Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Good shielding properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

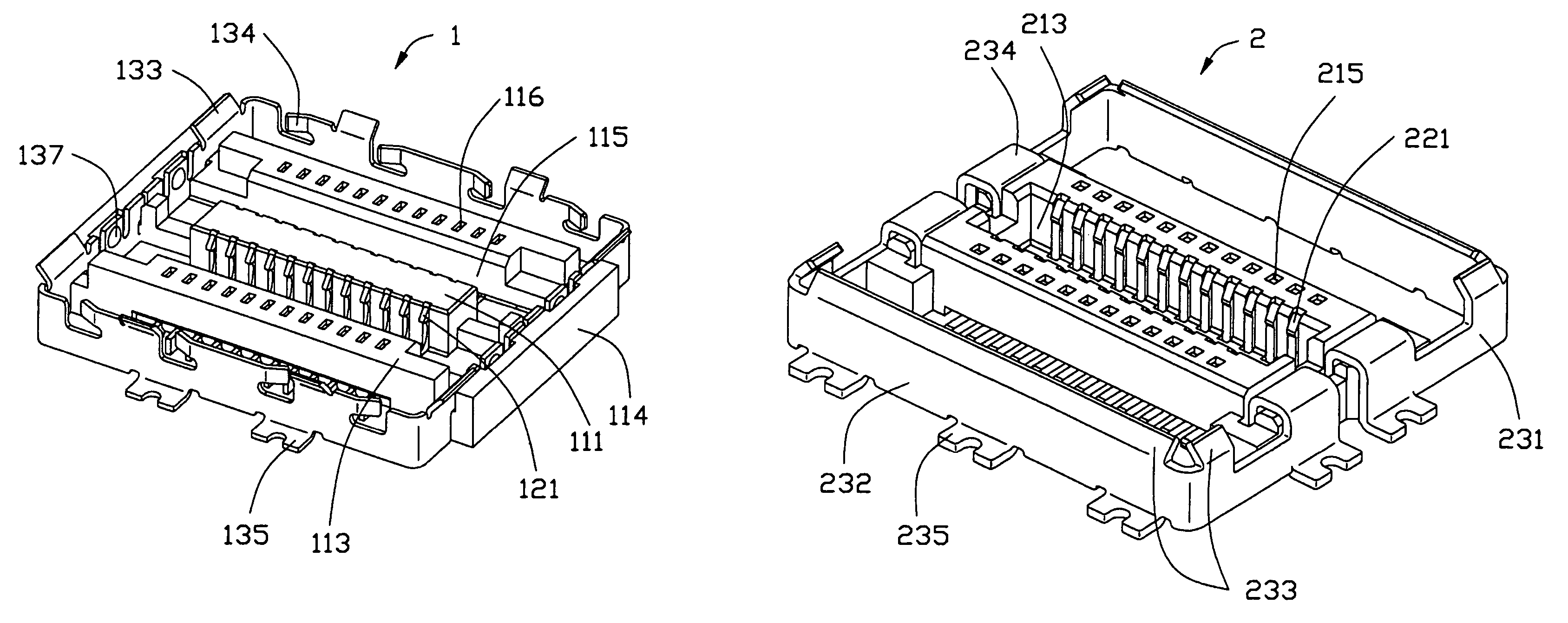

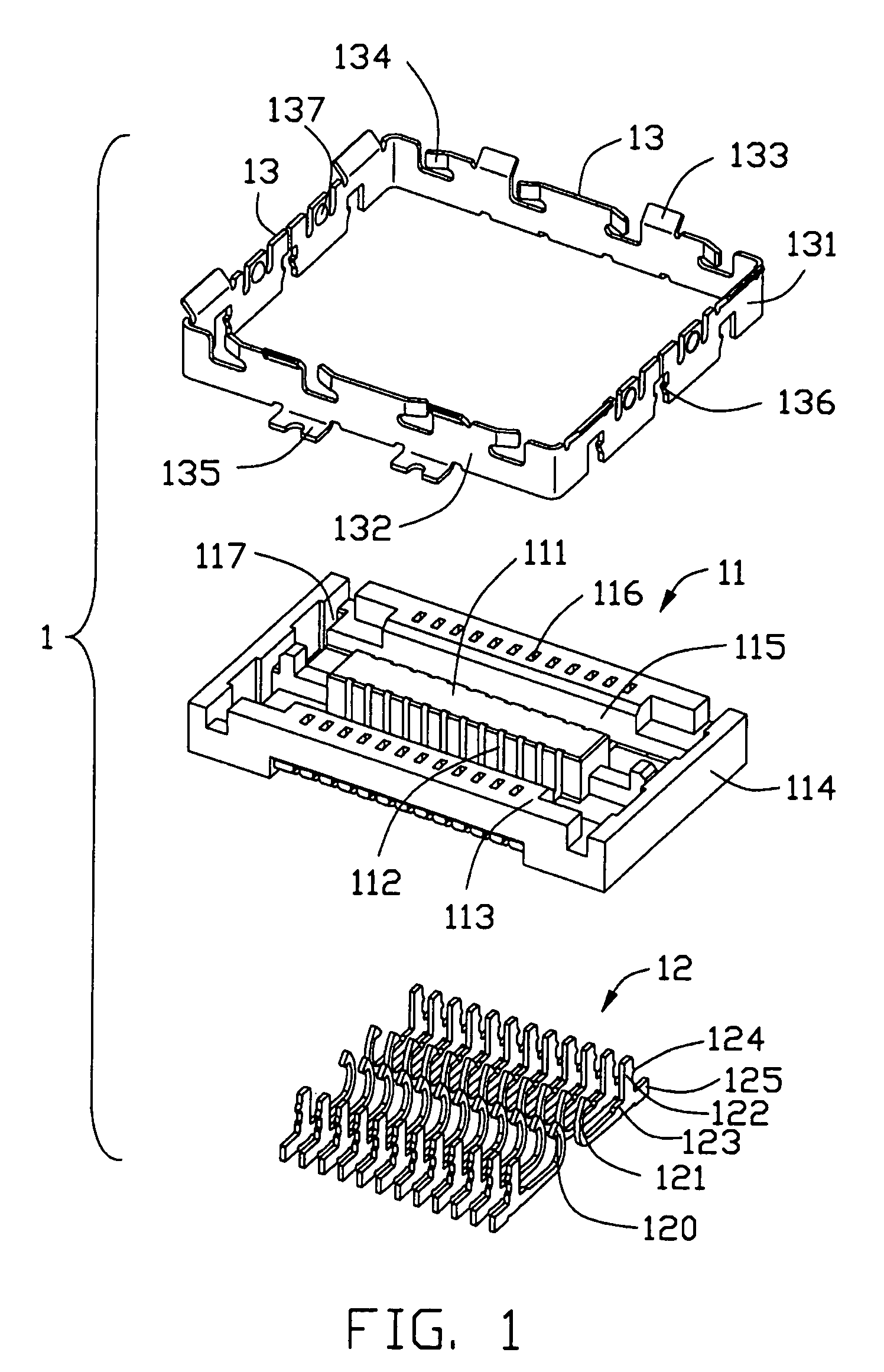

Shielded electrical connector assembly

InactiveUS7074085B2Good shielding propertiesEasy to assembleElectric discharge tubesTwo-part coupling devicesSurface mountingEngineering

An electrical connector for mounting on a circuit board includes an insulative housing (11) having a pair of side walls (113), a pair of end walls (114) and defining a mating opening (115), and a mounting face and a number of contact receiving slots (112); a plurality of contacts (12) received in the contact receiving slots and each having a soldering portion (125) extending along the mounting face for surface mounting on the circuit board; a pair of shielding plates (13) each having a main portion (132) located outside tail ends of the soldering portion, a bent portion (131) bent from opposite ends of the main potion and attached to the end walls and a grounding pad (135) extending along the mounting face for surface mounting on the circuit board.

