Method for preparing hexene-1 through C6 component isomerization

A technology for isomerization and hexene, which is used in isomerization to produce hydrocarbons, chemical instruments and methods, organic chemistry, etc., and can solve the problems of low selectivity of target products and low reaction space velocity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

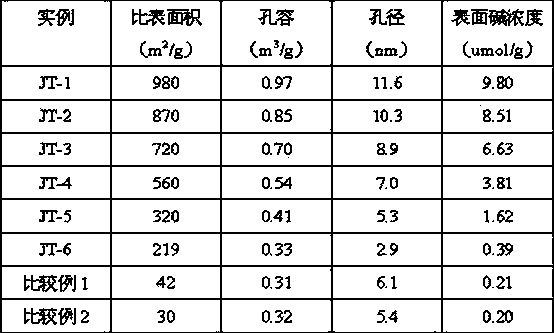

[0024] Weigh 50 grams of commercial MgO, add 112.5 grams of oxalic acid, and add an acid solution with a mass concentration of 5%. After the mixed solution is heated and stirred in a water bath at 50°C for 5 hours, the water in the solution is filtered with suction, and the product is dried at 120°C for 6 hours. The obtained product was calcined at 400° C. for 5 hours, and the obtained product was designated as JT-1.

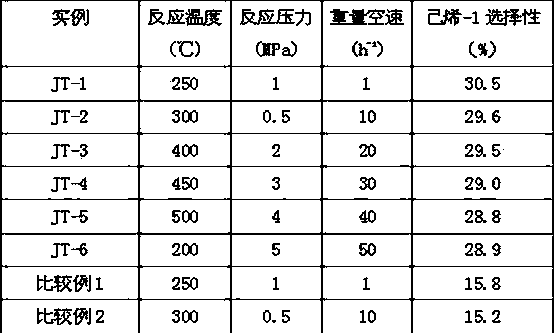

[0025] Install 10 grams of catalyst in a Φ25mm fixed-bed reactor, use mixed C6 components as raw materials at a weight space velocity of 1 hour -1 , 250°C and 1MPa conditions to evaluate the catalyst performance, the results are shown in Table 2.

[0026]

Embodiment 2

[0028] Weigh 50 grams of commercial MgO, add 120.09 grams of citric acid, and a solution with a mass concentration of 1%, to obtain a mixed solution, heat and stir it in a water bath at 80°C for 4 hours, then let it stand for 3 hours, filter the water in the solution, and the product is at 80°C After drying for 3 hours, the resulting product was supported on SiO 2 (5% by mass), calcined at 500°C for 8 hours, and the obtained product is designated as JT-2.

[0029] Install 10 grams of catalyst in a Φ25mm fixed-bed reactor, and use mixed C6 components as raw materials at a weight space velocity of 10 hours -1 , 300°C and 0.5MPa conditions to evaluate the catalyst performance, the results are shown in Table 2.

[0030]

Embodiment 3

[0032] Weigh 50 grams of commercial CaO, add 5.54 grams of carbonic acid, and a solution with a mass concentration of 10%, to obtain a mixed solution, heat and stir in a water bath at 90°C for 1 hour, then let it stand for 3 hours, filter the water in the solution, and bake the product at 100°C After drying for 10 hours, the obtained product was supported on activated carbon (mass content 10%), and calcined at 300°C for 12 hours, and the obtained product was designated as JT-3.

[0033] Install 10 grams of catalyst in a Φ25mm fixed-bed reactor, and use mixed C6 components as raw materials at a weight space velocity of 20 hours -1 , Catalyst performance was evaluated at 400°C and 2MPa, the results are shown in Table 2.

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com