Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Improve catalytic combustion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Broad-spectrum VOCs (Volatile Organic Compounds) catalytic combustion monolithic catalyst as well as preparation method and application thereof

ActiveCN108325526ALarge specific surface areaImprove catalytic performanceHeterogenous catalyst chemical elementsCatalyst activation/preparationCeriumCordierite

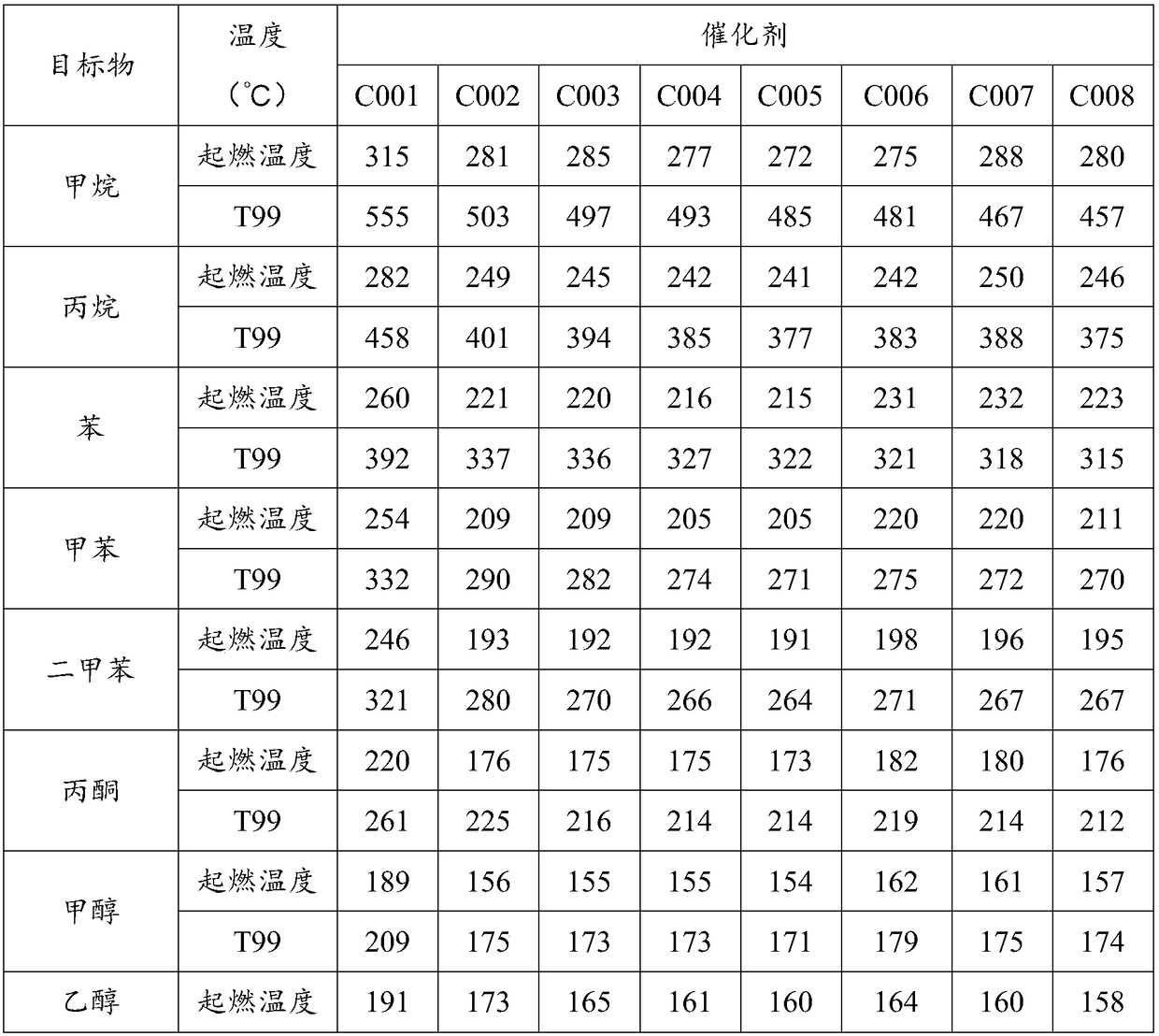

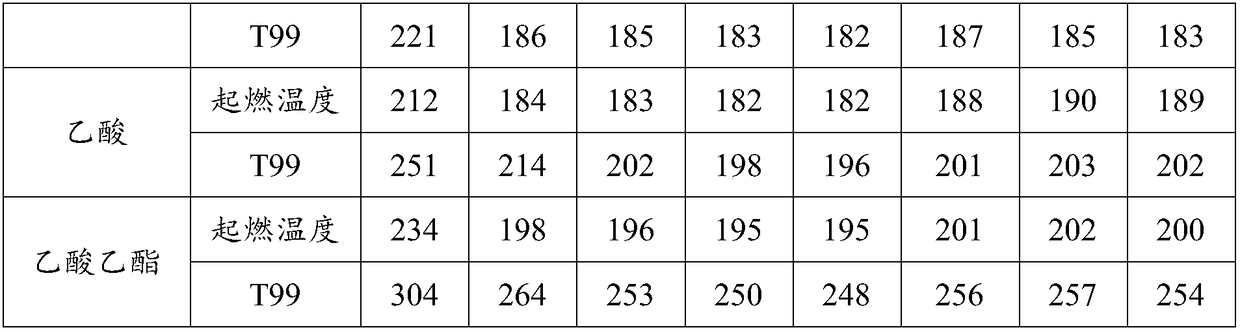

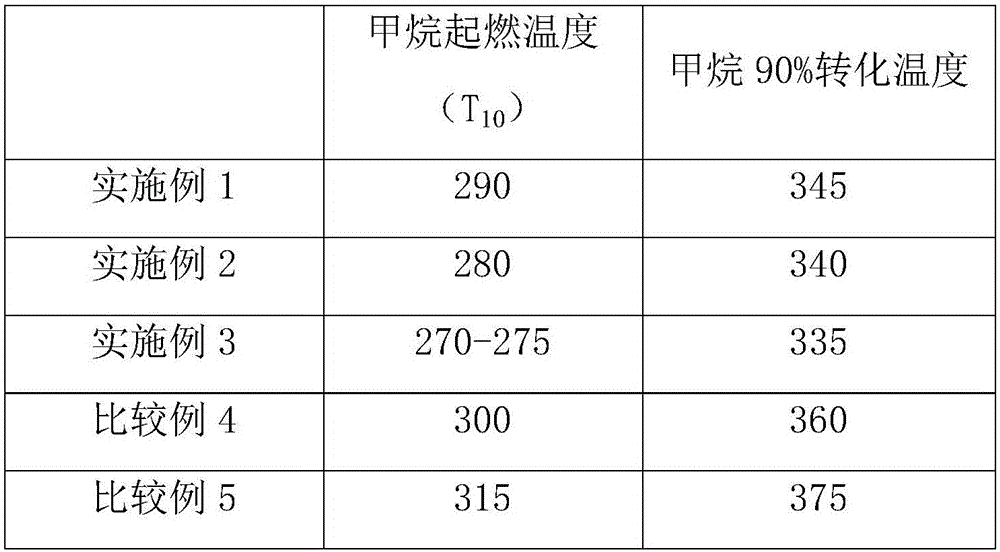

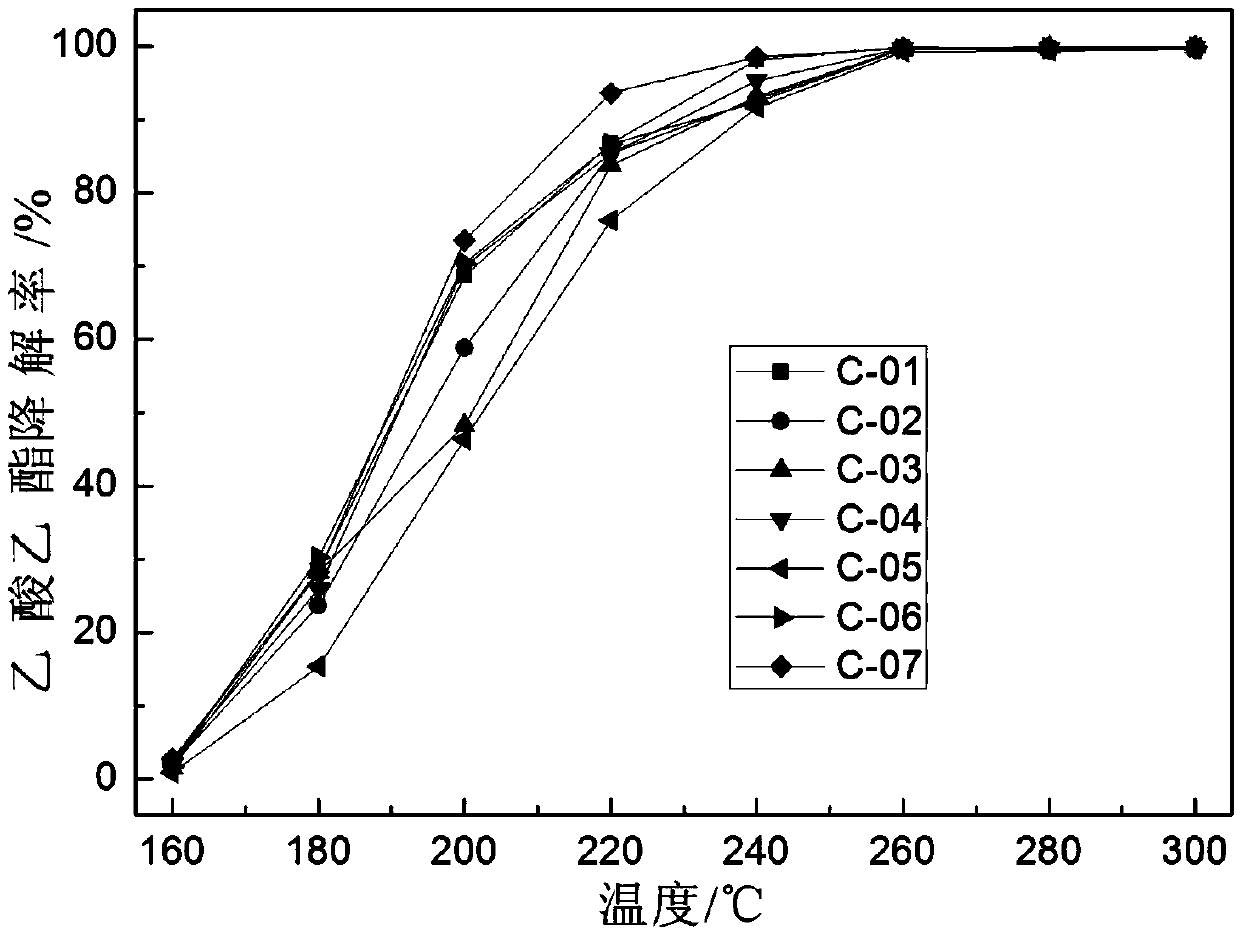

The invention provides a broad-spectrum VOCs (Volatile Organic Compounds) catalytic combustion monolithic catalyst and belongs to the technical field of catalysts. The catalyst comprises monolithic cordierite honeycomb ceramic, an auxiliary agent coating and an active coating; the auxiliary agent coating is prepared from one of active aluminum oxide, lanthanum modified active aluminum oxide or cerium modified active aluminum oxide, a rare-earth oxide compound and a binding agent; the active coating comprises one or two of noble metal palladium or noble metal platinum. The invention further provides a preparation method and application of the catalyst. The broad-spectrum VOCs catalytic combustion monolithic catalyst provided by the invention has low ignition temperature and high conversionefficiency on methane, propane and common volatile organic compounds, such as benzene, toluene, xylol, acetone, methanol, ethanol, acetic acid and ethyl acetate; the broad-spectrum VOCs catalytic combustion monolithic catalyst has common applicability. The catalyst has low gas flow resistance, low concentration of the volatile organic compounds and a wide air speed application range.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

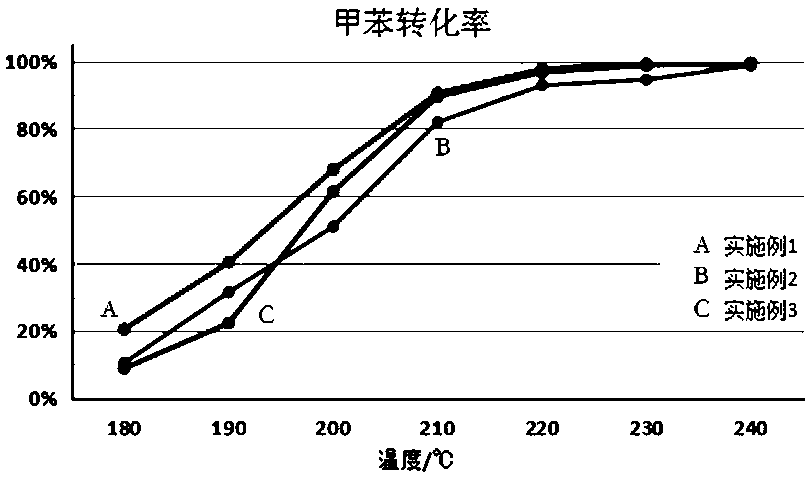

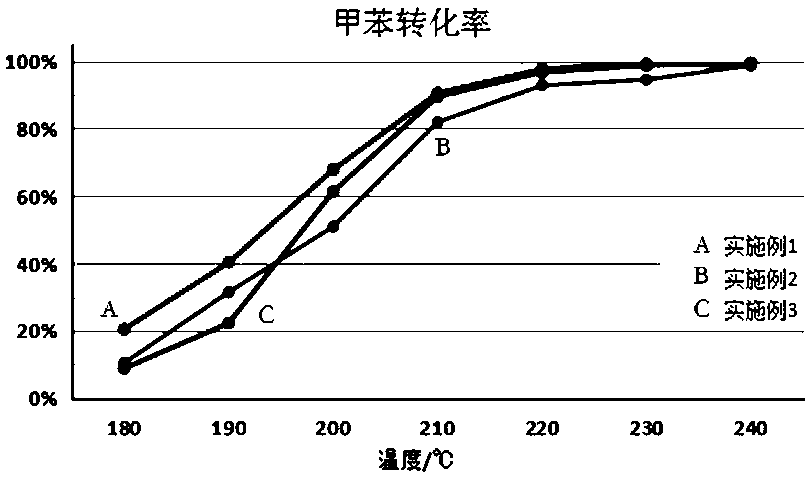

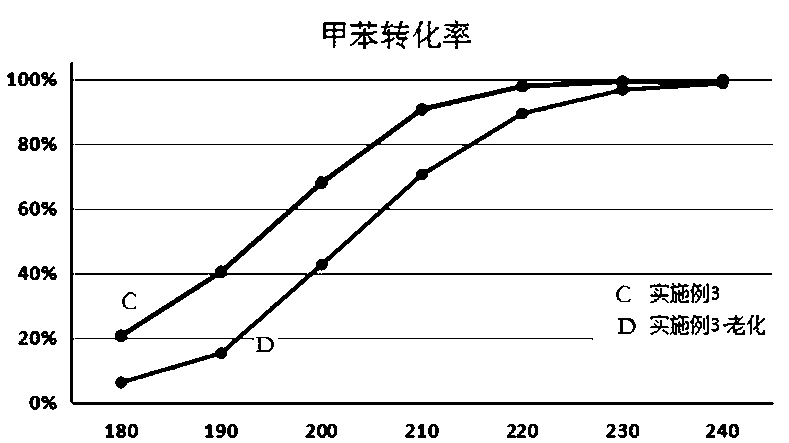

Method for preparing toluene catalytic combustion monolithic catalysts and application

InactiveCN105688904AReduce the temperatureImprove catalytic oxidation performanceHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystPhysical chemistry

The invention provides a method for preparing toluene catalytic combustion monolithic catalysts and application. The toluene catalytic combustion monolithic catalysts are Pd-based catalysts, a carrier for the toluene catalytic combustion monolithic catalysts is CeO2-Pr6O11 / Al2O3, CeO2-Pr6O11 mixed oxide with different Ce / Pr molar ratios is researched, accordingly, the optimal Ce / Pr proportions of the CeO2-Pr6O11 mixed oxide with the highest activity are found, and the toluene catalytic combustion monolithic catalysts are optimal in toluene catalytic oxidation activity when the Ce / Pr proportions are equal to 4:1. The method and the application have the advantages of excellent catalytic performance, low precious-metal content, good thermal stability and uniform coating.

