A kind of graphene-based energetic MOFs and preparation method thereof

A graphene-based, graphene-based technology, applied in offensive equipment, explosives, compressed gas generation, etc., to achieve the effects of overcoming energy reduction, improving combustion catalytic performance, and improving combustion stability and energy characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The present embodiment provides a preparation method of graphene-based energetic MOFs, which comprises the following steps:

[0059] Step 1, the preparation of graphene-organic acid metal complex:

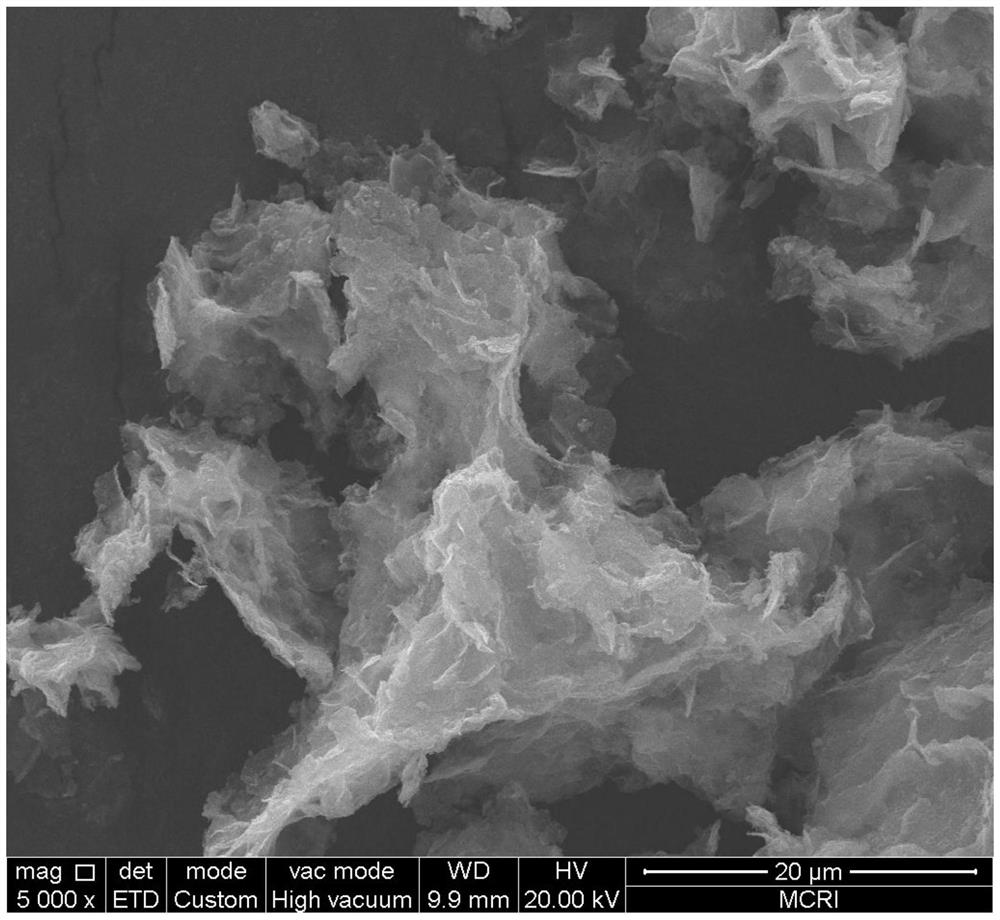

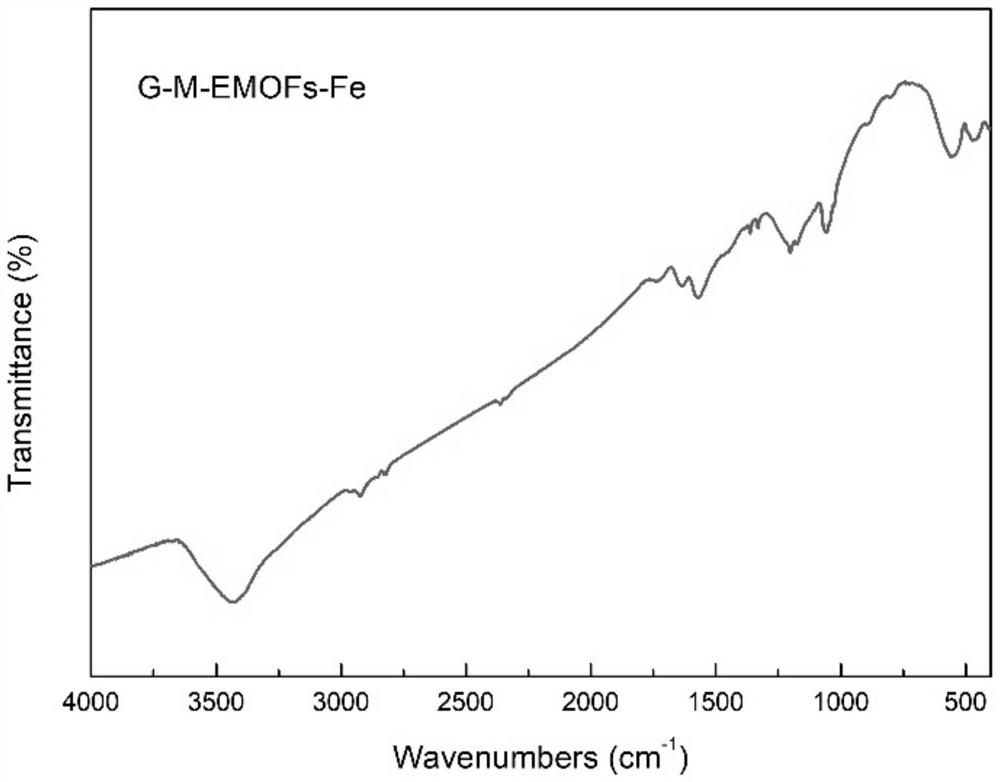

[0060] A gallic acid aqueous solution was added dropwise to the ethanol dispersion of graphene oxide, and the graphene-gallic acid composite (G-M) was obtained by refluxing for 3 h; then the graphene-gallic acid composite was dispersed in ethanol and mixed with chlorine The iron aqueous solution was mixed and reacted at 60 °C for 6 h to obtain graphene-iron gallate complex (G-M-Fe);

[0061] The concentration of ferrous chloride aqueous solution is 0.05g·mL -1 ;

[0062] The mass ratio between graphene oxide and gallic acid is 1:3.

[0063] The molar ratio between gallic acid and ferrous chloride was 2:1.

