A method for isomerizing low-carbon normal paraffins at low temperature

A low-temperature isomerization and n-paraffin technology, applied in isomerization hydrocarbon production, chemical instruments and methods, organic chemistry, etc., can solve the problems of high energy consumption, low isomerization rate and high reaction temperature of isomerization reaction problem, to achieve the effects of large increase in octane number, high isomerization rate, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

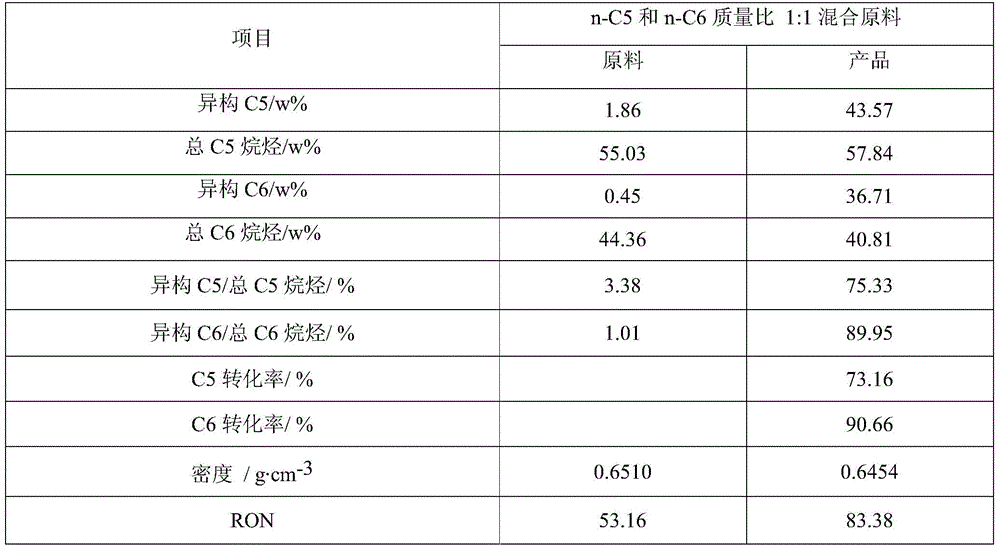

[0034] like figure 1 Shown, a kind of method of low-carbon n-paraffin low-temperature isomerization, comprises the following steps:

[0035] (1) The light hydrocarbon raw material mainly containing normal C5 and normal C6 is exchanged with the product at the bottom of the isomerization reactor through the feed pump, and the light hydrocarbon raw material after heat exchange is mixed with the cold low fraction bottom material and then enters C5 rectification tower, isomerized C5 is obtained from the top of the C5 rectification tower, normal C5 is obtained from the middle of the C5 rectification tower, heavy hydrocarbons are obtained from the bottom of the C5 rectification tower, and the heavy hydrocarbons enter the C6 rectification tower;

[0036](2) Obtain isomerized C6 from the top of the C6 rectification tower, heavy hydrocarbons are obtained from the bottom of the C6 rectification tower, normal C5 is obtained from the middle of the C5 rectification tower, and heavy hydrocar...

Embodiment 2

[0043] Basically the same as Example 1, the difference is:

[0044] The chlorine supplement system uses aluminum trichloride as the chlorination agent, the chlorine supplement amount is 8w% of the catalyst, the chlorine supplement condition is a temperature of 650°C, and the chlorine supplement time is 4 hours;

[0045] The reaction conditions of the isomerization reaction are isomerization reaction temperature 170°C, reaction pressure 2.0MPa, hydrogen-oil ratio 300:1, fresh raw material space velocity 0.5h -1 , the catalyst is a high-activity supported dual-function catalyst including a metal active component and a carrier, the metal active component is Pt and Pd, the Pt loading is 0.5w% of the catalyst, the Pd loading is 0w% of the catalyst, and the carrier is γ- Al 2 o 3 .

[0046] The light hydrocarbon raw material used in this example is reformed top oil, and the products after isomerization are shown in the table below.

[0047] project reforming hair oil...

Embodiment 3

[0050] Basically the same as Example 1, the difference is:

[0051] The chlorine supplement system uses aluminum trichloride as the chlorination agent, the chlorine supplement amount is 5w% of the catalyst, the chlorine supplement conditions are at a temperature of 550°C, and the chlorine supplement time is 2 hours;

[0052] The reaction conditions of the isomerization reaction are isomerization reaction temperature 120°C, reaction pressure 5.0MPa, hydrogen oil ratio 1200:1, fresh raw material space velocity 1.5h -1 , the catalyst is a high-activity supported dual-function catalyst including metal active components and supports, the metal active components are Pt and Pd, the Pt loading is 0.3w% of the catalyst, the Pd loading is 0.2w% of the catalyst, and the support is γ -Al 2 o 3 .

[0053] The light hydrocarbon raw material used in this example is a mixed raw material with a mass ratio of n-C5 and n-C6 of 3:1, and the products after isomerization are shown in the table b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com