Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "High isomerization activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alumina supporter containing modified gamma zeolite and its preparation method

ActiveCN1765492ALowering the freezing pointReduce crackingMolecular sieve catalystsCatalyst activation/preparationIon exchangeMetal

The invention discloses an alumina support containing Y zeolite and relative preparing method. The carrier utilizes the Y zeolite and alumina as carriers, while the property of zeolite can be changed via changing the metallic positive ions between the VIB group and / or VIII group to adjust the acid distribution, especially the proportion of B acid and L acid. The invention can be used a carrier of hydro-treating catalyst to fraction prepare the winter cleaning diesel fuel from poor diesel fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

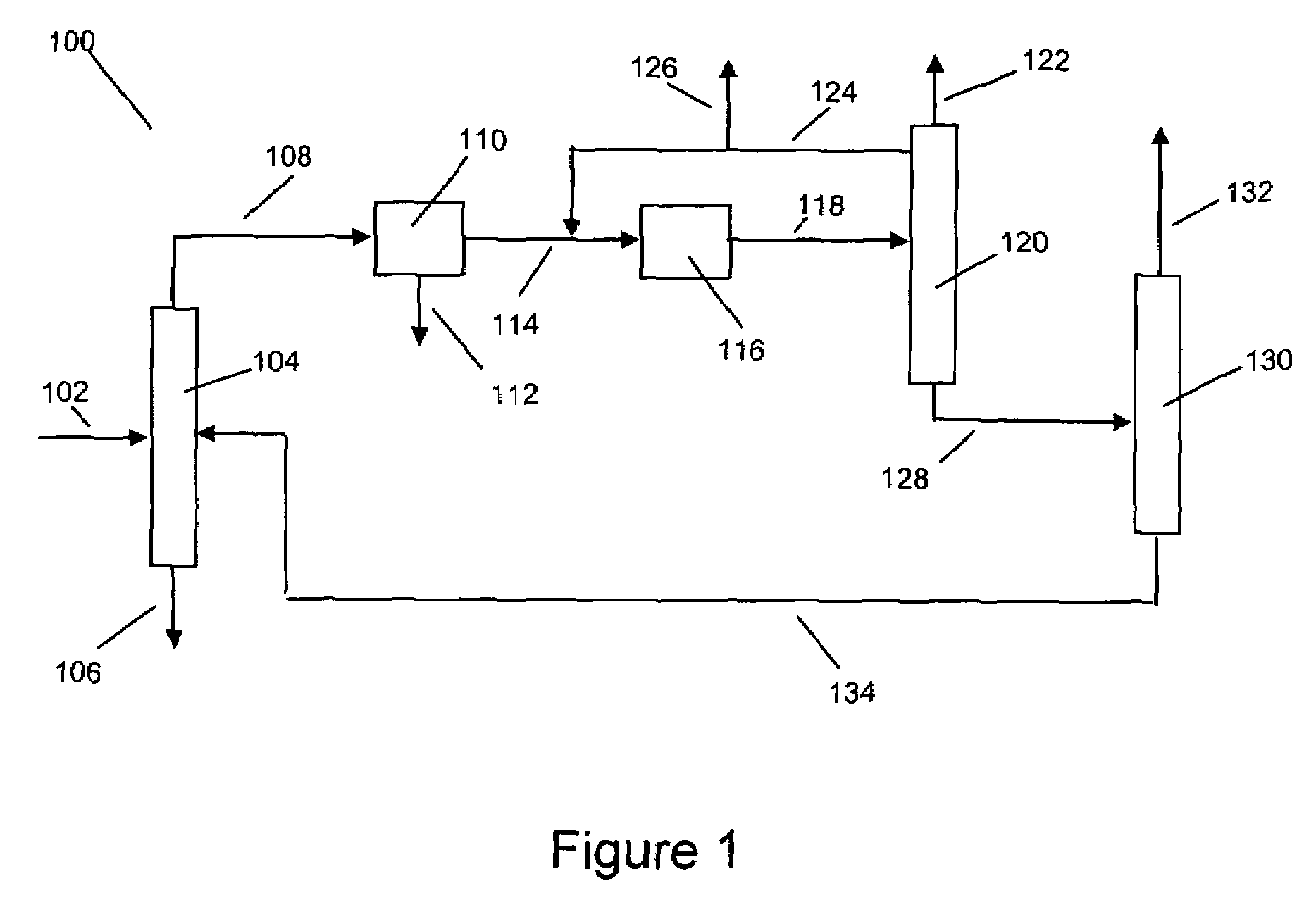

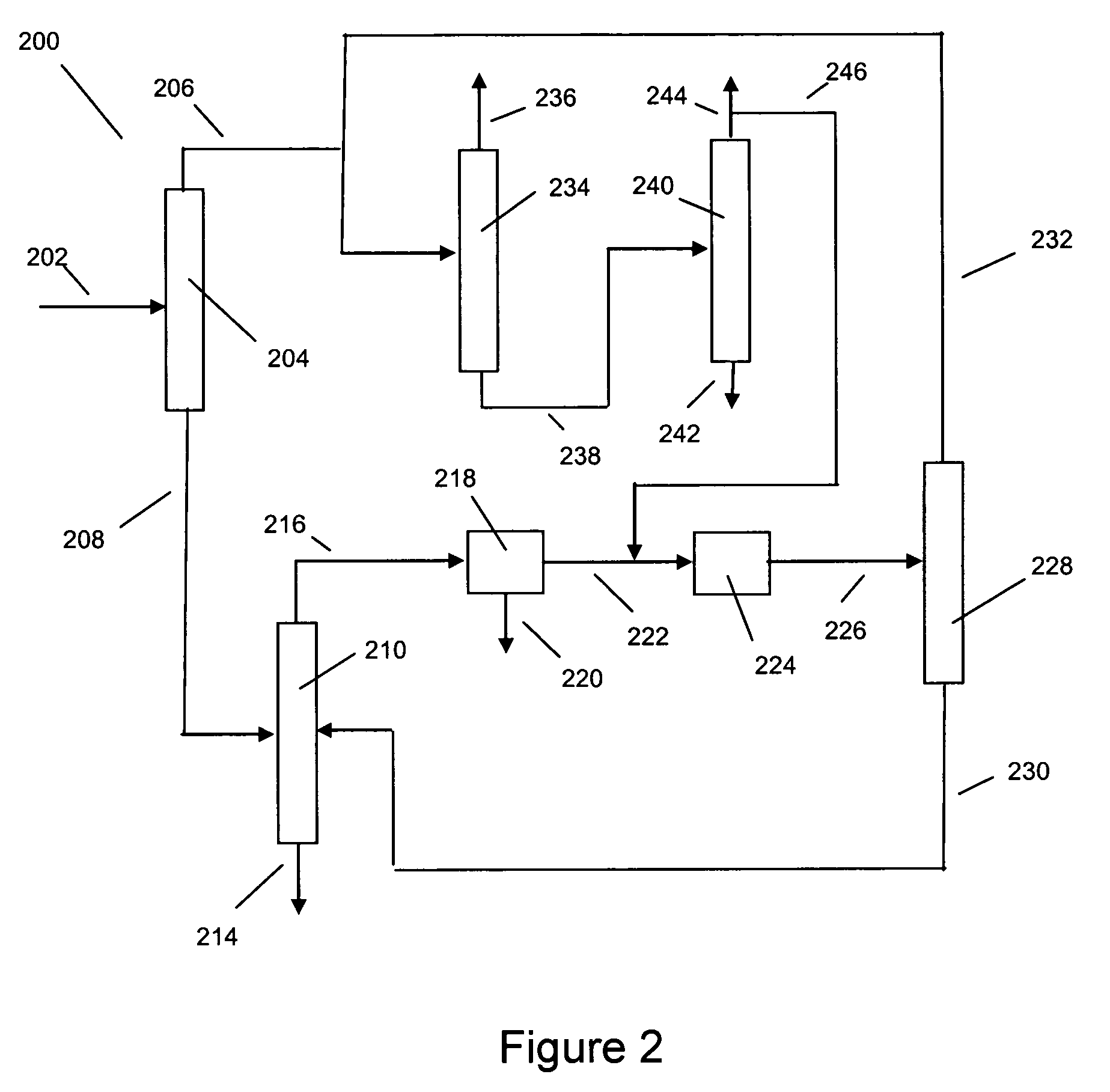

Xylene isomerization process and apparatus

InactiveUS8134037B2Speed up the processHigh isomerization activityHydrocarbon by isomerisationPhysical/chemical process catalystsIsomerizationXylene

Xylene isomerization processes, especially those processes in which ethylbenzene is also converted, are beneficially affected by adding benzene to the feed.

