C_4 olefin hydroisomerization catalyst and C_4 olefin hydroisomerization method

A technology for hydroisomerization and carbon tetraolefins, which is applied in the field of carbon tetraolefin hydroisomerization catalysts, can solve the problems of high catalyst cost, low olefin yield, and low reaction equilibrium index, and achieve low olefin hydrogenation rate, The effect of high reaction space velocity and improvement of the ability to resist the formation of green oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

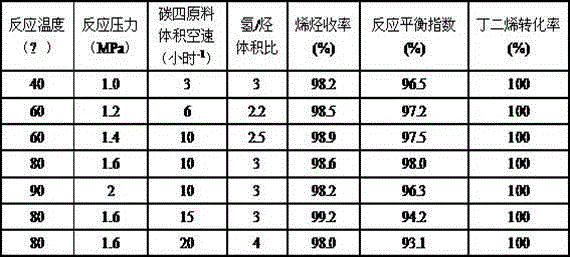

Examples

Embodiment 1

[0030] Weigh 30 grams of pseudo-boehmite, 140 grams of θ-alumina, 40 grams of δ-alumina, 9 grams of scallop powder, 40 grams of silica sol, mix, and then add polyvinyl alcohol-containing solution (mass concentration is 5%) 25 grams, 4.0 grams of nitric acid with a concentration of 68%, 310 ml of aqueous solution, extruded into a clover-shaped carrier with a diameter of 2.5 mm, and the wet strip was passed through 120 o C dried for 4 hours at 750 o C roasting for 4 hours. Vector Z1 was prepared.

[0031] Mix ammonium molybdate: nickel carbonate: ammonium carbonate: ammonia water = 0.005: 1.0: 1.0: 2.0 in proportion and stir evenly to prepare a solution with a metal nickel content of 10% and a molybdenum content of 0.1%, and place the carrier Z1 in the solution Equal impregnation in 60 o C drying for 8 hours, 450 o C was calcined for 4 hours to obtain Ni-based catalyst C1. The catalyst composition is shown in Table 1, wherein the contents of each component are based on the ...

Embodiment 2

[0034]Weigh 30 grams of pseudo-boehmite, 140 grams of θ-alumina, 20 grams of δ-alumina, 9 grams of scallop powder, 60 grams of silica sol, mix, and then add polyvinyl alcohol-containing solution (mass concentration is 5%) 25 grams, 4.0 grams of nitric acid with a concentration of 68%, 0.5 grams of magnesium nitrate, 310 ml of aqueous solution, extruded into a clover-shaped carrier with a diameter of 2.5 mm, and the wet strip was passed through 120 o C dried for 4 hours at 750 o C roasting for 4 hours.

[0035] Mix ammonium molybdate: nickel carbonate: ammonium carbonate: ammonia water = 0.02: 1.2: 1.0: 2.0 in proportion and stir evenly to prepare a solution with a metal nickel content of 12% and a molybdenum content of 0.5%, and place the carrier Z2 in the solution The same amount of impregnation is carried out in the impregnation solution, and the carrier is impregnated with the same amount in the impregnation solution, 60 o C drying for 8 hours, 450 o C was calcined for 4...

Embodiment 3

[0038] Weigh 30 grams of pseudo-boehmite, 140 grams of θ-alumina, 80 grams of δ-alumina, 9 grams of scallop powder, 80 grams of silica sol, mix, and then add polyvinyl alcohol-containing solution (mass concentration is 5%) 25 grams, 4.0 grams of nitric acid with a concentration of 68%, 0.1 g of magnesium nitrate, 310 ml of aqueous solution, extruded into a clover-shaped carrier with a diameter of 2.5 mm, and wet strips after 120 o C dried for 4 hours at 750 o C roasting for 4 hours. Vector Z3 was prepared.

[0039] Mix ammonium molybdate: nickel carbonate: ammonium carbonate: ammonia water = 0.05: 1.25: 1.0: 2.0 in proportion and stir evenly to prepare a solution with a metal nickel content of 13% and a molybdenum content of 1.5%, and place the carrier Z3 in the solution Equal impregnation in 60 o C drying for 8 hours, 450 o C was calcined for 4 hours to obtain Ni-based catalyst C3. The catalyst composition is shown in Table 1, wherein the contents of each component are b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com