A kind of production technology that uses anthraquinone method to prepare hydrogen peroxide

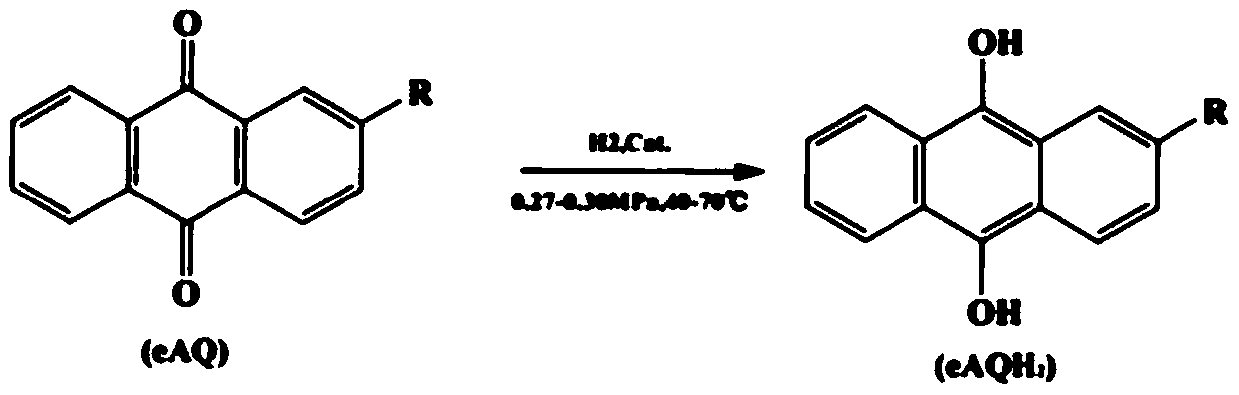

A hydrogen peroxide, production process technology, applied in the directions of peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, chemical instruments and methods, etc. Uneven cooling, incomplete oxidation of hydrogenation liquid, etc., to achieve the effect of strengthening catalytic hydrogenation reaction and oxidation reaction, strengthening gas-liquid/liquid-liquid mass transfer, good stability and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

