Flat enameled wire baking furnace

A baking furnace and enameled wire technology, applied in the field of enameled wire production, can solve problems such as product quality problems, heat energy reduction, insufficient baking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

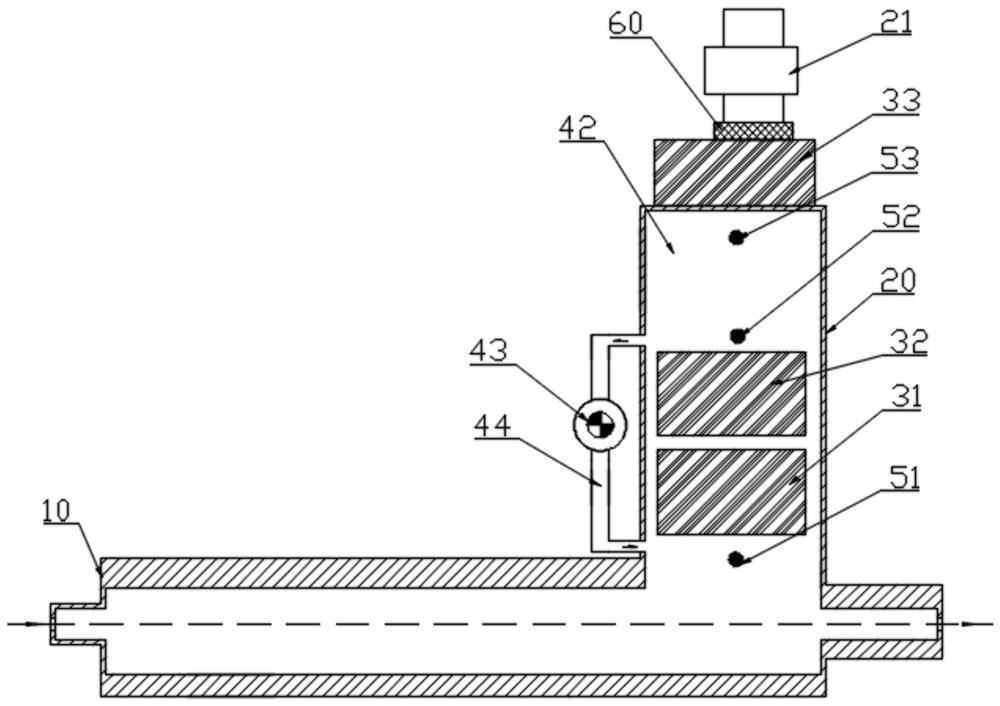

[0037] see Figure 1 to Figure 5 , a flat enameled wire baking furnace 10 of the present embodiment includes a baking furnace 10, an exhaust gas pipeline 20, a first fan 41, a first heat exchange pipe 42, a second fan 43, a return pipe 44, a second heat exchange pipe 45, The first thermocouple 51, the second thermocouple 52, the third thermocouple 53, the VOC automatic detection device 60 and the rotating device 70;

[0038] Specifically, the two ends of the baking furnace 10 are respectively provided with inlets and outlets for enameled wires to pass through;

[0039] Specifically, the first end of the waste gas pipeline 20 communicates with the position near the end of the baking furnace 10; the first catalytic combustion chamber 31, the second catalytic combustion chamber 32 and the third catalytic combustion chamber 33 are sequentially arranged in the waste gas pipeline 20 ; The second end of the waste gas pipeline 20 is provided with a blower 21;

[0040]The waste gas p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com