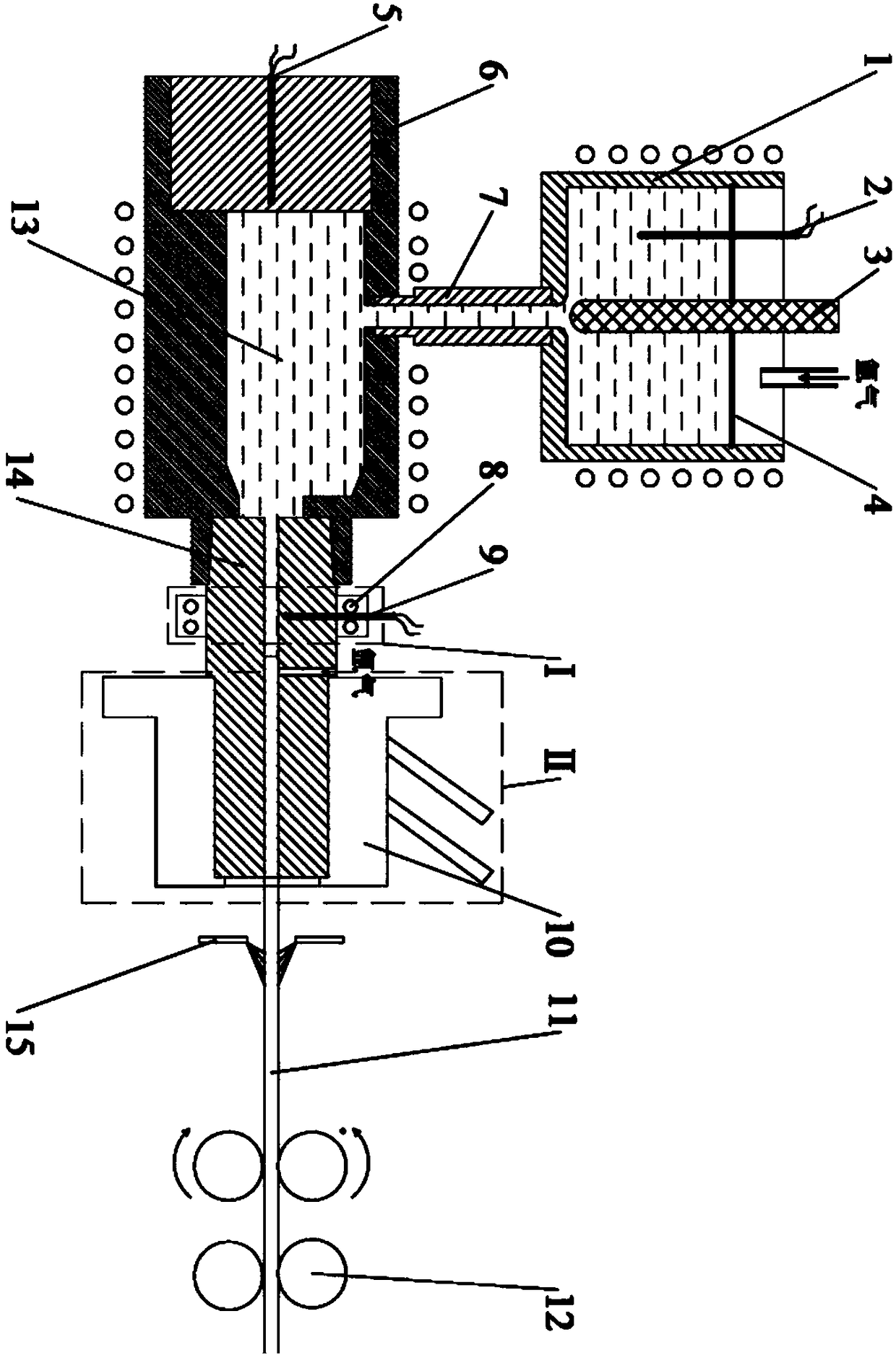

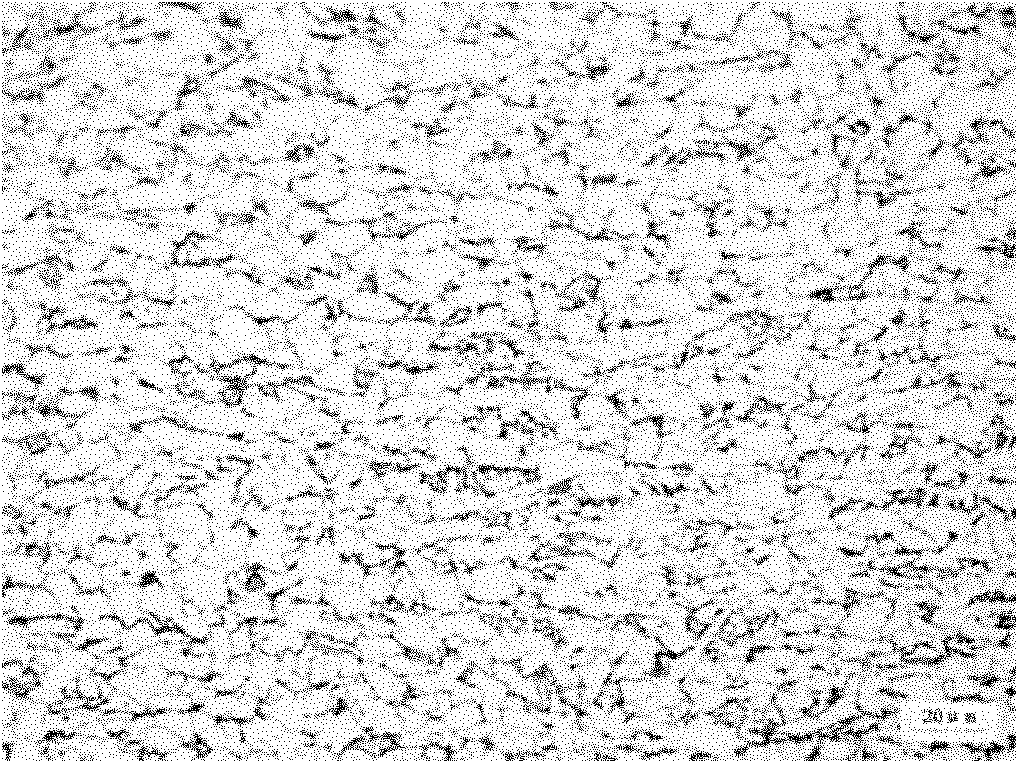

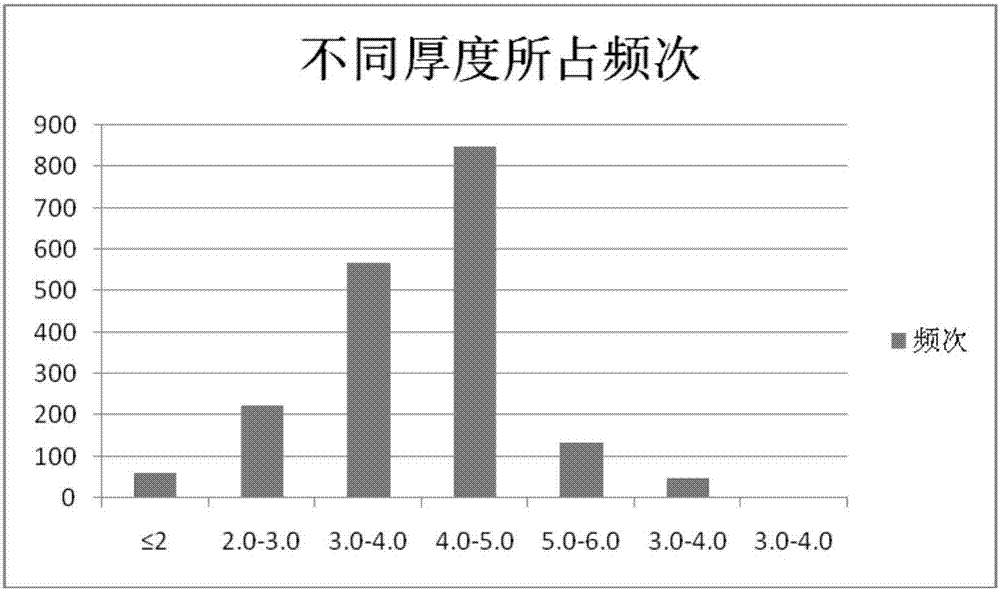

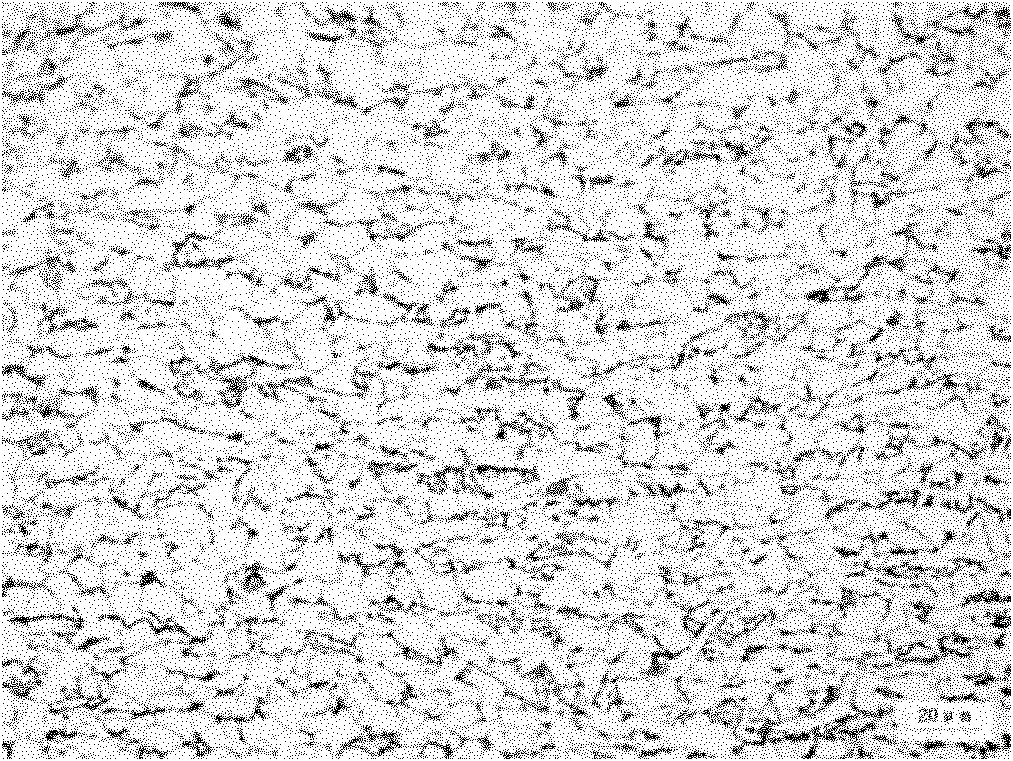

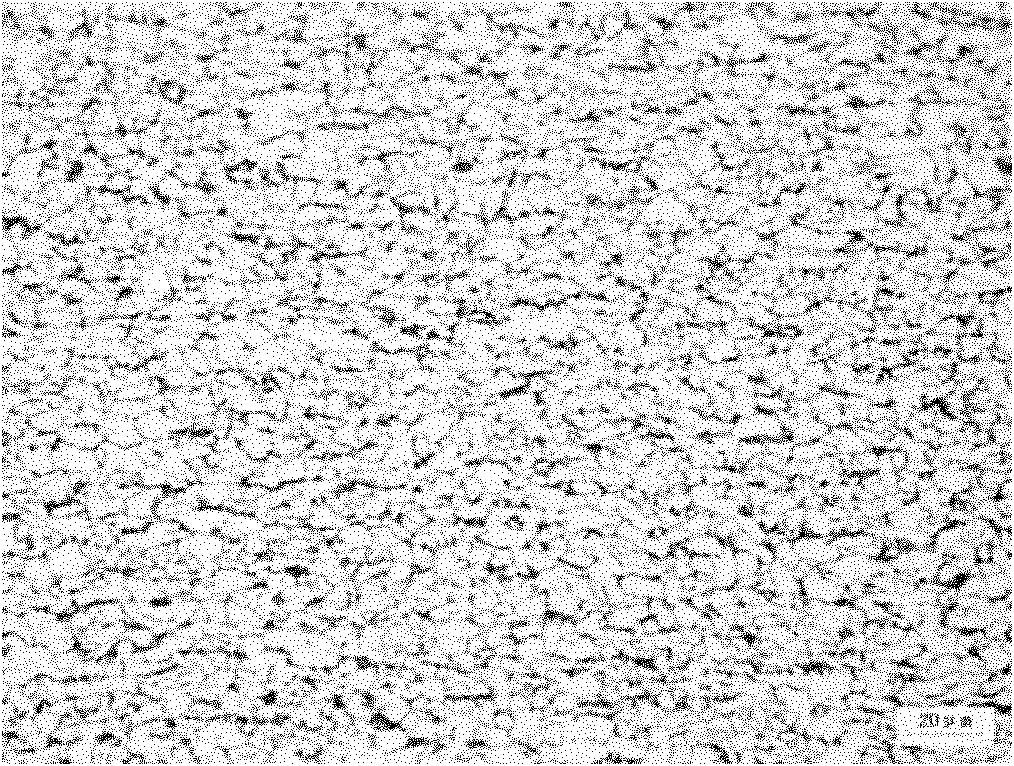

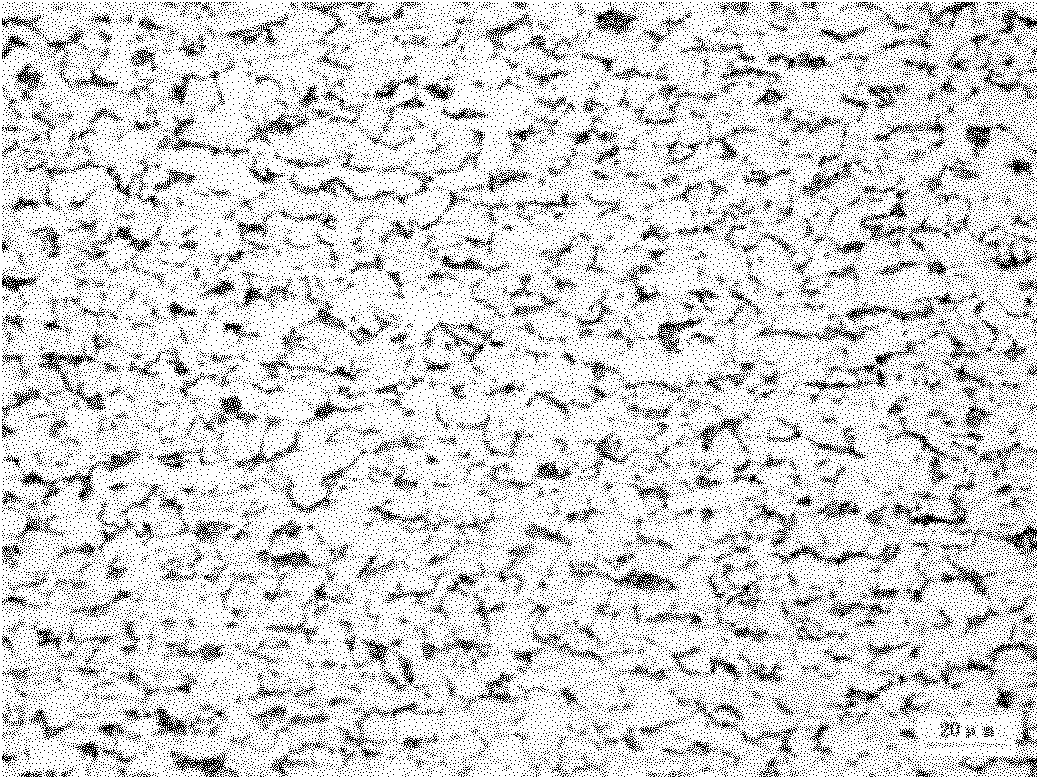

The invention relates to a high-iron cupronickel alloy pipe and a short-process production method thereof, and belongs to the technical field of metal materials. Compared with a BFe10-1-1 alloy, the cupronickel alloy BFe10-2-1 provided by the invention is increased in alloy iron element content from 1.0wt%-1.5wt% to 1.6wt%-2.5wt%, thereby greatly enhancing the corrosion-resistant property and mechanical property of the alloy. According to the short-process production method, a pipe billet with high inner-outer surface quality and high-axial orientation columnar crystal structure is prepared by adopting a heat-cold combined casting horizontal continuous casting technology, so that the cold machining property of high-iron cupronickel is greatly enhanced; the continuous casting pipe billet is directly subjected to cold rolling and / or cold-draw forming, a pipe is subjected to finished product annealing by adopting a proper annealing schedule to eliminate microsegregation, the average size of a recrystallized grain is controlled