Method for prolonging running period of acrylic acid device

A technology of operation cycle and acrylic acid, applied in chemical instruments and methods, preparation of carboxylate, preparation of organic compounds, etc., can solve the problems of decreasing catalyst activity, affecting economic benefits, reducing hot spot temperature of catalyst bed, etc. temperature, the effect of prolonging the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] Preparation of coated catalyst 1

[0020] Dissolve 339g of ammonium paramolybdate in 2400ml of pure water, add 520ml of 25% ammonia solution; dissolve 242g of cobalt nitrate and 130g of nickel nitrate in 300ml of pure water; water, in addition, 116g of ferric nitrate was dissolved in 300ml of water. At 50°C, add the mixed solution of cobalt nitrate and nickel nitrate to the vigorously stirred ammonium molybdate solution added with 5% citric acid-polyvinylpyrrolidone in advance, and react to form a sol. After half an hour, add the mixed solution of bismuth nitrate and iron nitrate, and add ammonia water or nitric acid during the addition to keep the pH value of the system between 1-6, so that the above-mentioned aqueous slurry can be obtained. After cooling the slurry to below 40° C., 720 ml of ethanol was added and stirred at high speed to form a water-organic phase slurry.

[0021] On the basis of continuously replenishing ethanol, the water in the slurry is separate...

Embodiment 1

[0035] (Propylene Oxidation Reaction)

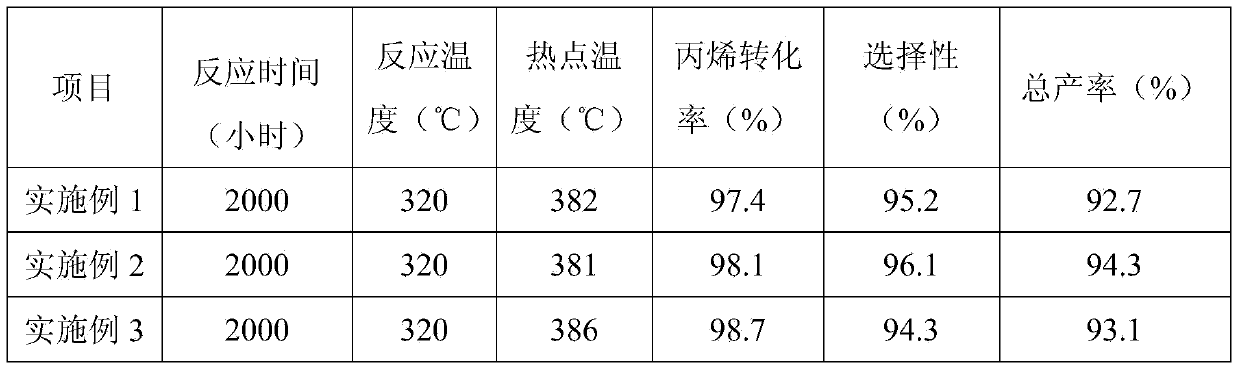

[0036] In a reaction tube with an inner diameter of 25 mm and a length of 4800 mm, the catalyst prepared in the above reference example is used to fill it to form a catalyst bed with a packing height of 3500 mm, and the remaining space in the reaction tube is filled with inert fillers. The specific loading method of the catalyst bed is: the catalyst bed near the reaction tube outlet is filled with the coating catalyst 2 carrying 33% active components, and the filling height is 2500mm; the catalyst bed near the reaction tube inlet is filled with the described The coated catalyst 1 loaded with 20% active components has a packing height of 1000mm. Feed into the feed gas consisting of 10% concentration of propylene, 17% concentration of steam and 73% concentration of air, at a pressure of 0.1MPa, the gas volume space velocity is 1800hr -1 propylene oxidation reaction. The resulting reaction structures are shown in Table 1.

Embodiment 2

[0038] (Propylene Oxidation Reaction)

[0039] In a reaction tube with an inner diameter of 25 mm and a length of 4800 mm, the catalyst prepared in the above reference example is used to fill it to form a catalyst bed with a packing height of 3500 mm, and the remaining space in the reaction tube is filled with inert fillers. The specific loading method of the catalyst bed is: the catalyst bed near the reaction tube outlet is filled with the coating catalyst 3 carrying 50% active components, and the filling height is 2500mm; the catalyst bed near the reaction tube inlet is filled with the described The coated catalyst 1 loaded with 20% active components has a packing height of 1000 mm. Feed into the feed gas consisting of 10% concentration of propylene, 17% concentration of steam and 73% concentration of air, at a pressure of 0.1MPa, the gas volume space velocity is 1800hr -1 propylene oxidation reaction. The resulting reaction structures are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com