Owner:NINGBO YUANXIANG ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

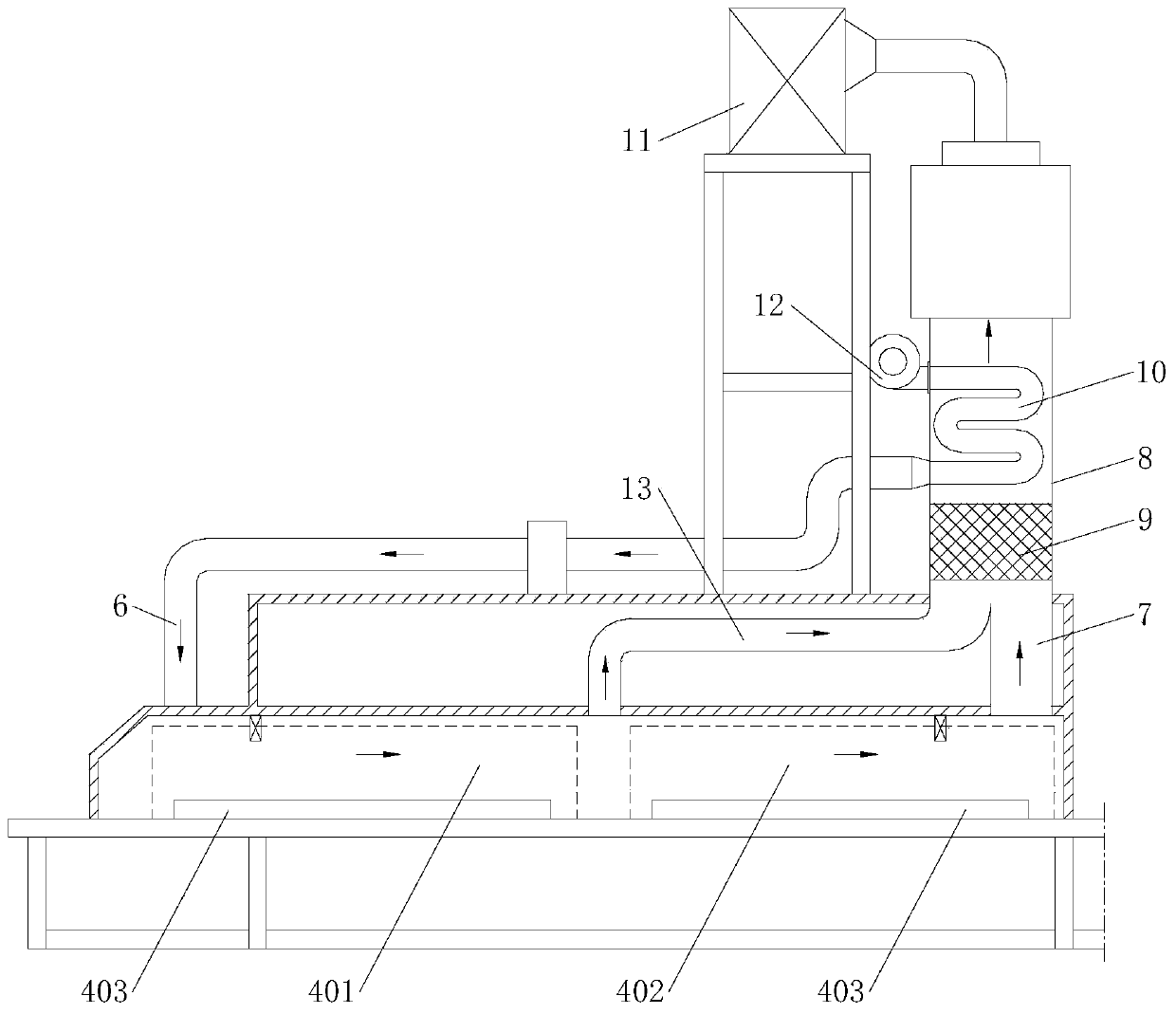

Result-controllable organic waste gas treatment device adopting catalytic combustion

InactiveCN105194941AAbundant resourcesEasy access to resourcesDispersed particle filtrationIncinerator apparatusRare earthRecuperator

The invention discloses a result-controllable organic waste gas treatment device adopting catalytic combustion. The result-controllable organic waste gas treatment device comprises a waste gas storage tank, a pretreatment unit, a preheating unit and a catalytic combustion unit, wherein the preheating unit comprises a heat exchanger and a preheater which are connected sequentially, a low-temperature pipeline and a high-temperature pipeline are arranged in the heat exchanger; the catalytic combustion unit comprises a fixed bed catalytic reactor which comprises a catalyst carrier and an active component, the catalyst carrier adopts a ceramic honeycomb structure, the active component is rare earth oxide, and a gas outlet of the high-temperature pipeline is connected with a gas concentration monitoring device II. The catalyst is cheap, easy to obtain, durable, safe, energy-saving and environment-friendly, a processing result is controllable, and the device is suitable for being popularized and used in organic waste gas treatment.

Owner:SUZHOU RHYMEBLUE ENVIRONMENTAL TECH CO

Integrated catalyst applied to catalytic combustion of methane and preparation method thereof

ActiveCN105797766AHigh activityImprove catalytic combustion performanceMolecular sieve catalystsMolecular sieveRare earth

The invention discloses an integrated catalyst applied to catalytic combustion of methane and a preparation method thereof. The integrated catalyst comprises a carrier and an active coating arranged on the carrier, wherein the active coating is prepared from rare earth composite aluminum oxide loaded with Pd and rare earth composite molecular sieve loaded with Pt according to a weight ratio of (1 to 1)-(5 to 1). The integrated catalyst can be applied to catalytic combustion of low-concentration methane; the active coating is prepared by mixing rare earth composite aluminum oxide loaded with Pd with rare earth composite molecular sieve loaded with Pt. The preparation method is simple and practicable; the prepared catalyst is high in activity and has an excellent catalytic combustion effect on methane.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

Precious metal low-load catalyst for VOCs (volatile organic chemicals) catalytic combustion and preparation method

InactiveCN107913719AReduce usageLow ignition temperatureHeterogenous catalyst chemical elementsIncinerator apparatusEnvironmental resistanceRare-earth element

The invention relates to the field of chemical industry and environmental protection, and aims to provide a precious metal low-load catalyst for VOCs (volatile organic chemicals) catalytic combustionand a preparation method. According to the catalyst, spherical aluminum oxide or a cordierite honeycomb ceramic serves as a carrier, 50-250g / m<3> of precious metals are loaded on the carrier to serveas main catalysts, 200-5000g / m<3> of transition metals or rare-earth elements serve as co-catalysts, 150-1000g / m<3> of alkaline metals or alkaline-earth metals serve as modifiers, and the precious metals include one or more of Pd, Pt, Rh or Ru. The transition metals, rare-earth metals and the alkaline metals or alkaline-earth metals are added and cooperate with the precious metals to jointly catalyze VOCs to degrade, the catalytic performance of the catalyst is improved, and the catalyst still has a good catalytic combustion performance even if the load of the precious metals is reduced. The catalyst is used for VOCs catalytic combustion and has the advantages of low VOCs treatment initiation temperature and high removal rate. Compared with a common commercial precious metal catalyst, theusage amount of the precious metals can be reduced by 25%, and the catalyst has quite remarkable advantages and economic benefits.