to 20-40 micrometers, the volume fraction of a precipitated phase is reduced to be less than 2%, so that the cupronickel pipe with excellent mechanical property and corrosion-resistant property is obtained. Compared with a BFe10-1-1 pipe produced through the traditional method, the BFe10-2-1 high-iron cupronickel pipe disclosed by the invention has the advantages of more excellent integral using property, short production process and high production efficiency and finished product rate.

Owner:UNIV OF SCI & TECH BEIJING

Corrosion-resisting ferroalloy material for fastener and preparation method thereof

The invention relates to a corrosion-resisting ferroalloy material for a fastener and a preparation method thereof. The ferroalloy material comprises the following components in percentage by weight: 0.08-0.10% carbon, 15-15.5% manganese, 0.3-0.6% silicon, 14.5-15.0% of chromium, 0.03-0.05% of molybdenum, 0.5-1.0% of nickel, 0.03-0.05% of vanadium, 0.1-0.3% of titanium, 0.01-0.03% of zirconium, 0.01-0.03% of boron, 0.3-0.5% of copper, 0.15-0.25% of nitrogen, 0.001-0.002% of lanthanum, and the balance of iron. The ferroalloy produced by the technical scheme is a ferroalloy material with relatively high mechanical properties, wear resistance, tenacity and wear resistance.

