Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "High reaction space velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing synthetic natural gas

InactiveCN102229827AHigh reaction space velocityThe ratio of hydrogen to carbon is easy to adjustGaseous fuelsNew energyMethanation

The invention discloses a method for producing synthetic natural gas, which belongs to the technical field of coal chemistry and new energy. The method for producing the synthetic natural gas comprises: dividing raw material gases from a general gas source into low-carbon synthetic gases with a hydrogen to carbon ratio, namely a (H2-CO2) to (H2+CO2) ratio, being 4.5 to 15.0 and high-carbon synthetic gases with a hydrogen to carbon ratio being 0 to 2.0; according to a reaction temperature requirement, mixing the low-carbon synthetic gases with steam at certain flow, allowing the mixed gases to enter a primary thermal-insulation reactor to undergo a methanation reaction, subjecting the gases from the primary thermal-insulation reactor to heat exchange, mixing the gases with the high-carbon synthetic gases at a certain flow, and allowing the newly mixed gases into a secondary thermal-insulation reactor to undergo a methanation reaction; repeating the previous process for several times; and finally, obtaining the synthetic natural gas by processes of heat exchange, cooling, drying, compression and the like. The method has the characteristics that: (1) circulating equipment is not used; (2) all reactions are performed in thermal-insulation reactors, multiple stages of reactors are connected in series, and the reaction space velocity is high; and (3) the hydrogen to carbon ratio of the whole reaction system can be regulated easily, and the methane content in the product gas may reach over 95 percent.

Owner:大连瑞克科技股份有限公司

Process for producing alkylene glycol

ActiveCN1721385AReduce swellingImprove thermal stabilityBulk chemical productionPreparation by hydrolysisHydration reactionReaction temperature

The present invention is preparation process of alkylene dyhydric alcohol, and aims at prolonging the service life of catalyst and raising its heat tolerance while maintaining its high conversion rate and selectivity. The technological scheme of the present invention is that the material including alkylene oxide and water in the molar ratio of 1 to 5-15 and macroporous composite resin catalyst are made to contact and react to produce alkylene dyhydric alcohol in the conditions of reaction temperature 60-150 deg.c, reaction pressure 0.5-2 MPa and liquid space velocity 3-6 / hr. The macroporous composite resin catalyst includes monomer, copolymerized monomer, nanometer material, initiator and two assistants and is treated with OH-, Cl-, HSO4-, CHO3- or HCOO- anionic compound. The present invention may be used in industrial production of ethylene oxide catalyzed synthesis of dyhydric alcohol.

Owner:CHINA PETROLEUM & CHEM CORP +1

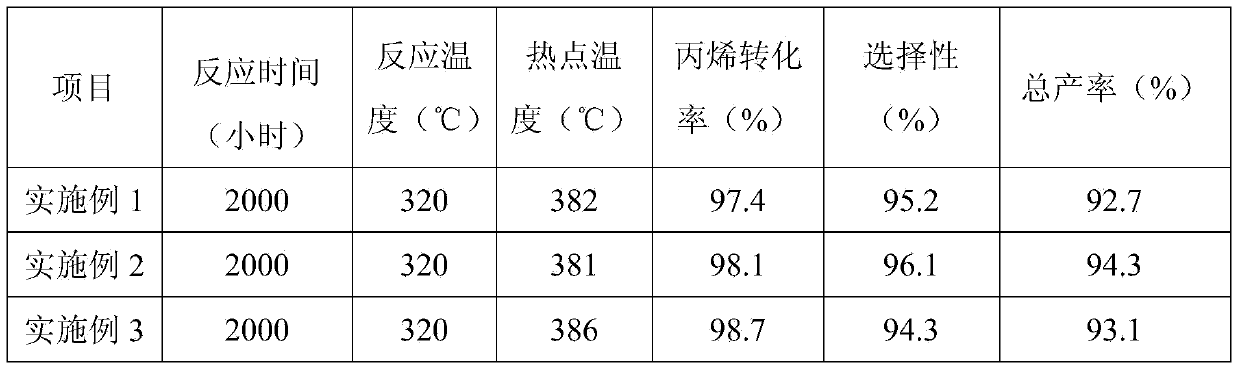

Catalyst for preparing propylene by disproportionation of butene

ActiveCN1611297ARaise the pHImprove conversion rateHydrocarbon by metathesis reactionMetal/metal-oxides/metal-hydroxide catalystsButeneAdditional values

The present invention relates to a catalyst for preparing propene by utilizing butene disproportionation. It is mainly aimed at solving the following problems of that previous technique has need of consuming ethylene with high additional value and in the process for preparing propene by means of butene disproportionation its space velocity is low, butene conversion rate is low, selectivity of propene is low and propene yield also is low. Said invention utilizes the technical scheme of adding copper or its oxide in the tungsten oxide / silicon dioxide catalytic system to better solve the said problems. Said invention can be used in industrial production for preparing propene by utilizing butene disproportionation.