Owner:JIANGSU ANQIER WASTE GAS PURIFICATION +1

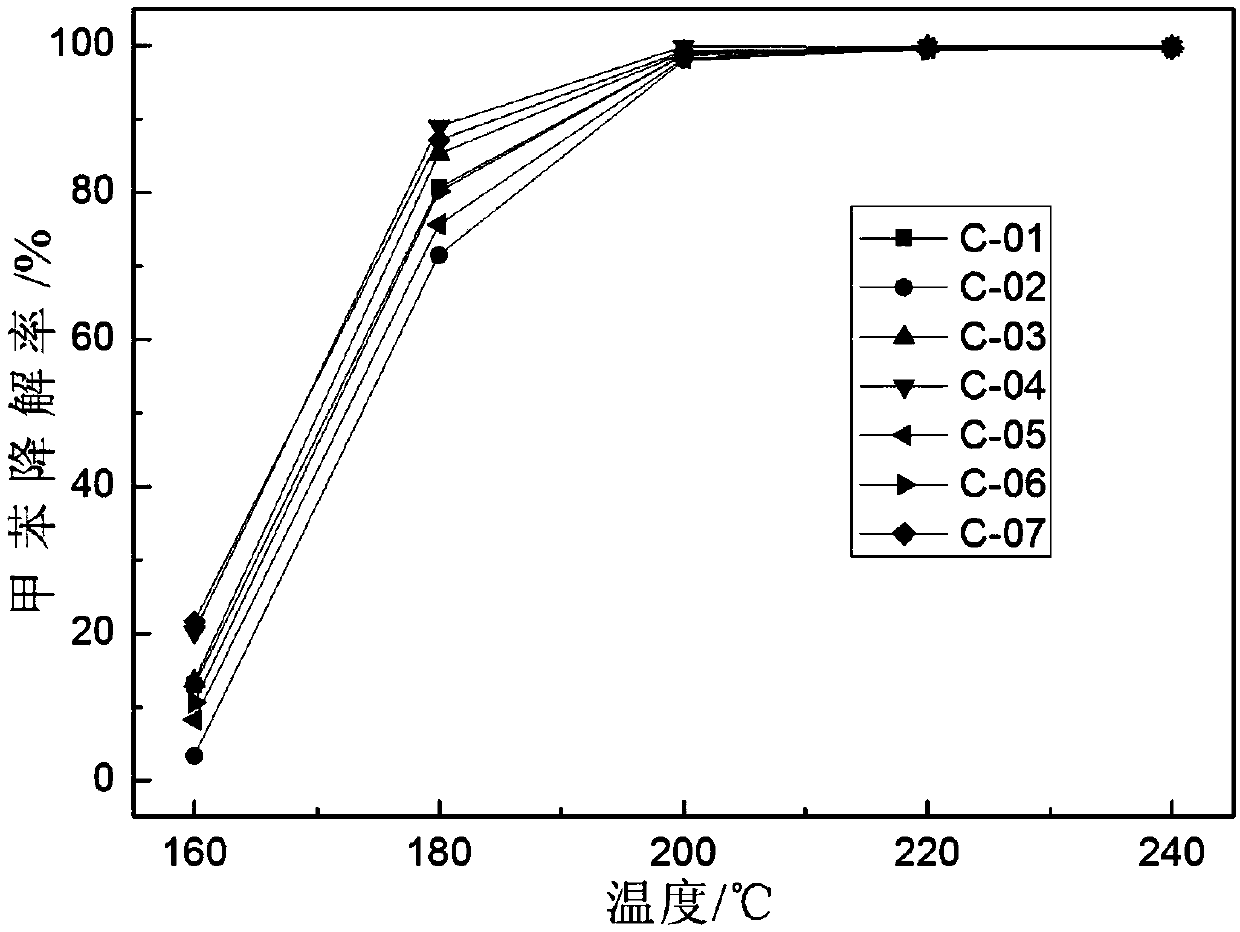

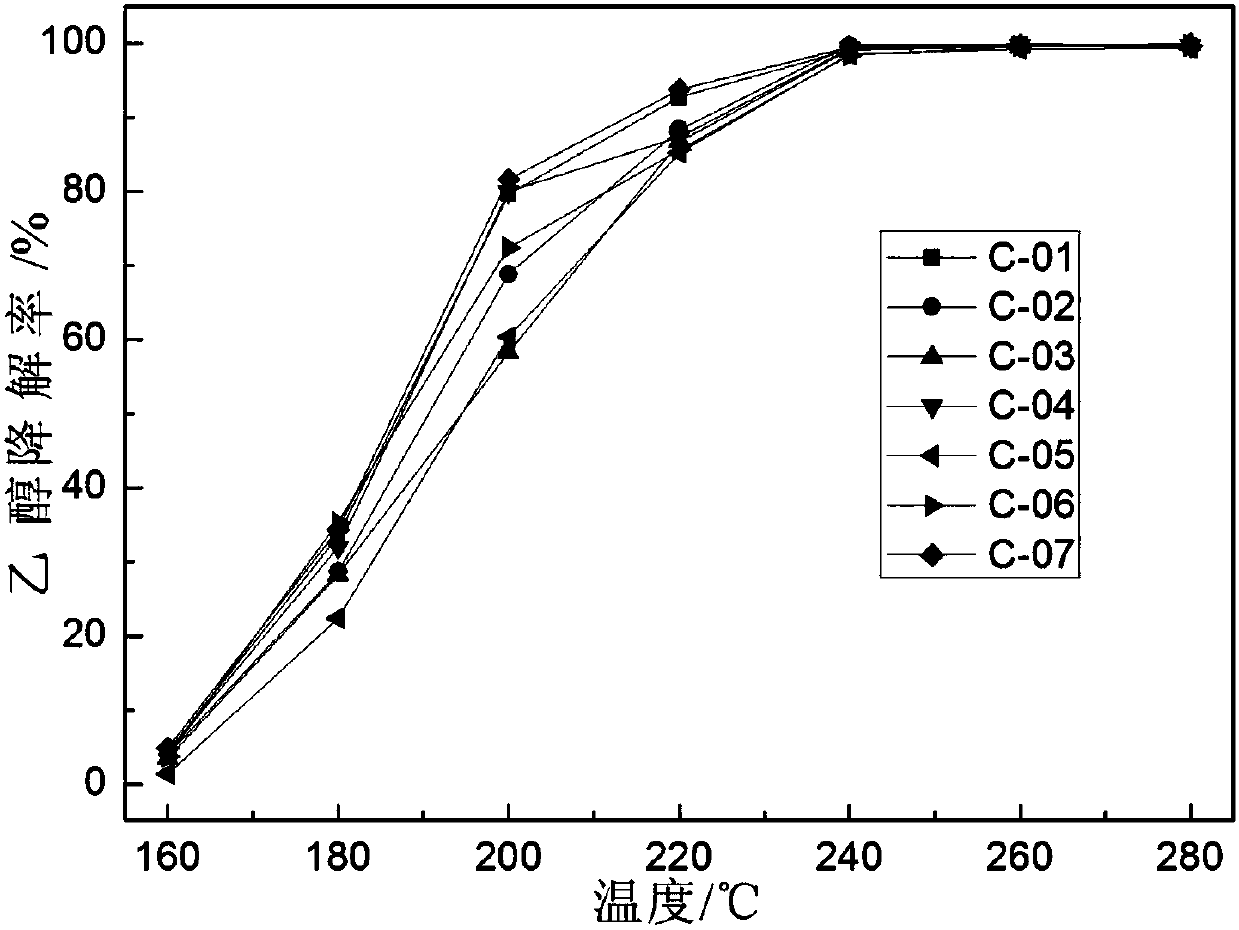

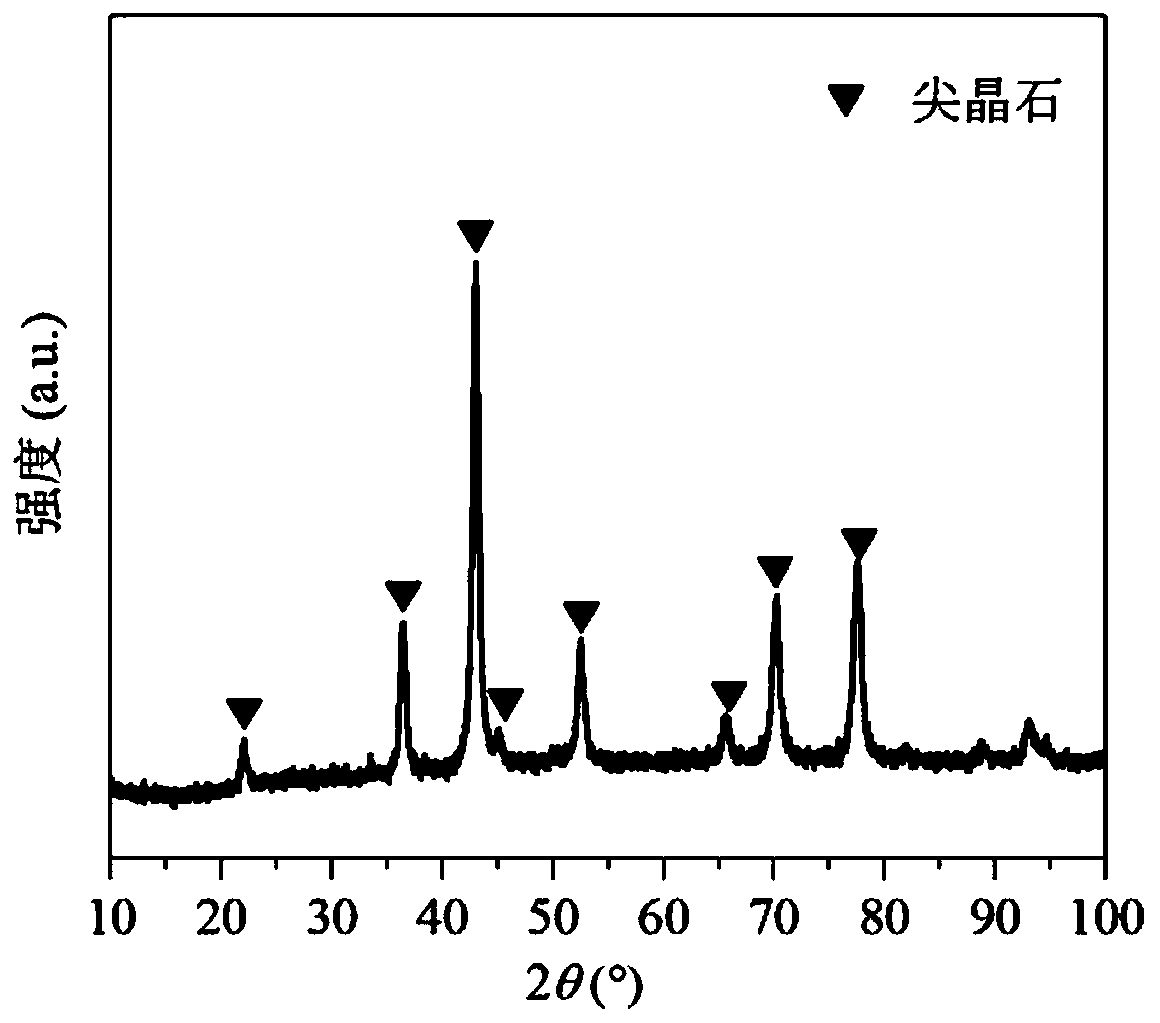

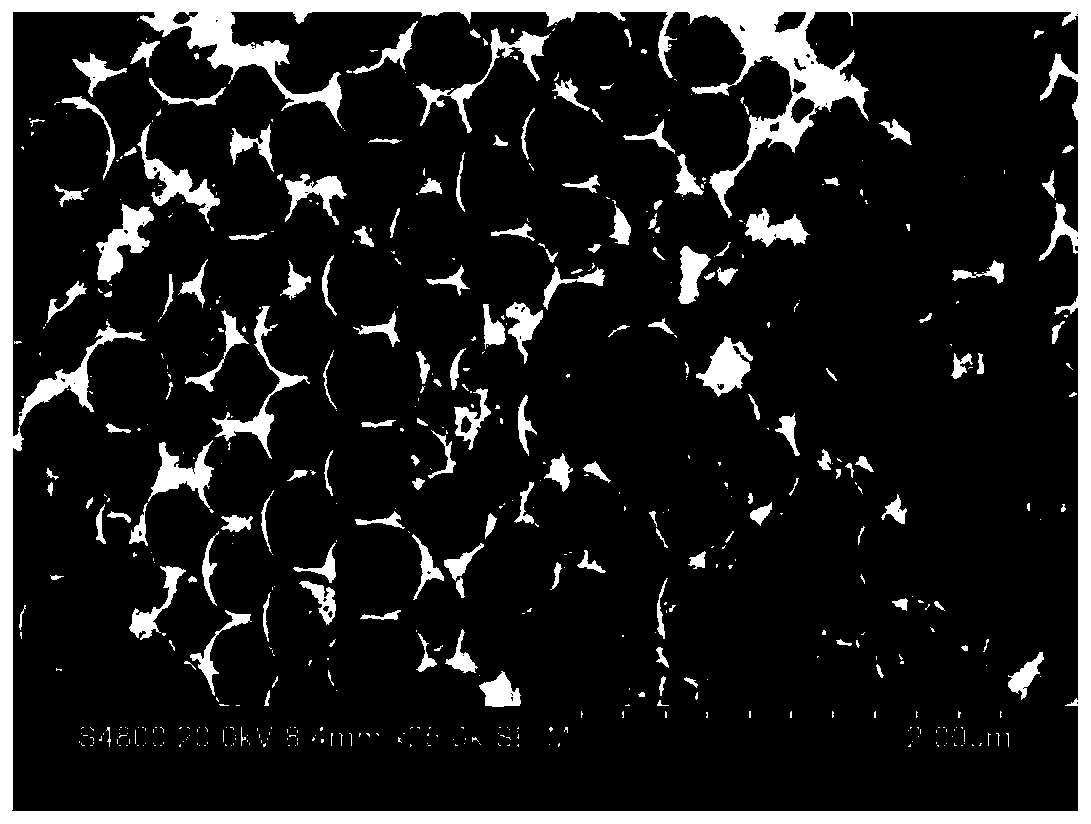

Cobalt-aluminum composite oxide catalyst and preparation method and application thereof

PendingCN110433806ALarge specific surface areaReduced Diffusion ResistanceIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsAluminum compositesOxide

The invention relates to the technical field of catalyst preparation, and discloses a cobalt-aluminum composite oxide catalyst and a preparation method and application thereof. The preparation methodcomprises the steps that metal salt solutions of cobalt and aluminum are taken as precursors correspondingly, polymer microspheres are taken as a template agent, templates are soaked in the precursorsolutions, then impregnation and roasting are conducted, and thus the cobalt-aluminum composite oxide catalyst is obtained. A three-dimensional ordered hierarchical pore structure with a mesoporous and macroporous structure is created through the polymer microspheres, thus the specific surface area of the catalyst is increased, the prepared catalyst has a large transmission pore channel, reactantmodules enter the pore channel from all directions advantageously, the diffusion resistance is lowered, thus the convective mass transfer efficiency between gases is improved, and the catalytic activity of the cobalt-aluminum composite oxide catalyst is facilitated; and meanwhile, through the large transmission channel, the situation that the modules are blocked when reacting on the pore wall or the pore channel of the transmission channel, and consequently, the reaction progress is influenced can further be effectively avoided, and the catalytic conversion efficiency of the catalyst is improved.

Owner:FUZHOU UNIVERSITY

Monolithic catalyst for methane catalytic combustion and preparation method thereof

InactiveCN104084199AHigh conversion rate of catalytic combustionImprove performanceFuel additivesMetal/metal-oxides/metal-hydroxide catalystsHoneycombCordierite

The invention discloses a monolithic catalyst for methane catalytic combustion and a preparation method thereof. The monolithic catalyst comprises a carrier, a coating on the carrier, and precious metal loaded on the coating, wherein the carrier is cordierite honeycomb ceramics, and the coating is a gamma-Al2O3 sol transition coating and a CeO2-Y2O3 sol assistant coating. The preparation method comprises the steps of impregnating the cordierite honeycomb ceramics in gamma-Al2O3 sol, drying and roasting to obtain a carrier coated with the gamma-Al2O3 sol transition coating; impregnating the carrier coated with the gamma-Al2O3 sol transition coating in CeO2-Y2O3 sol to obtain a carrier; and with Pd sol as an active ingredient, and coating the carrier with the Pd sol to obtain the monolithic catalyst, wherein the loading amount of the palladium accounts for 0.05-0.2 percent of the total weight of the monolithic catalyst, and the Pd sol is palladium nitrate sol, palladium acetate sol or palladium chloride sol. The monolithic catalyst has high catalytic combustion conversion rate to methane, and consumes few amount of Pd.

Owner:SOUTHEAST UNIV

Temperature-controllable organic exhaust gas catalytic combustion treatment device

InactiveCN105202552AExtend your lifeReduced activityChemical industryIncinerator apparatusReaction temperatureFixed bed

The invention discloses a temperature-controllable organic exhaust gas catalytic combustion treatment device which comprises an exhaust gas storage tank, a pretreatment unit, a preheating unit and a catalytic combustion unit, wherein the preheating unit comprises a heat exchanger and a preheater which are sequentially connected; the heat exchanger comprises a low-temperature pipeline and a high-temperature pipeline; the catalytic combustion unit comprises a fixed bed catalytic reactor and a temperature detector; the temperature detector is installed at a gas inlet of the catalytic combustion unit; the fixed bed catalytic reactor comprises a catalyst support and an active component; the catalyst support is in a ceramic honeycomb structure; and the active component is rare-earth oxides. The temperature-controllable organic exhaust gas catalytic combustion treatment device has the advantages of controllable reaction temperature, cheap and accessible catalyst, high durability and safety, energy saving and environment friendliness, and is suitable for popularization and use in organic exhaust gas treatment.