Owner:NINGBO TENGLING IND & TRADE

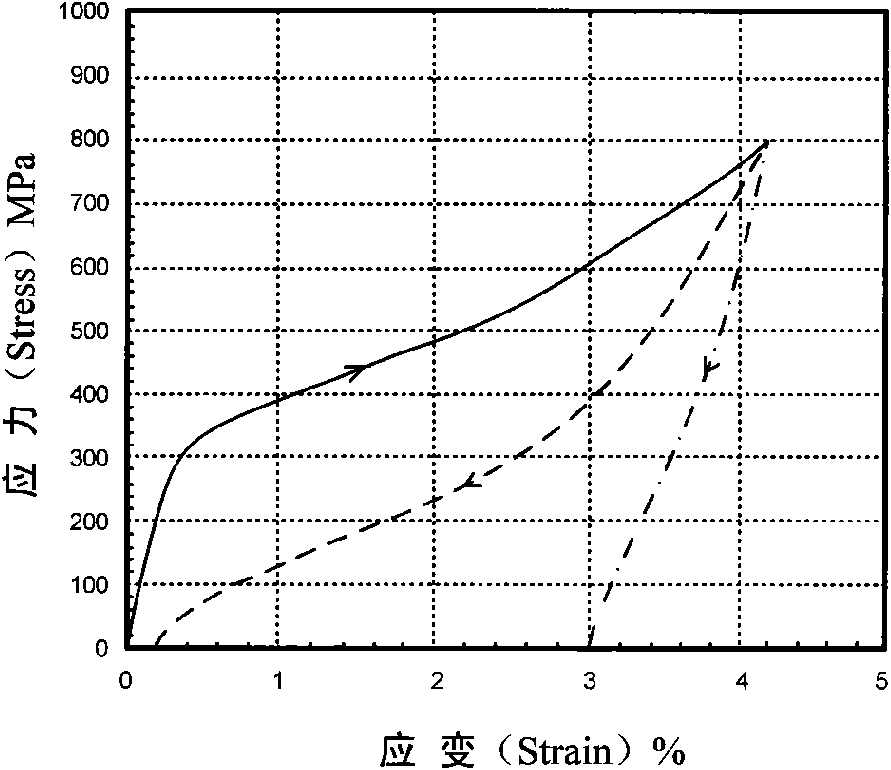

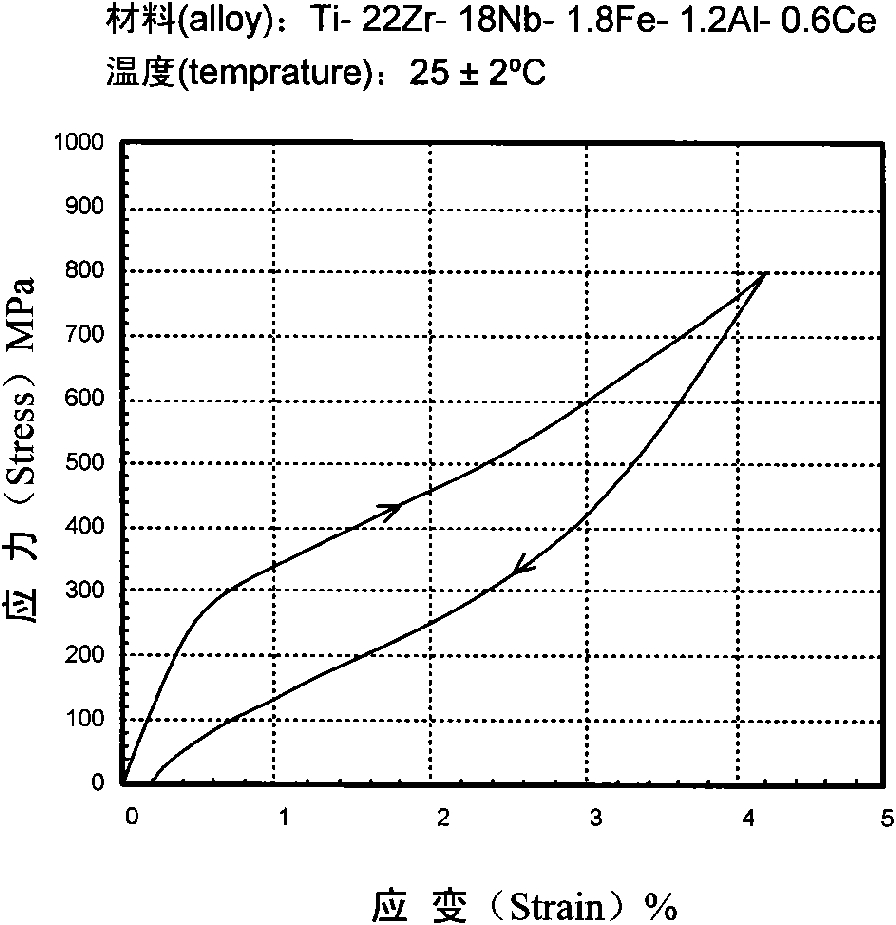

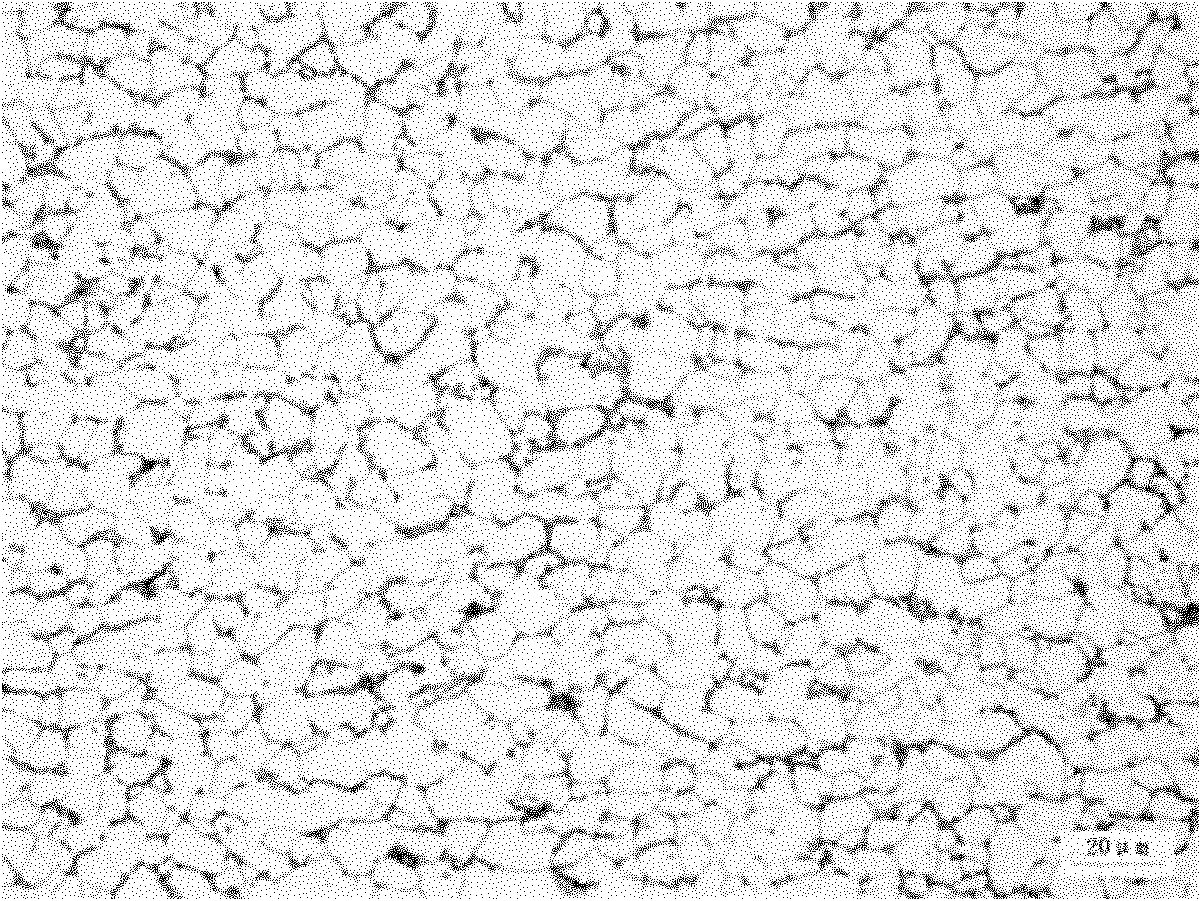

Ti-Zr-Nb-Fe-Al-Ce super elastic alloy and products thereof

InactiveCN101580906AImprove corrosion resistanceImprove high temperature oxidation resistanceImpression capsSurgeryBiocompatibility TestingShape-memory alloy

The invention relates to Ti-Zr-Nb-Fe-Al-Ce super elastic alloy and products thereof. Because of adding appropriate amount of Fe, Al and Ce elements, the super elastic alloy has high erosion resistance and oxidation resistance as well as excellent welding performance, cold workability, phase-changing super elasticity, shape memory property and biocompatibility. The welding performance, the cold workability and the biocompatibility of the alloy are better than those of TiNi shape memory alloy, while the super elasticity and the shape memory property are equivalent to those of the TiNi shape memory alloy. The Ti-Zr-Nb-Fe-Al-Ce super elastic alloy not only can be used as biomaterial capable of being implanted in a human body for a long time, but also can be used as industrial products made from the alloy such as spectacle frame, bra support, golf club head, pipe joint, spring and drive element; moreover, the alloy has the advantages of easy processing, low cost and wide application range.

Owner:深圳市星河泉新材料有限公司

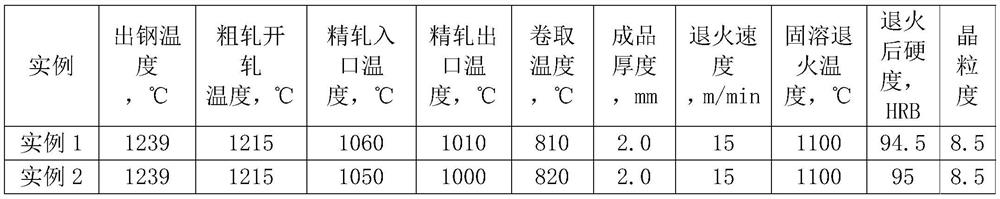

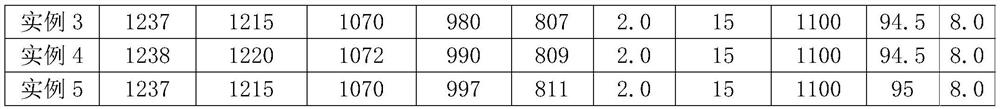

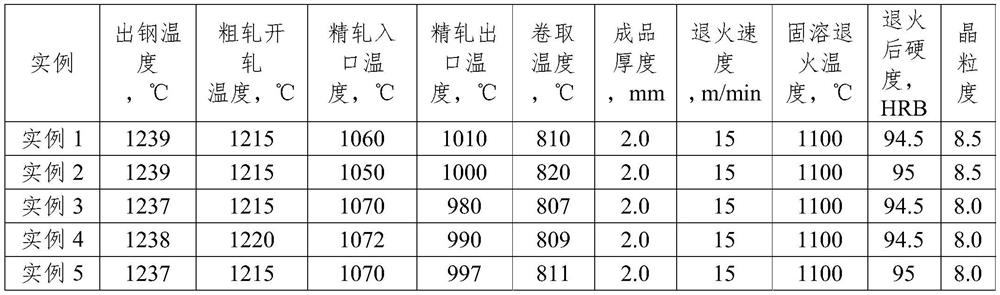

Method for producing hot-rolled steel coil

InactiveCN102127679AImprove plasticityImprove toughnessProcess efficiency improvementInsertion depthNitrogen

The invention relates to a method for producing a hot-rolled steel coil, which comprises the following steps of: 1) designing components, pretreating molten iron, smelting in a converter, switching nitrogen and argon, and tapping to obtain molten steel; 2) performing continuous casting on the molten steel to obtain a plate blank, wherein the content of the molten steel in a continuously cast intermediate ladle is controlled to be between 8 and 15t and the liquid level is controlled to be between 200 and 350mm when the intermediate ladle is not poured; and pouring is protected in the whole process, and the insertion depth of a long nozzle is between 300 and 400mm; 3) heating the plate blank; and 4) rolling and curling the heated plate blank. By the method, the content of C and Mn in the components of Q235q-D steel is reduced, the comprehensive performance of the Q235q-D steel is improved by appropriate rolling process and controlled cooling process, and a low-cost and high-performance Q235q-D hot-rolled steel coil is produced.

Owner:NINGBO IRON & STEEL

A non-vacuum melting horizontal continuous casting production process for high-strength and high-conductivity cu-cr-zr alloy rods

ActiveCN106735003BSolve easy oxidationSolve the problem of component segregation in the solidification processZr alloyImpurity

Owner:UNIV OF SCI & TECH BEIJING

Heat-resistant aluminum-alloy conductor material for cables and manufacture method thereof

InactiveCN101948971BImprove creep resistanceHigh tensile strengthSingle bars/rods/wires/strips conductorsMetal/alloy conductorsRare-earth elementElectrical conductor

Owner:绩溪欣意圣厚源电缆有限公司

Method for producing hot-rolled steel coils

InactiveCN102212748AReduce dosageSimple methodRoll mill control devicesManufacturing convertersNiobiumPosition control

The invention relates to a method for producing hot-rolled steel coils. The method comprises the following steps of: 1) designing components, pre-treating molten iron, smelting in a converter with nitrogen and argon switching, and tapping to obtain molten steel; 2) performing continuous casting on the molten steel to obtain a plate blank, wherein when pouring of a continuously cast intermediate ladle is stopped, the molten steel quantity of the intermediate ladle is controlled at 8 to 15 tons, the liquid level is 200 to 350 millimeters, full-process protective pouring is adopted, and the inserting depth of a long nozzle is 300 to 400 millimeters; 3) heating the plate blank; and 4) rolling the heated plate blank, and coiling. A thermo-mechanical control process + remote position control (TMCP+RPC) rolling process is adopted in the method; by using micro niobium treatment, the content of C and the content of Mn are greatly reduced, and the production cost is reduced; the obtained Q345q-C hot-rolled steel coils have good plasticity and toughness, and the elongation of the steel coils can be improved by over 8 percent; and meanwhile, the welding property of the steel coils is improved, and good surface quality of a continuously cast bloom is ensured.

Owner:NINGBO IRON & STEEL

Technical requirements for ultra-clean low carbon steel

InactiveCN104178600AImprove cold working performanceWill not cause brittleness in the heat-affected zone of weldingProcess efficiency improvementSolubilitySteelmaking

The invention discloses technical requirements for super cleanness and low carbon steel. The technical requirements comprise the following steps: a high temperature electric arc region in electric steelmaking absorbs nitrogen easily, and the temperature ranges from 330 DEG C to 510 DEG C; under a high chrome condition, the N solubility of molten steel is extremely high, and in the technology for producing low-nitrogen steel, molten steel denitrification is difficulty and limited by diffusion rate; during vacuum powder injection denitrification, effects are not caused during continuous denitrification; during converting and electric furnace oxidation periods, as well as VOD and AOD decarburization, the denitrification is obvious, during a converter decarburization process, a formula for the relation of a denitrification speed and a decarburization speed exists, since oxygen blowing decarburization is performed, a great amount of CO is produced, and for nitrogen, CO bubbles serve as small vacuum chambers, so that the nitrogen can be carried away; for high-purity ferrite stainless steel, a VCR (vacuum refining furnace) is adopted for smelting, so that a converter is adopted for steelmaking to the low-nitrogen steel, nitrogen absorption is prevented during tapping, secondary refining and continuous casting processes, through the strict technical requirements provided by the invention, cold processing performance of ultra-clean low-carbon steel is enhanced greatly, and a crisp welding heat-affected zone cannot be caused.