Owner:HON HAI PRECISION IND CO LTD

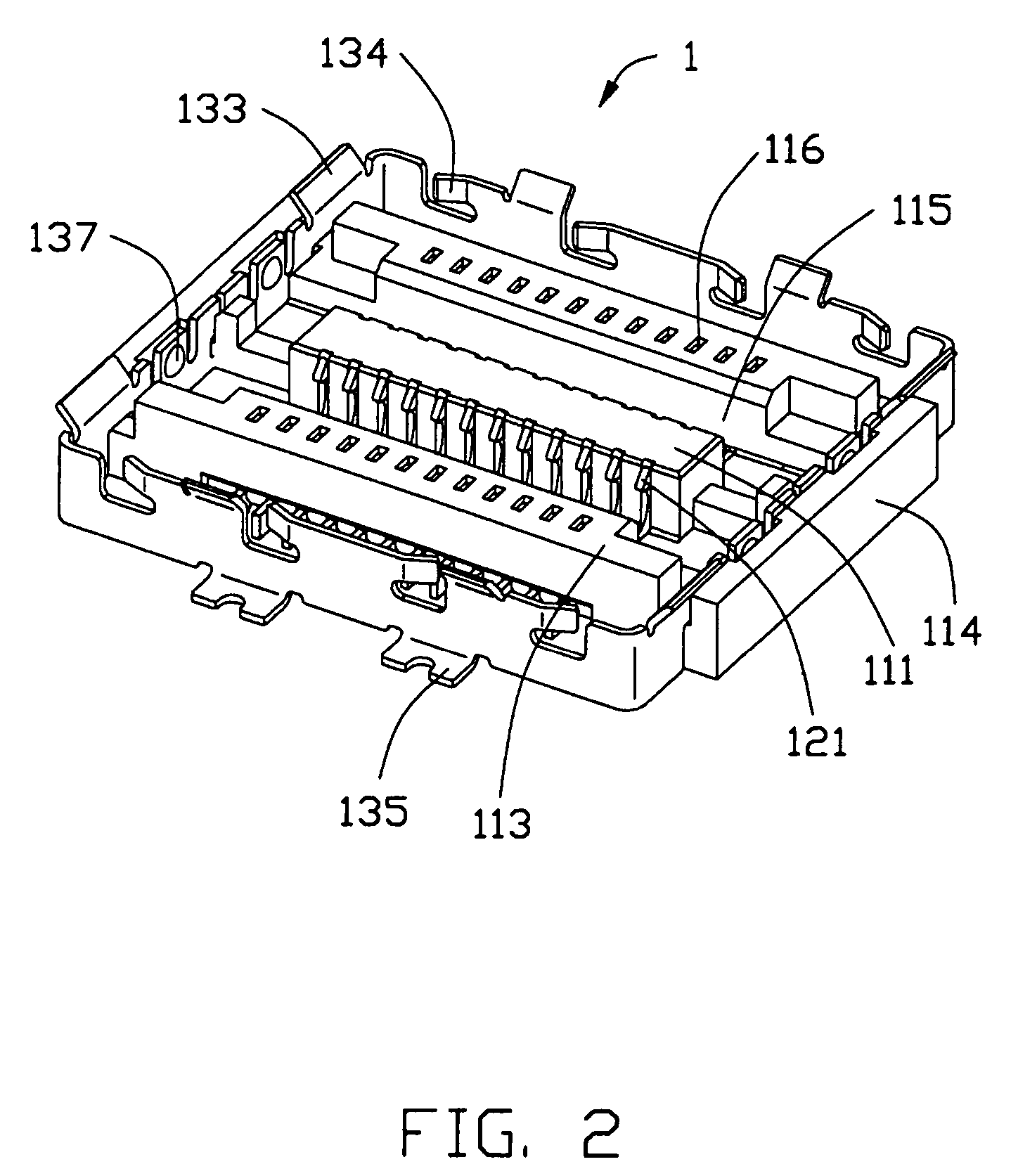

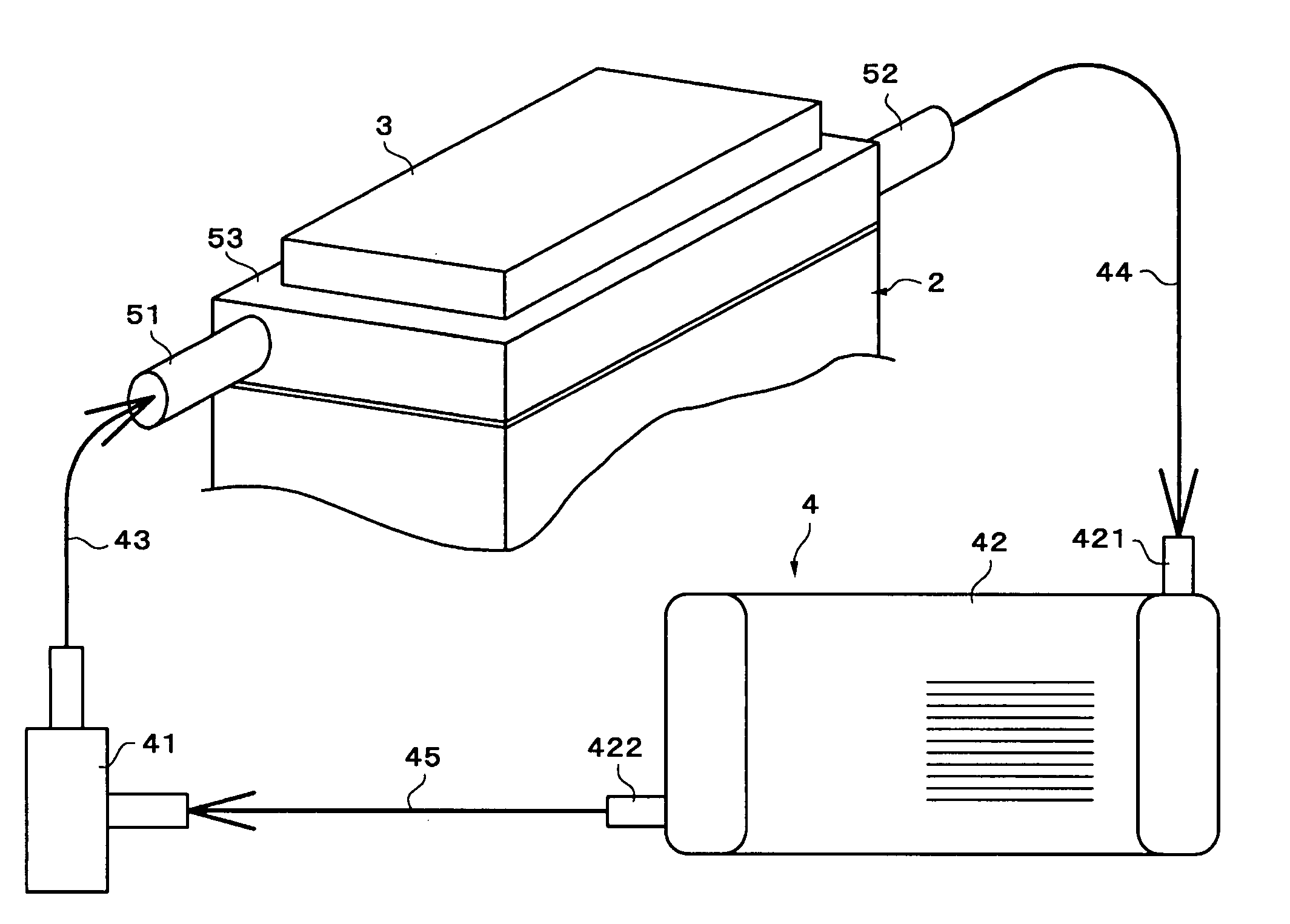

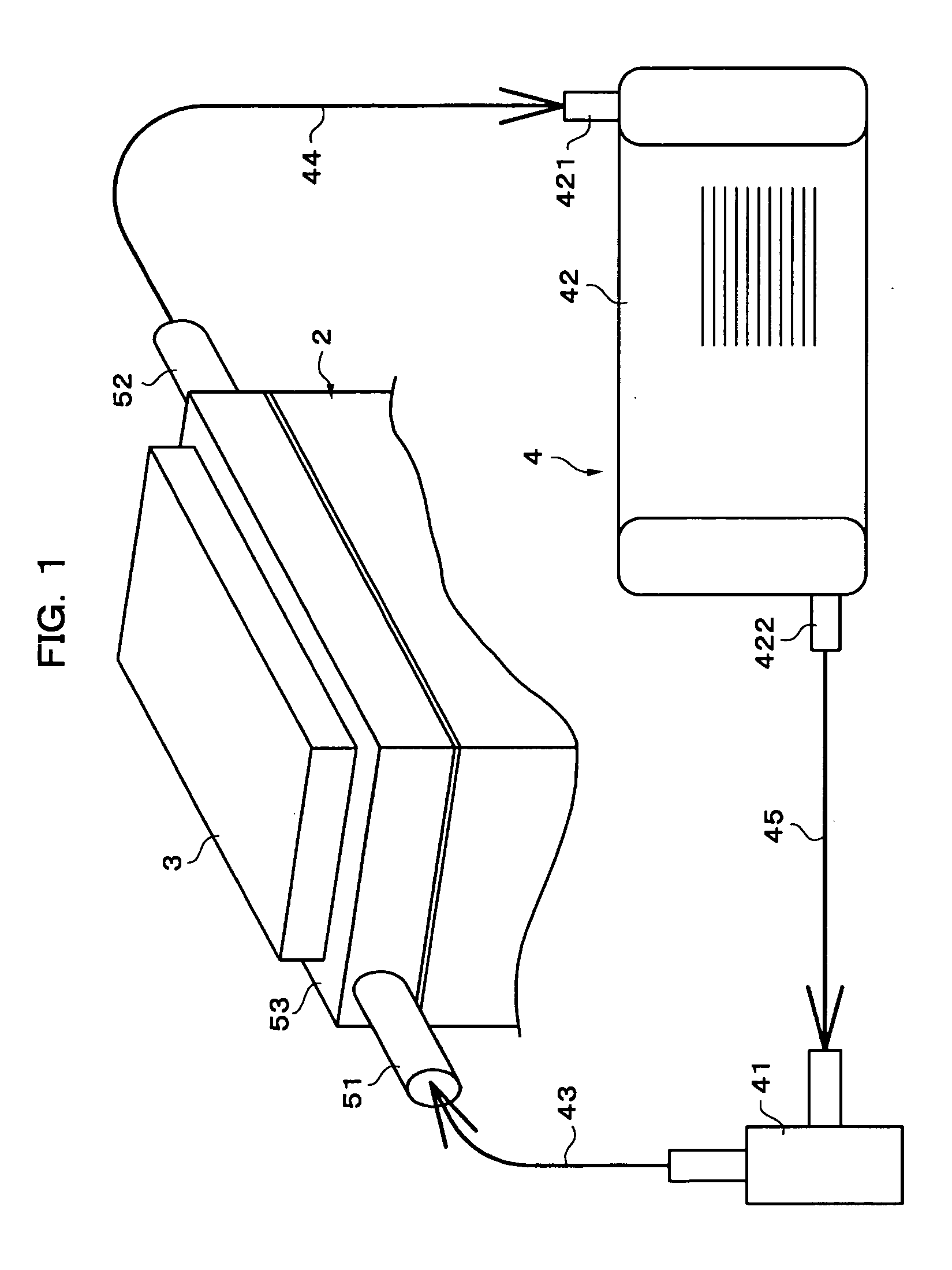

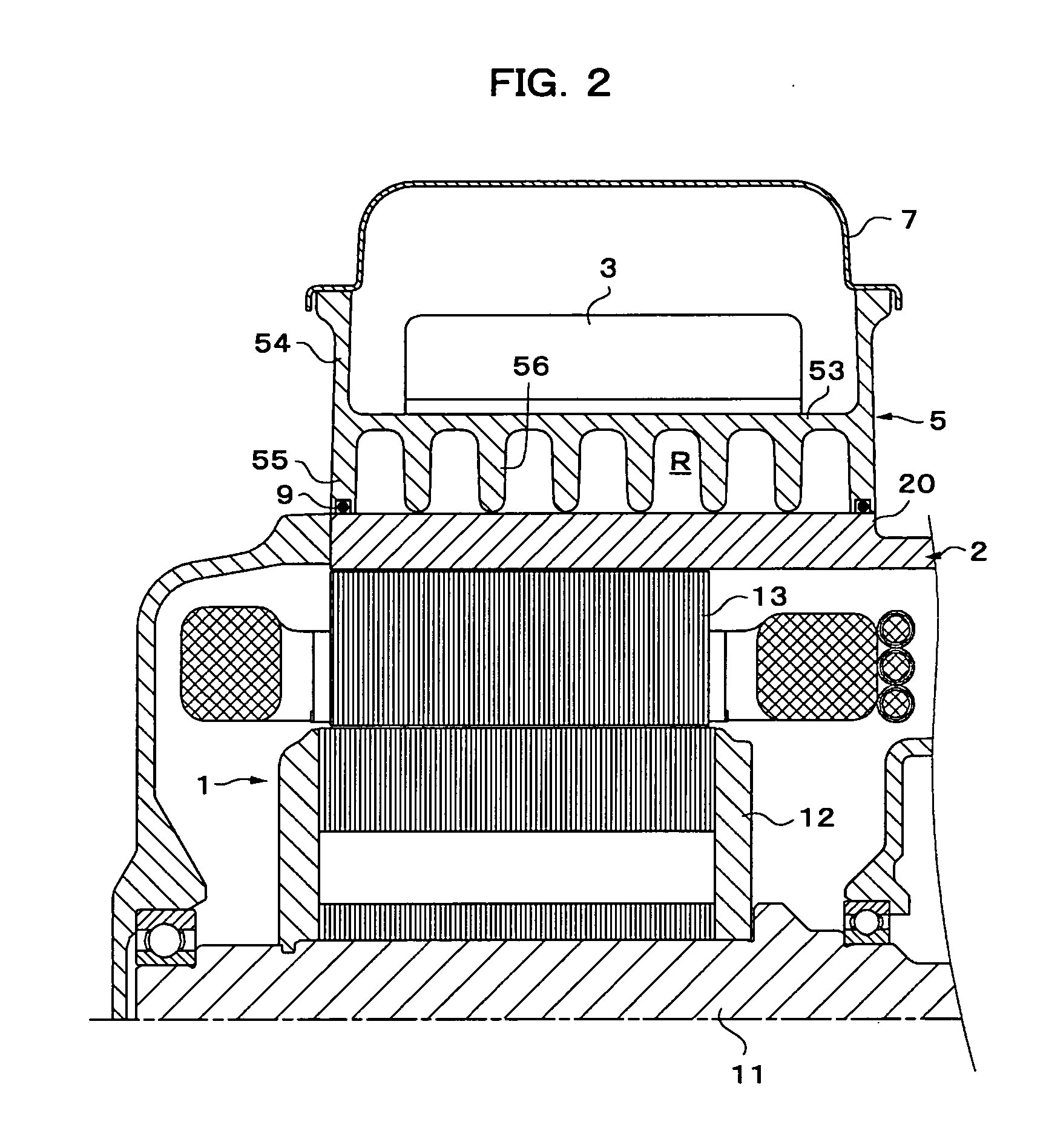

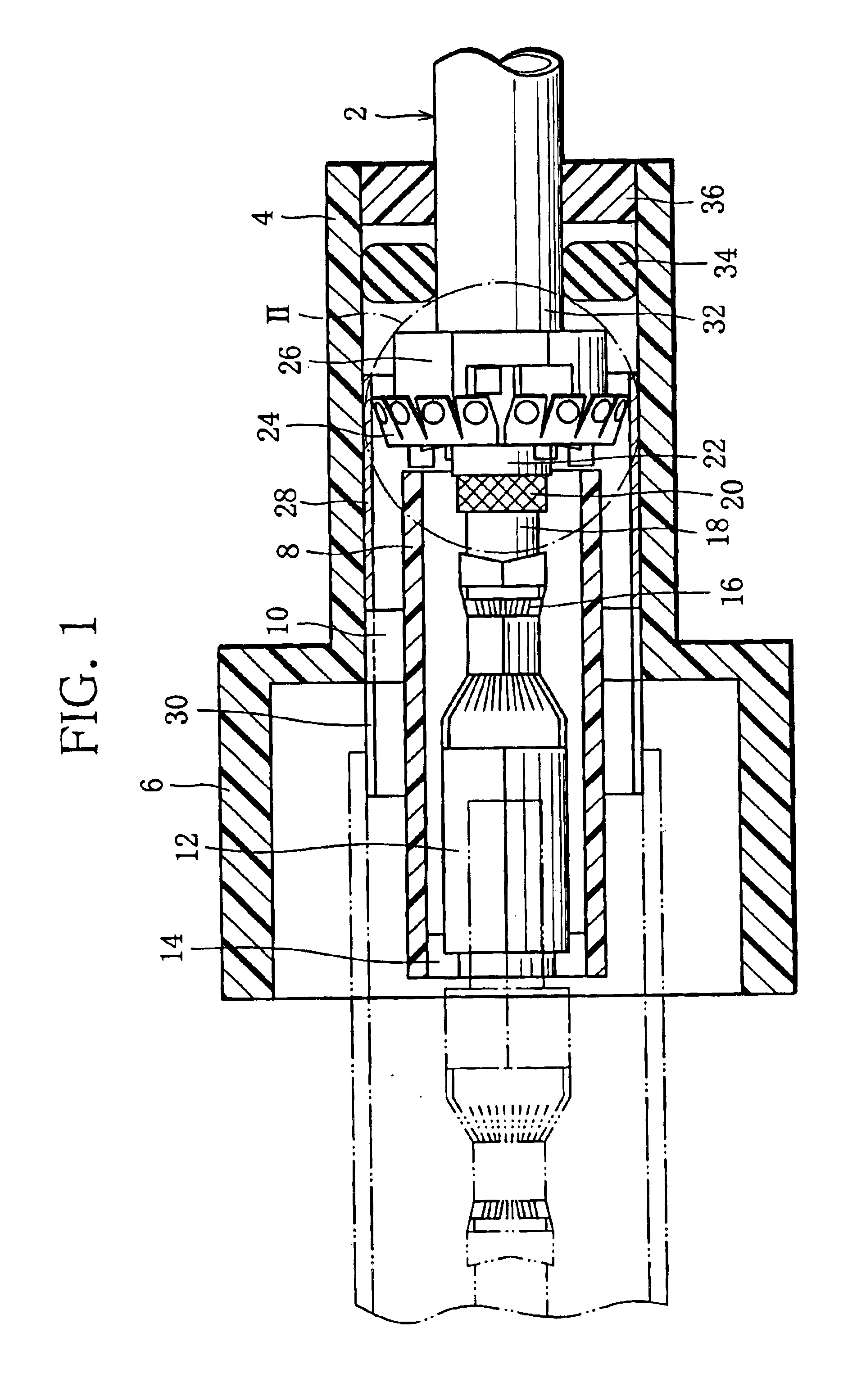

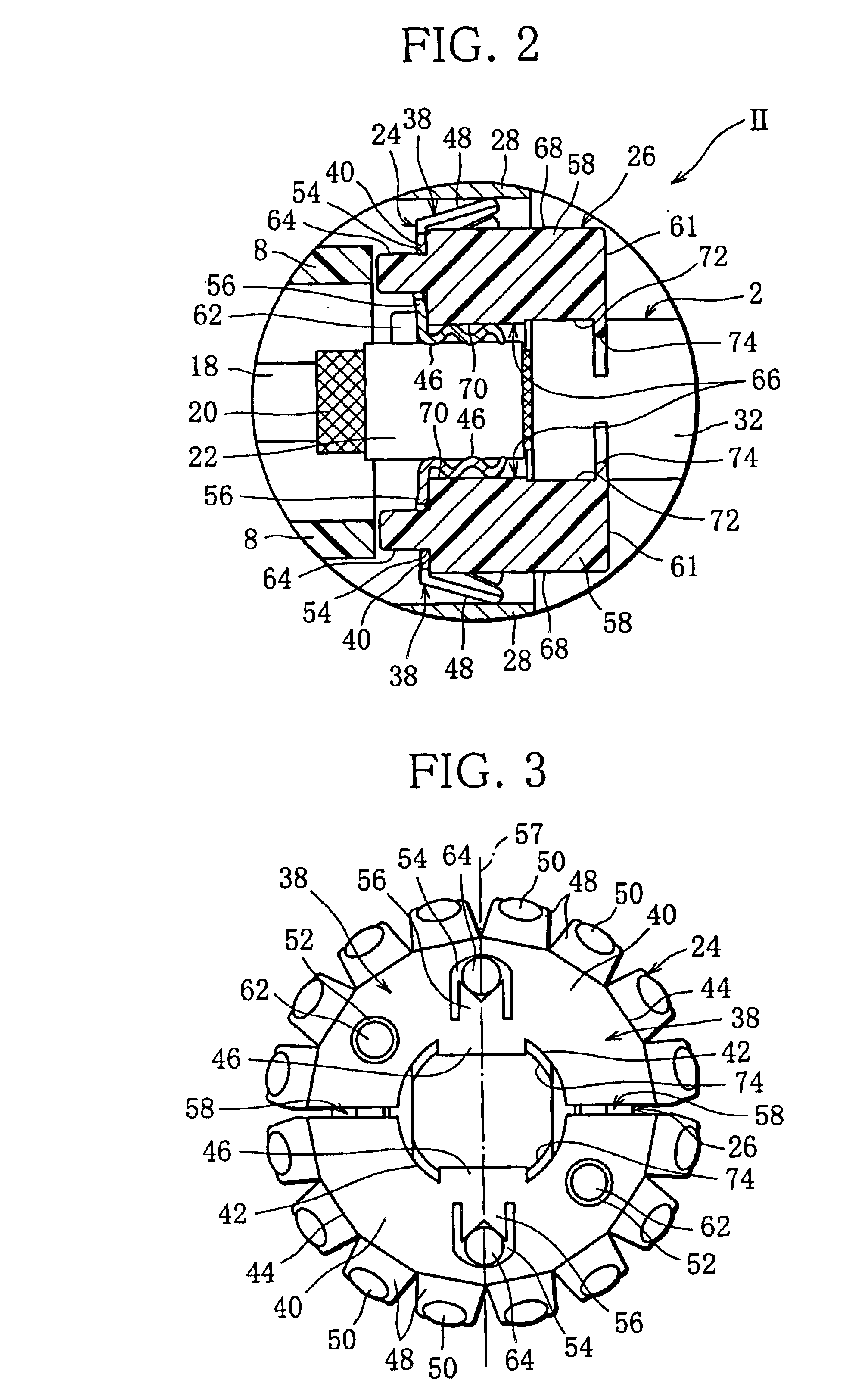

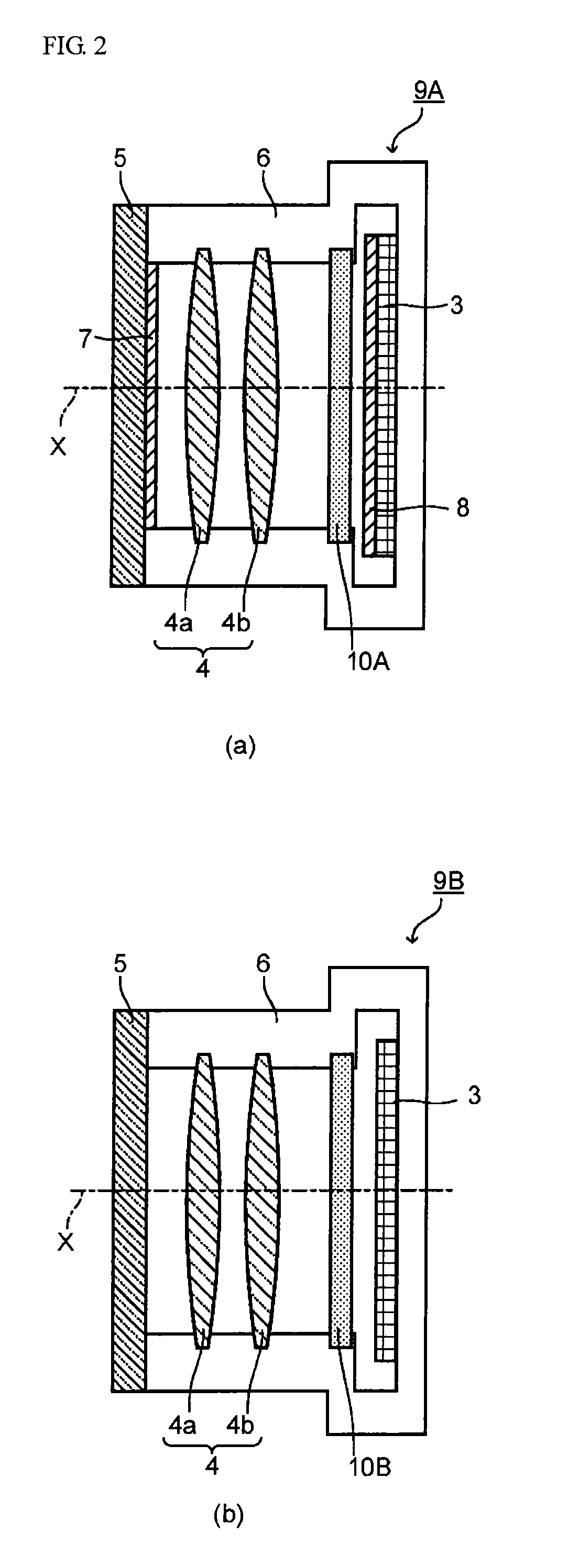

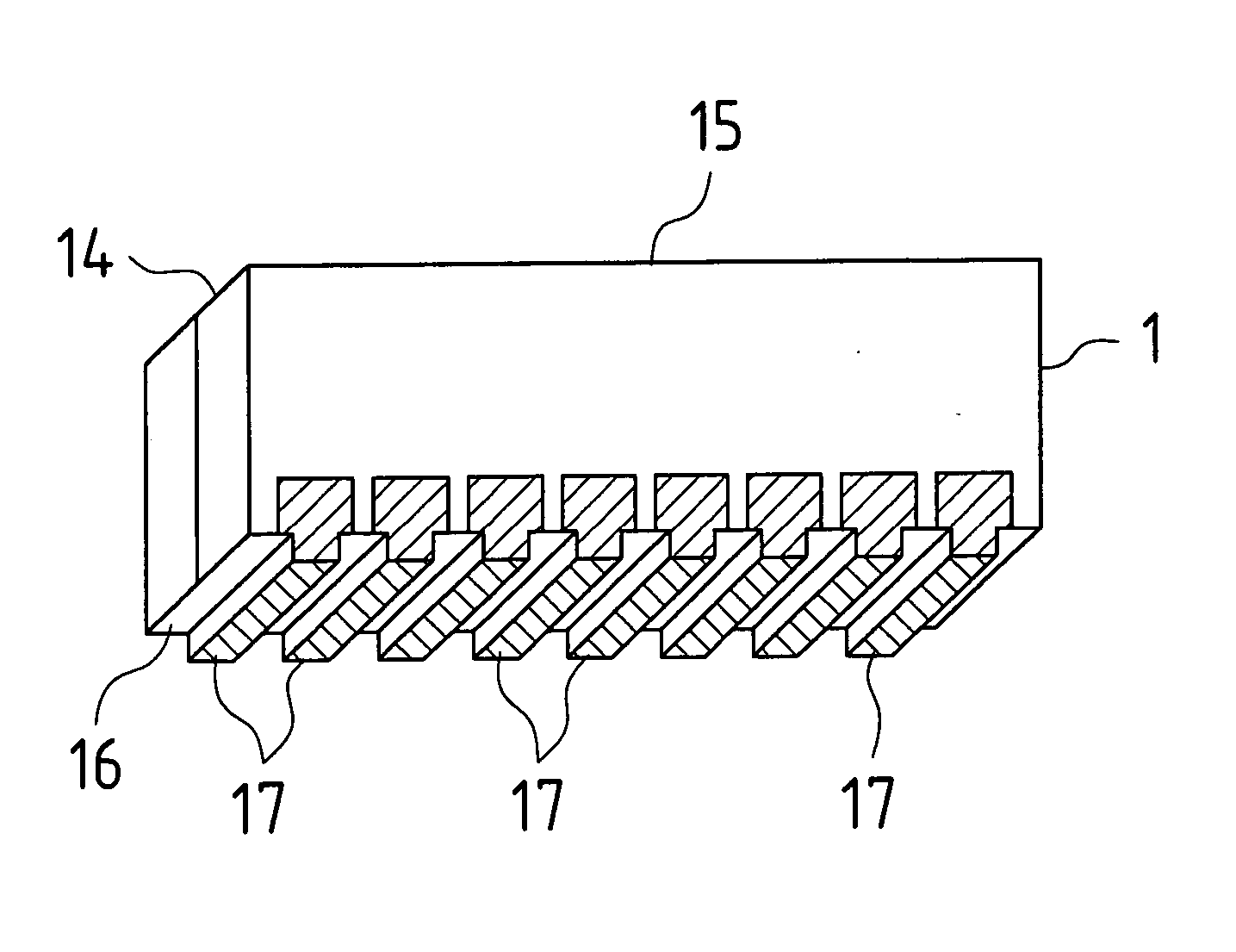

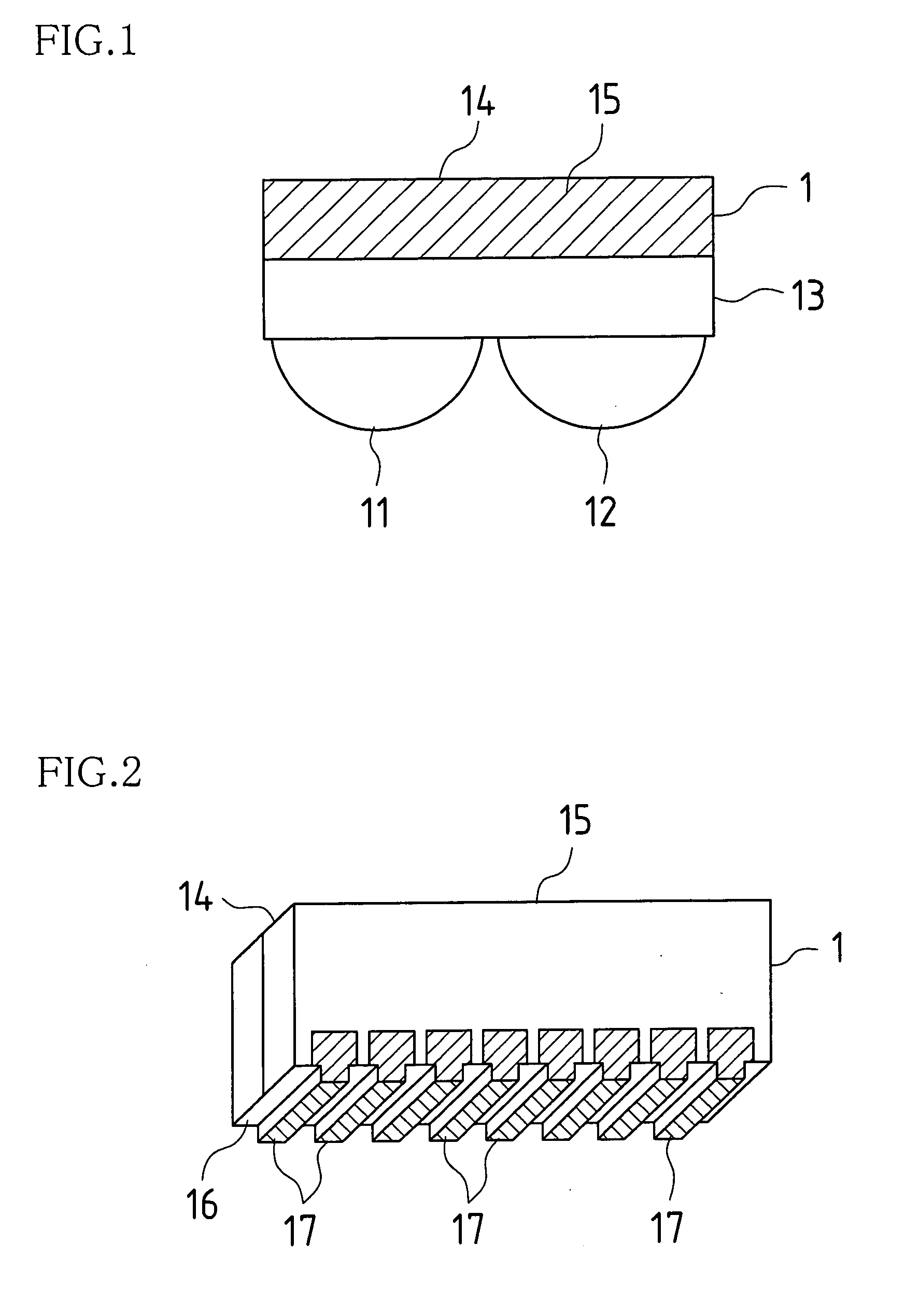

Drive device

InactiveUS20050253465A1Prevent excess flowIncrease the areaAssociation with control/drive circuitsElectric propulsion mountingEngineeringRefrigerant

A drive unit comprises an electric motor, a drive unit casing 2 accommodating therein the electric motor, an inverter 3 that controls the electric motor, and a flow passage of a refrigerant that cools the inverter. The inverter defines a space R between it and a heat sink 5 integral with a substrate of the inverter, and is mounted to the drive unit casing, the space being communicated to the flow passage of the refrigerant. The heat sink comprises fins 56 that cross the space R, and abuts against the drive unit casing in a state of low thermal conduction. Thereby, the heat sink is effectively cooled by heat exchange with a cooling refrigerant in wide areas. Also, the fins contact with the drive unit casing in a state of low thermal conduction via a heat insulation material, etc., whereby direct heat conduction is avoided and efficient cooling is enabled while temperature gradient conformed to heat-resistant temperatures of the inverter and the electric motor is maintained.

Owner:AISIN AW CO LTD

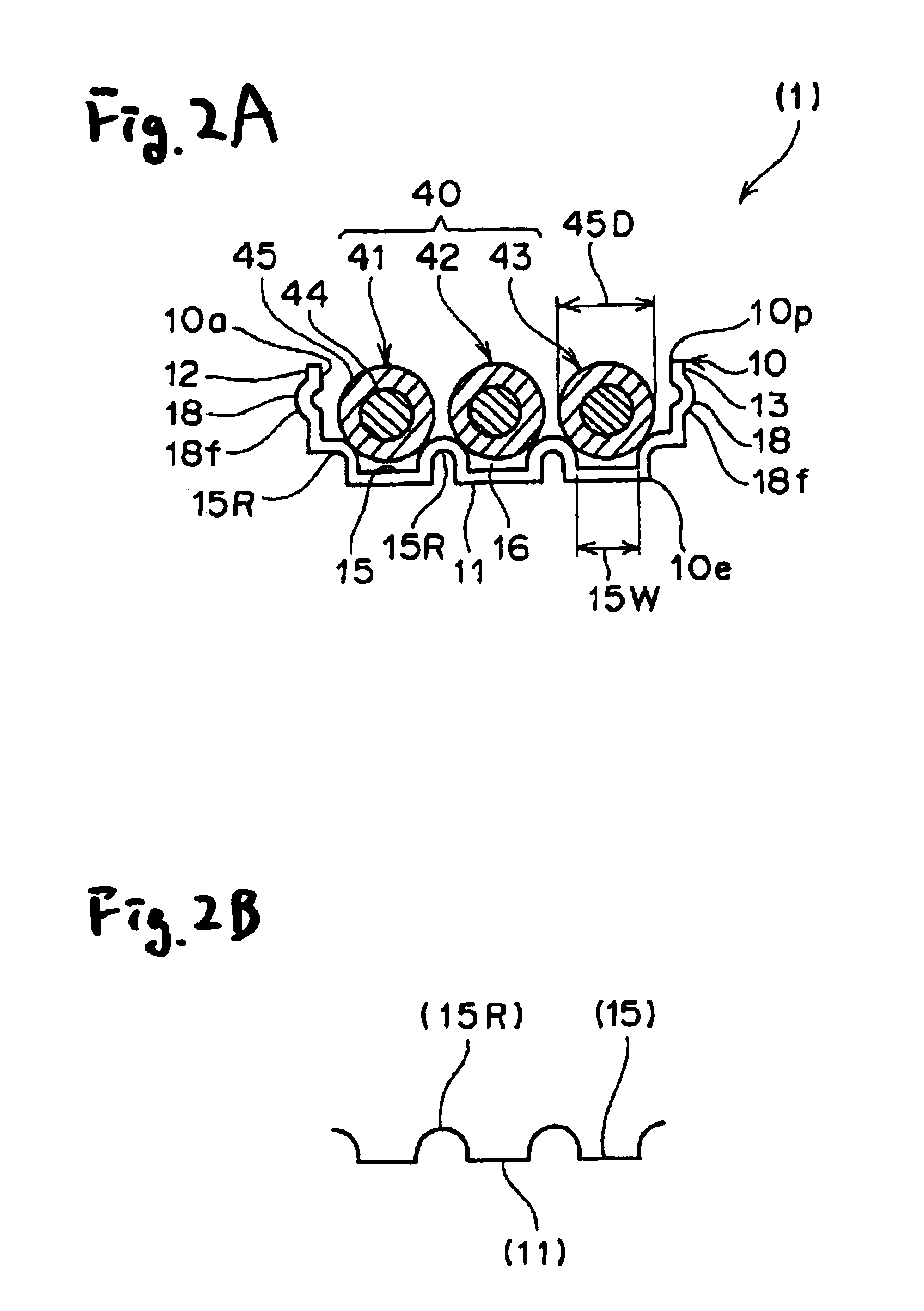

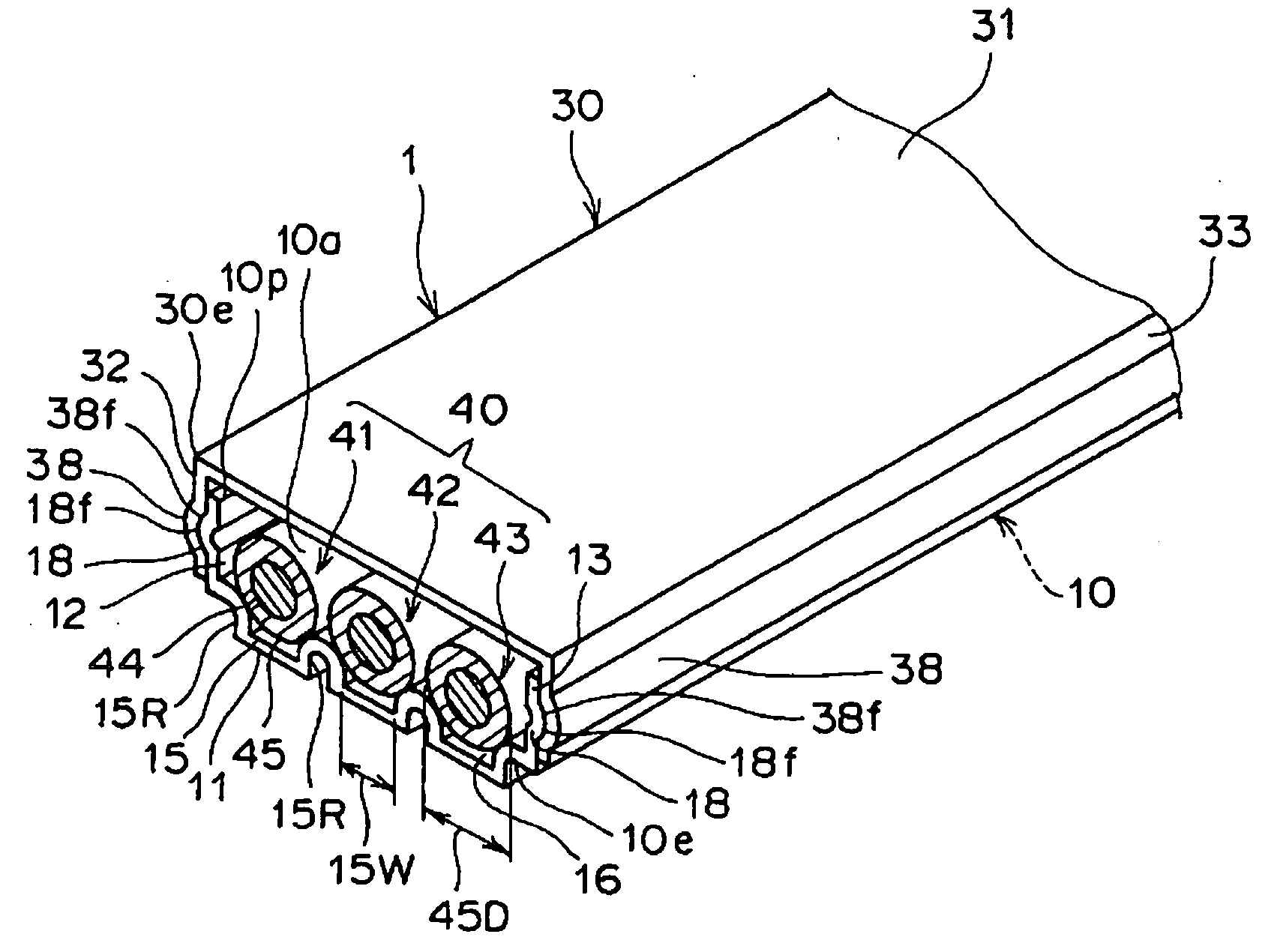

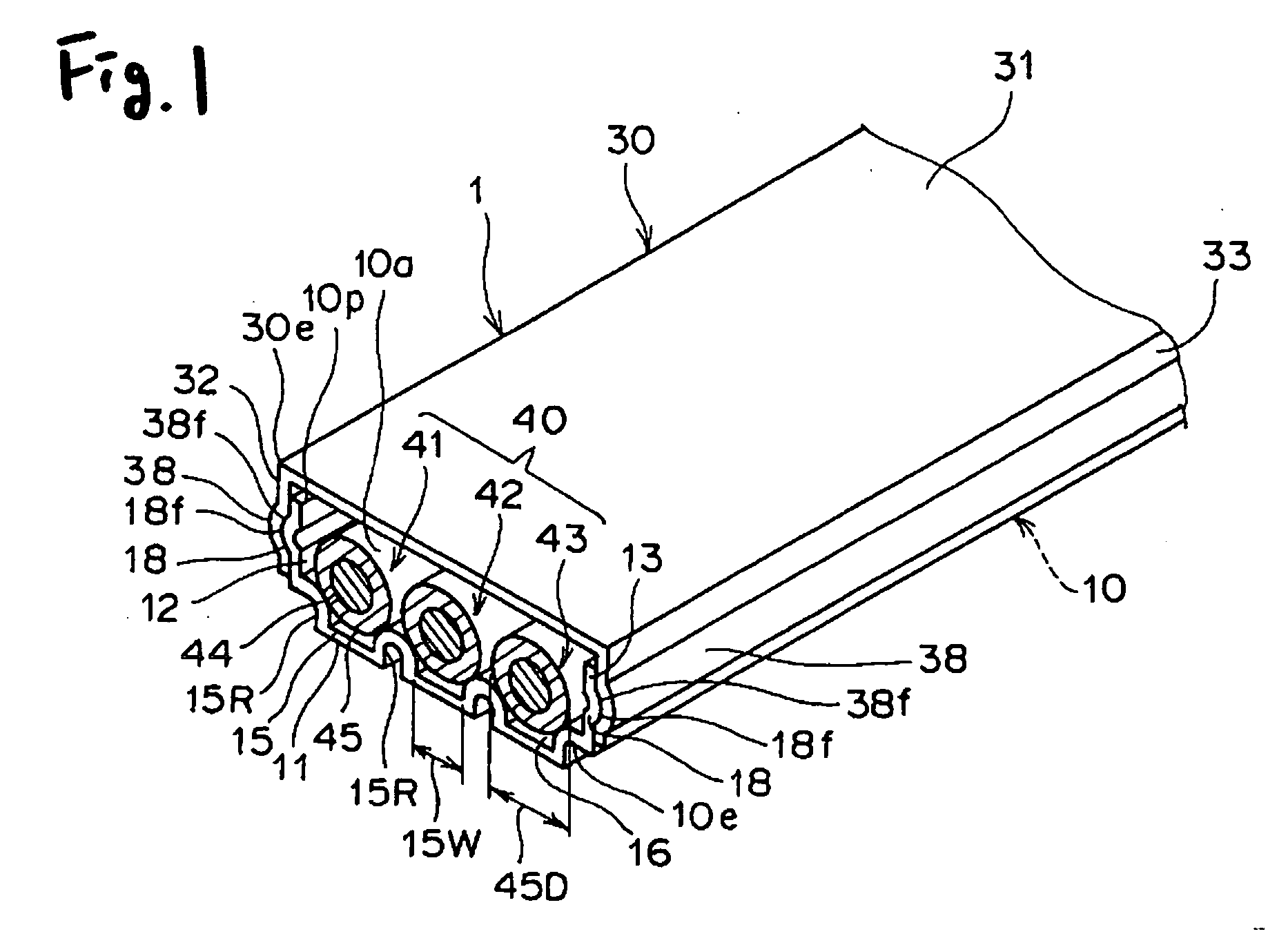

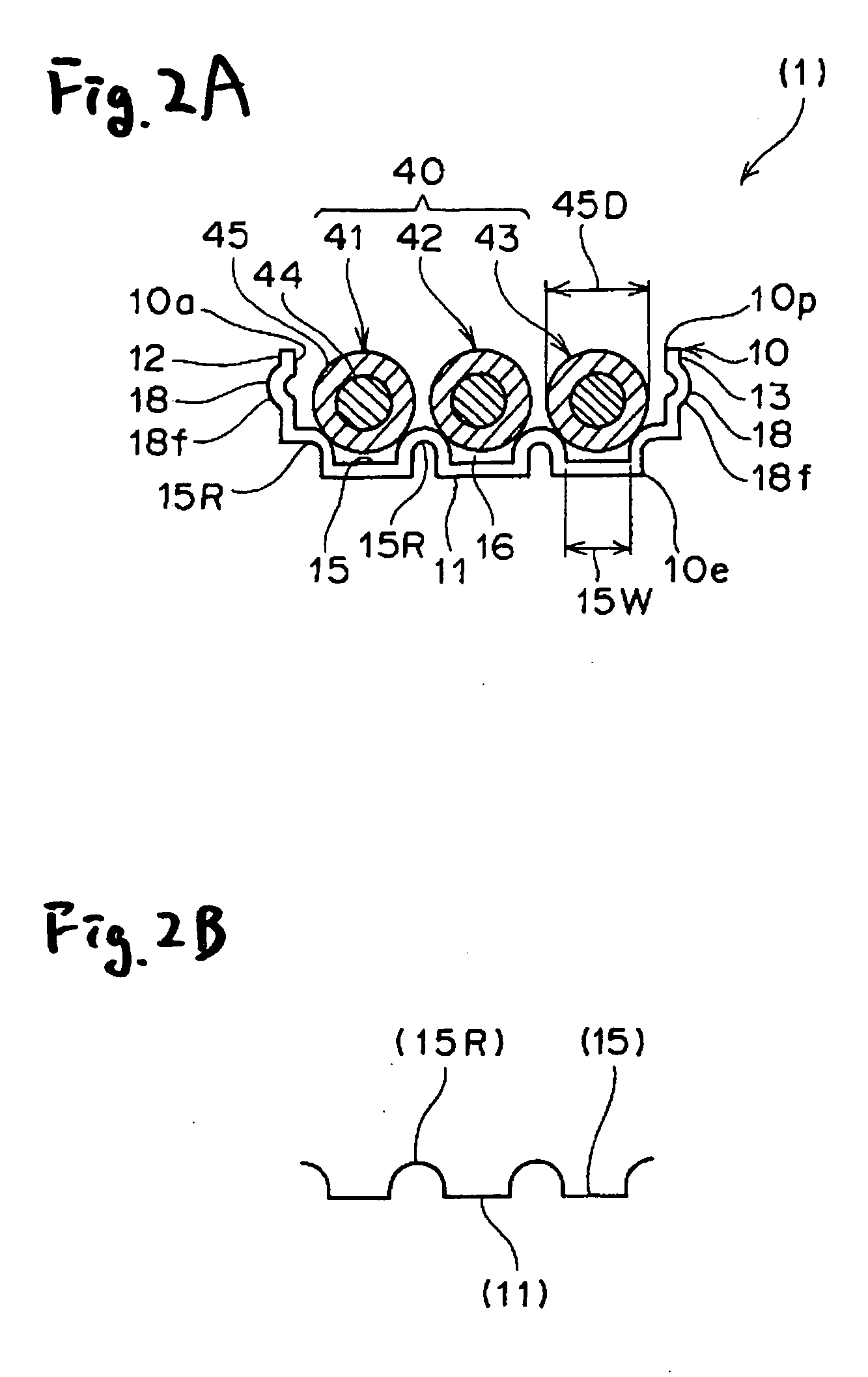

Protector

Owner:YAZAKI CORP

Protector

ActiveUS20050045357A1Good shielding propertiesPipe supportsInsulated cablesEngineeringElectrical and Electronics engineering

A protector includes a protector body which has a receiving portion for receiving at least one wire. A groove is formed on a bottom face of the receiving portion. The groove has a width smaller than a diameter of the wire.