Owner:SUZHOU RHYMEBLUE ENVIRONMENTAL TECH CO

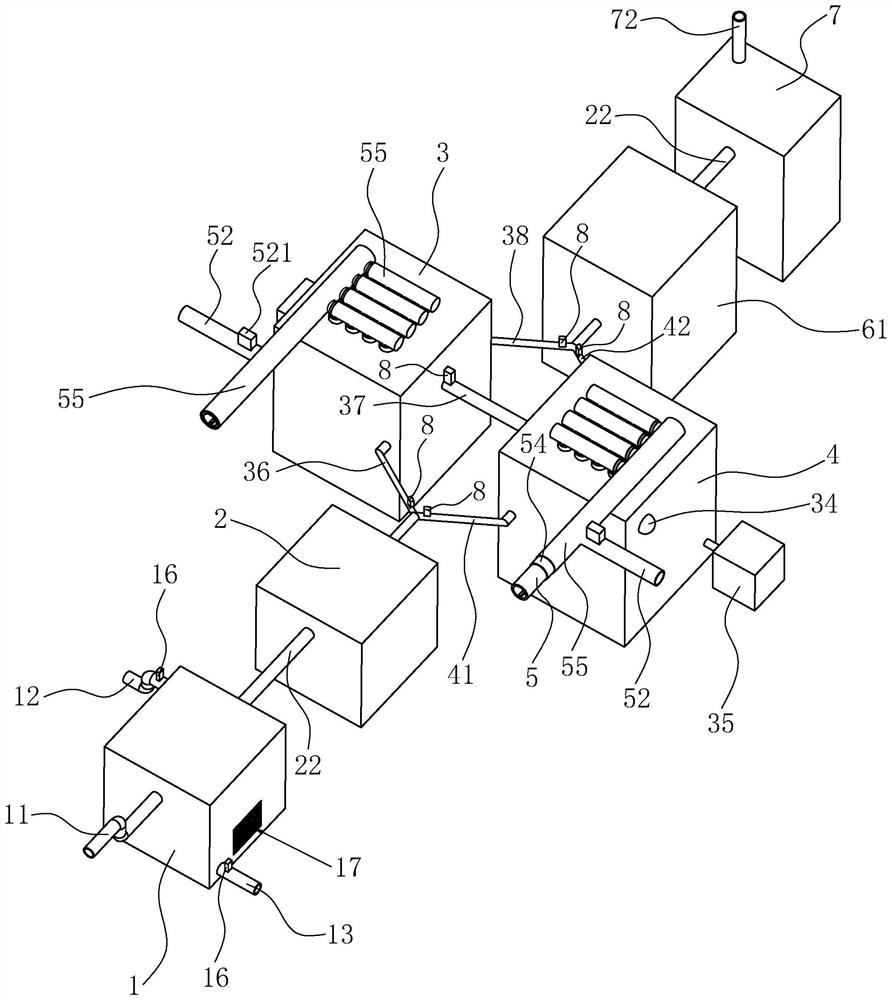

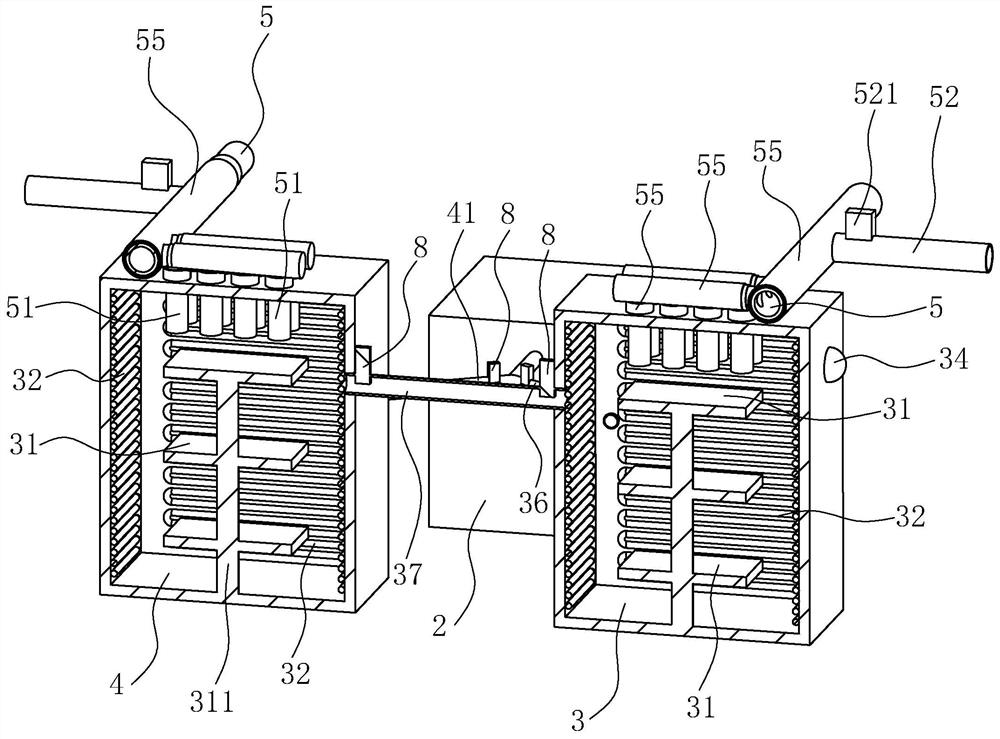

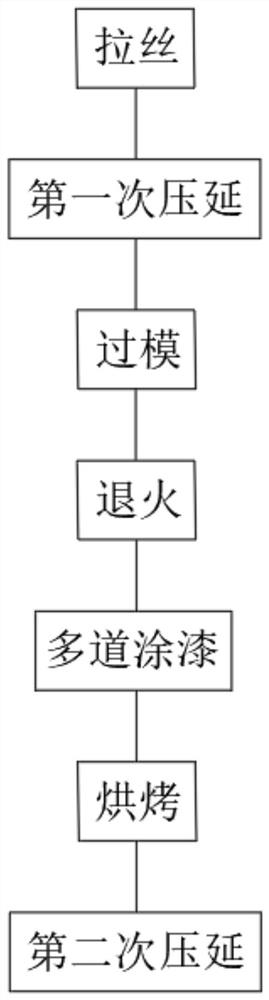

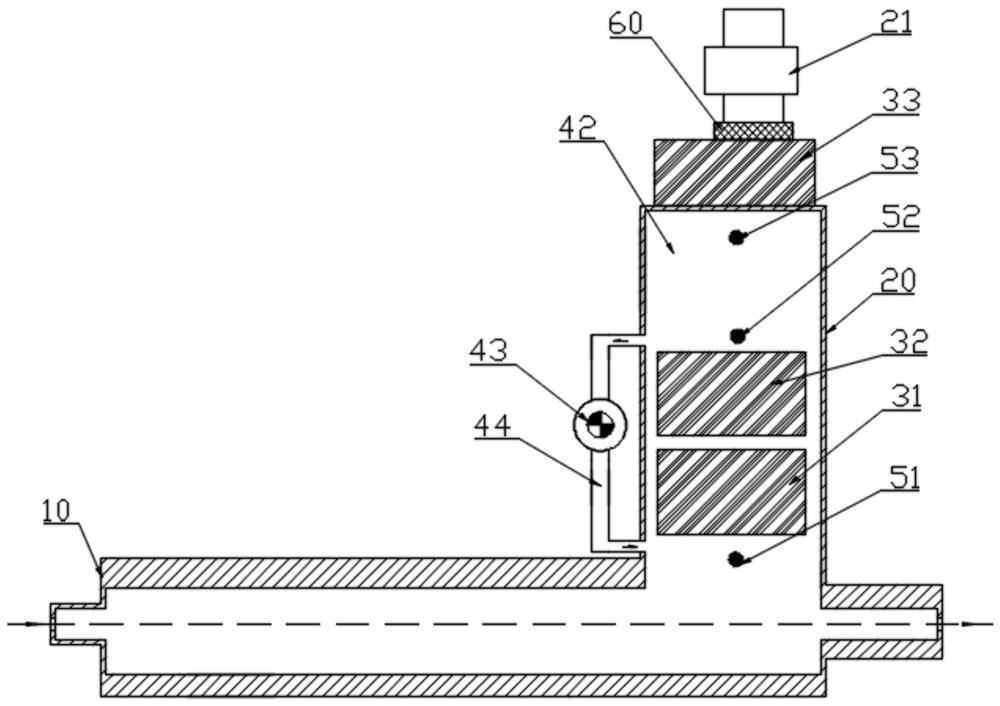

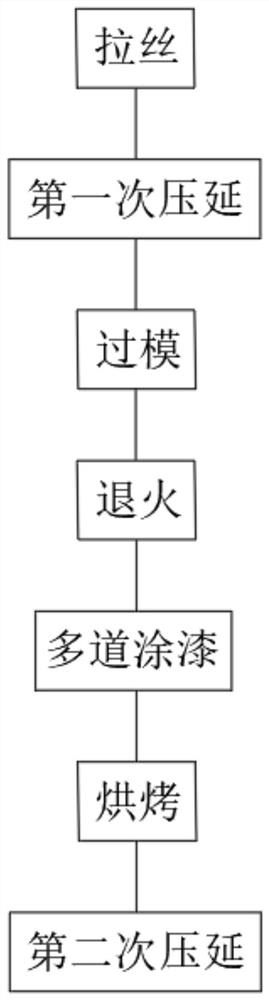

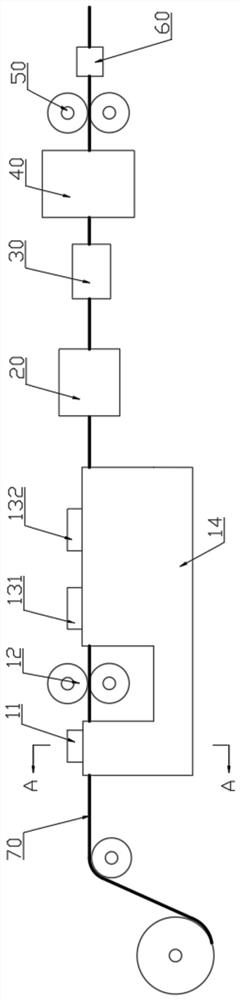

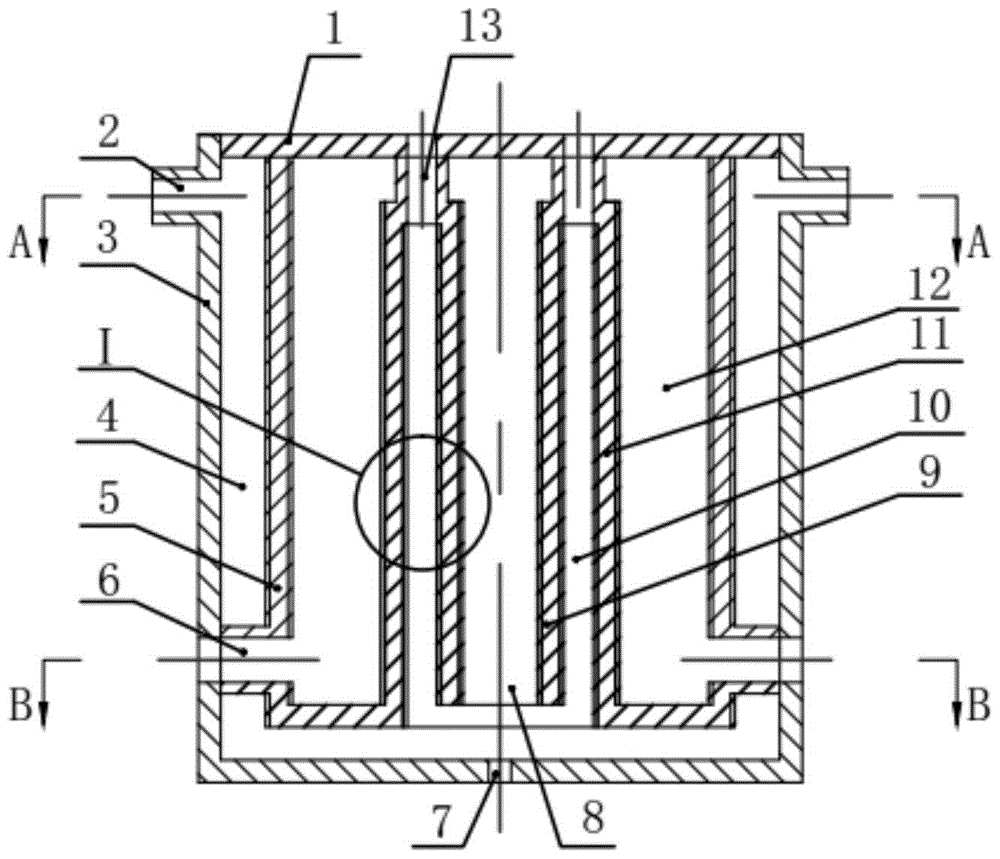

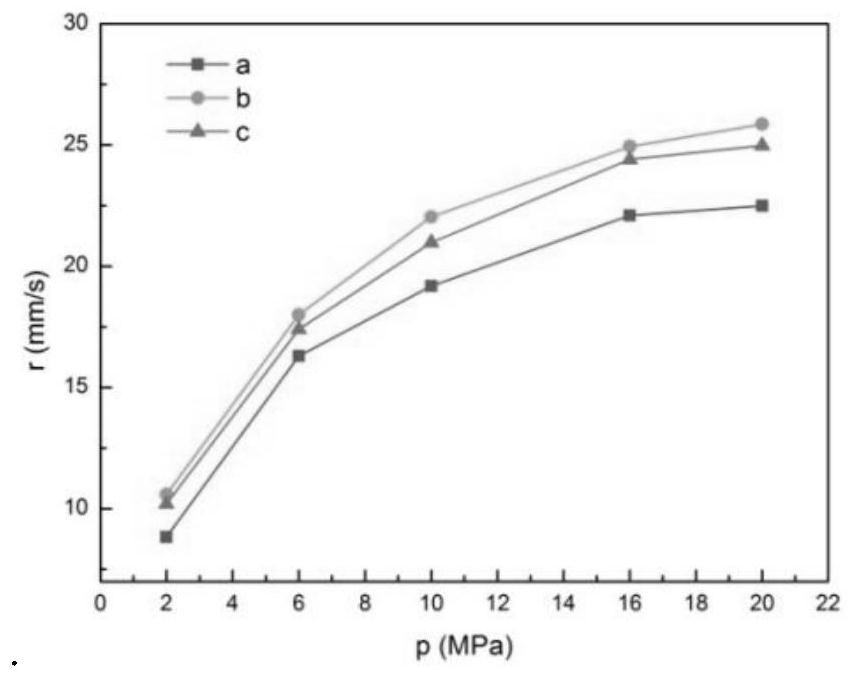

Processing technology of special self-adhesive enameled wire for household motor and device

ActiveCN110310782AImprove processing stabilityGood coating effectInsulating conductors/cablesCopper wireSelf adhesive

The invention discloses a processing technology of a special self-adhesive enameled wire for a household motor and a device. The processing technology comprises the steps of softening a copper bare wire through an annealing oven to obtain a copper wire A; sensing the copper wire A into a drying furnace for drying to obtain a copper wire B; coating the surface of the copper wire B with primer, sending the copper wire B into a first enamelling furnace, and drying the copper wire B for the first time in different temperature environments through the first enamelling furnace to obtain an enameledwire C; coating the surface of the enameled wire C with finish paint, then sending the enameled wire C into a second enamelling furnace, and drying the enameled wire C for the second time in differenttemperature environments through the second enamelling furnace to obtain an enameled wire D; and winding the enameled wire D to obtain a finished enameled wire. The working stability and the bondingeffect of the self-adhesive paint after being coated can be effectively improved according to the invention.

Owner:浙江郎立电工器材有限公司

Cerium-based rare-earth catalytic combustion improver and preparation method thereof

ActiveCN103113937AControl granularityGood combustion-supporting and purifying effectLiquid carbonaceous fuelsFuel additivesCeriumCarbon deposit

The invention provides a cerium-based rare-earth catalytic combustion improver. A preparation method of the cerium-based rare-earth catalytic combustion improver comprises the following steps of: forming a carrier by C16H35O4P and / or phosphorous or kerosene; dissolving rear-earth oxide in an H2SO4 or HCI solution to obtain rare-earth feed liquid; mixing the carrier and the feed liquid to obtain a load organic phase; and mixing the load organic phase and cerium-based rare-earth oxide to obtain the cerium-based rare-earth catalytic combustion improver. The invention also discloses the preparation method of the cerium-based rare-earth catalytic combustion improver. The cerium-based rare-earth catalytic combustion improver provided by the invention is low in cost and simple in preparation and operation processes, and the adjustable range of component parameters is wide. After the cerium-based rare-earth catalytic combustion improver is added, the heat value of fuel oil is increased by 10-15%, the content of CO, CH and NOx in discharged exhaust gas is reduced by 50-60%, an energy saving and emission reduction effect can be realized very well, and simultaneously carbon deposits can be effectively cleared away. The cerium-based rare-earth catalytic combustion improver is wide in the application range, has no side effects on equipment and is simple and convenient to add and operate.

