Modification method of SCR catalyst for removing chlorobenzene in flue gas by catalytic combustion and catalyst

An SCR catalyst, catalytic combustion technology, applied in combustion methods, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problems of high cost, lack of economy, no synergistic consideration of NOx and chlorobenzene removal, etc. , to achieve the effect of broad application prospects, reduction of processing costs, and enhancement of catalytic combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

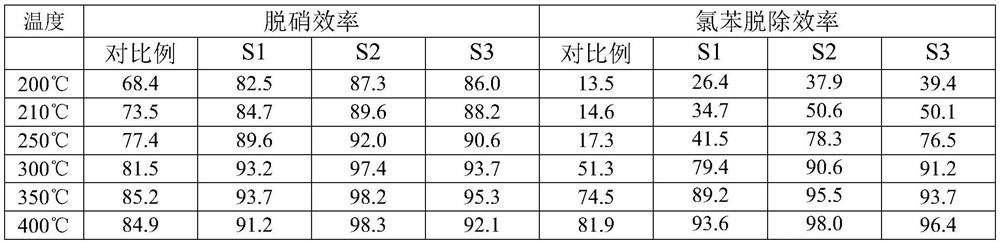

Examples

Embodiment 1

[0037] S1, take the typical V 2 o 5 -WO 3 / TiO 2 The catalyst is crushed and ground, and sieved with 200 mesh to obtain catalyst powder;

[0038] S2, add 300ml deionized water in 1L beaker, add 37g ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 4H 2O] to form a modified precursor solution;

[0039] S3. Add 200g of vanadium-tungsten-titanium catalyst powder in step S1 to the modified precursor solution in step S2, and continue stirring at 45°C until the water evaporates to form a viscous slurry, remove the magnet and stop stirring;

[0040] S4. Place the beaker containing the viscous slurry in an oven at 90°C for 12 hours, transfer the dried modified catalyst to a crucible, place it in a muffle furnace for calcination at 500°C for 4 hours, and obtain Enhanced modified catalyst S1 for removing chlorobenzene.

Embodiment 2

[0042] The difference between embodiment two and embodiment one is: the quality of ammonium molybdate is different.

[0043] S1, take the typical V 2 o 5 -WO 3 / TiO 2 The catalyst is crushed and ground, and sieved with 200 mesh to obtain catalyst powder;

[0044] S2, add 300ml deionized water in 1L beaker, add 76g ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 4H 2 O] to form a modified precursor solution;

[0045] S3. Add 200g of vanadium-tungsten-titanium catalyst powder in step S1 to the modified precursor solution in step S2, and continue stirring at 45°C until the water evaporates to form a viscous slurry, remove the magnet and stop stirring;

[0046] S4. Place the beaker containing the viscous slurry in an oven at 90°C for 12 hours, transfer the dried modified catalyst to a crucible, place it in a muffle furnace for calcination at 500°C for 4 hours, and obtain Enhanced modified catalyst S1 for removing chlorobenzene.

Embodiment 3

[0048] The difference between embodiment three and embodiment one is: the quality of ammonium molybdate is different.

[0049] S1, take the typical V 2 o 5 -WO 3 / TiO 2 The catalyst is crushed and ground, and sieved with 200 mesh to obtain catalyst powder;

[0050] S2, add 300ml deionized water in 1L beaker, add 104g ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 4H 2 O] to form a modified precursor solution;

[0051] S3. Add 200g of vanadium-tungsten-titanium catalyst powder in step S1 to the modified precursor solution in step S2, and continue stirring at 45°C until the water evaporates to form a viscous slurry, remove the magnet and stop stirring;

[0052] S4. Place the beaker containing the viscous slurry in an oven at 90°C for 12 hours, transfer the dried modified catalyst to a crucible, place it in a muffle furnace for calcination at 500°C for 4 hours, and obtain Enhanced modified catalyst S1 for removing chlorobenzene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com