Owner:YAZAKI CORP

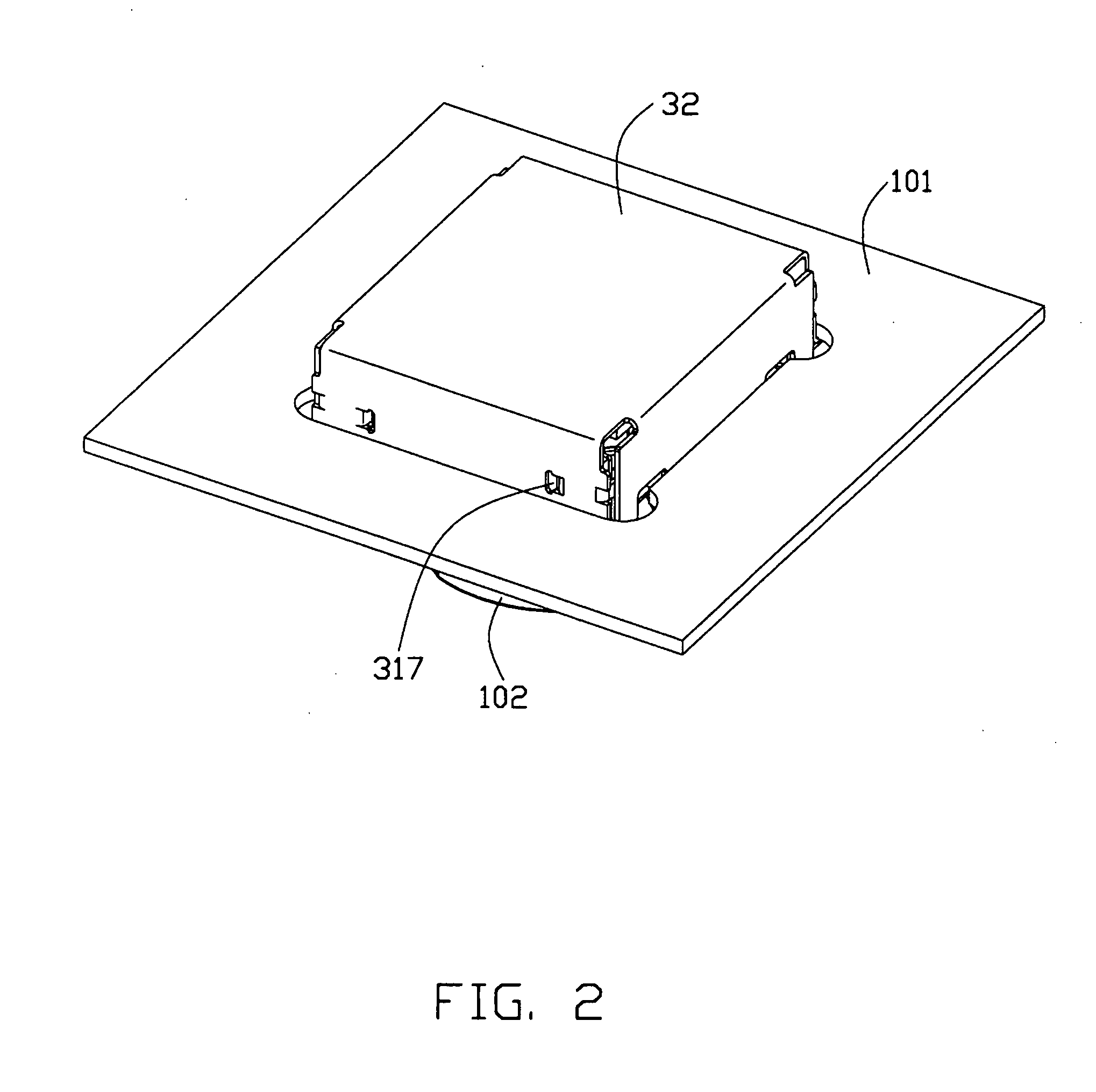

Electrical connector with improved shielding means

InactiveUS7232316B2Good shielding propertiesPrinted circuitsCoupling protective earth/shielding arrangementsEngineeringElectrical connector

A shielded electrical connector (100) for receiving a module includes a shielding shell (3) mounted to a printed circuit board, an insulative housing (1) assembled to the shell and equipped with a number of contacts (2). Each contact has a contacting portion (22) for contacting with the module and a soldering portion (23) extending beyond the shell for connection to the printed circuit board. The shell comprises a bottom plate (32) extending in a direction perpendicular to the module insertion direction and a plurality of side plates (310, 311, 312, 313) extending upwardly from the bottom plate and cooperating with the bottom plate to form a receiving space for receiving the module. Every two adjacent side plates are connected to each other.

Owner:HON HAI PRECISION IND CO LTD

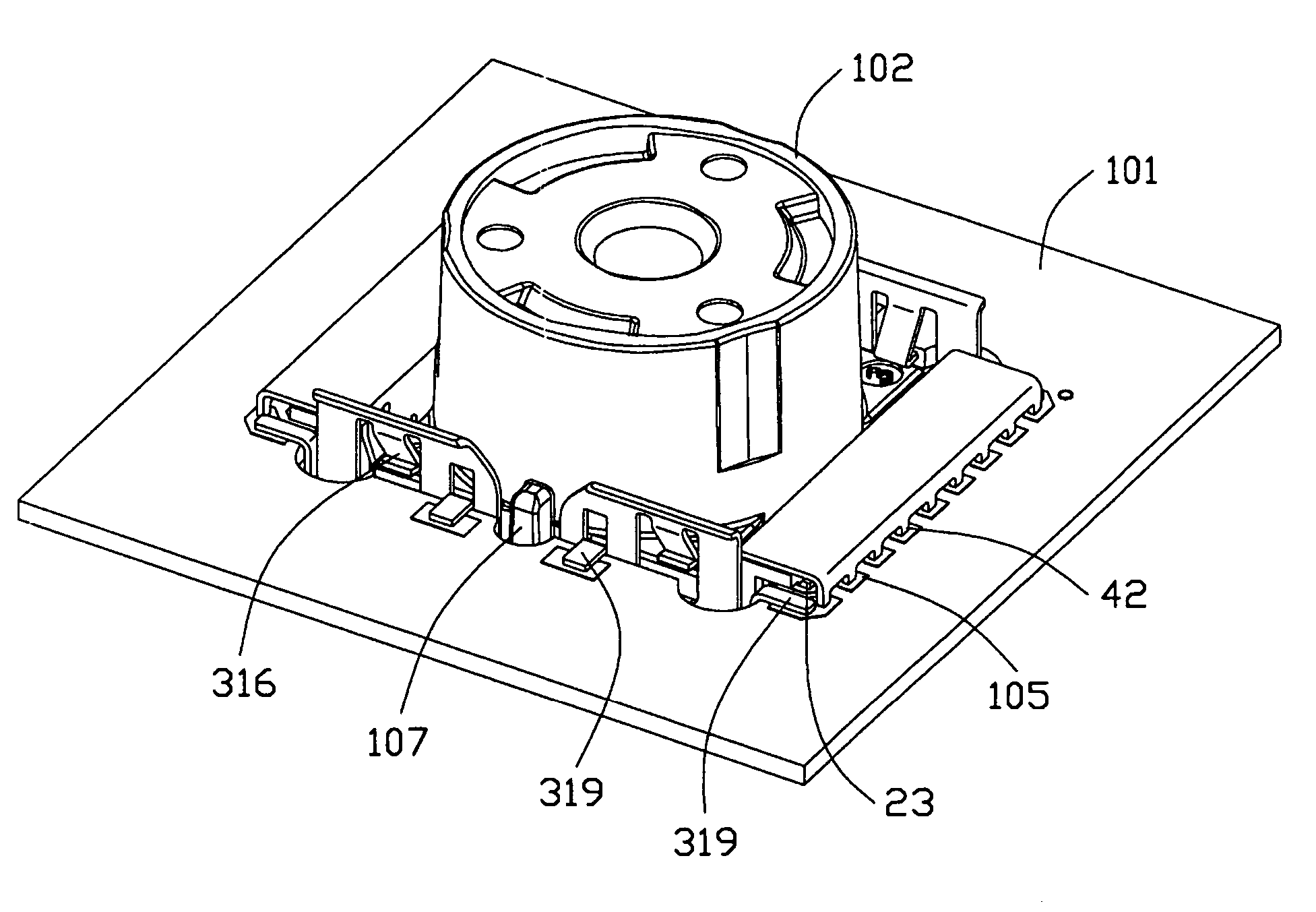

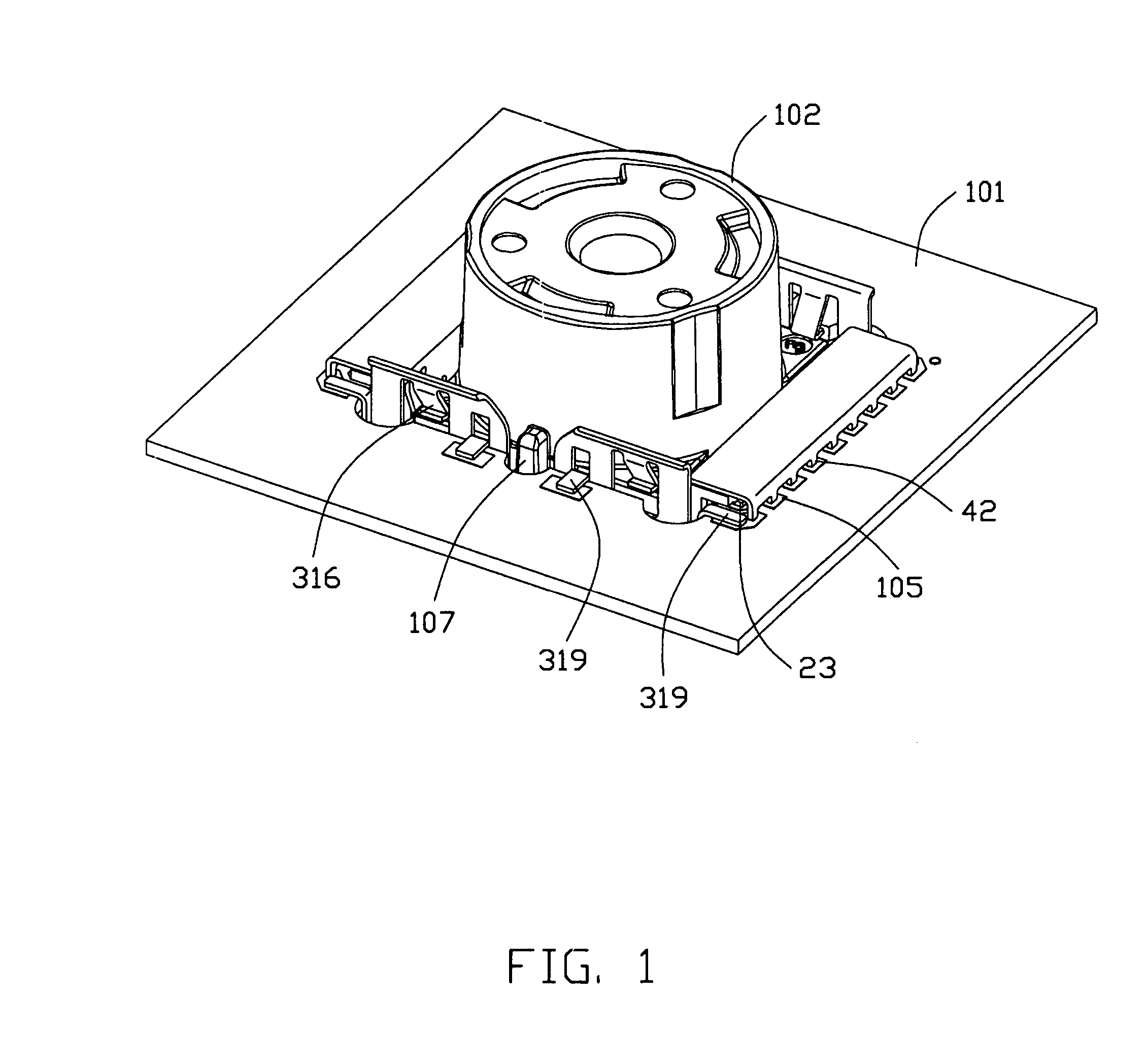

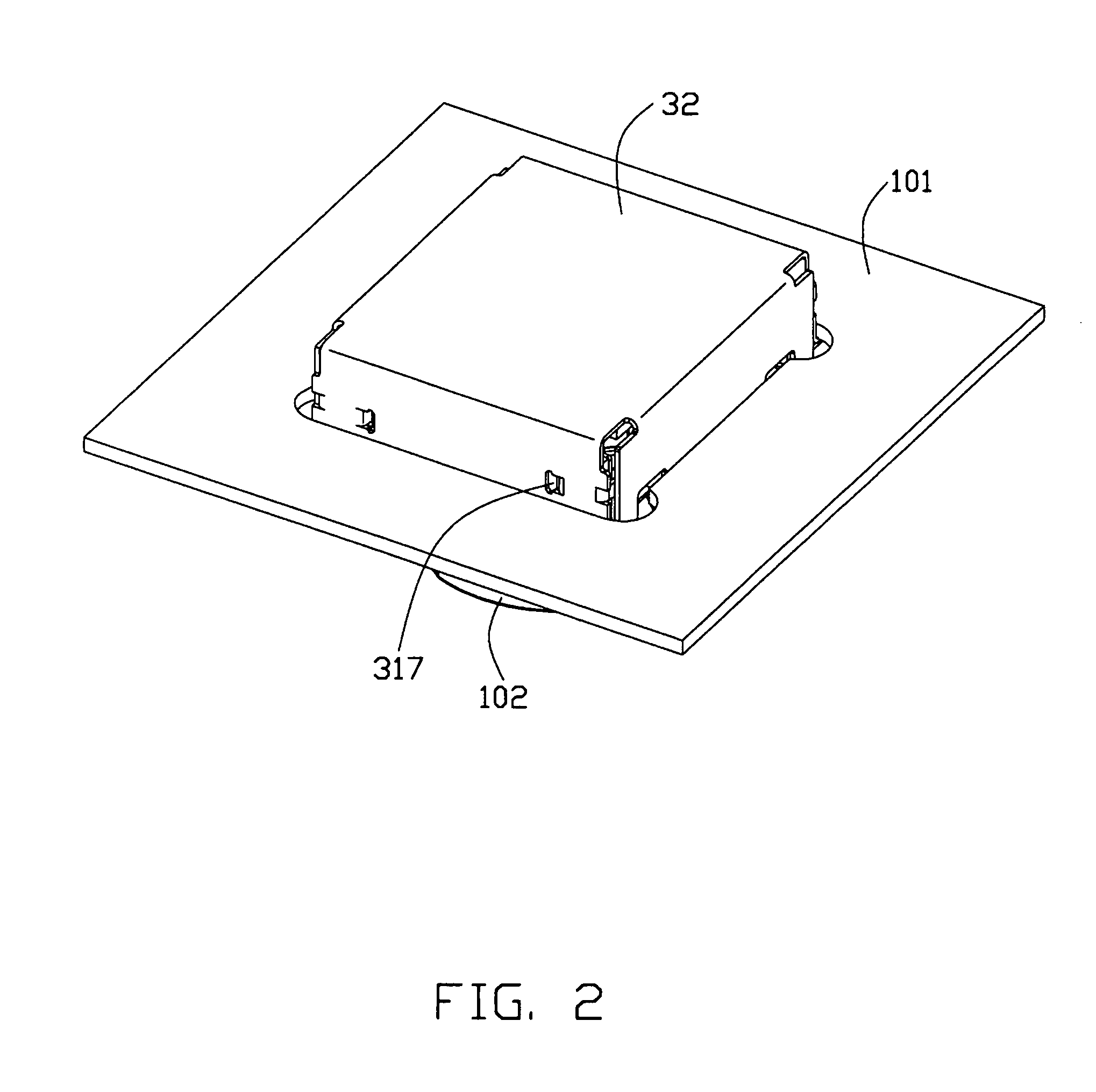

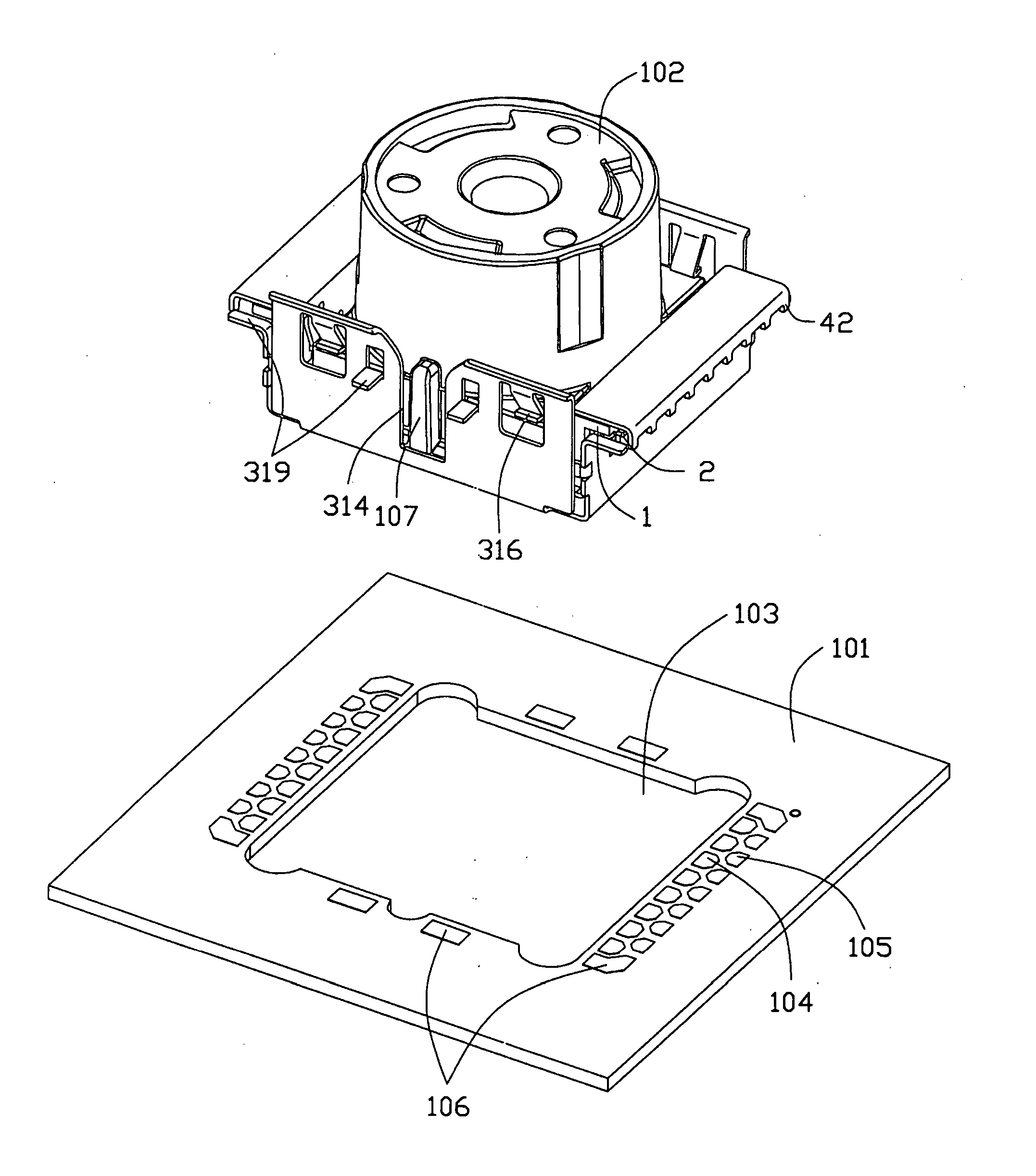

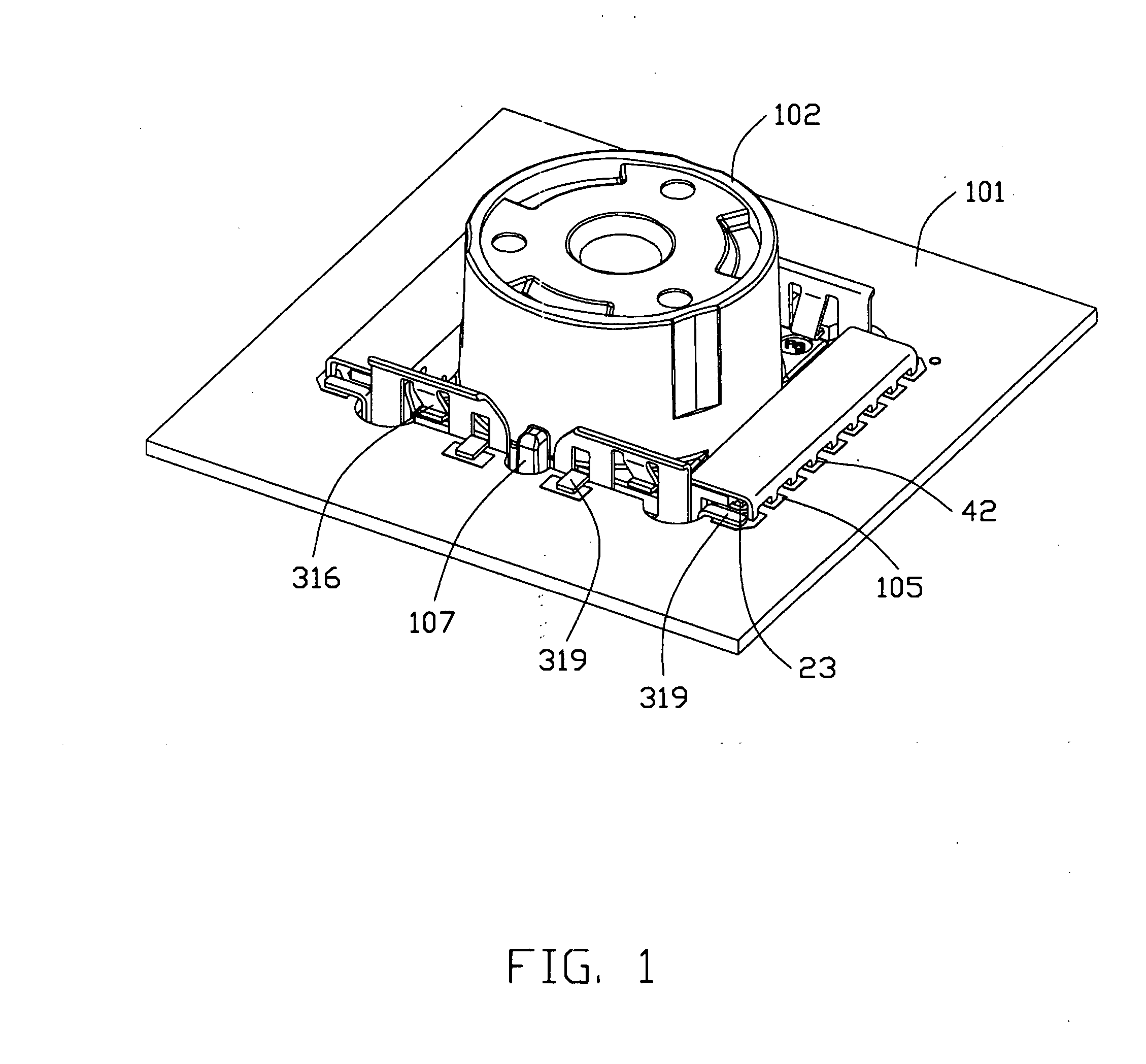

Electrical connector with improved shielding means

InactiveUS20060216996A1Good shielding propertiesPrinted circuitsCoupling protective earth/shielding arrangementsEngineeringElectrical connector

A shielded electrical connector (100) for receiving a module includes a shielding shell (3) mounted to a printed circuit board, an insulative housing (1) assembled to the shell and equipped with a number of contacts (2). Each contact has a contacting portion (22) for contacting with the module and a soldering portion (23) extending beyond the shell for connection to the printed circuit board. The shell comprises a bottom plate (32) extending in a direction perpendicular to the module insertion direction and a plurality of side plates (310, 311, 312, 313) extending upwardly from the bottom plate and cooperating with the bottom plate to form a receiving space for receiving the module. Every two adjacent side plates are connected to each other.