Owner:CHINA PETROLEUM & CHEM CORP +1

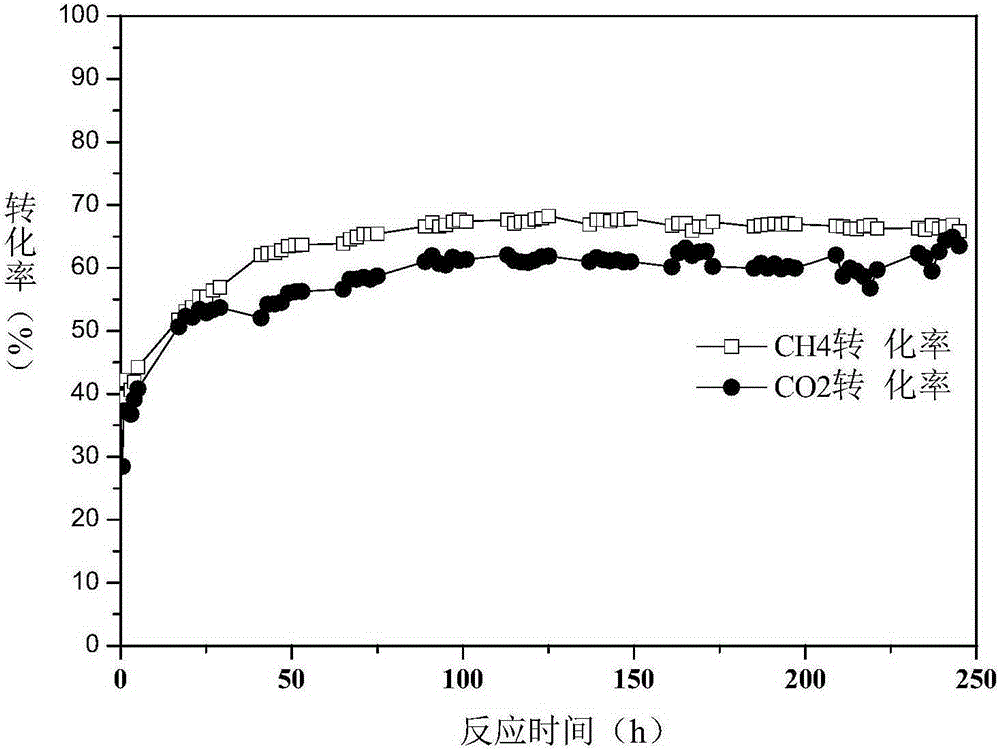

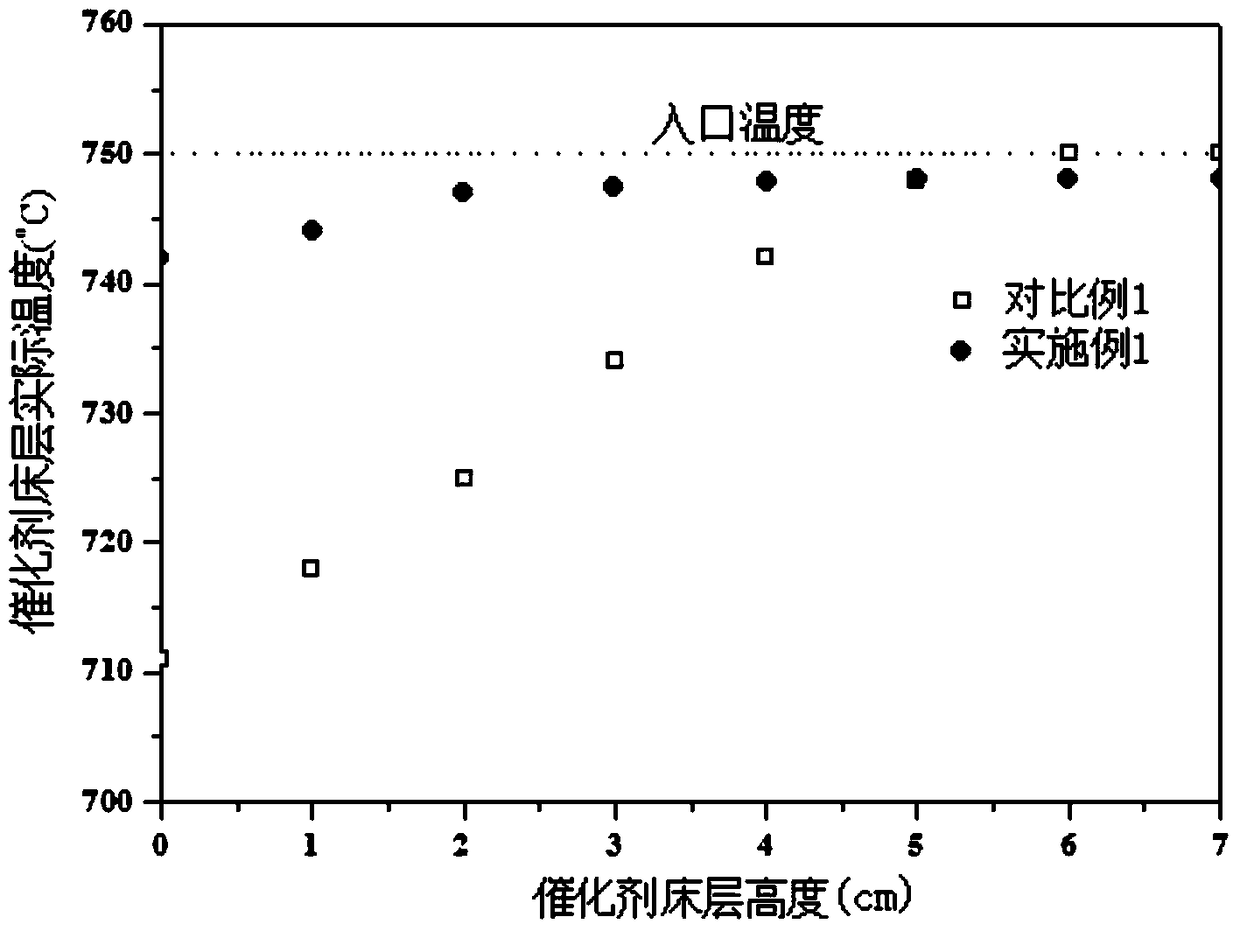

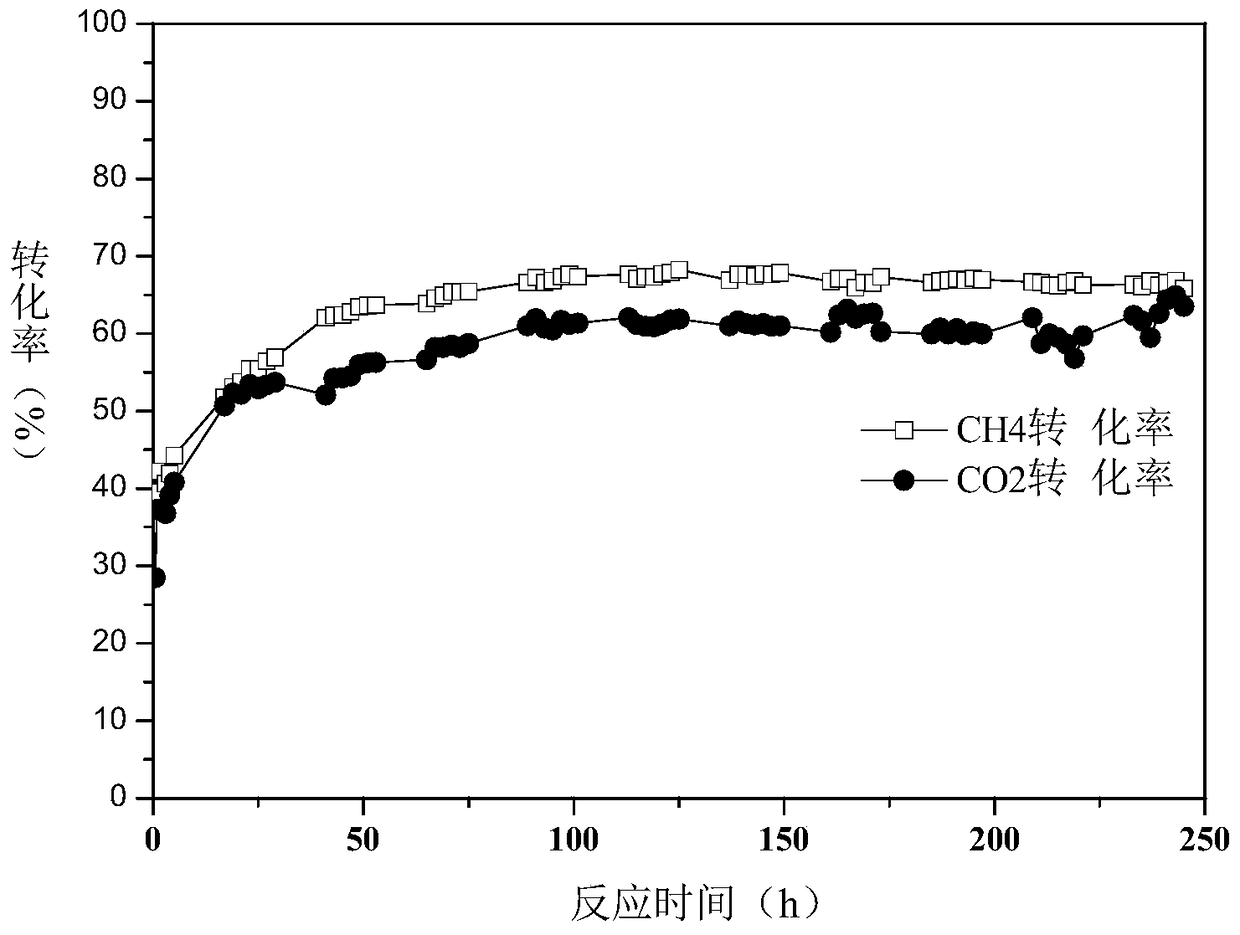

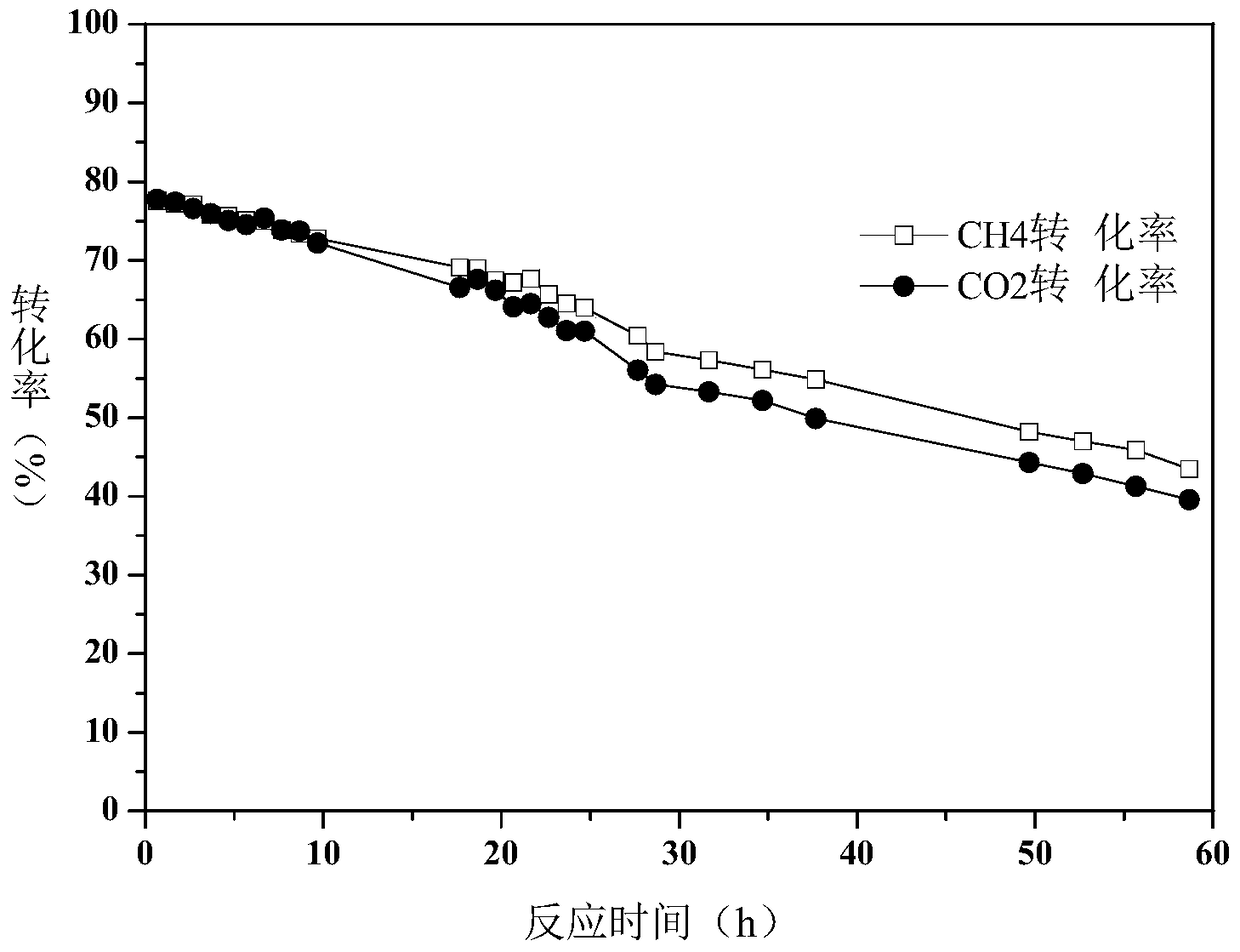

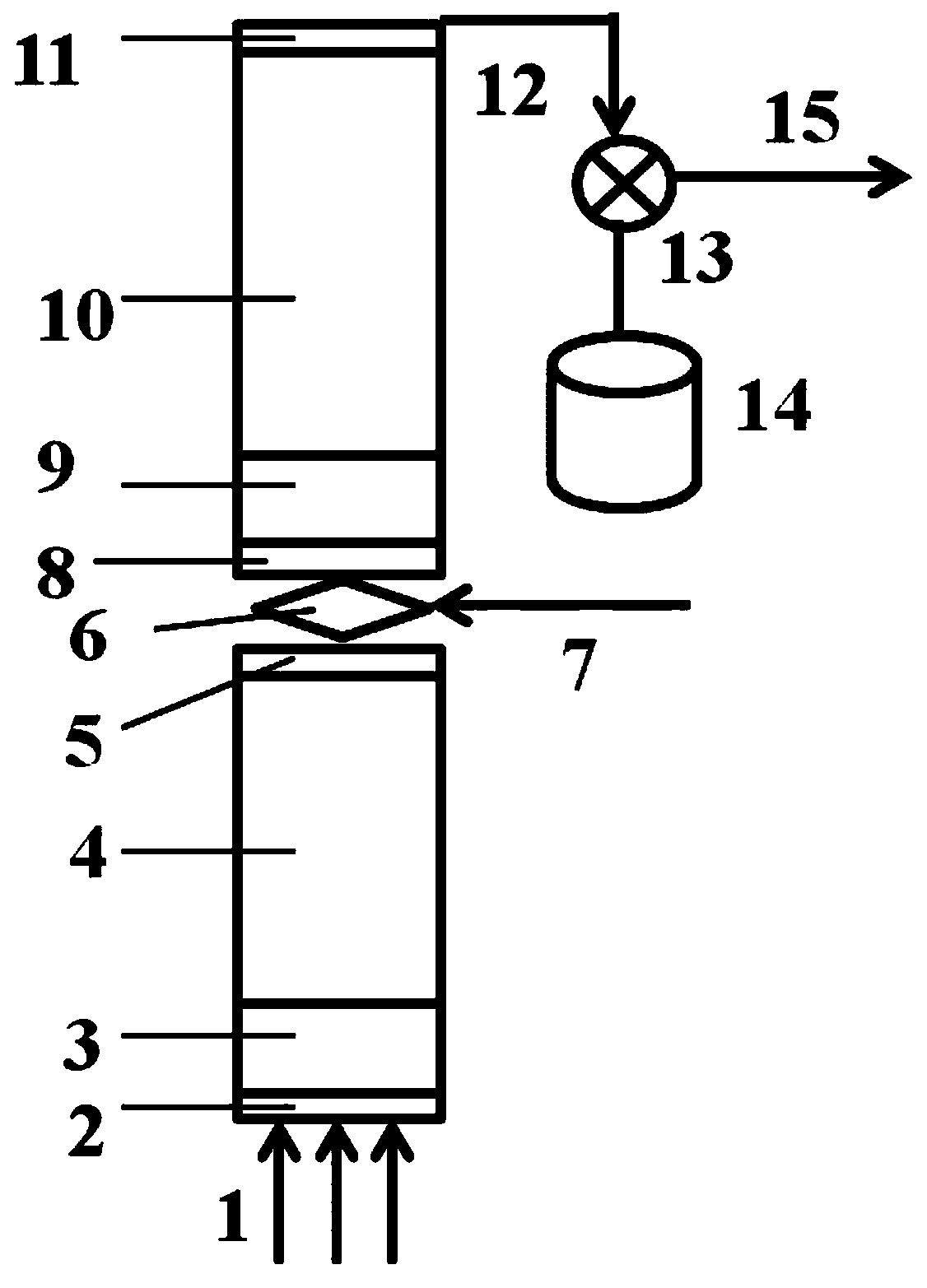

Method for preparing synthetic gas through dry reforming of methane

ActiveCN106608617AGuaranteed uptimeUniform temperature distributionHydrogenHydrogen/synthetic gas productionChemistryMetal

The invention relates to the field of preparation of synthetic gas through dry reforming of methane, and discloses a method for preparing synthetic gas through dry reforming of methane. The loading amount of an active metal component Ni in a catalyst in a catalyst bed of a dry reforming reaction of methane is controlled, and a Al2O3 carrier and / or a Al2O3 carrier modified with an auxiliary agent is adopted. Even in relatively high reaction velocity, temperature dispersion of the catalyst bed is basically uniform, and an area where carbon is easily thermodynamically accumulated can be avoided, so that the catalytic stability of a catalyst is greatly improved and the service life of the catalyst can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

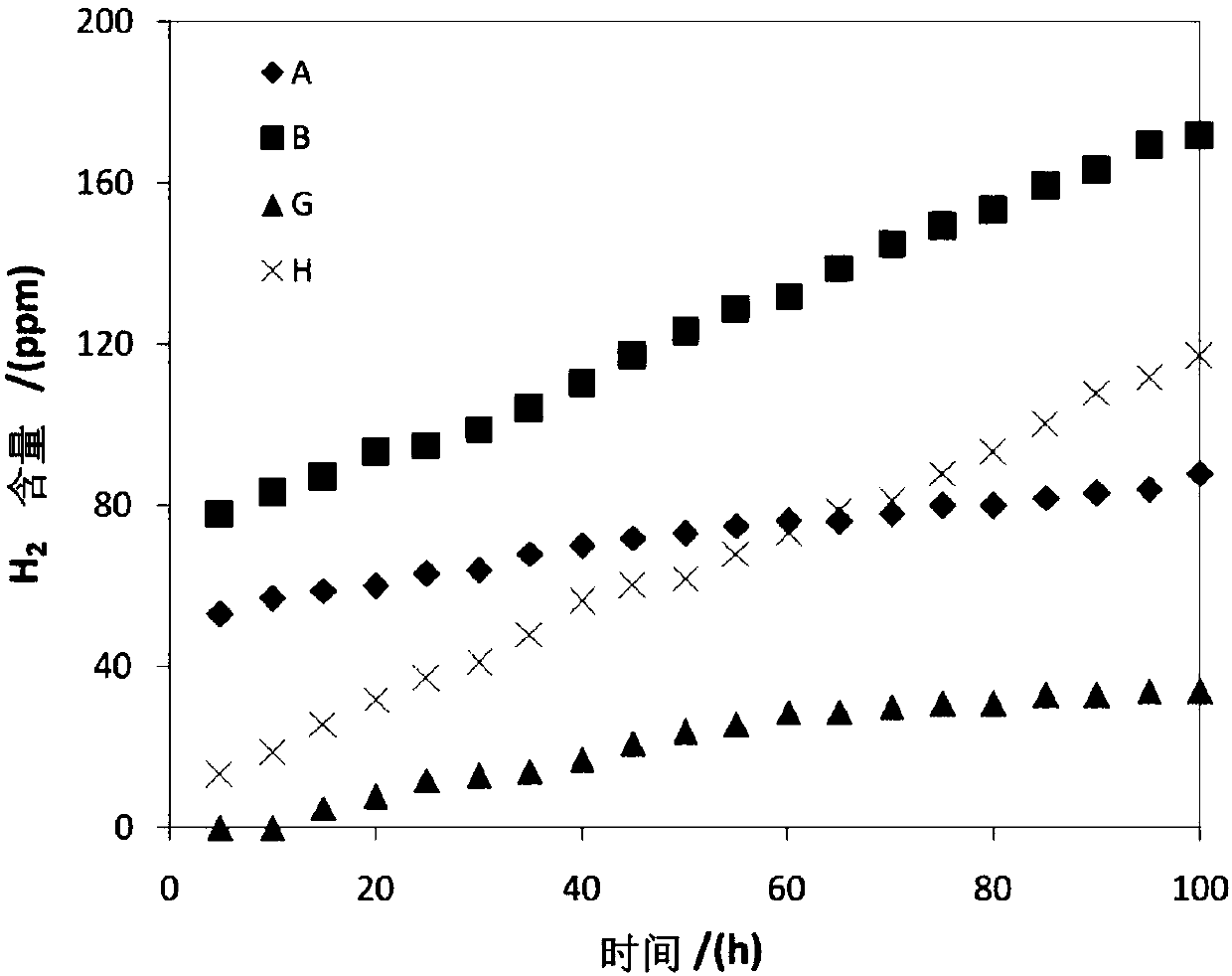

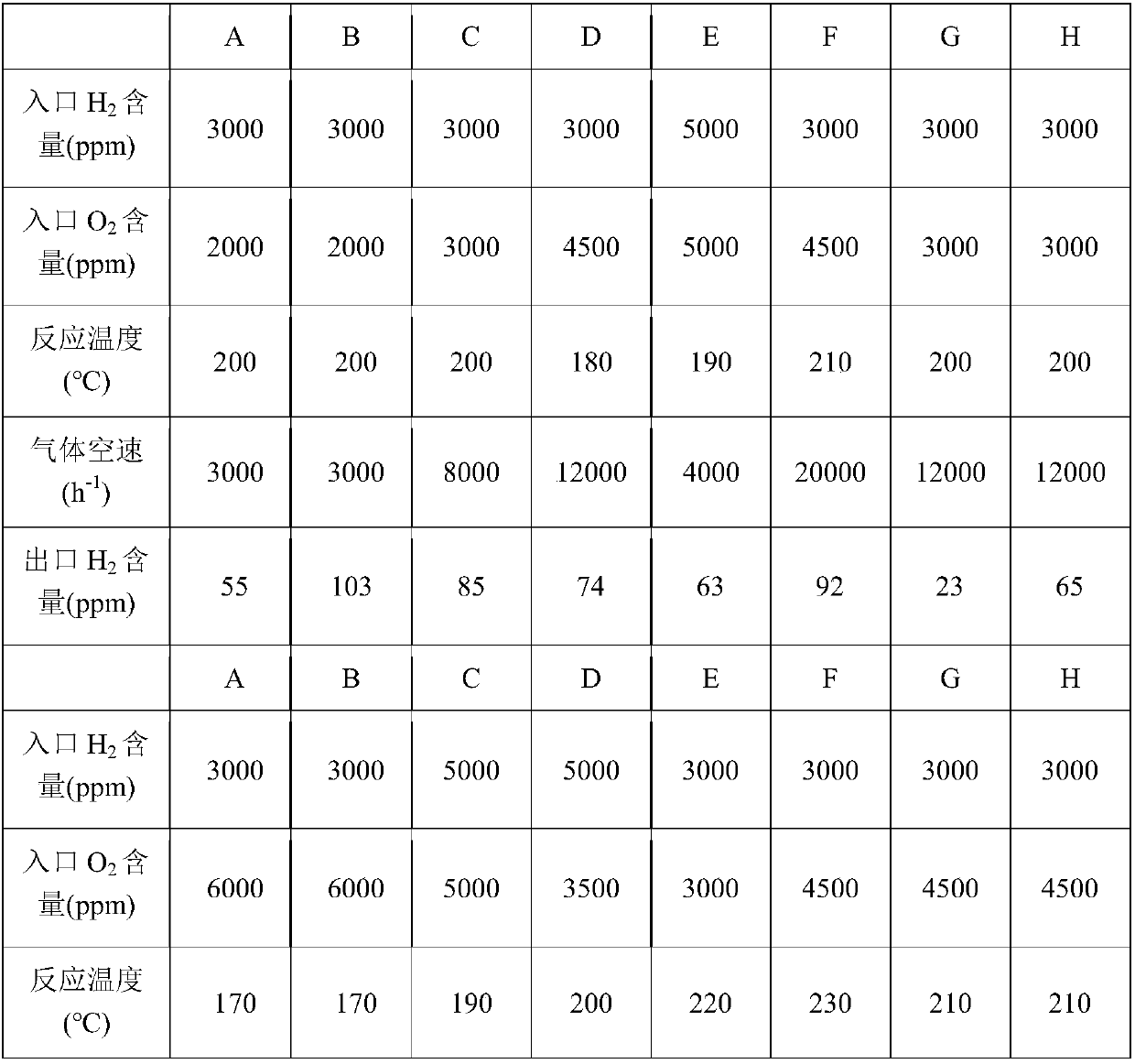

Monolithic catalyst and preparation and application thereof

ActiveCN107694562AHigh metal dispersionImprove hydrogenation activityMolecular sieve catalystsCatalyst activation/preparationOxalateHigh concentration

