Waste gas treatment device for screw extruder

A waste gas treatment device and screw extruder technology, applied in the direction of climate sustainability, greenhouse gas reduction, combustion methods, etc., can solve the problems of not making good use of the heat of combustion waste gas, affecting the living environment of residents, affecting air quality, etc. , to avoid direct emission of waste gas, improve energy utilization rate, and ensure the effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

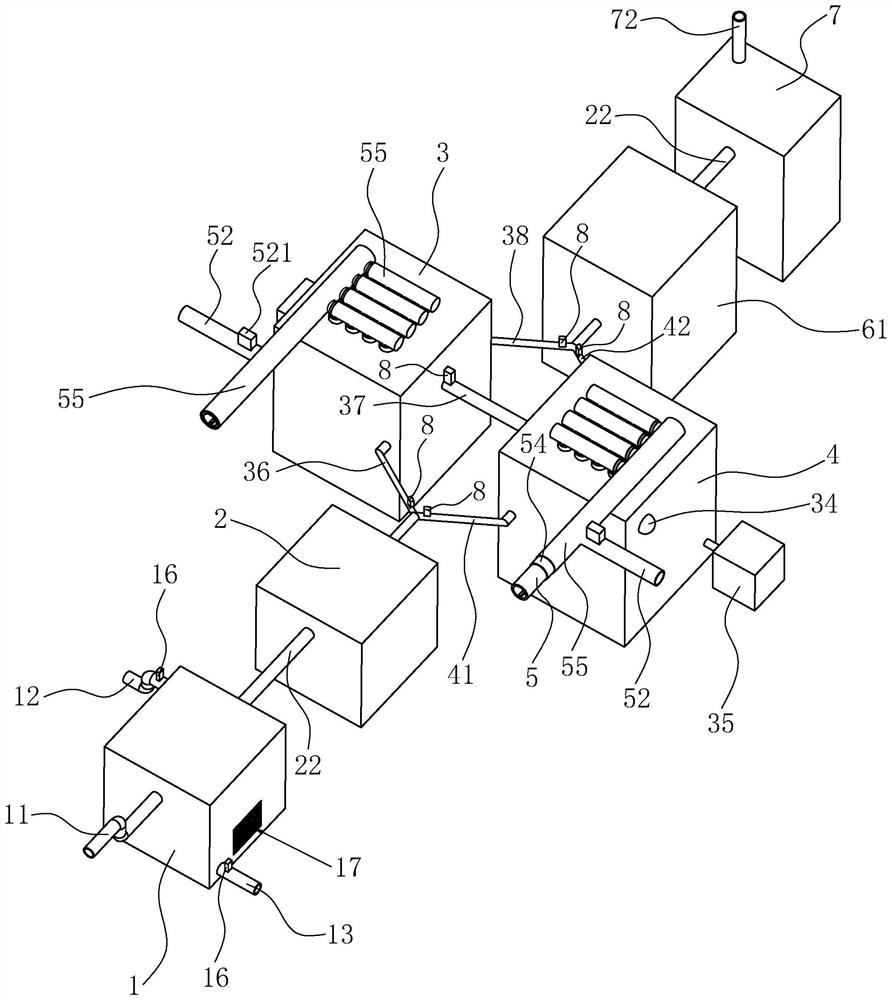

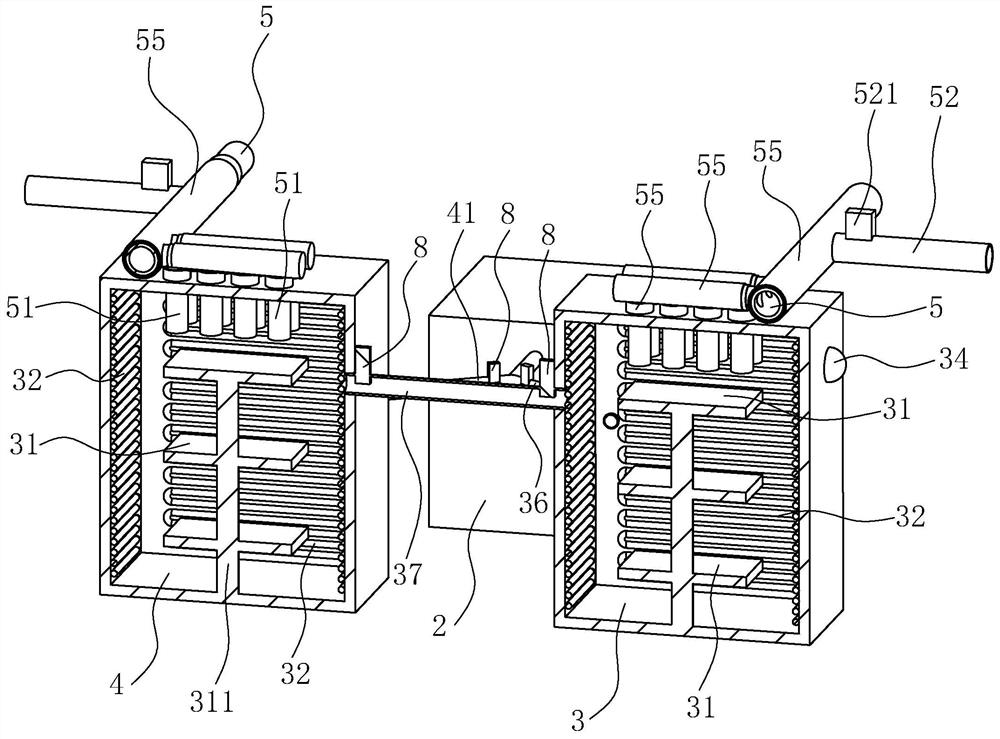

[0037] A waste gas treatment device for a screw extruder, such as figure 1 As shown, it includes spray chamber 1, preheating chamber 2, primary combustion chamber 3, water cooling box 6 (combined with Figure 6 ), dry box 7 and the secondary combustion chamber 4 that is arranged side by side with the primary combustion chamber 3 and has the same structure, the preheating chamber 2 and the water cooling box 6 are respectively located at the two sides of the primary combustion chamber 3 and the secondary combustion. Such as figure 1 As shown, the spray chamber 1 is connected with an air intake pipe 11, and the spray chamber 1 and the preheating chamber 2, the water cooling box 6 and the drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com