Owner:UOP LLC

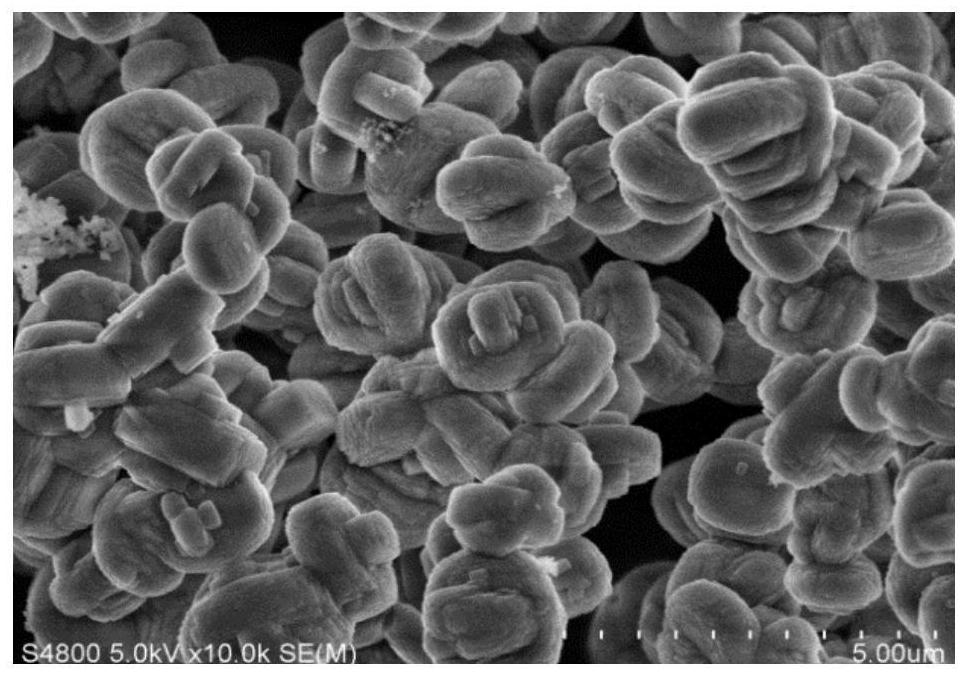

N-alkane low-temperature isomerization catalyst as well as preparation method and application thereof

ActiveCN105080578AHigh activityImprove stabilityHydrocarbon by isomerisationPhysical/chemical process catalystsAlkaneIsomerization

The invention discloses an n-alkane low-temperature isomerization catalyst as well as a preparation method and an application of the n-alkane low-temperature isomerization catalyst. The catalyst disclosed by the invention comprises the following components in percentage by weight: 0.1%-1.0% of loaded metal Pt, 5.0%-10.0% of an element Cl, and the balance of a carrier gamma-Al2O3. The preparation method of the catalyst disclosed by the invention comprises the following steps: dipping chloroplatinic acid on the carrier gamma-Al2O3, and then drying and roasting to obtain Pt / gamma-Al2O3 catalyst containing 0.1%-1% of the Pt; and firstly reducing a platinum-containing catalyst, then uniformly dipping a chlorinating agent on the surface of the Pt / gamma-Al2O3 catalyst by adopting a chlorinating way of liquid-phase dipping, and then carrying out programmed warming for curing the chlorinating agent to obtain the Pt / gamma-Al2O3-Cl n-alkane isomerization catalyst with high chloride loading quantity (5%) and uniform distribution of the chlorine element. The catalyst provided by the invention has relatively high chlorine content, also has good chlorine distribution, and achieves high acidity loading quantity, high isomerization activity and high stability of the catalyst.

Owner:BEIJING SINO SPHERE PETROCHEM TECH CO LTD

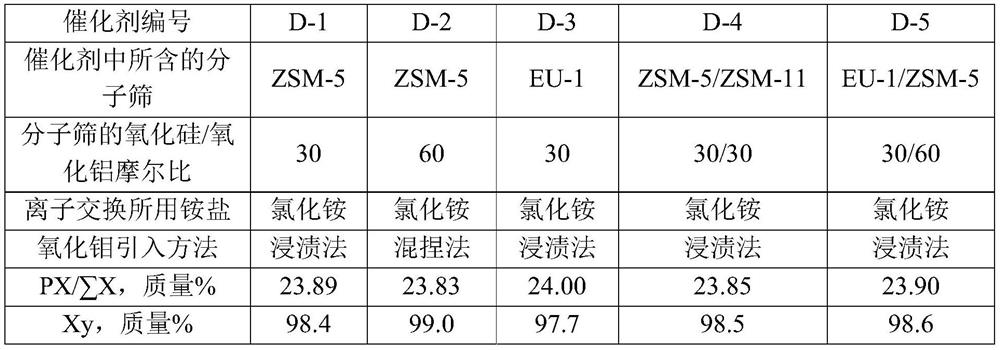

Ethylbenzene conversion and xylene isomerization processes and catalysts therefor

InactiveUS7381677B1Reduced activityHigh isomerization activityMolecular sieve catalystsMolecular sieve catalystMolecular sieveIsomerization

Catalysts comprise a combination of molecular sieve having a pore diameter of from about 4 to 8 angstroms and a catalytically-effective amount of molybdenum hydrogenation component and a sufficient amount of at least one platinum group metal hydrogenation component to enhance the isomerization activity of the catalyst.

Owner:UOP LLC

Hydroisomerization catalyst, process for producing the same, method of dewaxing hydrocarbon oil, process for producing hydrocarbon, and process for producing lube base oil

ActiveUS20130008827A1Suppressed cracking activityHigh isomerization activityMolecular sieve catalystsCatalytic naphtha reformingComposite oxideTitanium dioxide

The hydroisomerization catalyst of the present invention is a catalyst used for hydroisomerization of a hydrocarbon, including a support including a calcined zeolite modified with at least one metal selected from the group consisting of Na, K, Cs, Mg, Ca, Ba, and K, and having a thermal history that includes heating at 350° C. or more, and at least one inorganic oxide selected from the group consisting of alumina, silica, titania, boria, zirconia, magnesia, ceria, zinc oxide, phosphorus oxide, and a composite oxide containing a combination of at least two or more of these oxides; and at least one metal supported on the support and selected from the group consisting of elements belonging to Groups 8 to 10 of the periodic table, molybdenum and tungsten.