The invention provides a high-dispersion monolithic catalyst for selectively catalytic oxidization of H2 in the atmosphere of high-concentration CO and a preparation method and application of the high-dispersion monolithic catalyst. The catalyst is suitable for a fixed bed reactor and has a multilayer structure, wherein the multilayer structure includes but not limited to a shell layer, an activecomponent layer, a carrier coating and a honeycomb carrier layer. The catalyst can be applied to the process of the selectively catalytic oxidization of H2 in the atmosphere of the high-concentrationCO, wherein the ratio of H2 to O2 in feed gas is 1:1 to 1:3, the reaction temperature is 150-250 DEG C, and the pressure is 0.3-0.6 MPa; besides, when the airspeed is 3000-20000h<-1>, the content of output H2 is less than 100 ppm, so that the reaction requirements of subsequent vapor catalytic coupling synthesis of oxalate by using CO are met.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

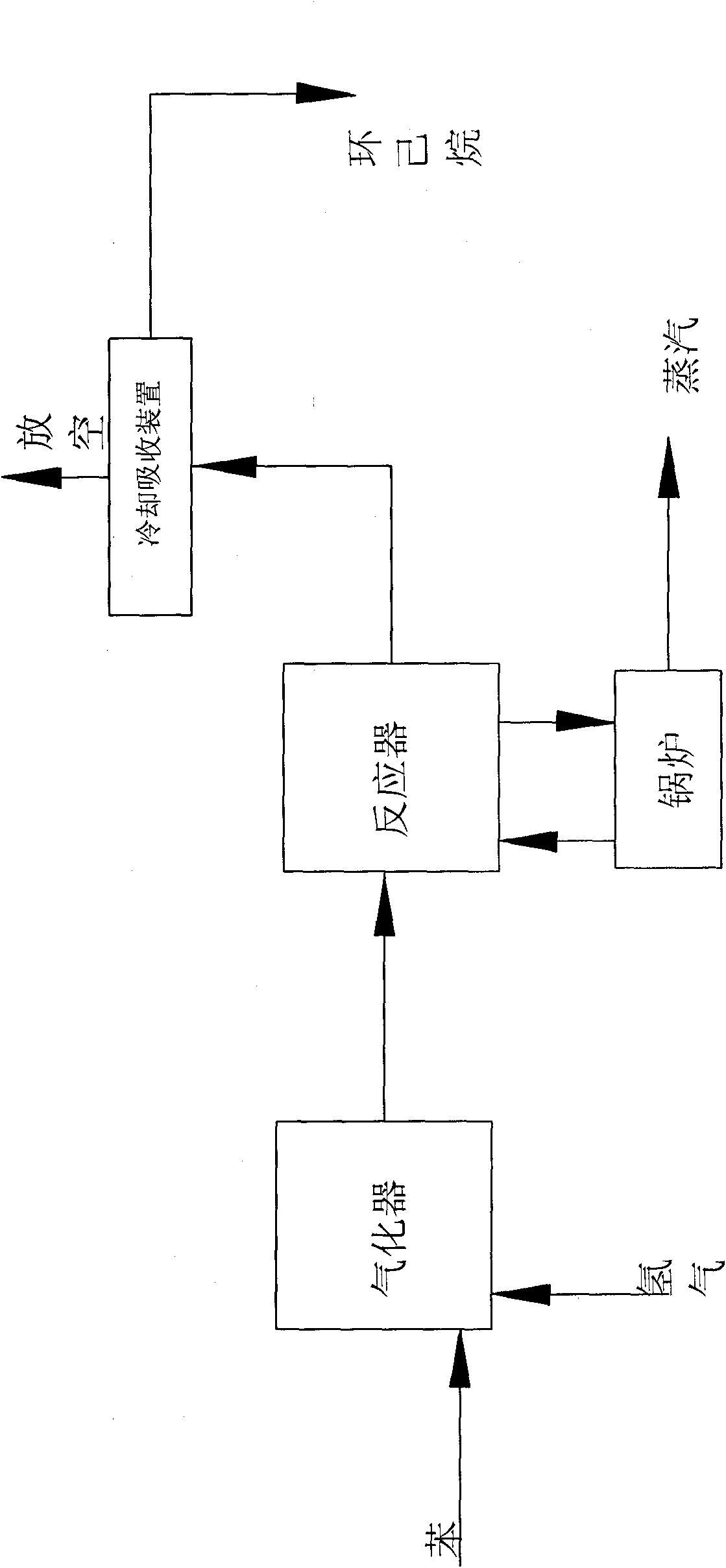

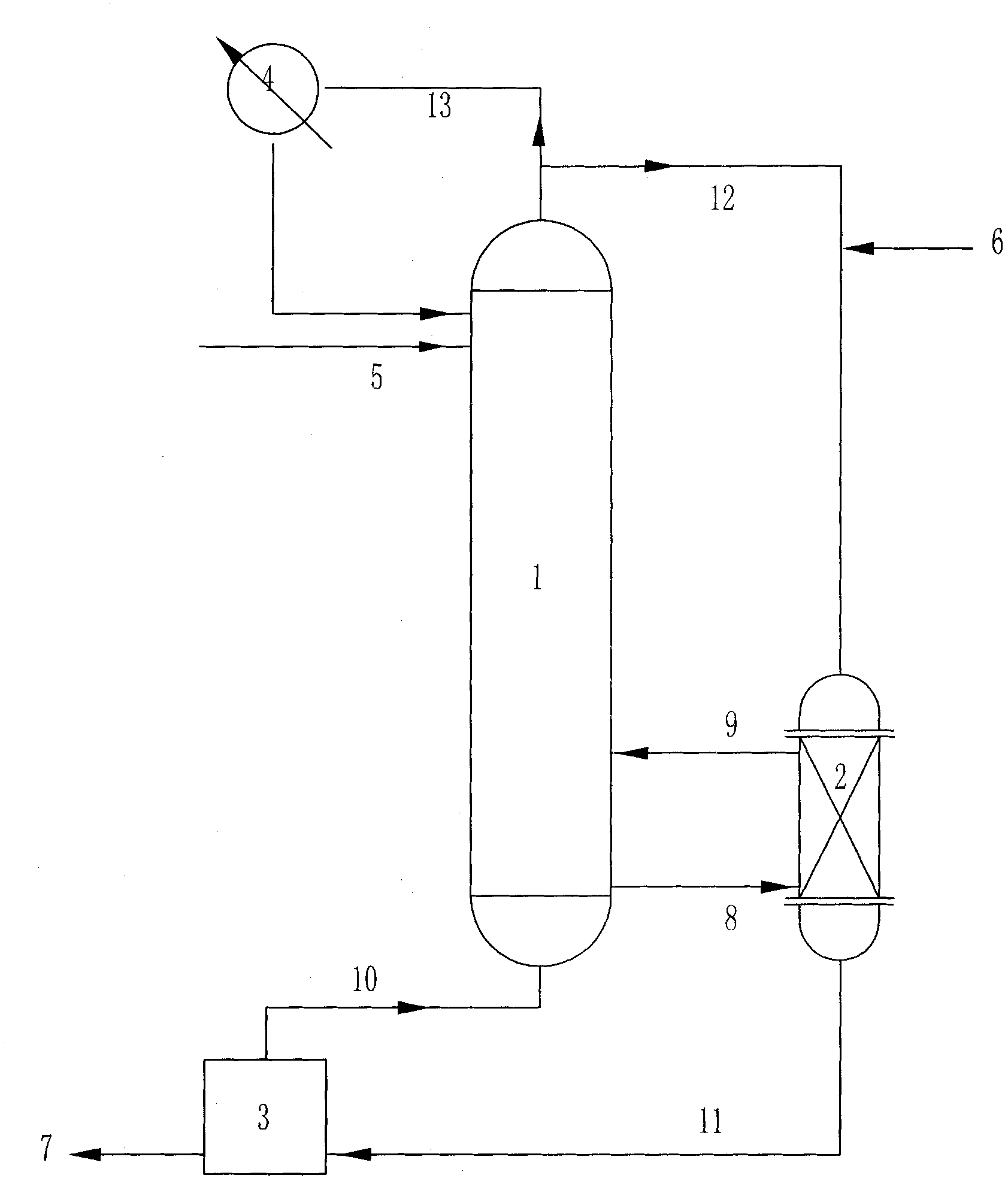

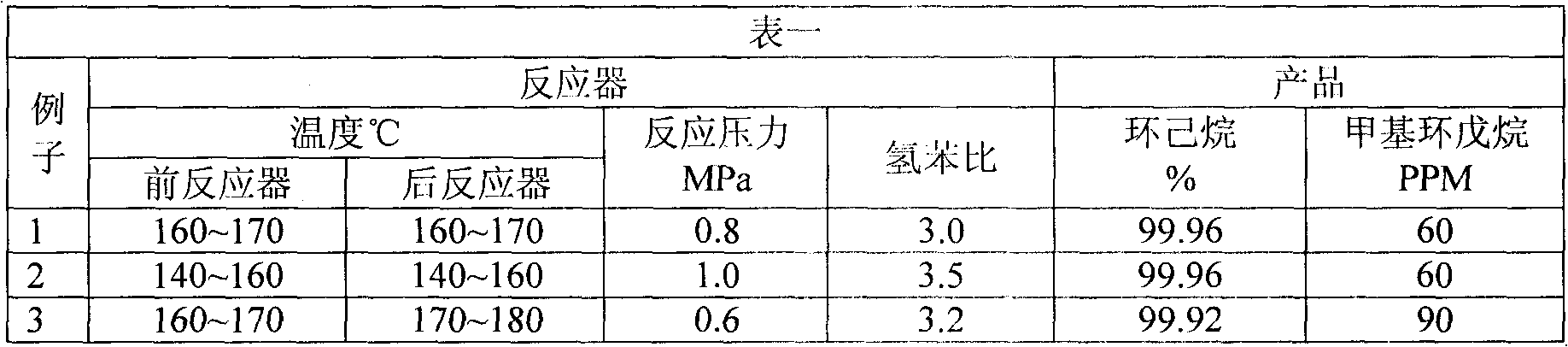

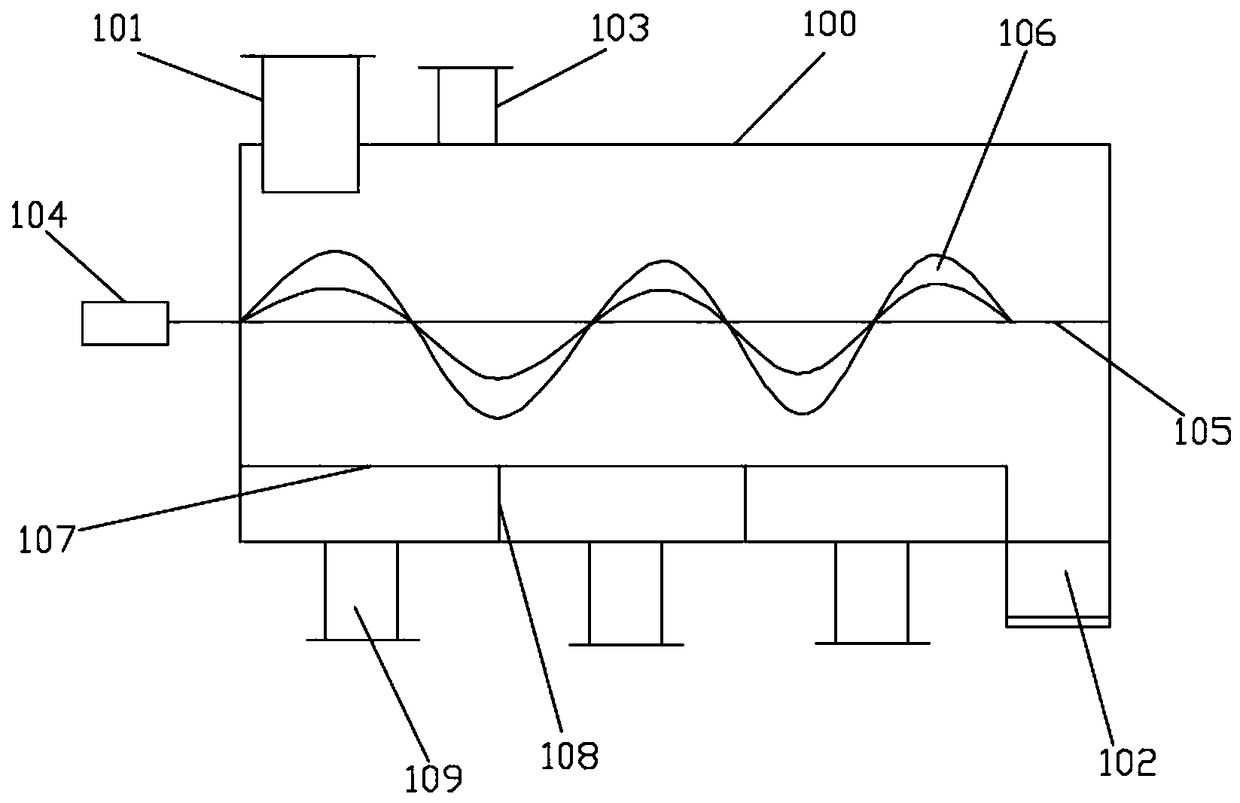

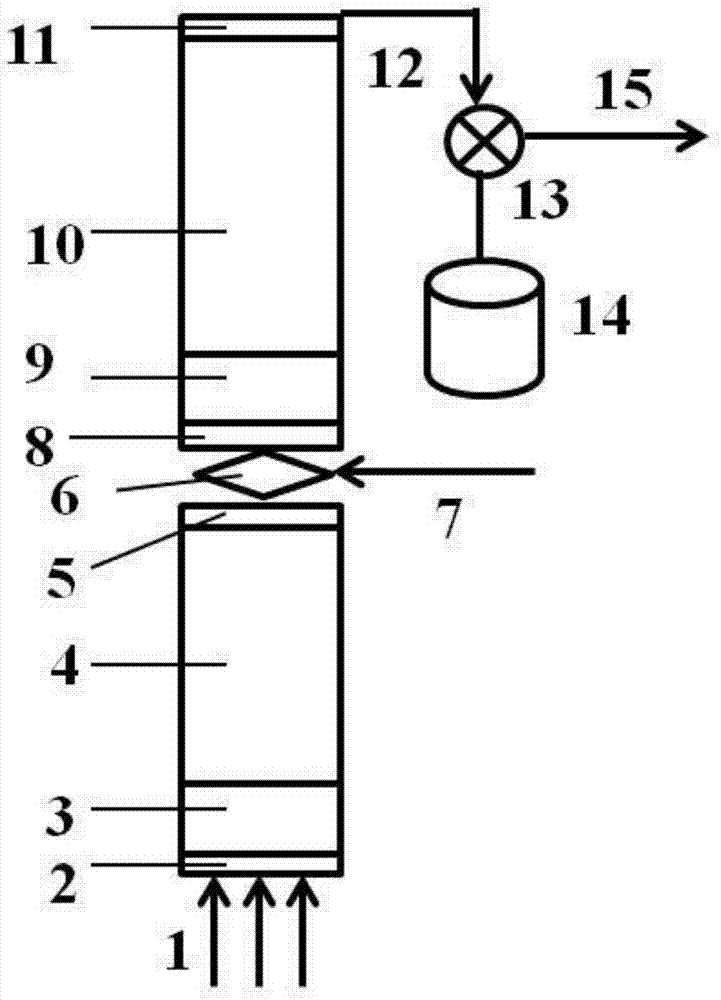

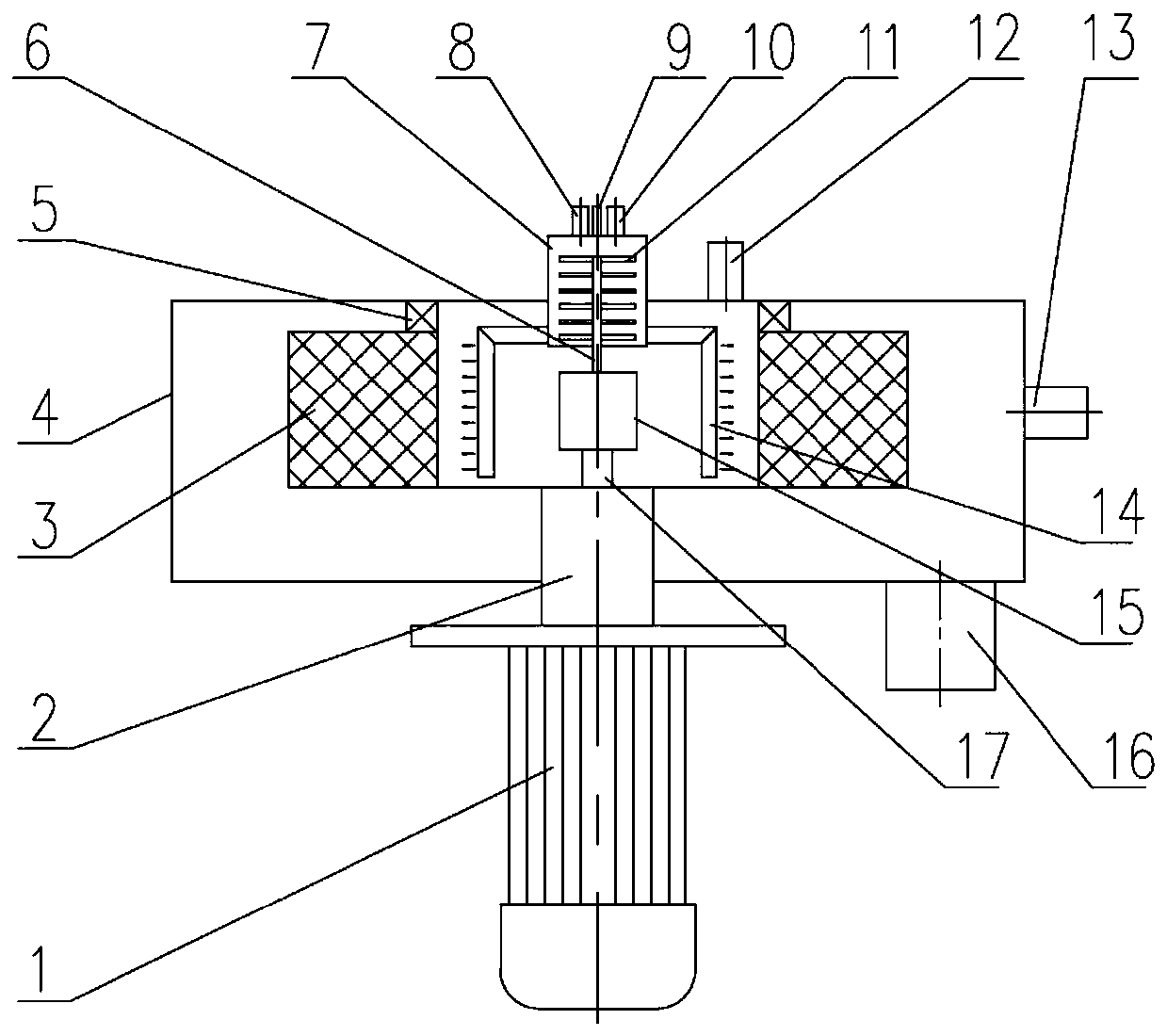

Device for producing cyclohexane by adding hydrogen in benzene and synthesis process

ActiveCN101898930ARemove in timeThe reaction temperature is easy to controlHydrocarbon by hydrogenationBenzeneHydrogen

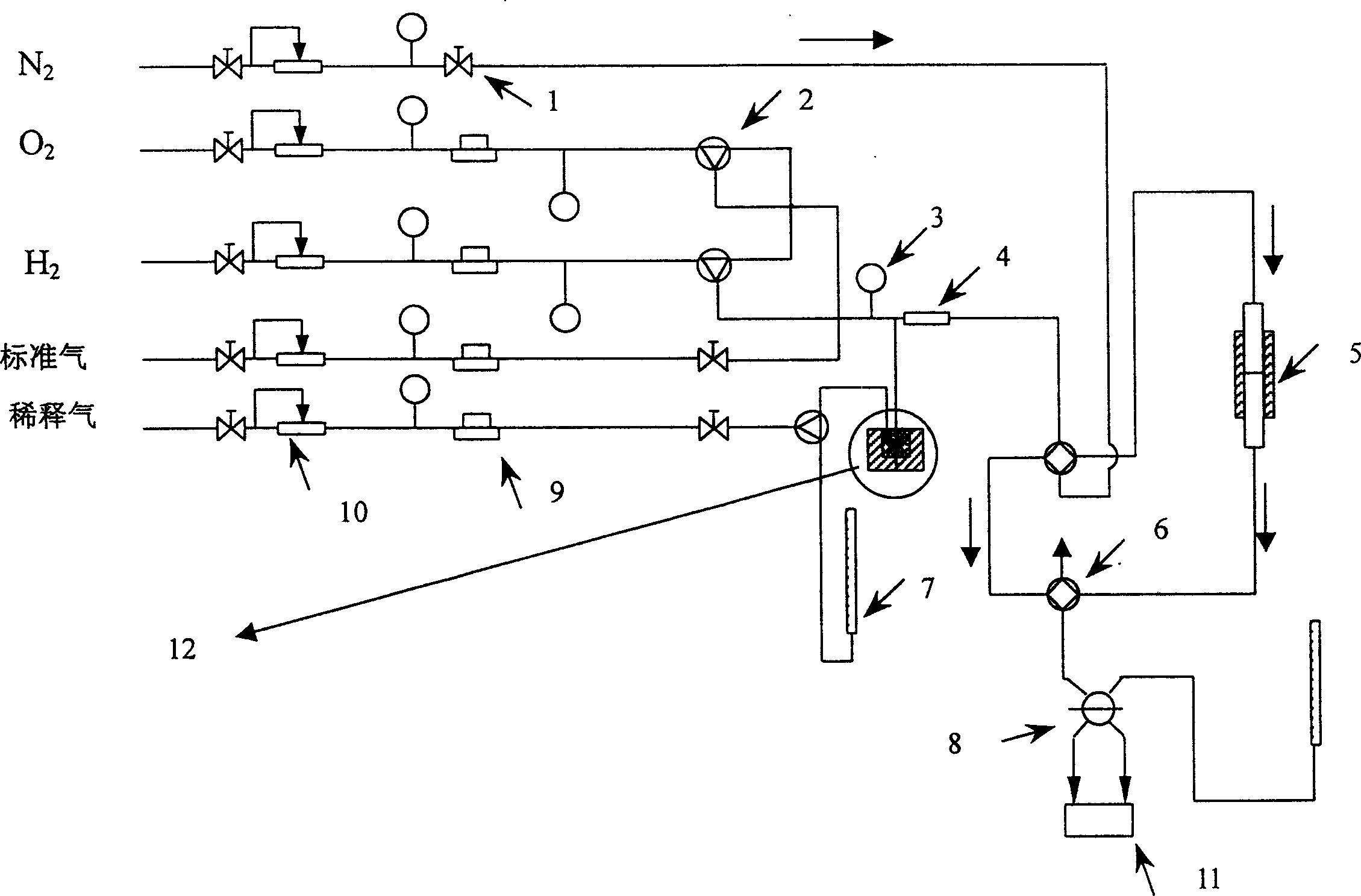

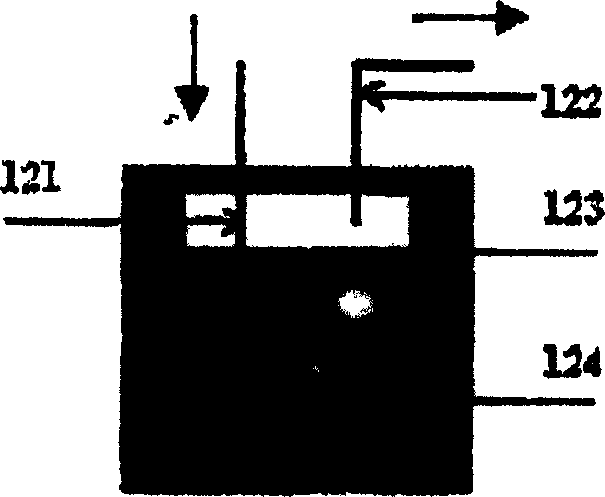

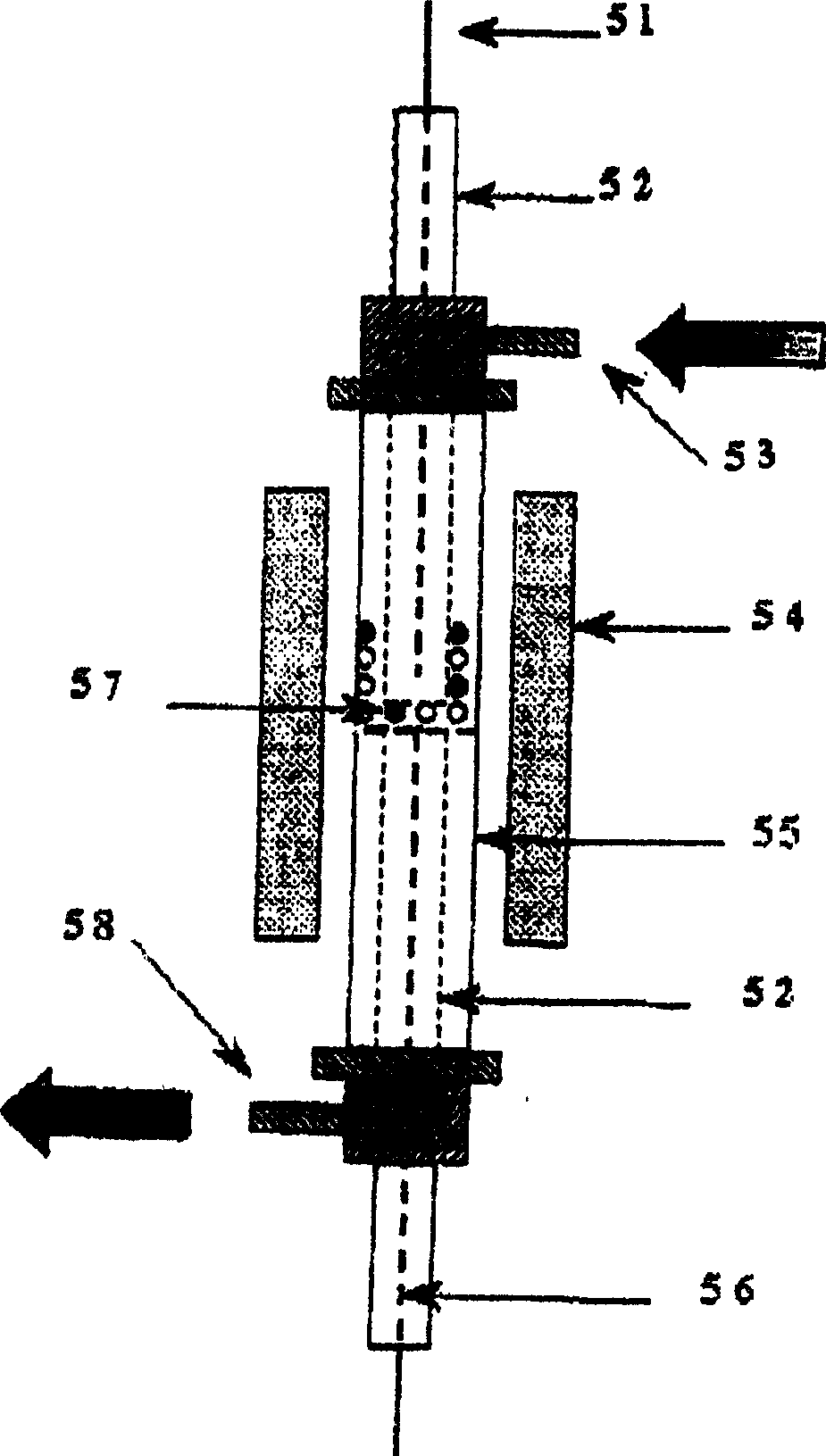

The invention discloses a device for producing cyclohexane by adding hydrogen in benzene and a synthesis process. The device mainly comprises a gasification tower (1) and a reactor (2), wherein a liquid phase benzene inlet (5) is arranged at the upper part of the gasification tower (1), a liquid phase benzene outlet is arranged at the lower part of the gasification tower (1), the liquid phase benzene outlet is