Method of treating dust collecting ash of hazardous waste harmlessly

A technology for harmless treatment and hazardous waste, which can be used in the removal of solid waste, auxiliary molding equipment, ceramic molding machines, etc. The effect of high defluorination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

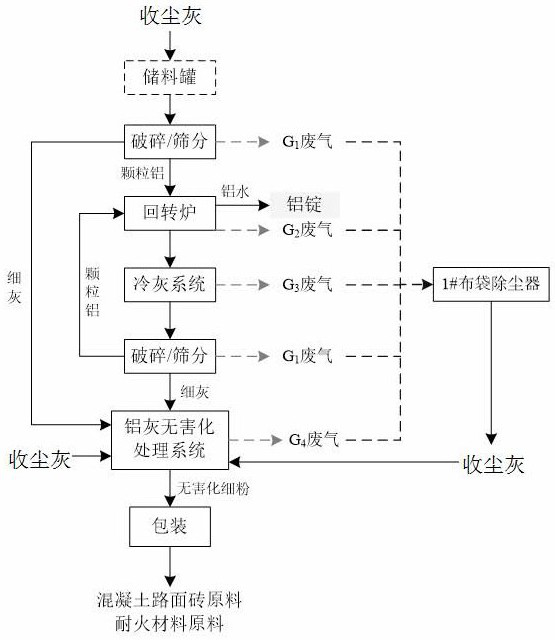

[0038] refer to figure 1 , a method for harmless treatment of hazardous waste dust collection, characterized in that: the method mainly includes the following steps:

[0039] (1) Collect the raw material dust and carry out the first crushing and screening, this step includes:

[0040] ①Convey the collected dust to the storage tank, then carry out vacuum pumping on the collected dust, and send it to the feeding port of the crushing and screening machine;

[0041] ②Sieve the above-mentioned dust collection ash through a crushing and screening machine, and sieve out granular aluminum and fine aluminum ash;

[0042] ③ Send the sieved fine aluminum ash to the rotary kiln storage barrel for subsequent processing by vacuum pumping;

[0043] ④Put the granular aluminum screened this time into a large bag, hoist it to the hopper with a crane, and put it into the rotary furnace for metal aluminum recovery;

[0044] Working principle of primary crushing and screening: belt feeding→vert...

Embodiment 2

[0083] refer to figure 1 , a method for harmless treatment of hazardous waste dust collection, characterized in that: the method mainly includes the following steps:

[0084] (1) Collect the raw material dust and carry out the first crushing and screening, this step includes:

[0085] ①Convey the collected dust to the storage tank, then carry out vacuum pumping on the collected dust, and send it to the feeding port of the crushing and screening machine;

[0086] ②Sieve the above-mentioned dust collection ash through a crushing and screening machine, and sieve out granular aluminum and fine aluminum ash;

[0087] ③ Send the sieved fine aluminum ash to the rotary kiln storage barrel for subsequent processing by vacuum pumping;

[0088] ④Put the granular aluminum screened this time into a large bag, hoist it to the hopper with a crane, and put it into the rotary furnace for metal aluminum recovery;

[0089] Working principle of primary crushing and screening: belt feeding→vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com