Owner:JIANGSU HAIWEI GROUP

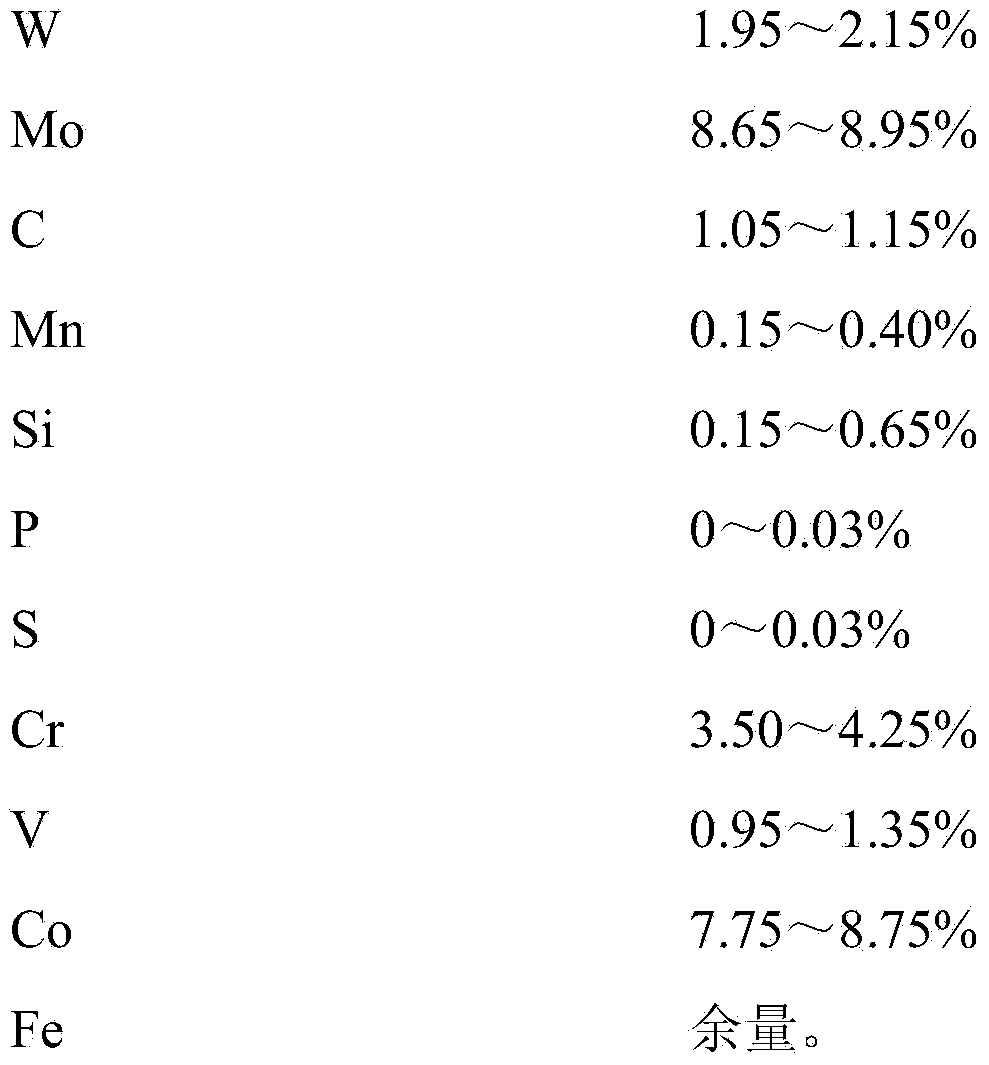

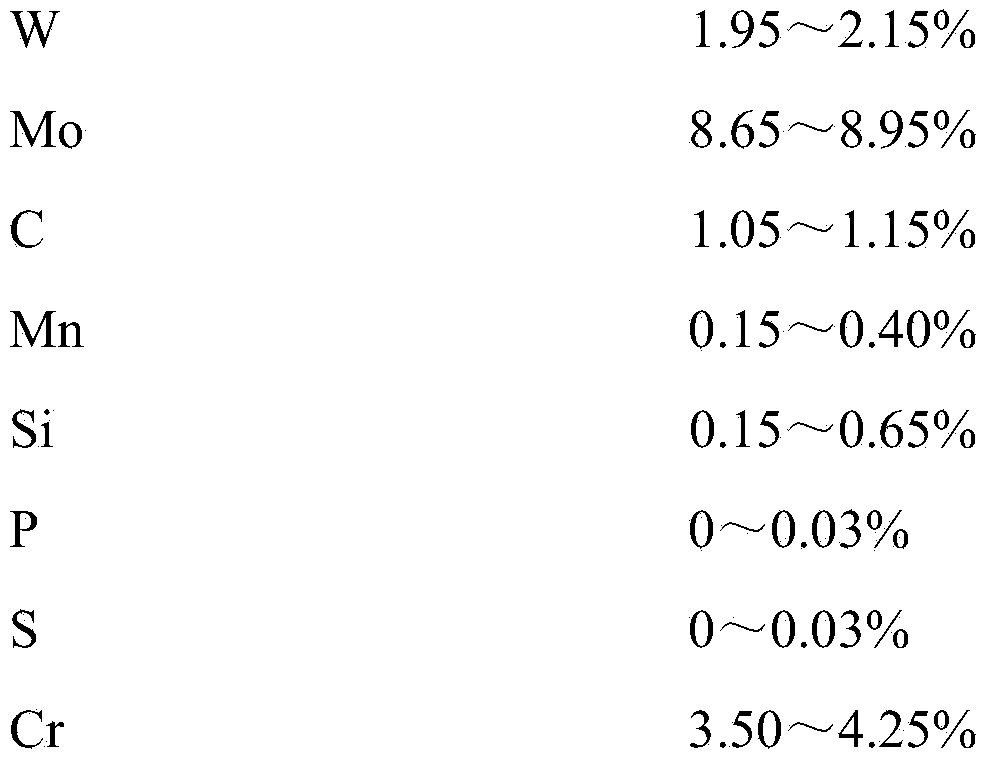

High-performance super-hard high-speed steel

ActiveCN103695789AImprove hot and cold processing performanceReduce decarburization sensitivityMetallic materialsHot working

The invention relates to high-performance super-hard high-speed steel, which belongs to the field of metal materials. The high-speed steel contains w which accounts for 1.95-2.15% of total mass of the high-speed steel and Mo which accounts for 8.65-8.95% of total mass of the high-speed steel. The invention has the positive effect of improving cold and hot working properties of the high-speed steel.

Owner:大连远东工具有限公司

Method for producing hot rolled steel coils

The invention relates to a method for producing hot rolled steel coils. The method comprises the following steps: 1) designing the components, pretreating molten iron, then carrying out converter smelting, carrying out nitrogen / argon changing over and carrying out tapping to obtain molten steel; 2) continuously casting the molten steel to obtain slabs, controlling the weight of the molten steel in the tundish to be 8-15t when casting of the continuous casting tundish is stopped, ensuring the liquid level to be 200-350mm; carrying out protective casting in the whole course and ensuring the insertion depth of the long nozzle to be 300-400mm; 3) heating the slabs; and 4) finally rolling and curling the heated slabs, thus obtaining the hot rolled steel coils. The method has the following beneficial effects: the TMCP (thermo-mechanical control process)+RPC (relaxation-precipitation-controlling phase transformation) rolling processes are adopted and the contents of C and Mn are substantially reduced by utilizing micro-niobium treatment, thus reducing the production cost; and the Q345R hot rolled steel coils obtained by the method have excellent plasticity and toughness, the elongation of the hot rolled steel coils is improved by more than 8%, and at the same time, the welding property of the materials is improved and good surface quality of the continuous casting slabs is ensured.

Owner:NINGBO IRON & STEEL

Low-cost and high-performance SPA-H hot rolled steel coil and preparation method thereof

InactiveCN106947915AImprove plasticityImprove toughnessManufacturing convertersProcess efficiency improvementLaminar coolingPre treatment

The invention relates to a low-cost and high-performance SPA-H hot rolled steel coil and a preparation method thereof. The low-cost and high-performance SPA-H hot rolled steel coil comprises, by mass, 0.07%-0.095% of C, 0.25%-0.35% of Si, 0.38%-0.48% of Mn, 0.085%-0.105% of P, 0.007% of S or the less, 0.25%-0.35% of Cu, 0.08%-0.20% of Ni, 0.50%-0.60% of Cr, 0.015%-0.045% of Als and the balance Fe and inevitable impurities. The preparation method comprises the steps of composition design, hot metal pretreatment, converter smelting, ladle furnace treatment, continuous casting, hot continuous rolling, laminar cooling and reeling, and the SPA-H hot rolled steel coil is obtained. The SPA-H hot rolled steel coil has excellent plasticity and toughness, cold processing performance is improved, the problem of bending cracking of large deformation in the using process of the SPA-H steel coil is avoided, quality objections are reduced, and comprehensive performance of SPA-H steel is improved.

Owner:NINGBO IRON & STEEL

Method for producing hot rolled steel coil

The invention relates to a method for producing a hot rolled steel coil. The method comprises the following steps of: 1) designing components, pretreating molten iron, smelting in a converter, switching between nitrogen and argon, and performing tapping to obtain molten steel; 2) performing continuous casting on the molten steel to obtain a plate blank, controlling tundish molten steel amount to be between 8t and 15t and liquid level to be between 200mm and 350mm when a continuous casting tundish stops pouring, and pouring under protection in the entire process, wherein the length of an inserted part of a long nozzle is between 300mm and 400mm; 3) heating the plate blank; and 4) finally rolling the heated plate blank and winding to obtain the hot rolled steel coil. In the method, a thermo mechanical control process (TMCP) and a relaxation-precipitation-control (RPC) rolling process are adopted, and C content and Mn content are greatly reduced by micro niobium treatment, so that production cost is reduced; the Q345q-E hot rolled steel coil produced by the method has high plasticity and toughness, and the elongation rate of the hot rolled steel coil is improved by more than 8 percent; meanwhile, the welding properties of materials are improved, and high surface quality of a continuous casting blank is guaranteed.

Owner:NINGBO IRON & STEEL

A chemical conversion film on the surface of a magnesium alloy and its preparation method

ActiveCN109355651BExcellent adhesionAchieve compactnessVacuum evaporation coatingSputtering coatingCeriumFilm-forming agent

The invention provides a chemical conversion film on the surface of a magnetism alloy and a preparation method thereof. Rare earth cerium ions are injected in the surface of the magnesium alloy in anion injecting mode to form anchoring points so as to improve the adaptation between a conversion film layer and the surface of the magnesium alloy; meanwhile, a surface treating agent with metallic oxysalt and sulfydryl-contained silane as a film forming agent is applied to the surface of the magnesium alloy; the type and the components of the surface treating agent are screened; the treatment process is improved to finally prepare the conversion film layer with high compactness and excellent corrosion resistance; and the conversion film layer can achieve excellent lubricity, alkali resistanceand coating property in subsequent cold working.