[0064] Step 2, the preparation of 1,1'-dihydroxy-5,5'-bitetrazole dihydroxyamine salt-based metal complex

[0065] 1,1'-dihydroxy-5,5'-bitetrazole dihydroxyamine sal...

Embodiment 2

[0082] The present embodiment provides a preparation method of graphene-based energetic MOFs, which comprises the following steps:

[0083] Step 1, the preparation of graphene-organic acid metal complex:

[0084] The tannic acid aqueous solution was added dropwise to the ethanolic dispersion of graphene oxide, and the graphene-tannic acid composite (G-D) was obtained by refluxing for 3 h; then the graphene-tannic acid composite was dispersed in ethanol, and mixed with nitric acid. The nickel aqueous solution was mixed and reacted at 50 °C for 12 h to obtain a graphene-nickel tannic acid complex (G-D-Ni);

[0085] The concentration of nickel nitrate aqueous solution is 0.05g·mL -1 ;

[0086] The mass ratio between graphene oxide and tannic acid was 1:5.

[0087] The molar ratio between tannic acid and nickel nitrate was 1:1.

[0088] Step 2, the preparation of 1,1'-dihydroxy-5,5'-bitetrazole dihydroxyamine salt-based metal complex

[0089] 1,1'-dihydroxy-5,5'-bitetrazole d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com