Owner:JIANGSU LIGANG SCI & TECH

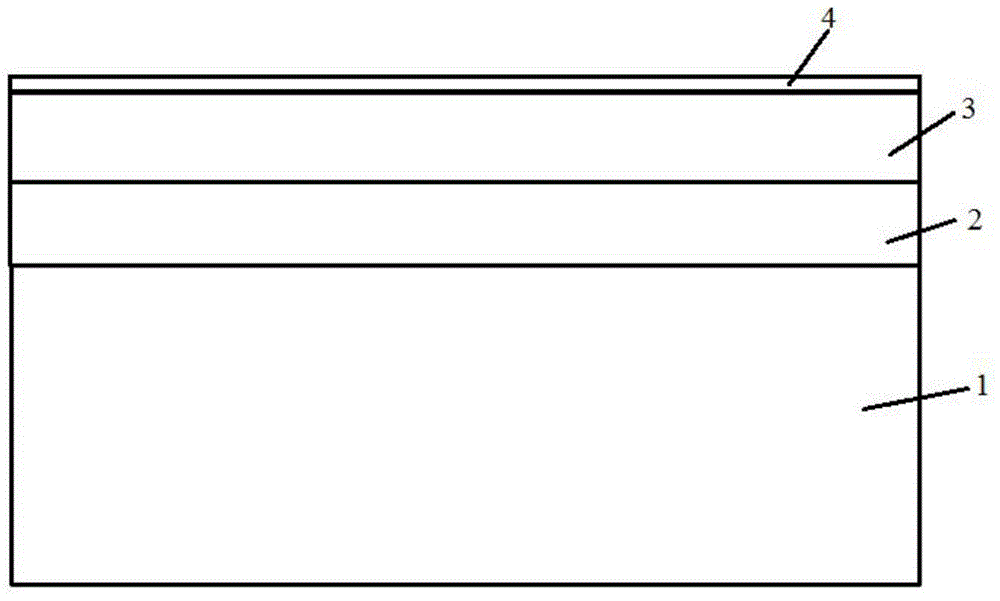

Double-layer structure catalyst for catalytic combustion of methane and preparation method thereof

ActiveCN105833897BHigh activityImprove catalytic combustion performanceMolecular sieve catalystsMolecular sieveRare earth

The invention discloses a double-layer structured catalyst used for methane catalytic combustion and a preparation method thereof. The double-layer structured catalyst comprises a carrier and an active coating arranged on the carrier, wherein the active coating comprises a rare-earth composite molecular sieve loaded Pt coating and a rare-earth composite aluminum oxide loaded Pd coating which are sequentially arranged; and a weight ratio of the rare-earth composite molecular sieve loaded Pt coating to the rare-earth composite aluminum oxide loaded Pd coating is 1:(1-1.4). The double-layer structured catalyst disclosed by the invention can be used for catalytic combustion of low-concentration methane, wherein the active coating is of a double-layer structure composed of the rare-earth composite molecular sieve loaded Pt coating and the rare-earth composite aluminum oxide loaded Pd coating; the preparation method is simple and easy to implement, the prepared catalyst is high in activity, and the catalytic combustion effect on methane is good.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

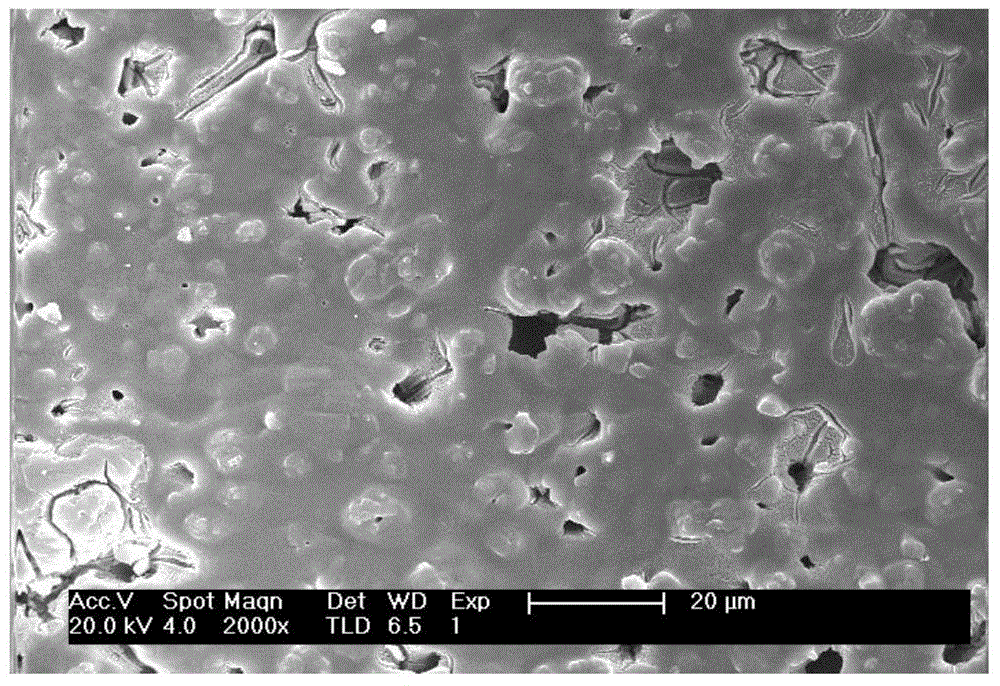

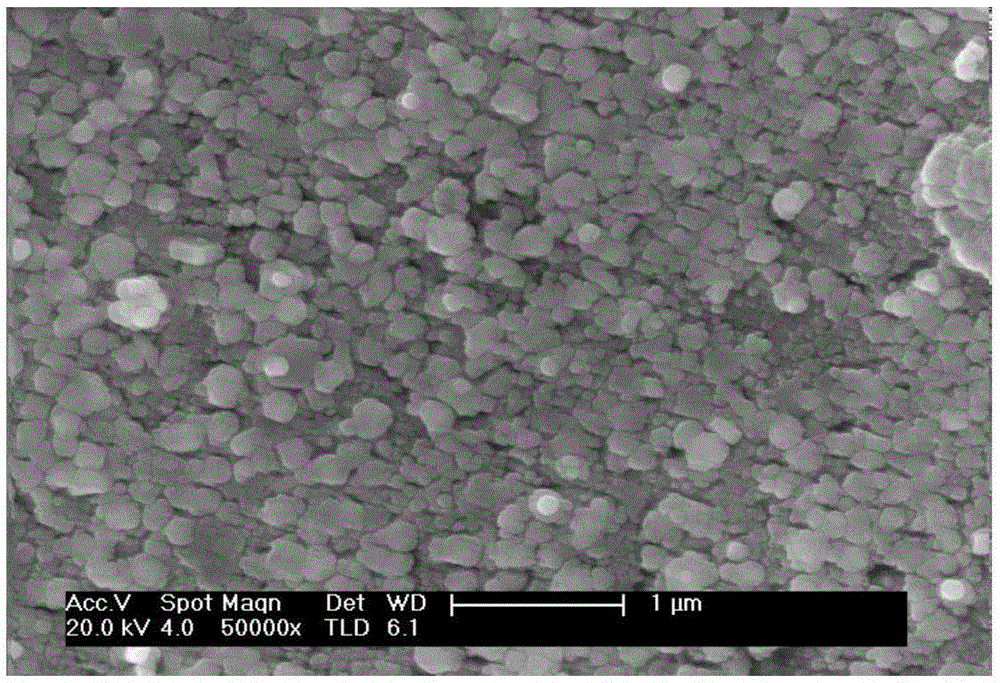

Single-coated multi-component catalyst and preparation method thereof

ActiveCN108889309AImprove performanceGood value for moneyIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsNano structuringPulse microwave

The invention discloses a single-coated multi-component catalyst and a preparation method thereof. The single-coated multi-component catalyst comprises a porous matrix and a mixed catalytic coating, wherein the mixed catalytic coating is applied on the surface of the porous matrix and composed of a catalytic active component and a bonding component which are blended at (1-3): (3-1) by weight percentage. The single-coated multi-component catalyst is simple in preparation and high in high-activity VOCs (volatile organic compounds) combustion catalyzing performance. The preparation method comprises taking ethylene glycol as dispersion reducing agent, in-situ applying one or more types of metal particles onto a La / Y / Pr-doped-and-modified CeZrOx powder through pulsed microwave assisted chemicalreduction; then mixing the coated powder with the prepared bonding component, single-coating the porous matrix with the mixture, and performing drying and baking processes to obtain the target single-coated multi-component catalyst. With precious metal particles and other particles in a composite nano-structure, the prepared single-coated multi-component catalyst is excellent in catalytic activity; meanwhile, the preparation method of the single-coated multi-component catalyst is simple and rapid and accordingly is applicable to large-scale production and application.

Owner:湖南明瑞环保科技有限公司

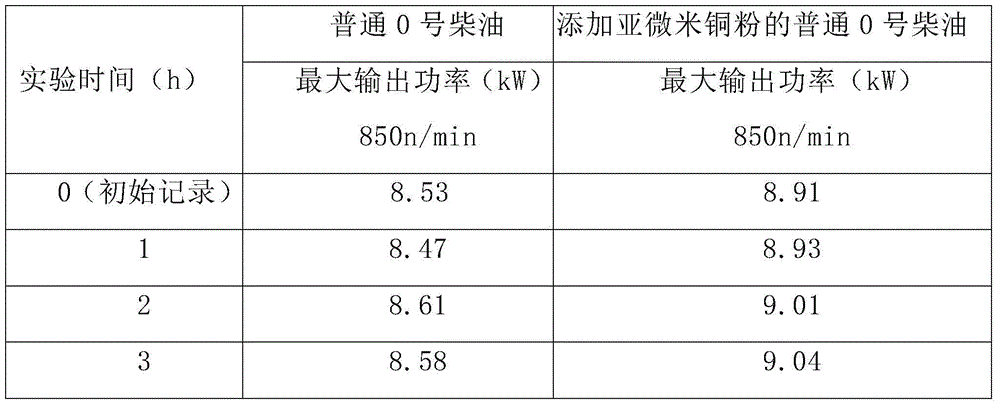

Method for improving output power of diesel engine

InactiveCN104481748AIncrease output powerImprove combustion efficiencyCombustion-air/fuel-air treatmentMachines/enginesMass ratioMicrometer

The invention discloses a method for improving output power of a diesel engine. The method comprises the steps that sub-micron copper powder is added to fuel oil of the diesel engine, the mass ratio of the sub-micron copper powder to the fuel oil of the diesel engine is 0.1-5.0:100, and the diameter of the sub-micron copper powder ranges from 0.1 micrometer to 10 micrometers. According to the method for improving the output power of the diesel engine, due to the facts that the sub-micron copper powder is added to the fuel oil of the diesel engine, the specific surface of the sub-micron copper powder is large, the number of surface active centers is multiple, and the sub-micron copper powder has good catalytic combustion performance, combustion efficiency of the fuel oil of the diesel engine can be greatly improved, the cylinder clearance is reduced through high adhesivity, and then the output power of the diesel engine is improved.

Owner:CHONGQING TAILU TECH DEV

Waste gas treatment device for screw extruder

PendingCN111911942AGuaranteed dust removal performanceIncrease profitDispersed particle separationCombustion technology mitigationCombustion chamberExhaust gas emissions

The invention provides a waste gas treatment device for a screw extruder, and relates to the technical field of rubber regeneration equipment. The waste gas treatment device comprises a spraying chamber, a preheating chamber and a primary combustion chamber, wherein a pipeline for communicating the spraying chamber and the preheating chamber is arranged between the spraying chamber and the preheating chamber, and a first gas supply pipe for communicating the preheating chamber and the primary combustion chamber is arranged between the preheating chamber and the primary combustion chamber; thespraying chamber is communicated with an intake pipe, a plurality of spraying heads are arranged at the top in the spraying chamber, and a preheating electric heating pipe is arranged on the inner wall of the preheating chamber; a plurality of layers of catalytic beds arranged up and down are arranged in the primary combustion chamber, a combustion electric heating pipe is arranged on the inner wall of the primary combustion chamber, and the primary combustion chamber is further connected to a first outlet pipe. A plurality of small heat transfer pipes which are parallel to each other and arearranged above the catalytic bed at the uppermost layer are further arranged in the primary combustion chamber, and penetrate through the primary combustion chamber and are communicated with a main heat transfer pipe for connecting the small heat transfer pipes. When the device is used, waste gas can be effectively treated, waste gas emission is guaranteed to be clean and free of pollution, heat generated by waste gas combustion can be fully utilized, and the energy utilization rate is increased.

Owner:NANTONG HUILI RUBBER

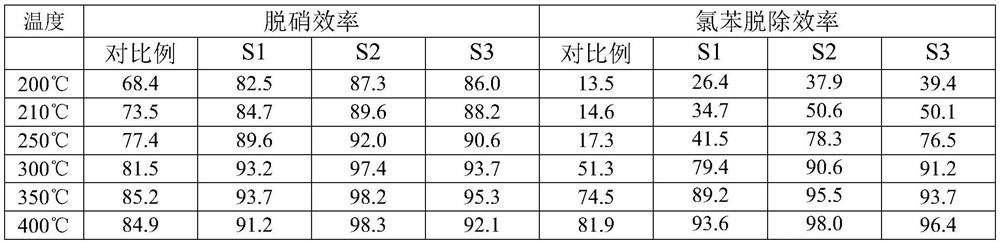

Modification method of SCR catalyst for removing chlorobenzene in flue gas by catalytic combustion and catalyst

PendingCN113559846AEnhanced Catalytic Combustion PerformanceReduce processing costsGas treatmentHeterogenous catalyst chemical elementsFlue gasIndustrial furnace

The invention relates to a modification method of an SCR catalyst for removing chlorobenzene in flue gas by catalytic combustion and a catalyst. The method comprises the following steps of: S1, preparing a vanadium-titanium catalyst, and grinding the catalyst to obtain vanadium-titanium catalyst powder; S2, preparing a modified precursor and adding the modified precursor into a water solution to obtain a modified precursor solution which comprises one or more of manganese, chromium, copper, zirconium, niobium and molybdenum; S3, adding the vanadium-titanium catalyst powder into the modified precursor solution to form a mixed solution; and S4, drying and calcining the mixed solution in the step S3 so as to obtain a modified catalyst of which the active component is one or more of oxides of manganese, chromium, copper, zirconium, niobium and molybdenum. According to the method, the vanadium-titanium catalyst is modified, the catalytic combustion performance of the vanadium-titanium catalyst on chlorobenzene is enhanced while the NOx removal performance is guaranteed, then cooperative treatment of industrial furnace flue gas NOx and chlorobenzene is achieved, and the industrial furnace flue gas treatment cost can be greatly reduced.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD +1

Production process for treating bone-shaped paint film of flat enameled wire

ActiveCN112735676AThe cost of customization is not highLow costApparatus for heat treatmentReduction of cables/conductors sizePolymer scienceElectrical performance

The invention relates to a production process for treating a bone-shaped paint film of a flat enameled wire. The thickness of the paint film of a bare wire is properly enlarged by 5-40microm on the upper limit of a set technical standard by using a painting device under the condition of not influencing the electrical property, adhesiveness and appearance of a product, and then the thickness is pressed by using a second calender, an R-angle paint film has bone-shaped plastic deformation which is the same as that of a wide-surface paint film, so that the problem that the boundary dimension exceeds the standard due to the bone shape of the paint film is well solved. According to the invention, the industrial production is actually overturned from the design, but the corresponding performance of the enameled wire is not reduced, and the consistency of the electrical performance and the size is improved by 20% or more.