Owner:HON HAI PRECISION IND CO LTD

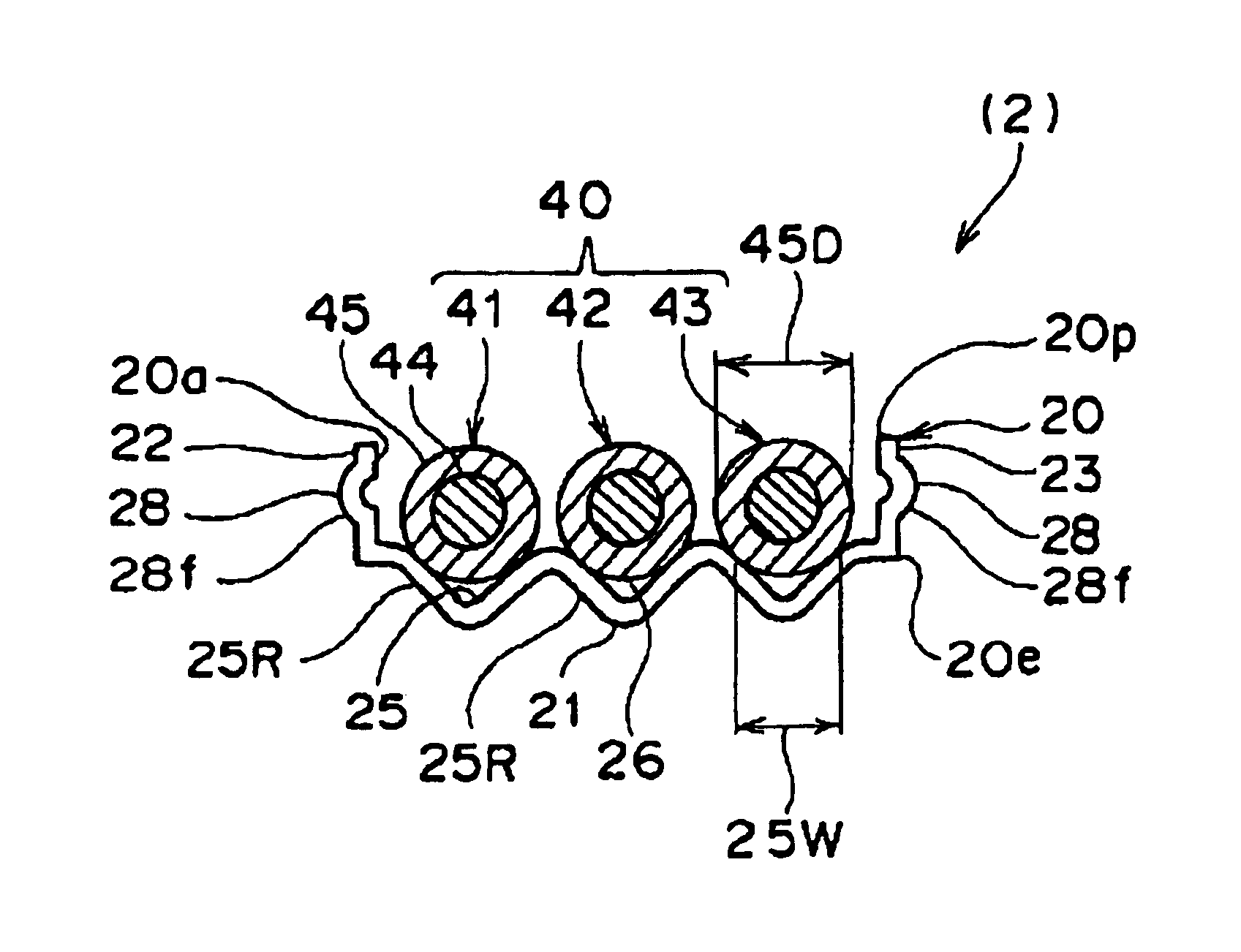

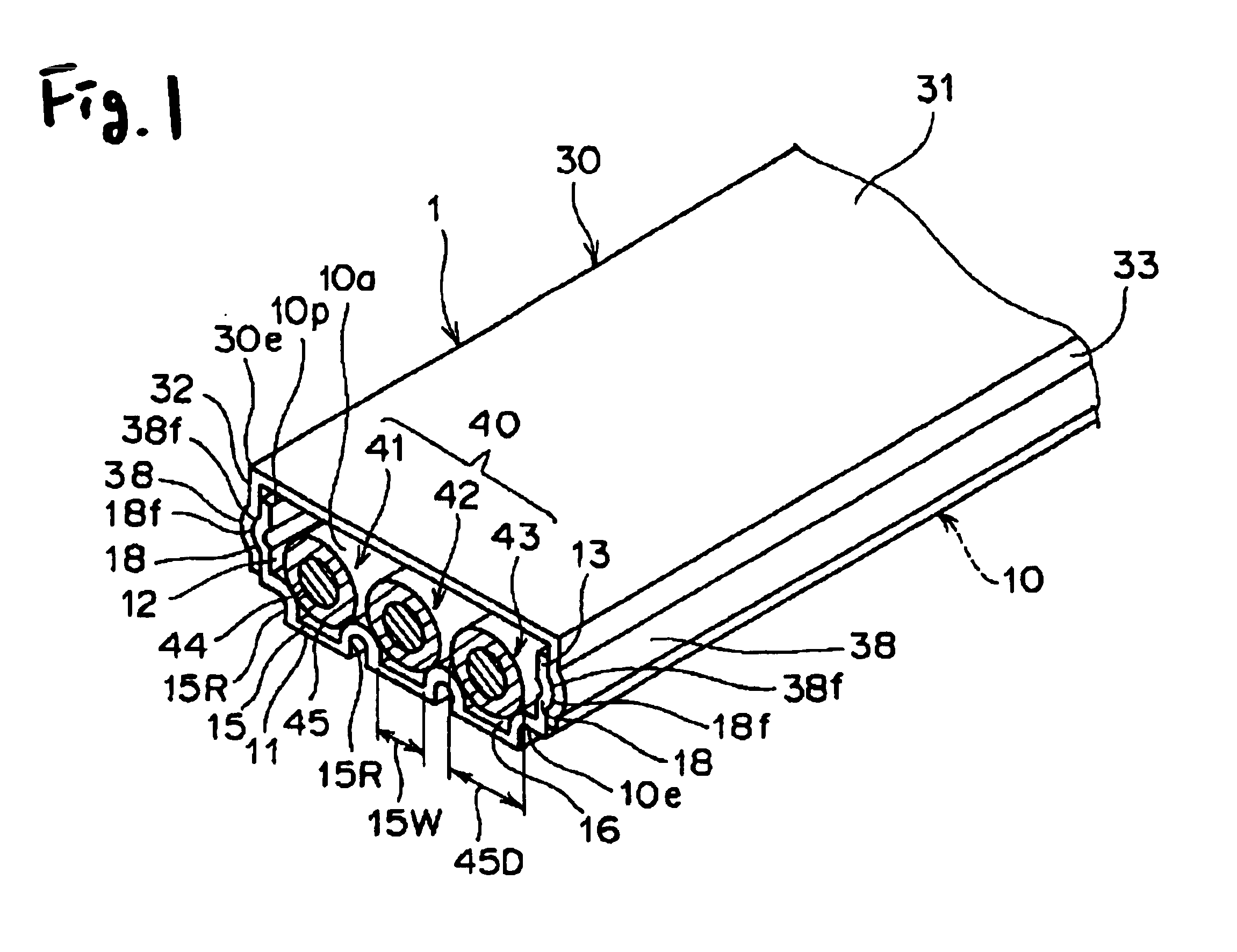

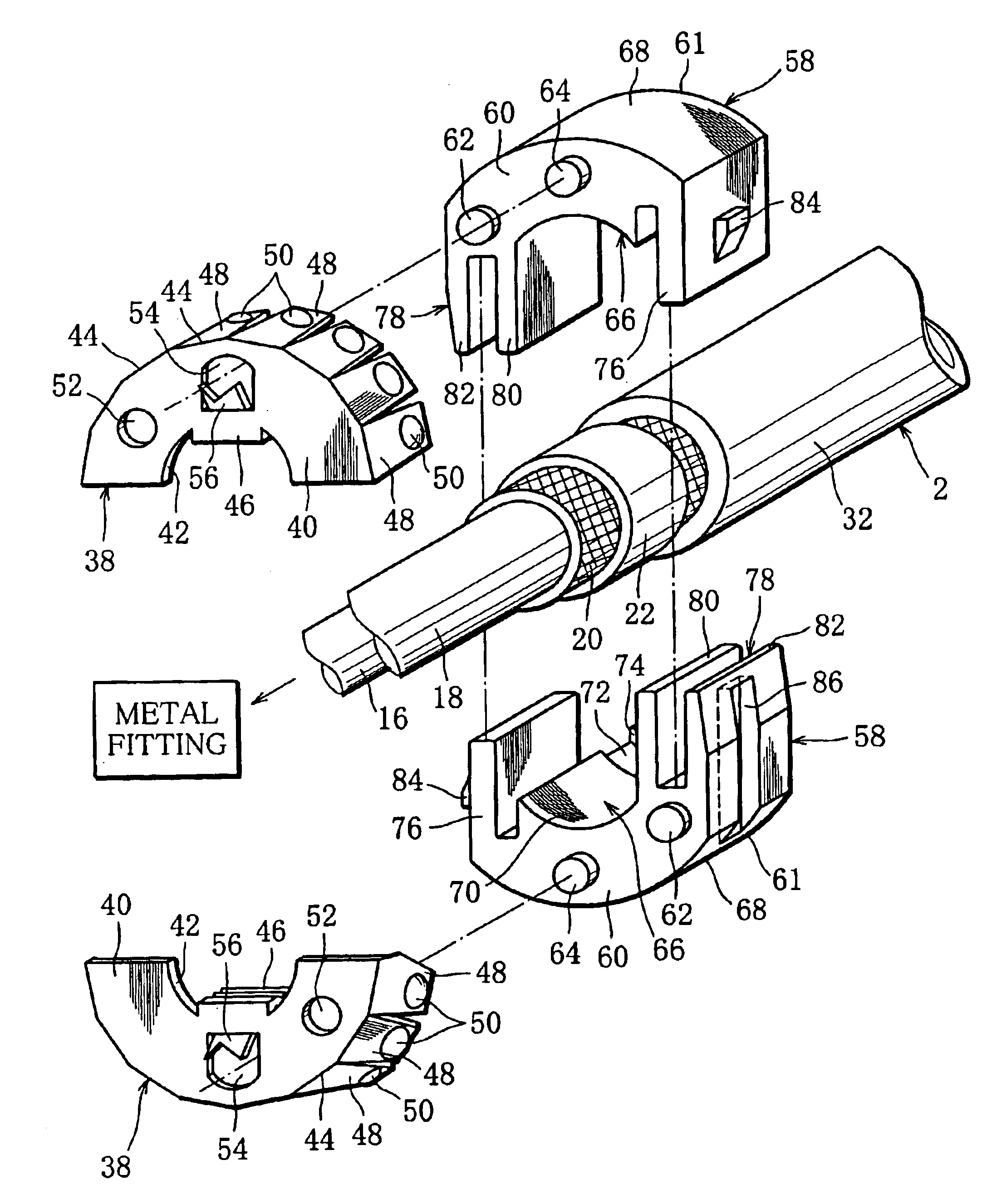

Shield electric cable connector

InactiveUS6916205B1Easily and automatically fixedGood shielding propertiesCoupling protective earth/shielding arrangementsConnection contact member materialShielded cable

A shield electric cable connector for electrically connecting a shield electric cable to a mate member, wherein the shield electric cable includes one terminal portion that is peeled for connecting said connector and the mate member. The terminal portion has a conductive shield layer exposed from a sheath of the shield electric cable. The connector includes a conductive shield pipe surrounding the terminal portion of the shield electric cable and a conductive shield-connecting member surrounding the shield layer between the exposed shield layer and the shield pipe, the shield-connecting member electrically connecting the exposed shield layer to the shield pipe. The shield-connecting member has a pair of halves for sandwiching the exposed shield layer from both sides in a radial direction of the exposed shield layer.

Owner:FURUKAWA ELECTRIC CO LTD

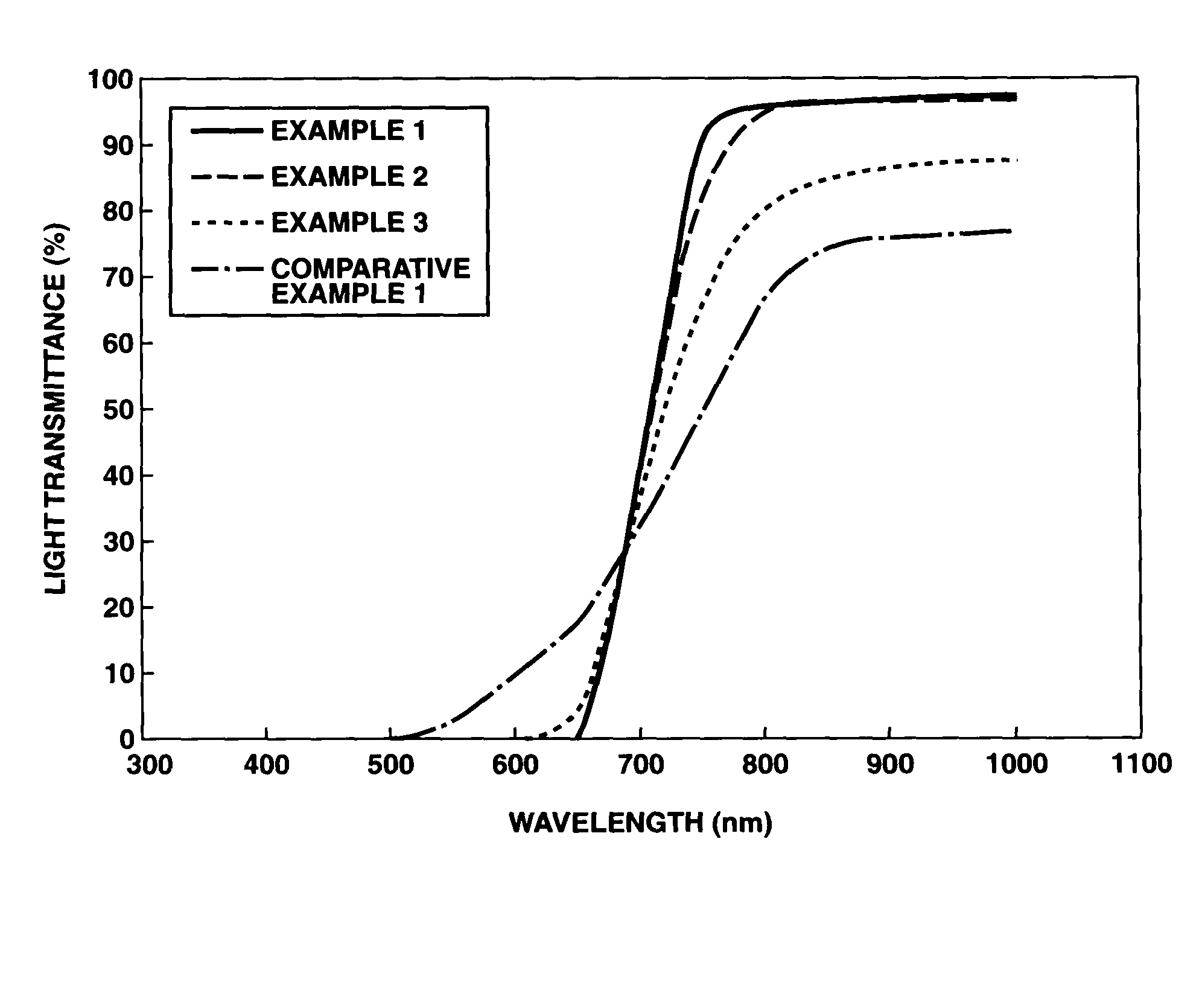

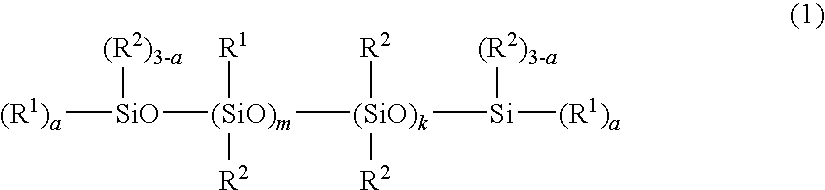

Visible light-shielding silicone rubber composition, cured product, and optoelectronic device

InactiveUS20100103507A1Improve transmission performanceImprove shielding effectOptical filtersSensing by electromagnetic radiationTransmittanceOpto electronic

A visible light-shielding silicone rubber composition is provided comprising (A) an organopolysiloxane, (B) an organohydrogenpolysiloxane, (C) a platinum catalyst, and (D) an azo dye. The azo dye has a light transmittance≦10% in a wavelength range of up to 650 nm and ≧80% in a wavelength range of at least 750 nm when a solution of the azo dye in ethanol is measured by a spectrophotometer. The composition cures into a film which shields visible light, but transmits IR light and is suited for encapsulation of LED.

Owner:SHIN ETSU CHEM IND CO LTD

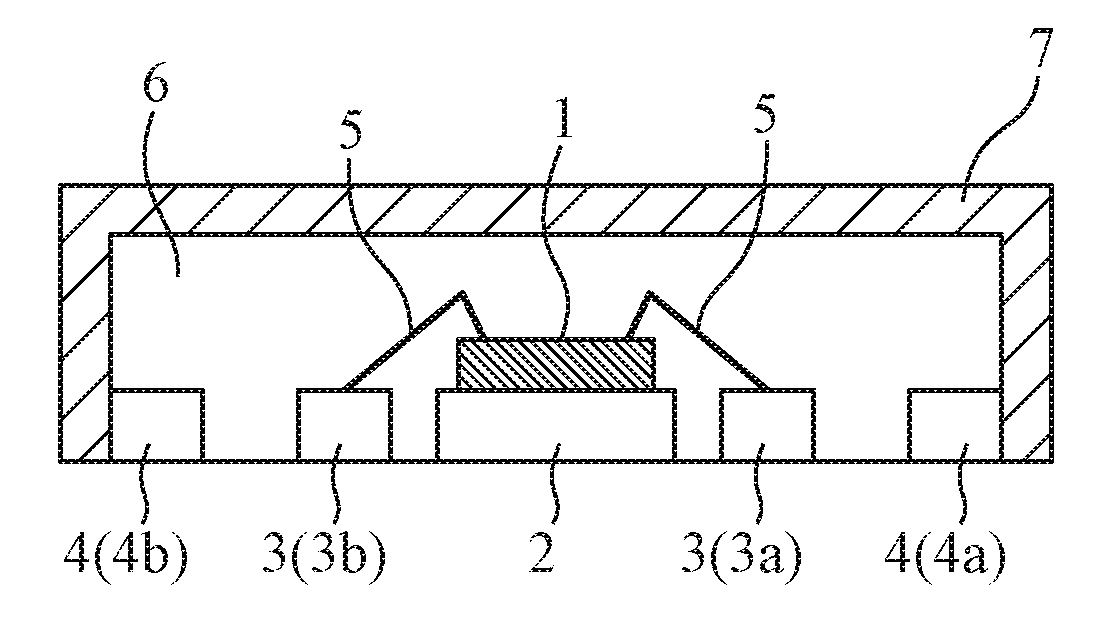

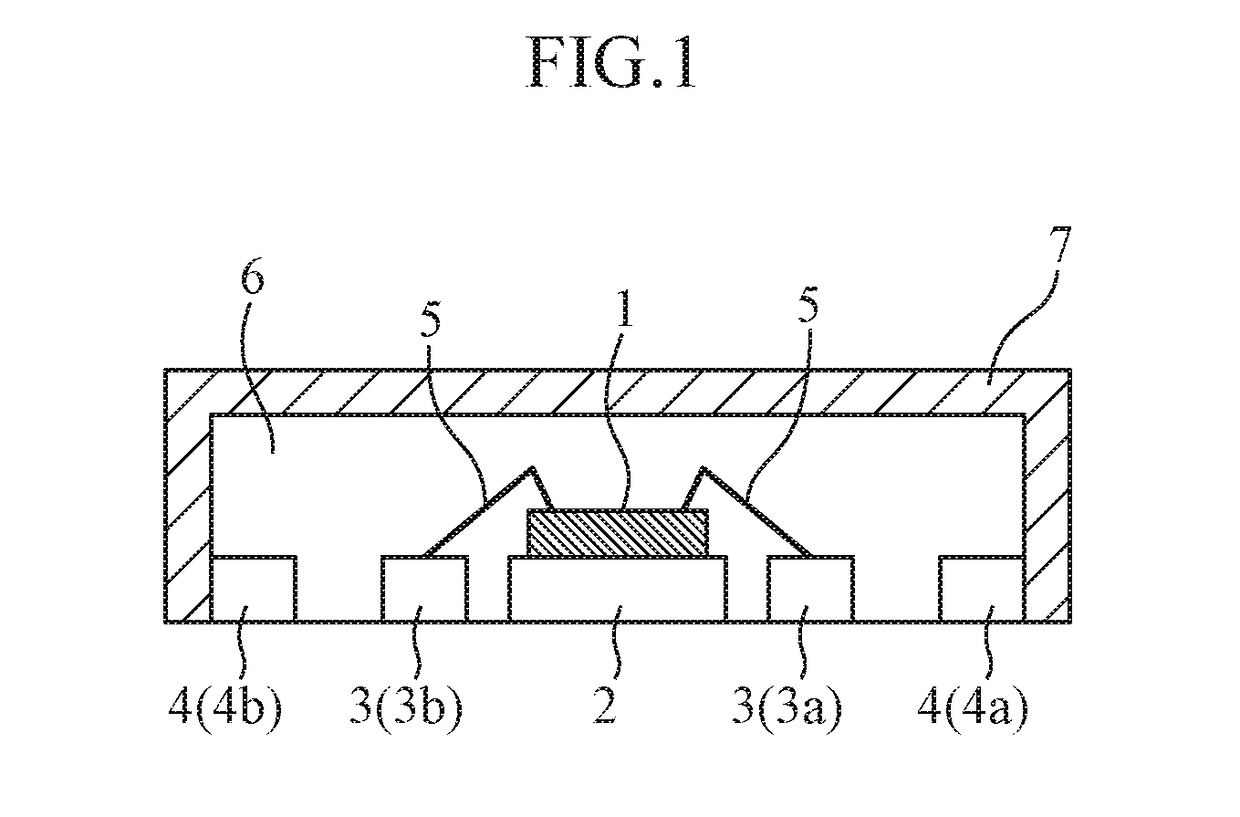

Semiconductor package

ActiveUS20170330838A1Good shielding propertiesSmall sizeSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A lead frame includes: a second terminal that is disposed to surround terminals on a package plane and can be grounded; and a conductive member that covers molded resin and is electrically connected to the second terminal.

Owner:MITSUBISHI ELECTRIC CORP

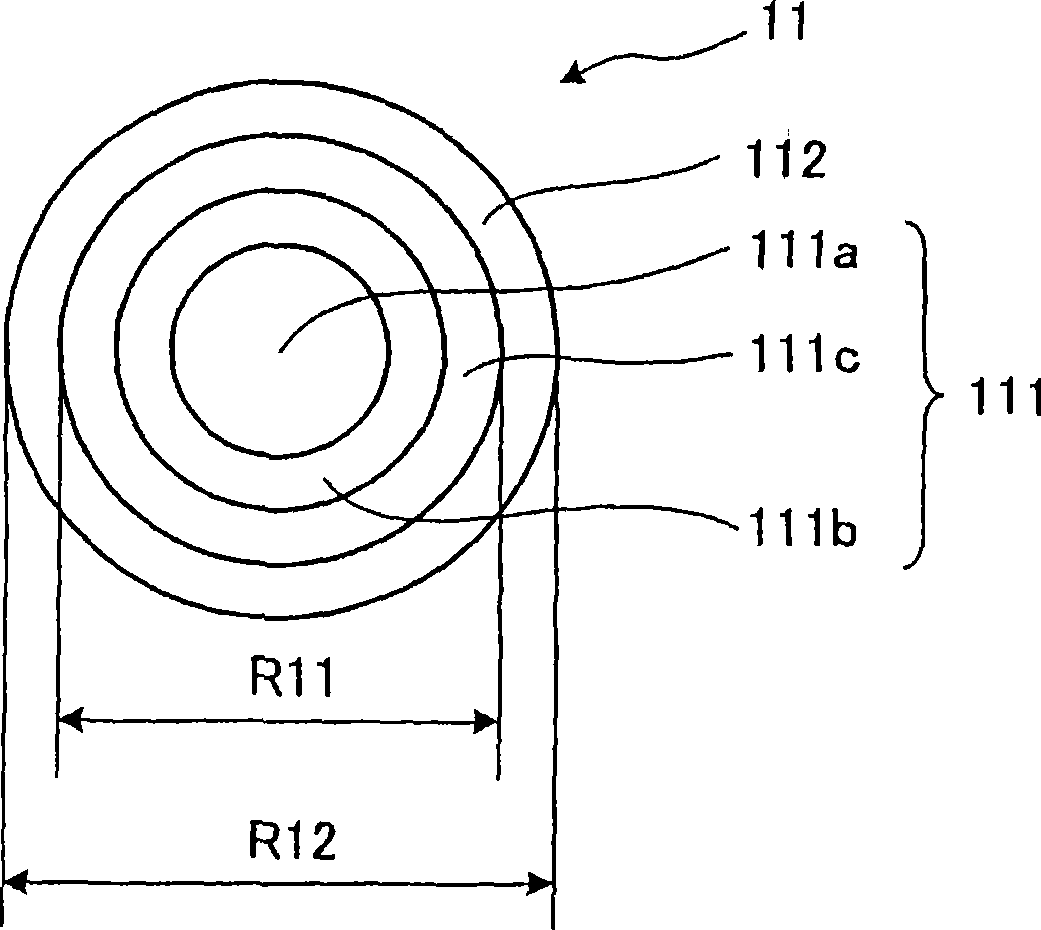

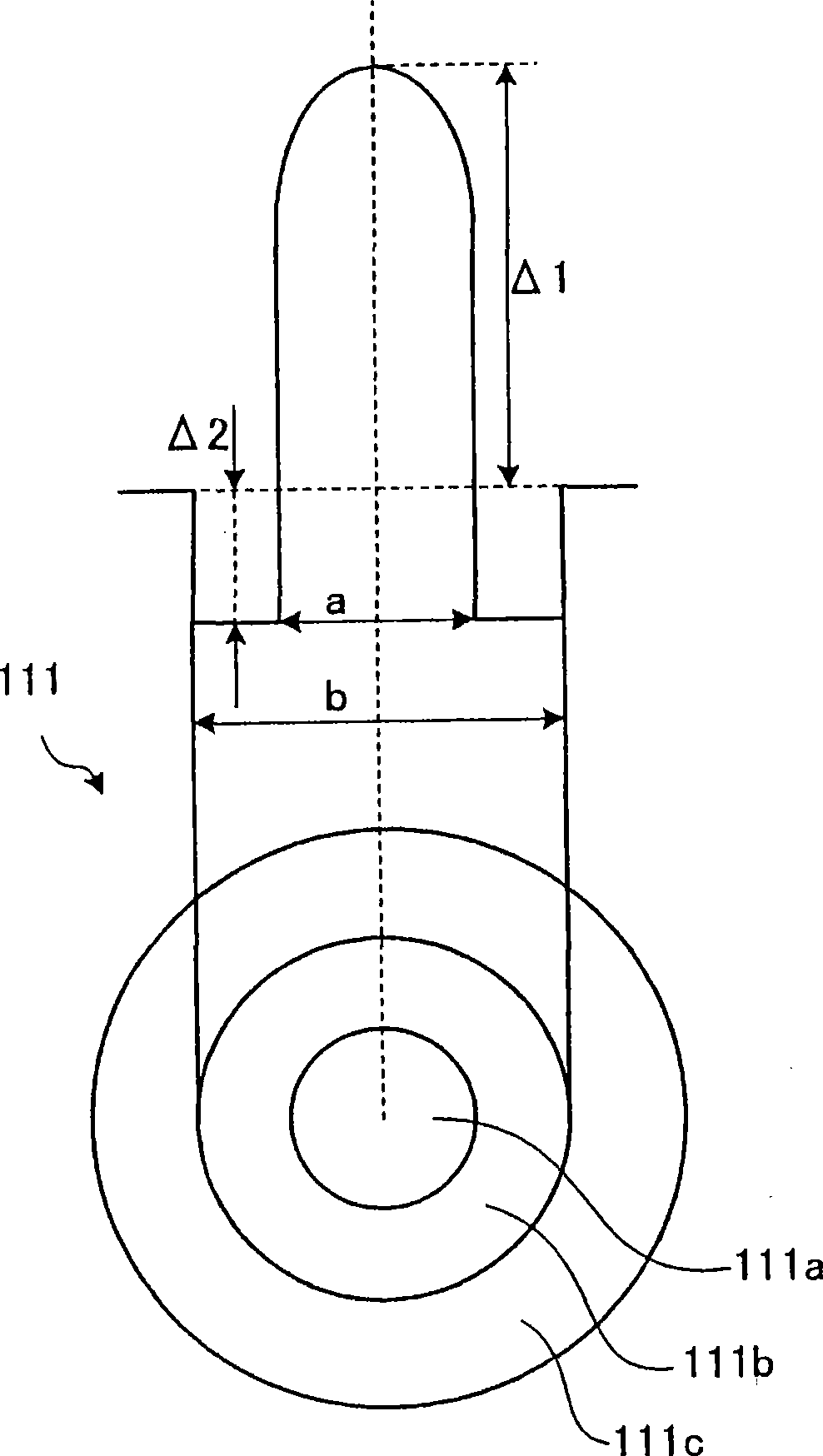

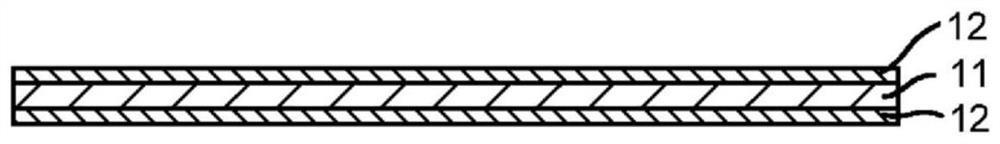

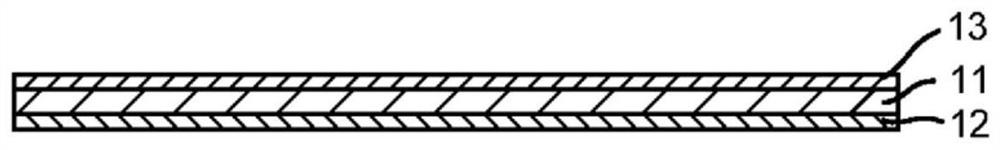

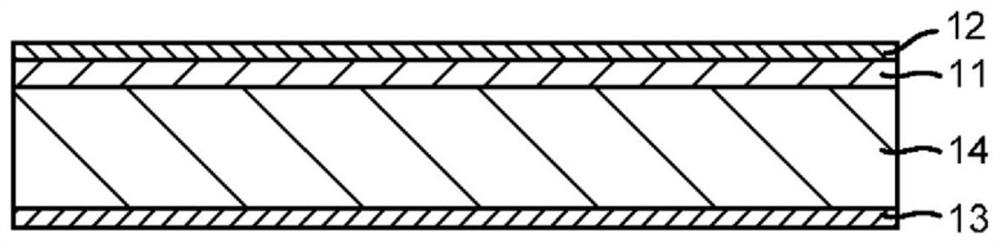

Coated optical fiber ribbon

InactiveCN101375195AIncrease flame retardancyGood shielding propertiesGlass optical fibreFibre mechanical structuresUV curingUltraviolet

An optical fiber ribbon of 300 [mu]m or less thickness comprising, parallelly disposed, optical fiber wires each having a glass optical fiber provided at its periphery with a wire coating, the optical fiber wires collectively clad by a tape coating, wherein the wire coating consists of a non-flame-retardant ultraviolet hardened resin and wherein the tape coating has a thickness of 40 [mu]m or more and consists of a flame-retardant resin. Thus, there can be provided an optical fiber ribbon that despite being thin, realizes good flame retardation and screening characteristics.

