A method to effectively reduce fugitive emissions of vocs in enameled wire painting process

A fugitive emission and enameled wire technology, applied in the direction of conductor/cable insulation, electrical components, circuits, etc., can solve the problems of reducing VOCs fugitive emissions and failing to ensure that VOCs fugitive emissions meet the standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] see Figure 1 to Figure 4 A method of effectively reducing VOCs fugitive emissions in the enameled wire painting process of the present embodiment comprises the following steps:

[0035] Step 1: Add a wrapped sheath to the paint outlet of the paint bucket (not shown) to ensure the seal between the paint outlet and the paint pipe (not shown);

[0036] Step 2: using a closed paint box (not shown);

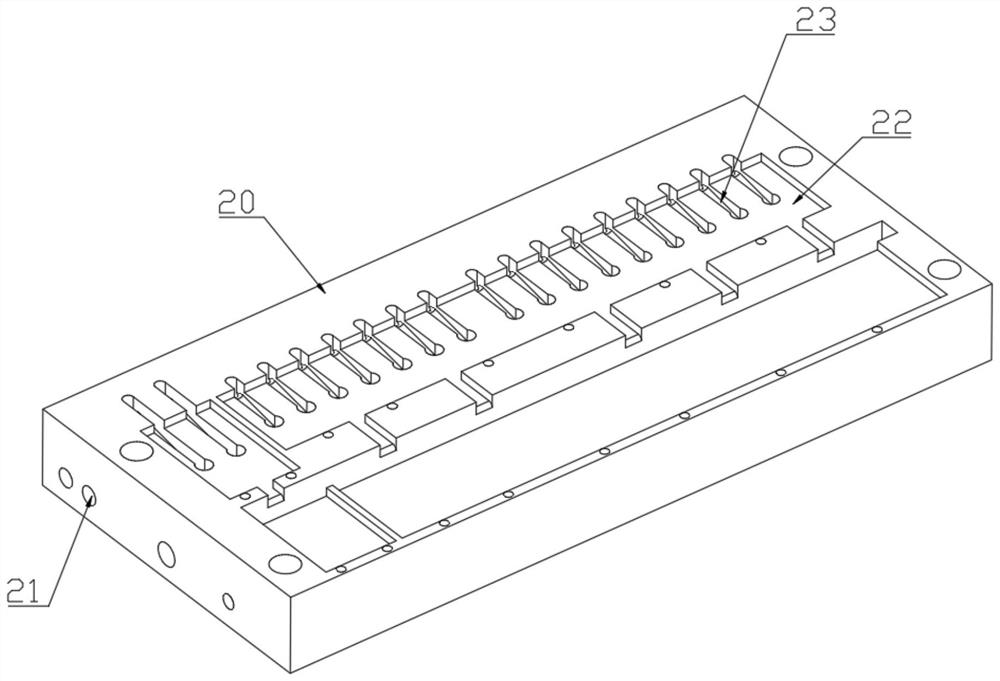

[0037] Step 3: use a closed paint tank for painting, and install a closed display window 24 outside the paint tank.

