A method for recycling coal-fired catalysts in chain furnaces

A coal-fired catalyst and catalyst technology, applied in the direction of fuel, solid fuel, combustion equipment, etc., can solve the problems that the catalyst cannot be recycled and the gasified coal powder particles are small, so as to improve the catalytic combustion effect, reduce dust emission, and reduce the cost of the catalyst Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

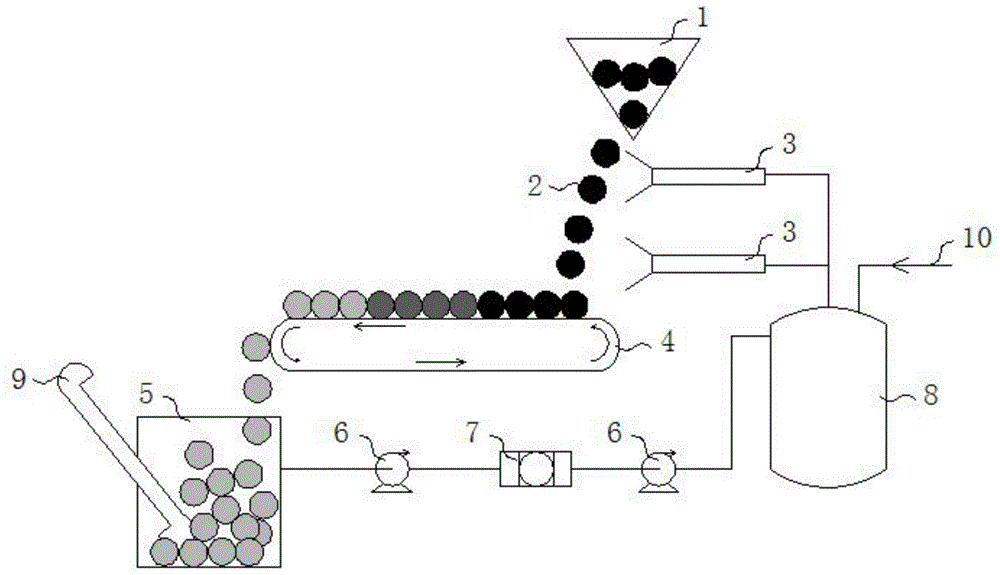

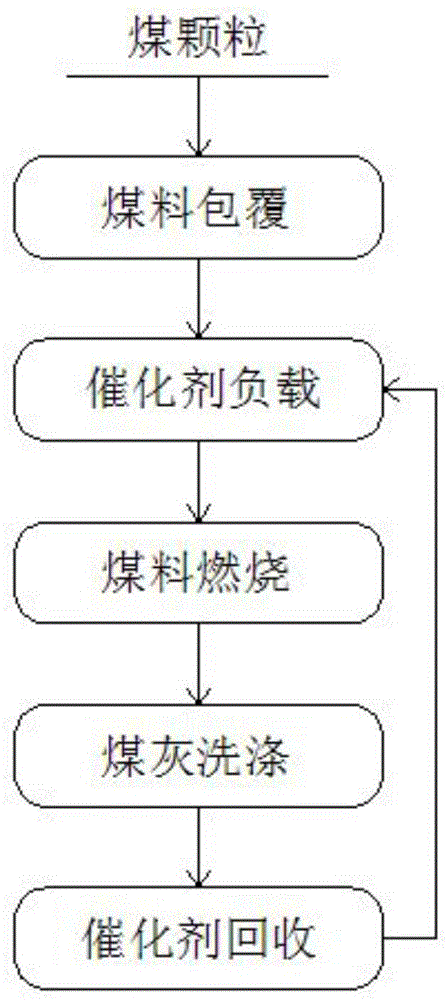

[0028] The invention provides a chain furnace coal-fired catalyst recycling method, the operation steps are as follows:

[0029] a, solution preparation: Ca(OH) 2 Mix with water to prepare Ca(OH) with a mass concentration of 15% 2 The solution is the coating agent slurry, mix KOH with water, and prepare a KOH solution with a mass concentration of 0.05%, which is the catalyst solution, ready for use;

[0030] b. Coal material coating: coating the outer surface of the coal material with the coating agent slurry to obtain the coated coal material, wherein the mass percentage of the used coating agent slurry to the coal material is 12%;

[0031] c. Catalyst loading: the catalyst solution is atomized, and then contacted with the coated dry coal material obtained in the b step to obtain the catalyst-loaded coal material, wherein the mass percentage of the water added to the atomization and the coal material is 14%, and the catalyst used The mass percent of the quality of solution ...

Embodiment 2

[0036] The invention provides a chain furnace coal-fired catalyst recycling method, the operation steps are as follows:

[0037] a, solution preparation: MgO is mixed with water, is mixed with the MgO solution that mass concentration is 20% and is coating agent slurry, and NaOH is mixed with water, and the NaOH solution that is mixed with mass concentration is 0.05% is catalyst solution, waits use;

[0038] b. Coal material coating: coating the outer surface of the coal material with the coating agent slurry to obtain the coated coal material, wherein the mass percentage of the used coating agent slurry to the coal material is 7%;

[0039]c. Catalyst loading: the catalyst solution is atomized, and then contacted with the coated dry coal material obtained in step b to obtain the catalyst-loaded coal material, wherein the mass percentage of the water added to the atomization and the coal material is 20%, and the catalyst used The mass percent of the quality of solution and coal...

Embodiment 3

[0044] The invention provides a chain furnace coal-fired catalyst recycling method, the operation steps are as follows:

[0045] a, solution preparation: Ca(OH) 2 Mix with water to prepare Ca(OH) with a mass concentration of 15% 2 The solution is the coating agent slurry, Na 2 CO 3 Mix with water to prepare Na with a mass concentration of 0.06% 2 CO 3 The solution is the catalyst solution, ready for use;

[0046] b. Coal material coating: coating the outer surface of the coal material with the coating agent slurry to obtain the coated coal material, wherein the mass percentage of the coating agent slurry used and the coal material is 11%;

[0047] c. Catalyst loading: the catalyst solution is atomized, and then contacted with the coated dry coal material obtained in the b step to obtain the catalyst-loaded coal material, wherein the mass percentage of the water added to the atomization and the coal material is 18%, and the catalyst used The mass percent of the quality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com