Owner:江西天仙精藏设备有限公司

Ti-Nb-Zr Alloy

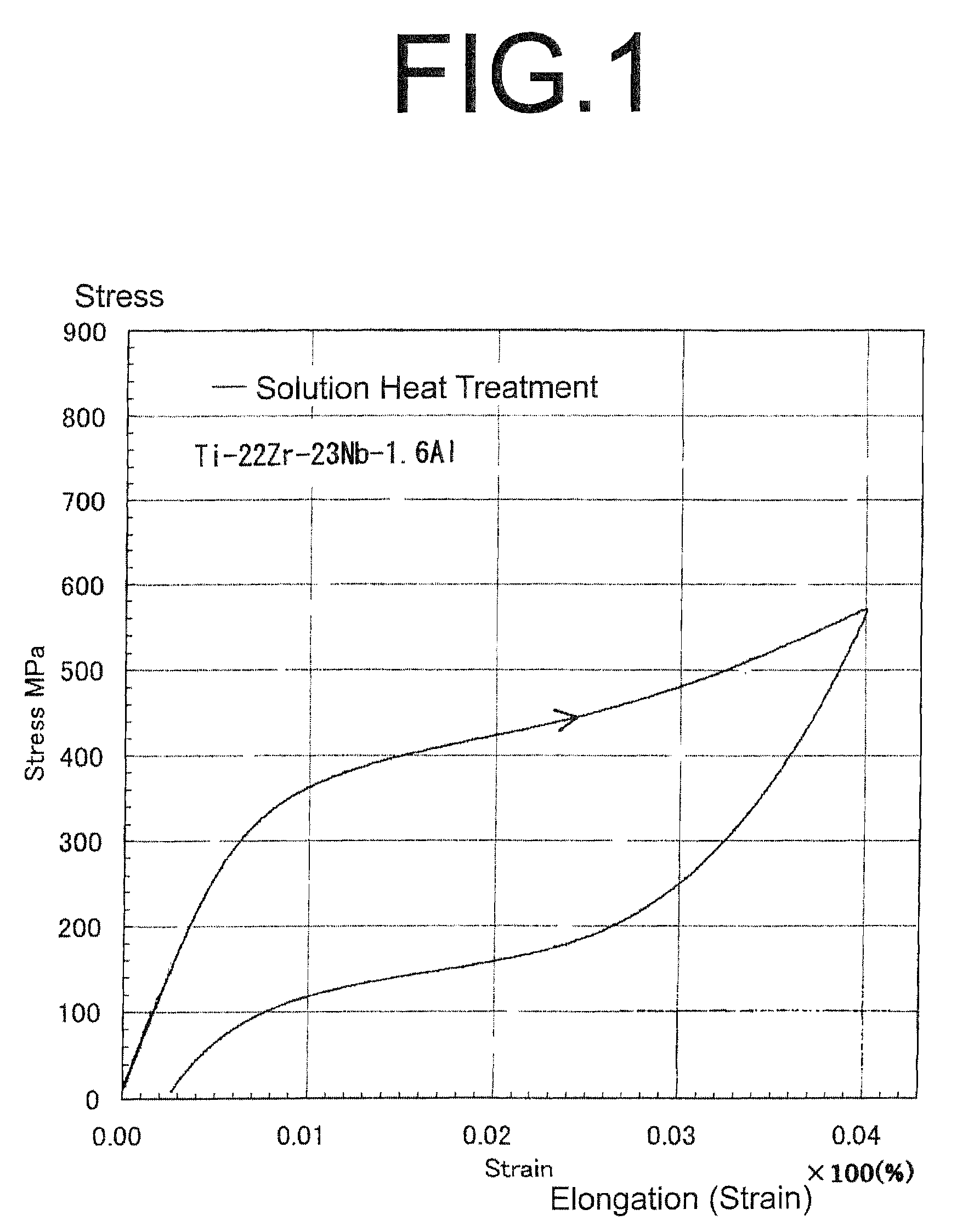

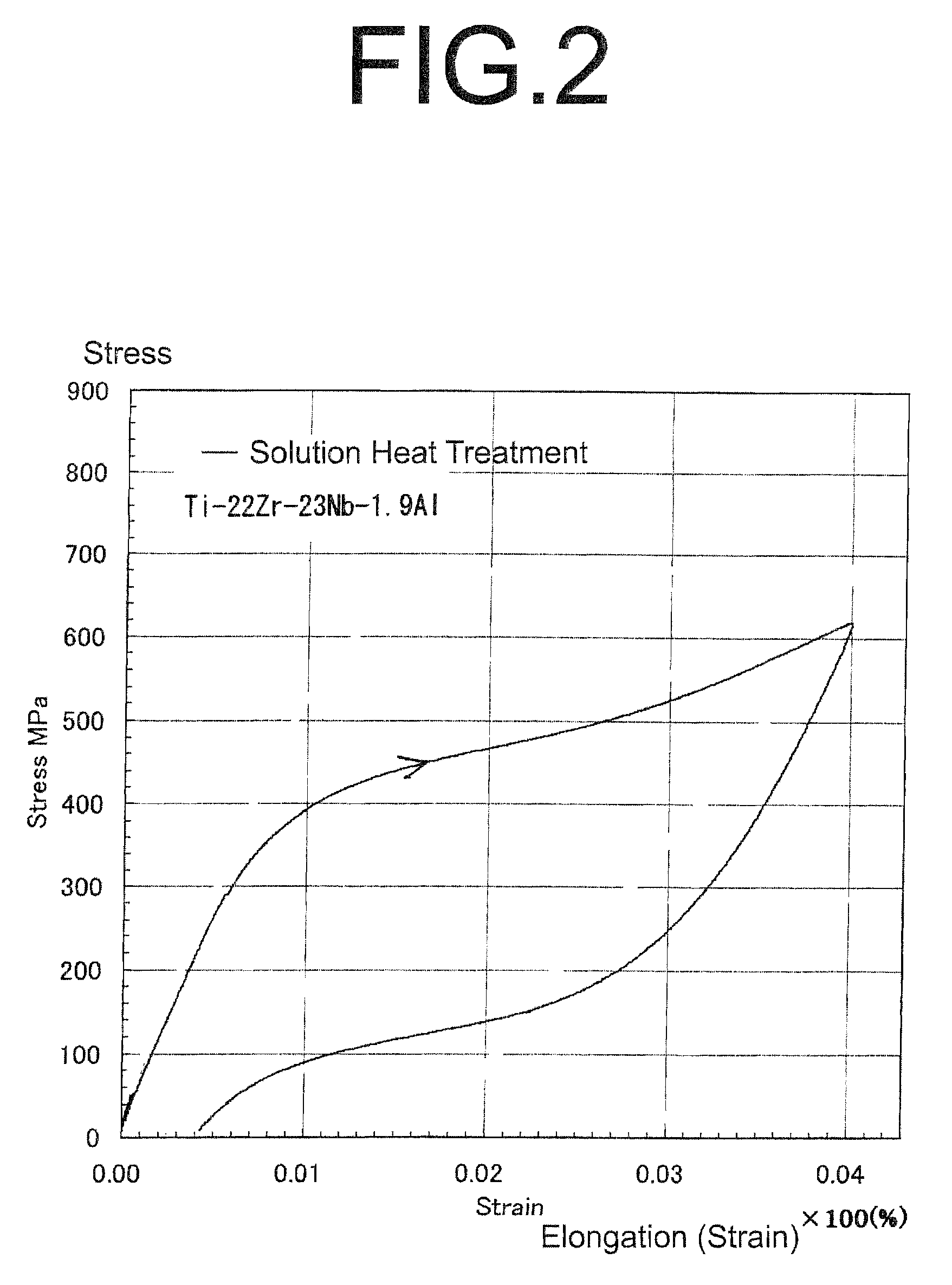

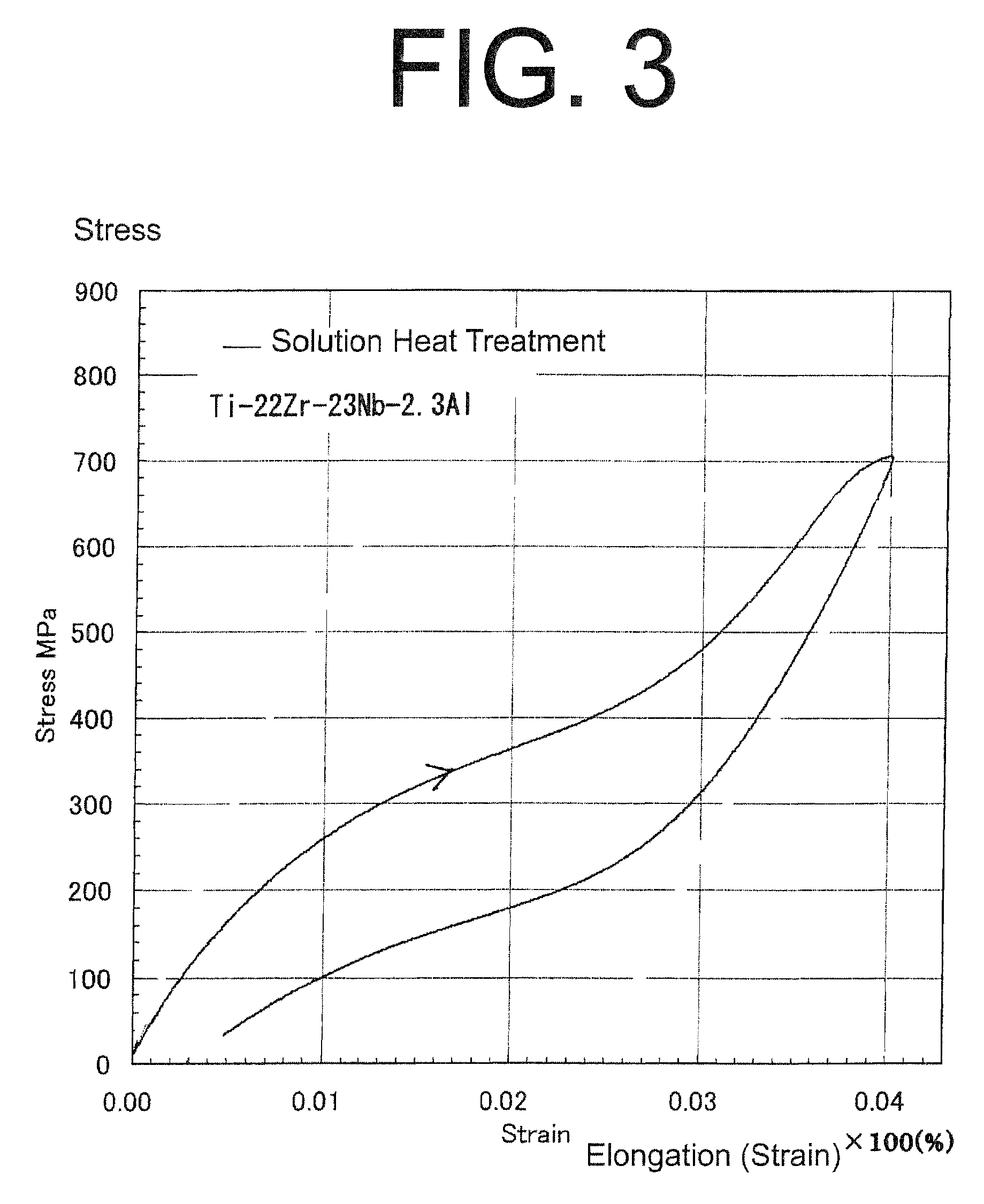

InactiveUS20080193323A1Improve cold working performanceProperty in practicalElemental compositionBiocompatibility Testing

