Manufacturing method of high nitrogen and low nickel copper-free austenitic stainless steel

A technology of austenitic stainless steel and its manufacturing method, which is applied in the fields of rolling, smelting of stainless steel, and manufacturing of high-nitrogen, low-nickel, copper-free austenitic stainless steel. The effect of low production cost and breakthrough performance bottleneck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention is now described.

[0020] The chemical composition of the high nitrogen and low nickel copper-free austenitic stainless steel of the present invention is: C: 0.12~0.16%, Si: 0.40~

[0025] Chromium equivalent Creq=%Cr+1.5×(%Si)

[0033] AOD smelting is divided into four stages: chemical steel stage, oxidation stage, reduction stage and refining stage. AOD tons of steel raw materials into the furnace:

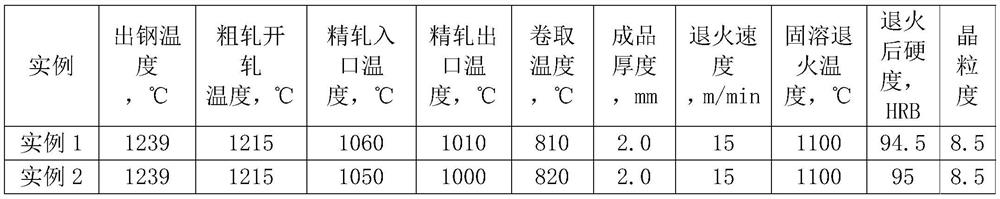

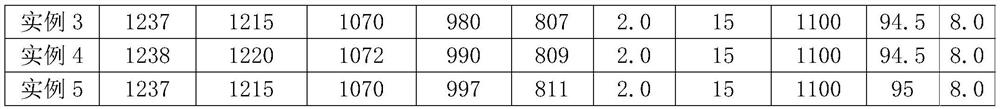

[0036] The billet heating temperature system: the temperature in the preheating section is 650-800 °C, the temperature in the heating section is 1220-1260 °C, and the temperature in the soaking section is 650-800 °C.

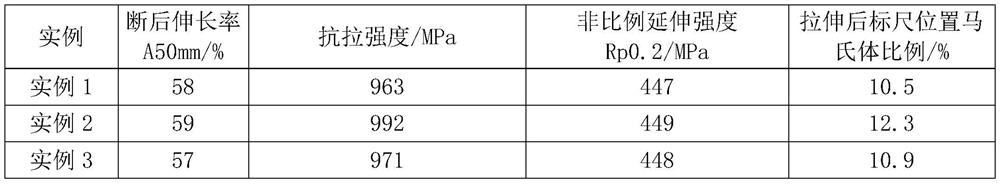

[0041] After annealing, the yield strength of the steel strip is Rp0.2 / MPa≥440Mpa, the tensile strength Rm≥950Mpa, and the elongation after breaking A≥

[0042] The production method of the high nitrogen and low nickel copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com