connected with a shell pass inlet of the reactor (2) through a pipeline (8), a shell pass outlet of the reactor (2) is connected to the gasification tower (1) through a pipeline (9), a gas phase outlet is arranged at the top of the gasification tower (1) and connected to a pipe pass of the reactor (2) through a pipe pass feed pipeline (12), a hydrogen material pipeline (6) is connected to the pipe pass feed pipeline (12), and a pipe pass discharge pipeline (11) is arranged at the bottom of the reactor (2). In the device, heat discharged from the intermediate reaction in the cyclohexane synthesis process is directly used for gasification of reaction material benzene so as to release the reaction heat without secondary heat exchange, therefore, the stable reaction conversion ratio is achieved, and the production capacity is improved.

Owner:SHANDONG HUALU HENGSHENG CHEM IND

A method for producing synthetic natural gas by utilizing methanol purge gas

InactiveCN102268307ARaise the gradeControl the temperature of the adiabatic reactionGaseous fuelsMethanationNew energy

The invention discloses a method for producing synthetic natural gas by using methanol purge gas, which belongs to the technical fields of coal chemical industry and new energy. This method of producing synthetic natural gas uses a multi-stage adiabatic methanation reactor, the inlet feed gas of the first adiabatic reactor is a mixture of methanol purge gas and coke oven gas, and the inlet feed gas of the second adiabatic reactor is The mixed gas of methanol purge gas and primary outlet gas undergoes three or more stages of reaction, and the CO and CO2 in the raw material gas are completely converted into methane through methanation reaction. The advantages of this method are: (1) No need for circulation equipment, saving investment and reducing operating costs; (2) All adiabatic reactors are used, with multi-stage series connection, high reaction space velocity and high grade of by-product steam.