Owner:JX NIPPON OIL & ENERGY CORP

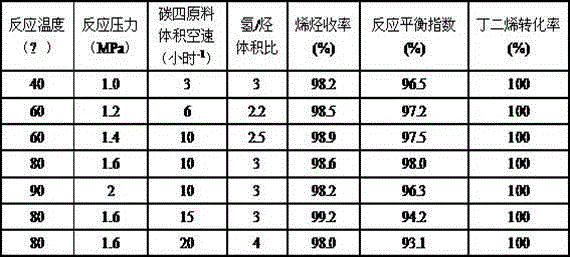

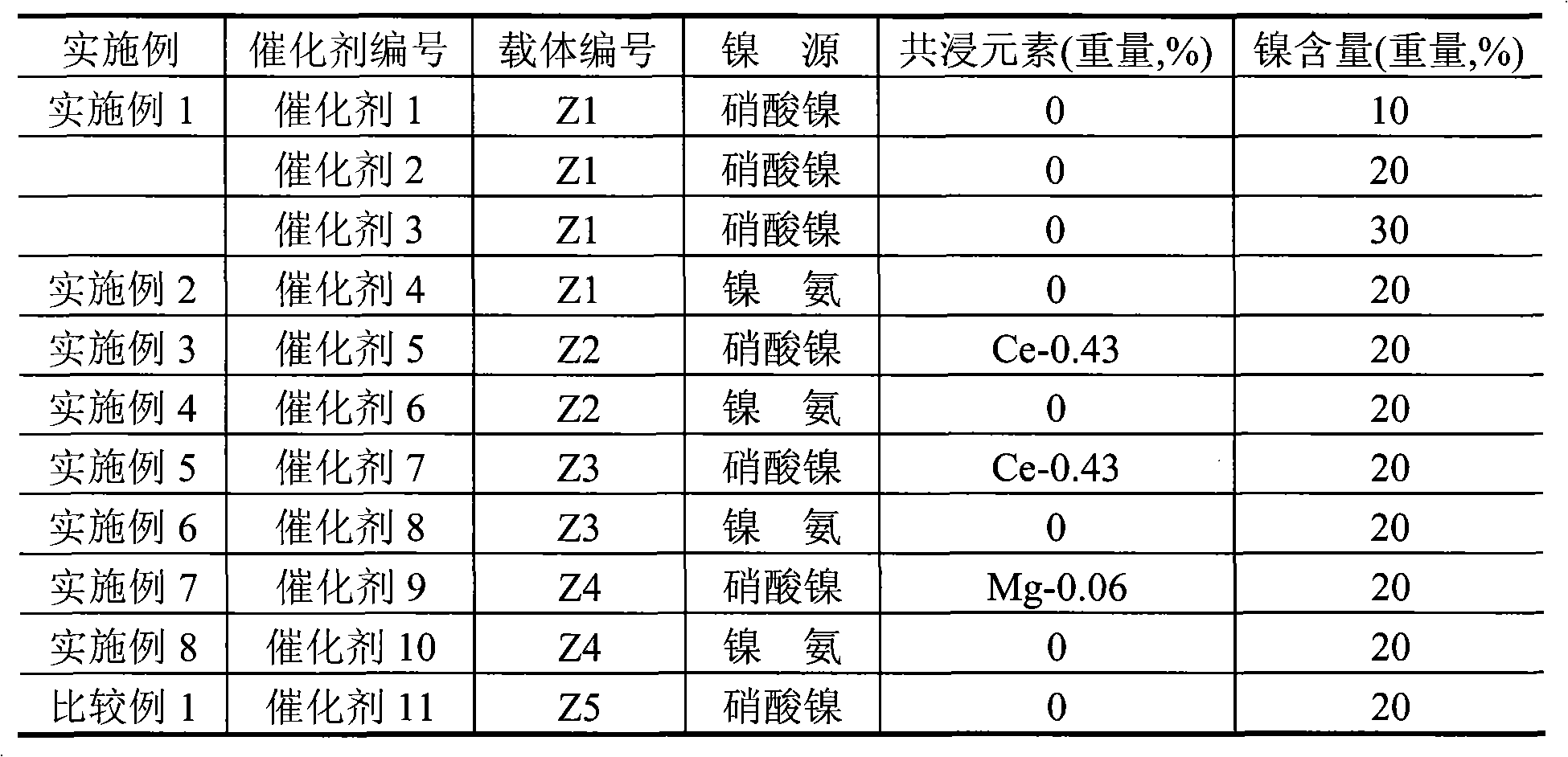

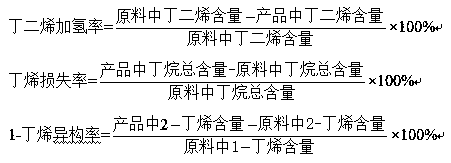

Nickel base catalyst for producing butylene-1 with butylenes-2 hydroisomerization containing a few butadiene

InactiveCN101428225AImproved pore size distributionHigh isomerization activityHydrocarbon by isomerisationMetal/metal-oxides/metal-hydroxide catalystsRare earthMetallic Nickel

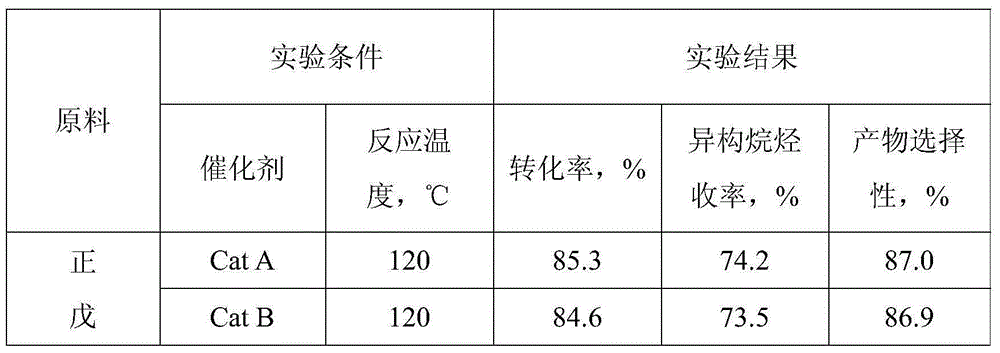

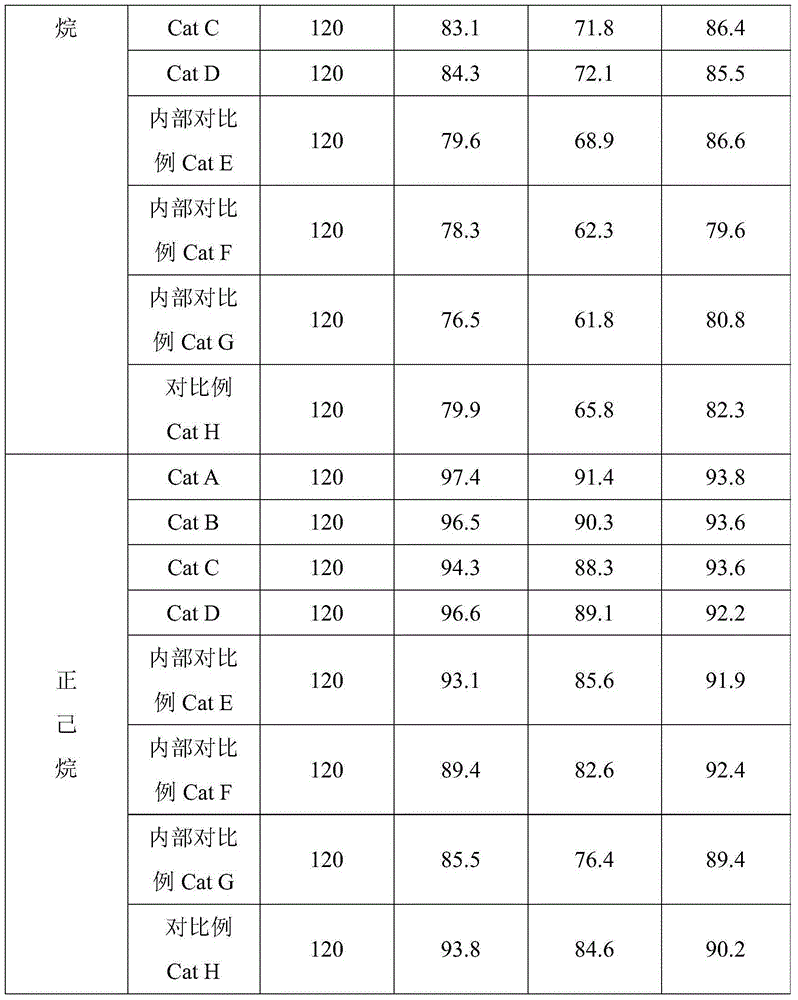

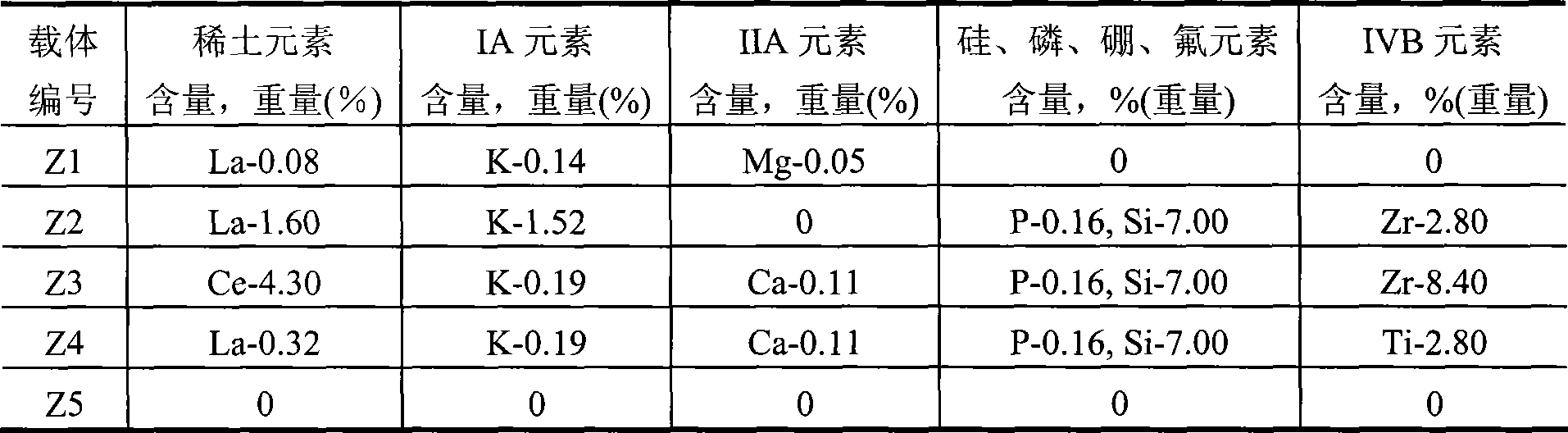

The invention relates to a Ni-based catalyst for butene-1 synthesis via hydroisomerization of butene-2 containing a small amount of butadiene, and mainly solves the technical problems of low equilibrium conversion rate of butene-1 and high hydrogenation rate of alkenes in the prior art. In order to solve the problems, the technical scheme is as follows: the components in weight percentages of the Ni-based catalyst for butene-1 synthesis via hydroisomerization of butene-2 containing a small amount of butadiene are as follows: 5.0% to 40.0% of metal nickel or an oxide thereof, 0.01% to 6.0% of at least one element selected from Cu and Ag or an oxide thereof, 0.01% to 6.0% of at least one element selected from rare earths or an oxide thereof, 0.01% to 2.0% of at least one element selected from the group IA or the group IIA in the periodic table of elements or an oxide thereof, 0% to 12.0% of at least one element selected from Si, P, B and F or an oxide thereof, 0% to 10.0% of at least one element selected from the group IVB in the periodic table of elements or an oxide thereof, and aluminum oxide carrier in balance amount. The Ni-based catalyst is applied to the industrial production of butene-1 from butene-2 in pyrolysis or refinery C4 fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

