Continuous dust removal regeneration filtration dust remover

A dust collector and filter technology, which is applied in the field of continuous dust removal and regenerative filter dust collectors, can solve the problems of insufficient dust removal, difficulty in dust removal, and poor effect of the filter material, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

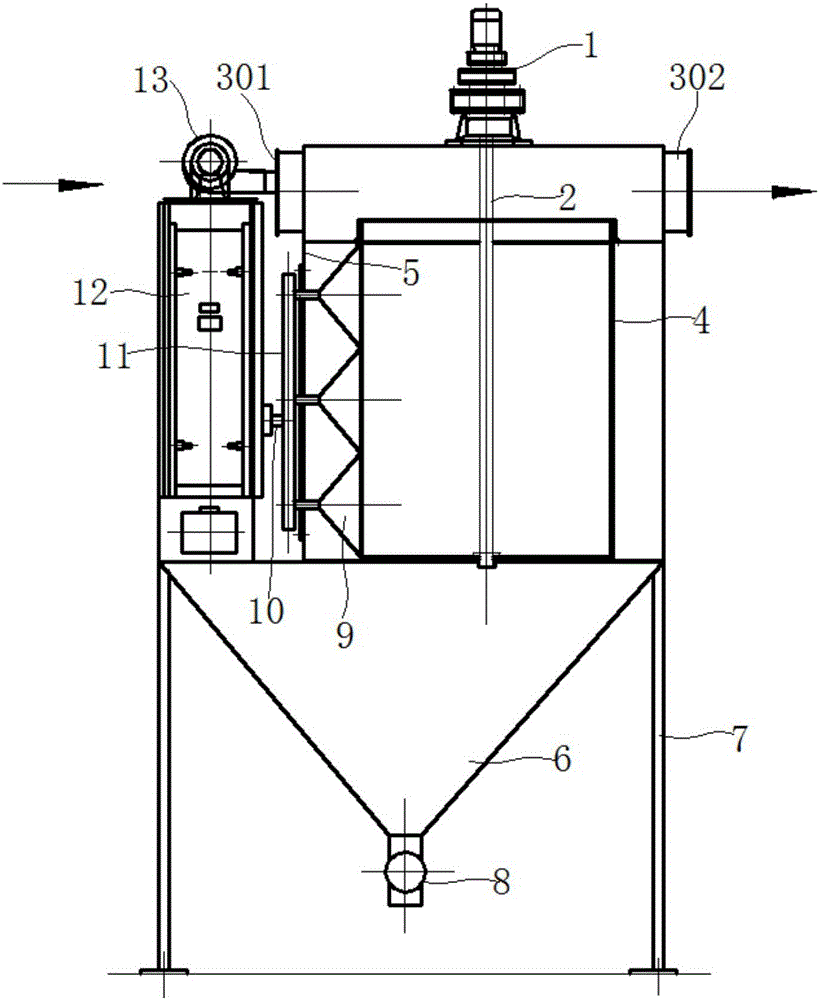

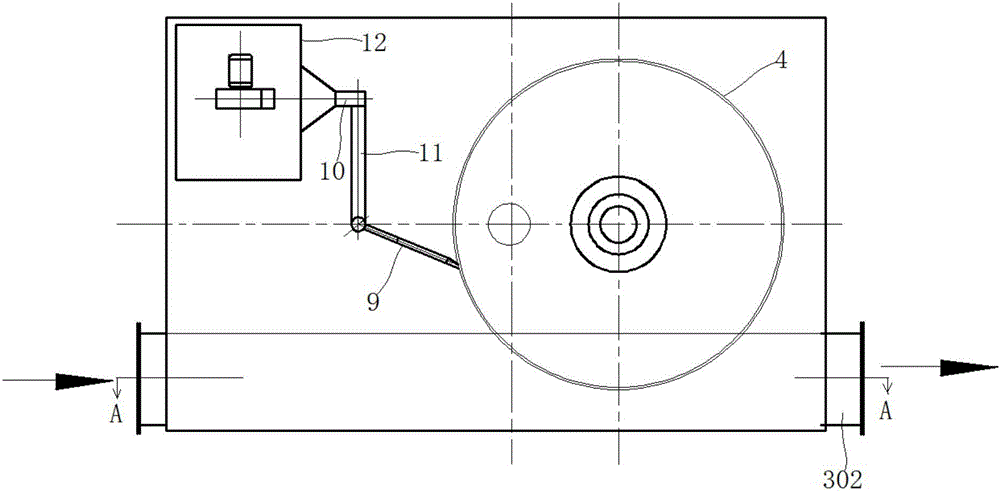

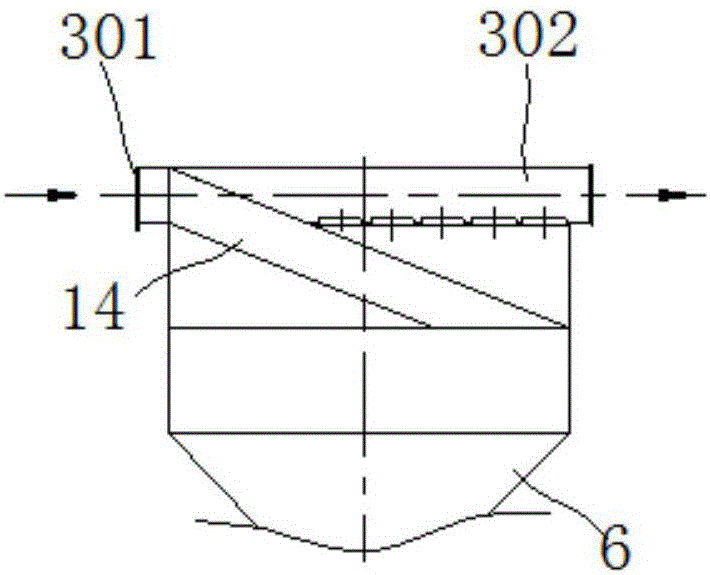

[0037] Such as Figure 1-Figure 3 As shown, a continuous dedusting regenerative filter dust collector in this embodiment includes a bracket 7, a dust collector box fixed above the bracket 7, a filter cartridge 4, a driving device for driving the filter cartridge 4 to rotate, and a dust collecting bucket 6 And the dust removal device, the bottom of the dust collector box is provided with a dust collecting bucket 6, and the bottom of the dust collecting bucket 6 is provided with a dust discharge valve 8, and the dust discharge valve 8 of this embodiment adopts a star-shaped air lock. A middle box body 5 is arranged in the box body of the dust collector, and the filter cartridge 4 is installed inside the middle box body 5. The filter cartridge 4 is made of DV chemical fiber composite material and has the characteristics of large dust holding capacity. Such as image 3 As shown, the air inlet 301 on the upper side of the dust collector box communicates with the inner space of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com