Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "High fluoride removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment method of fluorine-containing waste water of solar cell plant

ActiveCN102452738AImprove use valueEasy to operateGeneral water supply conservationCalcium/strontium/barium fluoridesWastewaterSolar cell

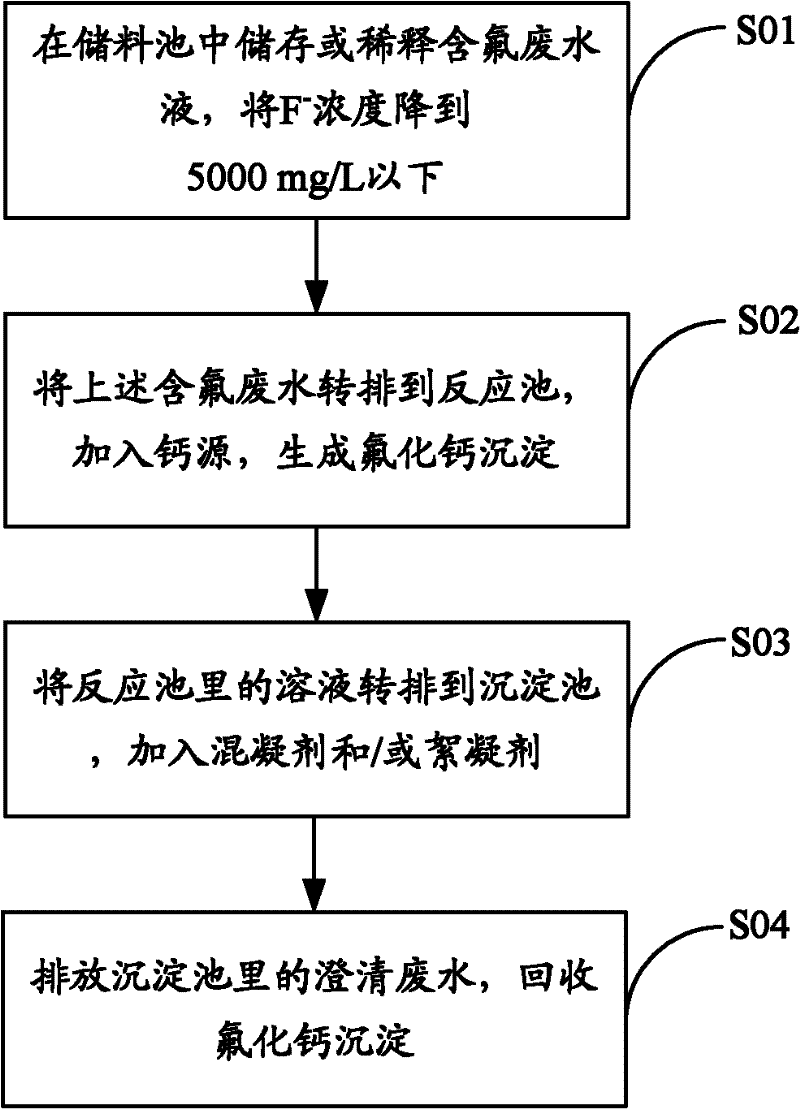

The invention is applicable to industrial fluorine-containing waste water treatment, and provides a treatment method of fluorine-containing waste water of solar cell plants; the method comprises the following steps: storing or diluting fluorine-containing waste water in a material-storing tank, decreasing the F- concentration to below 5000 mg / L; discharging the fluorine-containing waste water into a reaction tank, adding excessive calcium sources; discharging the solution in the reaction tank into a sedimentation tank, adding a coagulant and a flocculant; discharging the clarified waste water from the sedimentation tank, recovering calcium fluoride sediments. The calcium sources used in the invention has a wide source, is economical and cheap; the operation process is simple and practical; the fluorine-removing efficiency is high; and the treated product has high application value.

Owner:SHENZHEN TOPRAY SOLAR

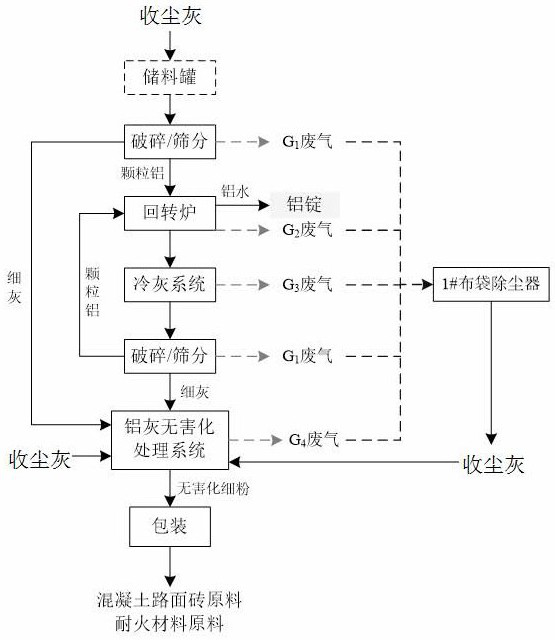

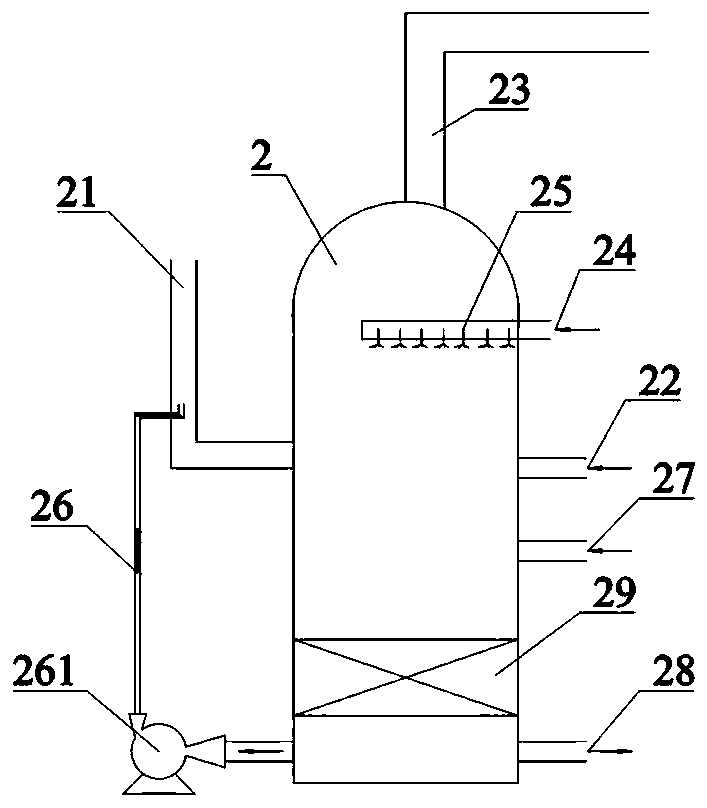

Device and method for removing fluorine ions in groundwater

ActiveCN102838199ASimple structureEasy to useWater contaminantsWater/sewage treatmentFiltrationWater quality