Owner:大连瑞克科技股份有限公司

Homogeneous catalyst for preparation of ethylene glycol by ethylene oxide hydration

InactiveCN1589969AHigh catalytic activityImprove catalytic selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyEthylene oxide

A homogenizing catalyst for preparing ethanediol from epoxy ethane by hydration is the neutral salt or weakly acidic salt or their mixture, which can be dissolved in reaction medium. Its advantage is high selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for prolonging running period of acrylic acid device

InactiveCN104193582AReduce hot spot temperatureReduce the use effectCatalyst protectionOrganic compound preparationPolymer scienceHeat resistance

The invention provides a method for prolonging the running period of an acrylic acid device. The method comprises the following steps: loading a catalyst without diluting by use of an inert filler, arranging coated catalyst bed layers having different heat resistances in a tube fixed-bed reactor according to the heat resistance in the axial direction of the reactor; and loading a coated catalyst relatively low in heat resistance in a position near the outlet of a reaction tube, and then orderly loading coated catalysts relatively high in heat resistance in such a manner that the coated catalyst close to the inlet of the reaction tube has the highest heat resistance, wherein the coated catalysts having different heat resistances are catalysts the inner cores of which are high-activity composite oxides with heat-resistant ceramic balls, and are obtained by controlling the sizes of the heat-resistant ceramic balls and the coating ratio of an active ingredient. Due to the adopted method, not only is the running period of the acrylic acid device prolonged, but also the production device has relatively high reaction efficiency.

Owner:CHINA NAT OFFSHORE OIL CORP +3

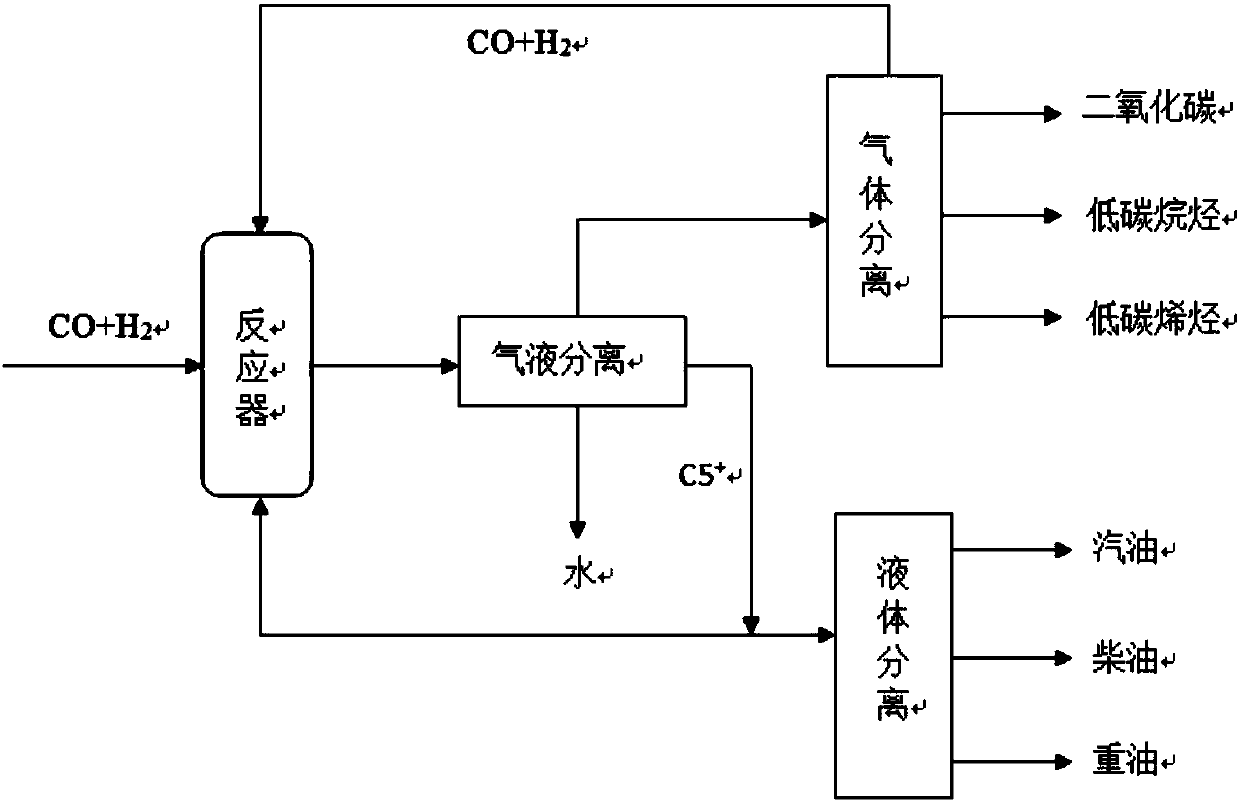

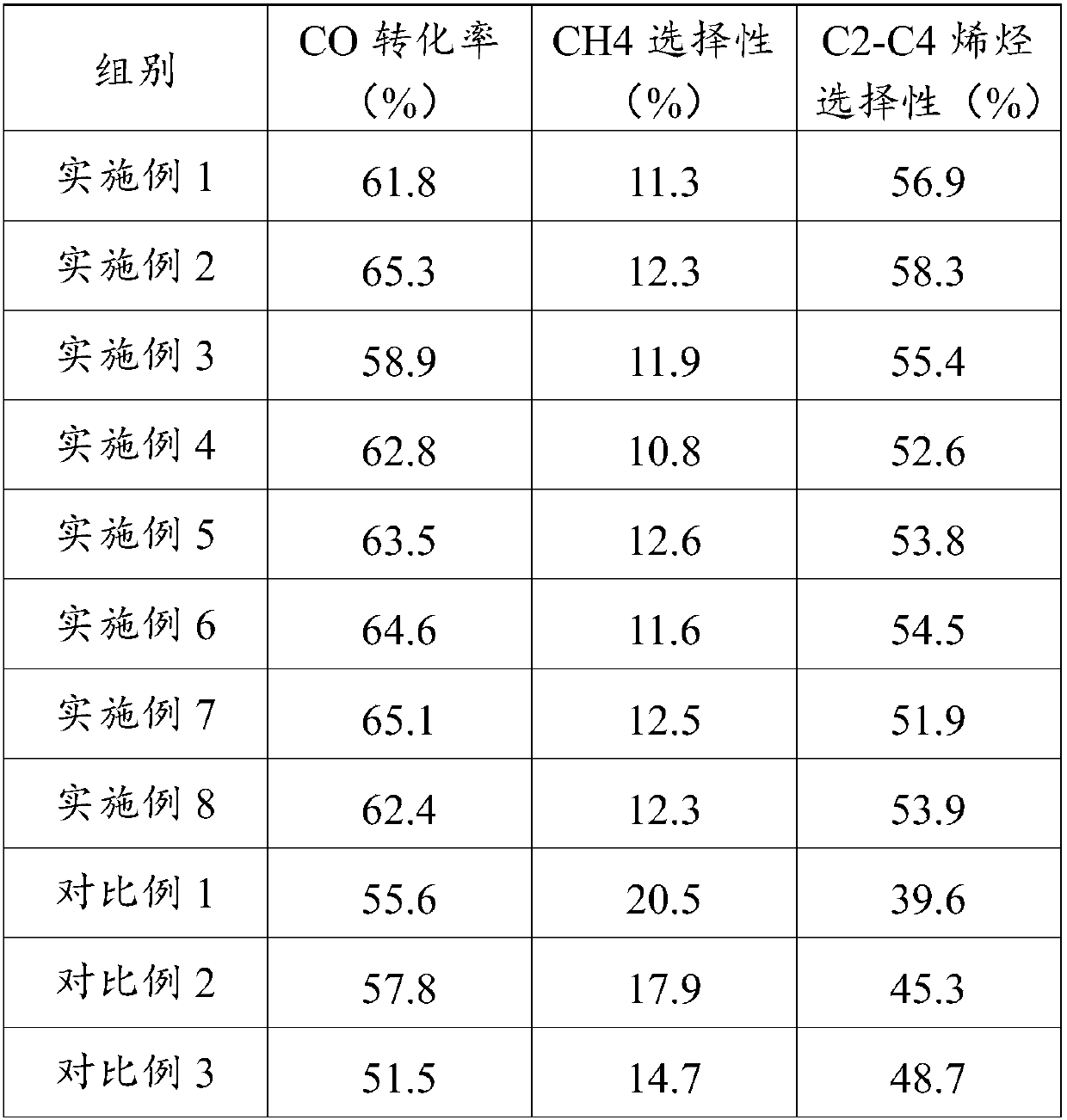

Method for producing low-carbon olefin by synthetic gas

ActiveCN107824214AHigh reaction space velocityLarge amount of processingHydrocarbon from carbon oxidesMolecular sieve catalystsSyngasMolecular sieve

The invention provides a method for producing low-carbon olefin by synthetic gas. The method comprises the following steps: carrying out Fischer-Tropsch synthesis-cracking reaction on the synthetic gas under the action of a multifunctional catalyst, wherein the reaction temperature is 250 DEG C to 400 DEG C, the reaction pressure is 0 to 5MPa, and the total volume space velocity of raw gas is 1000h<-1> to 10000h<-1>; then separating the low-carbon olefin out from a reaction product. The multifunctional catalyst is mainly prepared from the following components in parts by weight: 10 percent to60 percent of Fe2O3, 0.5 percent to 20 percent of MnO, 0.5 percent to 10 percent of K2O, 10 percent to 30 percent of Al2O3 and the balance of a molecular sieve. According to the method provided by theinvention, Fischer-Tropsch synthesis reaction and cracking reaction can be carried out at the same time; the problem in the prior art that the low-carbon olefin selectivity is low is solved; the technology has high sensitivity and the product distribution can be reasonably adjusted in a certain range according to the market quotations of ethylene, propylene and butylene; the method has the characteristics of simplicity in operation and remarkable synergistic effect.

Owner:SINOPEC ENG GRP CO LTD

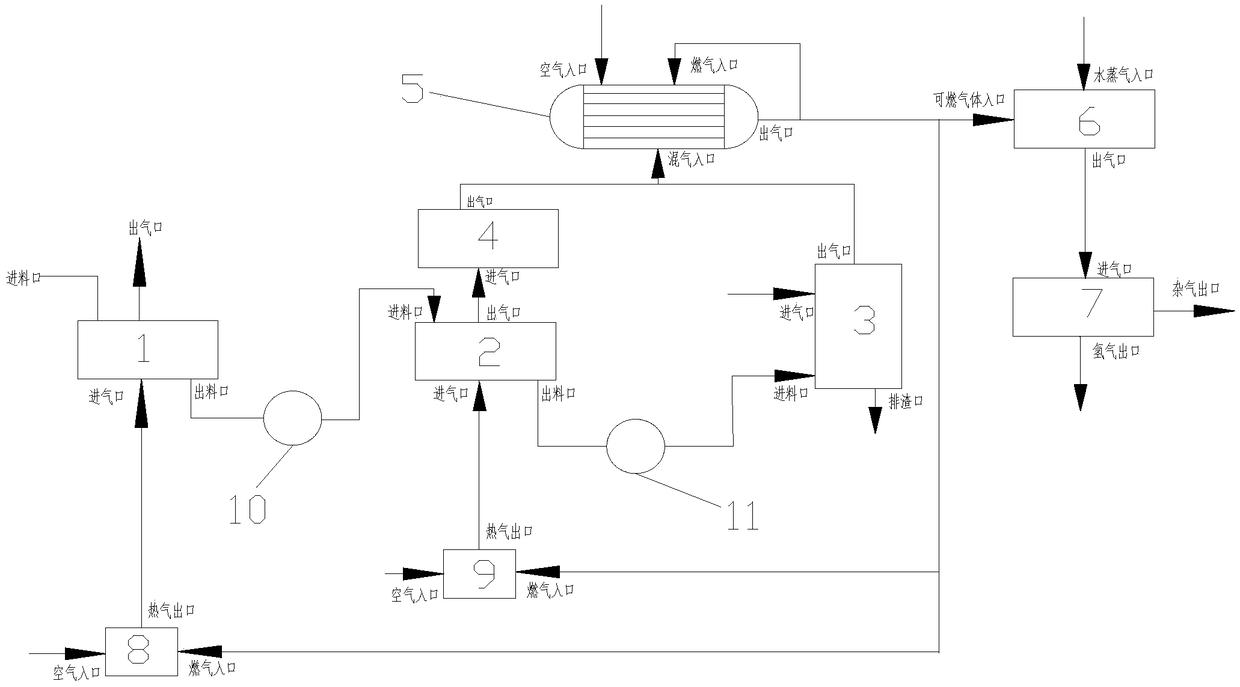

Dechlorination hydrogen production device for treating PVC-containing plastic wastes

A dechlorination hydrogen production device for treating PVC-containing plastic wastes comprises a first spiral moving bed, a second spiral moving bed, a fluidized bed, a dechlorination tower and a tar cracker; the first spiral moving bed is used for drying and dehydrating the PVC-containing plastic wastes to obtain a dried and dehydrated material; the second spiral moving bed is used for carryingout high temperature anaerobic pyrolysis on the dried and dehydrated material to generate a high-temperature pyrolysis gas and high-temperature pyrolysis wastes; the fluidized bed is used for carrying out high-temperature vaporization on the high-temperature pyrolysis wastes to generate a vaporized gas and ash; the dechlorination tower is used for dechlorinating the high-temperature pyrolysis gasto obtain a dechlorinated gas; and the tar cracker is used for carrying out tar cracking treatment on a mixed gas of the vaporized gas and the dechlorinated gas to obtain harmless combustible gases.The PVC-containing plastic wastes harmful to the environment are converted into the chlorine element-removed harmless combustible gases with high added values, so the utilization rate of urban waste resources is increased, and the pollution of the urban wastes to the environment is reduced.

