Magnesium oxide composite material for fluorine removal of water body and preparation method and application thereof

A composite material, magnesium oxyfluoride technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems such as difficulty in application and loss of active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A magnesium oxide composite material for removing fluoride from water, which is composed of the following raw materials in weight fractions: 30 parts of magnesium oxide, 2 parts of adhesive, and 40 parts of carrier particles; wherein the adhesive is cellulose acetate; the carrier particles are Activated carbon.

[0023] Preparation:

[0024] (1) Dissolve the adhesive with a solvent; the ratio of adhesive to solvent is 1:5 (w:v);

[0025] (2) Add the carrier particles into the adhesive solution, stir and mix evenly;

[0026] (3) Add magnesium oxide and mix well. Make magnesium oxide-adhesive agent-carrier particle composite;

[0027] (4) Place the magnesium oxide-adhesive agent-carrier particle composite in an oven for high-temperature curing at a temperature of 180° C. and a high-temperature curing time of 30 minutes to obtain a magnesium oxide composite material; the solvent is acetone.

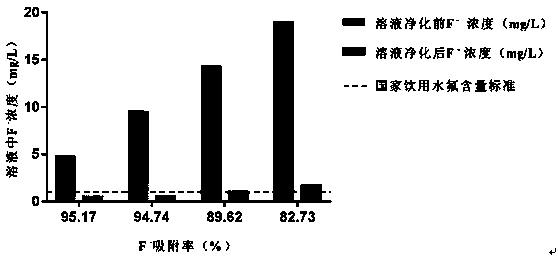

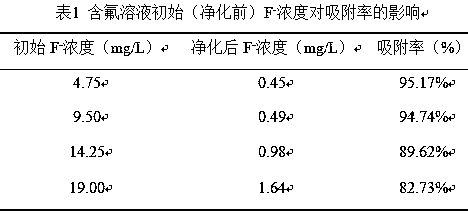

[0028] [Effect of removing fluorine in Example 1]

[0029] Fluoride removal ...

Embodiment 2

[0034] A water body defluoridation magnesium oxide composite material, which is composed of the following raw materials in weight fractions: 50 parts of magnesium oxide, 10 parts of adhesive, 60 parts of carrier particles; wherein the adhesive is polystyrene; the carrier particles are Chitosan.

[0035] Preparation:

[0036] (1) Dissolve the adhesive with a solvent; the ratio of adhesive to solvent is 1:30 (w:v);

[0037] (2) Add the carrier particles into the adhesive solution, stir and mix evenly;

[0038] (3) Add magnesium oxide and mix well. Make magnesium oxide-adhesive agent-carrier particle composite;

[0039] (4) Place the magnesium oxide-adhesive agent-carrier particle composite in an oven for high-temperature curing, the temperature is 150°C, and the high-temperature curing time is 20 minutes to obtain a magnesium oxide composite material; the solvent is dimethylformamide:tetrahydrofuran =4:6(v:v).

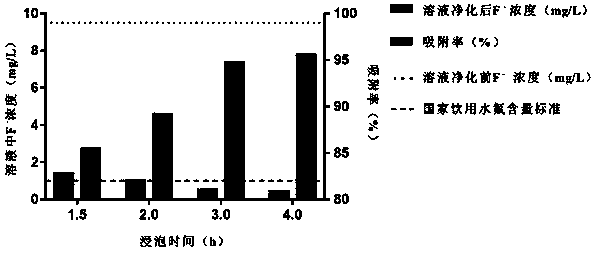

[0040] [Effect of removing fluorine in Example 2]

[0041] In...

Embodiment 3

[0046] A magnesium oxide composite material for removing fluoride from water, which is composed of the following raw materials in weight fractions: 45 parts of magnesium oxide, 18 parts of adhesive, and 55 parts of carrier particles; wherein the adhesive is cellulose acetate; the carrier particles are diatomite.

[0047] Preparation:

[0048] (1) Dissolve the adhesive with a solvent; the ratio of adhesive to solvent is 1:25 (w:v);

[0049](2) Add the carrier particles into the adhesive solution, stir and mix evenly;

[0050] (3) Add magnesium oxide and mix well. Make magnesium oxide-adhesive agent-carrier particle composite;

[0051] (4) Place the magnesium oxide-adhesive agent-carrier particle composite in an oven for high-temperature curing at a temperature of 230° C. and a high-temperature curing time of 150 minutes to obtain a magnesium oxide composite material; the solvent is acetone.

[0052] [Example 3 defluoridation effect]

[0053] The curing effect of magnesium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com