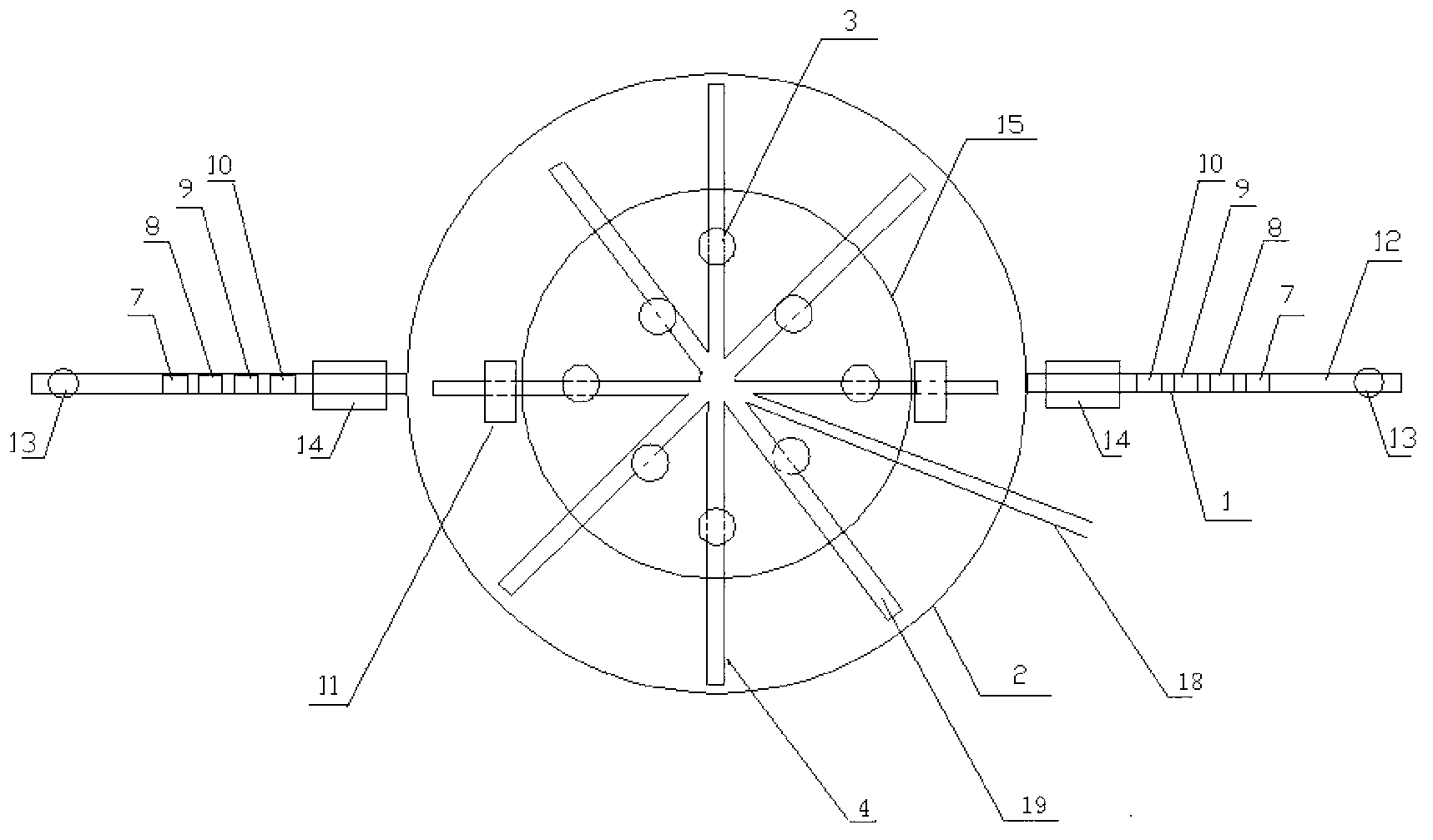

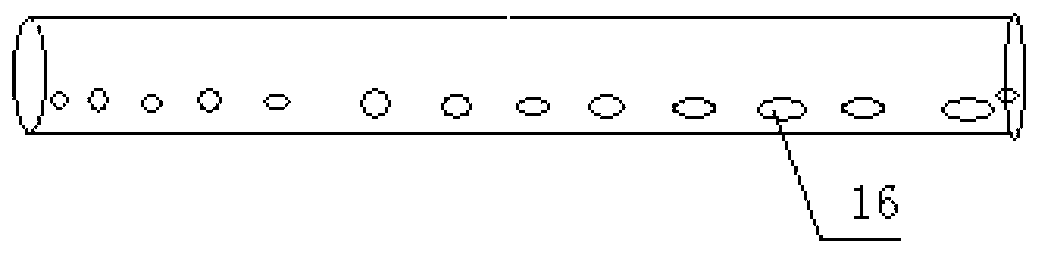

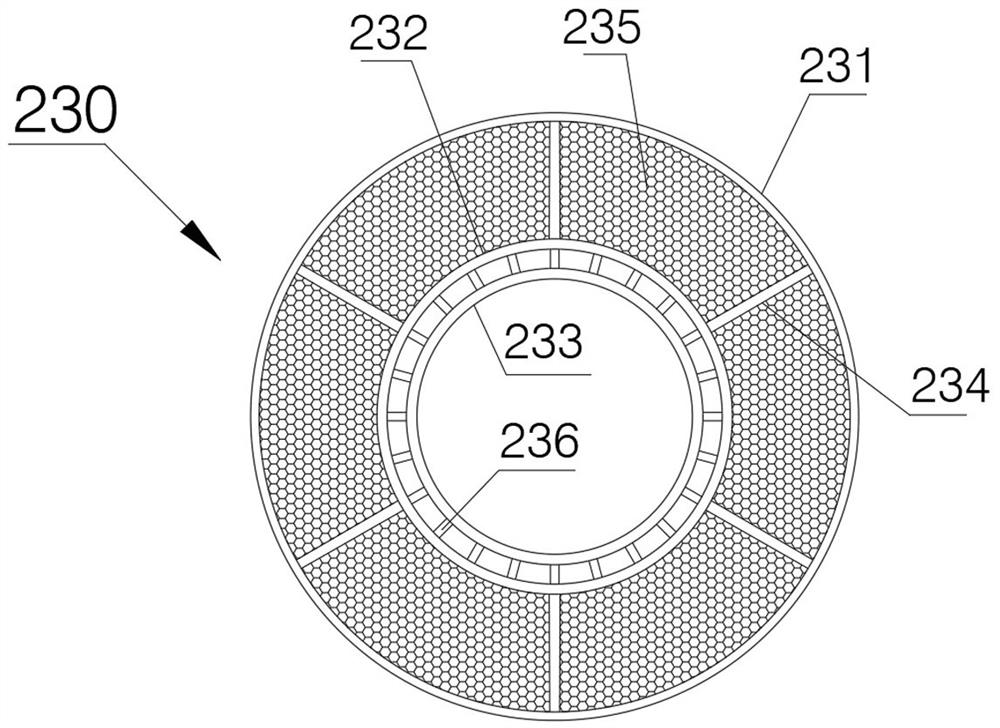

The invention provides a device for removing fluorine ions in groundwater, which comprises water inlet devices (1), a reaction device (2), ultra-filtration devices (3) and aeration devices (4), wherein the water inlet devices (1) are arranged on the reaction device (2) and are provided with material feed devices; the ultra-filtration devices (3) are arranged in the reaction device (2); the aeration devices (4) are arranged at the bottom of the reaction device (2) and aerate by aeration holes (16) on the aeration devices (4); the ultra-filtration devices (3) are provided with outlet pipes (5); and first water pumps (6) are arranged on the outlet pipes (5). The invention further provides a method for removing fluorine by the device for removing fluorine ions. The device for removing fluorine ions in groundwater has the characteristics of simple structure, convenient use, low cost, good fluorine removing effect, and high effluent quality.

Owner:HOHAI UNIV

Defluorination material and preparation and application thereof

InactiveCN106975456AImprove stabilityGood defluoridation effectOther chemical processesWater contaminantsSulfateMetal-organic framework

The invention discloses a defluorination material, which comprises a metal organic framework material, wherein metal hydroxide is dispersed on the surface of the metal organic framework material and / or in holes; the metal hydroxide is at least one of Mg(OH)2, M(OH)3 and Zr(OH)4; and M is a trivalent metallic element. The invention further discloses the defluorination material which is obtained through activating the metal organic framework material at 180-260 DEG C, putting the metal organic framework material into a solution into which a water-soluble salt of magnesium, a water-soluble salt of M and a water-soluble salt of zirconium are dissolved, regulating the pH of a system to be 8.0-9.5 by using a fixing agent, carrying out stirring reaction, carrying out solid-liquid separation, washing and drying. In addition, the invention further discloses an application of the defluorination material in defluorination of a zinc sulfate solution. The preparation method of the defluorination material is simple, and the prepared material has large specific surface area and uniformly dispersed metal groups, has good compatibility on fluorin ions and has very high selectivity and high defluorination efficiency.

Owner:CENT SOUTH UNIV

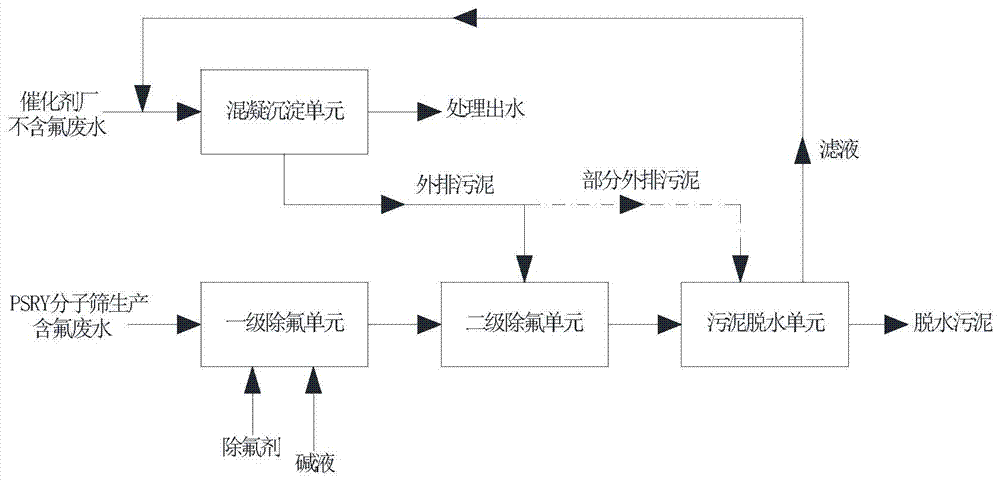

A treating method of fluorine-containing waste water

InactiveCN104512973AReduce dosageAvoid the impact of the defluoridation processWater contaminantsMultistage water/sewage treatmentWater solubleFluorine containing

A treating method of fluorine-containing waste water is disclosed. The fluorine-containing waste water comprises F-, SO4<2-> and Al<3+>. The method includes: bringing the fluorine-containing waste water and a water-soluble aluminum-source fluorine removing agent into contact and adjusting the pH value of the fluorine-containing waste water to be not lower than 5 to perform neutralization and sedimentation reactions; bringing the fluorine-containing waste water after the neutralization and sedimentation reactions and discharged sludge from a coagulating sedimentation treating unit of waste water free of fluorine into contact; and subjecting the obtained mixture to sludge dehydration to obtain dehydrated sludge and filtrate. The method can perform effective fluorine removal treatment for the fluorine-containing waste water having high contents of the F-, the SO4<2-> and the Al<3+>.

Owner:CHINA PETROLEUM & CHEM CORP +1

Defluorination material for zinc sulfate solution and preparing method

InactiveCN106179180ALow costThe effect of removing F is beneficialIon-exchange process apparatusOther chemical processesRare-earth elementHigh concentration

The invention discloses a defluorination material for a zinc sulfate solution in the zinc smelting process and a preparing method. The defluorination material is mainly prepared from oxide containing aluminum elements, rare earth elements, iron elements and magnesium elements. The preparing method includes the steps that aluminum hydroxide powder is placed into iron-magnesium salt mixed liquid, the mixture is stirred, alkaline is added to adjust pH, and the obtained mixture stands and is subjected to suction filtration; the obtained sample is added into a rare earth salt solution, the mixture is stirred again, alkaline is added to adjust pH, and the obtained mixture is subjected to suction filtration and dried; finally, the obtained product is placed into a high-temperature resistance furnace and roasted under the ventilation condition, and the defluorination material is obtained. The preparing method is simple, and the product is stable in nature, has high selective adsorbability and high adsorbing capacity for high-concentration fluorinion in the zinc sulfate solution and can be recycled with a simple method. When the material is applied to removing the high-concentration fluorinion in the zinc sulfate solution, the concentration of F in the solution can be effectively and rapidly reduced, the enterprise cost can be reduced, and environment pollution can be reduced. The material is suitable for large-scale industrial application.

Owner:CENT SOUTH UNIV +1

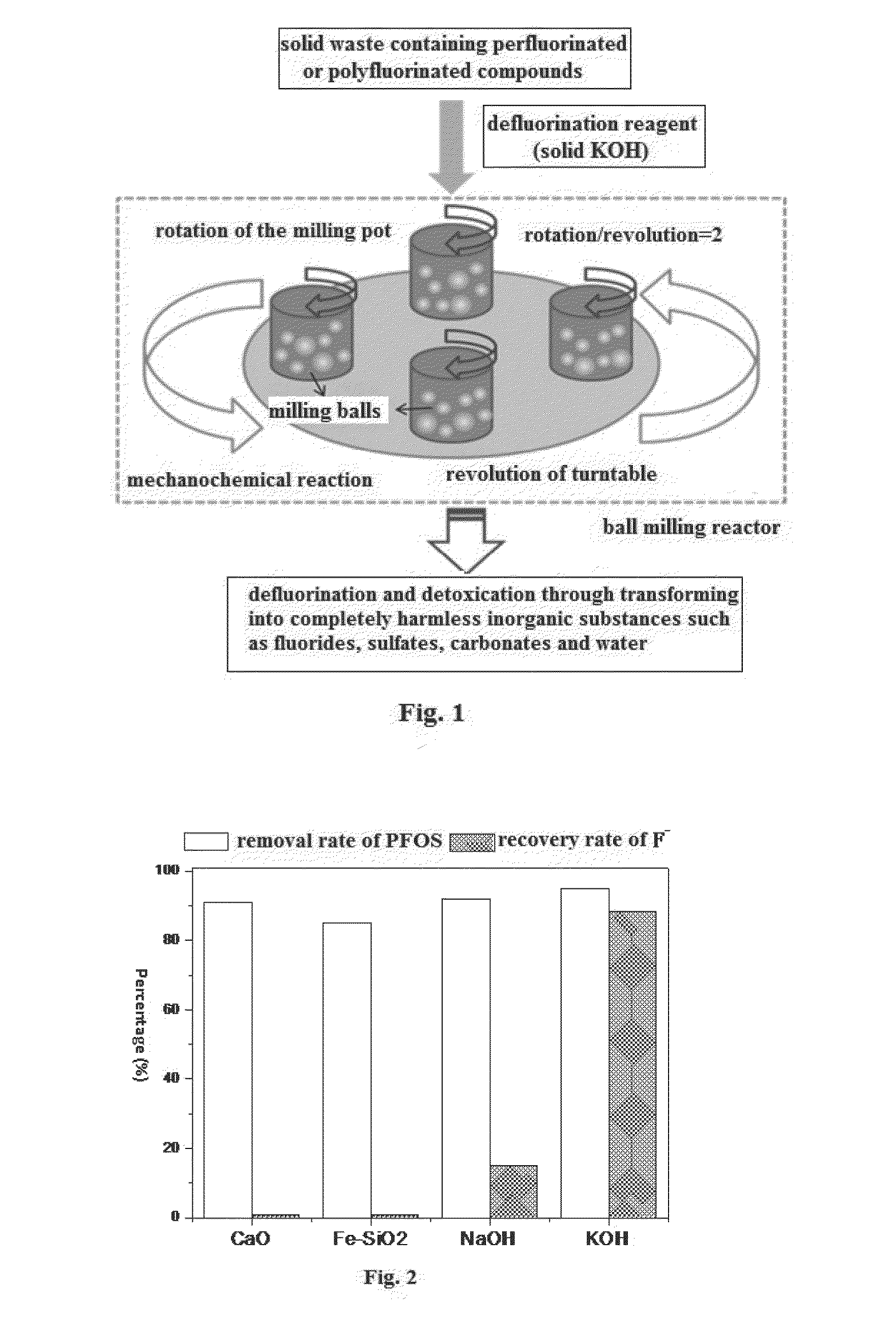

Method for mechanochemical treatment of solid wastes containing perfluorinated or polyfluorinated compounds