Owner:FURUKAWA ELECTRIC CO LTD

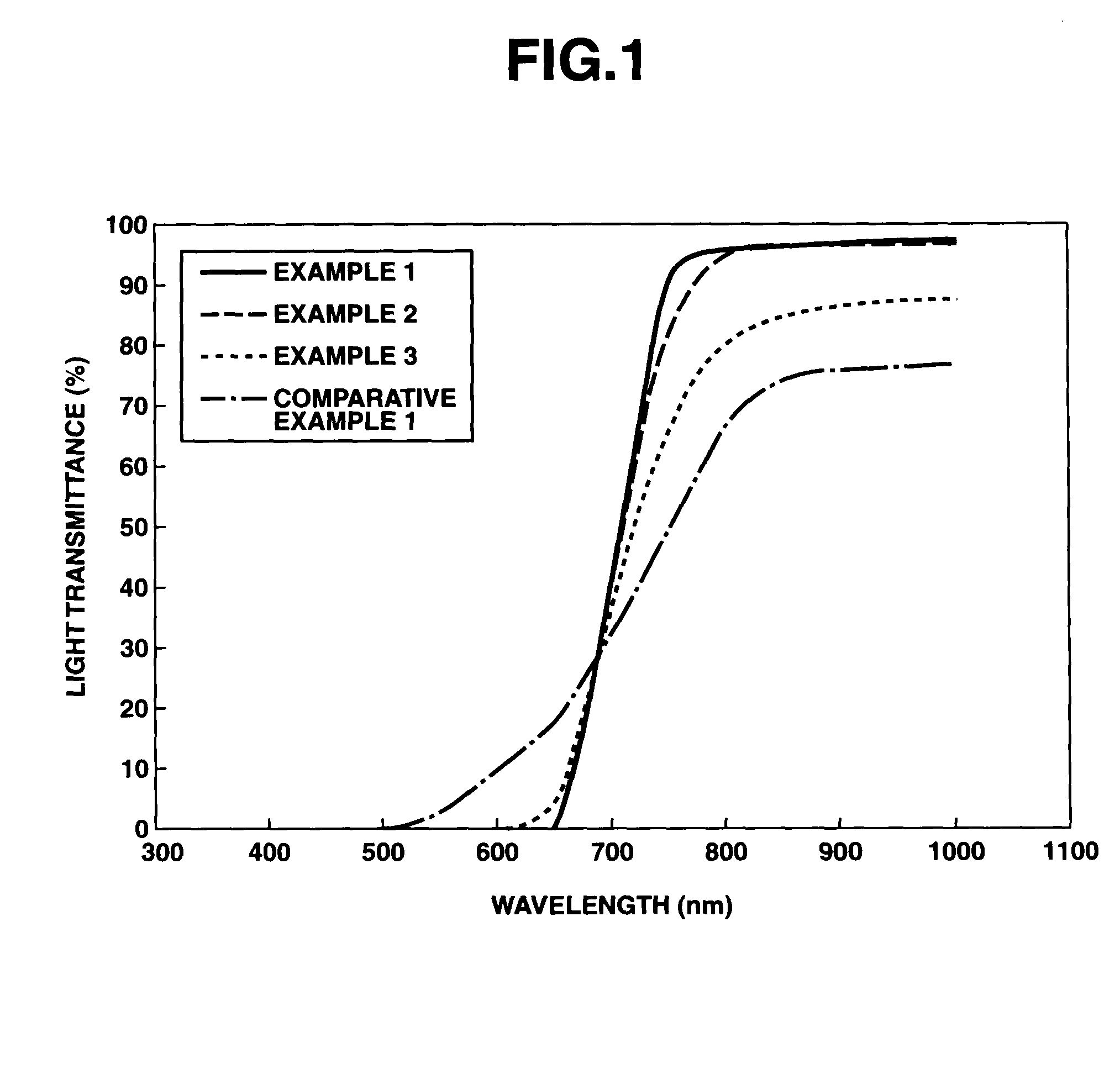

Optical filter, solid-state imaging element, imaging device lens and imaging device

ActiveUS9268072B2Sufficient downsizingLow costMethine/polymethine dyesOptical filtersInfraredRefractive index

The present invention relates to an optical filter, a solid-state imaging element and an imaging device lens which contain a near infrared ray absorbing layer having a specific near infrared ray absorbing dye dispersed in a transparent resin having a refractive index of 1.54 or more, and also relates to an imaging device containing the solid-state imaging element or the imaging device lens. The near infrared ray absorbing layer has a transmittance of visible light of from 450 to 600 nm of 70% or more, a transmittance of light in a wavelength region of from 695 to 720 nm of not more than 10%, and an amount of change of transmittance of not more than −0.8.

Owner:ASAHI GLASS CO LTD

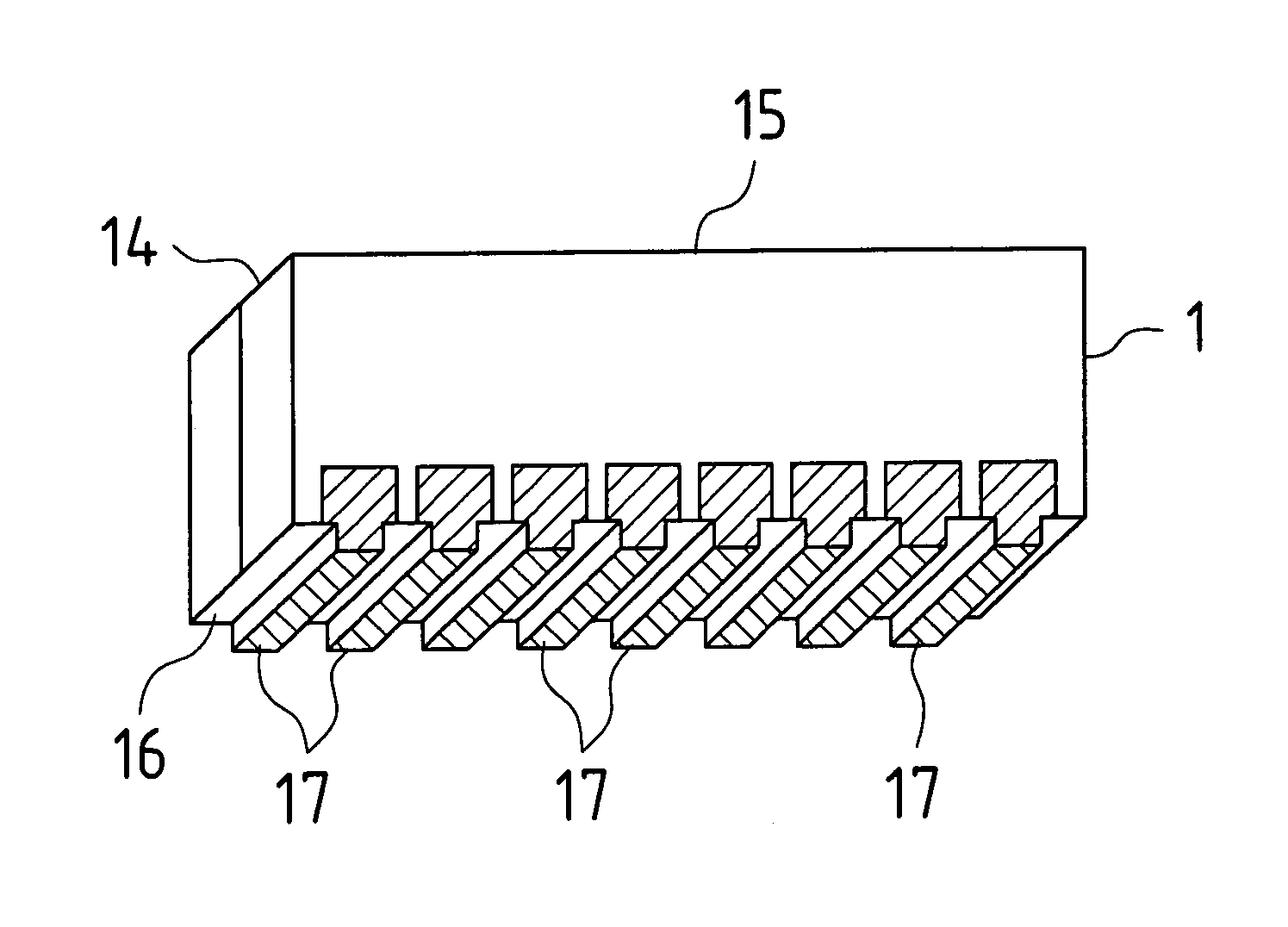

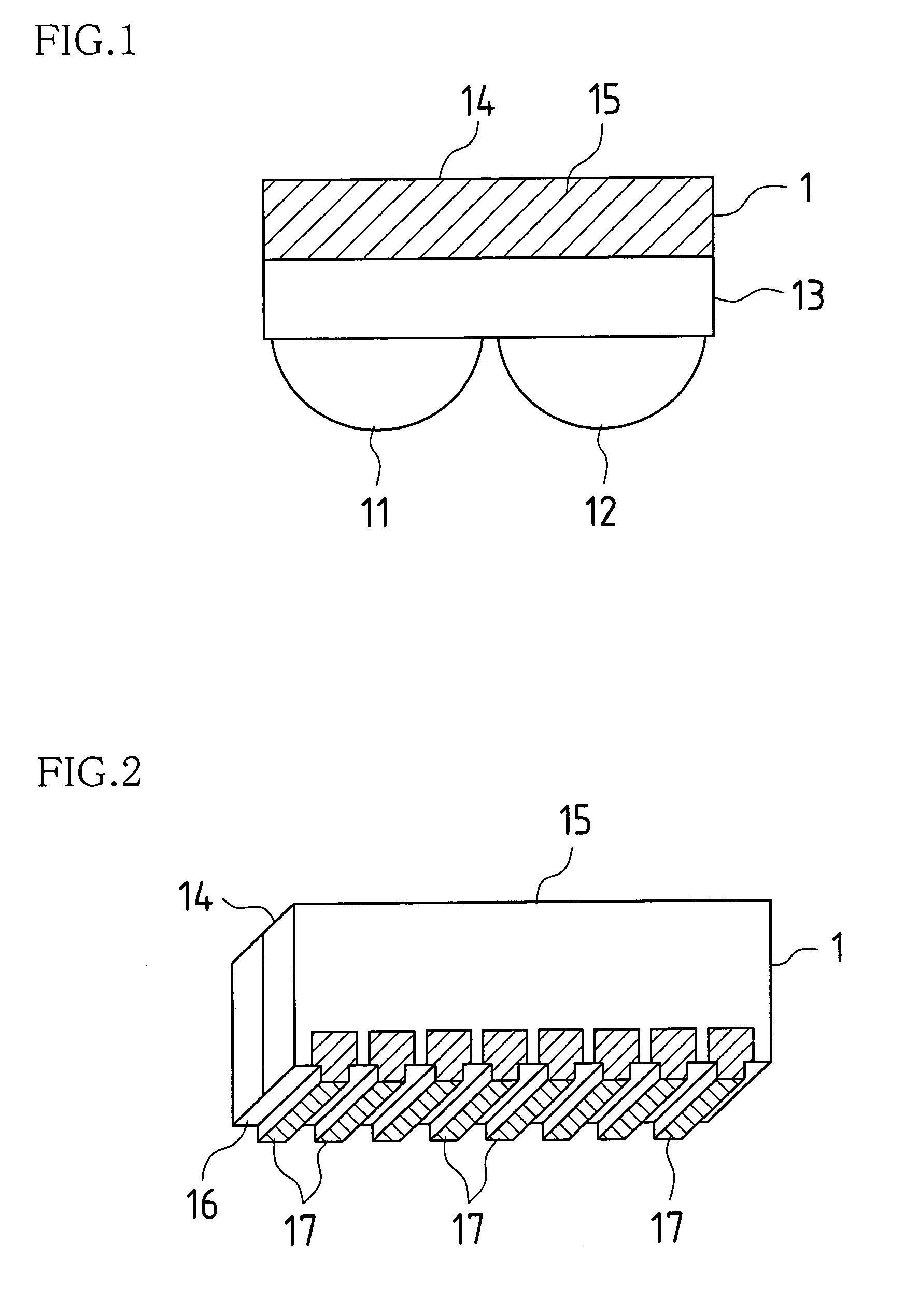

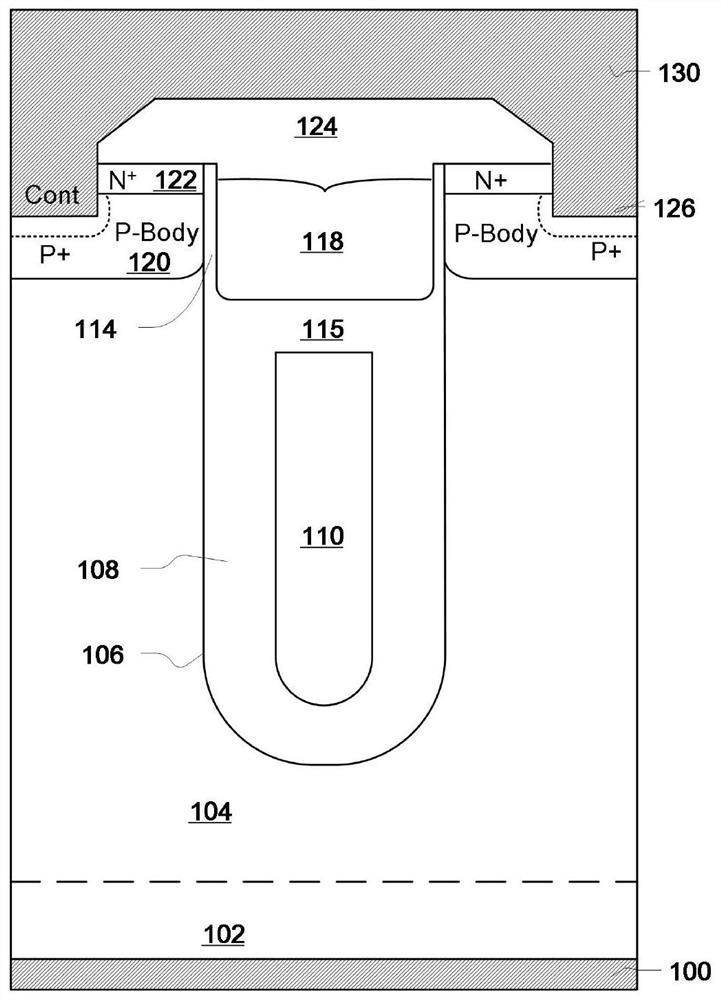

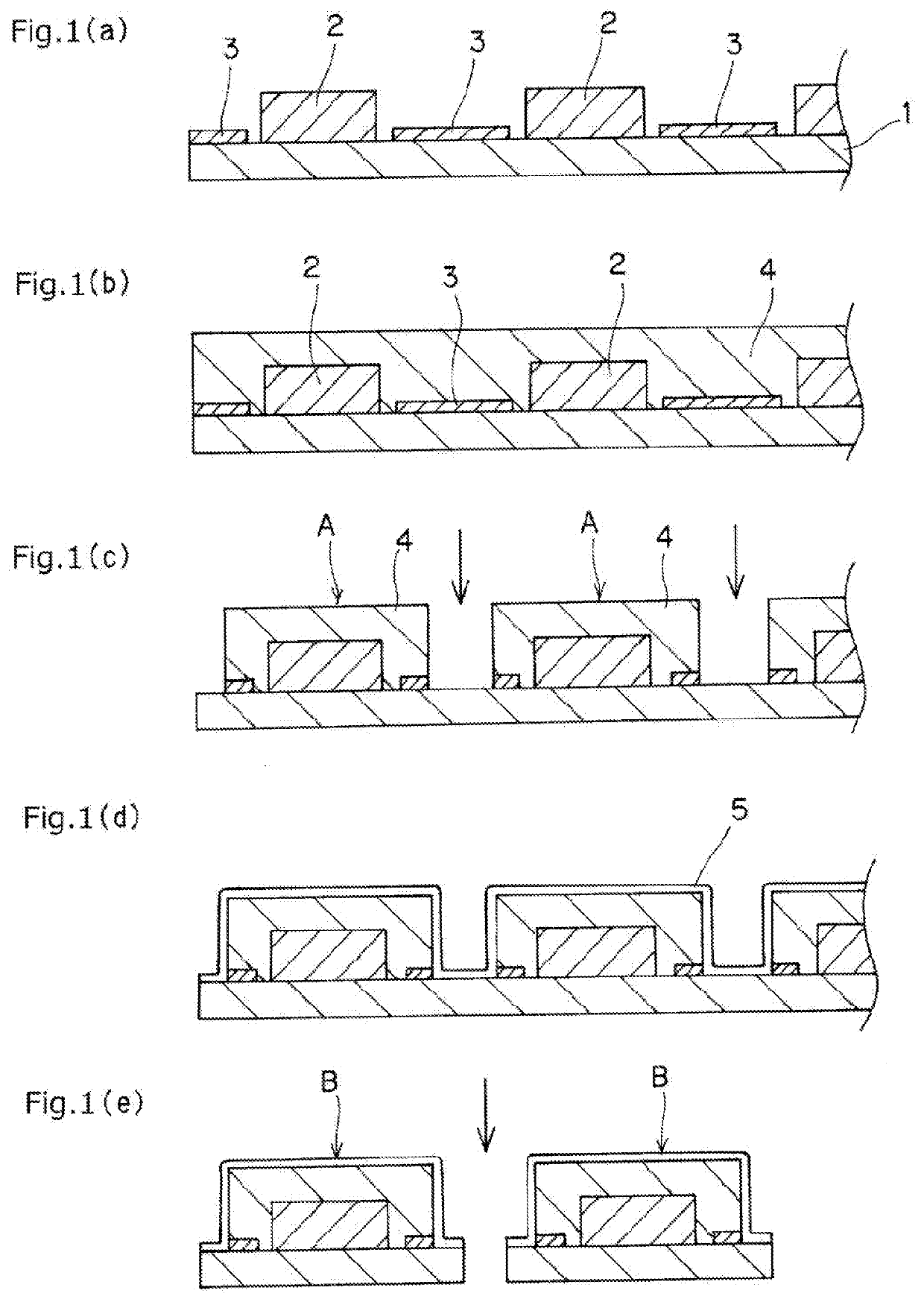

Semiconductor device and manufacturing method for same

InactiveUS7199452B2Good shielding propertiesHigh sensitivityMagnetic/electric field screeningSemiconductor/solid-state device detailsSemiconductor chipGround plane

A semiconductor device in which semiconductor chip(s) is or are mounted onto substrate(s) incorporating patterned wiring and the entirety or entireties has or have been sealed with resin(s), wherein by forming electrically conductive pattern(s) for shielding at end face(s) at top(s) of substrate(s) and attaching such electrically conductive pattern(s) to region(s) of ground plane pattern(s) on circuit board(s) of apparatus(es) which is or are provided with such semiconductor device(s), it is possible to shield semiconductor device(s) even without use of shield case(s). In such case, by applying material(s) possessing good shielding characteristics, e.g., gold plating, over electrically conductive pattern(s), it is possible to increase sensitivity with respect to electromagnetic noise and improve shielding effect (anti-electromagnetic-noise effect).

Owner:SHARP KK

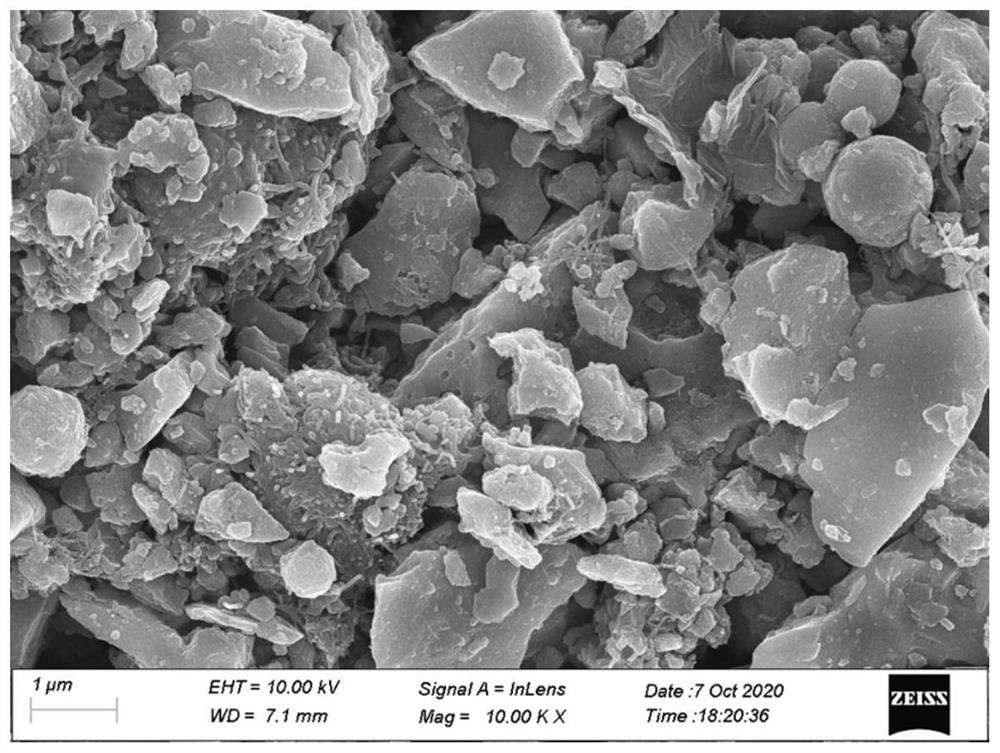

Conductive coating material and production method for shielded package using conductive coating material

ActiveUS20200299523A1Prevent discolorationImprove shielding effectMagnetic/electric field screeningSemiconductor/solid-state device detailsConductive coatingFirming agent

A conductive coating material is disclosed including at least (A) 100 parts by mass of a binder component including 5 to 30 parts by mass of solid epoxy resin that is solid at normal temperature and 20 to 90 parts by mass of liquid epoxy resin that is liquid at normal temperature, (B) 200 to 1800 parts by mass of silver-coated copper alloy particles in which the copper alloy particles are made of an alloy of copper, nickel, and zinc, the silver-coated copper alloy particles have a nickel content of 0.5% to 20% by mass, and the silver-coated copper alloy particles have a zinc content of 1% to 20% by mass with respect to 100 parts by mass of the binder component (A), and (C) 0.3 to 40 parts by mass of a curing agent with respect to 100 parts by mass of the binder component (A).