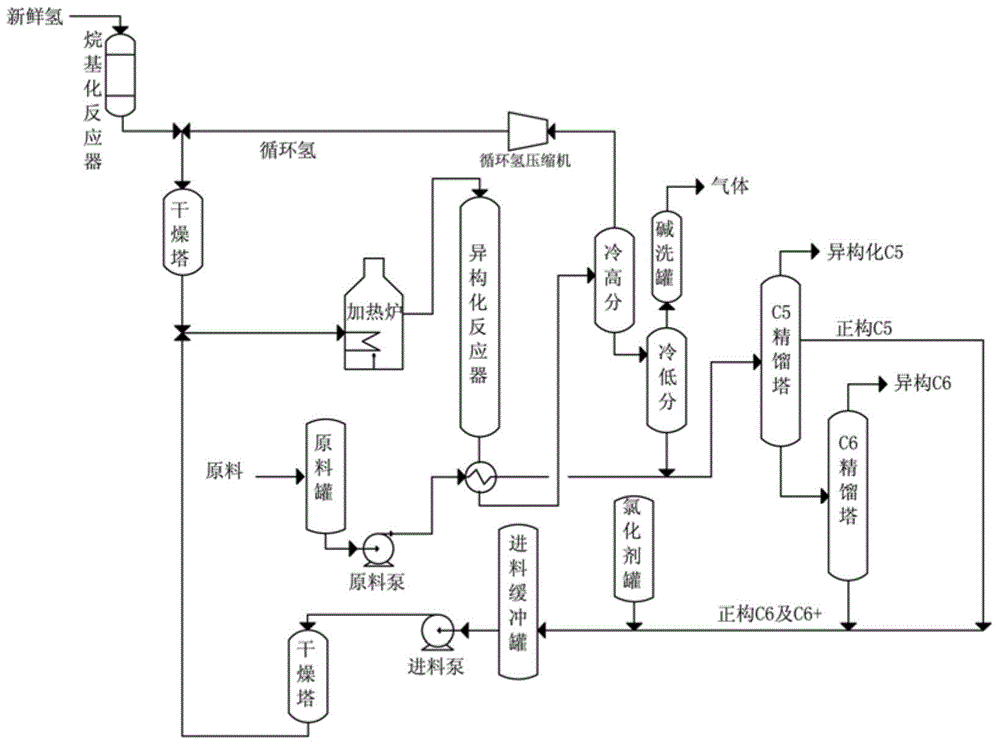

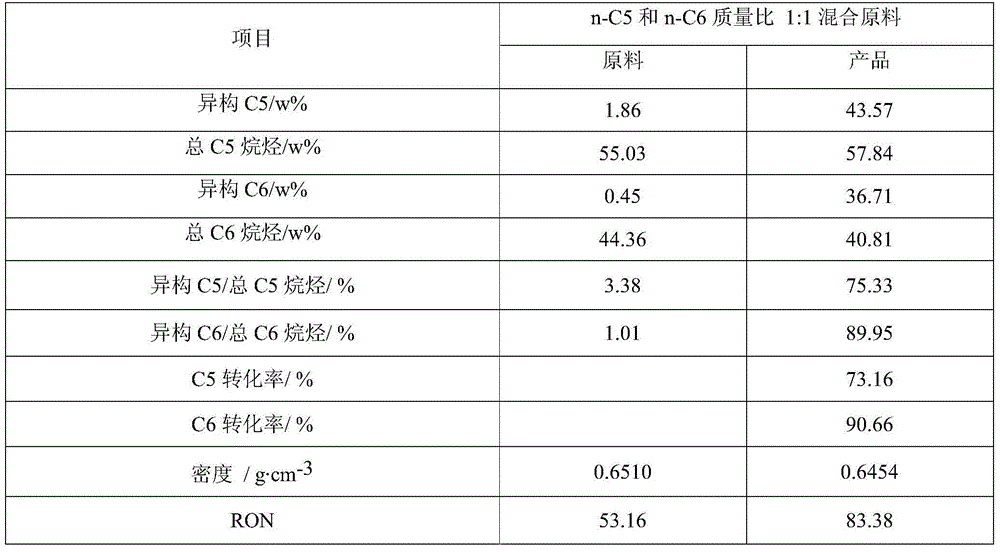

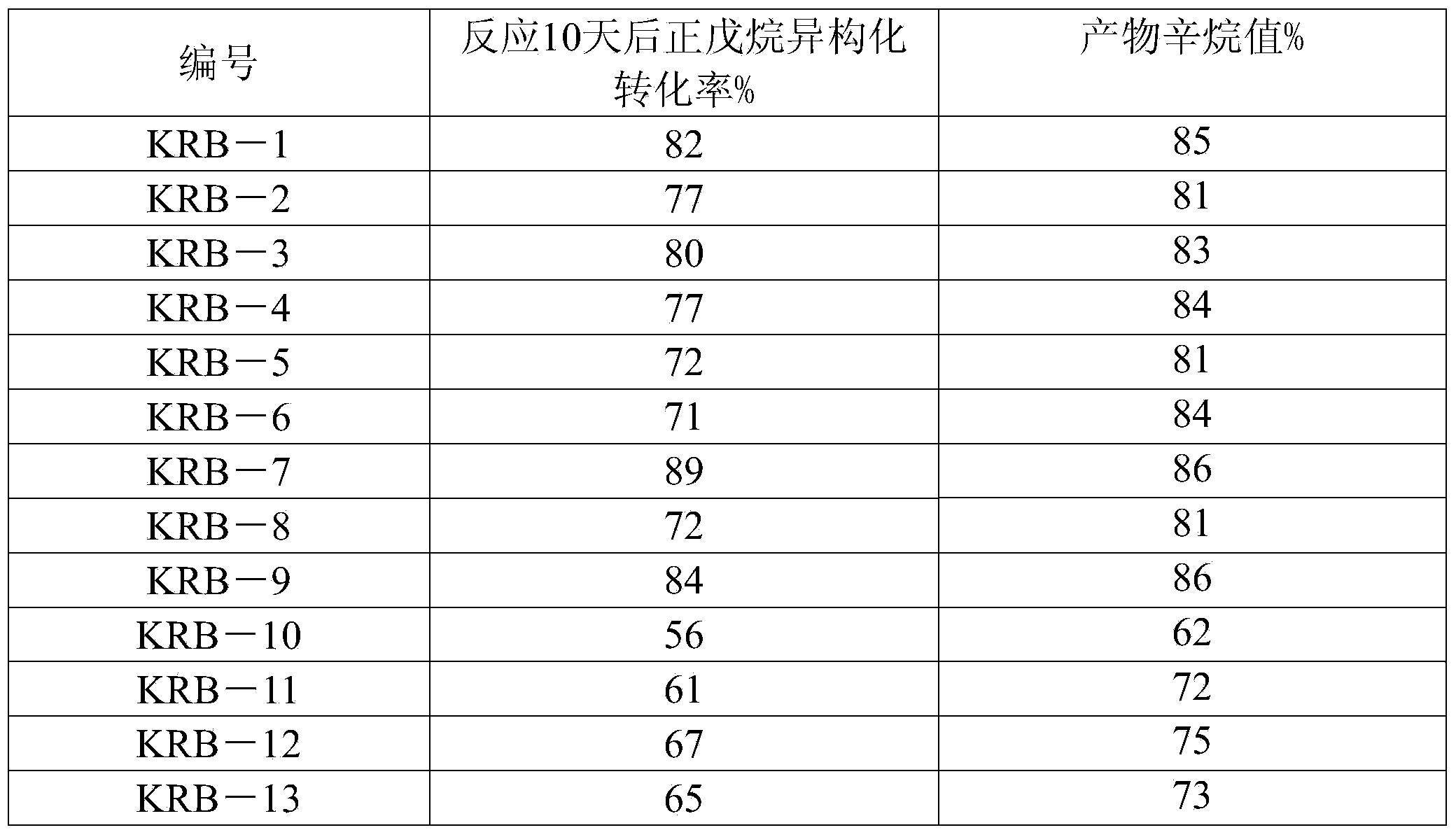

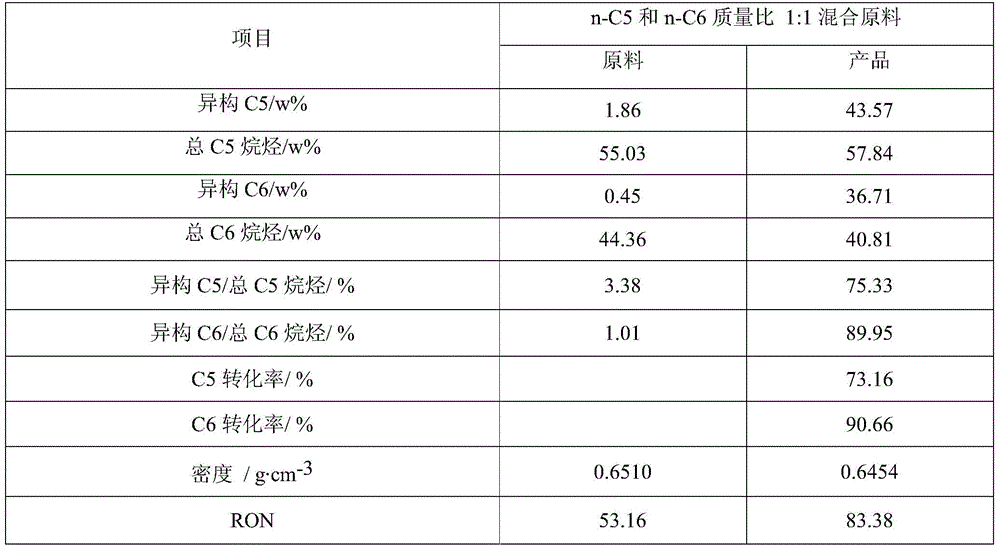

Low-temperature isomerization method for low-carbon normal alkanes

ActiveCN104892337AHigh isomerization activityImprove stabilityHydrocarbon by isomerisationMetal/metal-oxides/metal-hydroxide catalystsAlkaneLiquid product