ActiveUS20150174440A1Reduce consumptionMeet cutting requirementsChemical protectionChemical reactionHigh energy

A method for mechanochemical treatment of solid wastes containing perfluorinated or polyfluorinated compounds is provided. It belongs to the field of environment-polluting wastes treatment, and comprises the following steps: mixing the solid waste containing perfluorinated or polyfluorinated compounds with the defluorination reagent under normal temperature and pressure conditions, putting the mixture into a planetary high-energy ball milling reactor; adopting the mechanochemical reaction to realize high-effective degradation and defluorination of perfluorinated or polyfluorinated compounds. When being adopted to degrade perfluorinated or polyfluorinated compounds, this method enjoys such advantages as simple treatment procedure, mild reaction conditions (conducted under normal temperature and pressure conditions), lower energy consumption and operating cost, complete degradation and defluorination of the target pollutants, completely inorganic and harmless end products and free of liquid or gas byproducts.

Owner:TSINGHUA UNIV

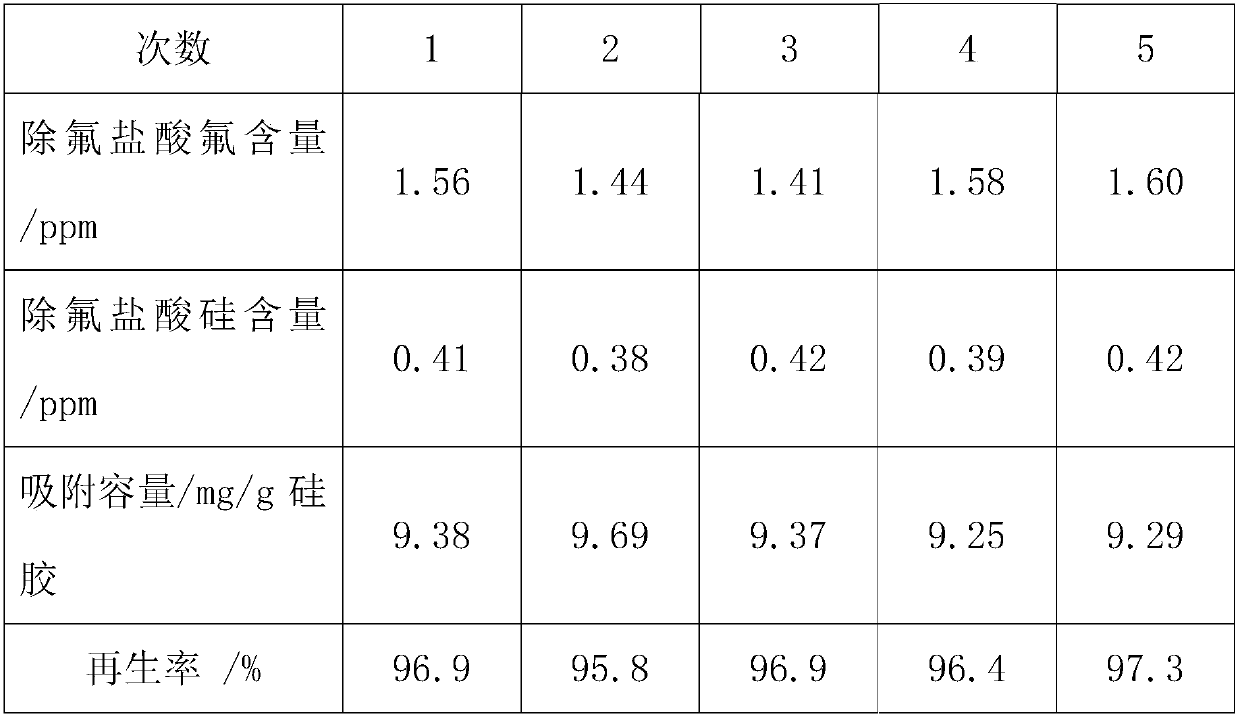

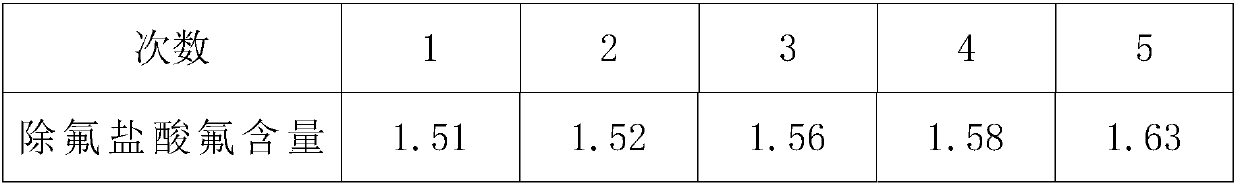

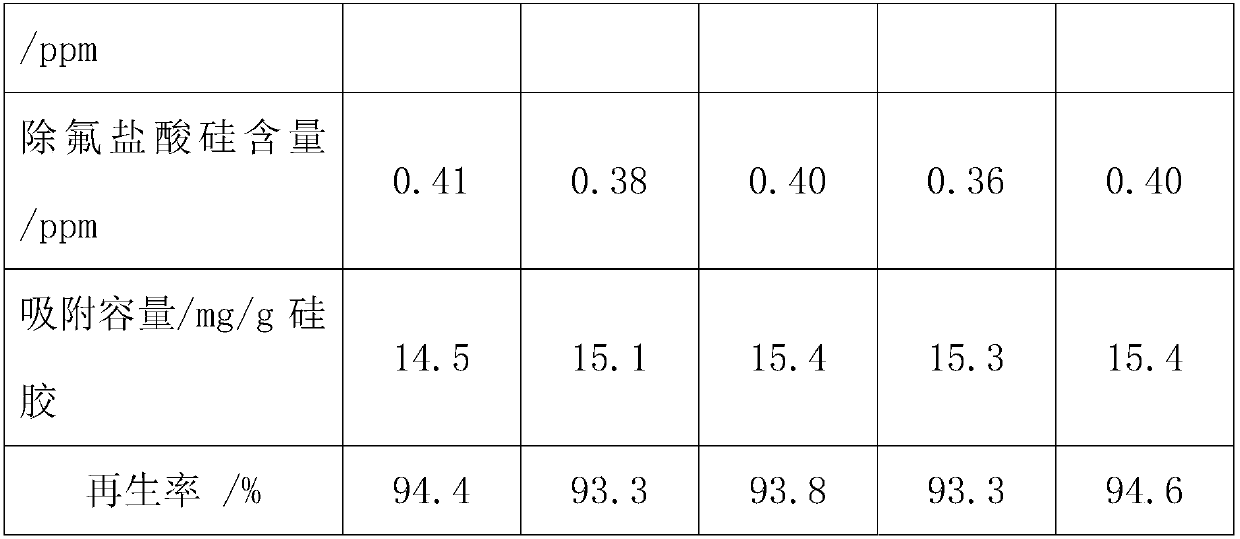

Defluorination method of fluorine-containing hydrochloric acid

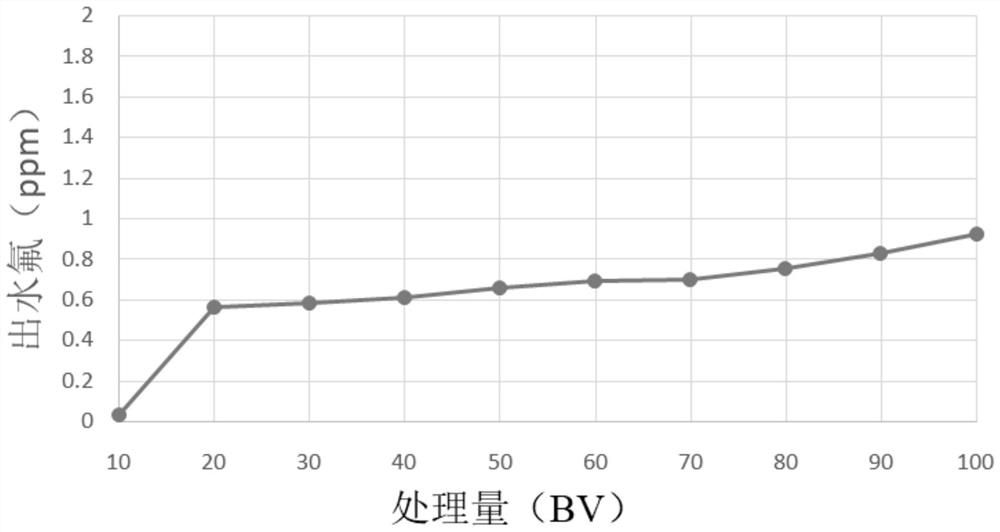

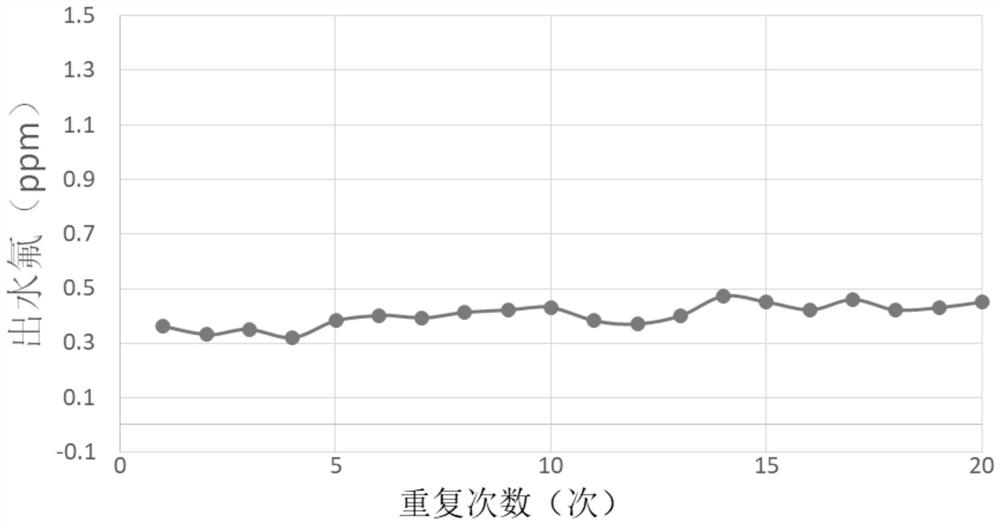

InactiveCN107892275AImprove fluorine removal and regeneration efficiencyHigh fluoride removal efficiencyIon-exchange process apparatusChlorine/hydrogen-chloride purificationHydrogen fluorideFilter paper

The invention discloses a defluorination method of fluorine-containing hydrochloric acid. The method includes the following steps that 1, firstly, fluorine-containing hydrochloric acid is weighed andadded in a reaction device, silica gel is added into the reaction device so as to make the silica gel fully contact with fluorine-containing hydrochloric acid, the adsorption reaction occurs between hydrogen fluoride and silica gel in hydrochloric acid, and fluorinion is removed; 2, silica gel obtained after fluorine is adsorbed is subjected to water-bath shaking in a thermostatic oscillator for 1-2 h, the temperature of water bath is 20-30 DEG C, a regenerant is used for washing, the silica gel is treated to be neutral, after being adsorbed and dried by filter paper, the silica gel is placedin the reaction device, fluorine is separated out from the silica gel, the silica gel can be regenerated, and the silica gel obtained after regeneration is used for fluorine removal from hydrochloricacid in the next cycle. The method is simple in process, low in cost, convenient and safe to operate, high in fluoride removal efficiency, and suitable for defluoridation of low-fluorine hydrochloricacid.

