Integrated catalyst applied to catalytic combustion of methane and preparation method thereof

A monolithic catalyst, methane catalytic combustion technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as difficulty in applying methane catalytic combustion, and achieve simple preparation methods, good effects, The effect of high catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

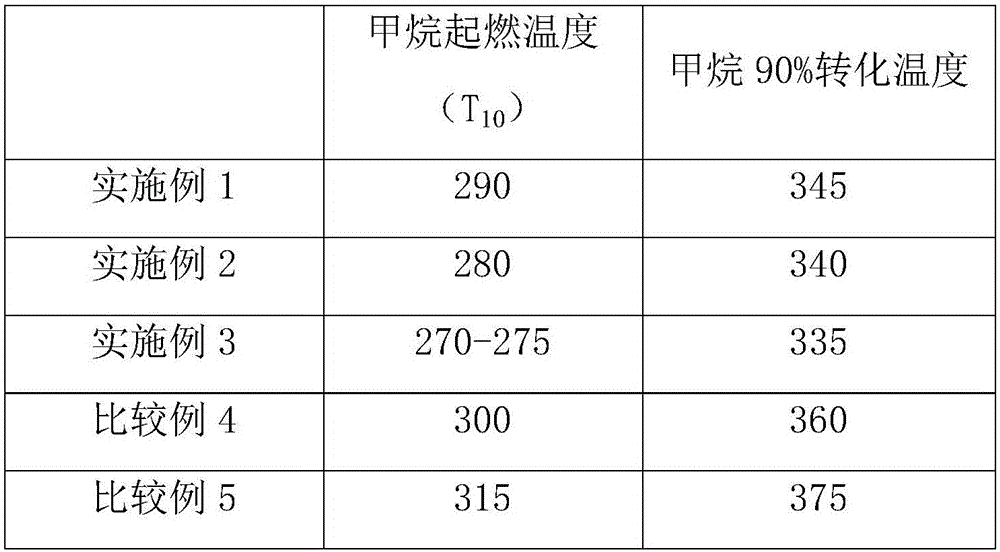

Examples

preparation example Construction

[0033] The preparation method of the monolithic catalyst for methane catalytic combustion of the present invention may comprise the following steps:

[0034] S1. Preparation of rare earth composite alumina loaded Pd and rare earth composite molecular sieve loaded Pt.

[0035] In this step S1, the preparation of rare earth composite alumina supported Pd includes the following steps:

[0036] Alumina is impregnated with an aqueous solution of soluble rare earth salts, dried at 100-120°C and calcined at 500-1000°C after impregnation to obtain rare earth composite alumina. Among them, the soluble rare earth salt is nitrate or acetate; the nitrate is one or more of lanthanum nitrate, cerium nitrate, praseodymium nitrate and praseodymium nitrate; the acetate is lanthanum acetate, cerium acetate, praseodymium acetate and praseodymium acetate one or more of. After high-temperature roasting, the soluble rare earth salt forms rare earth oxides, which correspond to one or more of lanth...

Embodiment 1

[0048] Preparation of Pd supported on rare earth composite alumina: Weigh a certain amount of lanthanum nitrate, add it to deionized water, and stir until it is completely dissolved to form an aqueous solution of lanthanum nitrate; 2 o 3 Immerse in an aqueous solution of lanthanum nitrate, stir, dry at 120°C for 3 hours, and roast at 550°C for 3 hours to obtain rare earth composite alumina; lanthanum nitrate forms lanthanum oxide, and its weight content is 5% of alumina. Weigh a certain amount of palladium nitrate solution, and use the equal volume impregnation method to impregnate the prepared rare earth composite alumina into the palladium nitrate solution, stir, dry at 120°C for 3 hours, and roast at 550°C for 3 hours to obtain the supported rare earth composite alumina Pd; the weight content of Pd in the rare earth composite alumina supported Pd is 1%.

[0049] Preparation of Pt-loaded rare earth composite molecular sieve: Weigh a certain amount of cerium nitrate, add i...

Embodiment 2

[0052] Prepare rare earth composite alumina-loaded Pd and rare earth composite molecular sieve loaded Pt according to Example 1; respectively weigh 80g rare earth composite alumina loaded Pd and 40g rare earth composite molecular sieve loaded Pt, and the rest of the steps are the same as in Example 1 to prepare monolithic catalysts. The coating loading in the monolithic catalyst was 120 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com