Ti-Nb-Zr Alloy

a superelastic alloy and shape memory technology, applied in the field of shape memory and superelastic alloy, can solve the problems of degrading the low-temperature properties of the human body, the inability to use a member relating to the human body, and the superelasticity and shape memory effect, and achieves low-temperature properties in the practical range and high cold workability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

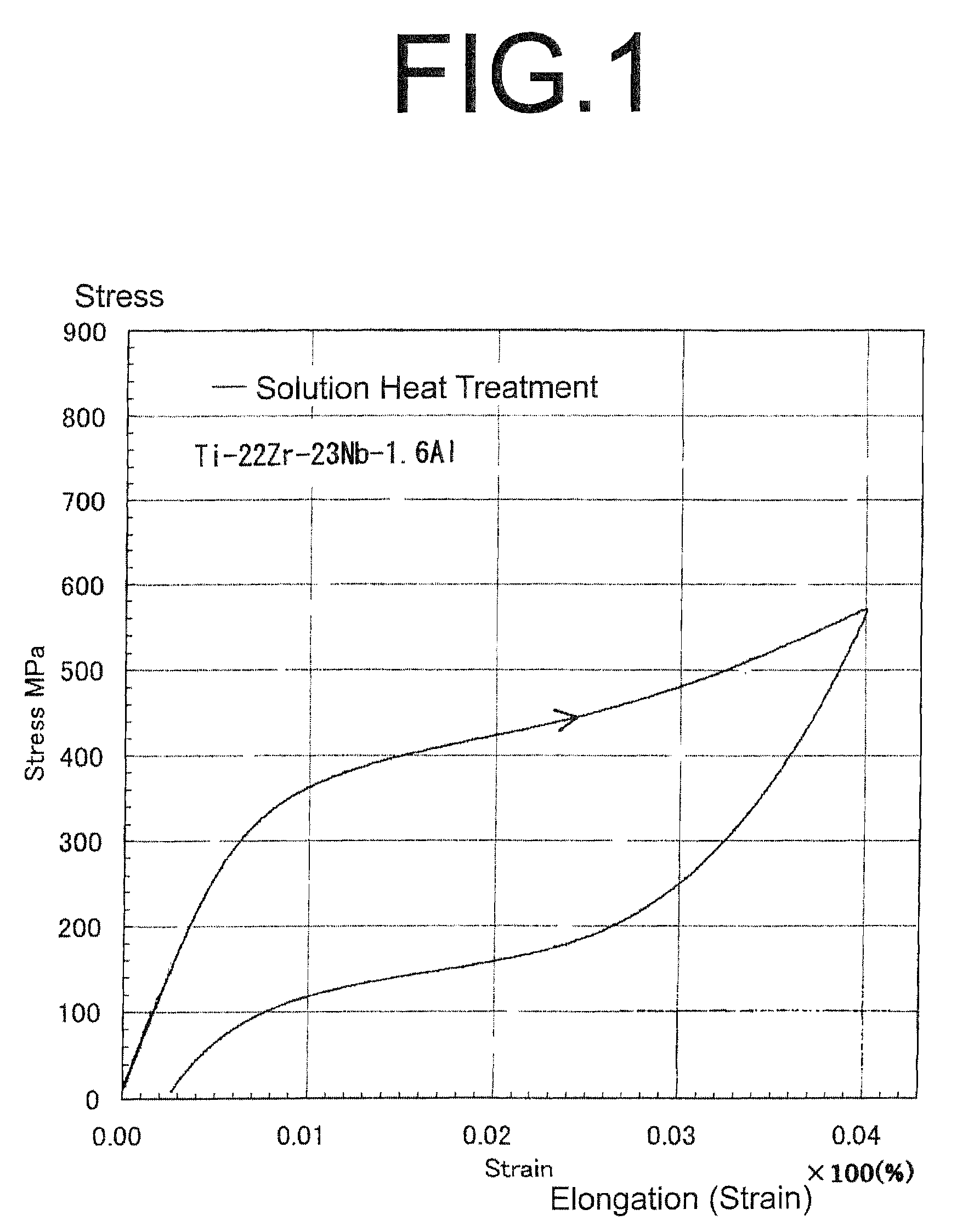

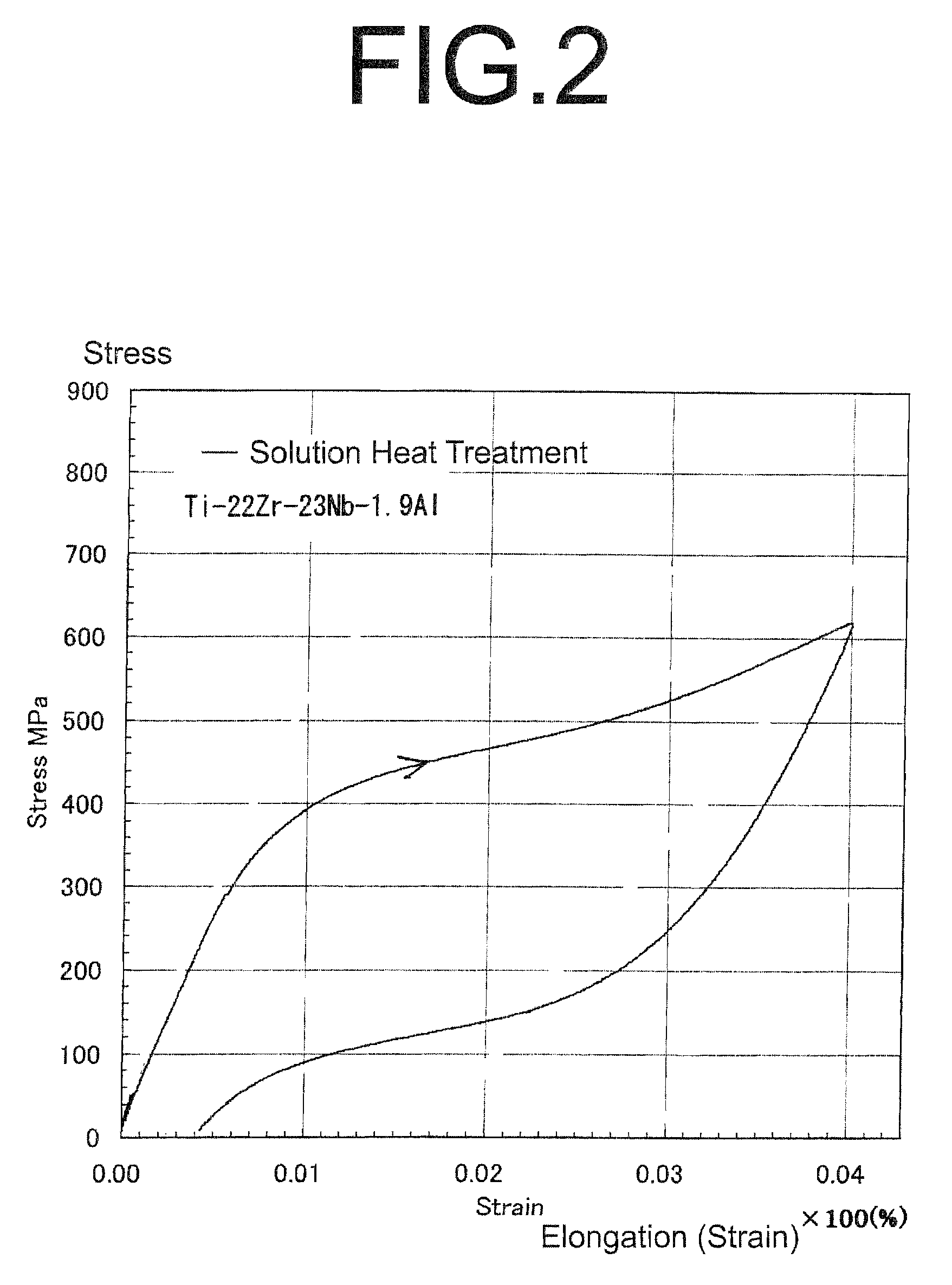

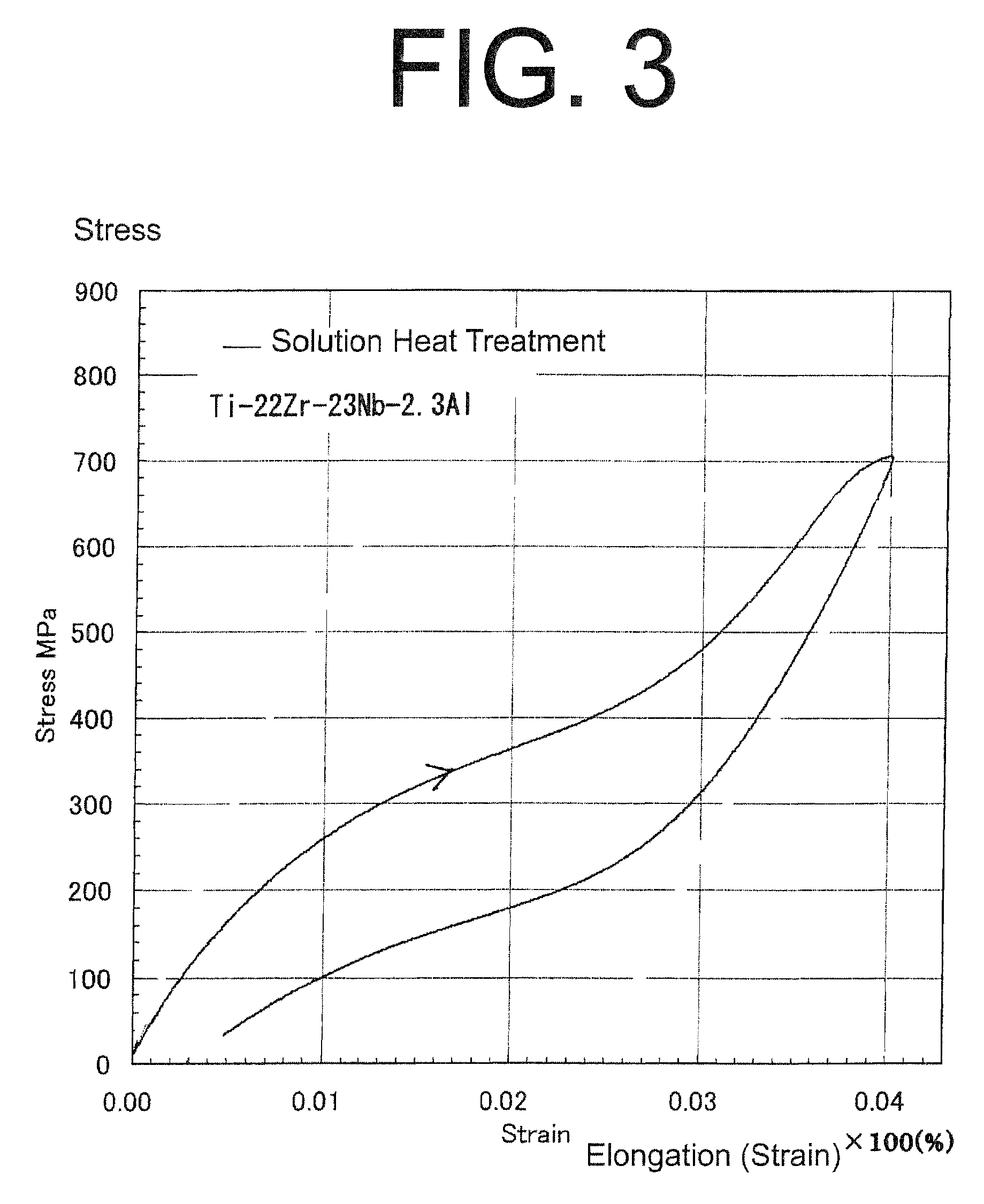

[0033]Three kinds of plates containing 23 wt % Nb, 22 wt % Zr, and 1.6, 1.9 and 2.3 wt % Al, the balance being Ti alloy were prepared. These plates were subjected to solution heat treatment by heating at 800° C., and then were water quenched. The stress-elongation curves of the three kinds of specimens are shown in FIGS. 1 to 3. In all cases, a plastic deformation elongation of 4% was given to the plates, then the load was removed. In