Owner:JUHUA GROUP TECH CENT

Preparation method of industrial water fluorine removal agent

ActiveCN104085973AGood defluoridation effectHigh fluoride removal efficiencyWater/sewage treatmentEthylenediamineSodium hydroxide

The invention discloses a preparation method of an industrial water fluorine removal agent, and belongs to the technical field of industrial water fluoride removal. The industrial water fluorine removal agent is prepared from the following synthetic raw materials: acrylic acid, de-ionized water, acrylamide, urea, sodium carbonate, ferrous hydroxide, aluminum hydroxide, 10%-30% sodium hydroxide, active carbon, 10% ethylenediamine, nitrilo, ammonium persulfate, sodium hydrogen sulfite and calcium chloride. The preparation method comprises the following steps: preparing the synthetic raw materials, polymerizing and mixing to prepare the industrial water fluorine removal agent. The preparation method has the advantages that the prepared fluorine removal agent is high and stable in fluorine removal efficiency, and has a good fluorine removal effect on low-fluorine water with fluoride content of 20-50mg / L; a medicament preparation process is simple.

Owner:SHOUGANG CORPORATION

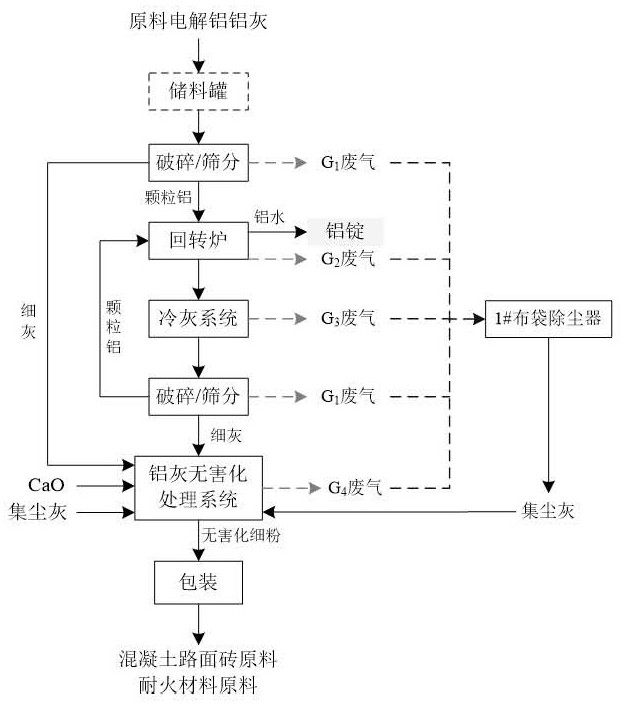

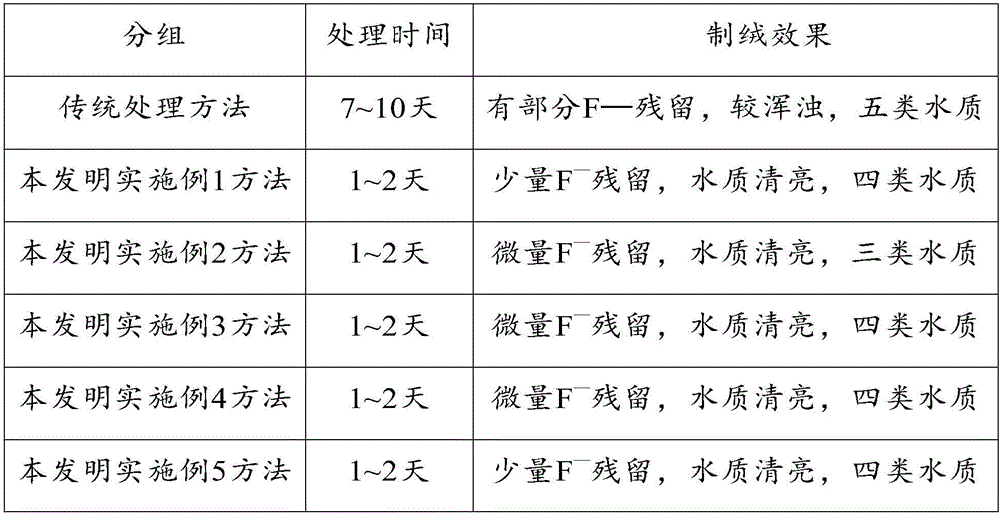

Method used for carrying out innocent treatment on hazardous waste electrolytic aluminum ash

InactiveCN111607709ALarge amount of processingHigh fluoride removal efficiencySolid waste managementProcess efficiency improvementIngot castingWastewater

The invention discloses a method used for carrying out innocent treatment on hazardous waste electrolytic aluminum ash. The method is characterized by mainly comprising the following steps that firstly, raw material electrolytic aluminum ash is subjected to first-time breaking and screening; secondly, particle aluminum is subjected to melting and ingot casting; thirdly, the particle aluminum is subjected to secondary breaking and screening; and fourthly, the collected fine aluminum ash is subjected to dry method fluorine removal aluminum ash harmless treatment. The treatment method is large intreatment amount, high in fluorine removal efficiency (generally larger than 99%), free of draining fluorine containing waste water, free of secondary pollution and equipment and equipment corrosionand the like, and capital construction cost and running cost are both low.

Owner:重庆新格环保科技有限公司

Method for deeply removing fluorine from LiHCO3 solution recycled and leached from waste lithium batteries

ActiveCN112853120AMeet preparation requirementsAvoid decompositionWaste accumulators reclaimingProcess efficiency improvementTitanium zirconiumLithium carbonate

The invention belongs to the technical field of lithium ion battery recovery, and provides a method for deeply removing fluorine from an LiHCO3 solution recycled from waste lithium batteries. The method is used for preparing battery-grade lithium carbonate by taking the LiHCO3 solution as a stock solution. The method comprises the following steps of A, preparing raw materials; B, performing alkali washing on a fluorine removal agent; B, introducing CO2 to regulate and control the pH of a system; D, removing the fluorine from the LiHCO3 solution; and E, regenerating the fluorine removal agent. According to the method, the fluorine removal agent containing elements such as aluminum, titanium, zirconium and nitrogen is added into the LiHCO3 solution, and the CO2 gas is blown to regulate and control the reaction pH, so that the deep fluorine removal effect can be achieved, the LiHCO3 solution system can be ensured to be unchanged, meanwhile, new impurities are not introduced, the subsequent preparation requirements of the battery-grade lithium carbonate are met, and the product quality is improved.

Owner:衢州华友资源再生科技有限公司 +1

Utilization method of phosphate ores

InactiveCN105692575ALow viscosityDimensionally stableCalcium/strontium/barium sulfatesPhosphoric acidCalcium phosphorusTri calcium phosphate

The invention discloses a utilization method of phosphate ores. The utilization method comprises the following steps: crushing and finely grinding the phosphate ores to obtain phosphate ore powder; stirring the phosphate ore powder and hydrochloric acid to react at a room temperature for 0.5 hour to 6 hours; carrying out solid-liquid separation; carrying out fluorine removal, impurity removal, calcium-phosphorus separation (sedimentation, filtering, extracting, drying and the like) on a liquid solution; furthermore, treating a residual calcium chloride solution; finally, obtaining products including fertilizer-grade calcium hydrogen phosphate, feed-grade calcium hydrogen phosphate, phosphorus-nitrogen composite flame retardant, tricalcium phosphate, calcium sulfate whiskers and the like, and also obtaining a diluted hydrochloric acid solution; rectifying and concentrating the diluted hydrochloric acid solution and returning the solution back to a phosphate ore powder acidolysis procedure. According to the utilization method, the used hydrochloric acid can be circularly utilized, and the hydrochloric acid can be generated; the obtained hydrochloric acid is used for decomposing the phosphate ores again and the acidolysis cost is low; meanwhile, the phosphorus chemical products including the fertilizer-grade calcium hydrogen phosphate, the feed-grade calcium hydrogen phosphate, the phosphorus-nitrogen composite flame retardant, the tricalcium phosphate, the calcium sulfate whiskers and the like can also be obtained, so that the comprehensive utilization efficiency of the phosphate ores is high and the economic benefits are good.

Owner:GUIZHOU INST OF METALLURGY & CHEM ENG

Method for defluoridation in acid preparation by brasses

InactiveCN101591007ASimple and efficient operationHigh fluoride removal efficiencySulfur compoundsAqueous solutionAcid preparations

The invention discloses a method for defluoridation in acid preparation by brasses, which comprises the following steps: (1) adding Na2SO3 as a fluorine fixing agent in solution; (2) performing the proportion of adding quantity of sodium silicate and fluorine content in the solution according to 1.1 kg / kgF of the sodium silicate; (3) obtaining the required quantity of the sodium silicate by calculation, preparing 5 percent aqueous solution with the sodium silicate, adding the sodium silicate solution into a cooling recycle acid, wherein the adding point of the sodium silicate solution is positioned in the last grade of a washing device, the temperature is 20 DEG C, the cooling recycle acid containing 5 percent sodium silicate solution is sprayed from a cooling tower, the gas goes from bottom to top, and the cooling tower is required to be over 6m. The method has simple operation without adding other devices, high defluoridation efficiency, can reduce fluorin of an HF form in dilute acid to be less than 0.1 g / L executed according to the steps, thereby making the residue quantity of the fluorin in the gas reduced to the standard requirement which is less than 2 mg / Nm and ensuring the safety operation of a post system.