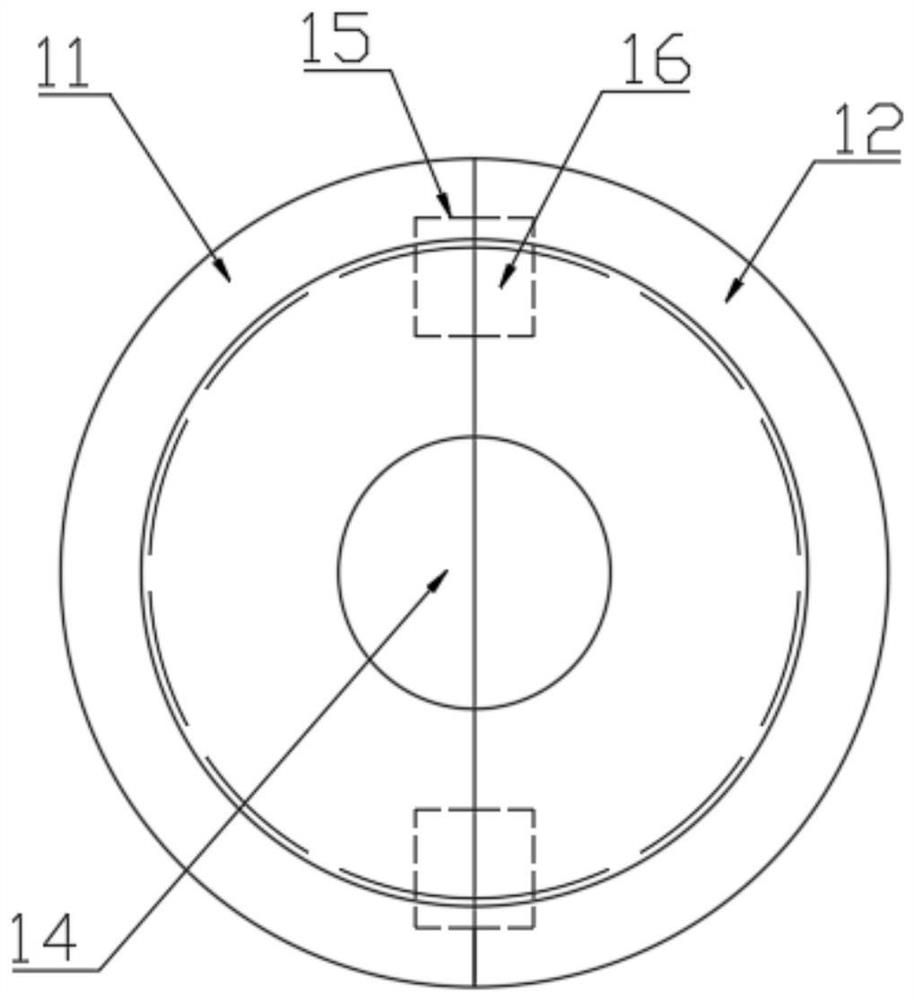

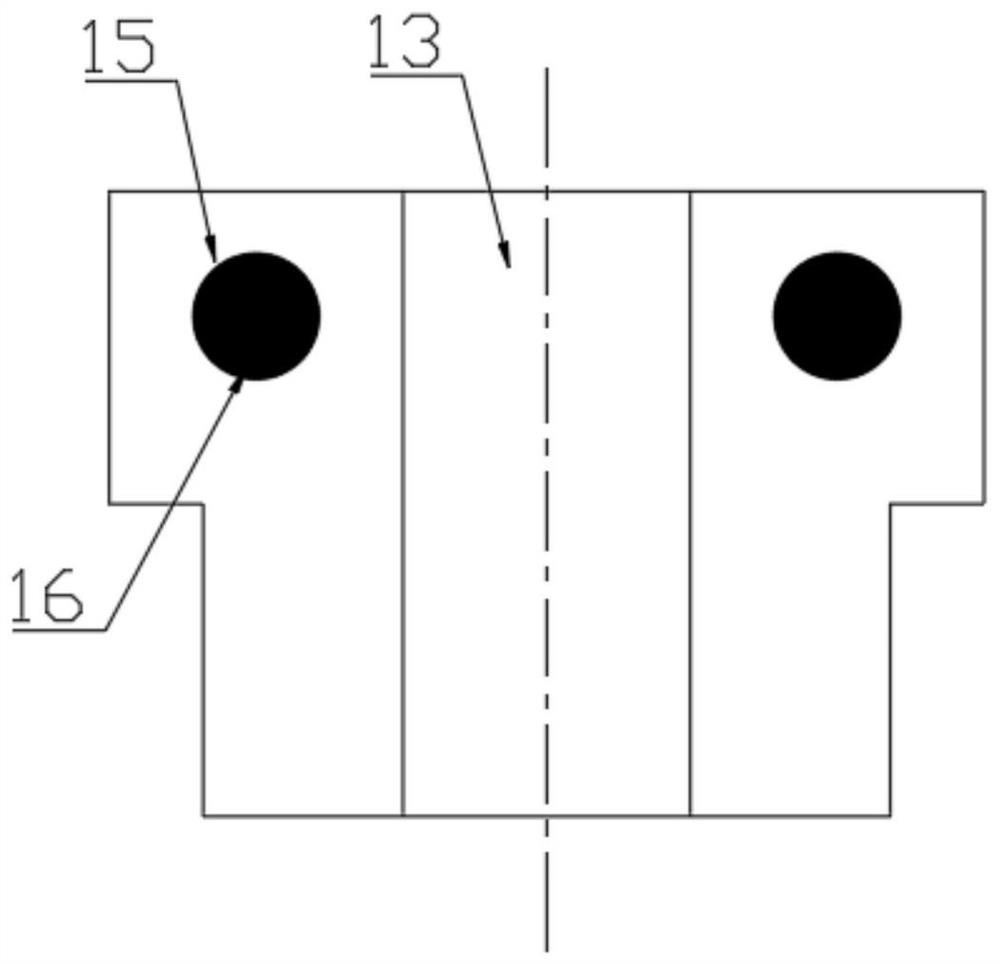

[0038] In this preferred embodiment, in step one, the wrapping sheath includes a first set 11 and a second set 12; the first set 11 and the second set 12 are detachably connected; the first set 11 and the second set 12 are respectively provided with semicircular grooves 13 on the contact surfaces. After the first set 11 and the second set 12 are connected, the semicircular grooves 13 are combined into a round hole 14, which can be sealed and wrapped for paint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com