Alkylation raw material selective hydrogenation catalyst and preparation method thereof

A technology for selective hydrogenation and catalyst, applied in the direction of carbon compound catalyst, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. Unfavorable industrial application implementation and other problems, to achieve the effect of high 1-butene isomerization activity and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

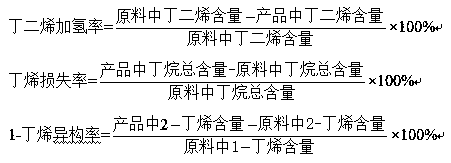

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Take 100g of clean white sepiolite to crush, soak, remove the scum, filter and dry; add 5.5g of metatitanic acid to the dried sepiolite, crush to less than 160 mesh, roast at 435℃ for 7h to obtain modified sepiolite A ; The mass percentage composition of white sepiolite is: SiO 2 67%, MgO31%, FexOy2 O 3 , CaO;

[0032] 2) Modified sepiolite A was extruded into strips with 3g of auxiliary sesame powder, dried, and roasted at 435°C for 8 hours to obtain catalyst carrier B;

[0033] 3) PdCl 2 Add dilute HCl to make PdCl 2 Solution, the pH of the solution is 2, immersed in the same volume as the carrier B for 13 minutes, then drained, and roasted at 400°C for 8 hours to obtain the finished hydrogenation catalyst H-1;

[0034] The hydrogenation catalyst H-1 consists of 0.25% Pd, 2.5% titanium dioxide, and the rest is sepiolite components and additives. The pore volume of the catalyst is 0.35mL / g ~0.40 mL / g, the pore diameter is 90% is 12nm~20nm, and the specific surface area is...

Embodiment 2

[0036] 1) Take 100g of clean white sepiolite to crush, soak, remove the scum, filter and dry; add 4.5% metatitanic acid to the dried sepiolite, pulverize to less than 160 mesh, roast at 420℃ for 7.8h to obtain modified sepiolite A; The mass percentage composition of white sepiolite is: SiO 2 68%, MgO30%%, FexOy2 O 3 , CaO;

[0037] 2) Modified sepiolite A is mixed with 5g of sesame powder and 5g of lignocellulose and extruded into strips, dried, and calcined at 450°C for 8 hours to obtain catalyst carrier B;

[0038] 3) PdCl 2 Add dilute HCl to make PdCl 2 Solution, the pH value of the solution is 2.1, and the carrier B is immersed in the same volume for 15 minutes, then drained, and calcined at 420°C for 8 hours to obtain the finished hydrogenation catalyst H-2;

[0039] The composition of hydrogenation catalyst H-1 includes 0.28% Pd, 2.0% titanium dioxide, and the rest is sepiolite components and additives. The pore volume of the catalyst is 0.35mL / g ~0.40 mL / g, the pore diameter ...

Embodiment 3

[0041] 1) Take 100g of clean white sepiolite to crush, soak, remove the scum, filter and dry; add 5% metatitanic acid to the dried sepiolite, pulverize to less than 160 mesh, roast at 450℃ for 6.3h to obtain modified sepiolite A; The mass percentage composition of white sepiolite is: SiO 2 66%, MgO2%, FexOy2 O 3 , CaO;

[0042] 2) Modified sepiolite A was extruded into strips with 5g of auxiliary sesame powder, dried, and calcined at 460°C for 8 hours to obtain catalyst carrier B;

[0043] 3) PdCl 2 Add dilute HCl to make PdCl 2 The solution, the pH value of the solution is 2.3, the same volume as the carrier B is immersed for 15 minutes, then drained, and roasted at 400°C for 8 hours to obtain the finished hydrogenation catalyst H-3;

[0044] The hydrogenation catalyst H-1 consists of 0.23% Pd, 2.3% titanium dioxide, and the rest is sepiolite components and additives. The pore volume of the catalyst is 0.35mL / g ~0.40 mL / g, the pore diameter is 90% is 12nm~20nm, and the specific sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com