Owner:WENGFU (GRP) CO LTD

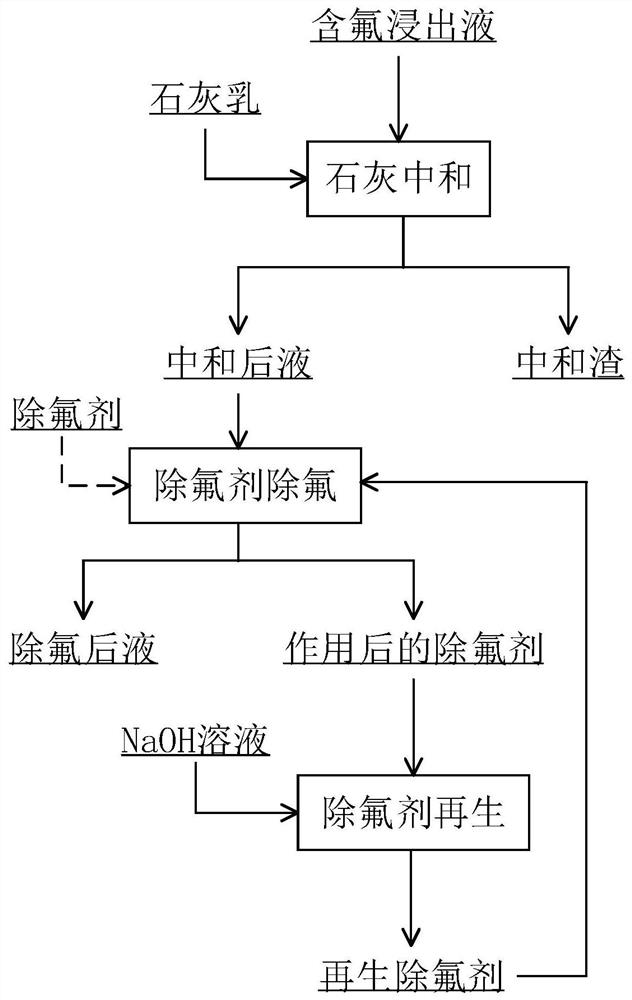

Two-stage fluorine removal method for fluorine-containing material

ActiveCN112267023AReduce fluorine contentSimple and fast operationWaste accumulators reclaimingBattery recyclingPregnant leach solutionSlag

The invention belongs to the technical field of hydrometallurgy and resource recovery, and particularly relates to a fluorine removal method for a fluorine-containing material. The fluorine removal method comprises the following steps that 1), fluorine-containing solid powder containing one or two or more elements of cobalt, nickel and manganese is taken and leached with sulfuric acid to obtain fluorine-containing leachate; 2) a lime milk solution is added into the fluorine-containing leachate for carrying out neutralization reaction; 3) after the reaction is finished, filtering is carried outto obtain neutralized slag and a neutralized solution; (4) a fluorine removal agent is added into the neutralized solution for reaction; 5) after the reaction is finished, filtering is carried out toobtain a fluorine-removed solution and an acted fluorine-removed agent; and 6) regeneration treatment is carried out on the acted fluorine-removed agent by using a NaOH solution to obtain a regenerated fluorine removal agent. The method is simple and convenient in operation and high in fluorine removal efficiency, can reduce the fluorine content in the solution to be less than 10 mg / L, and is suitable for fluorine removal of a single cation solution system or a polycation solution system.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +2

Process for removing fluorine from trifluoroacetic acid

InactiveCN101948378AShort processEasy to operateOrganic compound preparationCarboxylic compound separation/purificationFiltrationTrifluoroacetic acid

The invention discloses a process for removing fluorine from trifluoroacetic acid. The process comprises the following steps of: adding fluorine-containing trifluoroacetic acid and excessive active aluminum oxide into a reaction kettle, wherein complex reaction is performed on fluorine-containing impurities in the trifluoroacetic acid and the active aluminum oxide; and AlF2+ complex ions produced by the complex reaction are adsorbed on the surface of the active aluminum oxide; continuously distilling the trifluoroacetic acid, from which the fluorine is removed, out of the reaction kettle, condensing and collecting the trifluoroacetic acid; continuously adding both the fluorine-containing trifluoroacetic acid and the active aluminum oxide into the reaction kettle at the same time to keep liquid level in the reaction kettle constant; and pumping out the active aluminum oxide, to which the AlF2+ complex ions are adsorbed, from the bottom of the reaction kettle, removing the active aluminum oxide by filtration of a filter, and circulating filtrate into the reaction kettle. The process of the invention has the advantages of short process flow, easy operation, high fluorine removal efficiency, cheap and readily available fluorine removing agent and low fluorine removal cost.

Owner:HUZHOU YUANZHENG CHEM

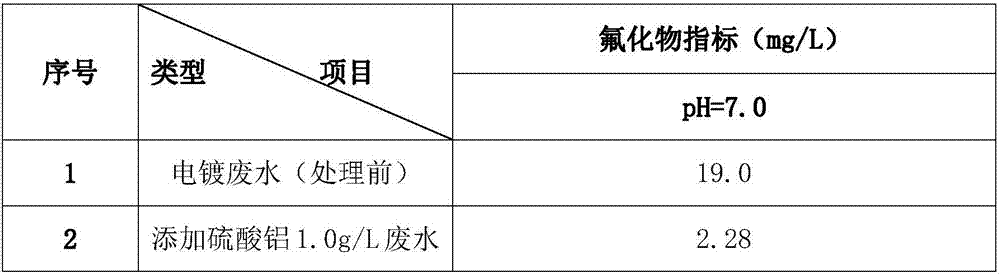

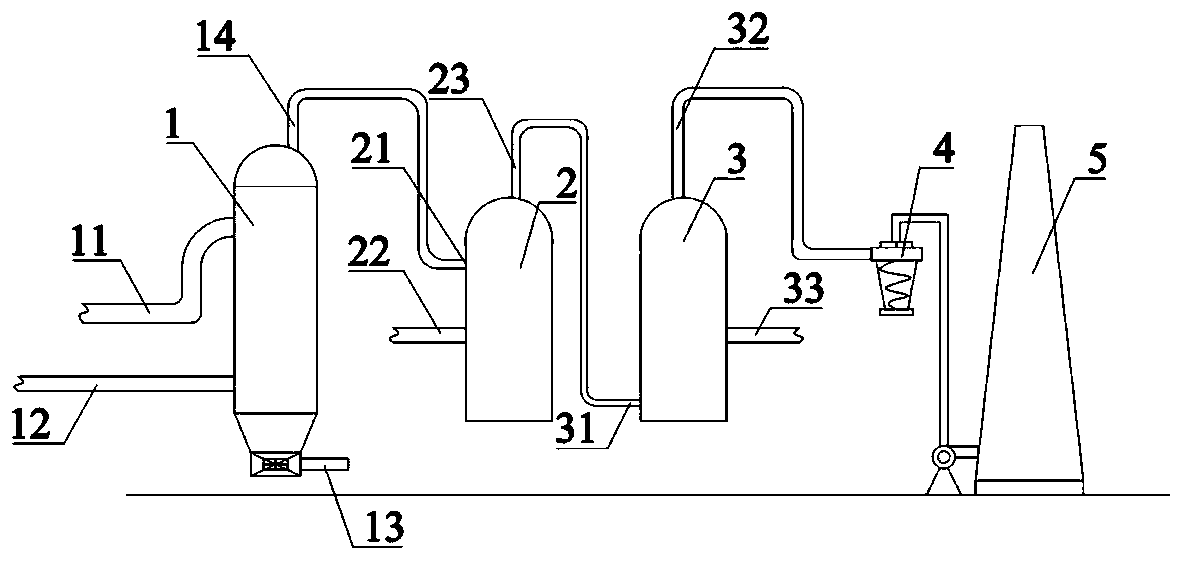

Deep defluorination system and method for electroplating wastewater

PendingCN107487939AReduce fluoride contentImprove processing efficiencyWater contaminantsWaste water treatment from metallurgical processActivated sludgePhysical chemistry

The invention discloses a deep defluorination system and method for electroplating wastewater. The system comprises a biochemical treatment unit and a deep defluorination unit which are connected in sequence. The method comprises the following steps: S1, performing biochemical treatment on the electroplating wastewater; S2, performing deep defluorination treatment on the electroplating wastewater subjected to the biochemical treatment in S1, wherein the electroplating wastewater subjected to the deep defluorination treatment can meet the standard and then be discharged. According to the deep defluorination system and the deep defluorination method for the electroplating wastewater, procedures of dephosphorizing the electroplating wastewater by using a biochemical active sludge method and then performing adsorption precipitation are added, so that fluorinions are preliminarily removed; furthermore, through the adoption of a deep defluorination treatment process, preliminary precipitation treatment is carried out firstly by using a polyacrylamide aqueous solution, then chemical precipitation is carried out by jointly using calcium salt and aluminum salt, and finally secondary precipitation treatment is carried out by using the polyacrylamide aqueous solution, so that the fluoride content is effectively reduced, the discharge of fluoride in the electroplating wastewater is avoided, the electroplating wastewater treatment efficiency and the social and economical benefits are improved, clean production, energy conservation and emission reduction are achieved, and pollution to the environment is reduced.

