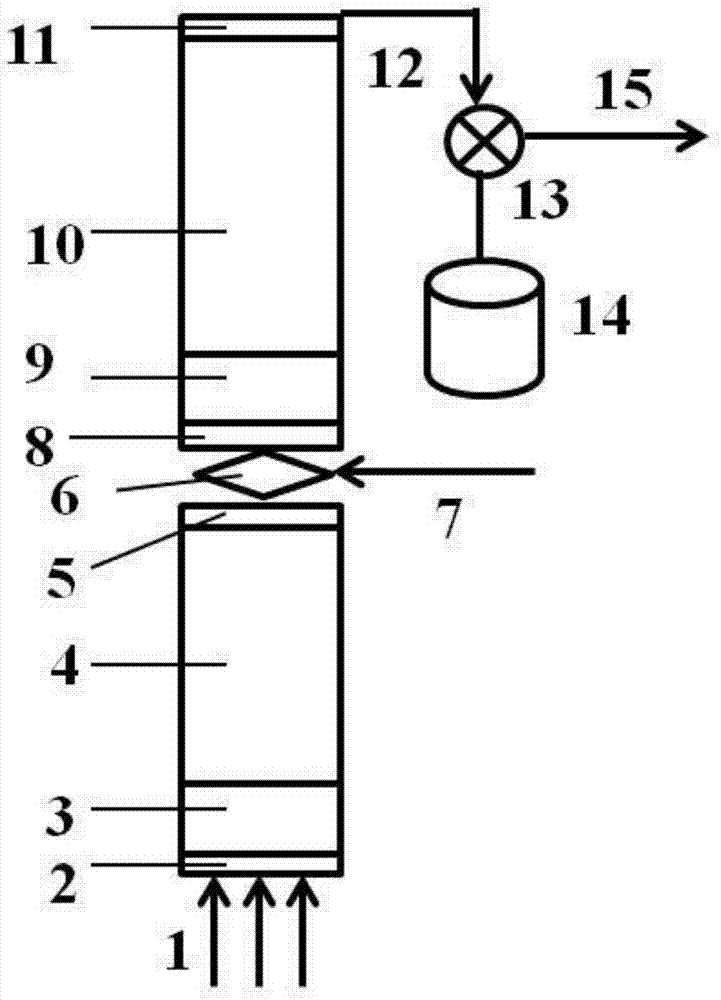

Two-stage fluidized bed CO dehydrogenation purification reaction technology and used catalyst

A fluidized bed and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst activation/preparation, etc. Hydrogen reaction space velocity limitation, the reactor is not easy to be over-amplified and other problems, to achieve the effect of solving industrial amplification problems, high selectivity and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: one, the preparation of lower end fluidized bed catalyst:

[0031] Take by weighing 200g of spherical titanium oxide with a diameter of 2-3mm, prepare the catalyst according to the mass percentage of Pd in the catalyst (referred to as the loading capacity) of the catalyst being 0.8%, and the loading capacity of Ag being 0.8%, and the steps are as follows:

[0032] According to the loading capacity of Pd, 2.67g of palladium chloride and 1.75g of sodium chloride (molar ratio is 1:2) were dissolved in 200ml of deionized water to prepare sodium chloropalladate impregnation solution, and the titanium oxide The carrier was immersed in the impregnating solution for 12 hours, and the solution was filtered out. The carrier impregnated with Pd was dried in an oven at 150°C for 8 hours, washed with deionized water at 50°C for 3 times, and then the sample was dried in an oven at 150°C. 10h;

[0033] 2.55gAgNO 3 Dissolve in 200ml deionized water to prepare silver...

Embodiment 2

[0040] Prepare lower end catalyst PdAgClx / TiO according to the catalyst preparation method of embodiment 1 2 , wherein the loading of Pd is 0.6%, and the loading of Ag is 0.6%.

[0041] According to the catalyst preparation method of Example 1, prepare the top catalyst PdO-Ag 2 O / TiO 2 , wherein the loading of Pd is 0.4%, and the loading of Ag is 0.4%.

[0042] React according to the reaction technique of embodiment 1 and feed gas, in the gas of lower end fluidized bed outlet, H 2 The content is 3650ppm, O 2 The content is 670ppm, and the H in the gas at the outlet of the fluidized bed at the upper end 2 The content is 10ppm.

Embodiment 3

[0044] According to the catalyst preparation method of Example 1, the PdAgCl / TiO with a Pd loading of 0.4% and an Ag loading of 0.4% was obtained 2 Catalyst and PdO-Ag with 0.9% Pd loading and 0.9% Ag loading 2 O / TiO 2 catalyst.

[0045] React according to the reaction technique of embodiment 1 and feed gas, in the gas of lower end fluidized bed outlet, H 2 The content is 4770ppm, O 2 The content is 1670ppm, and the H in the gas at the outlet of the fluidized bed at the upper end 2 The content is 0ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com