The invention relates to a low-temperature isomerization method for low-carbon normal alkanes, wherein the low-temperature isomerization method includes the following steps: (1) carrying out heat exchange of a light hydrocarbon raw material containing normal C5 and normal C6 as principal components with an isomerization product, and after heat exchange, rectifying to obtain heterogeneous C5, normal C5 and a heavy hydrocarbon; (2) rectifying the heavy hydrocarbon again, to obtain heterogeneous C6 and a heavy hydrocarbon, mixing the normal C5 with the heavy hydrocarbon, and then supplementing chlorine; (3) carrying out drying dehydration on the material obtained after chlorine supplement, mixing with dried fresh hydrogen and circulating hydrogen, heating, and carrying out an isomerization reaction under the action of a catalyst after heating; and (4) after carrying out heat exchange of the isomerization product with a fresh raw material, carrying out first gas-liquid separation, wherein the obtained non-condensable gas is circulating hydrogen; and carrying out gas-liquid separation on the obtained liquid again, mixing the obtained liquid with a fresh raw material, and then rectifying. The yield of the liquid product obtained by the low-temperature isomerization method is more than 98%, the isomerization rate is 60%-90%, and the octane value can be increased by 10-30.

Owner:NINGBO ZHONGXUN ENVIRONMENTAL TECH CO LLC

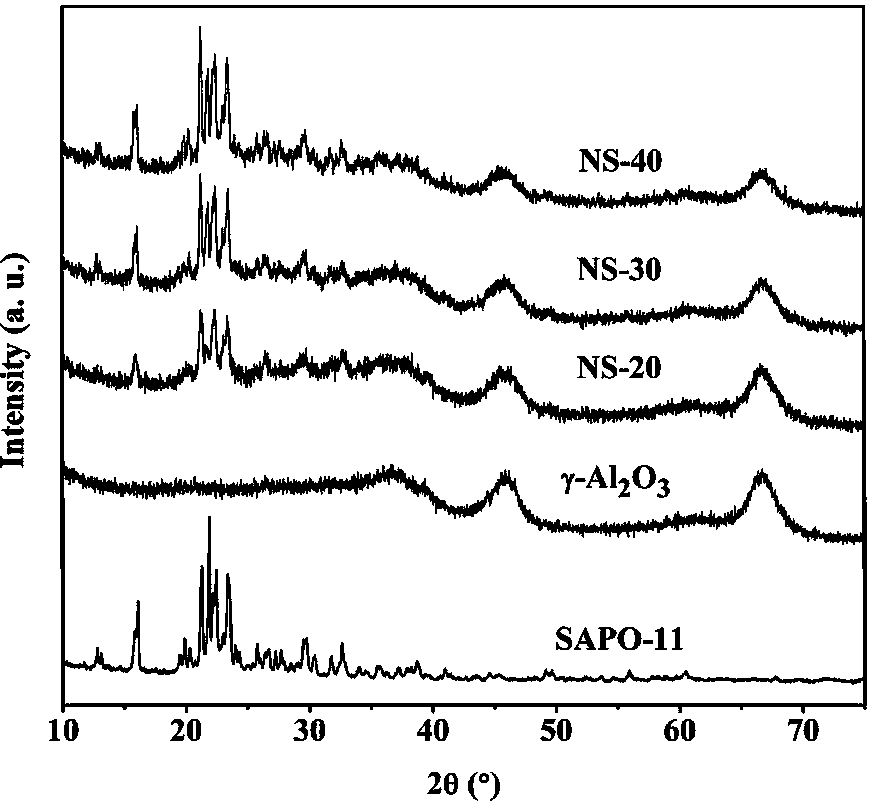

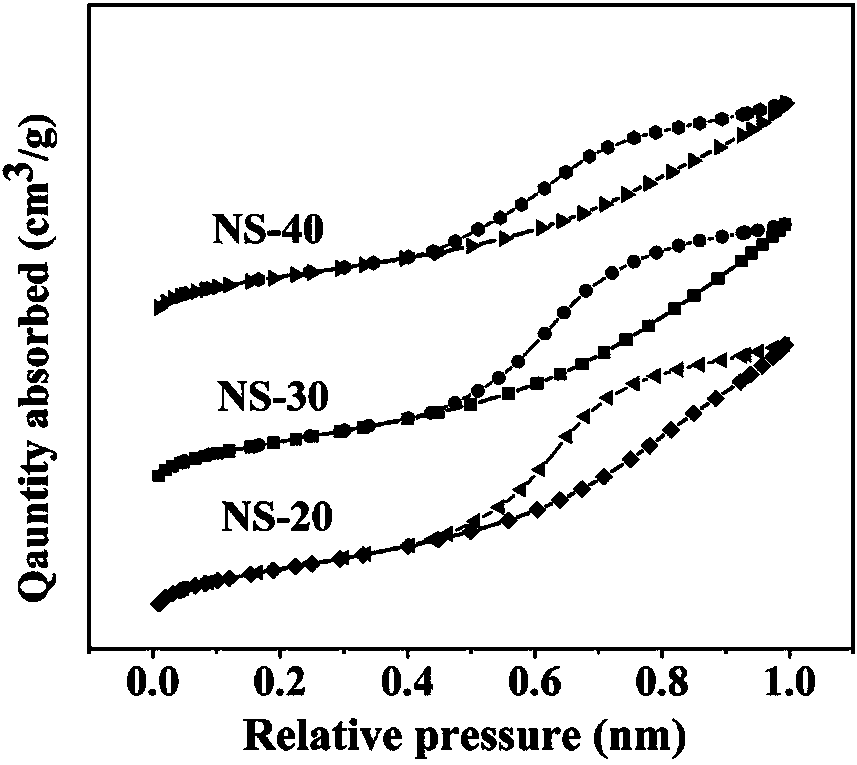

Preparation method and application method of non-noble metal reforming catalyst

ActiveCN103638968AGood reforming reaction performancePlay an acidic functionMolecular sieve catalystsNaphtha reformingPtru catalystAluminium hydroxide

A preparation method and an application method of a non-noble metal reforming catalyst. The catalyst comprises a Ni2P active component and a composite carrier. The composite carrier comprises gama-Al2O3 and SAPO-11. The preparation method comprises the following steps: firstly, adding sesbania powder into raw materials of aluminium hydroxide dry gel powder, pseudo-boehmite and SAPO-11, then adding nitric acid aqueous solution, performing kneading, strip extrusion, air drying, drying and roasting to prepare a composite carrier of gama-Al2O3-SAPO-11; secondly, preparing a nickel hypophosphite impregnation liquid at 60-80 DEG C, controlling the molar ratio of phosphorus to nickel, impregnating the composite carrier by constant temperature supersaturation impregnation, performing air drying and vacuum drying to obtain a catalyst precursor; finally, putting the catalyst precursor in a tubular furnace, and roasting in N2 to prepare the Ni2P / gama-Al2O3-SAPO-11 catalyst. Compared with the prior art, the preparation method is simple in process, low in preparation temperature, and mild in reaction conditions; the prepared catalyst is high in dispersity, can be used in naphtha reforming reaction, has high aromatic hydrocarbon yield and activity stability, and is low in price.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

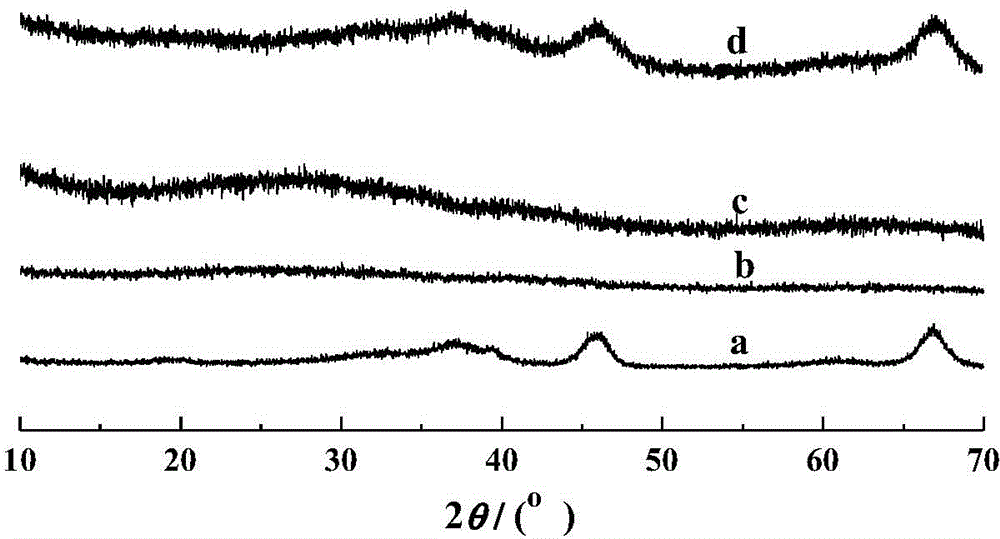

Hydroisomerization catalyst, method of dewaxing hydrocarbon oil, process for producing base oil, and process for producing lube base oil

ActiveUS8372263B2High yieldHigh isomerization activityMolecular sieve catalystsCatalyst activation/preparationMolecular sieveIon exchange

A hydroisomerization catalyst according to the present invention is obtained by calcining a catalyst composite including an ion-exchanged molecular sieve or a calcined material thereof which is obtained by performing ion exchange of a molecular sieve containing an organic template in a solution containing a cation species and using water as a main solvent and at least one metal which is selected from a group consisting of metals belonging to Groups 8-10 of the Periodic Table of the Elements, molybdenum, and tungsten supported on the ion-exchanged molecular sieve or a calcined material thereof.

