Single coating multi-component catalyst and preparation method thereof

A secondary coating, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, combustion methods, etc., can solve the problems of harmful environment, large load, complicated operation, etc., to increase high temperature resistance and service life. Increase the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

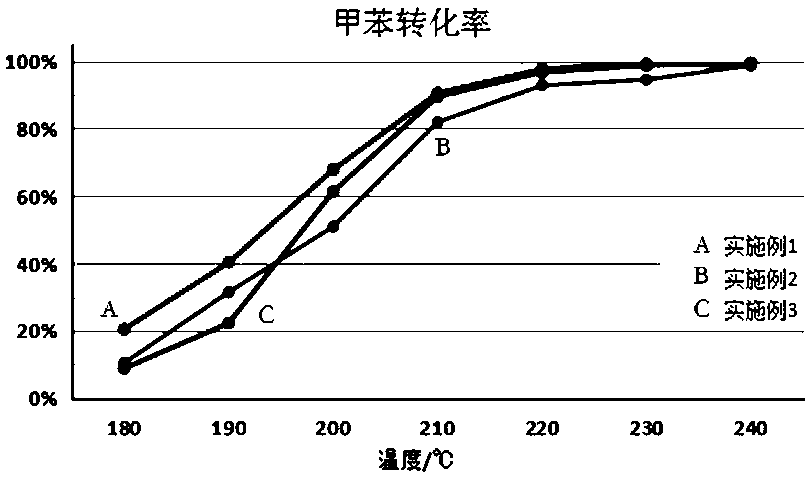

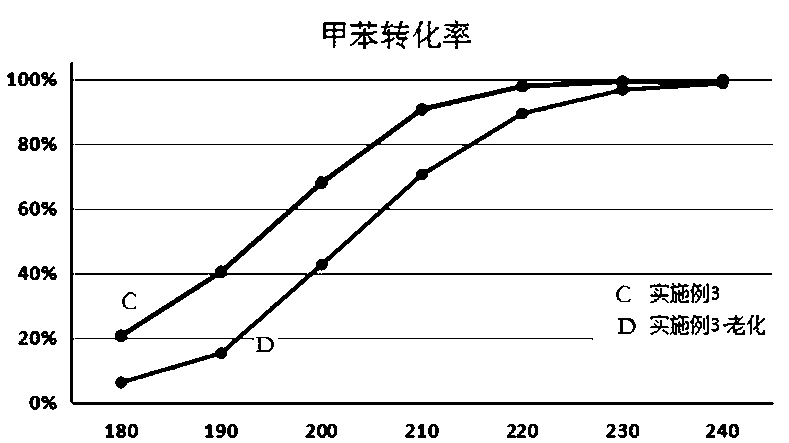

Examples

preparation example Construction

[0035] To achieve the above object, the present invention also provides a method for preparing a single-coated multi-component catalyst, comprising the following steps:

[0036] Step 1, prepare 0.5-2wt% H 2 PtCl 6 -Ethylene glycol solution and preparation of 0.5-2wt% Cu(NO 3 ) 2 - ethylene glycol solution;

[0037] Step 2, weigh 0.5-2wt% H 2 PtCl 6 -Ethylene glycol solution and 0.5-2wt% Cu(NO 3 ) 2 -Ethylene glycol solution or 0.5-2wt% H alone 2 PtCl 6 -Add the ethylene glycol solution into the microwave reactor, stir for 10-30min to make the mixture uniform and form the first solution;

[0038] Step 3, weigh a certain amount of CeZrO x The solid solution powder is added to the above-mentioned first solution under stirring, and the second solution is formed after continuing to stir for 0.5-2h; the amount of the CeZrOx solid solution powder added is 15-50wt% of the total liquid mass;

[0039] Step 4, adjust the pH=8-11 of the second solution with 1M NaOH-ethylene gl...

Embodiment 1

[0053] Weigh 12g of prepared 1% H 2 PtCl 6 -Ethylene glycol solution, 4g prepared 1% Cu(NO 3 ) 2 - Add the ethylene glycol solution into the microwave reactor and stir for 20 minutes to make the mixture uniform.

[0054] Weigh 9g of 5%La, Y-doped CeZrO x Add the solid solution powder into the above mixed solution under stirring, and stir for 1 h. After adjusting the pH of the solution to 10 with an appropriate amount of NaOH-ethylene glycol solution, turn on the microwave reactor for reaction. The working conditions are set: time 10S, relaxation time 60S, the process is repeated 5 times, and the microwave power is 1KW.

[0055] Weigh Al respectively 2 o 3 4.5g, false boehmite 5g, add 55g H 2 O, after stirring for 1 h, concentrated HNO 3 Adjust pH=3 and continue stirring for 2h. The obtained colloidal solution was added into the above-mentioned solution after the microwave reaction, stirred for 1 h and mixed evenly to obtain a catalyst slurry.

[0056] Immerse the po...

Embodiment 2

[0058] Weigh 10g of prepared 1.5% PdCl 2 -Ethylene glycol solution, 3g prepared 0.5% Co(NO 3 ) 2 -Ethylene glycol solution, 1g prepared 1% Cu(NO 3 ) 2 - Add the ethylene glycol solution into the microwave reactor and stir for 20 minutes to make the mixture uniform.

[0059] Weigh 9g of 10% Y, Pr-doped CeZrO x Add the solid solution powder into the above mixed solution under stirring, and stir for 1 h. After adjusting the pH of the solution to 9 with an appropriate amount of NaOH-ethylene glycol solution, turn on the microwave reactor for reaction. The working conditions are set: time 10S, relaxation time 90S, the process is repeated 6 times, and the microwave power is 1KW.

[0060] Weigh Al respectively 2 o 3 5g, 4.5g alumina monohydrate, add 60g H 2 O, after stirring for 1 h, concentrated HNO 3 Adjust pH=4 and continue stirring for 2h. The obtained colloidal solution was added into the above-mentioned solution after the microwave reaction, stirred for 1 h and mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com