Treatment method for improving wood cellulose enzymolysis saccharification

A technology of cellulase and treatment method, which is applied in the field of wood cellulose treatment and improving the treatment field of wood cellulose enzymatic hydrolysis and saccharification, which can solve the problems of high consumption cost, achieve the elimination of biological resistance, improve the efficiency of enzymatic hydrolysis, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

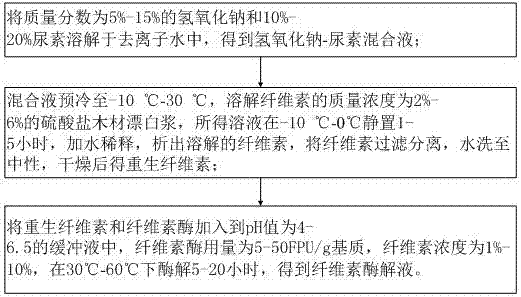

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 5% sodium hydroxide and 10% urea in deionized water to obtain a sodium hydroxide-urea mixture; pre-cool the mixture to -10 °C, dissolve kraft softwood bleached pulp, and add to the obtained solution The mass concentration of cellulose is 2%,; the obtained solution is left standing at -10 ℃ for 1 hour, diluted with water, and 80% of the dissolved cellulose is precipitated, the cellulose is filtered and separated through a sand core funnel, washed with water until neutral, and air-dried Prepare white, fibrous regenerated cellulose; add regenerated cellulose and cellulase to the acetic acid-sodium acetate buffer solution with a pH value of 4, the dosage of cellulase is 20 FPU / g, and the mass concentration of cellulose is 5% , and enzymatically hydrolyzed at 30°C for 11 hours to obtain a cellulose hydrolyzate rich in reducing sugars, and the saccharification rate of cellulose was measured to be 75.8%.

[0031] Set up a control sample, use the same cellulase dosage ...

Embodiment 2

[0033]Dissolve 6% sodium hydroxide and 12% urea in deionized water to obtain a sodium hydroxide-urea mixture; pre-cool the mixture to -20 °C, dissolve kraft softwood bleached pulp, and add to the obtained solution The mass concentration of cellulose is 5%,; the obtained solution is left standing at -5 °C for 2 hours, diluted with water, and 75% of the dissolved cellulose is precipitated, the cellulose is filtered and separated through a filter cloth, washed with water until neutral, and dried in an oven to obtain White, fibrous regenerated cellulose; add regenerated cellulose and cellulase to citric acid-sodium citrate buffer solution with a pH value of 4, the amount of cellulase is 30 FPU / g, and the mass concentration of cellulose is 5% , enzymatically hydrolyzed at 60°C for 15 hours to obtain a cellulose hydrolyzate rich in reducing sugars, and the saccharification rate of cellulose was measured to be 86.8%;

[0034] Set up a control sample, use the same cellulase dosage of ...

Embodiment 3

[0036] Dissolve 9% sodium hydroxide and 15% urea in deionized water to obtain a sodium hydroxide-urea mixture; pre-cool the mixture to -25°C to dissolve kraft softwood bleached pulp, and obtain a solution The mass concentration of cellulose in the medium is 6%; the obtained cellulose solution is left standing at 0°C for 3 hours, diluted with water, and 85% of the dissolved cellulose is precipitated, filtered and separated through filter paper, washed with water until neutral, and air-dried for a period of time, and then Obtain white, fibrous regenerated cellulose with oven drying; Add regenerated cellulose and cellulase in the citric acid-sodium citrate buffer solution of 5.5 pH value, enzyme consumption is 50FPU / g, and cellulose mass concentration is 7%, hydrolyzed at 50°C for 20 hours to obtain a cellulose hydrolyzate rich in reducing sugars, and the saccharification rate of cellulose was measured to be 93.4%;

[0037] Set up a control sample, use the same cellulase dosage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com