Owner:NIPPON OIL CORP

Ethylbenzene Conversion and Xylene Isomerization Processes and Catalysts Therefor

InactiveUS20070270624A1Low naphthene generation activityIncreased isomerization activityHydrocarbon by isomerisationMolecular sieve catalystMolecular sieveIsomerization

Catalysts comprise a combination of molecular sieve having a pore diameter of from about 4 to 8 angstroms and a catalytically-effective amount of molybdenum hydrogenation component and a sufficient amount of at least one platinum group metal hydrogenation component to enhance the isomerization activity of the catalyst.

Owner:UOP LLC

C_4 olefin hydroisomerization catalyst and C_4 olefin hydroisomerization method

ActiveCN104437522ASuppress generationInhibition of deep hydrogenationHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsPore diameterAlkene

The invention relates to a catalyst and a method for preparing butane-2 by C_4 olefin hydroisomerization, and the catalyst and the method are mainly used for solving the technical problems in the prior art of low reaction balance index, low olefin yield and high catalyst cost. In order to better solve the problems, the technical scheme adopted by the invention is as follows: the catalyst comprises the following components in parts by weight: (a) 10-20 parts of metal nickel or an oxide thereof; (b) 0.1-5 parts of metal molybdenum or an oxide thereof; (c) 75-90 parts of aluminum oxide-silicon dioxide composite carrier, wherein the pore volume of the catalyst is 0.5-0.9 ml / g, the specific surface area is 150-190 m<2> / g, the average aperture is 13-16 nm, and the pore volume with pore diameter larger than 10 nm occupies 20-60% of the total pore volume. The catalyst can be used in the industrial production of increasing the production of butane-2 by C_4 fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nickle base catalyst for producing butane-1 by hydro-isomerization of butane-2

ActiveCN101491760AImproved pore size distributionHigh isomerization activityHydrocarbon by isomerisationMetal/metal-oxides/metal-hydroxide catalystsIsomerizationRare earth

The invention relates to a nickel-based catalyst for preparing butane-1 by butane-2 hydroisomerization, and mainly solves the technical problems of low equilibrium conversion rate and high olefin hydrogenation rate of butane-2 hydroisomerization catalyst butane-1 in the prior art. By adopting the technical proposal that the nickel-based catalyst for preparing the butane-1 by the butane-2 hydroisomerization comprises the following components in percentage by weight: (a) 5.0 to 40.0 percent of metal nickel or oxides thereof, (b) 0.01 to 6.0 percent of at least one element or oxides thereof selected from rare earth, (c) 0.01 to 2.0 percent of at least one element or oxides thereof selected from IA or IIA in the periodic table of elements, (d) 0 to 12.0 percent of at least one element or oxides thereof selected from silicon, phosphorus, boron or fluorine, (e) 0 to 10.0 percent of at least one element or oxides thereof selected from IVB in the periodic table of elements, and (f) the balance being aluminum oxide carrier; and the nickel-based catalyst the solves the problems well, and can be used in the industrial production of the butane-1 prepared by cracking C4 or butane-2 component rich in refinery C4.

Owner:CHINA PETROLEUM & CHEM CORP +1

Xylene isomerization with an added benzene

InactiveUS7371914B1Speed up the processHigh isomerization activityHydrocarbon by isomerisationHydrocarbonsIsomerizationPhotochemistry

Owner:UOP LLC

Light-hydrocarbon isomerization catalyst and method for preparing same

InactiveCN103464210AExcellent isomerization performanceLarge specific surface areaHydrocarbon by isomerisationCatalyst carriersHydrogen fluoridePolymer science

The invention discloses light-hydrocarbon isomerization catalyst and a method for preparing the light-hydrocarbon isomerization catalyst. Resin ribbon ball-shaped active carbon having high specific surface area and a micro-hole structure serves as the carrier, is roasted under high temperature and is activated through hydrogen fluoride to obtain a carrier with high specific surface area and a mesoporous structure, palladium loading is then carried out according to a liquid phase deposition method, and modifying is carried out through fluorine-containing chlorides at the same time to obtain the light-hydrocarbon isomerization catalyst. The light-hydrocarbon isomerization catalyst has extremely large specific surface area and a proper hole structure, and has good isomerization performance after modifying is carried out through the fluorine-containing chlorides. High activity of the light-hydrocarbon isomerization catalyst can still be kept after long-period operation and the light-hydrocarbon isomerization catalyst is long in service life.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

A multi-metal catalyst for naphtha reforming and a preparing method thereof

ActiveCN105582965AHigh isomerization activityGood aromatization selectivityPhysical/chemical process catalystsCatalytic naphtha reformingRare-earth elementIndium

A multi-metal catalyst for naphtha reforming is disclosed. The catalyst comprises a composite carrier and active components the contents of which are calculated based on the carrier. The active components comprise 0.04-3.0% by mass of platinum, 0.04-5.0% by mass of a VIIB-group metal, 0.01-3.0% by mass of a third metal component and 0.5-5.0% by mass of a halogen. The third metal component is selected from rare earth elements, indium or yttrium. The composite carrier comprises 0-80% by mass of gamma-aluminium oxide and 20-100% by mass of mesoporous gamma-aluminium oxide. A preparing method of the mesoporous gamma-aluminium oxide includes dipping amorphous mesoporous aluminium oxide with a solution of a platinum-containing compound, filtering to obtain solid, drying the solid and calcinating at 300-700 DEG C. A template is poly(ethylene oxide)-poly(propylene oxide)-poly(ethylene oxide) triblock copolymer. The mole ratio of the template to an aluminum source compound is 1:1-200. The mole ratio of aliphatic alcohol to the aluminum source compound is 20-100:1. The catalyst is used for naphtha reforming and is high in isomerization activity and good in aromatization selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for hydrogenation conversion of Fischer-Tropsch synthetic wax and preparation method and application thereof

ActiveCN112337506ALow selectivityReduce the amount of strong acidMolecular sieve catalystsHeterogenous catalyst chemical elementsMolecular sievePtru catalyst

The invention provides a catalyst for hydrogenation conversion of Fischer-Tropsch synthetic wax and a preparation method and application thereof. The catalyst comprises the following components: Ni, Whydrogenation metal, a Y-type molecular sieve, an isomerization molecular sieve and aluminum oxide; the preparation method of the catalyst comprises the following steps: firstly, mixing and pulping aluminum oxide and water, and then sequentially adding a USY molecular sieve and a Ni metal compound to form a mixture; secondly, putting the mixture into a closed reaction kettle for dynamic hydrothermal treatment; thirdly, after treatment, adding an isomerization molecular sieve, fully stirring, filtering, drying, adding dilute nitric acid, performing extrusion molding, and roasting; and finally,impregnating the W metallide by adopting an equivalent-volume impregnation method, drying and roasting to finally obtain the hydrocracking catalyst. The hydrocracking catalyst prepared by the methodprovided by the invention has appropriate acid properties, pore properties and metal dispersibility, can effectively reduce the secondary cracking performance in the hydrocracking process of Fischer-Tropsch synthetic wax, and improves the yield and product properties of light fuel oil.