Owner:惠州金茂源环保科技有限公司

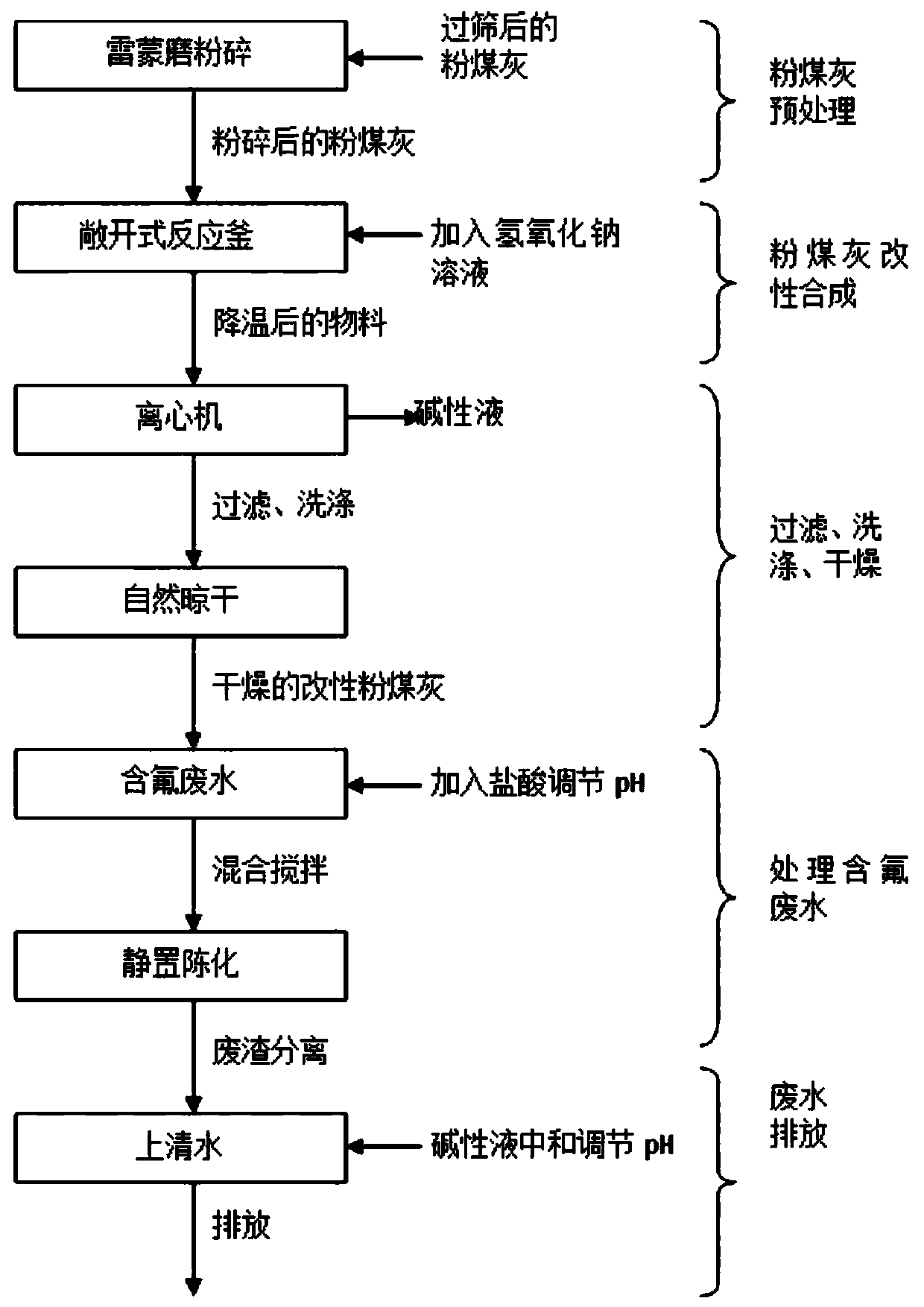

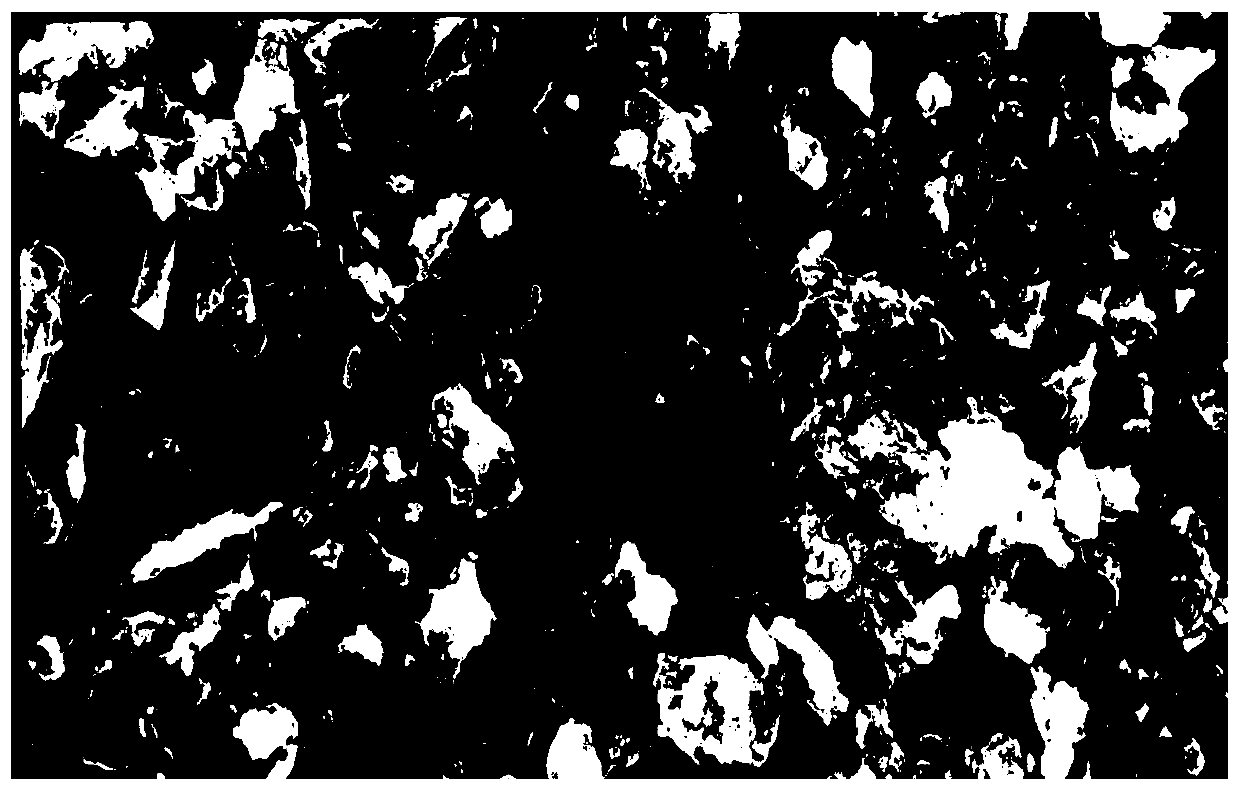

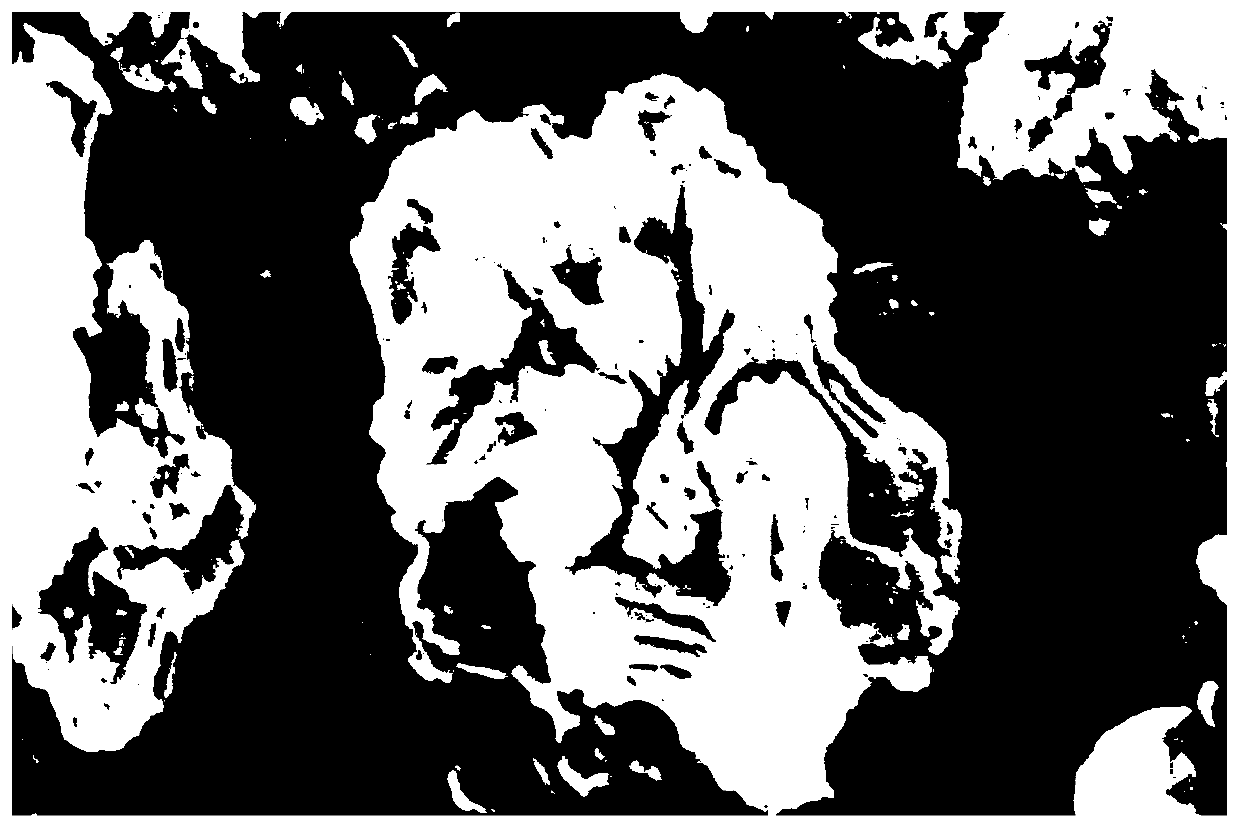

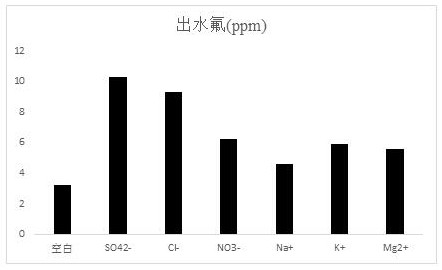

Method for treating high-fluorine-content wastewater by utilizing fly ash

InactiveCN110961074AHigh fluoride removal efficiencyOther chemical processesAluminium silicatesSlagWastewater

The embodiment of the invention discloses a method for treating high-fluorine-content wastewater by utilizing fly ash, and relates to the technical field of sewage treatment, wherein the method comprises the following steps: a, modifying the fly ash; b, adding a hydrochloric acid solution into the high-fluorine-content wastewater requiring to be treated to adjust the pH value to 5.5-6.5, adding the modified fly ash obtained in the step a, and carrying out mixing and stirring reaction at the temperature of 15-20 DEG C for 2 h; c, after the reaction in the step b is finished, standing and agingfor 1-2 h to separate slag from water; and d, adjusting the supernatant of the wastewater subjected to slag-water separation to be neutral by the alkaline solution in the step a, and discharging. According to the method, the industrial solid waste fly ash is modified, then the modified fly ash is adopted to treat the high-fluorine-content wastewater, high fluorine removal efficiency can be achieved, and the method has innovativeness and economical efficiency.

Owner:王永红

Efficient humic acid fluorion adsorbent

ActiveCN104096547ALess impuritiesHigh purityOther chemical processesAlkali metal oxides/hydroxidesSorbentManganese

The invention discloses efficient humic acid fluorion adsorbent. The efficient humic acid fluorion adsorbent comprises, by weight part, 35 to 38 parts of humic acid, 4 to 5 parts of ferric chloride, 28 to 32 parts of aluminum chloride, 4 to 5 parts of manganese chloride, 68 to 72 parts of zirconium chloride, 7 to 10 parts of calcium chloride, 49 to 52 parts of mixed pulverized coal and 55 to 60 parts of sodium hydroxide solutions. The zirconium chloride, the ferric chloride, the aluminum chloride, the manganese chloride and the calcium chloride are sequentially dissolved in water to obtain an iron, aluminum, manganese, zirconium and calcium mixed solution; the humic acid is added to the sodium hydroxide solutions to obtain an alkaline sodium humate solution, the alkaline sodium humate solution is stirred and added to the iron, aluminum, manganese, zirconium and calcium mixed solution, and a PH (Potential Of Hydrogen) value is adjusted to filter to obtain solid mixture; the solid mixture is heated, pressed and dried after being washed to obtain humic acid metal complex; the mixed pulverized coal and the humic acid metal complex are stirred to obtain the efficient humic acid fluorion adsorbent. The efficient humic acid fluorion adsorbent has the advantages of being wide in raw material source, simple in preparation technology, high in adsorption capacity and high in defluorination efficiency and accordingly greatly reducing costs.