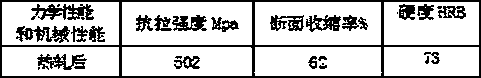

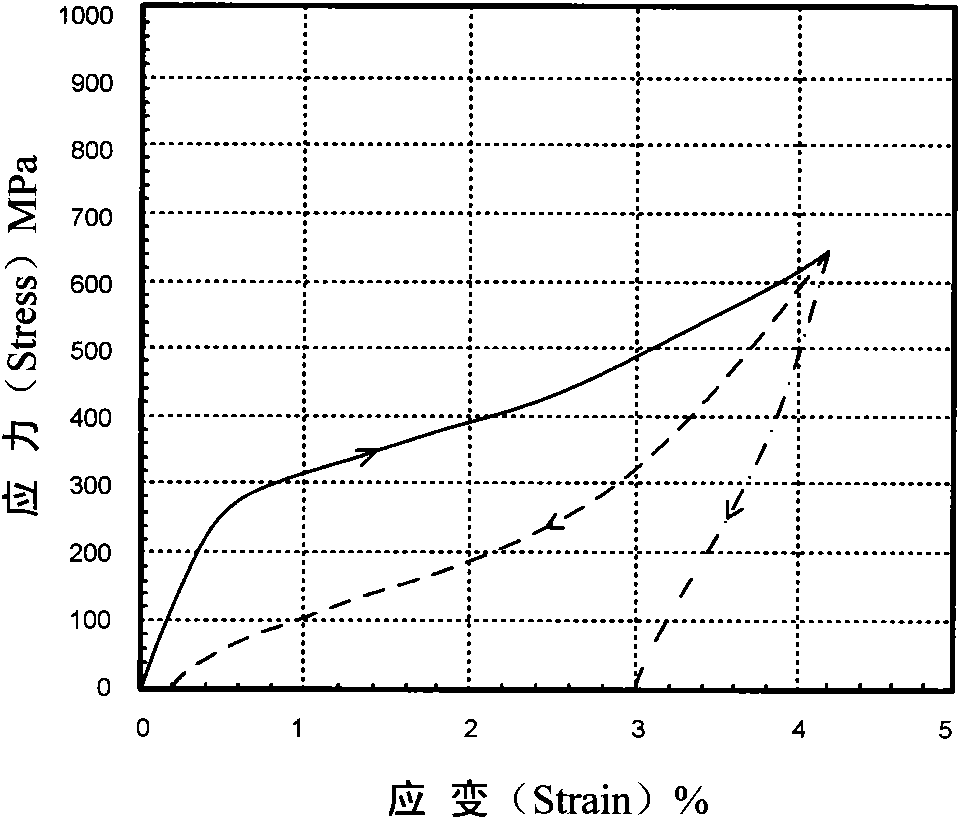

An object of the present invention is to develop a shape memory and superelastic alloy that does not contain nickel, and has superelasticity and shape memory properties even if being subjected to heat treatment in spite of high biocompatibility, moreover having high cold workability. The Ti—Nb—Zr base alloy is comprising an alloy composition consisting of 40 to 60 wt % Ti, 18 to 30 wt % Nb, 18 to 30 wt % Zr, and 0.77 to 3.7 wt % at least one metal additional element selected from Al, Sn, In and Ga. The Ti—Nb—Zr base alloy is a practical alloy in which the principal components form a strong and dense oxidation film to exhibit high biocompatibility, and also the alloy has superelasticity and shape memory properties, high cold workability, and high low-temperature properties.

Owner:JAPAN BASIC MATERIAL

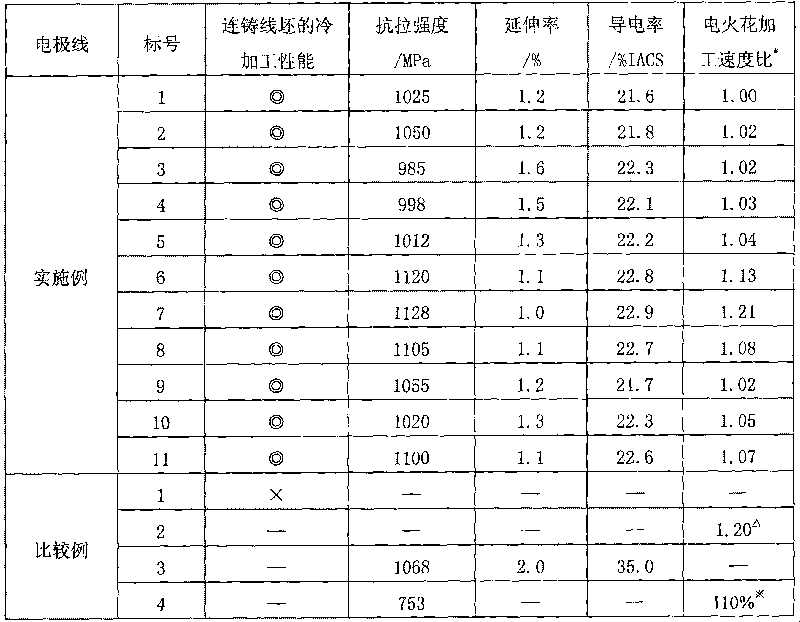

Electrode wire for slow-travel wire spark erosion fabrication and preparation method thereof

ActiveCN101439429BReduce copper contentIncreased zinc contentElectrical-based machining electrodesMicro structureImpurity

Owner:NINGBO BODE HIGHTECH CO LTD

Core-spun yarn containing rare earth, niobium, vanadium, boron titanium-silicon nitride alloy powder

InactiveCN106399628AImprove compactnessImprove hot rolling performanceProcess efficiency improvementNiobiumFerrosilicon

The invention relates to alloy powder of a core-spun yarn, and particularly relates to rare earth, niobium, vanadium, boron titanium-silicon nitride alloy powder of a core-spun yarn. The alloy powder is prepared from the following elements in mass percent: 1.0 to 2.5% of Al, 10 to 25% of N, 2.5 to 5.0% of Mn, 1.0 to 2.5% of Mg, 25 to 40% of Ti, 25 to 35% of Si, 0.5 to 1.0% of Nb, 0.5 to 1.0% of V, 0.5 to 1.0% of B, 1.0 to 2.0% of rare earth, less than or equal to 0.1% of P, less than or equal to 0.1% of S and the balance of Fe. The alloy powder is added to microalloyed steel by adopting a method of the core-spun yarn, so that the problem of low recovery rate can be solved, the consumption of ferrosilicon and ferromanganese can be reduced, and the development of titanium-silicon nitride and an alloy application of the core-spun yarn has obvious economic benefits.

Owner:浙江宝信炉料股份有限公司

Preparation technology for fine-grained steel 510L

InactiveCN102534362AImprove cold working performanceImprove product qualityManufacturing convertersSteelmakingFerrosilicon

A preparation technology for fine-grained steel 510L belongs to the field of steelmaking industry, can reduce the cost, improve the grain size grade of a product and the cold working performance of steel material, and has the following technological processes: a pre-processing process, that is, removing sulphur from molten iron by blowing passivated magnesium to the molten iron, and controlling the passivated magnesium blowing quantity, the blowing pressure and the blowing flow rate, so as to prolong the contact time between magnesium and the molten iron; and making steel with a revolving furnace, that is, a sublance steel making technology is adopted, mid-carbon fe-mn, ferrosilicon and ferro-aluminum are added into output steel for deoxygenation and alloying, the content of oxygen in the molten steel is controlled after deoxygenation and alloying, finally Nb iron is added into output steel for micro-alloying of Nb in the steel liquid, a steel ladle is stirred through bottom argon blowing during steel outputting, refining is carried out after micro-alloying of steel output by the revolving furnace, the ingredients and the temperature of the molten steel are trimmed by adding alloy or feeding aluminum wire by a wire feeding machine; moreover, an LF Furnace adopts the soft argon blowing process so as to remove foreign materials in the molten steel maximally, which improves the cleanliness of the molten steel; and the steel rolling process adopts a method capable of controlling rolling and cold. The invention has the advantages that the product quality is improved considerably; the cost is reduced; the grain size grade of the product is improved; and the cold working performance of the steel material is improved.

Owner:吉林建龙钢铁有限责任公司

Method for producing hot rolled steel coils

InactiveCN102127699BReduce dosageSimple methodProcess efficiency improvementNiobiumMaterials science

The invention relates to a method for producing hot rolled steel coils. The method comprises the following steps: 1) designing the components, pretreating molten iron, then carrying out converter smelting, carrying out nitrogen / argon changing over and carrying out tapping to obtain molten steel; 2) continuously casting the molten steel to obtain slabs, controlling the weight of the molten steel in the tundish to be 8-15t when casting of the continuous casting tundish is stopped, ensuring the liquid level to be 200-350mm; carrying out protective casting in the whole course and ensuring the insertion depth of the long nozzle to be 300-400mm; 3) heating the slabs; and 4) finally rolling and curling the heated slabs, thus obtaining the hot rolled steel coils. The method has the following beneficial effects: the TMCP (thermo-mechanical control process)+RPC (relaxation-precipitation-controlling phase transformation) rolling processes are adopted and the contents of C and Mn are substantially reduced by utilizing micro-niobium treatment, thus reducing the production cost; and the Q345R hot rolled steel coils obtained by the method have excellent plasticity and toughness, the elongation of the hot rolled steel coils is improved by more than 8%, and at the same time, the welding property of the materials is improved and good surface quality of the continuous casting slabs is ensured.

Owner:NINGBO IRON & STEEL

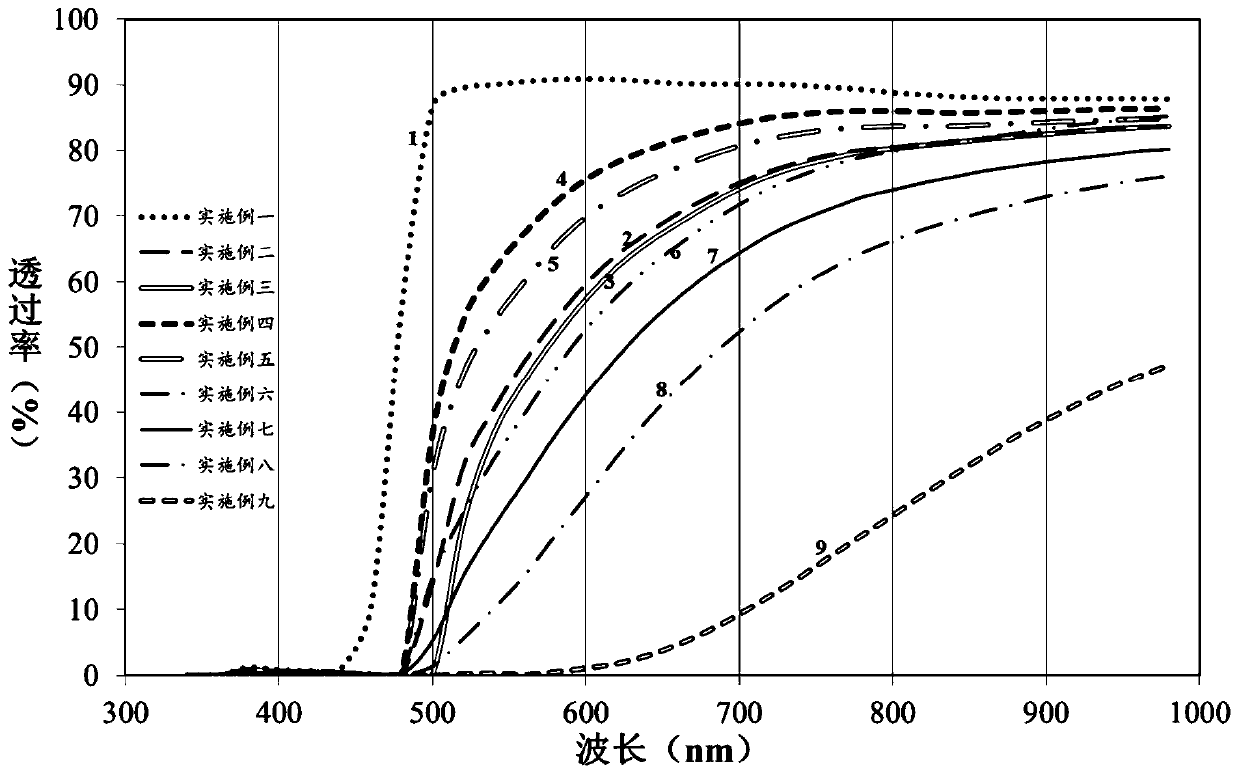

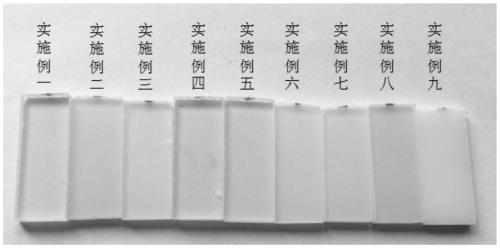

Yellow opal glass material, and preparation method and application thereof

InactiveCN110467345AReduce volatilityImprove homogenizationGlass furnace apparatusGlass shaping apparatusTemperature controlBoron oxide