Owner:TATSUTA ELECTRICWIRE & CABLE

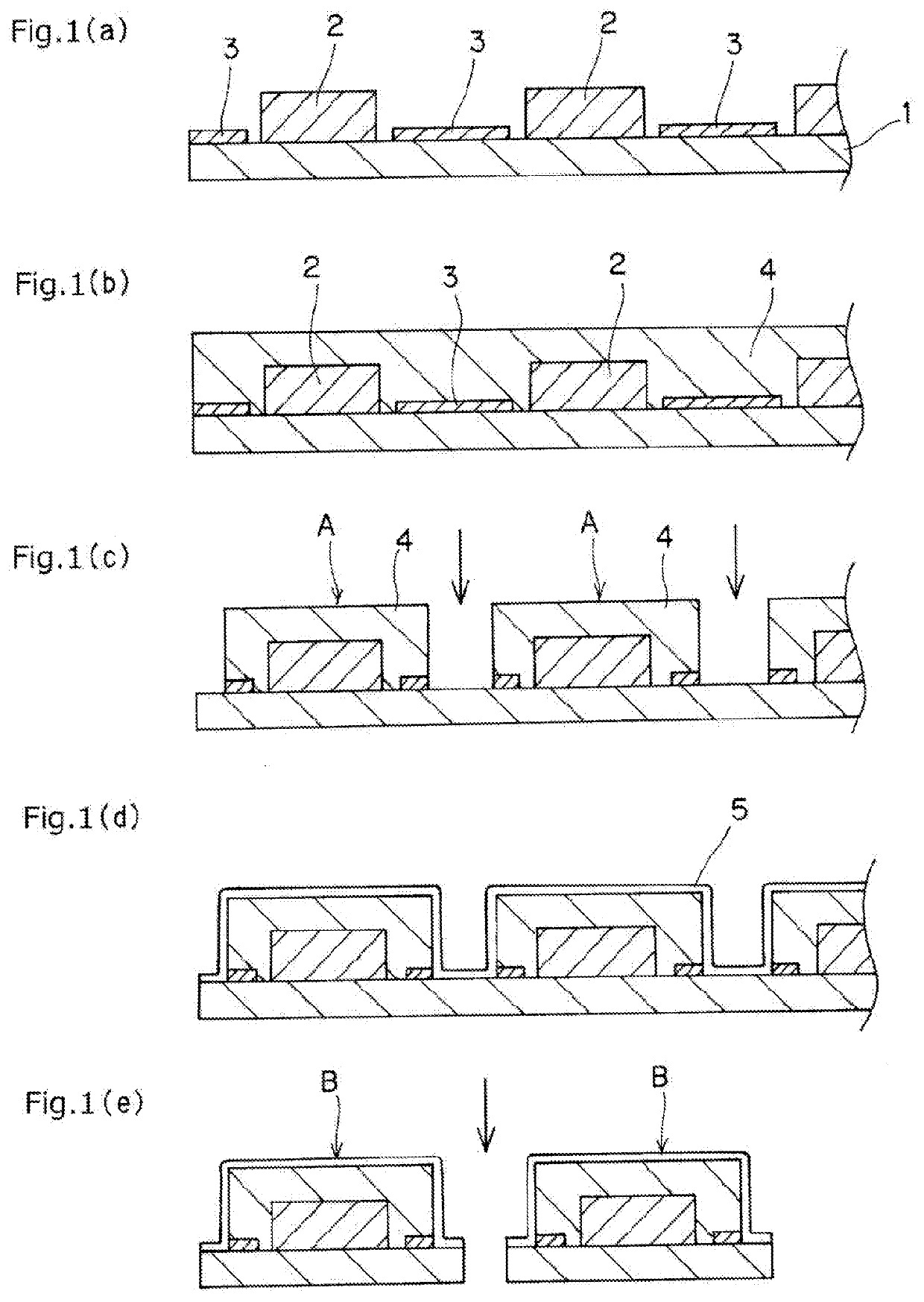

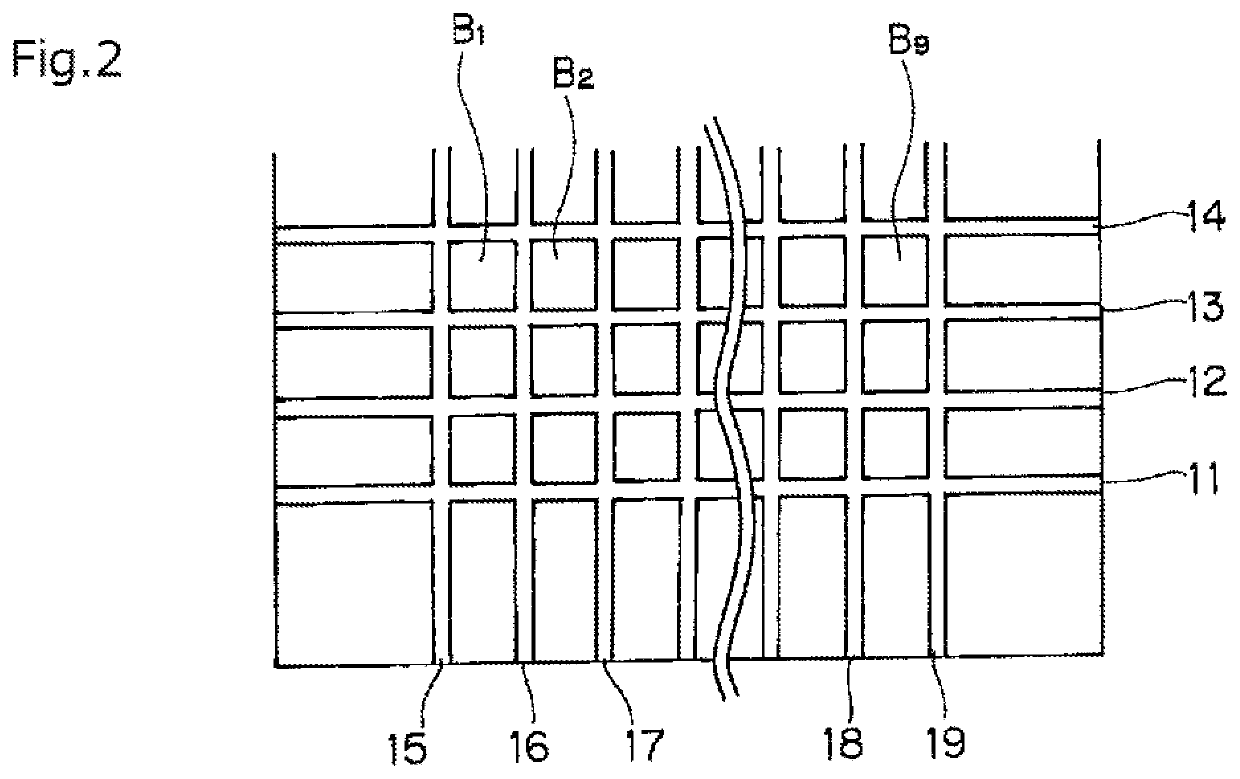

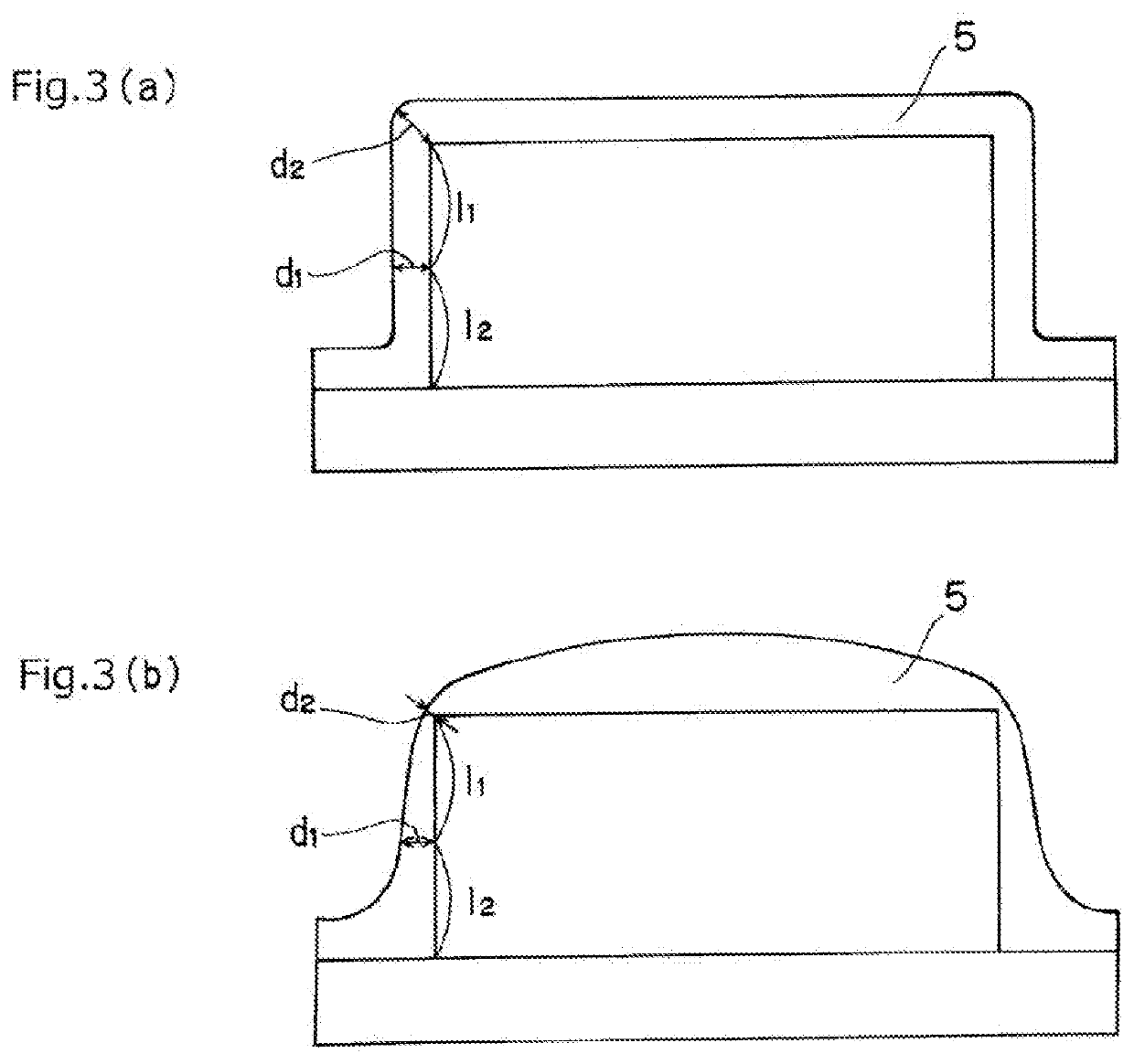

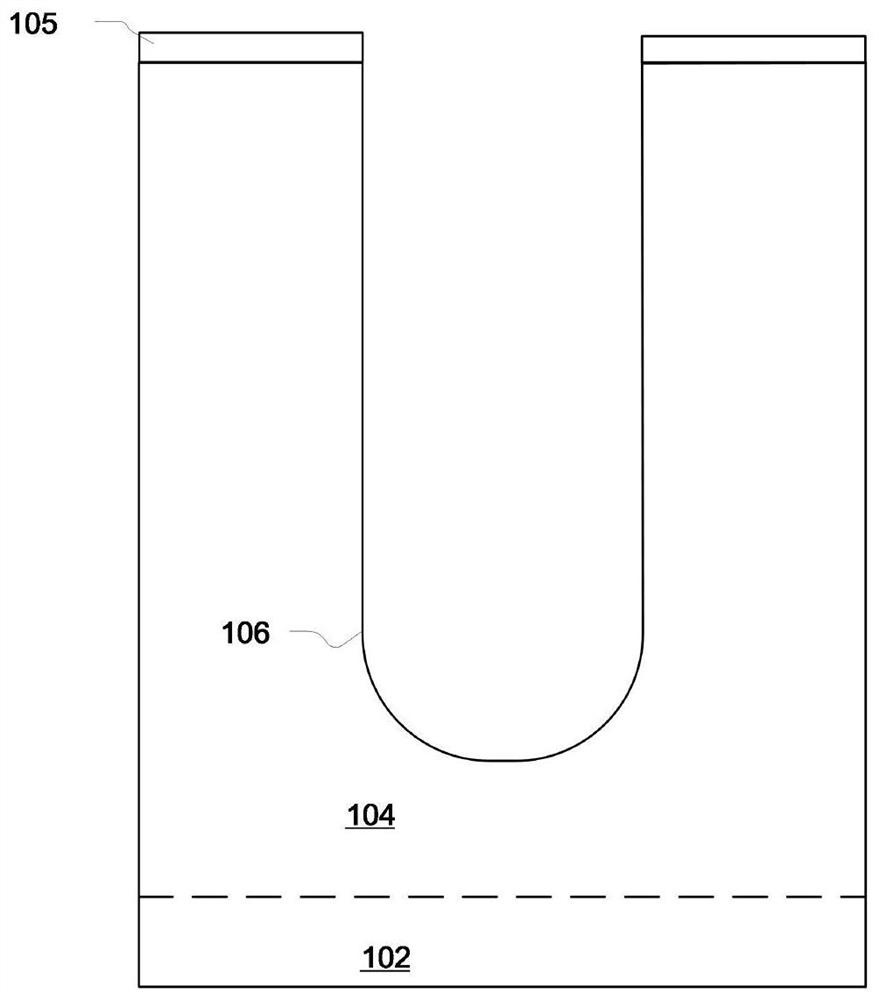

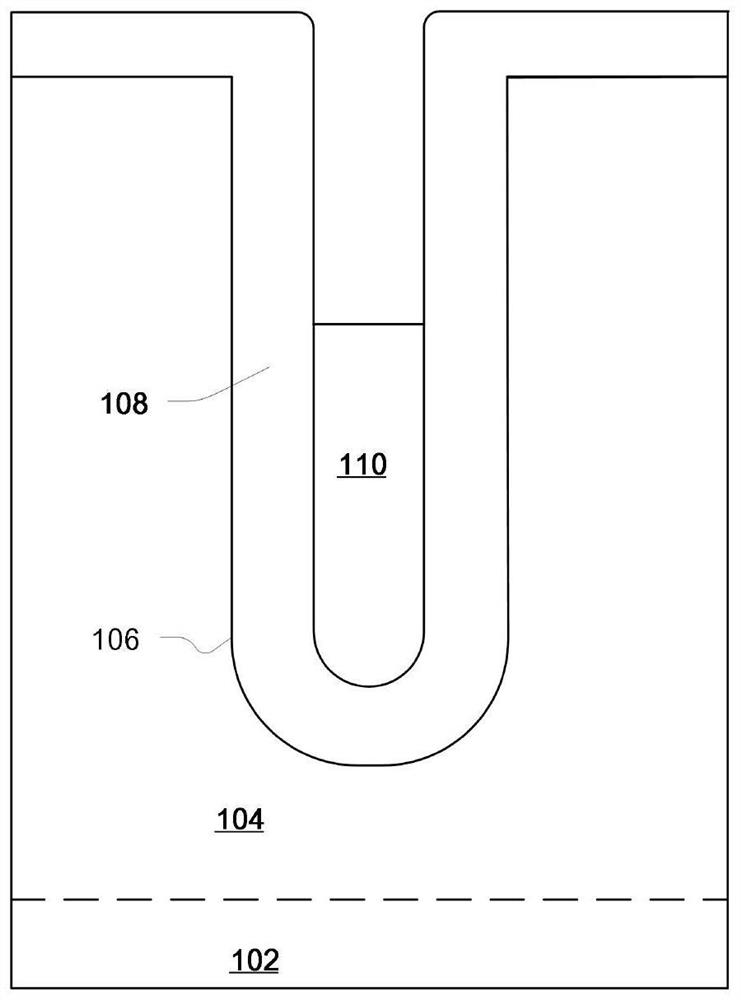

Shield gate trench MOSFET manufacturing method

ActiveCN113745337AReduce processing timeIncreased process step throughputSemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetGate oxide

The invention relates to a shield gate trench MOSFET manufacturing method, which comprises the following steps: growing a shield gate oxide layer on the side wall of a trench of an epitaxial layer, then conducting filling with shield gate polycrystalline silicon, and etching back the shield gate polycrystalline silicon to a first target depth; depositing a silicon nitride layer with a target thickness T to form a dielectric isolation layer for isolating the shield gate polycrystalline silicon and the device gate, and etching the silicon nitride layer back to the surface of the epitaxial layer; etching the shield gate oxide layer to a second target depth, and etching the silicon nitride layer to a first target thickness K, so as to enable the upper surface of the silicon nitride layer to extend out of the surface of the shield gate oxide layer; and growing a gate oxide layer, depositing gate polycrystalline silicon, and etching the gate polycrystalline silicon to a third target depth to form the shield gate trench MOSFET. The shield gate trench MOSFET and the manufacturing method thereof have the advantages of stable structure, high production efficiency, low cost and the like.

Owner:深圳利普芯微电子有限公司

Semiconductor device and manufacturing method for same

InactiveUS20040173877A1Good shielding propertiesHigh sensitivityThyristorMagnetic/electric field screeningSemiconductor chipGround plane

A semiconductor device in which semiconductor chip(s) is or are mounted onto substrate(s) incorporating patterned wiring and the entirety or entireties has or have been sealed with resin(s), wherein by forming electrically conductive pattern(s) for shielding at end face(s) at top(s) of substrate(s) and attaching such electrically conductive pattern(s) to region(s) of ground plane pattern(s) on circuit board(s) of apparatus(es) which is or are provided with such semiconductor device(s), it is possible to shield semiconductor device(s) even without use of shield case(s). In such case, by applying material(s) possessing good shielding characteristics, e.g., gold plating, over electrically conductive pattern(s), it is possible to increase sensitivity with respect to electromagnetic noise and improve shielding effect (anti-electromagnetic-noise effect).

Owner:SHARP KK

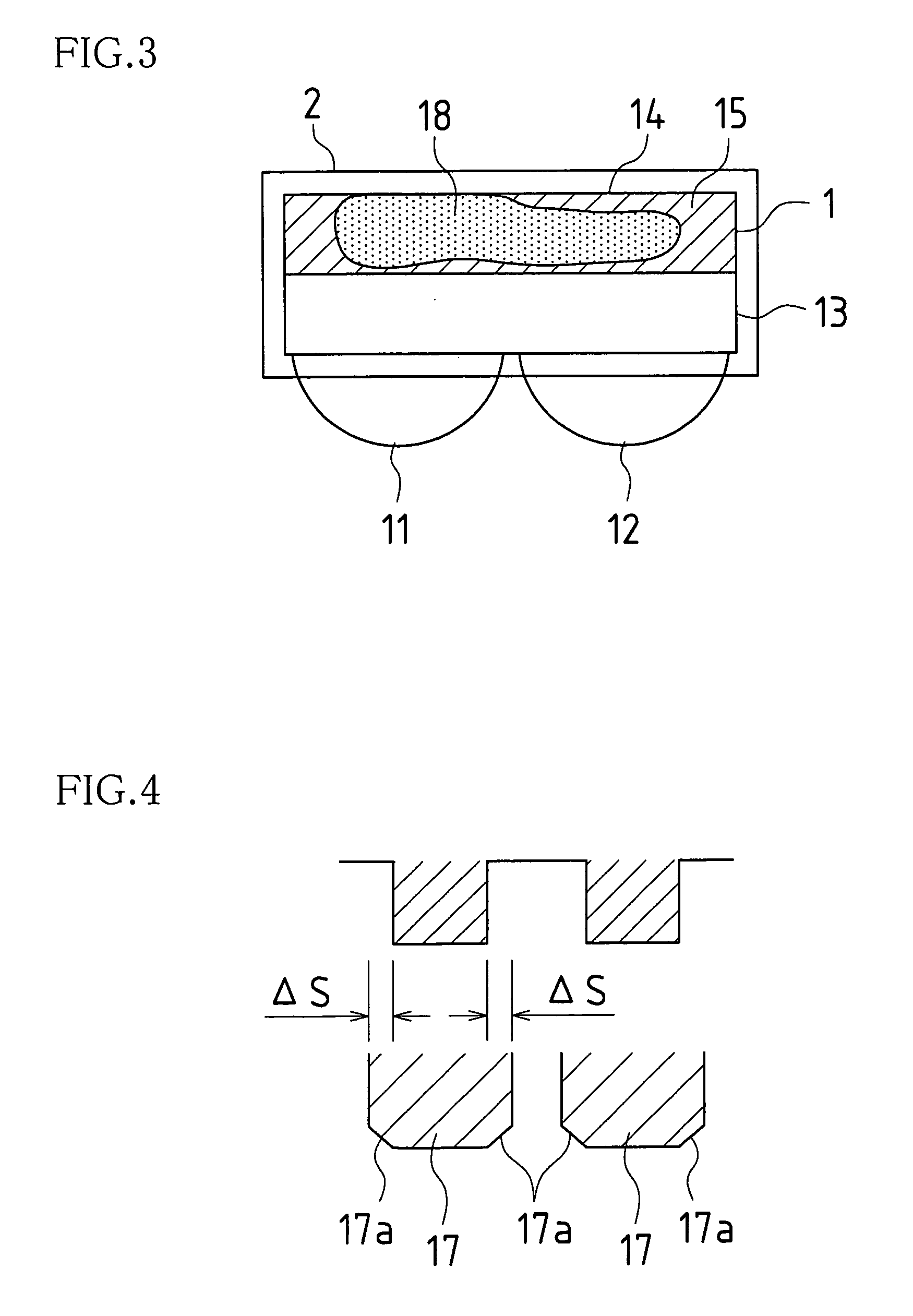

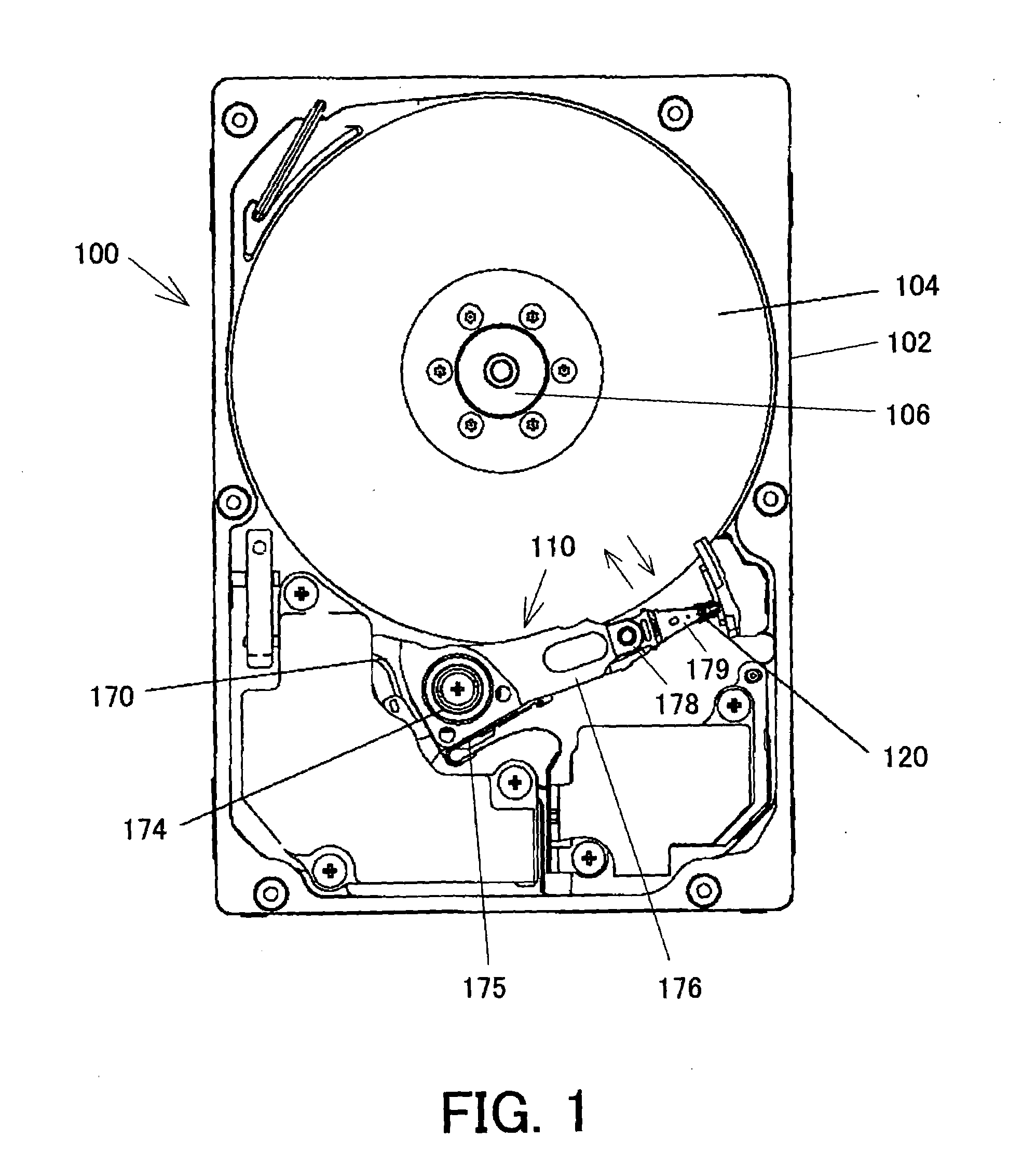

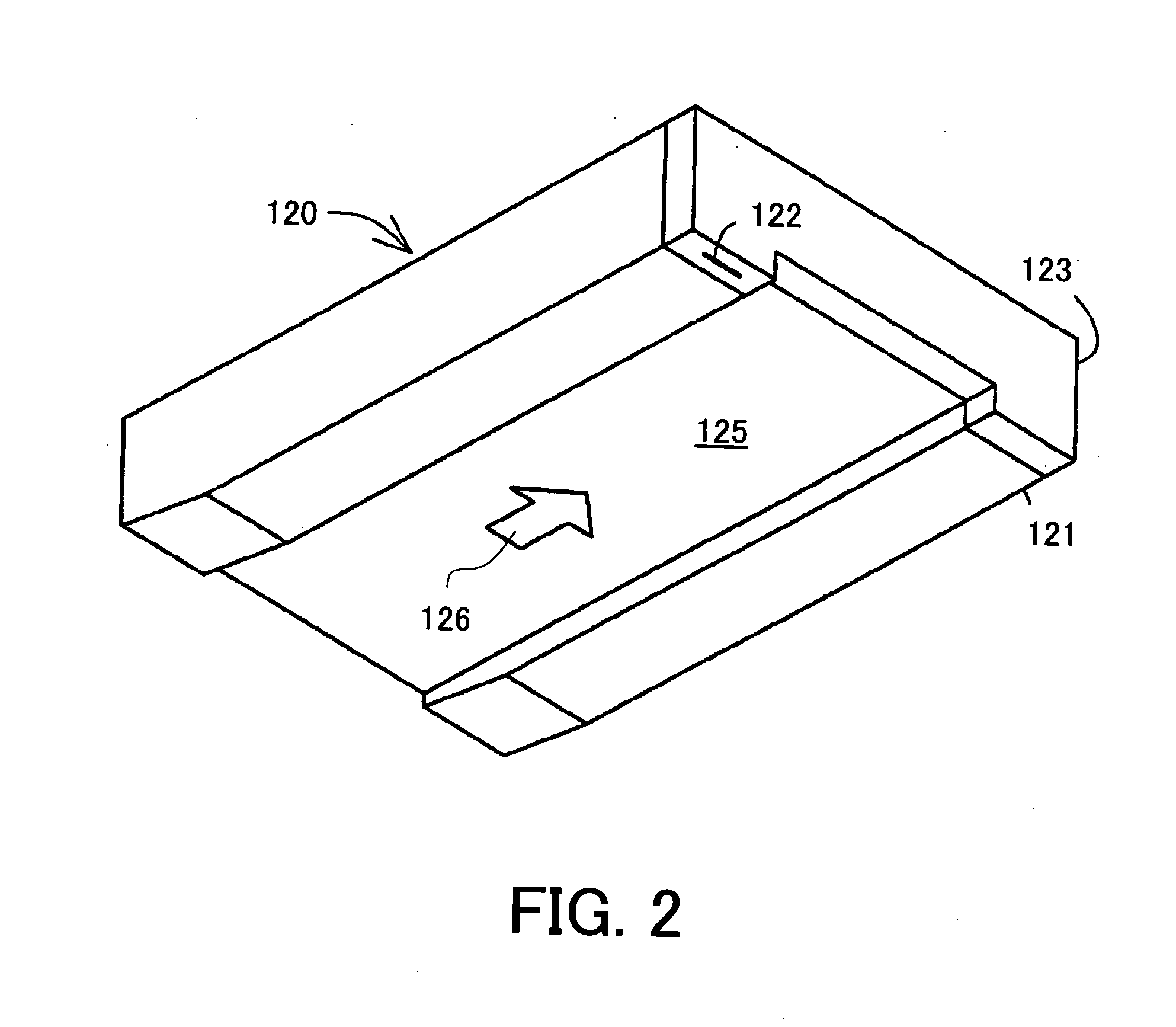

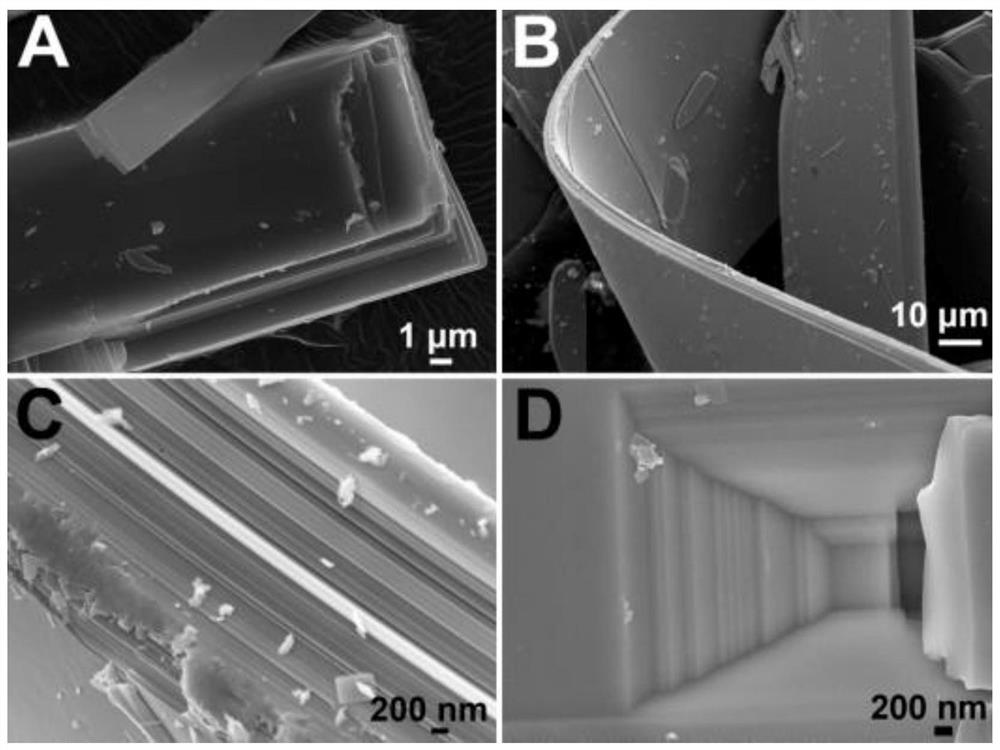

Magnetoresistive device, read head and storage having the same

InactiveUS20080013220A1Good shielding propertiesHigh sensitivityElectrical transducersRecord information storageNon magneticSpin valve

A method for manufacturing a magnetoresistive device that includes a spin-valve film, and a terminal layer that applies a sense current in a direction of a lamination surface in the spin-valve film, the spin-valve film including a pair of uncoupled ferromagnetic layers, and a non-magnetic metal layer that separates the pair of uncoupled ferromagnetic layers from each other, one of the ferromagnetic layers having a fixed direction of magnetization, and the other of the ferromagnetic layers having a freely variable direction of magnetization includes the steps of forming the terminal layer through sputtering, and preventing a formation of a sharp part on the terminal layer while interrupting the forming step.