Owner:ANHUI JINYANG FLUORINE CHEM

Preparation method of iron-titanium oxide defluorination adsorbent

PendingCN106215848ALarge adsorption capacityHigh fluoride removal efficiencyOther chemical processesWater contaminantsTitaniumDissolution

The invention discloses an iron-titanium oxide for defluorination in solutions. The iron-titanium oxide is characterized by comprising iron and titanium, and the molar ratio of iron to titanium is 0.1 to 10; the difference between the saturated adsorption capacity of the iron-titanium oxide to fluorine in the solution with the pH value of 3 to 6 and the saturated adsorption capacity of the iron-titanium oxide to fluorine in the solution with the pH value of 7 ranges from -12.5 mg / g to 15.1 mg / g. The invention further discloses a preparation method and application of the iron-titanium oxide. The iron-titanium oxide has the advantages of being high in adsorption capacity, free of dissolution of harmful ions, high in adsorption defluorination efficiency and the like in the solution with the pH value of 3 to 6.

Owner:TSINGHUA UNIV

Preparation method of fluorine removal adsorbent modified by biopolymer composite material

ActiveCN113070046AIncrease surface areaRelative density is smallOther chemical processesWater contaminantsBiopolymerSorbent

A preparation method of a fluorine removal adsorbent modified by a biopolymer composite material comprises the following steps: respectively dissolving chitosan and pectin in deionized water or acid, mixing and heating the two solutions, and carrying out a biopolymer cross-linking reaction; adding a molecular sieve soaked in deionized water into the mixed solution, performing reduced pressure distillation, adding chloroacetic acid and a sodium hydroxide aqueous solution, and grafting the chloroacetic acid to modify the chitosan-pectin biopolymer composite material; adding metal nitrate dissolved in a mixed solution of ethanol and water into the modified molecular sieve, performing reduced pressure distillation, adding a sodium hydroxide solution, stirring at room temperature, and doping metal ions into crystal lattices of the modified polymer; and filtering redundant mixed solution, washing to be neutral with de-daubing water, and drying in a drying oven to obtain the modified defluorination adsorbent. The method is simple in preparation process, low in cost, easy to recycle and high in defluorination efficiency in wastewater.

Owner:JIANGSU HELPER FUNCTIONAL MATERIALS

Method for treating fluoride containing waste water in silicon wafer production process

InactiveCN105668863AEfficient removalReduce concentrationWater treatment parameter controlWater contaminantsReverse osmosisAramid

The invention discloses a method for treating fluoride containing waste water in the silicon wafer production process. The method is characterized by comprising the steps that the modes of lime neutralizing, flocculating settling and reverse osmosis concentration are adopted for treating the fluoride containing waste water; the ratio of the adding amount of lime in lime neutralizing to the weight of the waste water is 1:(150-250), and the lime is calcium oxide or calcium hydroxide; a defluorination flocculating agent is adopted for sedimentation in the flocculating settling process, an aramide roll type reverse osmosis membrane is adopted in the reverse osmosis concentration process, and the waste water is treated at the pressure of 0.5 Mpa to 1 Mpa and the temperature of 40 DEG C to 50 DEG C. The method is good in F-waste water treatment effect, low in energy consumption, low in cost, simple in process operation, good in repeatability and evenness and easy to popularize.

Owner:林淑录

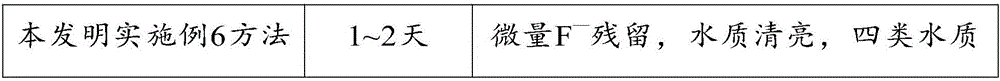

Method of treating dust collecting ash of hazardous waste harmlessly

InactiveCN111618072ALarge amount of processingHigh fluoride removal efficiencySolid waste disposalAuxillary shaping apparatusAluminiumCorrosion

The invention discloses a method of treating dust collecting ash of hazardous waste harmlessly. The method is characterized by primarily comprising the following steps of (1) carrying out first time crushing and screening on a raw material collecting dust; (2) melting and casting granular aluminum; (3) carrying out second time crushing and screening on granular aluminum; and (4) carrying out harmless treatment on aluminum ash by dry process defluorination on collected fine aluminum ash. The method is large in treatment capacity, high in defluorination efficiency (usually greater than 99%) andfree of secondary pollution and equipment corrosion, and fluorine-containing wastewater is not discharged and the like, and the capital expenditure and the operating cost are relatively low. The dustcollecting aluminum ash is crushed and screened, a rotary furnace recovers metal aluminum, and then the aluminum ash is then mixed with raw materials such as sand, cement, coal ash, a marble crushed material, granite and the like and auxiliary agents after aluminum removal and denitrification harmless treatment of thermal treatment by the high temperature rotary furnace, and is processed to concrete pavement bricks, so that the dust collecting ash is utilized effectively.

Owner:重庆新格环保科技有限公司

Fluorine-containing wastewater treatment device and method

ActiveCN112047558AHigh fluoride removal efficiencySmall footprintWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentFluorideFluorine containing

The invention relates to a fluorine-containing wastewater treatment method and a fluorine-containing wastewater treatment device. The method comprises the following steps: step 1, enriching fluorine ions in wastewater to a certain region by utilizing an external electrostatic field; step 2, separating the wastewater in the fluorine ion enrichment region from the wastewater in the less fluorine ionregion; step 3, removing most fluorine ions from the wastewater rich in fluorine ions by using a chemical precipitation method; step 4, enriching fluorine ions in the wastewater to a certain area byutilizing the external electrostatic field again after the step 3 is finished; step 5, separating the wastewater in the fluorine ion enrichment region and the wastewater in the less fluorine ion region again; step 6, removing most of the remaining fluoride ions from the re-separated fluoride ion enriched wastewater by using a flocculation precipitation method; and step 7, forcibly separating precipitates, floccules, floaters and clear liquid in the wastewater through the centrifugal effect; the de-fluorination efficiency of fluorine-containing wastewater can be remarkably improved, the de-fluorination cost is reduced, the occupied area is small, and wastewater de-fluorination can be continuously and efficiently achieved.

Owner:FUJIAN LONGFU CHEM

Method for improving reverse osmosis defluorination efficiency

ActiveCN103288179AImprove interception efficiencyReduce concentrationWater/sewage treatment bu osmosis/dialysisTriethanolamineFluorine

The invention discloses a method for improving the reverse osmosis defluorination efficiency, which comprises the following steps of: adding triethanolamine into raw water needing defluorination; and performing reverse osmosis membrane treatment through a reverse osmosis membrane to remove fluorine ions. The removal rate of fluorine ions can exceed 99%.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

Load type fluorine removal agent and preparation method thereof

InactiveCN107252675AImprove performanceLarge adsorption capacityOther chemical processesSilicon compoundsFixed bedAdsorption effect

The invention discloses a load type fluorine removal agent which comprises yellow sand and an inorganic fluorine removal agent depositing on the surface of yellow sand. The mass ratio of the inorganic fluorine removal agent to the yellow sand is 4: 1 to 1: 1. The load type fluorine removal agent disclosed by the invention is suitable for an industrial fixed bed. By taking the yellow sand as a loading carrier, the load type fluorine removal agent is stable in performance, large in adsorption and high in fluorine removal efficiency. The fluorine removal agent disclosed by the invention can be regenerated in situ and can be repeatedly used, and still has a good adsorption effect after regeneration for many times. The load type fluorine removal agent disclosed by the invention is wide in source of raw materials which are easily available, and is low in cost. The preparation equipment and processing course of the load type fluorine removal agent are simple, the reaction condition is wild and the load type fluorine removal agent is suitable for industrial batch production.

Owner:JIANGSU HELPER FUNCTIONAL MATERIALS

Magnesium oxide composite material for fluorine removal of water body and preparation method and application thereof

InactiveCN108745270ARich sourcesLow priceOther chemical processesWater contaminantsAdhesiveOxide composite

The invention provides a magnesium oxide composite material for fluorine removal of a water body and a preparation method and application thereof. The fluorine removal material is characterized in that inert particles are used as a carrier, and the magnesium oxide is coated to the surface of the carrier by an adhesive and is cured, so as to form the magnesium oxide composite material. The magnesium oxide composite material is prepared from the following components of 30 to 50 parts of magnesium oxide, 0.1 to 20 parts of adhesive and 40 to 60 parts of carrier particles. The magnesium oxide composite material has the characteristics that the adsorption and fluorine removal activity of the magnesium oxide is reserved, the magnesium oxide is effectively cured, and the loss in the use process is greatly reduced; the sources of the raw materials are rich, the price is low, and the preparation is simple; the fluorine removal efficiency is higher, and the fluorine removal requirement of drinking water can be met.

Owner:TIANJIN MEDICAL UNIV

Method for preparing fluorine removal agent and treating fluorine-containing waste liquid

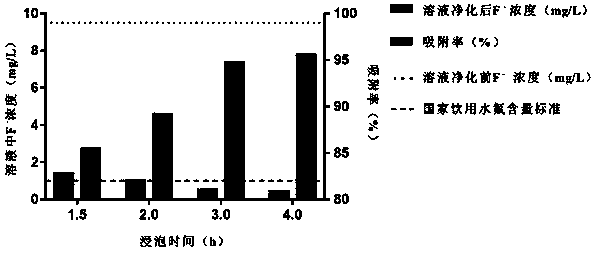

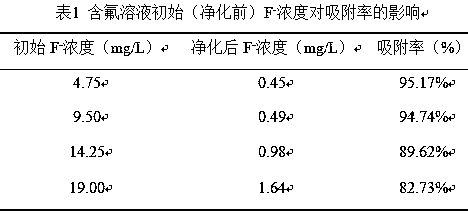

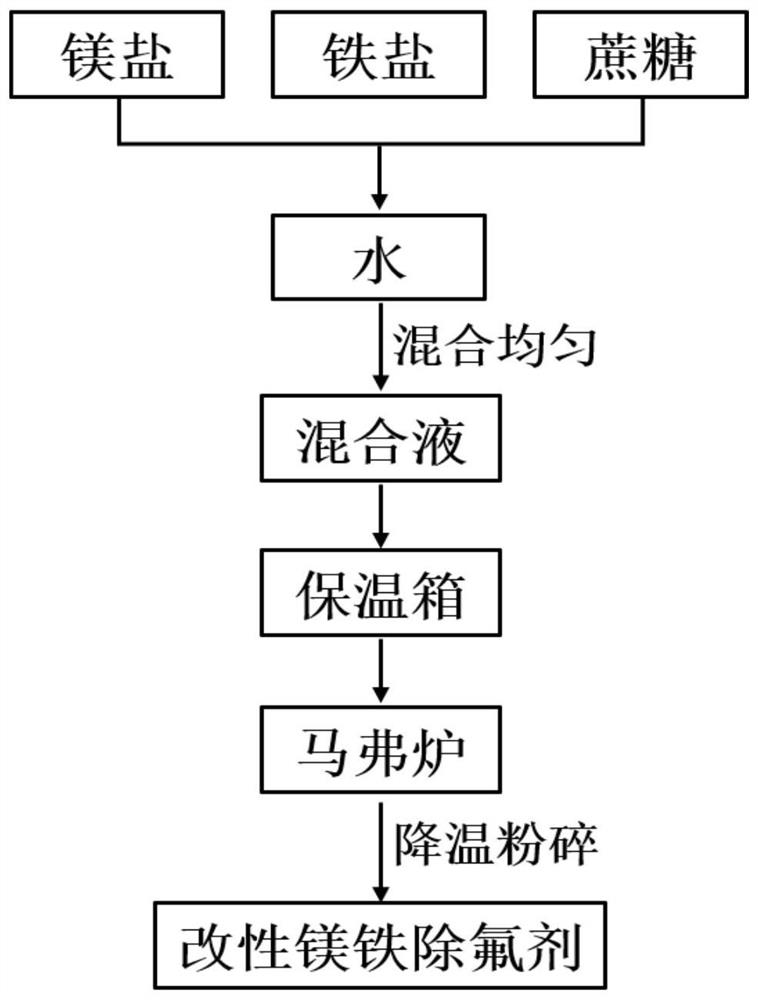

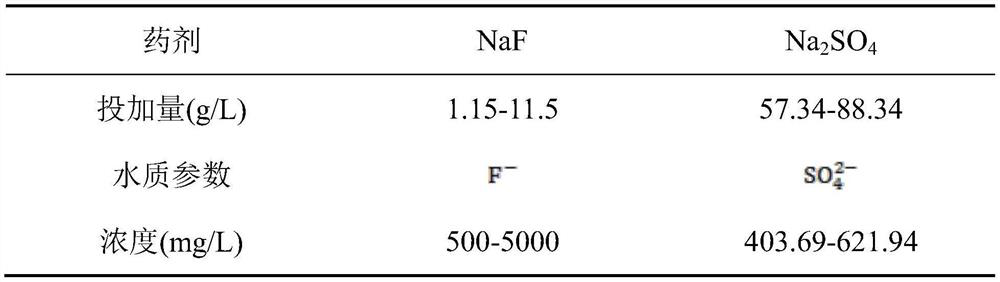

InactiveCN113735236AEasy to makeEasy to operateWater contaminantsWater/sewage treatment by flocculation/precipitationSulfate radicalsSucrose