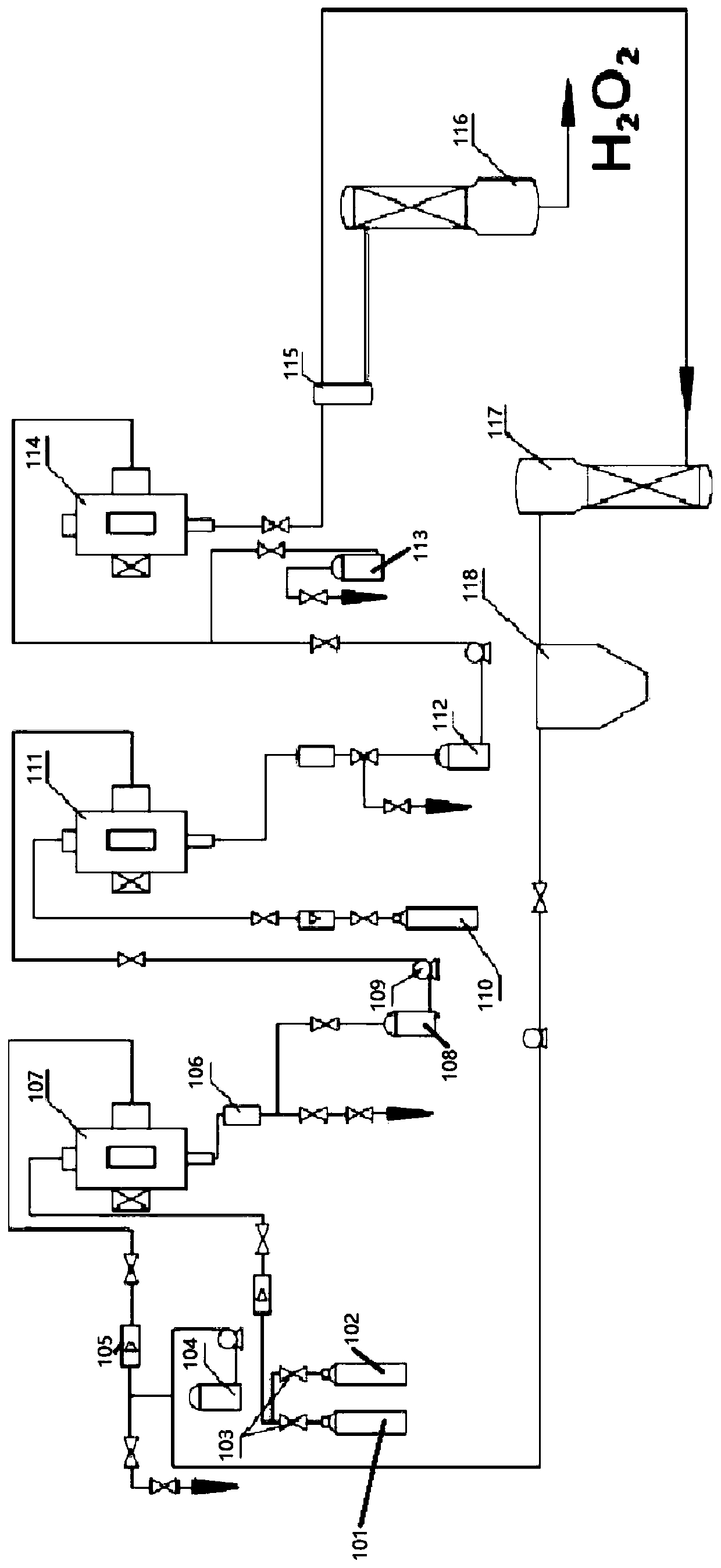

[0087] Such as figure 2 Shown, a kind of production technology that uses anthraquinone method to prepare hydrogen peroxide comprises the steps:

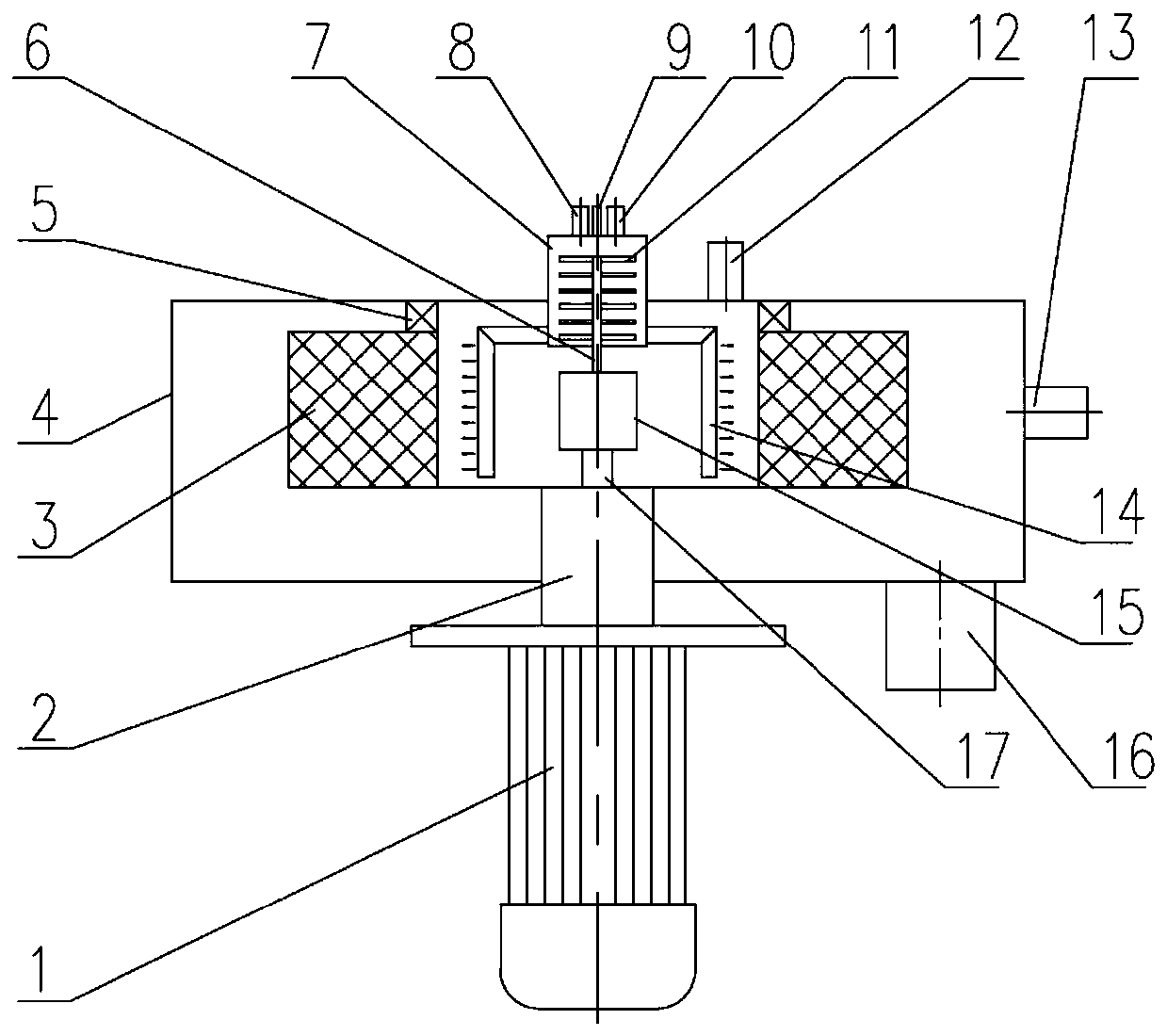

[0088] (1) Pd / Al 2 o 3 The catalyst is loaded in the rotor of the hydrogenation supergravity reactor, the solution containing anthraquinone is poured into the raw material tank, and the feeding pump is turned on to make the liquid circulate and fully wet the catalyst;

[0089] The solution containing anthraquinone is composed of 1,3,5-trimethylbenzene, trioctyl phosphate and 2-ethylanthraquinone; the volume ratio of 1,3,5-trimethylbenzene to trioctyl phosphate is 75:25 The concentration of 1,3,5-trimethylbenzene is 660mL / L; the concentration of trioctyl phosphate is 220mL / L; the concentration of 2-ethylanthraquinone is 120g / L.

[0090] (2) Introduce nitrogen to purge the hydrogenation high-gravity rotating bed reactor; after introducing hydrogen for reduction and activation for 1-24 hours, exhaust it with nitrogen; open the high-...

Embodiment 2

[0100] Such as figure 2 Shown, a kind of production technology that uses anthraquinone method to prepare hydrogen peroxide comprises the steps:

[0101] (1) Pd / Al 2 o 3 The catalyst is loaded in the rotor of the hydrogenation supergravity reactor, the solution containing anthraquinone is poured into the raw material tank, and the feeding pump is turned on to make the liquid circulate and fully wet the catalyst;

[0102] The solution containing anthraquinone is composed of 1,3,5-trimethylbenzene, trioctyl phosphate and 2-ethylanthraquinone; wherein the volume ratio of 1,3,5-trimethylbenzene and trioctyl phosphate is 80: 25; the concentration of 1,3,5-trimethylbenzene is 760mL / L; the concentration of trioctyl phosphate is 240mL / L; the concentration of 2-ethylanthraquinone is 110g / L;

[0103] (2) Introduce nitrogen to purge the hydrogenation high-gravity rotating bed reactor; after introducing hydrogen for reduction and activation for 1-24h, exhaust it with nitrogen; open the...

Embodiment 3

[0113] Such as figure 2 Shown, a kind of production technology that uses anthraquinone method to prepare hydrogen peroxide comprises the steps:

[0114] (1) Pd / Al 2 o 3 The catalyst is loaded in the rotor of the hydrogenation supergravity reactor, the solution containing anthraquinone is poured into the raw material tank, and the feeding pump is turned on to make the liquid circulate and fully wet the catalyst;

[0115] The solution containing anthraquinone is composed of 1,3,5-trimethylbenzene, trioctyl phosphate and 2-ethylanthraquinone; wherein the volume ratio of 1,3,5-trimethylbenzene and trioctyl phosphate is 80: 20; the concentration of 1,3,5-trimethylbenzene is 800mL / L; the concentration of trioctyl phosphate is 200mL / L; the concentration of 2-ethylanthraquinone is 110g / L.

[0116] (2) Introduce nitrogen to purge the hydrogenation supergravity rotary bed reactor; after introducing hydrogen for reduction and activation for 1-24h, exhaust it with nitrogen; open the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| oxidation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com