Owner:FUJITSU LTD

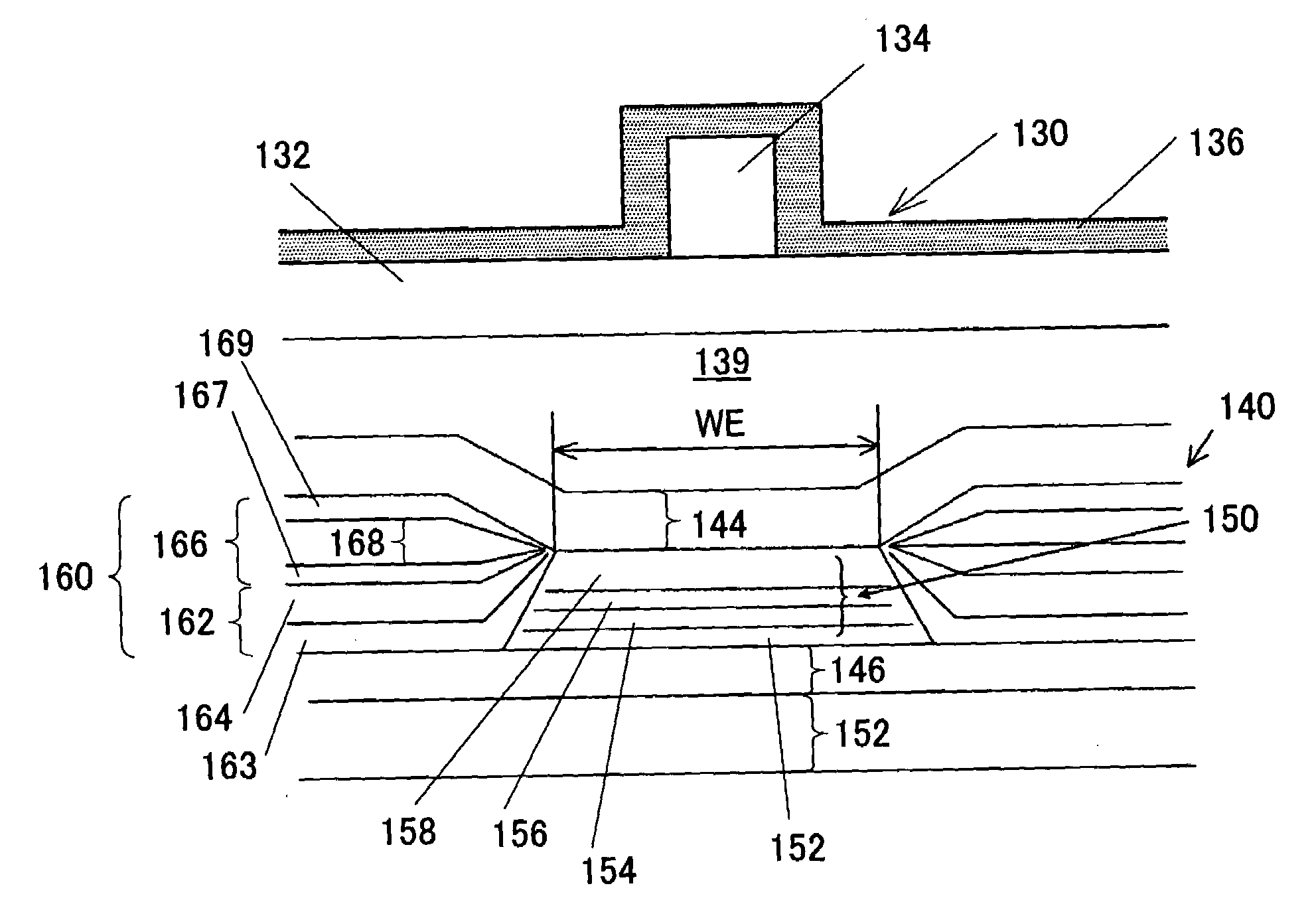

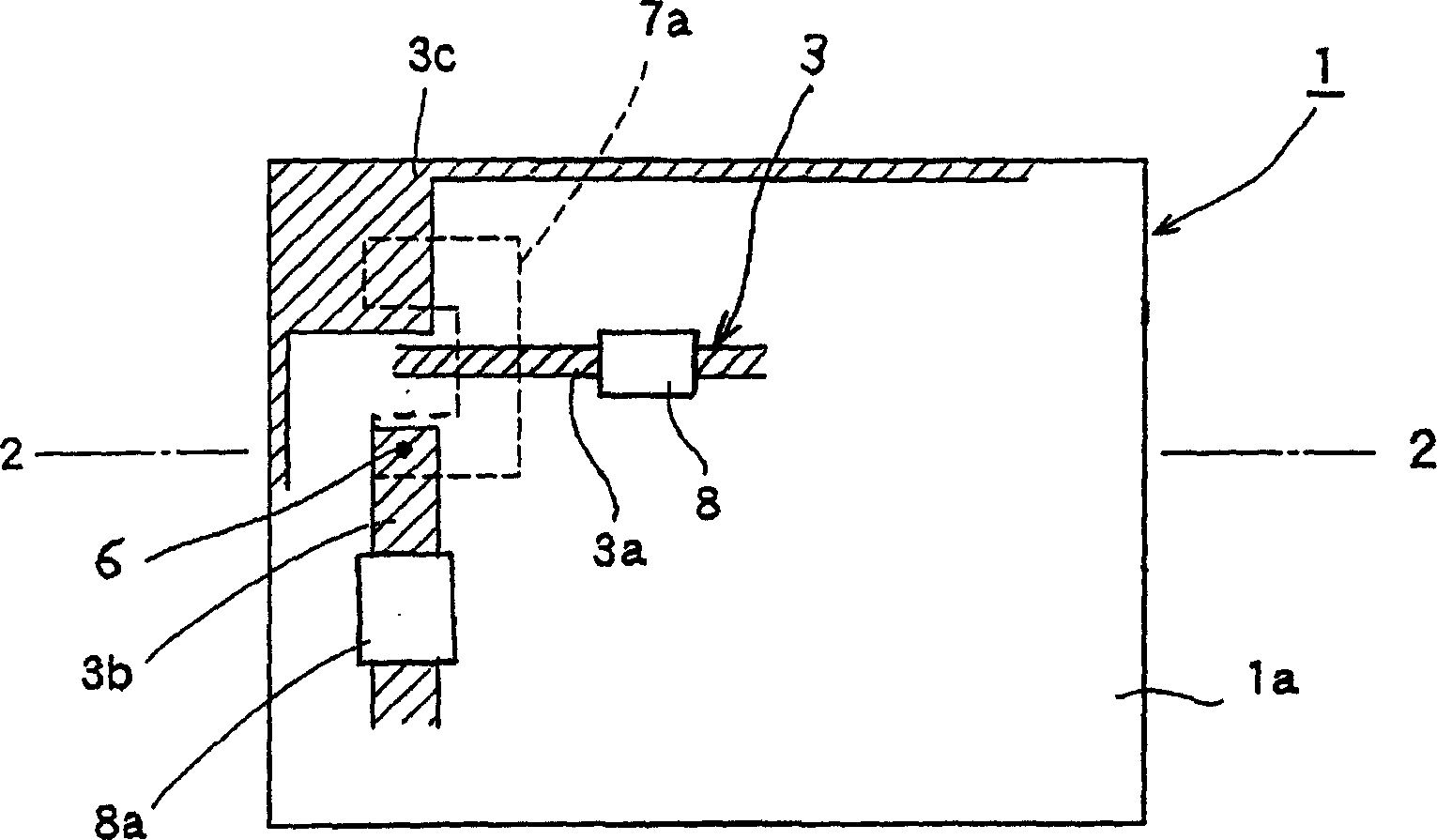

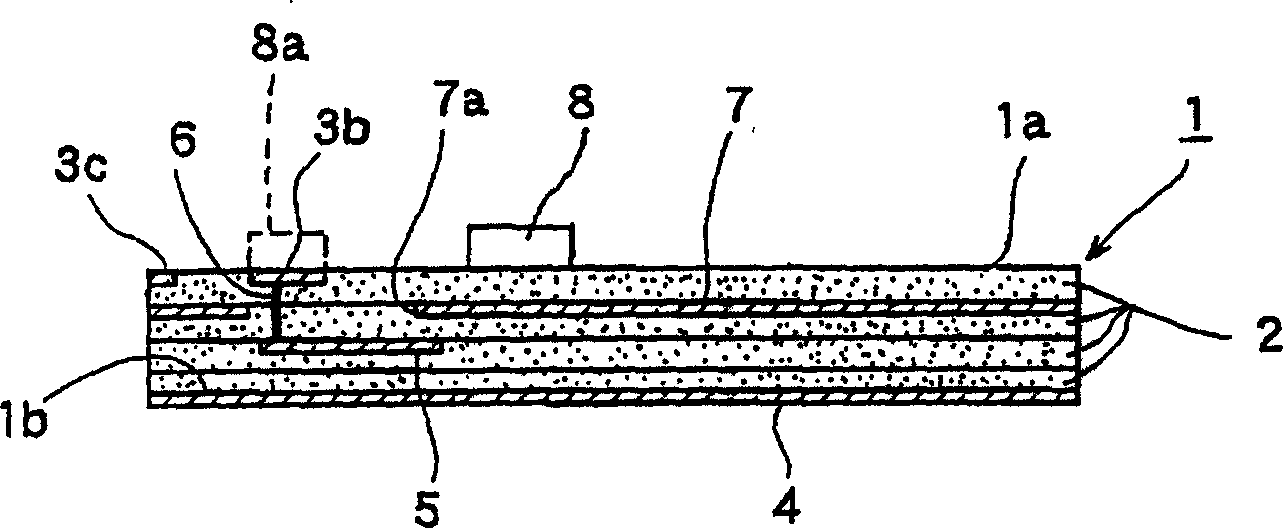

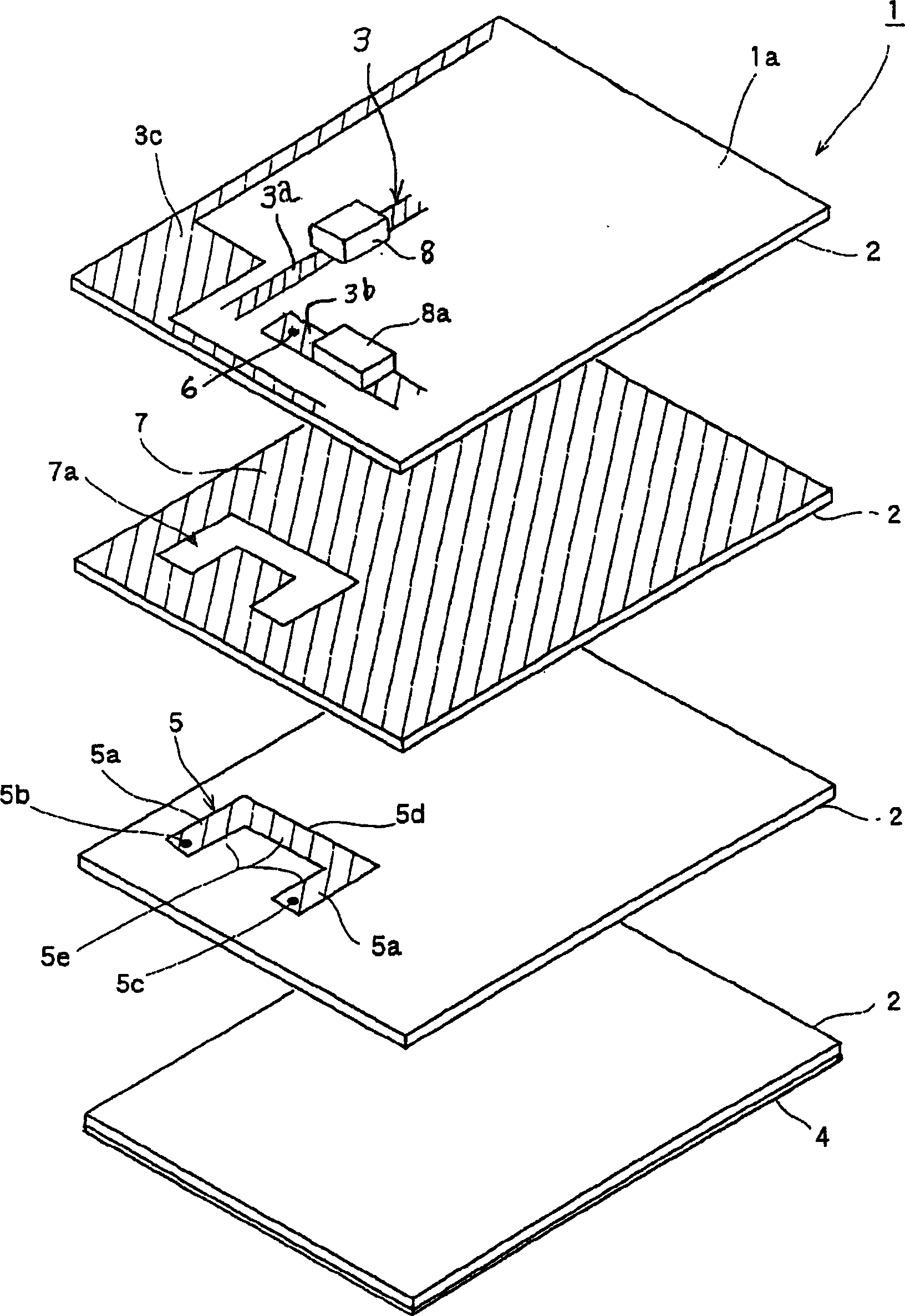

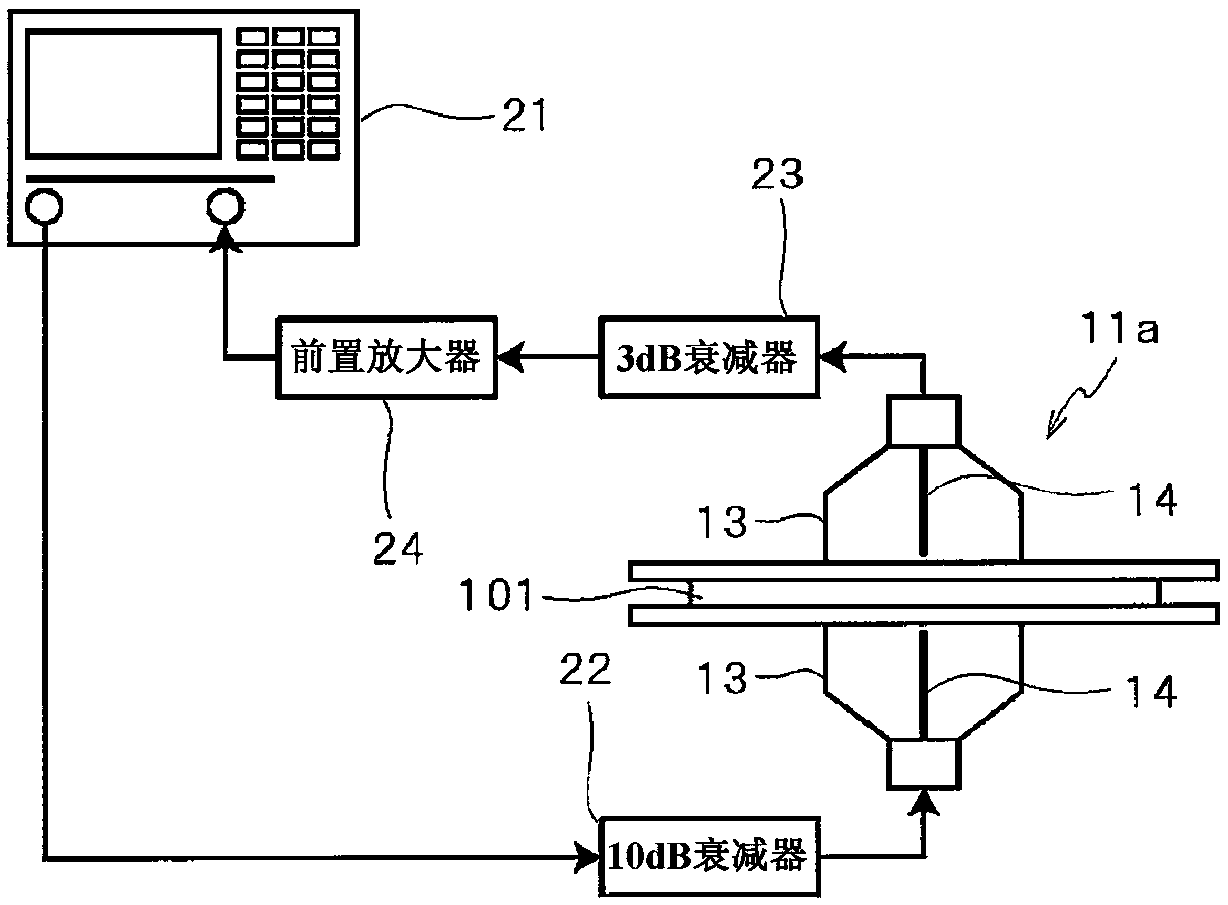

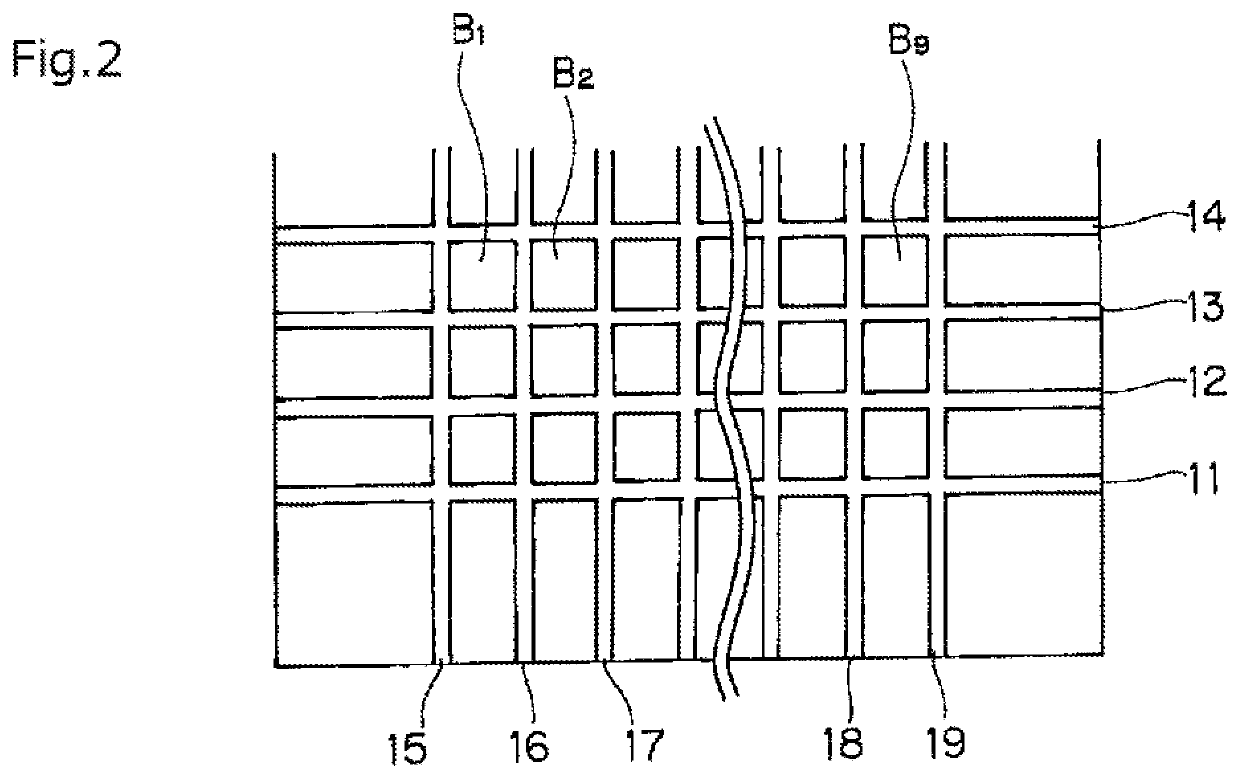

Voltage controlled oscillator small in reduction of inductance and Q

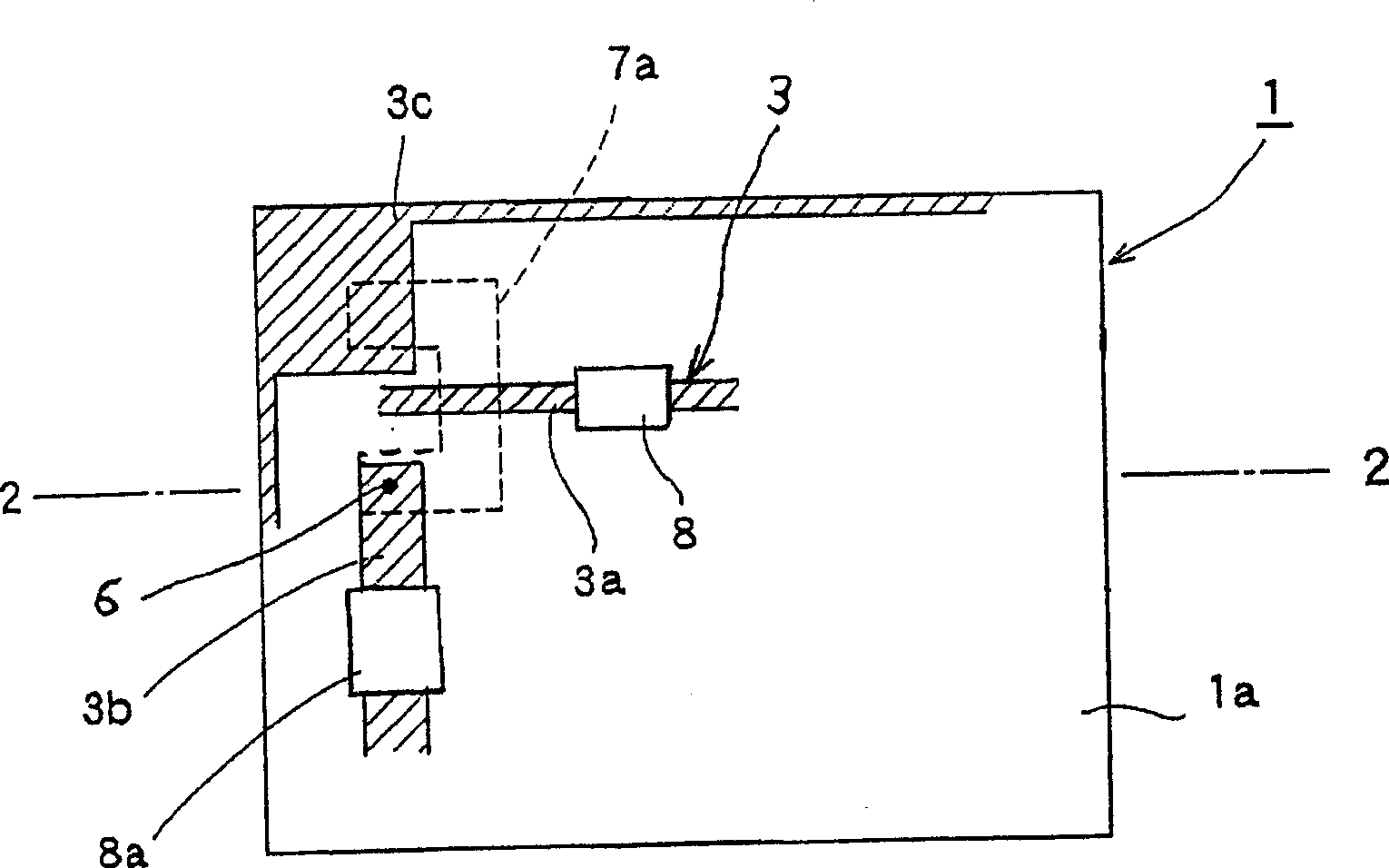

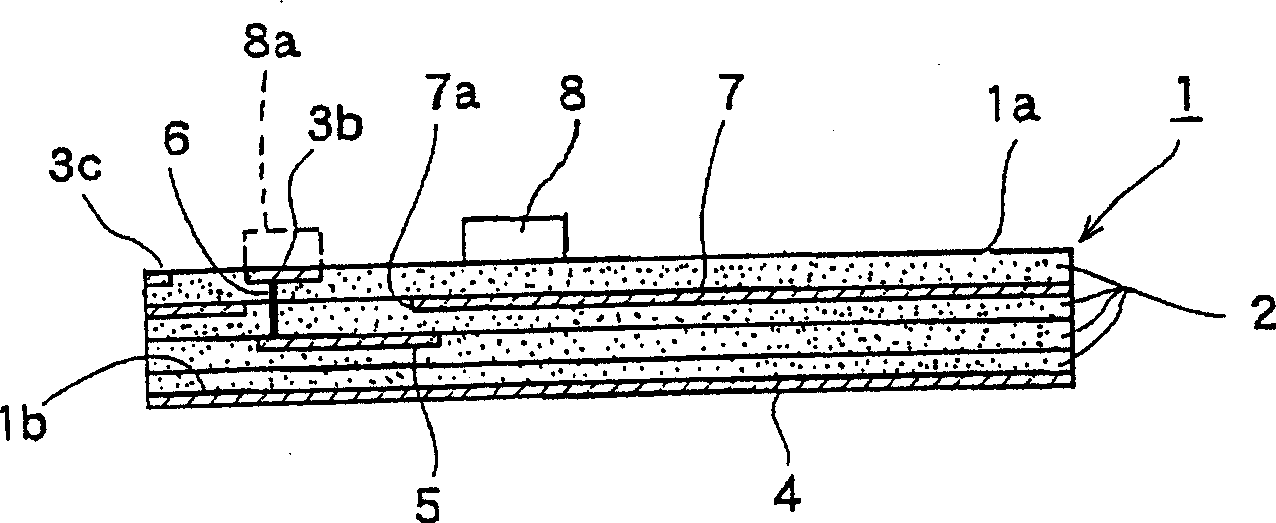

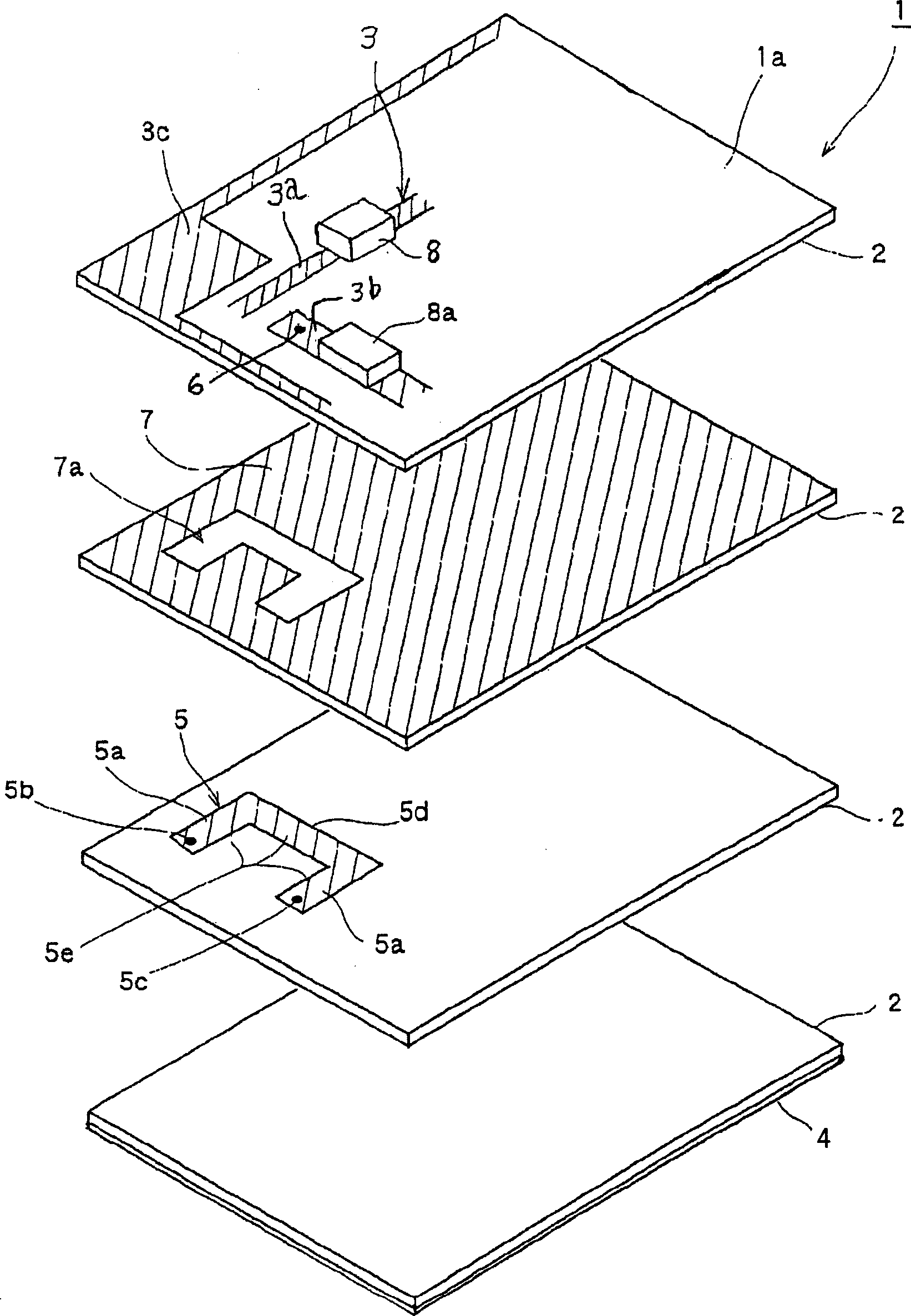

InactiveCN1622448AAdjust quicklyEasy to adjustPrinted circuit aspectsHigh frequency circuit adaptationsHigh current densityElectrical conductor

The voltage-controlled oscillator of the present invention comprises: a circuit substrate (1) formed by stacking a plurality of insulating substrates (2); a wiring pattern (3) formed on the surface of the circuit substrate (1); The electronic component (8) mounted on it; the resonant stripline (5) provided on the inner layer of the circuit substrate (1); the circuit substrate (1) between the wiring pattern (3) and the stripline (5) The grounding pattern (7) formed on the inner layer of the grounding pattern (7) reduces the inductance and the Q value by passing the conductor removal portion (7a) of the grounding pattern (7) near the part with high current density including the strip line (5). Furthermore, a portion of the strip line (5) and the wiring pattern (3) are shielded by the ground pattern (7), and as a result, a voltage controlled oscillator with good shielding characteristics is obtained. Provided is a voltage-controlled oscillator with good shielding properties between a strip line and a wiring pattern, and with less drop in inductance and Q value.

Owner:ALPS ALPINE CO LTD

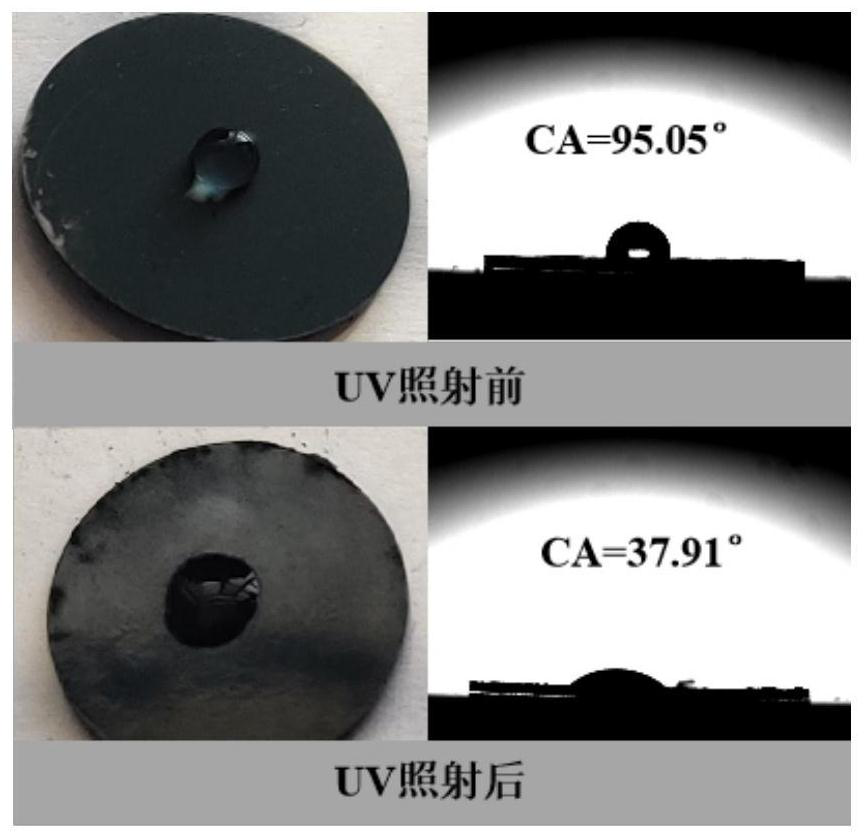

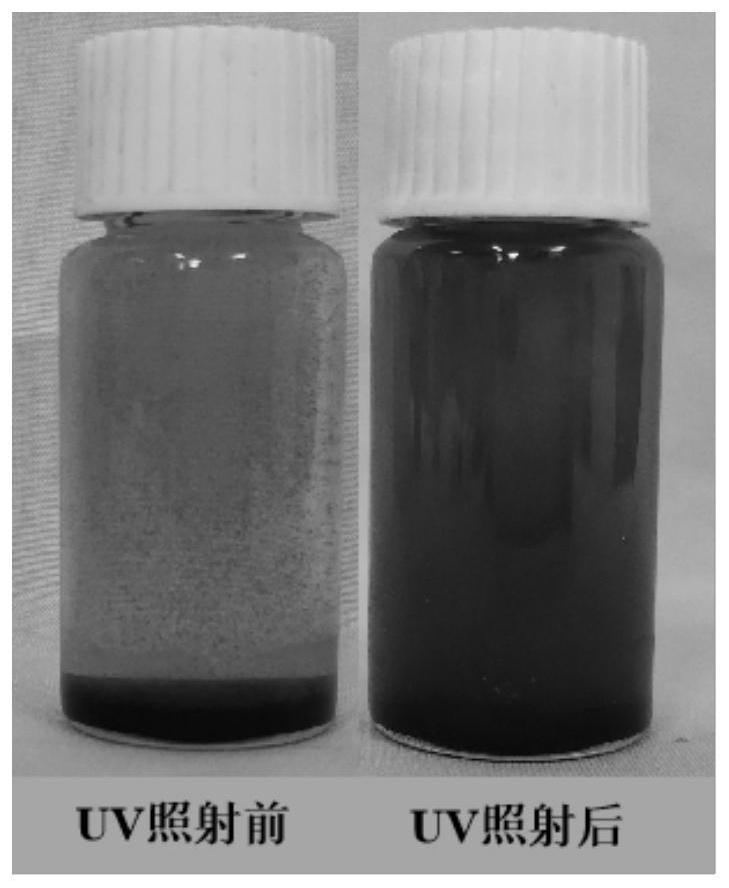

Ultraviolet photosensitive corrosion-resistant and wear-resistant filler, preparation method thereof and application of ultraviolet photosensitive corrosion-resistant and wear-resistant filler in coating

ActiveCN114806247ASolve the problem of poor water repellencyGood dispersionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer sciencePolymer resin

