Nickel base crouse vent gas hydrogenation catalysts and coprecipitation manufacturing method

A technology of hydrogenation catalyst and Claus tail gas, which is applied in the direction of chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of expensive catalyst and achieve good Low-temperature catalytic activity, simple preparation method, and the effect of reducing construction and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

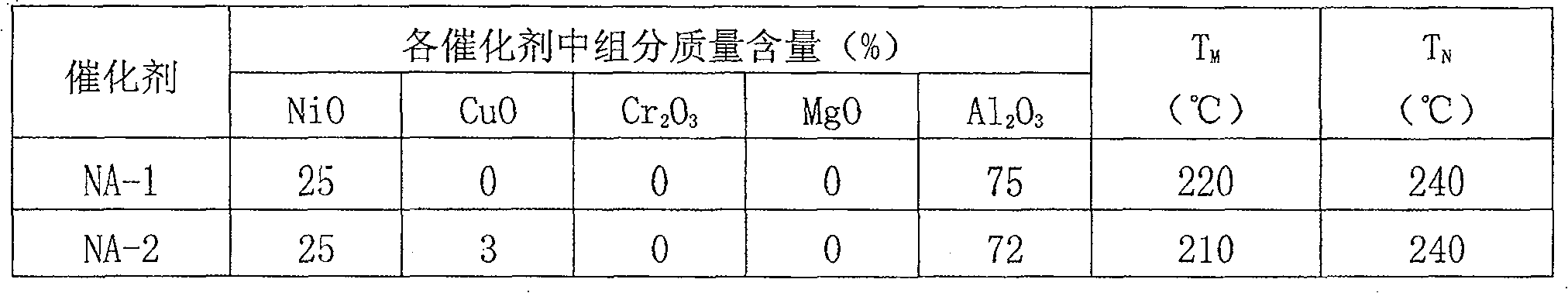

[0020] A nickel-based Claus tail gas hydrogenation catalyst, which consists of main active components NiO, alumina (Al 2 o 3 ) components, the mass percentage of each component is: the main active component NiO 25%, aluminum oxide 75%. See NA-1 of Table 2.

[0021] A kind of coprecipitation preparation method of nickel-based Claus tail gas hydrogenation catalyst, it comprises the steps:

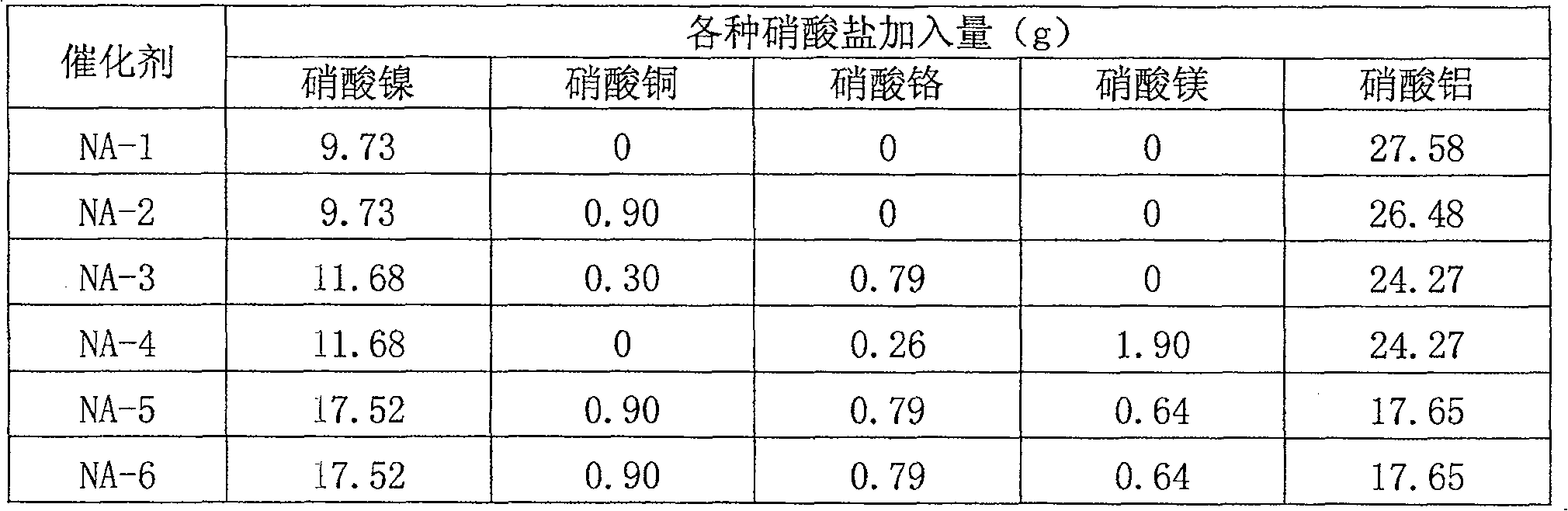

[0022] 1) Dissolve a certain amount of nickel nitrate and aluminum nitrate (see NA-1 in Table 1 for the specific addition amount, 9.73 grams of nickel nitrate, and 27.58 grams of aluminum nitrate) in 250 ml of deionized water to form a mixed solution A;

[0023] 2) Prepare an aqueous solution B of polyethylene glycol with a mass concentration of 10%, wherein the molecular weight of polyethylene glycol is 2000, and set aside;

[0024] 3) Under constant stirring at 60°C, add ammonia solution and mixed solution A with a mass concentration of 10% to 250ml aqueous solution B at the same time, c...

Embodiment 2

[0030] A nickel-based Claus tail gas hydrogenation catalyst, which is composed of three components: main active component, auxiliary active component and alumina, and the mass percentage of each component is: main active component 25%, auxiliary active The composition is 3%, and the aluminum oxide is 72%. Among them, the main active component is nickel oxide, and the auxiliary active component is copper oxide.

[0031] A kind of coprecipitation preparation method of nickel-based Claus tail gas hydrogenation catalyst, it comprises the steps:

[0032] 1) A certain amount (see NA-2 in Table 1 for specific additions, 9.73 grams of nickel nitrate, 0.90 grams of copper nitrate, 26.48 grams of aluminum nitrate) of nickel nitrate, aluminum nitrate and auxiliary components were dissolved in 250ml of deionized water to prepare Mixed solution A; the auxiliary component is copper nitrate;

[0033]2) Prepare an aqueous solution B of polyethylene glycol with a mass concentration of 10%, wh...

Embodiment 3

[0038] A nickel-based Claus tail gas hydrogenation catalyst, which is composed of three components: main active component, auxiliary active component and alumina, and the mass percentage of each component is: main active component 30%, auxiliary active Component 4%, alumina 66%; wherein, the main active component is nickel oxide, the auxiliary active components are chromium oxide and copper oxide, and the mass percentages of chromium oxide and copper oxide are: chromium oxide 3%, copper oxide 1 %.

[0039] A kind of coprecipitation preparation method of nickel-based Claus tail gas hydrogenation catalyst, it comprises the steps:

[0040] 1) A certain amount (see NA-3 in Table 1 for the specific addition amount, 11.68 grams of nickel nitrate, 0.30 grams of copper nitrate, 0.79 grams of chromium nitrate, 24.27 grams of aluminum nitrate) nickel nitrate, aluminum nitrate and auxiliary components were dissolved in 250ml In deionized water, mixed solution A is made, and the auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com