Owner:广东松田科技股份有限公司

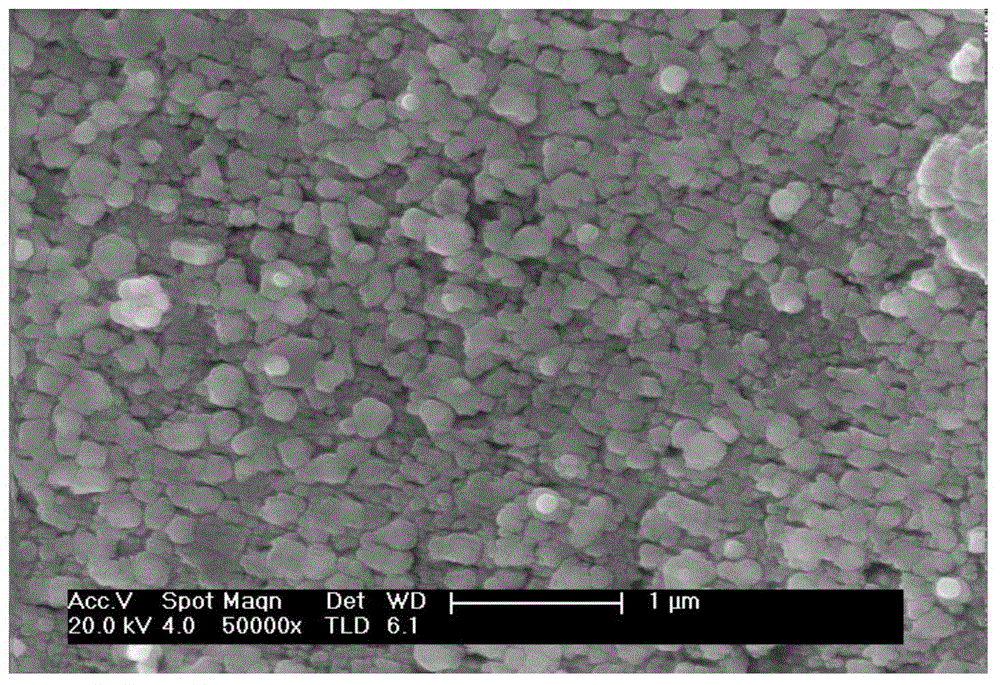

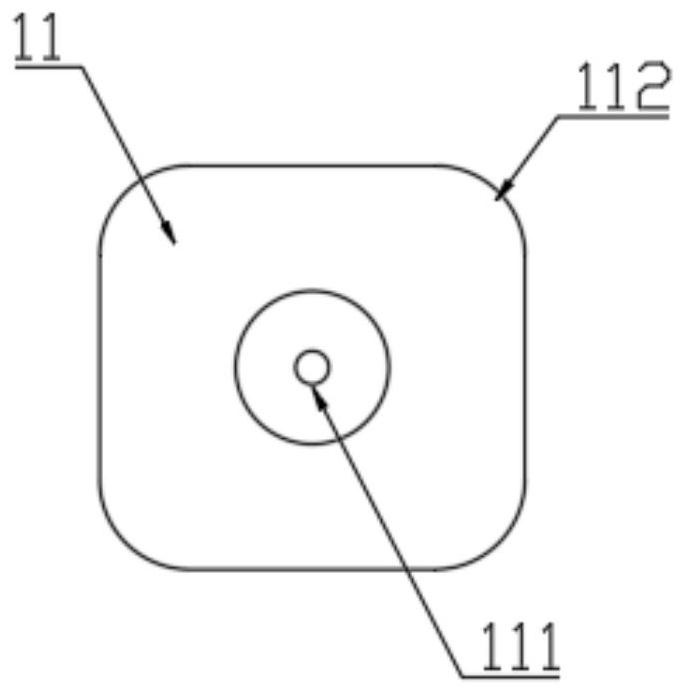

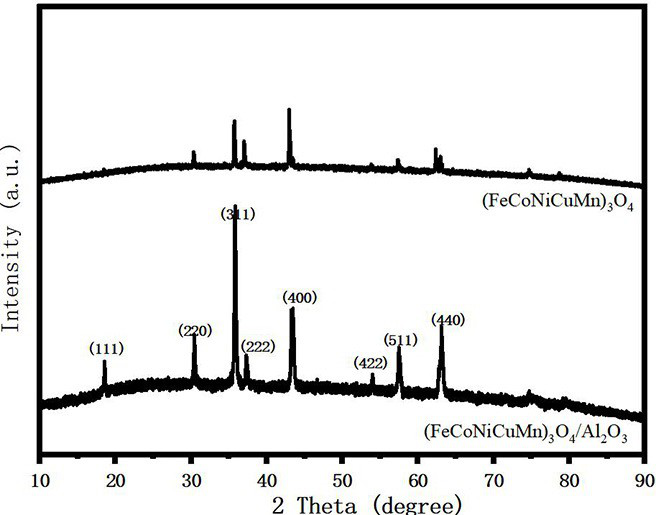

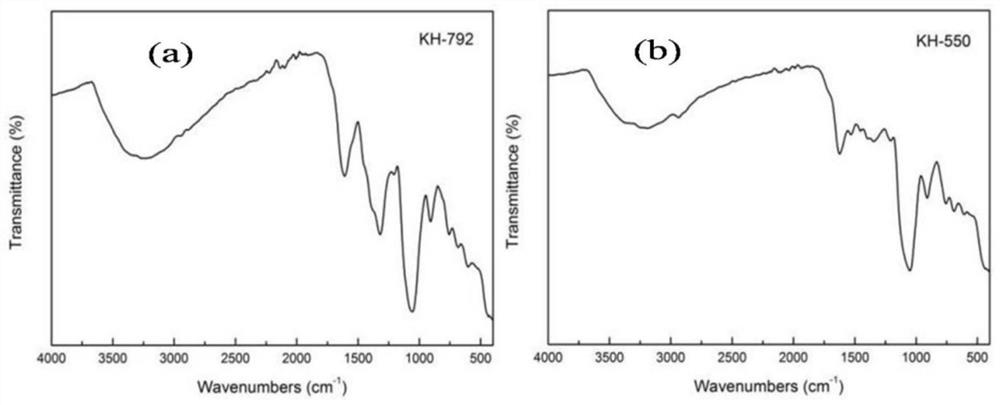

Catalyst for catalytic combustion of organic volatile waste gas and preparation method thereof

ActiveCN113649022ASmall grain sizeImprove catalytic combustion performanceHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystPhysical chemistry

The invention relates to a catalyst for catalytic combustion of organic volatile waste gas and a preparation method of the catalyst. A carrier of the catalyst is gamma-Al2O3; and an active component of the catalyst is a five-membered spinel structure high-entropy oxide. The preparation method comprises the following steps: according to the type of the active component in the prepared catalyst, weighing soluble salt according to an equimolar ratio of metal ions, dissolving the soluble salt in deionized water, adding citric acid according in proportion, and performing stirring at room temperature to obtain clear sol; adding a certain amount of a gamma-Al2O3 carrier precursor, and conducting stirring to obtain a mixture; transferring the mixture into water, and conducting evaporating water under a rapid stirring condition to obtain viscous gel; and drying, grinding and calcining the prepared viscous gel to obtain a catalyst product. The catalyst has relatively good low-temperature activity and relatively high hydrothermal stability; and the method reduces the grain size of high-entropy oxide, increases the specific surface area of the catalyst, improves the combustion performance, reduces the content of the high-entropy oxide in the catalyst, and lowers cost.

Owner:天津环科环境咨询有限公司

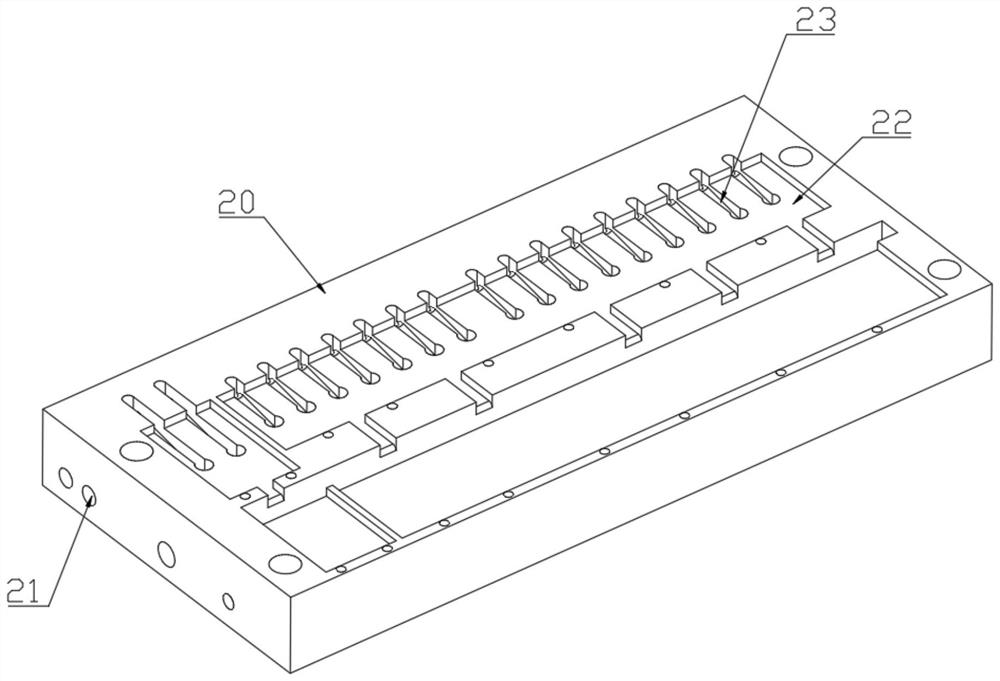

Flat enameled wire baking furnace

ActiveCN112802638AAchieve co-rotationCompact structureFurnace typesIncinerator apparatusThermodynamicsExhaust fumes

The invention relates to a flat enameled wire baking furnace which comprises a baking furnace body, a waste gas pipeline, a first fan, a first heat exchange pipe and a rotating device. By arranging the first fan and the first heat exchange pipe, external fresh air is input into the first heat exchange pipe, heat exchange is conducted through waste gas heat in the waste gas pipeline, then the heat is recycled into the baking furnace for use, and energy is saved. A plurality of branch pipes are used for conveying hot air into the baking furnace, so that the enameled wire can be uniformly heated, and a series of quality problems of products caused by excessive baking of one side of the enameled wire and insufficient baking of the other side are solved. The branch pipes are driven to rotate through the rotating device, so that all positions in the baking furnace can uniformly obtain heat of hot air output by the branch pipes, and the enameled wires in the baking furnace are further uniformly heated.

Owner:广东松田科技股份有限公司

A production process for treating bone-shaped paint film of flat enameled wire

ActiveCN112735676BThe cost of customization is not highLow costApparatus for heat treatmentReduction of cables/conductors sizePolymer scienceBone shape

The invention relates to a production process for treating the bone-shaped paint film of flat enameled wire. Without affecting the electrical performance, adhesion and appearance of the product, the thickness of the paint film on the bare wire is properly adjusted to the upper limit of the established technical standard by using a painting device. 5-40μm thicker, and the thickness is pressed by the second calender, so that the "R" corner paint film has a "bone-like" plastic deformation that is the same as that of the wide-face paint film, which is a good solution to the problem of excessive dimensions caused by the "bone-like" paint film . The present invention actually subverts industrial production from the design point of view, but the corresponding performance of the enameled wire will not decrease, but the electrical performance and size consistency will be improved by more than 20%.

Owner:广东松田科技股份有限公司

A method to effectively reduce fugitive emissions of vocs in enameled wire painting process

ActiveCN112735691BAvoid direct contactAvoid drippingInsulating conductors/cablesLacquerProcess engineering

Owner:广东松田科技股份有限公司

Catalyst for exhaust gas purification and preparation method thereof

ActiveCN112206781BHigh oxygen storage performanceImprove redox performanceGas treatmentHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

The invention discloses a catalyst for exhaust gas purification and a preparation method thereof. The catalyst is CuFe co-doped with samarium (Sm) and erbium (Er) as active components 2 o 4 , denoted as CuFe (2‑x‑y) SM x Er y o 4 ; where x is 0.02-0.04; y is 0.02-0.04; the carrier is CeO 2 ; The CuFe (2‑x‑y) SM x Er y o 4 The mass ratio to cerium oxide is 1:4 to 1:9. The ionic radius and redox potential of the active components of the catalyst are improved by Sm and Er co-doping, thereby improving the catalytic activity of the catalyst, while cerium oxide not only acts as a carrier, but also cerium oxide itself has excellent oxygen storage capacity and oxidation-reduction potential. Reduction performance, which promotes each other with the active components. Due to the synergistic effect between the two, the catalytic activity of the catalyst is significantly improved, making it more excellent in the catalytic combustion performance of volatile organic compounds VOCs, and significantly reduced The light-off temperature is an ideal catalyst for treating VOCs.