Owner:广东国能中林实业有限公司

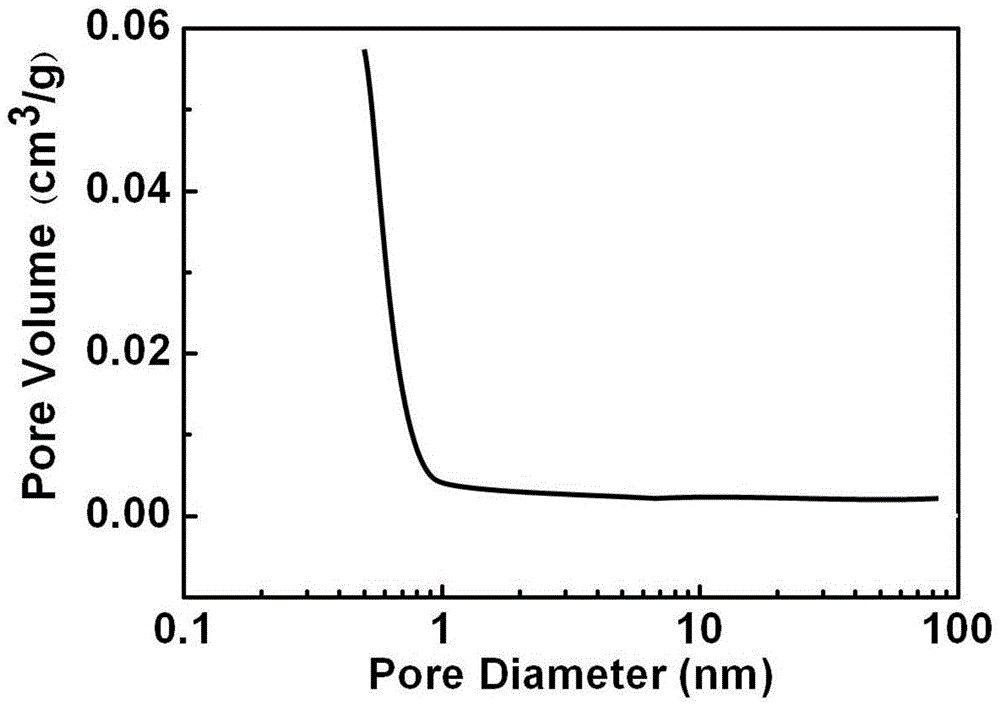

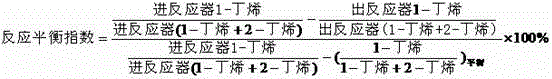

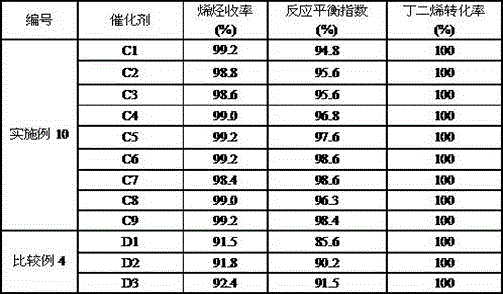

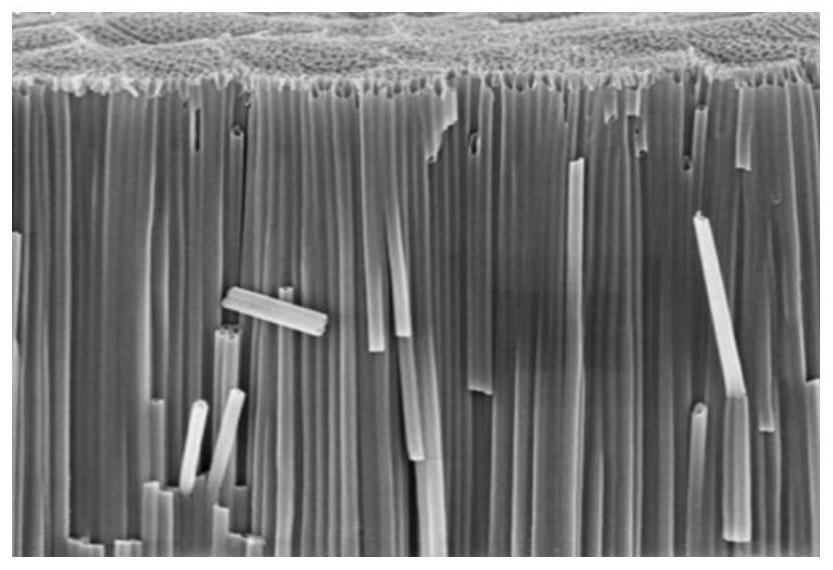

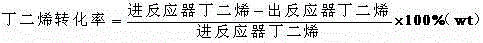

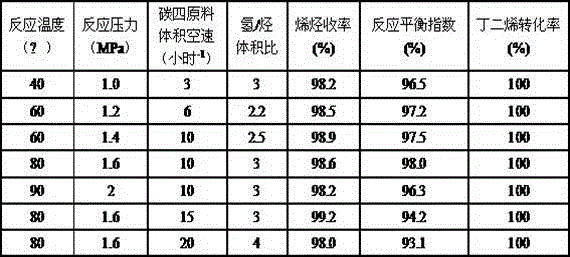

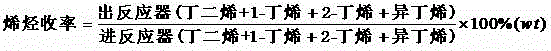

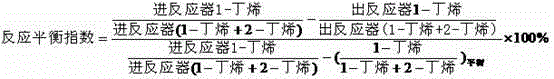

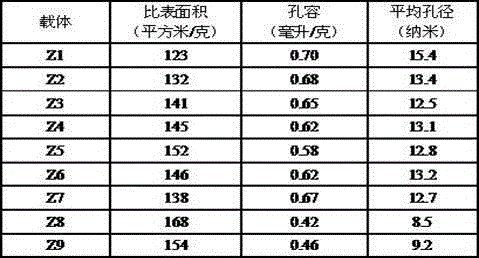

C_4 olefin hydroisomerization catalyst and C_4 olefin hydroisomerization method

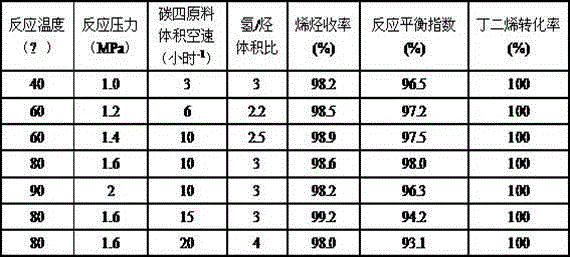

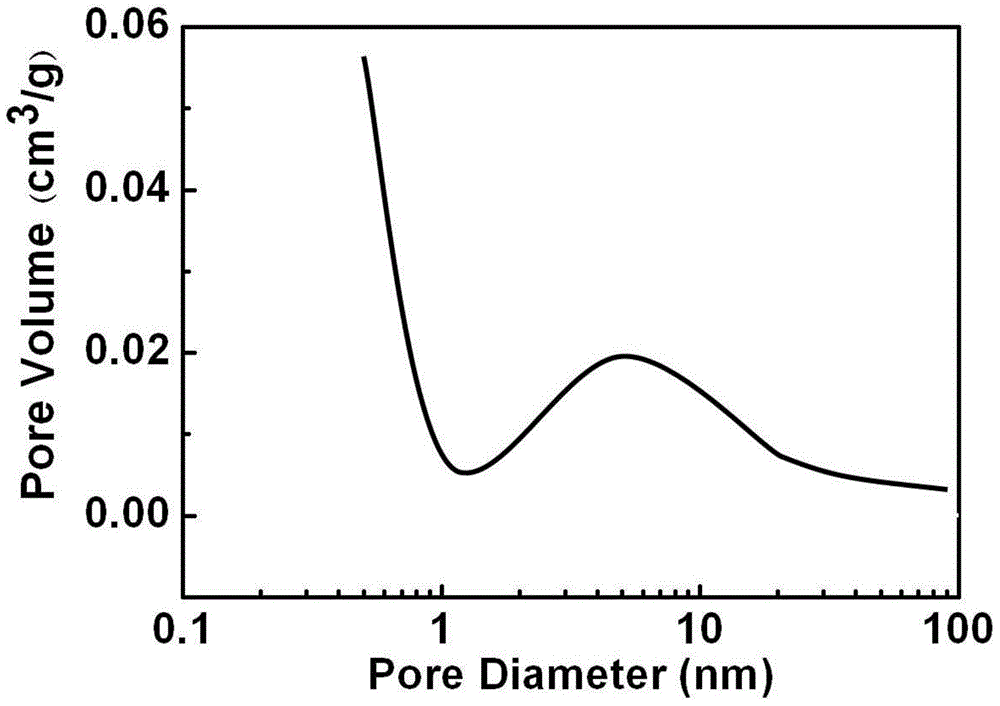

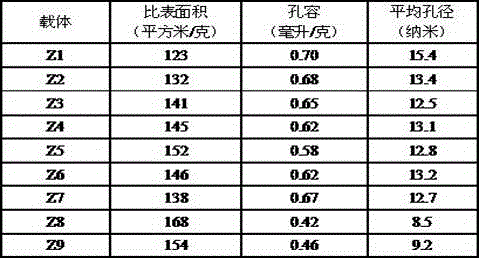

ActiveCN104437522ASuppress generationInhibition of deep hydrogenationHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsPore diameterAlkene

The invention relates to a catalyst and a method for preparing butane-2 by C_4 olefin hydroisomerization, and the catalyst and the method are mainly used for solving the technical problems in the prior art of low reaction balance index, low olefin yield and high catalyst cost. In order to better solve the problems, the technical scheme adopted by the invention is as follows: the catalyst comprises the following components in parts by weight: (a) 10-20 parts of metal nickel or an oxide thereof; (b) 0.1-5 parts of metal molybdenum or an oxide thereof; (c) 75-90 parts of aluminum oxide-silicon dioxide composite carrier, wherein the pore volume of the catalyst is 0.5-0.9 ml / g, the specific surface area is 150-190 m<2> / g, the average aperture is 13-16 nm, and the pore volume with pore diameter larger than 10 nm occupies 20-60% of the total pore volume. The catalyst can be used in the industrial production of increasing the production of butane-2 by C_4 fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

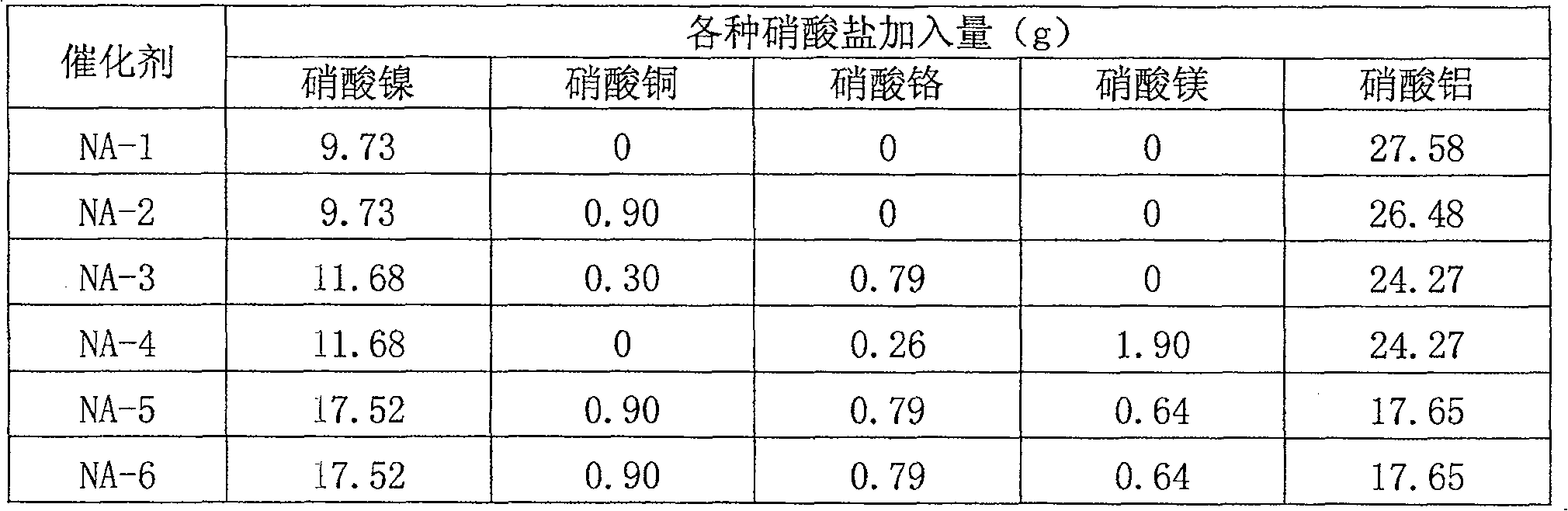

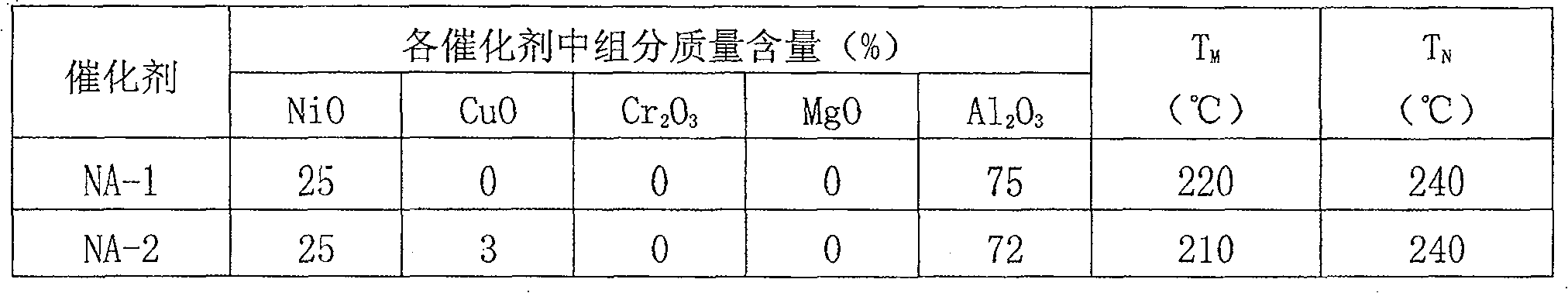

Nickel base crouse vent gas hydrogenation catalysts and coprecipitation manufacturing method

InactiveCN101108349ALow costExtended service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentCoprecipitation

The invention relates to a hydrogenation catalyst for the tail gas of Crouse sulphur recycle device and the preparation method. A nickel pyridyl Crouse tail gas hydrogenation catalyst is characterized in that: the catalyst is mainly composed of an active component, an assistance active component and alumina three components, the quality per centage of each component is: the main active component is 20.1 to 60 per cent, the assistance active component 0 to 10 per cent, the alumina 40 to 79.9 per cent, the sum of the three components is 100 per cent; wherein, the main active component is nickel oxide, the assistance active component is one of chrome oxide, aerugo and iron oxide or a mixture of one or two in above three substances, when being a mixture of one or two in above three substances, the mixture ratio among the oxide is random. The invention has the characters of good low temperature catalyzing activity and low cost.

Owner:WUHAN UNIV OF TECH

Method for preparing tert-butyl (meth)acrylate

ActiveCN110270323AHigh activityHigh reaction space velocityOrganic compound preparationCarboxylic acid esters preparationNiobiumFixed bed

The invention discloses a method for preparing tert-butyl (meth)acrylate. The method is characterized in that liquid acrylic acid and liquid isobutylene are mixed according to a molar ratio of 0.5:1.0 to 3.0:1.0, and then are reacted in a fixed bed tubular reactor, the reactor is filled with a niobium-zirconium composite oxide catalyst, and a molar ratio of niobium to zirconium in the niobium-zirconium composite oxide is 1:(0.01-2).