Owner:SHAANXI YANCHANG PETROLEUM GRP

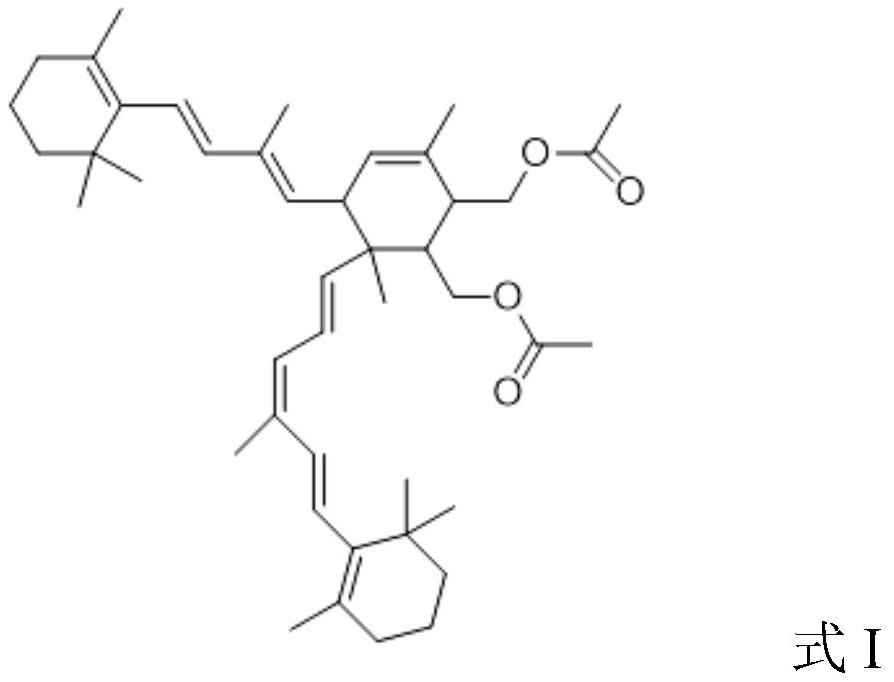

Vitamin A isomerization method

ActiveCN113429326AHigh isomerization activityImprove conversion rateOrganic chemistry methodsIsomerizationVitamin A Alcohol

The invention discloses a vitamin A isomerization method. The method comprises the steps of (1) controlling the content of vitamin dimers in VA crude oil containing 11-cis-vitamin A and 9-cis-vitamin A to be 0.001-0.02%; and 2) carrying out an isomerization reaction on the VA crude oil obtained in the step 1) under the action of a homogeneous metal catalyst to generate the all-trans vitamin A. According to the method, 11-cis-vitamin A and 9-cis-vitamin A in the VA crude oil can be isomerized into all-trans vitamin A efficiently at the same time, and the conversion rate of the total cis-vitamin A is high.

Owner:WANHUA CHEM GRP CO LTD

Naphtha reforming catalyst and preparation method therefor

ActiveCN105582966AHigh selectivityGood aromatization selectivityPhysical/chemical process catalystsCatalytic naphtha reformingIsomerizationPolyethylene oxide

The invention relates to a naphtha reforming catalyst. The naphtha reforming catalyst comprises a complex carrier and the following active ingredients in percentage by mass (based on the carrier): 0.04-3.0% of platinum, 0.04-5.0% of VII group B metal and 0.5-5.0% of halogen; the complex carrier contains the ingredients in percentage by mass: 0-80% of gamma-alumina and 20-100% of mesoporous gamma-alumina; and a preparation method for the mesoporous gamma-alumina comprises the steps of mixing a template agent, fatty alcohol, inorganic acid and an aluminum source compound, carrying out a full reaction at the pH value of 1 to 7 and the temperature of 1 DEG C to 100 DEG C, drying a reaction product, carrying out roasting for 2 to 12 hours at the temperature of 300 DEG C to 600 DEG C so as to obtain amorphous mesoporous alumina, then, dipping the amorphous mesoporous alumina by a platiniferous compound solution, drying solids, and then, carrying out roasting at the temperature of 300 DEG C to 700 DEG C, wherein the template agent is a polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, the mole ratio of the template agent to the aluminum source compound is 1: (1 to 200), and the mole ratio of the fatty alcohol to the aluminum source compound is (20 to 100): 1. The catalyst has relatively high selectivity of isomerization and aromatization.

Owner:CHINA PETROLEUM & CHEM CORP +1

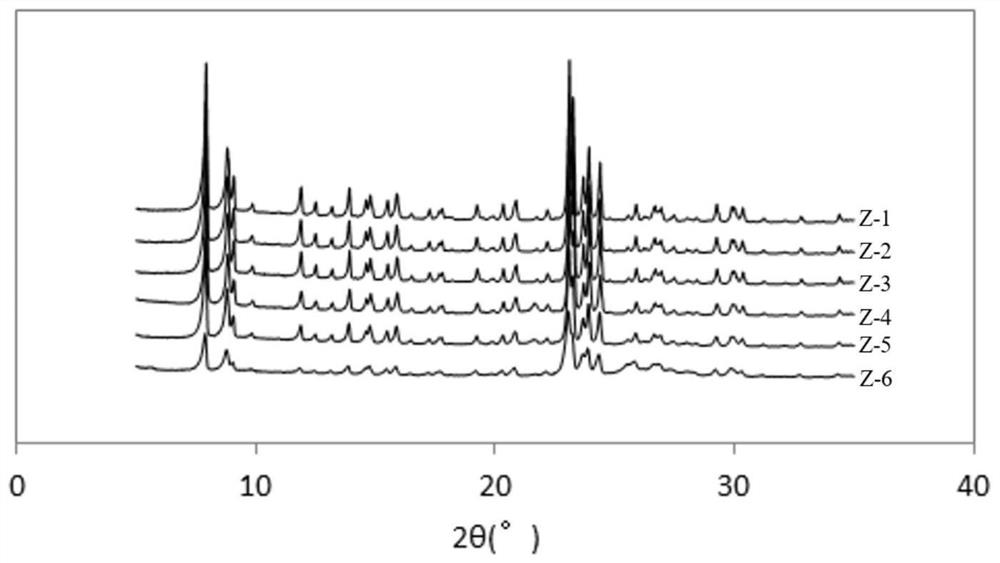

Molecular Sieve and Catalyst Incorporating the Sieve

InactiveUS20100092351A1Favorable balance of activity and selectivity and stabilityIncreased isomerizationMolecular sieve catalystsHydrocarbonsMolecular sieveSilicon

One exemplary embodiment can be a molecular sieve for a catalyst for isomerizing xylenes. Generally, the molecular sieve, including at least one of an MFI, MEL, FER, MOR, TON, MTW, EUO, and MTT zeolite, can include:at least about 40%, by weight, silicon;about 0.5-about 7.0%, by weight, gallium; andabout 0.1-about 2.0%, by weight, of another IUPAC Group 13 element wherein the silicon, gallium and the another IUPAC Group 13 element are calculated on an elemental basis.

Owner:UOP LLC

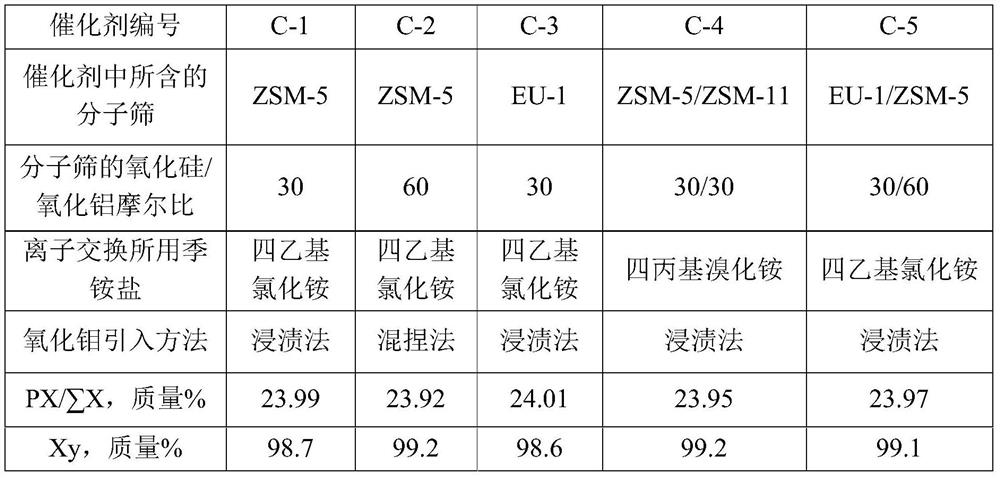

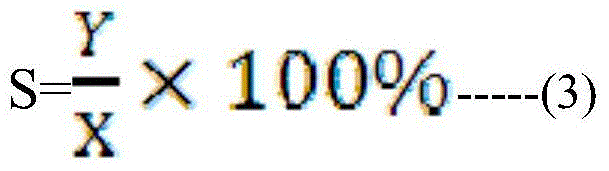

Alkyl aromatic hydrocarbon non-hydroisomerization catalyst as well as preparation method and application thereof

PendingCN114425412AHigh isomerization activityHigh selectivityHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveIsomerization

The invention relates to an alkyl aromatic hydrocarbon non-hydroisomerization catalyst as well as a preparation method and application thereof. The quaternary ammonium salt with the molecular size larger than the pore size of the molecular sieve is adopted for conducting ion exchange on the Na-type molecular sieve used by the catalyst, and the prepared catalyst can be used for alkyl aromatic hydrocarbon liquid-phase non-hydroisomerization reaction and has the advantages of being high in isomerization activity, high in para-alkyl aromatic hydrocarbon selectivity and capable of saving energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkylation raw material selective hydrogenation catalyst and preparation method thereof

PendingCN111054328AGood catalytic activityHigh 1-butene isomerization activityHydrocarbon by hydrogenationCatalystsChemistryNoble metal