the case of FIG. 1 (Al: 1.6 wt %), a residual strain of about 2% was developed, and as a result, a superelastic deformation elongation of 3.8% was exhibited as given in Table 2. In the case of FIG. 2 (Al: 1.9 wt %), a residual strain of about 3% was developed, and as a result, a superelastic deformation elongation of 3.7% was exhibited as given in Table 2. In the case of FIG. 3 (Al: 2.3 wt %), a residual strain of about 4% was developed, and as a result, a superelastic deformation elongation of 3.6% was exhibited as given in Table 2. It is found that t...

example 2

[0034]The stress-elongation curve in the case where a plate (width=2.47 mm, thickness=0.9979 mm) containing 23.2 wt % Nb, 22.1 wt % Zr, and 1.27 wt % Al, the balance being Ti alloy was subjected to solution heat treatment by heating at 800° C., and then was water quenched is shown by a solid line. When a stress of 520 MPa was applied, a plastic elongation of 4% was exhibited, and when the stress was removed, a residual strain of about 0.2% was developed, and superelasticity (superelastic elongation is about 3.8%) was exhibited (FIG. 4).

example 3

[0035]A plate (width=2.47 mm, thickness=1.001 mm) containing 23.2 wt % Nb, 22.1 wt % Zr, and 1.27 wt % Al, the balance being Ti alloy was subjected to solution heat treatment by heating at 800° C. for 30 minutes. The tensile stress (MPa) vs. elongation (%) of this plate was as shown in FIG. 5. When a stress of 699.2 MPa was applied at the first time, an elongation of 4% was exhibited, and when the stress was removed, a residual strain of 0.7% was present. When a stress of about 731.05 MPa was applied again, an elongation of 4.7% was exhibited, and when the stress was removed, a residual strain of 0.72% was developed from the point of load 0 at the first time. The figure reveals that the superelasticity (and shape memory properties) appeared (FIG. 5).

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature properties | aaaaa | aaaaa |

| temperature properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com