Owner:SHANGHAI HUAYI NEW MATERIAL

Nickel base crouse vent gas hydrogenation catalysts and coprecipitation manufacturing method

InactiveCN100591418CLow costExtended service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentPolyethylene glycol

The invention relates to a hydrogeneration catalyst for the tail gas of a Crouse sulphur recycle device and a preparation method for the catalyst. A nickel-based Crouse tail gas hydrogeneration catalyst, which is characterized in that the catalyst essentially comprises a main active component, a secondary active component and alumina, the mass percentage of each component is like follows: the mainactive component 20.1-60%, the secondary active component 0-10%, the alumina 40-79.9%, the sum of the three components is 100%; wherein, the main active component is nickel oxide, the secondary active component is one or the mixture of any two or three of chrome oxide, copper oxide and iron oxide, when the secondary active component is a mixture, the compounding ratio among the oxides is random.The invention has the advantages of the good catalyzing activity at low temperature and the low cost.

Owner:WUHAN UNIV OF TECH

Two-stage fluidized bed CO dehydrogenation purification reaction technology and used catalyst

ActiveCN107497425AHigh selectivityReduce consumptionCatalyst activation/preparationCarbon monoxideFluidized bedGas phase

The invention discloses a two-stage fluidized bed CO dehydrogenation purification reaction technology and a used catalyst. The reaction technology is as follows: two fluidized beds are in up-and-down arrangement, a reaction gas is fed in from the bottommost of a reactor, and enters an upper fluidized bed reactor for reaction, after heat exchange condensation of the gas reacted in the upper fluidized bed reactor, a gas phase component is used as a carbonylation reaction raw material gas, and a liquid component enters a storage tank. A catalyst used in a lower fluidized bed is PdAgClx / TiO2 (x = 1-3), can be used for selective oxidation of H2 at low temperature to reduce or avoid consumption of CO raw material gas, the H2 in the raw material gas CO is reduced to 5000ppm or less after reaction in the lower fluidized bed, a catalyst used in an upper fluidized bed is PdO-Ag2O / TiO2, can be used for oxidatively transform the H2 as much as possible at high temperature, and the H2 in the CO raw material gas is reduced to 50ppm or less after reaction in the upper fluidized bed. The method can effectively solve the industrial enlargement problem of raw material gas CO oxidation dehydrogenation process in coal-based ethylene glycol synthesis technology.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

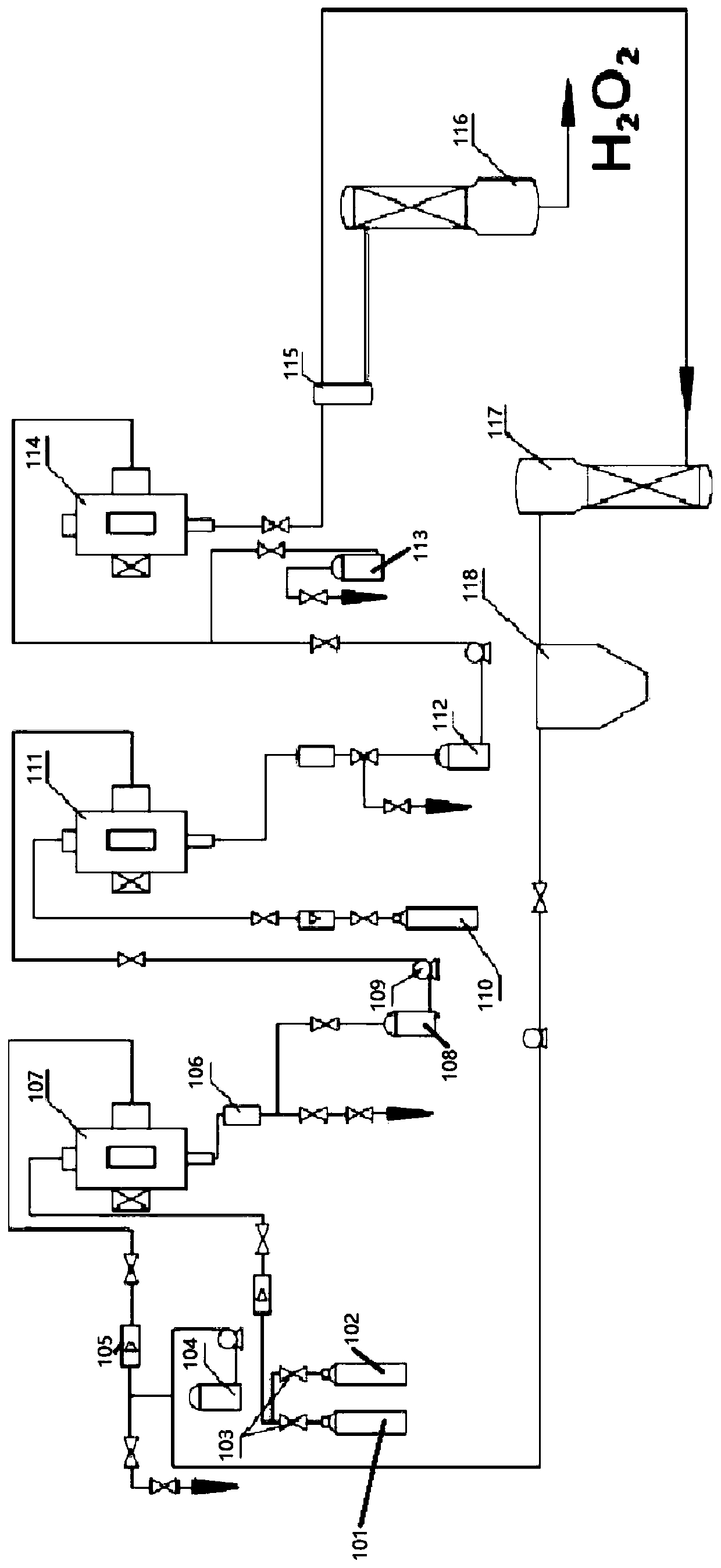

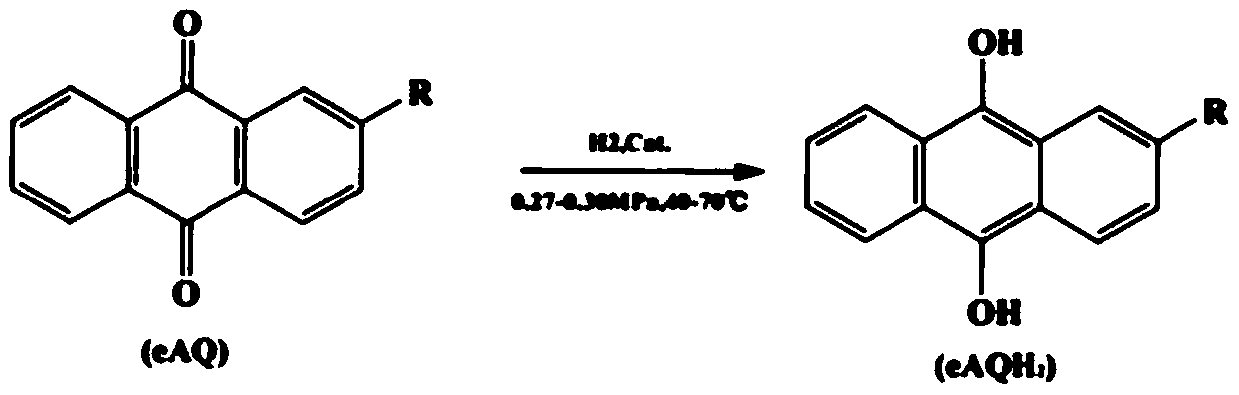

A kind of production technology that uses anthraquinone method to prepare hydrogen peroxide

ActiveCN107473188BExtension of timeImprove mass transfer efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolubilityHydrazine compound

The invention discloses a production process for preparing hydrogen peroxide by using an anthraquinone process. The production process comprises the following steps: sequentially connecting a hydrogenation hyper-gravity reactor, an oxidation hyper-gravity reactor and an extraction hyper-gravity reactor in series; inputting hydrogen and an anthraquinone-containing solution into a feeding cavity to perform gas-liquid two-phase high-efficiency mixing, and forming a gas-liquid mixture to carry out a hydrogenation reaction so as to obtain a working solution containing oxanthranol; inputting oxygen and the working solution containing oxanthranol into the feeding cavity to perform gas-liquid two-phase high-efficiency mixing, and forming a gas-liquid mixture to carry out an oxidation reaction so as to obtain a working solution containing hydrogen peroxide and anthraquinone; enabling the working solution containing hydrogen peroxide and anthraquinone and deionized water to enter the extraction hyper-gravity reactor to extract; and separating after extraction, thereby obtaining the hydrogen peroxide. According to the production process, gas-liquid solid-phase mass transfer can be intensified by insoluble hydrogen by efficiently utilizing reducing hydrogen when the liquid solubility reaches supersaturation; and moreover, according to the method disclosed by the invention, the hydrogenation efficiency is more than or equal to 13g / L, and the oxidation reaction conversion rate is more than or equal to 95%.

Owner:BEIJING UNIV OF CHEM TECH

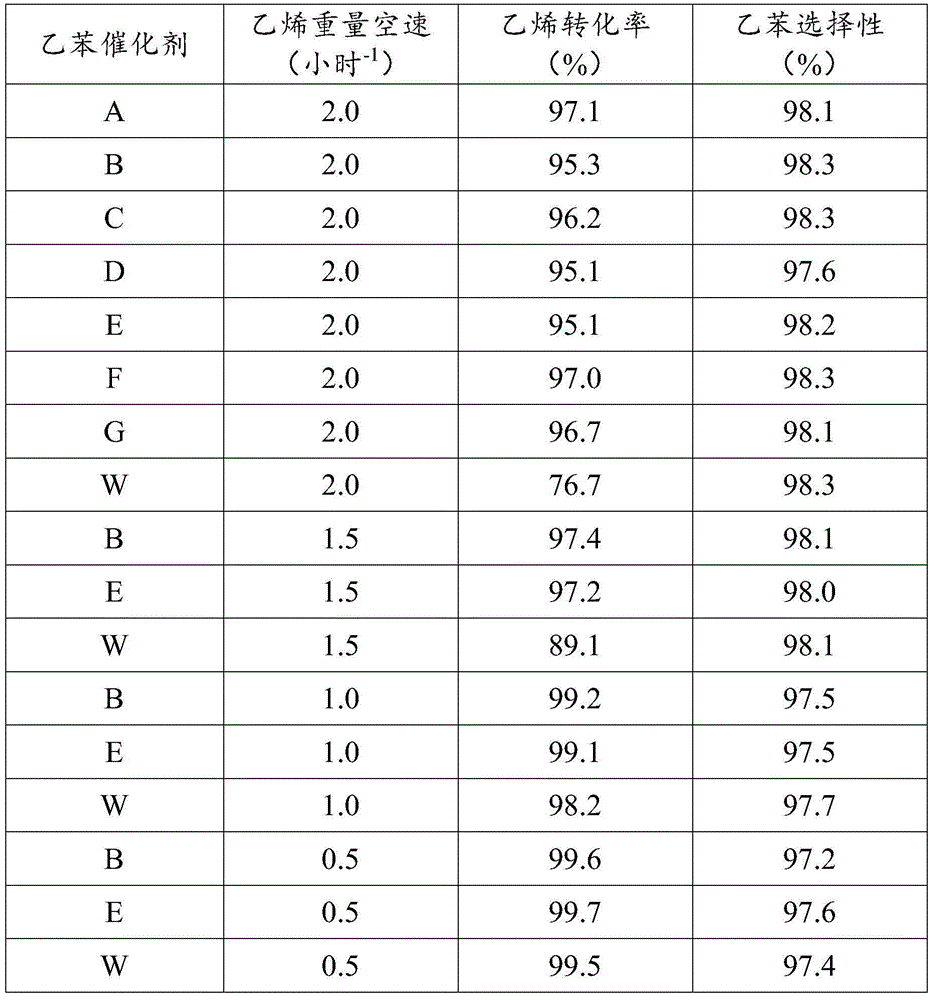

A method of synthesizing a mesoporous MCM-22 molecular sieve and uses of the molecular sieve

InactiveCN105439165ADiffusion fastHigh reaction space velocityMolecular sieve catalystsHydrocarbonsMolecular sieveSilicon

The invention relates to a method of synthesizing a mesoporous MCM-22 molecular sieve and uses of the molecular sieve, and mainly overcomes a problem in the prior art that synthetic methods of MCM-22 molecular sieves are tedious in operation and not suitable for industrial production. According to a technical scheme adopted by the method, a silicon source, an aluminum source, an alkali source containing OH<->, a template R, water and carbon black (C) are mixed, the mole ratio of Al2O3:SiO2:OH<->:R:H2O:C is (0.01-0.10):1:(0.01-0.40):(0.01-0.50):(5-50):(0.1-5.0), the mixture is crystallized at 130-170 DEG C for 20-100 h, and a crystallization product is washed with water, dried and calcinated to obtain the mesoporous MCM-22 molecular sieve. The problem is overcome by adoption of the technical scheme. The mesoporous MCM-22 molecular sieve can be used for industrial production of ethylbenzene produced from benzene and ethylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst and method for preparing butene-2 by hydroisomerization of butene-1

ActiveCN104437498BHigh yieldLow hydrogenation rateHydrocarbon by isomerisationHydrocarbon by hydrogenationAlkeneOrganic chemistry

The invention relates to a catalyst and a method for preparing butene-2 through butene-1 hydroisomerization. The technical problems in the prior art the n-butene hydroisomerization is low in conversion rate, the total olefin yield is low and the butene-2 is low in selectivity are mainly solved. With the adoption of the technical scheme, a mixed-phase alumina carrier consisting of theta-phase alumina and delta-phase alumina is adopted, the theta-phase alumina accounts for 60-90wt%, and the delta-phase alumina accounts for 10-40wt%. The problems are well solved, and the catalyst and method can be used for industrial production of cracking C4 fractions and increasing the yield of butene-2.

