Method used for carrying out innocent treatment on hazardous waste electrolytic aluminum ash

A technology for harmless treatment and hazardous waste, which is applied in the field of harmless treatment of electrolytic aluminum and aluminum ash, can solve problems such as waste of aluminum resources and the environment, and achieves low capital construction costs and operating costs, large processing capacity, and fluorine removal efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

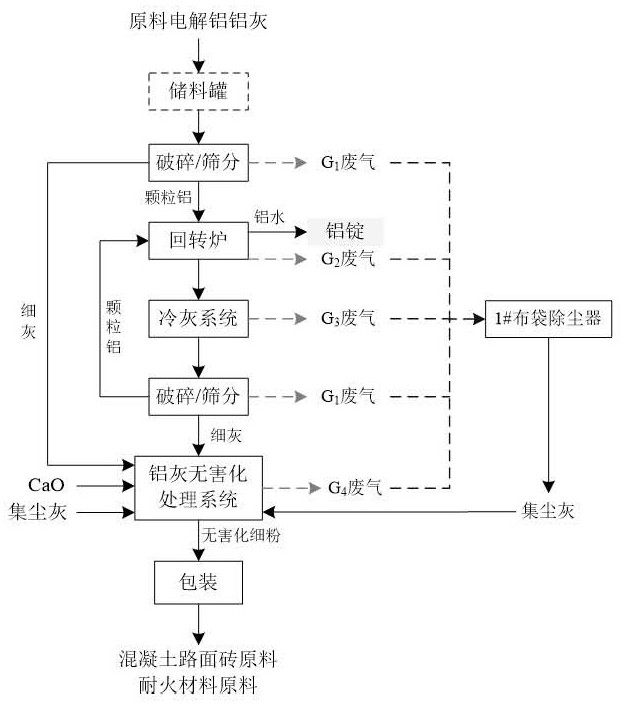

[0040] refer to figure 1 , a method for harmless treatment of hazardous waste electrolytic aluminum ash, characterized in that: the method mainly includes the following steps:

[0041] (1) The raw material electrolytic aluminum ash is crushed and screened for the first time. This step includes:

[0042] ①Convey the collected electrolytic aluminum ash to the storage tank, then carry out vacuum pumping on the electrolytic aluminous ash, and send it to the feeding port of the crushing and screening machine;

[0043] ②Sieve the above-mentioned electrolytic aluminum ash through a crushing and screening machine, and sieve out granular aluminum and fine aluminum ash;

[0044] ③ Send the sieved fine aluminum ash to the rotary kiln storage barrel for subsequent processing by vacuum pumping;

[0045] ④Put the granular aluminum screened this time into a large bag, hoist it to the hopper with a crane, and put it into the rotary furnace for metal aluminum recovery;

[0046] (2) Melting ...

Embodiment 2

[0093] refer to figure 1 , a method for harmless treatment of hazardous waste electrolytic aluminum ash, characterized in that: the method mainly includes the following steps:

[0094] (1) The raw material electrolytic aluminum ash is crushed and screened for the first time. This step includes:

[0095] ①Convey the collected electrolytic aluminum ash to the storage tank, then carry out vacuum pumping on the electrolytic aluminous ash, and send it to the feeding port of the crushing and screening machine;

[0096] ②Sieve the above-mentioned electrolytic aluminum ash through a crushing and screening machine, and sieve out granular aluminum and fine aluminum ash;

[0097] ③ Send the sieved fine aluminum ash to the rotary kiln storage barrel for subsequent processing by vacuum pumping;

[0098] ④Put the granular aluminum screened this time into a large bag, hoist it to the hopper with a crane, and put it into the rotary furnace for metal aluminum recovery;

[0099] (2) Melting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com