Hydraulic low-pressure large drift diameter rotating joint

A rotary joint and large-diameter technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of small diameter of rotary joints and coaxial transmission of oil inlet and outlet, so as to avoid damping and The effect of the shock phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and example.

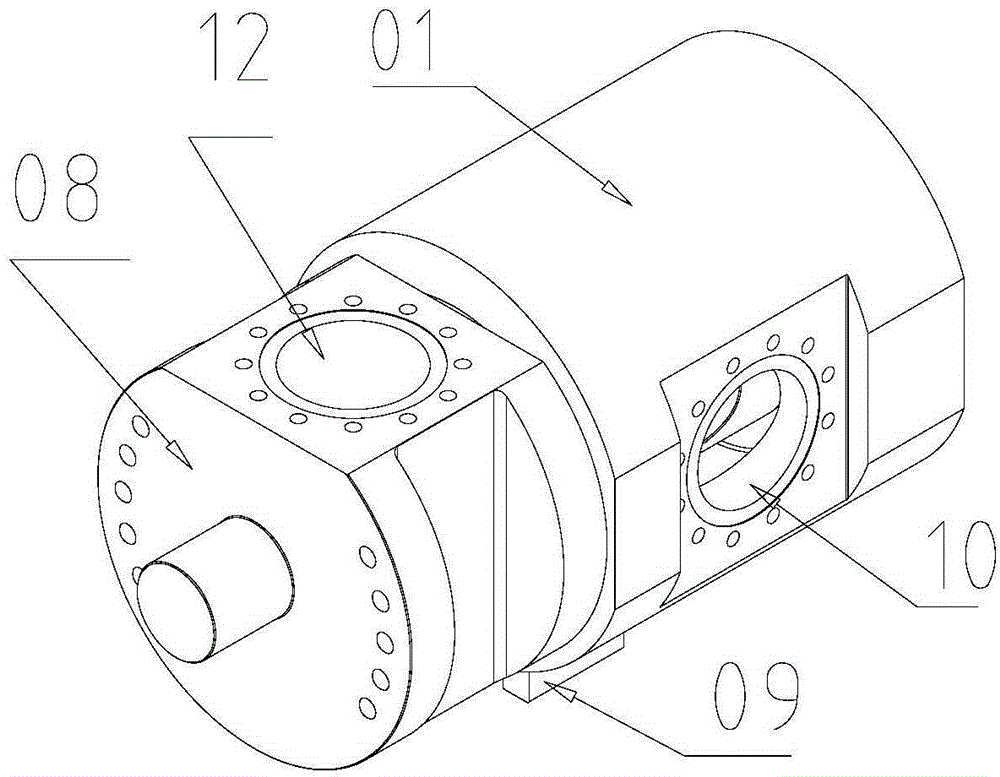

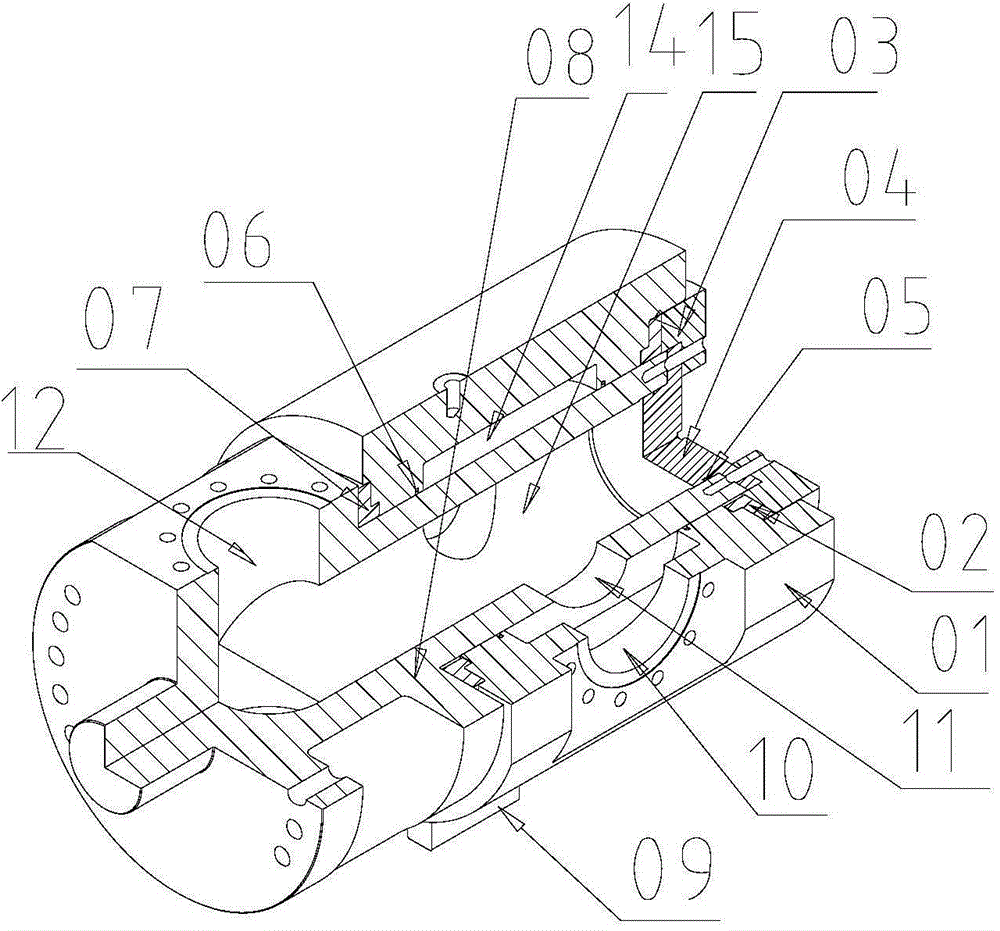

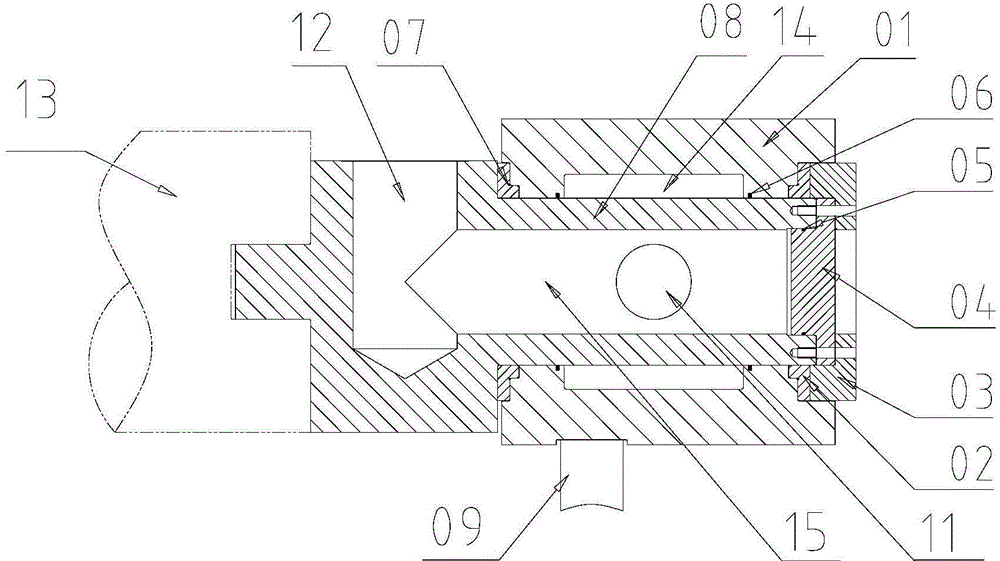

[0014] The front end of the valve core 08 is fastened to one side of the trunnion 13 of the rotary extruder by bolts, and the direction of the oil outlet 12 is perpendicular to the rotation center line of the extruder, so that the hydraulic pipeline can rotate together with the main working cylinder of the rotary extruder.

[0015] The valve body 01 is fastened on the fixed bracket 09 by bolts to prevent the valve body 01 from rotating. The spool 08 is provided with a diameter 15 vertically connected to each other, the diameter of the diameter 15 can reach 250mm, and the rated pressure can reach 5Mpa. The area of the cross-section of the internal diameter 15 of the spool 08 is equal to the sum of the areas of the two oil inlets 11 of the spool 08, so that the hydraulic oil enters the spool 08 smoothly and avoids damping and impact. The rear portion of the spo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com