Owner:广州尖峰生物制品有限公司

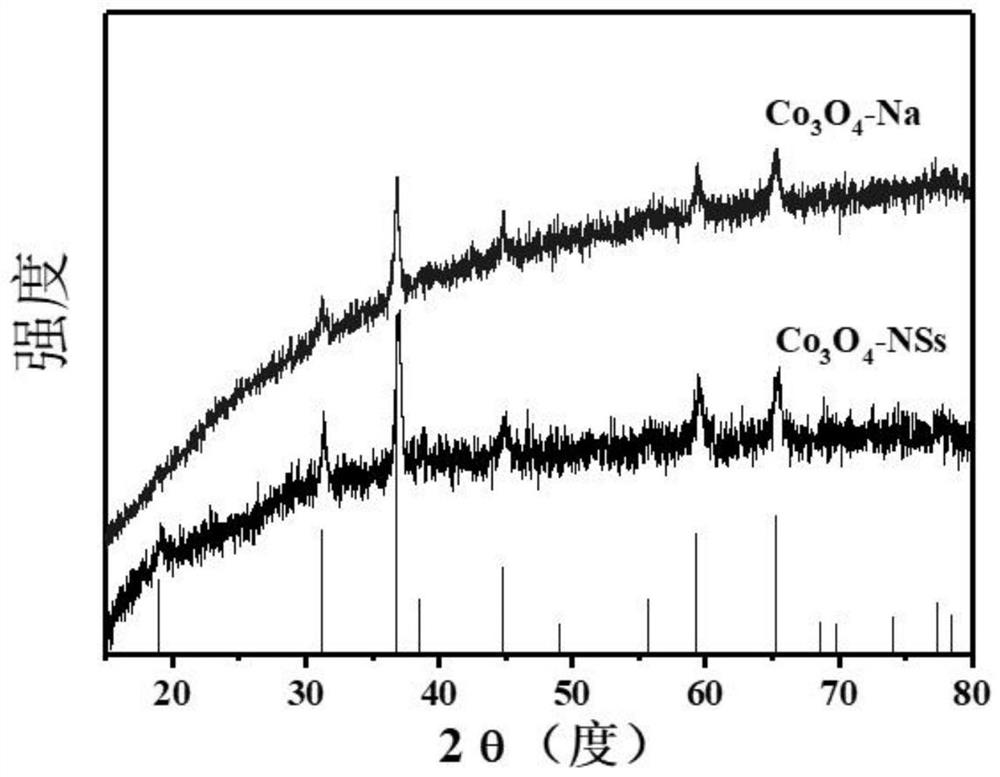

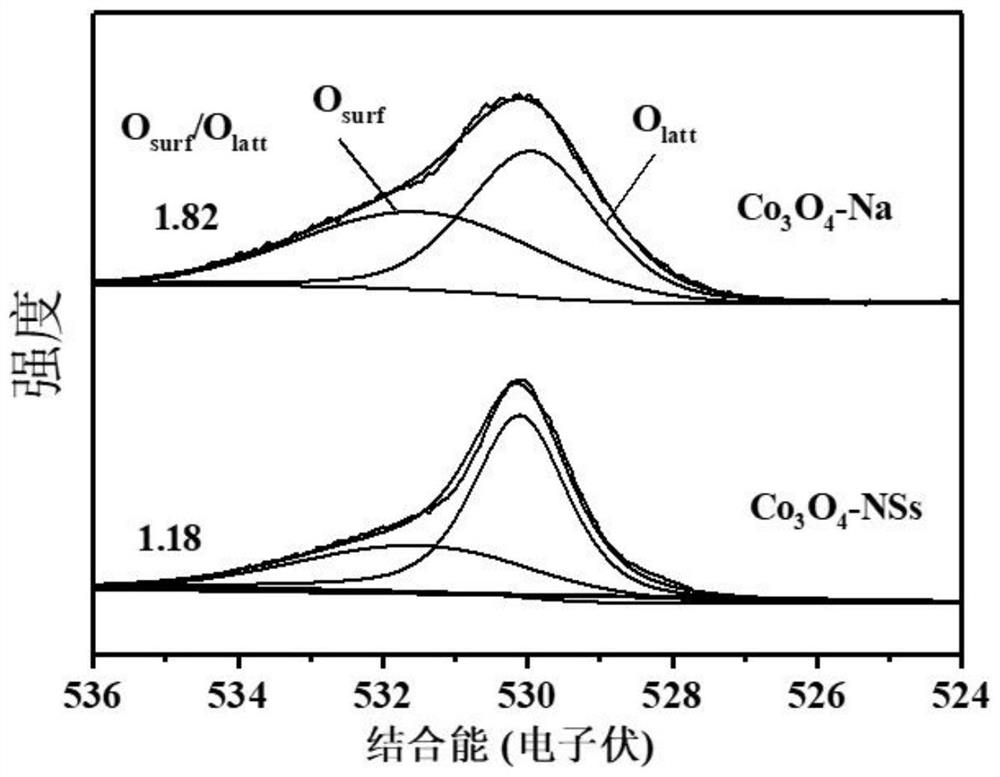

A kind of cobalt tetroxide catalyst for catalytic combustion of methane and its preparation and application

ActiveCN109762614BReaction conditions are easy to controlImprove catalytic combustion performanceMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMethane

The invention discloses a Co3O4 catalyst for methane catalytic combustion as well as preparation and application. A preparation method is characterized by taking cobalt acetate as a precursor, carrying out hydrothermal reaction under an alkaline environment, and then carrying out high-temperature roasting, thus obtaining a Co3O4 nanosheet; treating the Co3O4 nanosheet through sodium metal, thus obtaining the Co3O4 nanosheet for the methane catalytic combustion. The Co3O4 nanosheet for the methane catalytic combustion has more surface defect positions and reactive oxygen species, excellent methane catalytic combustion performance is shown, and larger potential in aspect of replacement of a noble metal catalyst is obtained.

Owner:QINGDAO UNIV

Monolithic catalyst for catalytic combustion of methane and preparation method thereof

ActiveCN105797766BHigh activityImprove catalytic combustion performanceMolecular sieve catalystsMolecular sieveRare earth

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

Efficient energy-saving device of gas stove

InactiveCN104359138ALow priceRaw materials are easy to getDomestic stoves or rangesLighting and heating apparatusContact timeProcess engineering

The invention discloses an efficient energy-saving device of a gas stove. The efficient energy-saving device of the gas stove comprises a combustion catalysis plate, a windproof cylinder capable of enclosing the whole flame, and support legs, wherein the combustion catalysis plate is of a combustion catalyst loaded porous plate and is mounted at the upper part of the inner wall of the windproof cylinder; the support legs are arranged at the lower part of the windproof cylinder. The efficient energy-saving device of the gas stove is simple in structure, high in effect and convenient to use; the windproof cylinder is capable of preventing wind from blowing away the flame; by virtue of the porous plate, fire can be uniformly distributed, so that the heat loss is greatly reduced; the catalyst is firmly attached onto the porous plate; the catalyst is long in contact time with the flame, large in contact area and high in catalytic combustion effect; the combustion is completed; the highest heat is released; the NOx and incomplete combustion products are reduced; the efficient energy-saving device has the advantages of being efficient and environmentally friendly, and has an energy-saving effect.

Owner:巢雨

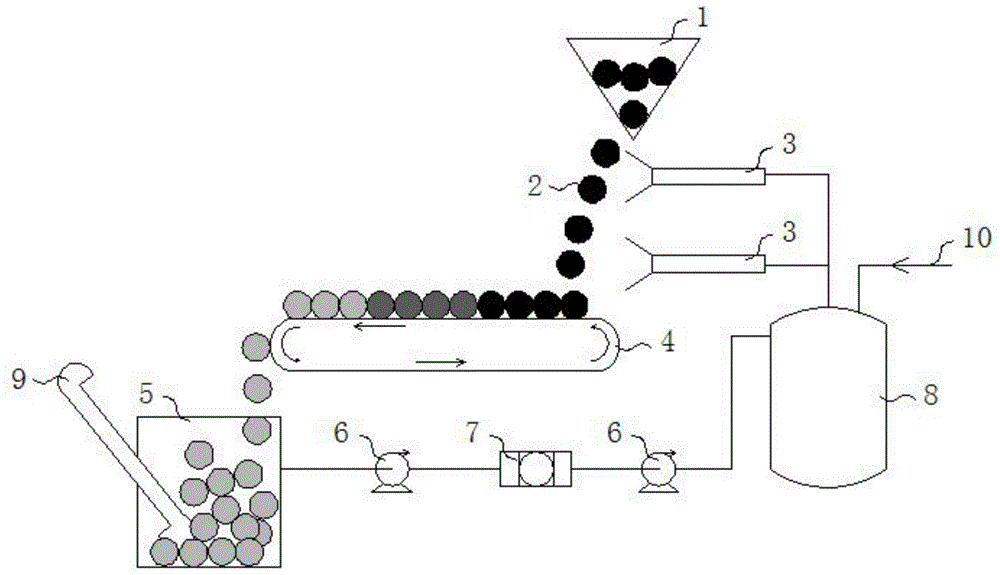

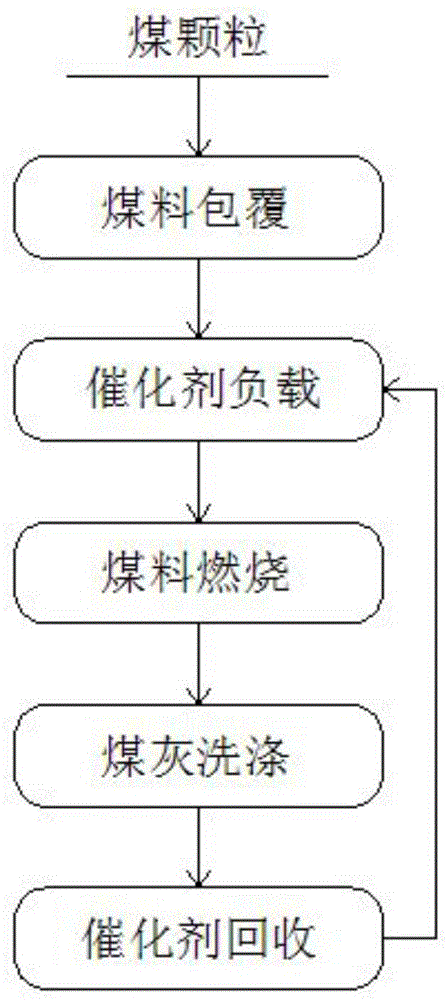

A method for recycling coal-fired catalysts in chain furnaces

ActiveCN104696947BAchieve recyclingEasy to recycleSolid fuelsSolid fuel combustionFixed bedEngineering

The invention relates to a method for recycling of a fuel coal catalyst of a chain-grate boiler. The method comprises the steps of coating the outer surface of coal with a coating agent solution, then performing catalyst loading, immersing the coal ash into water after the coal loaded with a catalyst is burnt, and finally filtering and recycling mixed liquor, so as to obtain the catalyst which can be used repeatedly. The method has the benefits that the liquid catalyst is sufficiently utilized, the catalytic combustion effect of a fixed bed fuel coal boiler is greatly improved, the catalyst recovery and recycling rates are correspondingly increased, the efficiency of the fuel coal boiler is further improved, the catalyst cost is reduced, and meanwhile the dust emission during the combustion process is greatly reduced.

Owner:BEIJING FUYUAN TIANHANG TECH

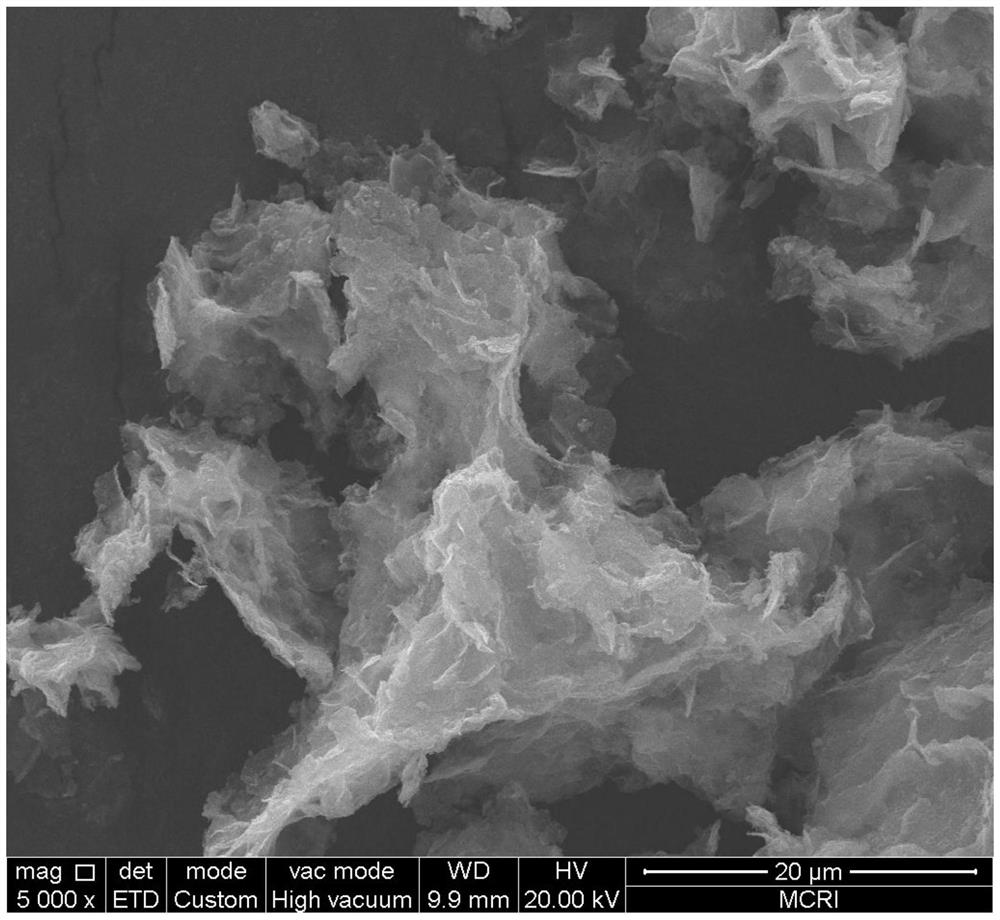

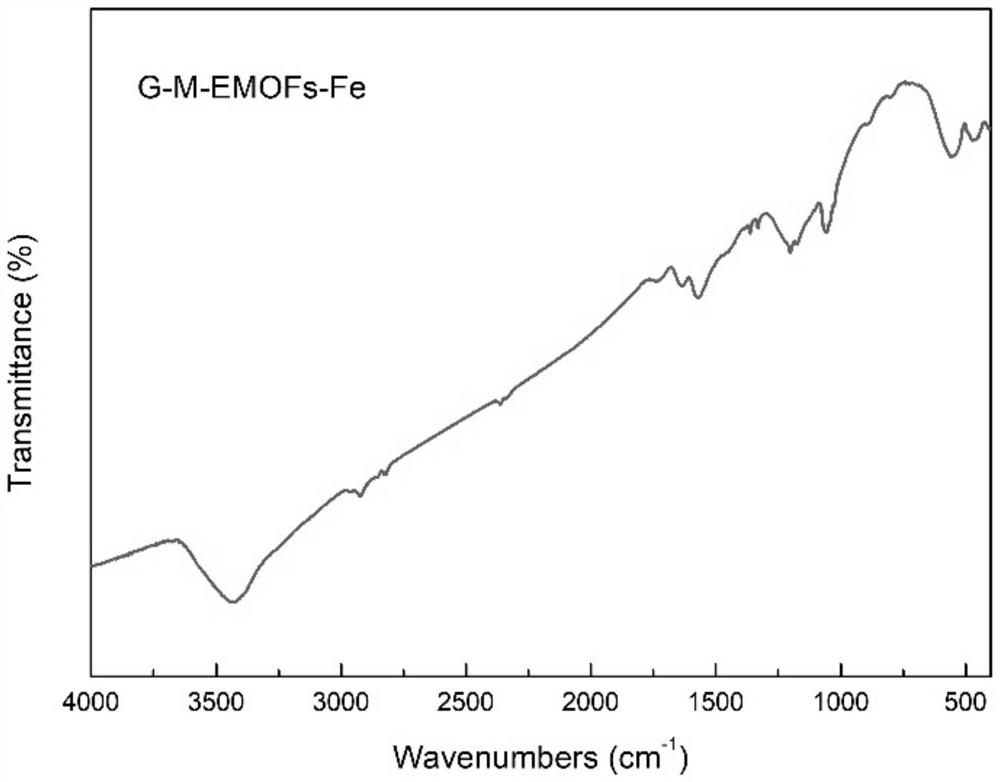

A kind of graphene-based energetic MOFs and preparation method thereof

ActiveCN112940273BEnergizedOvercoming the disadvantages of energy reductionNon-explosive/non-thermic compositionsPressure gas generationPtru catalystFreeze-drying

The invention provides a graphene-based energetic MOFs and a preparation method thereof. In the method, a graphene-organic acid metal complex is ultrasonically dispersed in methanol, and 1,1'-dihydroxy-5,5'-diphenyl The azole dihydroxylamine salt-based metal complex is dissolved in DMF, the two solutions are stirred and mixed, placed in the polytetrafluoroethylene lining of a stainless steel autoclave, and reacted at 180°C-200°C for 48-60h, and cooled to After room temperature, filtration, washing, and freeze-drying were performed to obtain graphene-based energetic MOFs. The graphene-based energetic MOFs of the present invention realize the energeticization of graphene-organic acid metal complexes. When the synthesized graphene-based energetic MOFs are used as combustion catalysts, they not only maintain good combustion catalytic performance, but also overcome The disadvantage of the inert catalyst reducing the energy of the solid propellant can be used as a functional energetic combustion catalyst.