The invention especially relates to a yellow opal glass material, and a preparation method and application thereof, belonging to the technical field of yellow opal glass. The yellow opal glass material comprises the following components by mass percentage: silicon dioxide, sodium oxide, potassium oxide, zinc oxide, boron oxide and calcium fluoride, with the balance being a coloring agent. The preparation method comprises the following steps: 1) melting: mixing the components and melting the mixed components into glass liquid; 2) clarification and molding: clarifying and homogenizing the glassliquid; and 3) annealing and color development: placing the homogenized glass liquid in a mold which is located at the front end of a mesh belt annealing traction furnace, subjecting the outer surfaceof the glass liquid to cooling and preliminary molding, then allowing the formed glass to enter an annealing furnace for continuous annealing under the traction of a rear-end mesh belt, and after annealing and cooling in the furnace, allowing the glass to enter a color developing and annealing furnace with precise temperature control for continuous annealing and color development. The preparationmethod of the invention realizes the continuity of production process, reduces the stress non-uniformity of the glass material, and is a stable preparation technology for the yellow opal glass material.

Owner:SHANDONG KANGYOU GLASS MATERIAL CO LTD

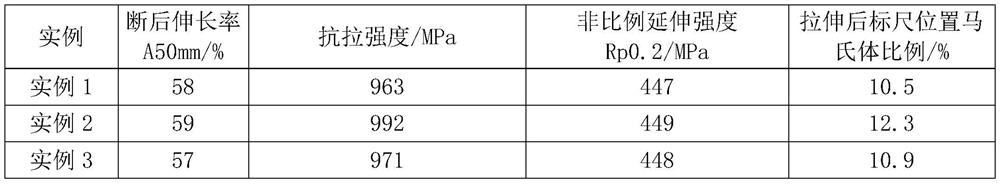

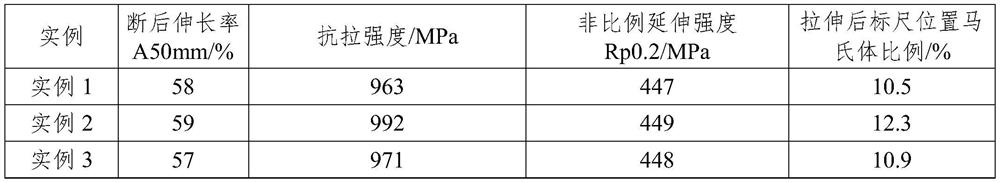

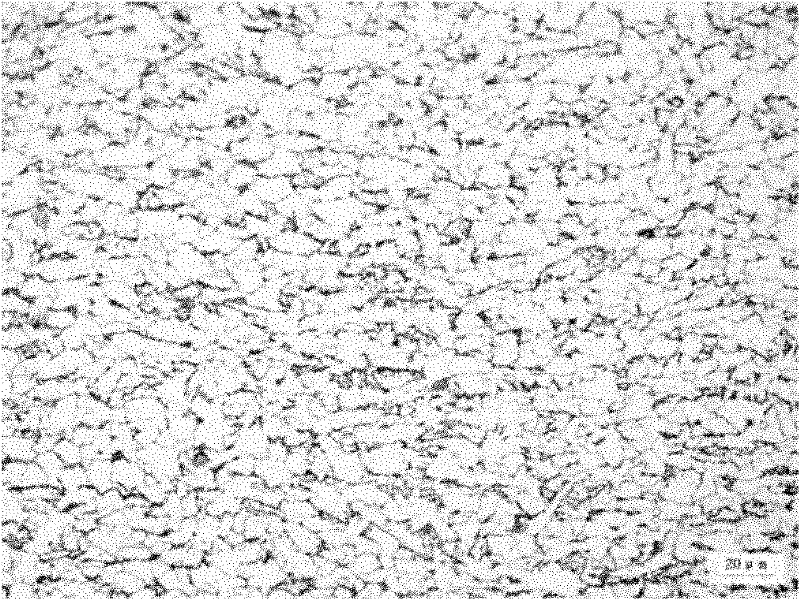

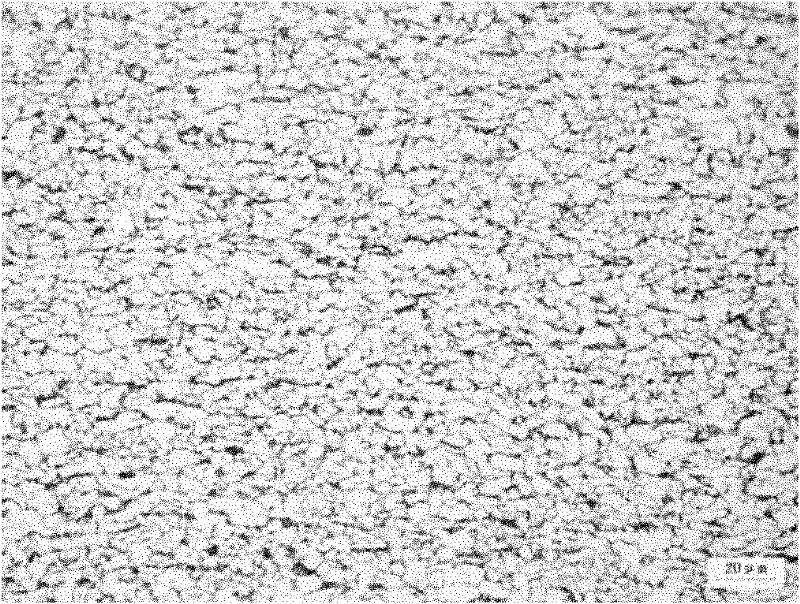

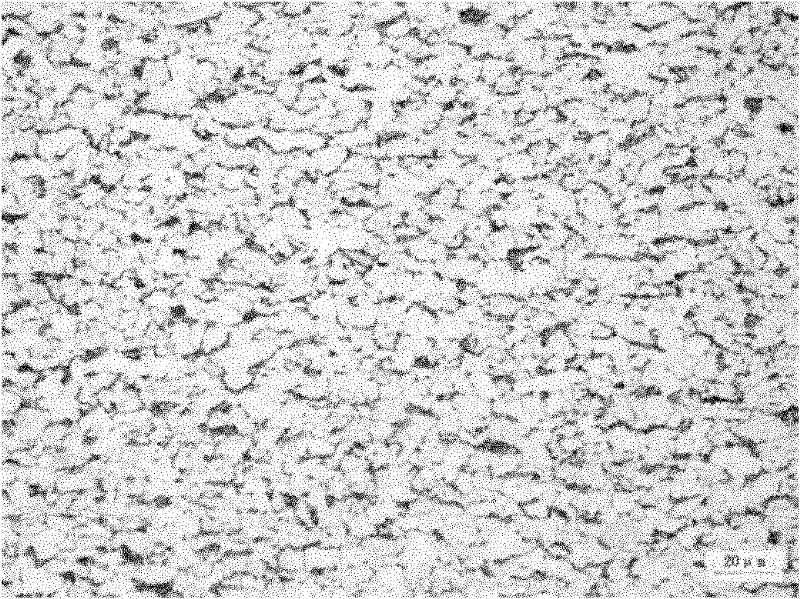

Manufacturing method of high nitrogen and low nickel copper-free austenitic stainless steel

ActiveCN111961989BReduce manufacturing costImprove performanceProcess efficiency improvementTransformation hardeningSS - Stainless steel

The invention provides a method for manufacturing a high-nitrogen, low-nickel, copper-free austenitic stainless steel. The components of the high-nitrogen, low-nickel, copper-free austenitic stainless steel are: C: 0.12-0.16%wt%, Si: 0.40- 0.50%wt%, Mn: 8.0~10.0%wt%, P: ≤0.045%wt%, S≤0.005%wt%, Cr: 14.5~15.0%wt%, Ni: 1.0~1.3%wt%, N: 0.18 ~0.20%, the rest is Fe and unavoidable impurity elements. The present invention solves the problem of serious transformation hardening degree of nickel-saving austenite cold-worked martensite while reducing the production cost of the enterprise, optimizes the cold-working performance of the product and improves the limit reduction ratio of the first cold rolling, and reduces the risk of cold-rolling cracking quality and economical efficiency. loss.

