Dechlorination hydrogen production device for treating PVC-containing plastic wastes

A technology for hydrogen production device and plastic waste, applied in plastic recycling, hydrogen, fuel, etc., can solve problems such as uneven temperature distribution, restrictions on wide application, and insufficient combustion, so as to reduce reaction temperature, improve utilization rate, reduce Effect of Reactor Volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

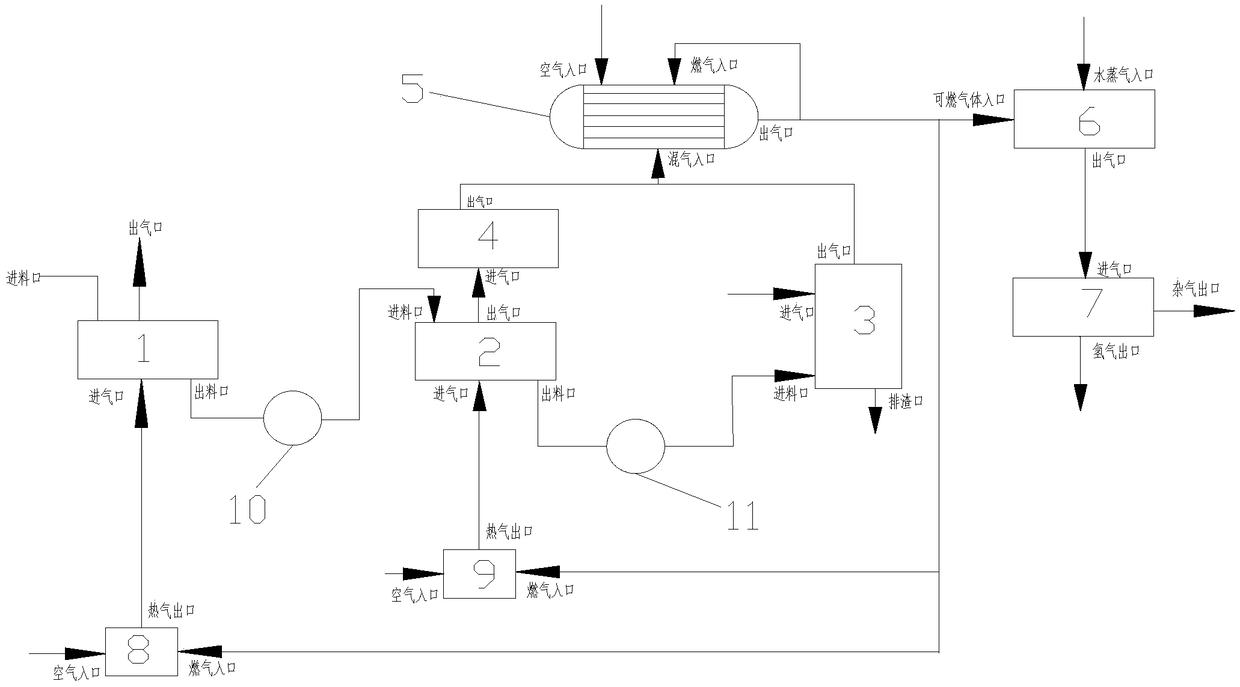

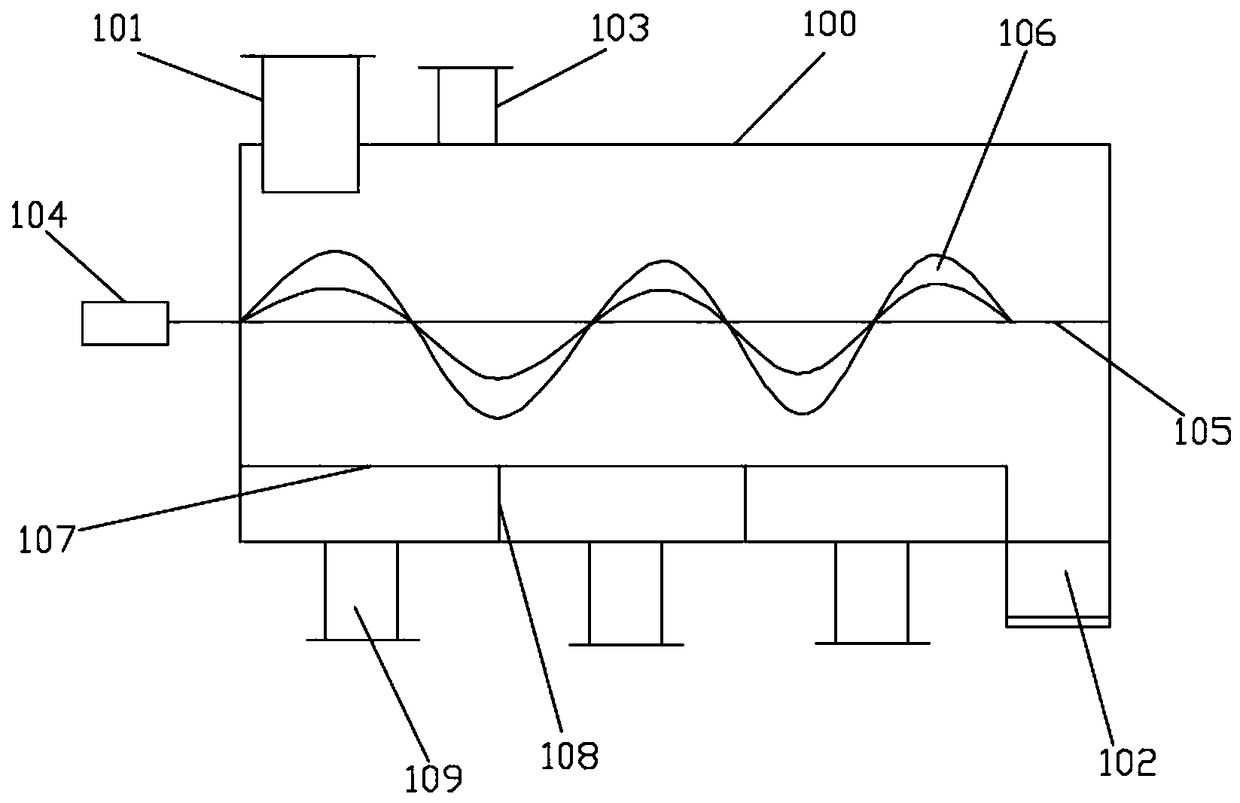

[0023] Please refer to Figure 1 to Figure 2 , a hydrogen dechlorination device for processing plastic waste containing PVC, comprising a first spiral moving bed 1, a second spiral moving bed 2, a fluidized bed 3, a dechlorination tower 4 and a tar cracker 5; the first A spiral moving bed 1 is used for drying and dehydrating plastic waste containing PVC to obtain dry dehydrated materials; a second spiral moving bed 2 is used for high-temperature pyrolysis of dry and dehydrated materials to generate high-temperature pyrolysis gas and waste materials; Bed 3 is used for high-temperature vaporization of high-temperature pyrolysis waste, and produces vaporized gas and ash; dechlorination tower 4 is used for dechlorination treatment of high-temperature pyrolysis gas, and dechlorination gas is obtained; tar cracker 5 is used for The mixed gas of vaporized gas and dechlorinated gas is subjected to tar cracking treatment to obtain harmless combustible gas.

[0024] It can be seen from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com