N-alkane low-temperature isomerization catalyst as well as preparation method and application thereof

A low-temperature isomerization and normal paraffin technology, which can be used in isomerization to produce hydrocarbons, catalysts for physical/chemical processes, chemical instruments and methods, etc., and can solve the problems of low utilization rate of effective Cl and inability to ensure uniform distribution of Cl. , to achieve the effect of improving activity and stability, increasing effective active specific surface area, and improving isomerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

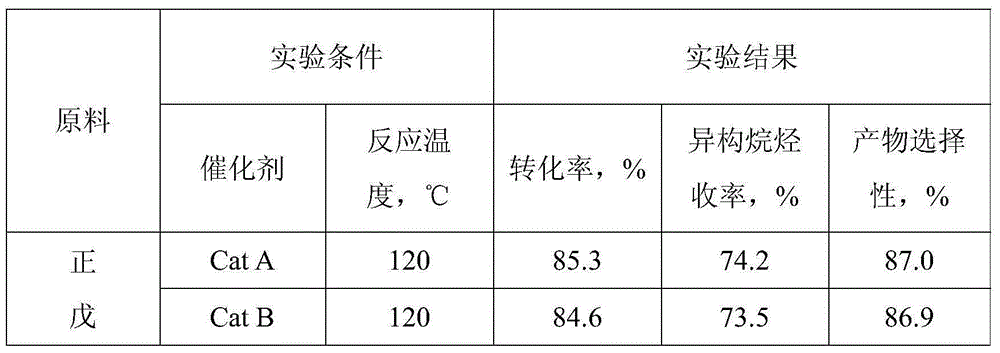

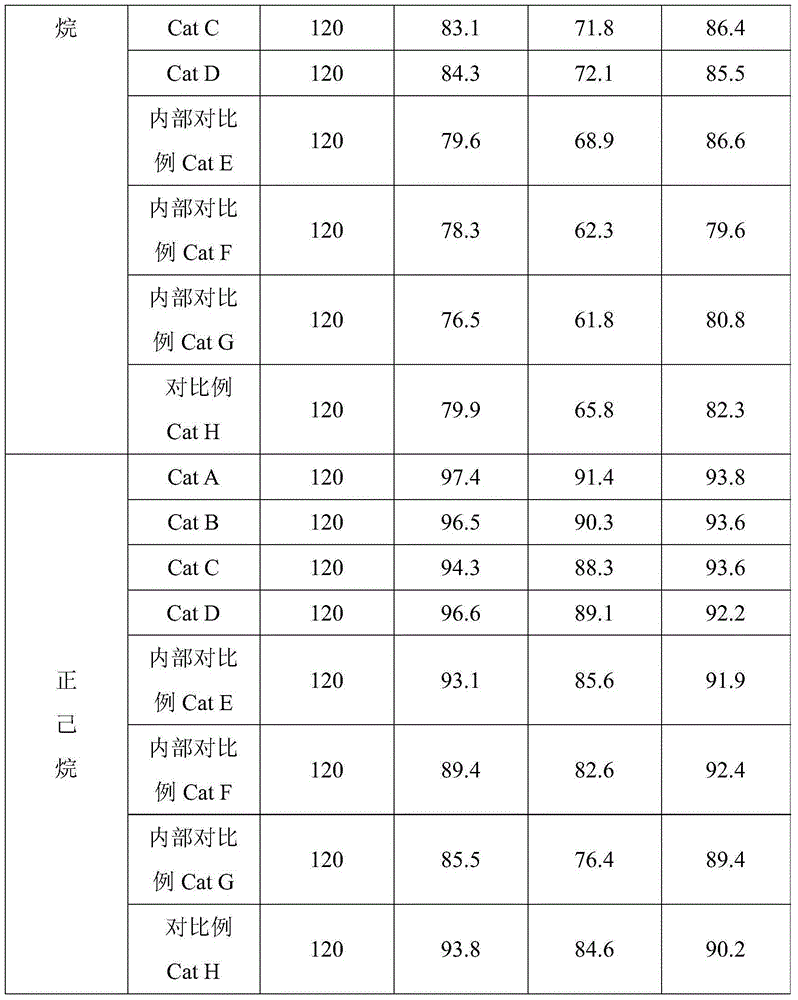

Examples

Embodiment 1

[0029] Get 20 parts by weight of chloroplatinic acid, impregnate it into γ-Al of 100 parts by weight 2 o 3 On the carrier, γ-Al 2 o 3 The specific surface area of the carrier is 220m 2 / g, the pore volume is 0.55ml / g, and then the impregnated product is placed in an oven at 100°C for drying treatment for 2h, and then placed in a muffle furnace at 500°C for 5h.

[0030] The obtained product is reduced by hydrogen, the reduction temperature in the reactor is 250°C, the hydrogen pressure is 2MPa, and the reduction time is 2h; then the hydrogen pressure is kept at 0.1MPa, and the reaction temperature is lowered to 20°C to obtain Catalyst to be chlorinated.

[0031] AlCl 3 Dissolved in ethyl acetate solvent, where AlCl 3 The Cl concentration is 18% of the solution mass. Under the condition that the temperature is 20°C, the catalyst is chlorinated in liquid phase on the reaction device, chlorinated at normal pressure for 15 hours, and the volume space velocity is 2 hours. -...

Embodiment 2

[0038] Get 30 parts by weight of chloroplatinic acid and impregnate it into 80 parts by weight of γ-Al 2 o 3 On the carrier, γ-Al 2 o 3 The specific surface area of the carrier is 200m 2 / g, the pore volume is 0.60ml / g, and then the impregnated product is dried in an oven at 100°C for 4h, and then baked in a muffle furnace at 600°C for 2h.

[0039] The obtained product is reduced by hydrogen, the reduction temperature in the reactor is 450°C, the hydrogen pressure is 1MPa, and the reduction time is 3h; then the hydrogen pressure is kept at 0.1MPa, and the reaction temperature is lowered to 30°C to obtain Catalyst to be chlorinated.

[0040] AlCl 3 Dissolved in a mixed solvent of ethyl acetate and chloroform (4:1), where AlCl 3 The concentration of Cl is 16% of the solution mass. Under the condition that the temperature is 30°C, the catalyst is chlorinated in liquid phase on the reaction device, chlorinated at normal pressure for 15h, and the volume space velocity is 1....

Embodiment 3

[0047] Get 25 parts by weight of chloroplatinic acid, impregnate it into γ-Al of 120 parts by weight 2 o 3 On the carrier, γ-Al 2 o 3 The specific surface area of the carrier is 240m 2 / g, the pore volume is 0.75ml / g, and then the impregnated product is dried in an oven at 110°C for 4h, and then baked in a muffle furnace at 700°C for 3h.

[0048] The obtained product is reduced by hydrogen, the reduction temperature in the reactor is 250°C, the hydrogen pressure is 3MPa, and the reduction time is 4h; then the hydrogen pressure is kept at 0.5MPa, and the reaction temperature is lowered to 25°C to obtain Catalyst to be chlorinated.

[0049] AlCl 3 Dissolved in a mixed solvent of ethyl acetate and chloroform (3:1), where AlCl 3 The Cl concentration is 15% of the solution mass. Under the condition that the temperature is 25°C, the catalyst is chlorinated in liquid phase on the reaction device, chlorinated at normal pressure for 15 hours, and the volume space velocity is 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com