Owner:广西柳钢中金不锈钢有限公司 +1

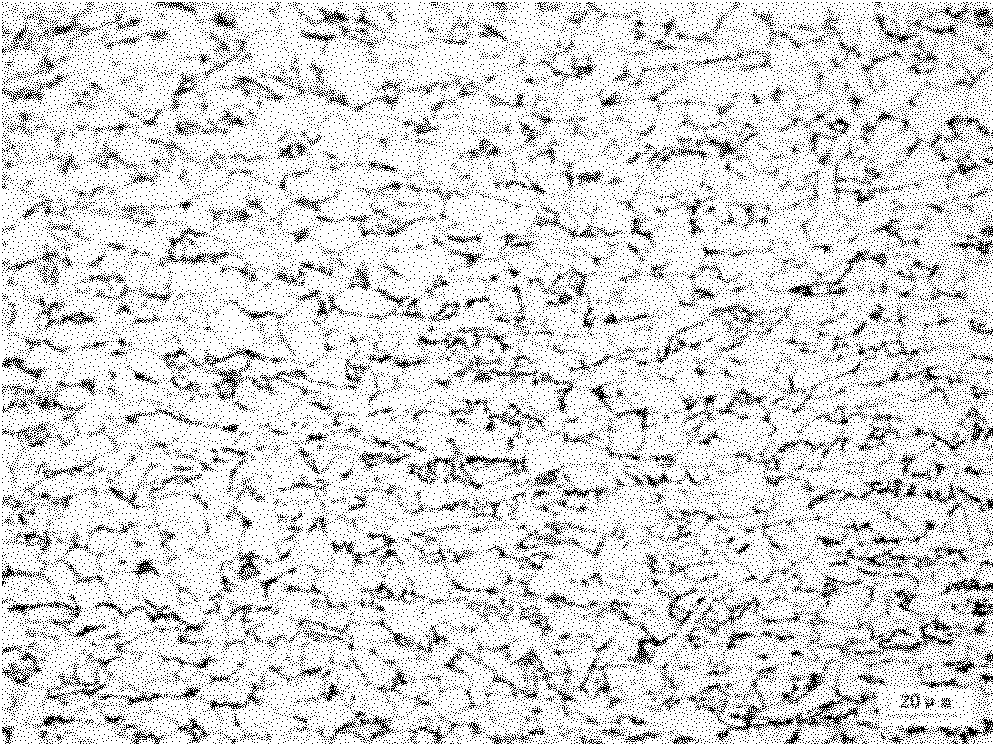

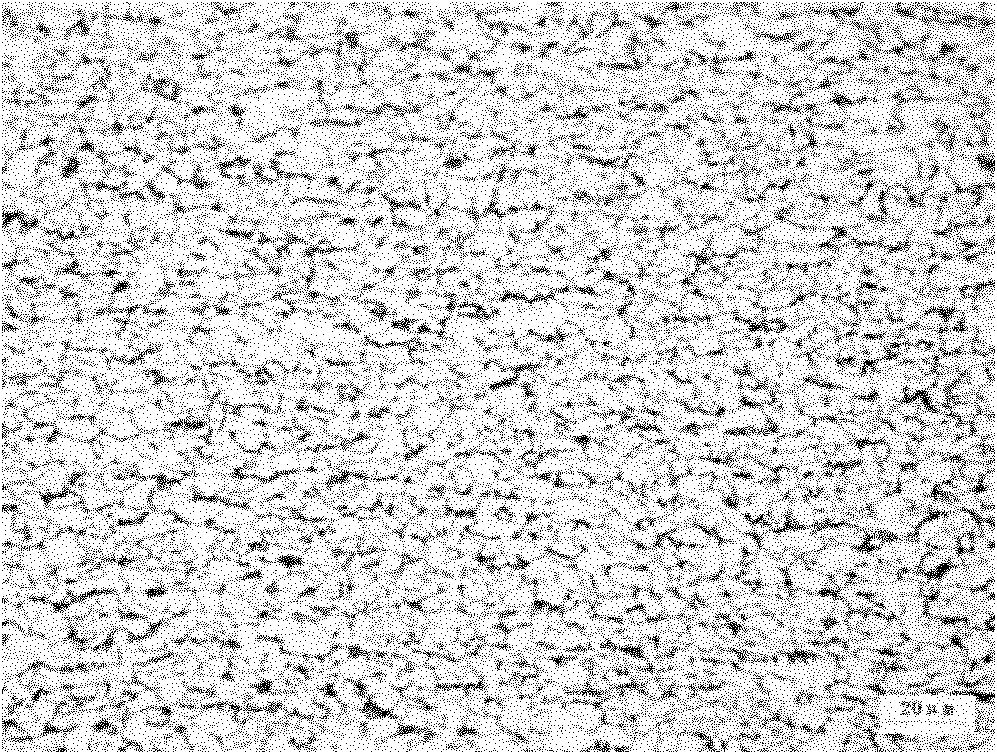

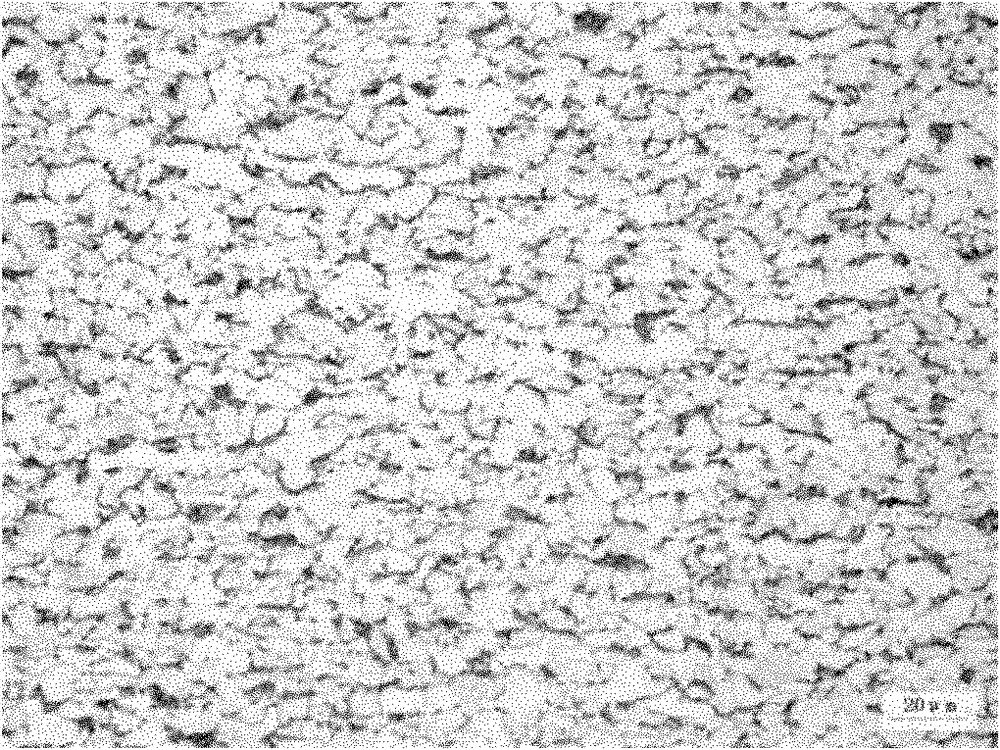

A kind of high-iron cupronickel alloy pipe material and its short-process production method

The invention relates to a high-iron cupronickel alloy pipe and a short-process production method thereof, and belongs to the technical field of metal materials. Compared with a BFe10-1-1 alloy, the cupronickel alloy BFe10-2-1 provided by the invention is increased in alloy iron element content from 1.0wt%-1.5wt% to 1.6wt%-2.5wt%, thereby greatly enhancing the corrosion-resistant property and mechanical property of the alloy. According to the short-process production method, a pipe billet with high inner-outer surface quality and high-axial orientation columnar crystal structure is prepared by adopting a heat-cold combined casting horizontal continuous casting technology, so that the cold machining property of high-iron cupronickel is greatly enhanced; the continuous casting pipe billet is directly subjected to cold rolling and / or cold-draw forming, a pipe is subjected to finished product annealing by adopting a proper annealing schedule to eliminate microsegregation, the average size of a recrystallized grain is controlled to 20-40 micrometers, the volume fraction of a precipitated phase is reduced to be less than 2%, so that the cupronickel pipe with excellent mechanical property and corrosion-resistant property is obtained. Compared with a BFe10-1-1 pipe produced through the traditional method, the BFe10-2-1 high-iron cupronickel pipe disclosed by the invention has the advantages of more excellent integral using property, short production process and high production efficiency and finished product rate.

Owner:UNIV OF SCI & TECH BEIJING

High Nitrogen Low Nickel Copper Free Austenitic Stainless Steel

ActiveCN112063936BReduce manufacturing costImprove performanceTransformation hardeningSS - Stainless steel

The invention provides a high-nitrogen, low-nickel, copper-free austenitic stainless steel. The components are: C: 0.12-0.16%wt%, Si: 0.40-0.50%wt%, Mn: 8.0-10.0%wt%. , P: ≤0.045%wt%, S≤0.005%wt%, Cr: 14.5-15.0%wt%, Ni: 1.0-1.3%wt%, N: 0.18-0.20%, and the rest are Fe and unavoidable impurity elements. The present invention solves the problem of serious transformation hardening degree of nickel-saving austenite cold-worked martensite while reducing the production cost of the enterprise, optimizes the cold-working performance of the product and improves the limit reduction rate of the first cold rolling, and reduces the risk of cold-rolled cracking quality and economical efficiency. loss.

Owner:广西柳钢中金不锈钢有限公司 +1

Mo-containing ferritic stainless steel and manufacturing method thereof

The invention discloses Mo-containing ferritic stainless steel, which comprises the following chemical elements in percentage by mass: less than or equal to 0.025 percent of C, less than or equal to 0.025 percent of N, less than or equal to 1.0 percent of Si, less than or equal to 1.0 percent of Mn, less than or equal to 0.04 percent of P, less than or equal to 0.03 percent of S, more than 20.0 percent and less than or equal to 22.0 percent of Cr, more than 0 percent and less than or equal to 1.0 percent, less than or equal to 1.3 percent of (Ni+Cu), more than or equal to 0.5 percent and lessthan or equal to 1.2 percent of Mo, more than or equal to 10(C+N) and less than or equal to 0.8 percent of (Ti+Nb), less than or equal to 0.015 percent of O, and the balance of Fe and other inevitable impurities. Correspondingly, the invention also discloses a manufacturing method for the steel. Compared with the conventional SUS444 and SUS436L steel, the Mo-containing ferritic stainless steel has the advantages of greatly reducing manufacturing cost, maintaining pitting corrosion resistance and chlorine-ion stress corrosion resistance, and being suitable for water system medium environments.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Method for producing hot rolled steel coil

The invention relates to a method for producing a hot rolled steel coil. The method comprises the following steps of: 1) designing components, pretreating molten iron, smelting in a converter, switching between nitrogen and argon, and performing tapping to obtain molten steel; 2) performing continuous casting on the molten steel to obtain a plate blank, controlling tundish molten steel amount to be between 8t and 15t and liquid level to be between 200mm and 350mm when a continuous casting tundish stops pouring, and pouring under protection in the entire process, wherein the length of an inserted part of a long nozzle is between 300mm and 400mm; 3) heating the plate blank; and 4) finally rolling the heated plate blank and winding to obtain the hot rolled steel coil. In the method, a thermomechanical control process (TMCP) and a relaxation-precipitation-control (RPC) rolling process are adopted, and C content and Mn content are greatly reduced by micro niobium treatment, so that production cost is reduced; the Q345q-E hot rolled steel coil produced by the method has high plasticity and toughness, and the elongation rate of the hot rolled steel coil is improved by more than 8 percent; meanwhile, the welding properties of materials are improved, and high surface quality of a continuous casting blank is guaranteed.

Owner:NINGBO IRON & STEEL

Method for producing hot rolled steel coils for ship building

InactiveCN102127694AReduce dosageSimple methodProcess efficiency improvementMarine engineeringStructural engineering

The invention relates to a method for producing hot rolled steel coils for ship building. The method comprises the following steps: 1) designing the components, pretreating molten iron, then carrying out converter smelting, carrying out nitrogen / argon changing over and carrying out tapping to obtain molten steel; 2) continuously casting the molten steel to obtain slabs, controlling the weight of the molten steel in the tundish to be 8-15t when casting of the continuous casting tundish is stopped, ensuring the liquid level to be 200-350mm; carrying out protective casting in the whole course and ensuring the insertion depth of the long nozzle to be 300-400mm; 3) heating the slabs; and 4) finally rolling and curling the heated slabs, thus obtaining the hot rolled steel coils. The method has the following beneficial effects: the TMCP (thermo-mechanical control process)+RPC (relaxation-precipitation-controlling phase transformation) rolling processes are adopted and the contents of C and Mn are substantially reduced by utilizing micro-niobium treatment, thus reducing the production cost; and the grade A32 hot rolled steel coils obtained by the method have excellent plasticity and toughness, the elongation of the hot rolled steel coils is improved by more than 8%, and at the same time, the welding property of the materials is improved and good surface quality of the continuous casting slabs is ensured.

Owner:NINGBO IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com