The invention discloses an alkylation raw material selective hydrogenation catalyst and a preparation method thereof and belongs to the technical field of hydrogenation catalysts. The catalyst is characterized by comprising the following components in percentage by weight: 0.2%-0.3% of Pd, 1.0%-5.0% of titanium dioxide and the balance of sepiolite and auxiliary agents. The preparation method comprises the following steps: preparing sepiolite, crushing, soaking, removing scum, filtering, drying; adding meta-titanic acid powder accounting for 4-6% of the mass of the sepiolite into the dried sepiolite, crushing the sepiolite and the meta-titanic acid powder together until the particle size is smaller than 160 meshes, performing roasting modification for 6-8 hours at the roasting temperature of 400-500 DEG C to obtain modified sepiolite; adding the modified sepiolite, extruding into strips, airing, roasting to obtain a catalyst carrier; preparing a PdCl2 solution, carrying out isopyknic impregnation on the PdCl2 solution and the carrier obtained in the step (3), carrying out draining, and carrying out roasting so as to obtain the finished catalyst. The selective hydrogenation catalysthas catalytic activity equivalent to that of a noble metal catalyst, is low in cost, and also has very high 1-butene isomerization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of normal paraffin low-temperature isomerization catalyst and its preparation method and application

ActiveCN105080578BHigh activityImprove stabilityHydrocarbon by isomerisationPhysical/chemical process catalystsAlkanePtru catalyst

The invention discloses an n-alkane low-temperature isomerization catalyst as well as a preparation method and an application of the n-alkane low-temperature isomerization catalyst. The catalyst disclosed by the invention comprises the following components in percentage by weight: 0.1%-1.0% of loaded metal Pt, 5.0%-10.0% of an element Cl, and the balance of a carrier gamma-Al2O3. The preparation method of the catalyst disclosed by the invention comprises the following steps: dipping chloroplatinic acid on the carrier gamma-Al2O3, and then drying and roasting to obtain Pt / gamma-Al2O3 catalyst containing 0.1%-1% of the Pt; and firstly reducing a platinum-containing catalyst, then uniformly dipping a chlorinating agent on the surface of the Pt / gamma-Al2O3 catalyst by adopting a chlorinating way of liquid-phase dipping, and then carrying out programmed warming for curing the chlorinating agent to obtain the Pt / gamma-Al2O3-Cl n-alkane isomerization catalyst with high chloride loading quantity (5%) and uniform distribution of the chlorine element. The catalyst provided by the invention has relatively high chlorine content, also has good chlorine distribution, and achieves high acidity loading quantity, high isomerization activity and high stability of the catalyst.

Owner:BEIJING SINO SPHERE PETROCHEM TECH CO LTD

Isomerization catalyst containing modified mordenite and application thereof

ActiveCN103041844AReduced lytic activityHigh activityHydrocarbon by isomerisationMolecular sieve catalystsAlkanePtru catalyst

The invention discloses an isomerization catalyst containing modified mordenite and an application thereof. The catalyst is prepared from the following components in percentage by weight: 0.01-5% of noble metal element in the group VIII, 10-80% of phosphorus-modified mordenite, 0.1-10% of additives and the balance of binder containing 0.5-5.0% of halogen, wherein the weight of phosphorus in the modified mordenite accounts for 0.1-10%. The catalyst is used for the isomerization of C4-C12 alkane, has the characteristics of high catalytic activity and high isoolefine selectivity and can be used for producing the high-octane gasoline blending component.

Owner:CHINA PETROLEUM & CHEM CORP +1

Isomerization catalyst containing modified mordenite and application thereof

ActiveCN103041844BReduced lytic activityHigh activityHydrocarbon by isomerisationMolecular sieve catalystsAlkanePtru catalyst

The invention discloses an isomerization catalyst containing modified mordenite and an application thereof. The catalyst is prepared from the following components in percentage by weight: 0.01-5% of noble metal element in the group VIII, 10-80% of phosphorus-modified mordenite, 0.1-10% of additives and the balance of binder containing 0.5-5.0% of halogen, wherein the weight of phosphorus in the modified mordenite accounts for 0.1-10%. The catalyst is used for the isomerization of C4-C12 alkane, has the characteristics of high catalytic activity and high isoolefine selectivity and can be used for producing the high-octane gasoline blending component.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing low-sodium ZSM-5 molecular sieve and application of low-sodium ZSM-5 molecular sieve in xylene isomerization catalyst

ActiveCN114426292AHigh isomerization activityReduce manufacturing costHydrocarbon by isomerisationMolecular sieve catalystsXylyleneMolecular sieve

The invention relates to a method for preparing a low-sodium ZSM-5 molecular sieve and application of the low-sodium ZSM-5 molecular sieve in a xylene isomerization catalyst. According to the method for preparing the low-sodium ZSM-5 molecular sieve, the dispersing agent is added, and the morphology and surface acid distribution of the prepared molecular sieve can be optimized, so that the isomerization activity of the catalyst is improved, and higher p-xylene yield is obtained; meanwhile, the ZSM-5 molecular sieve can be used for preparing the catalyst without ammonium exchange, so that the discharge of nitrogen-containing wastewater is reduced, the preparation cost of the catalyst is reduced, and the environmental protection pressure is also relieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of naphtha reforming catalyst and preparation method thereof

ActiveCN105582966BHigh isomerization activityGood aromatization selectivityPhysical/chemical process catalystsCatalytic naphtha reformingIsomerizationPolyethylene oxide

A naphtha reforming catalyst, comprising a composite carrier and active components with the following content calculated on the basis of the carrier: 0.04-3.0% by mass of platinum, 0.04-5.0% by mass of Group VIIB metals, and 0.5-5.0% by mass of halogens. The composite support includes 0-80% by mass of γ-alumina and 20-100% by mass of mesoporous γ-alumina, and the preparation method of said mesoporous γ-alumina comprises template agent, fatty alcohol, inorganic acid Mix with aluminum source compound, fully react at pH 1-7, 1-100°C, dry the reaction product, and roast at 300-600°C for 2-12 hours to obtain amorphous mesoporous alumina, then use platinum-containing compound Solution impregnation, take the solid matter and dry it and bake it at 300-700°C. The template agent is polyethylene oxide-polypropylene oxide-polyethylene oxide tri-block copolymer, and the mole ratio of the template agent and the aluminum source compound The ratio is 1:1-200, and the molar ratio of the fatty alcohol to the aluminum source compound is 20-100:1. The catalyst has high isomerization and aromatization selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method of vitamin A isomerization

ActiveCN113429326BHigh isomerization activityImprove conversion rateOrganic chemistry methodsIsomerizationVitamin A Alcohol

Owner:WANHUA CHEM GRP CO LTD

Hydroisomerization catalyst, process for producing the same, method of dewaxing hydrocarbon oil, process for producing hydrocarbon, and process for producing lube base oil

ActiveUS9598650B2Suppressed cracking activityHigh isomerization activityHydrocarbon by isomerisationMolecular sieve catalystsSilicon dioxideComposite oxide

Owner:JX NIPPON OIL & ENERGY CORP

Supported metal catalyst for olefin isomerization reaction and preparation method thereof

ActiveCN114433197AHigh catalytic activityLong one-way operation cycleHydrocarbon by isomerisationMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to a supported metal catalyst for olefin isomerization reaction and a preparation method thereof. The catalyst comprises a molecular sieve and a supported metal supported on the molecular sieve, and the silica-alumina ratio of the catalyst is (200-2000): 1; the specific surface area is greater than or equal to 500 m < 2 > / g; the loaded metal is selected from one or more of magnesium, calcium, barium, scandium, titanium, vanadium, chromium, nickel, copper and zinc; the content of the loaded metal is 0.1-5wt%, and the oxide of the loaded metal is calculated and the dry basis weight of the molecular sieve is taken as a reference; the proportion of the mesopore volume of the catalyst to the total pore volume is more than or equal to 60 vol%, the mesopore volume and the total pore volume of the molecular sieve are measured by adopting a nitrogen adsorption BET specific surface area method, and the pore diameter range of the mesopore volume is more than 2 nanometers and less than 100 nanometers.

Owner:北京探微精细化工科技有限公司 +1

A method for isomerizing low-carbon normal paraffins at low temperature

ActiveCN104892337BHigh isomerization activityImprove stabilityHydrocarbon by isomerisationMetal/metal-oxides/metal-hydroxide catalystsLiquid productAlkane

The invention relates to a low-temperature isomerization method for low-carbon normal alkanes, wherein the low-temperature isomerization method includes the following steps: (1) carrying out heat exchange of a light hydrocarbon raw material containing normal C5 and normal C6 as principal components with an isomerization product, and after heat exchange, rectifying to obtain heterogeneous C5, normal C5 and a heavy hydrocarbon; (2) rectifying the heavy hydrocarbon again, to obtain heterogeneous C6 and a heavy hydrocarbon, mixing the normal C5 with the heavy hydrocarbon, and then supplementing chlorine; (3) carrying out drying dehydration on the material obtained after chlorine supplement, mixing with dried fresh hydrogen and circulating hydrogen, heating, and carrying out an isomerization reaction under the action of a catalyst after heating; and (4) after carrying out heat exchange of the isomerization product with a fresh raw material, carrying out first gas-liquid separation, wherein the obtained non-condensable gas is circulating hydrogen; and carrying out gas-liquid separation on the obtained liquid again, mixing the obtained liquid with a fresh raw material, and then rectifying. The yield of the liquid product obtained by the low-temperature isomerization method is more than 98%, the isomerization rate is 60%-90%, and the octane value can be increased by 10-30.

Owner:NINGBO ZHONGXUN ENVIRONMENTAL TECH CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com