The invention relates to a method for preparing a fluorine removal agent and treating fluorine-containing waste liquid. The method comprises steps: adopting MgCl2, MgSO4, FeCl3, Fe2 (SO4) 3 and cane sugar as raw materials and adding according to a proportion; dissolving with deionized water, stirring on a magnetic stirrer, drying, calcining, taking out, cooling to room temperature, and crushing to obtain the modified magnesium-iron fluorine removal agent. The method for treating fluorine-containing waste liquid comprises the following steps: adding the modified magnesium-iron fluorine removal agent and a magnesium fluoride seed crystal into the acidic fluorine-containing waste liquid, stirring and standing to realize effective separation of mud and water; the method is used for treating the acidic fluorine-containing waste liquid containing high-concentration sulfate radicals, and the defect that high-concentration sulfate radicals in waste liquid in a traditional calcium salt method consume a calcium source can be effectively overcome by treating the acidic fluorine-containing waste liquid through the modified magnesium-iron fluorine removal agent; meanwhile, due to the existence of ferric salt, the problem that in a traditional magnesium salt method, magnesium fluoride sludge is poor in settleability, and consequently the fluorine content of supernate is too high is solved, magnesium fluoride in the waste liquid is induced to be nucleated and grow through magnesium fluoride crystal seeds, the reaction rate is increased, the treatment process of the acidic fluorine-containing waste liquid is shortened, the treatment cost is reduced, and the method is an efficient and environment-friendly technological method.

Owner:NORTHEASTERN UNIV LIAONING

Functionalized silicon dioxide modified defluorination material as well as preparation and application thereof

ActiveCN112777672AEasily chelatedIncrease surface areaWater contaminantsWater/sewage treatment by magnetic/electric fieldsIon exchangeEngineering

The invention relates to a functionalized silicon dioxide modified defluorination material and preparation and an application thereof, and a preparation method of the functionalized silicon dioxide modified defluorination material comprises the following steps: reacting acidified mesoporous silicon dioxide nanoparticles with chitosan oligosaccharide in an acidic aqueous solution, and after the reaction is completed, obtaining chitosan oligosaccharide modified mesoporous silica nanoparticles; reacting chitosan oligosaccharide modified mesoporous silica nanoparticles with dicarboxylic acid in an acidic aqueous solution, then reacting with a metal compound, and treating in an alkaline solution after the reaction is completed so that metal hydroxides are generated on the surfaces of the mesoporous silica nanoparticles, and obtaining the functionalized silica modified defluorination material. According to the functionalized silicon dioxide modified fluorine removal material, dicarboxylic acid connected with chitosan oligosaccharide is used for chelating metal ions, the bonding stability of the metal ions is improved, and the modified material can remove fluorine ions through the dual effects of ion exchange and electrostatic adsorption.

Owner:JIANGSU HELPER FUNCTIONAL MATERIALS

Synthesis method of adsorbent for removing fluorine in high salt

PendingCN114082407AGood chemical stabilityLow costOther chemical processesWater contaminantsSorbentNitrate salts

The invention relates to a synthesis method of an adsorbent for removing fluorine in high salt, and belongs to the technical field of separation of fluorine-containing wastewater. The synthesis method of the adsorbent comprises the following steps: (1) swelling chloromethylated resin in an organic solvent, respectively adding an alkali and a quinoline amide derivative, stirring and reacting to obtain a mixture containing resin, and carrying out solid-liquid separation to take a solid phase which is modified chloromethylated bead resin 1; (2) adding a quinoline derivative and the organic solvent into the modified chloromethylated bead resin 1 in the step (1), stirring and mixing, and carrying out heating reflux reaction to obtain chloromethylated bead modified resin 2; and (3) adding a nitrate solution into the chloromethylated bead modified resin 2 obtained in the step (2), and reacting to obtain the defluorination adsorbent after the reaction is finished. The prepared modified defluorination material is simple in preparation process, low in cost, easy to recycle and high in defluorination efficiency in wastewater.

Owner:JIANGSU HELPER FUNCTIONAL MATERIALS

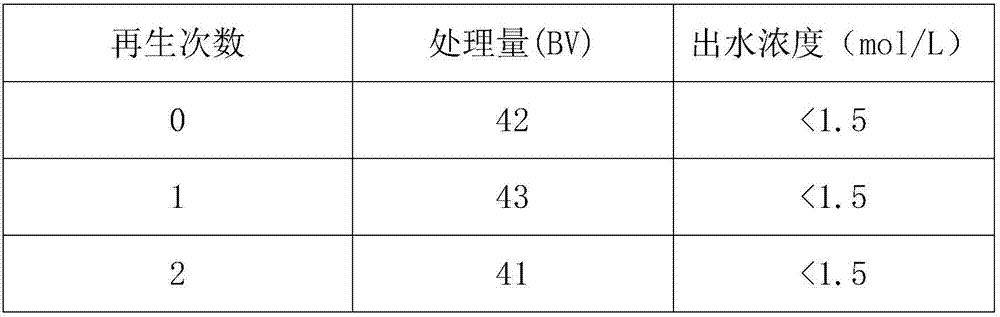

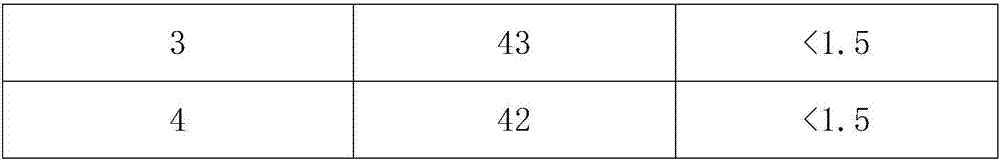

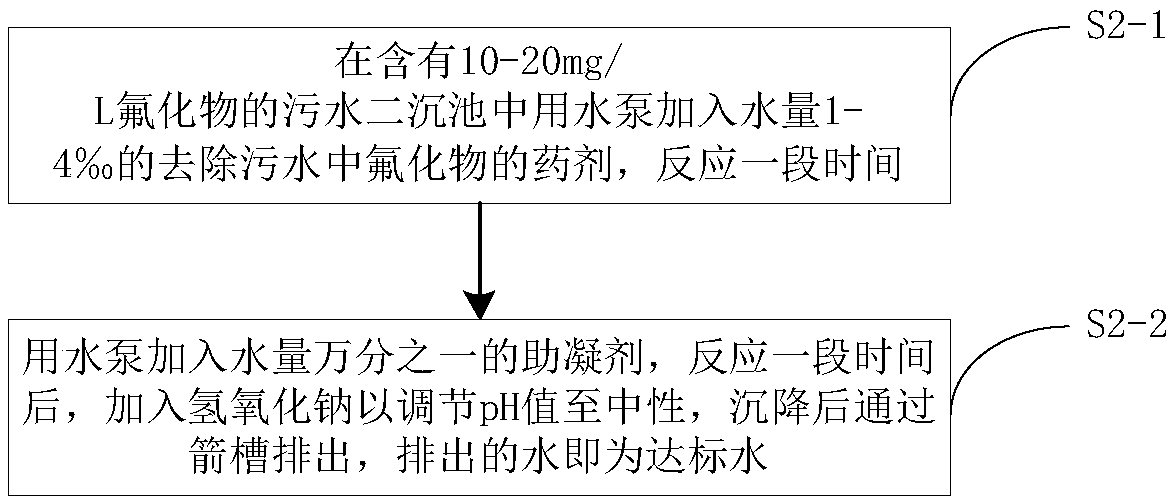

Medicament for removing fluoride in sewage, preparation method of medicament and sewage treatment method

InactiveCN109516537AIncrease contentImprove biodegradabilityWater contaminantsWater/sewage treatment by neutralisationAfter treatmentMedicine

The invention discloses a medicament for removing fluoride in sewage, a preparation method of the medicament and a sewage treatment method, and belongs to the technical field of sewage treatment. Themedicament is prepared from the following components in percentage by mass: 25-35% of glucose, 4-6% of a flocculant, 1-2% of inorganic acid, 8-10% of metal carbonate, and 47-62% of water. The medicament is liquid, operation is convenient, the mud generation amount is less, and the cost is low. The fluoride removal efficiency is high, after treatment, the fluorine content can be decreased to 1.5 mg / L or below, the obvious effect is achieved in a plurality of local sewage treatment plants, and the medicament is suitable for the various types of sewage treatment plants.

Owner:石家庄盈聚环保科技有限公司

Pyrite-to-sulfuric acid flue gas defluorination equipment and pyrite-to-sulfuric acid flue gas defluorination process method

InactiveCN111036038AImprove processing efficiencyCompact structureGas treatmentDispersed particle separationFlue gasPyrite

The invention relates to pyrite-to-sulfuric acid flue gas defluorination equipment, which comprises a reaction furnace, an efficient washing tower and a middle washing tower, wherein the efficient washing tower comprises a first defluorination material inlet, and the middle washing tower comprises a second defluorination material inlet formed in the side wall. According to the invention, a two-stage washing tower with defluorination gradient is arranged to treat so as to improve the defluorination efficiency, and different defluorination materials can be added to achieve efficient defluorination treatment; the equipment is small in occupied area and high in defluorination efficiency, and is suitable for transformation and upgrading of old factories; the process method of the pyrite-to-sulfuric acid flue gas defluorination equipment comprises the following steps: S1, introducing furnace gas into the efficient washing tower; S2, adding a first defluorination material into the efficient washing tower; S3, adding a second defluorination material into the middle washing tower; and S4, discharging the treated furnace gas; and the process method has the advantages of high defluorination efficiency and convenience in raw material obtaining of pyrite-to-sulfuric acid preparation plants, and is suitable for transformation and upgrading of old plants.

Owner:洛阳丰瑞氟业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com