Processing technology of special self-adhesive enameled wire for household motor and device

A household motor and processing technology, which is applied in the manufacture of circuits, electrical components, cables/conductors, etc., can solve the problems of difficult control of the temperature of the circulating air flow, low adhesion stability of the paint layer, low working stability, etc., and achieve a good process Stability and coating effect, reduction of flaking or incomplete adhesion to each other, improvement of stability and performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

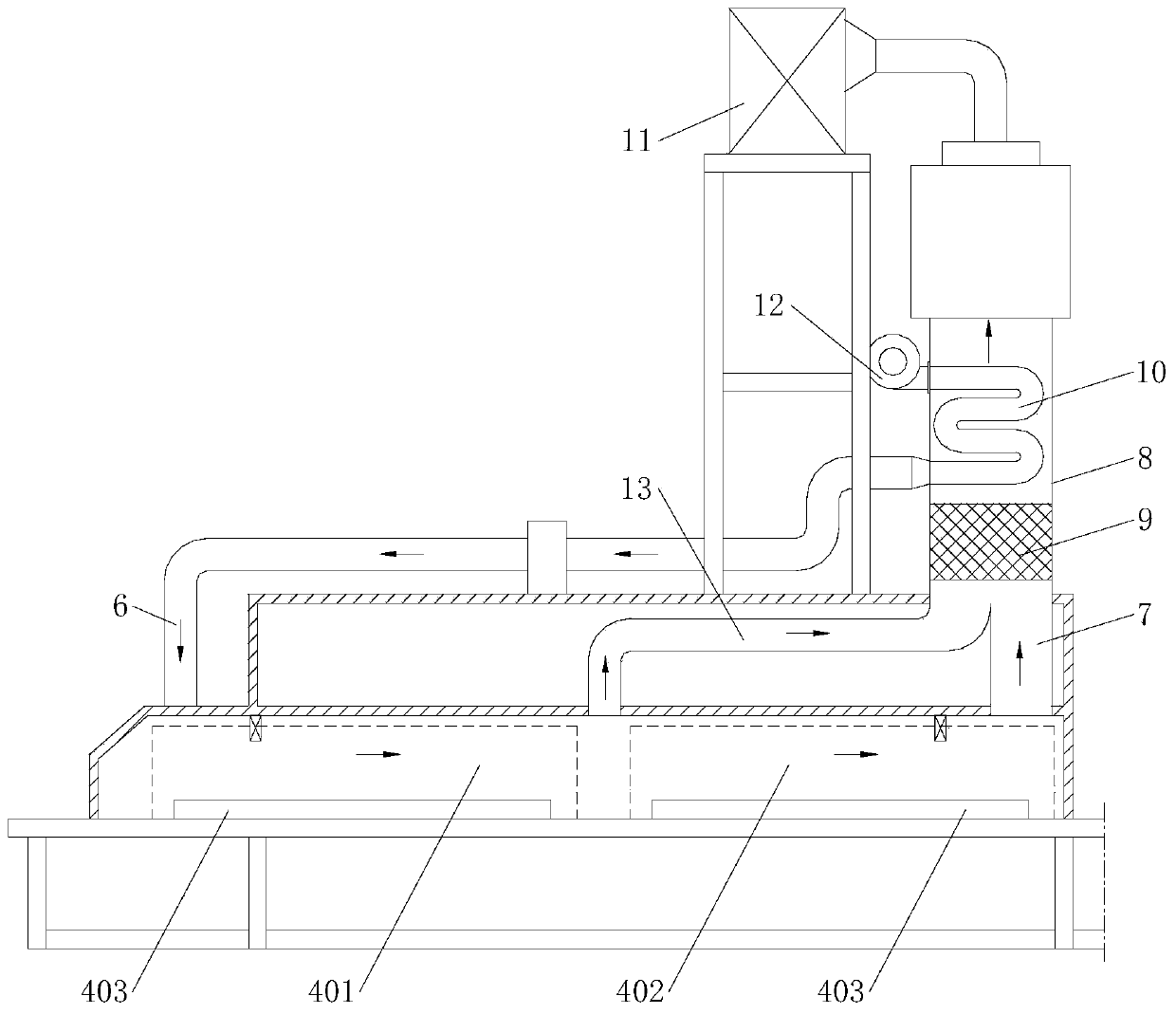

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0028] Example. A processing technology for self-adhesive enameled wire dedicated to household motors, the composition of which is as followsfigure 1 shown, including the following steps:

[0029] ① Soften the bare copper wire through an annealing oven, and wrap the water vapor on the outside of the bare copper wire during the softening process to obtain A copper wire;

[0030] ②Put the A copper wire into the drying furnace for drying to obtain the B copper wire;

[0031] ③ Coat the surface of the B copper wire with a primer and send it to the first enameled furnace. The B copper wire is dried for the first time under different temperature environments through the first enamelled furnace. The drying temperature is conveyed with the B copper wire. The direction gradually increases to get C enameled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com