Owner:XIAN MODERN CHEM RES INST

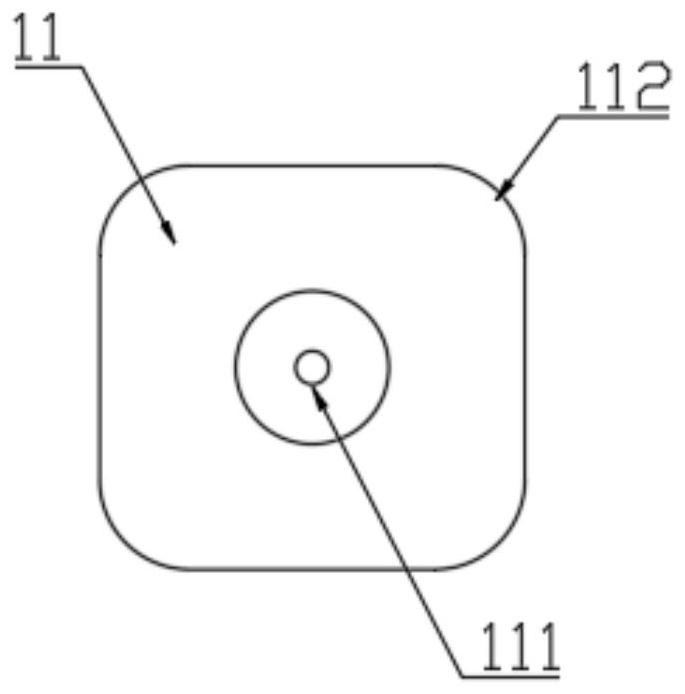

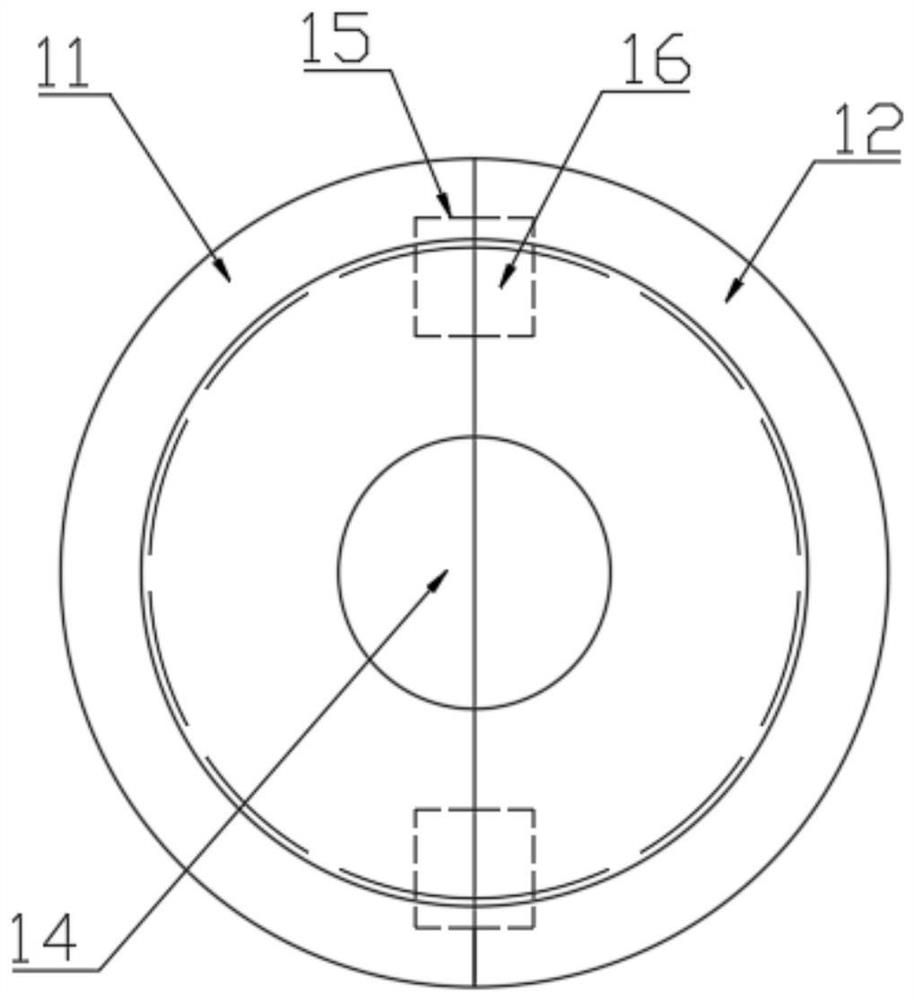

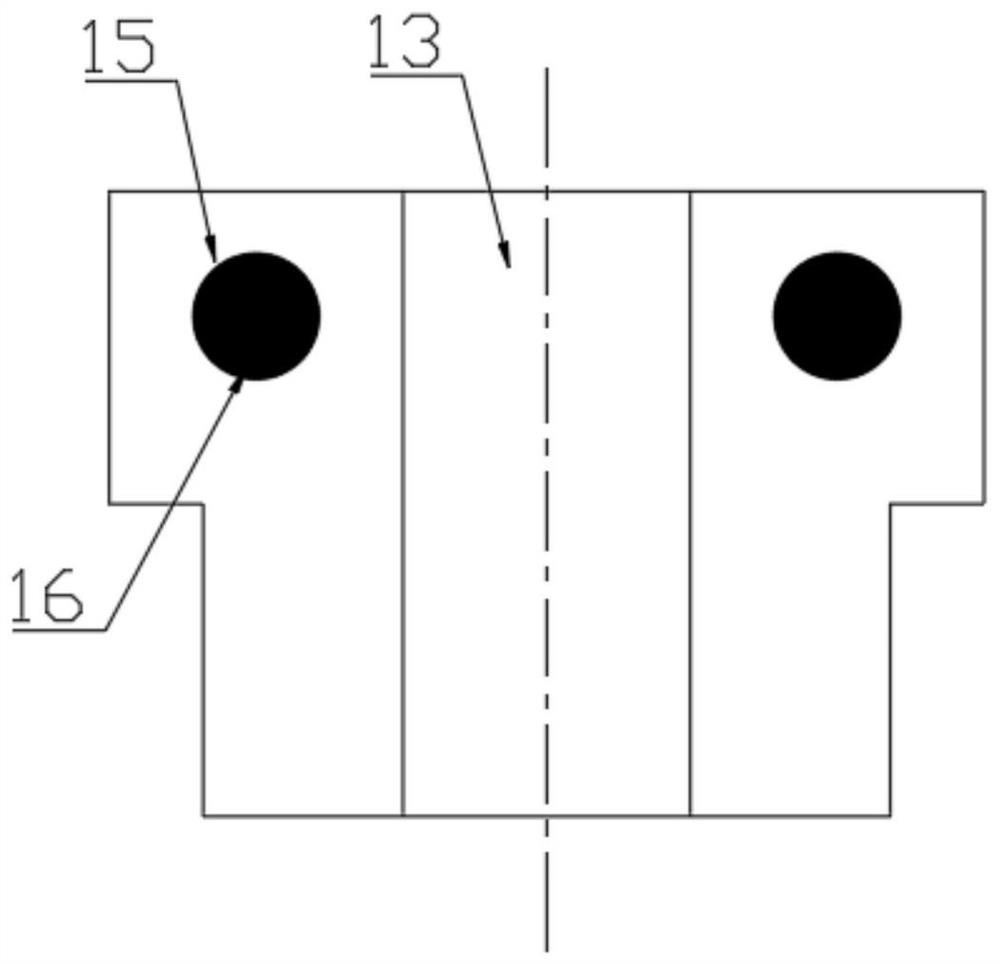

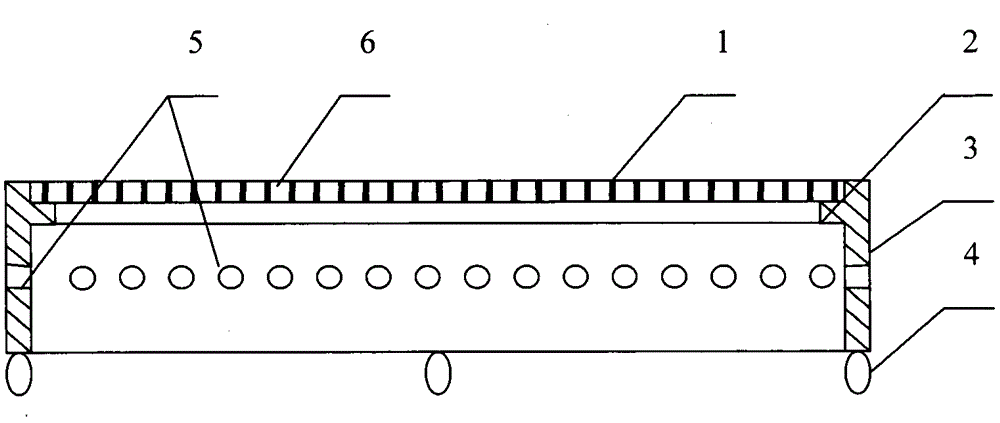

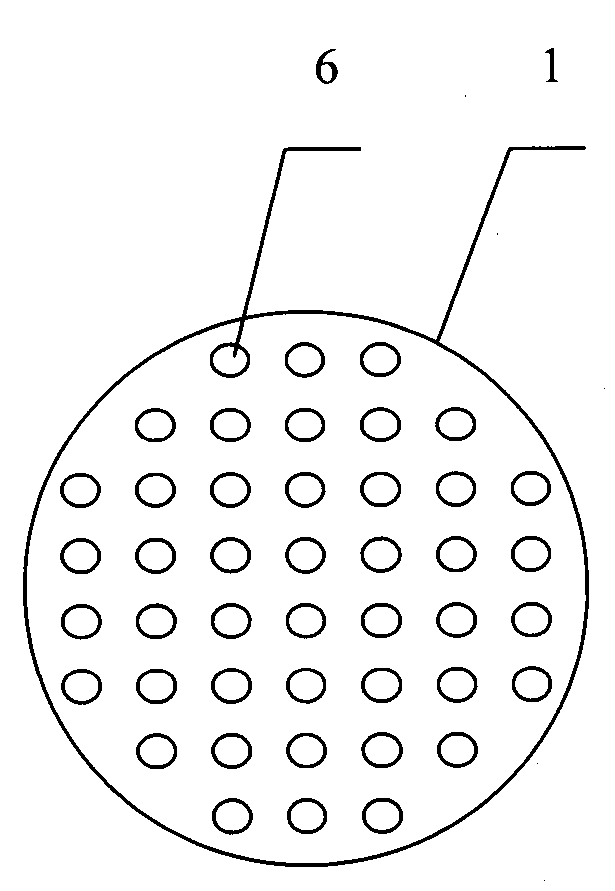

A micro-combustor for catalytic reforming of liquid fuel

ActiveCN104235839BIncrease the areaImprove heat transfer performanceBurnersCatalytic reformingCombustion chamber

The invention relates to a combustion device, in particular to a catalytic reforming microburner of liquid fuel. The catalytic reforming microburner of the liquid fuel comprises a round top cover plate and a shell connected with the top cover plate into a whole, wherein the top cover plate is provided with two symmetrical fuel inlet holes; the upper part of the side surface of the shell is provided with two symmetrical air inlet holes; the lower part of the side surface of the shell is provided with two symmetrical vent holes; the center of the bottom of the shell is provided with an igniter hole; a fuel channel and an air channel are in crossed communication at an angle of 90 degrees; the fuel channel and the air channel are communicated with one side of a combustion chamber; an exhaust duct is communicated with the other side of the combustion chamber. The catalytic reforming microburner of the liquid fuel has the beneficial effects that the fuel channel and the surface of the combustion chamber are provided with annular threads to enlarge heat exchange areas and reinforce heat exchange between fuel and high-temperature smoke; the fuel channel and the surface of the combustion chamber are respectively provided with cracking catalyst / reforming catalyst and combustion catalyst, and liquid fuel can be enabled to efficiently burn in the microburner.

Owner:ZHEJIANG UNIV

A kind of graphene-Schiff base nickel compound for solid propellant and preparation method thereof

ActiveCN110981651BImprove catalytic combustion performanceNon-explosive/non-thermic compositionsPtru catalystSalicylaldehyde

The invention discloses a preparation method of a graphene-Schiff base nickel composite, the structural formula of which is shown in I or II. Its synthesis process comprises the following steps: (1) using a coupling agent to modify graphene oxide to obtain aminated graphene; (2) reacting aminated graphene with salicylaldehyde to synthesize graphene Schiff base ligands; (3) Graphene-Schiff base ligand reacted with nickel nitrate to prepare graphene-Schiff base nickel composite. The graphene-Schiff base nickel composite synthesized by the method can significantly improve the burning rate of the modified double-base propellant containing HMX, and is an efficient combustion catalyst for solid propellants.

Owner:XIAN MODERN CHEM RES INST

Single coating multi-component catalyst and preparation method thereof

ActiveCN108889309BImprove performanceGood value for moneyIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsCooking & bakingNano structuring

The invention discloses a single-coated multi-component catalyst and a preparation method thereof. The single-coated multi-component catalyst comprises a porous matrix and a mixed catalytic coating, wherein the mixed catalytic coating is applied on the surface of the porous matrix and composed of a catalytic active component and a bonding component which are blended at (1-3): (3-1) by weight percentage. The single-coated multi-component catalyst is simple in preparation and high in high-activity VOCs (volatile organic compounds) combustion catalyzing performance. The preparation method comprises taking ethylene glycol as dispersion reducing agent, in-situ applying one or more types of metal particles onto a La / Y / Pr-doped-and-modified CeZrOx powder through pulsed microwave assisted chemicalreduction; then mixing the coated powder with the prepared bonding component, single-coating the porous matrix with the mixture, and performing drying and baking processes to obtain the target single-coated multi-component catalyst. With precious metal particles and other particles in a composite nano-structure, the prepared single-coated multi-component catalyst is excellent in catalytic activity; meanwhile, the preparation method of the single-coated multi-component catalyst is simple and rapid and accordingly is applicable to large-scale production and application.

Owner:湖南明瑞环保科技有限公司

Monolithic catalyst for catalytic combustion of methane and preparation method thereof

InactiveCN104084199BHigh conversion rate of catalytic combustionImprove performanceFuel additivesMetal/metal-oxides/metal-hydroxide catalystsHoneycombCordierite

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com