Owner:CHINA PETROLEUM & CHEM CORP +1

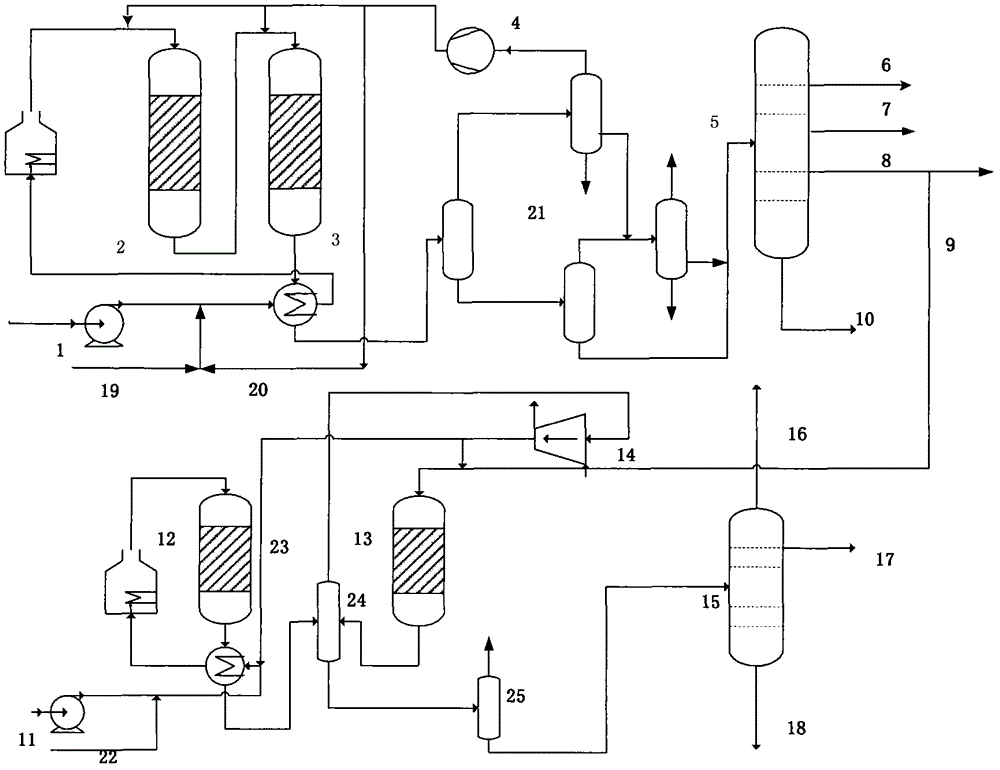

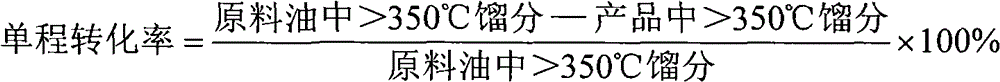

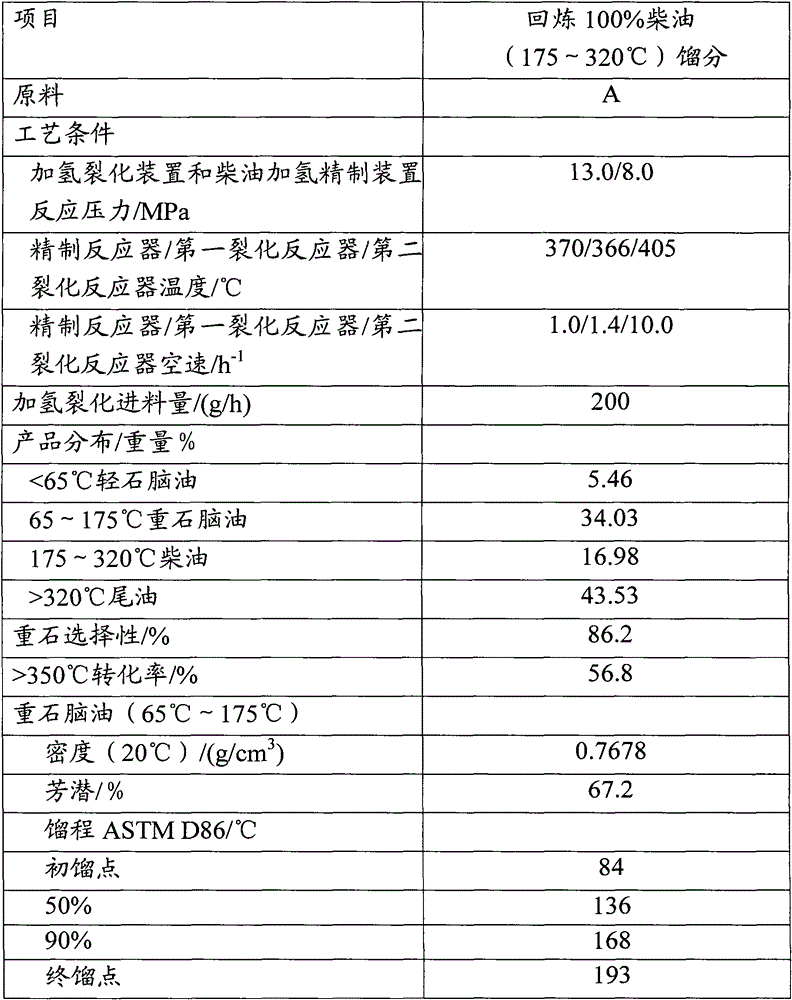

Combined hydrogenation method of producing chemical materials

ActiveCN103059972BHigh yieldHigh selectivityTreatment with hydrotreatment processesNaphthaDiesel fuel

The invention discloses a combined hydrogenation method of producing chemical materials. The method comprises the steps of: mixing hydrocracking material oil with hydrogen, and then entering a mixture into a hydrorefining reactor and a first hydrocracking reactor by adopting a once serial process; further cracking 10-100% diesel fraction with the temperature of 175-320 DEG C in the second hydrocracking reactor which is arranged in a diesel refining unit, wherein the cracked oil is a mixed fraction of naphtha and diesel; and further fractioning the mixed fraction in a fractionating system of the diesel refining device to obtain light naphtha, high-aromatic latent heavy naphtha and the diesel fraction. By adopting the method disclosed by the invention, the hydrocracking device and the diesel refining device are combined to produce the chemical material; and the reaction pressure of the diesel refining device is low and middle pressure, and improvement of the aromatic latent of the heavy naphtha and reduction of hydrogen consumption are facilitated in the second hydrocracking process.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for producing synthesis gas by dry reforming of methane

ActiveCN106608617BAvoid service lifeOvercome the defect of short service lifeHydrogenBulk chemical productionMetalReaction velocity

The invention relates to the field of preparation of synthetic gas through dry reforming of methane, and discloses a method for preparing synthetic gas through dry reforming of methane. The loading amount of an active metal component Ni in a catalyst in a catalyst bed of a dry reforming reaction of methane is controlled, and a Al2O3 carrier and / or a Al2O3 carrier modified with an auxiliary agent is adopted. Even in relatively high reaction velocity, temperature dispersion of the catalyst bed is basically uniform, and an area where carbon is easily thermodynamically accumulated can be avoided, so that the catalytic stability of a catalyst is greatly improved and the service life of the catalyst can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Two-stage fluidized bed CO dehydrogenation purification reaction technology and catalysts used

ActiveCN107497425BReduce consumptionHigh reaction space velocityCatalyst activation/preparationCarbon monoxideFluidized bedGas phase

The invention discloses a two-stage fluidized bed CO dehydrogenation purification reaction technology and a used catalyst. The reaction technology is as follows: two fluidized beds are in up-and-down arrangement, a reaction gas is fed in from the bottommost of a reactor, and enters an upper fluidized bed reactor for reaction, after heat exchange condensation of the gas reacted in the upper fluidized bed reactor, a gas phase component is used as a carbonylation reaction raw material gas, and a liquid component enters a storage tank. A catalyst used in a lower fluidized bed is PdAgClx / TiO2 (x = 1-3), can be used for selective oxidation of H2 at low temperature to reduce or avoid consumption of CO raw material gas, the H2 in the raw material gas CO is reduced to 5000ppm or less after reaction in the lower fluidized bed, a catalyst used in an upper fluidized bed is PdO-Ag2O / TiO2, can be used for oxidatively transform the H2 as much as possible at high temperature, and the H2 in the CO raw material gas is reduced to 50ppm or less after reaction in the upper fluidized bed. The method can effectively solve the industrial enlargement problem of raw material gas CO oxidation dehydrogenation process in coal-based ethylene glycol synthesis technology.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

TiO2 catalyst for catalytically eliminating benzene series in air and preparation method of TiO2 catalyst

PendingCN113083269ALow costHigh reaction space velocityPhysical/chemical process catalystsSurface reaction electrolytic coatingPtru catalystReaction temperature

The invention provides a TiO2 catalyst for catalytically eliminating benzene series in air, and belongs to the field of catalytic purification of benzene series pollution; the TiO2 catalyst is obtained through an anodic oxidation method, and has a porous ordered nanotube structure. The preparation process of the TiO2 catalyst comprises the steps of primary oxidation, secondary oxidation, ammonium fluoride soaking, high-temperature annealing and the like. According to the catalyst, the TiO2 oxide which is formed by oxidizing non-noble metal titanium and has a porous ordered nanotube structure is used as an active component, so that the cost of the catalyst is greatly reduced, and the catalyst is high in specific surface area and good in stability, shows good benzene series catalytic combustion activity at a high reaction air speed and a low reaction temperature, and has a good application value.

Owner:NANJING MASTER HEALTH TECH CO LTD

Carbon tetraolefin hydroisomerization catalyst and method

ActiveCN104437522BHigh yieldLow hydrogenation rateHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsState of artPore diameter

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst and method for preparing butene-2 through butene-1 hydroisomerization

ActiveCN104437498AAdjust hole structureHelp long runHydrocarbon by isomerisationHydrocarbon by hydrogenationButeneAlkene

The invention relates to a catalyst and a method for preparing butene-2 through butene-1 hydroisomerization. The technical problems in the prior art the n-butene hydroisomerization is low in conversion rate, the total olefin yield is low and the butene-2 is low in selectivity are mainly solved. With the adoption of the technical scheme, a mixed-phase alumina carrier consisting of theta-phase alumina and delta-phase alumina is adopted, the theta-phase alumina accounts for 60-90wt%, and the delta-phase alumina accounts for 10-40wt%. The problems are well solved, and the catalyst and method can be used for industrial production of cracking C4 fractions and increasing the yield of butene-2.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing alkylidene dibasic alcohol

ActiveCN1285554CReduce swellingImprove thermal stabilityBulk chemical productionPreparation by hydrolysisAlkaneHydration reaction

The invention relates to a method for preparing alkylene glycol, and mainly solves the problems of short service life and poor heat resistance of the catalyst used in the prior art under the condition of high conversion rate and selectivity. The present invention uses alkylene oxide and water as raw materials, at a reaction temperature of 60 to 150°C, a reaction pressure of 0.5 to 2.0 MPa, a water / alkylene oxide molar ratio of 5 to 15:1, and a liquid space velocity of 3 to 10 MPa. 6 hours -1 Under conditions, the raw material is contacted with a macroporous composite resin catalyst to generate an alkylene glycol, wherein the macroporous composite resin catalyst includes monomers, comonomers, nanomaterials, initiators, and auxiliary agent one and auxiliary agent two components, and OH for macroporous composite resin - , Cl - 、HSO 4 - 、HCO 3 - or HCOO - The technical scheme of anion compound treatment solves this problem well, and can be used in the industrial production of ethylene oxide catalytic hydration to form dihydric alcohol.

Owner:CHINA PETROLEUM & CHEM CORP +1

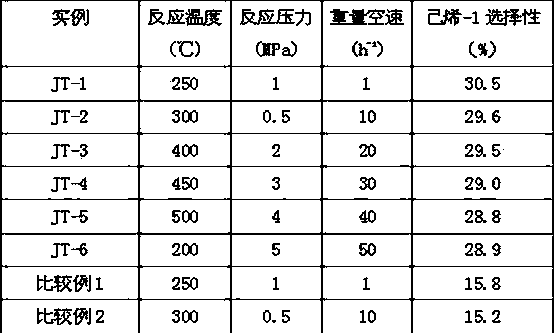

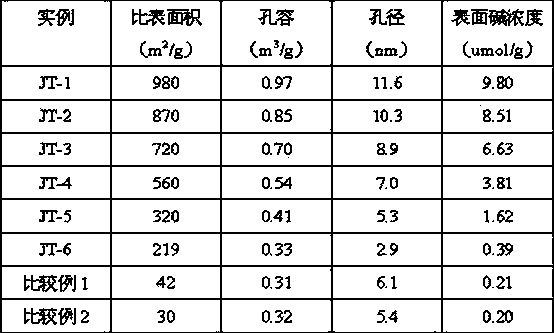

Method for preparing hexene-1 through C6 component isomerization

ActiveCN103420775AHigh selectivityHigh reaction space velocityHydrocarbon by isomerisationMetal/metal-oxides/metal-hydroxide catalystsIsomerizationReaction temperature

The present invention relates to a method for preparing hexene-1 through C6 component isomerization, wherein problems of low target product selectivity and low reaction space velocity in the prior art are mainly solved with the present invention. The technical scheme comprises that a C6 component is adopted as a raw material, and the raw material and a catalyst are subjected to a contact reaction at a reaction temperature of 200-400 DEG C under a reaction pressure of 0-5 MPa at a weight space velocity of 1-50 h<-1> to produce a hexene-1-containing effluent, wherein a specific surface area of the isomerization catalyst is 200-1000 m<2> / g, a pore volume is 0.3-1.0 m<3> / g, an average pore size is 6-12 nm, and a surface alkaline site concentration is 0.3-10.0 mumol / g. With the technical scheme, the problems in the prior art are well solved, and the method can be used for industrial production of hexene-1 preparation through mixing C6 component isomerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing hydrogen by catalytic partial oxidation of liquid hydrocarbon

The invention discloses a process for preparing hydrogen by catalytic partial oxidation of liquid hydrocarbon using nickel based and / or noble metal as supported catalyst of the active component, controlling the reaction temperature between 750-900 deg. C, airspeed between 1.0X10#+[3] l / kg / hí½12.5X10#+[5] l / kg / h, using oxygen as oxidation agent for partial oxidation reaction for the liquid hydrocarbons, wherein inert diluted gas can be added, the mol ratio of the inert diluted gas and liquid hydrocarbons is between 0-15.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing ethanediol by homogeneous catalytic hydration of epoxyethane

InactiveCN1245366CHigh catalytic activityImprove catalytic selectivityPreparation by hydrolysisSolubilityEthylene oxide

The invention relates to a kind of method of manufacturing ethylene glycol by homogeneous catalysis hydration with ethylene epoxide. The invention mainly solves the problems existed in previous technique, such as large use amount of catalyst, difficulty of separate and reclaiming-recycling usage, longer reaction time or long reaction time with no catalyst, and low selectivity of ethylene glycol. In the process of homogeneous catalysis hydration to manufacture ethylene glycol with ethylene epoxide, the invention uses neutral salt or weak acid salt or their mixture that all have solubility in reaction medium as catalyst, and controls the weight percent concentration of catalyst in reaction system with 10-3000ppm. The technique scheme described above can solve the problems mentioned above, and can be used in industrial production of homogeneous catalysis hydration to manufacture ethylene glycol with ethylene epoxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing alkylidene dibasic alcohol

ActiveCN1285553CReduce swellingImprove thermal stabilityBulk chemical productionPreparation by hydrolysisAlkaneHydration reaction

The invention relates to a method for preparing alkylene dihydric alcohols, and mainly solves the problems of short service life and poor heat resistance of catalysts used in the prior art under conditions of high conversion rate and selectivity. The present invention uses alkylene oxide and water as raw materials, at a reaction temperature of 60 to 150°C, a reaction pressure of 0.5 to 2.0 MPa, a water / alkylene oxide molar ratio of 5 to 15:1, and a liquid space velocity of 3 to 10 MPa. 6 hours -1 Under the conditions, the raw material is contacted with the composite resin catalyst to generate alkylene glycol, wherein the composite resin catalyst includes monomers, comonomers, nanomaterials, initiators and auxiliary components, and the composite resin uses OH - , Cl - 、HSO 4 - 、HCO 3 - or HCOO - The technical scheme of anion compound treatment solves this problem well, and can be used in the industrial production of ethylene oxide catalytic hydration to form dihydric alcohol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com