The invention relates to an ultraviolet photosensitive anti-corrosion wear-resistant functional filler which comprises the following components in parts by weight: 150-300 parts of ultraviolet photosensitive main filler; 150 to 300 parts of an ultraviolet photosensitive auxiliary filler; 10 to 110 parts of a flaky filler; 15 to 110 parts of a rod-like material; 10-50 parts of a chemical modifier; and 5-20 parts of red phosphorus. The preparation method of the filler comprises the following steps: uniformly mixing and stirring the photosensitive main filler, the photosensitive auxiliary filler, the flaky filler, the rod-like material, the deionized water, the chemical modifier and the red phosphorus in proportion, carrying out hydrothermal reaction at 50-350 DEG C, filtering, washing, drying, grinding and grading to obtain the ultraviolet photosensitive anti-corrosion wear-resistant functional filler. The hydrophobicity of the photosensitive material is improved through surface modification, the dispersity of the filler in the coating is improved by means of the catalytic characteristic of the photosensitive material, the cross-linking performance of the filler and a polymer resin matrix is improved through a pre-cross-linking reaction, and finally the composite coating is endowed with excellent corrosion resistance and wear resistance.

Owner:NORTHEAST GASOLINEEUM UNIV

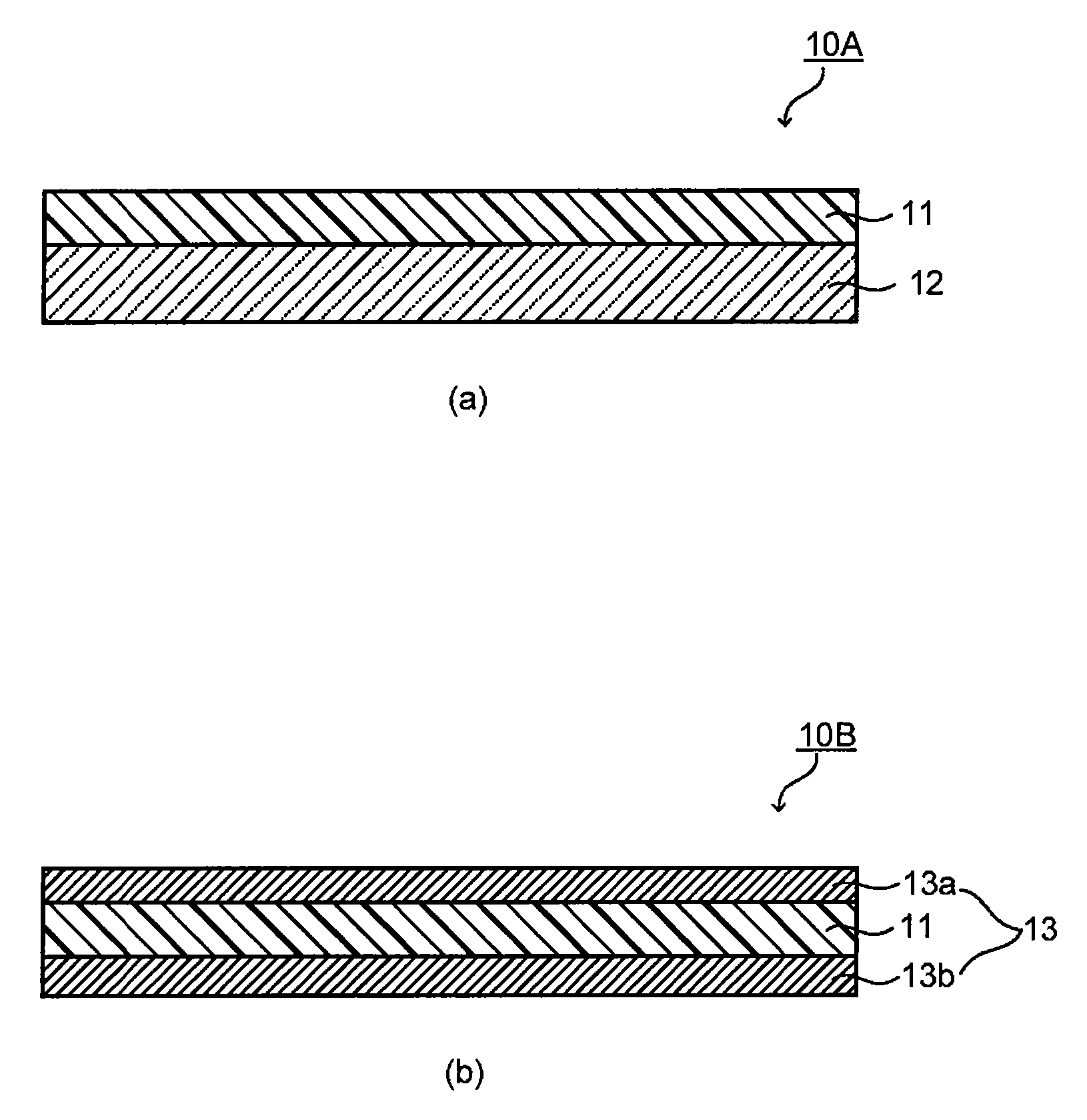

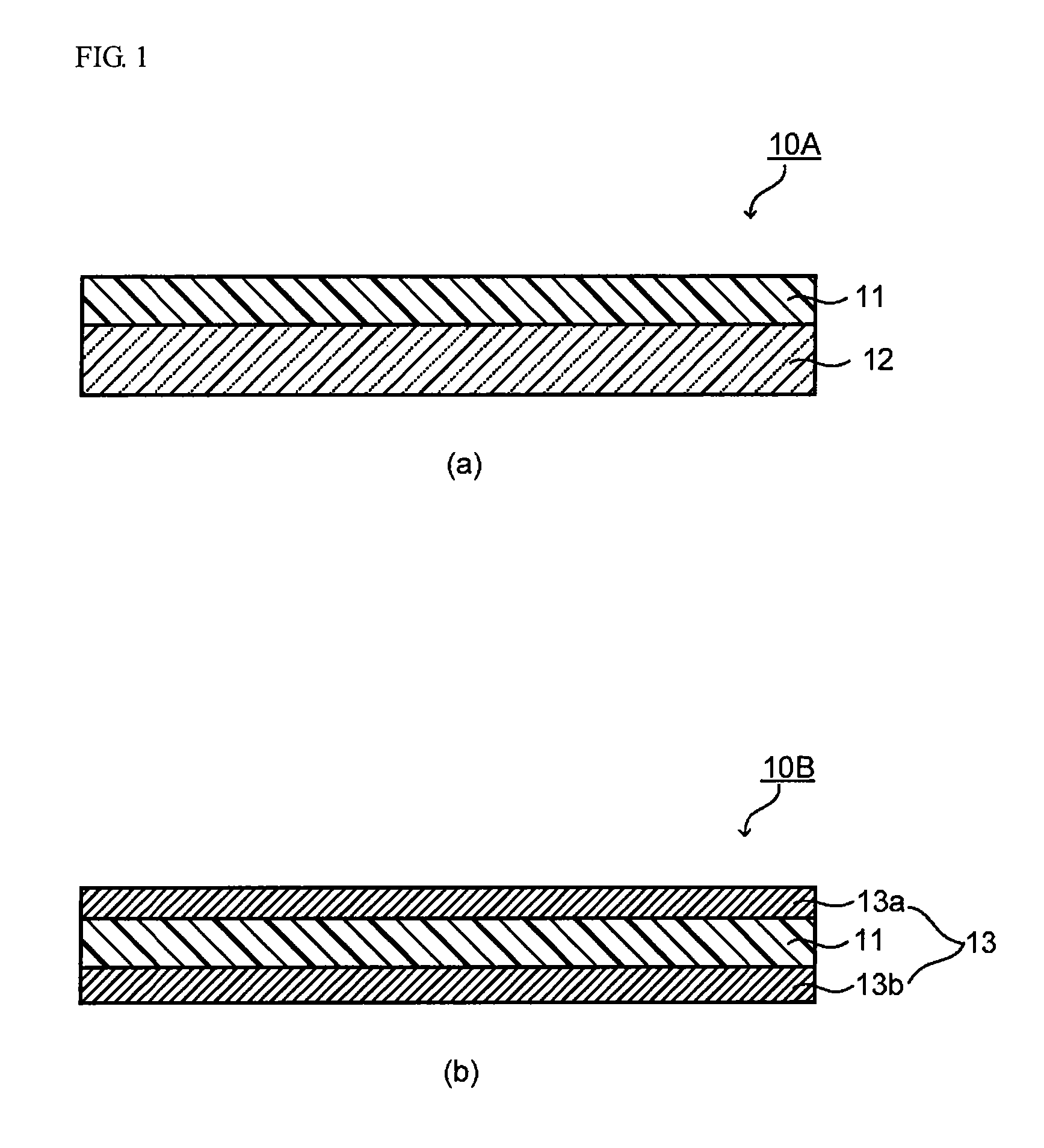

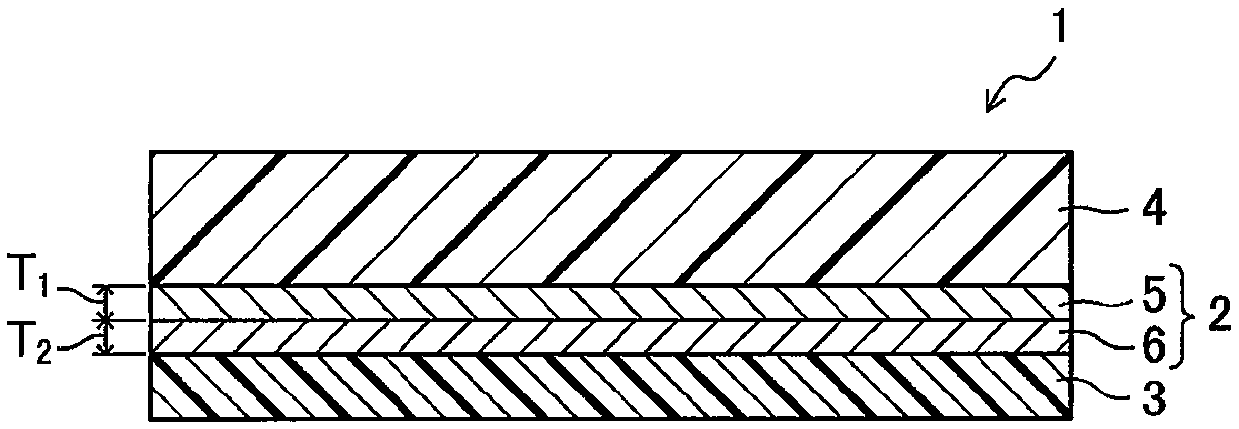

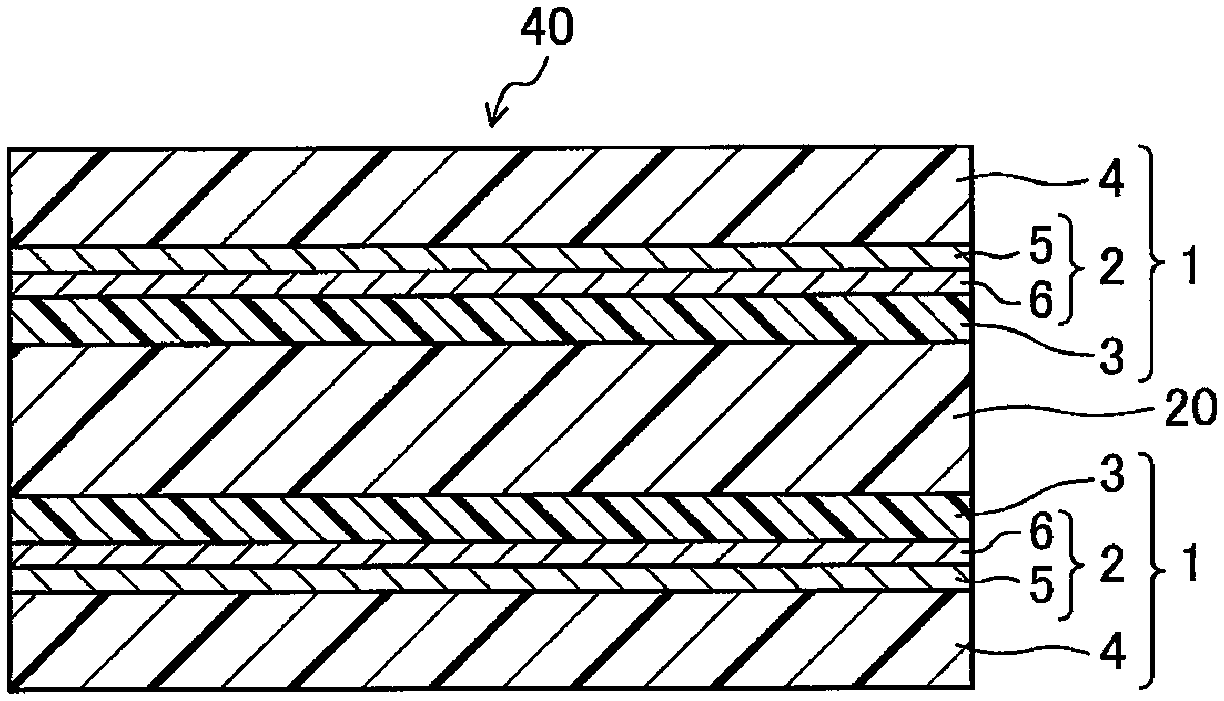

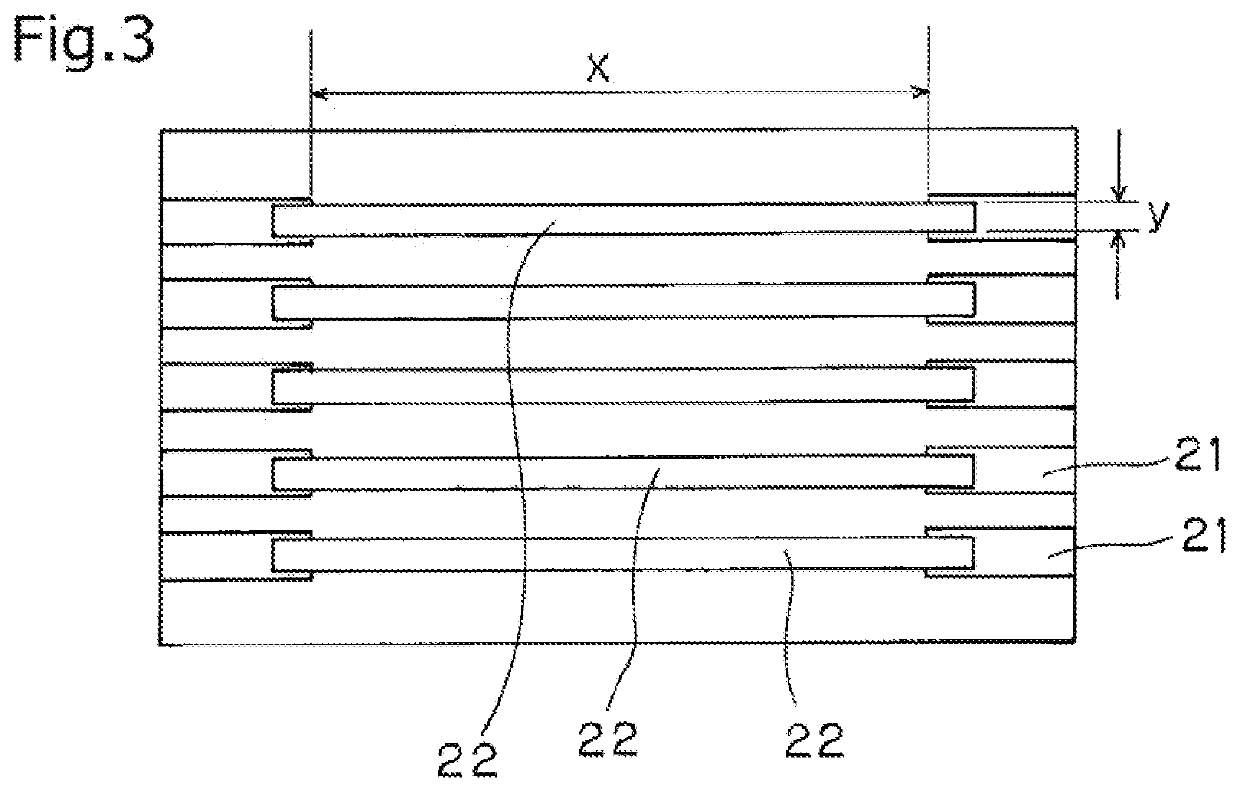

Electromagnetic wave shield film, and shielded printed wiring board equipped with same

InactiveCN110268812AGood shielding propertiesShielding materialsCross-talk/noise/interference reductionCopperMetal

The purpose of the present invention is to provide: an electromagnetic wave shield film having excellent transmission characteristics for high frequency signals and having excellent shielding characteristics with respect to electromagnetic waves in the high frequency region; and a shielded printed wiring board equipped with the electromagnetic wave shield film. An electromagnetic wave shield film 1 comprises: a shield layer constituted by a first metal layer in which nickel is the main component and a second metal layer in which copper is the main component; an adhesive layer provided to the second metal layer side of the shield layer; and a protective layer provided to the first metal layer side which is opposite the second metal layer side of the shield layer. A thickness T1 of the first metal layer is 2 to 10 [mu]m, and a thickness T2 of the second metal layer is 2 to 10 [mu]m.

Owner:TATSUTA ELECTRICWIRE & CABLE

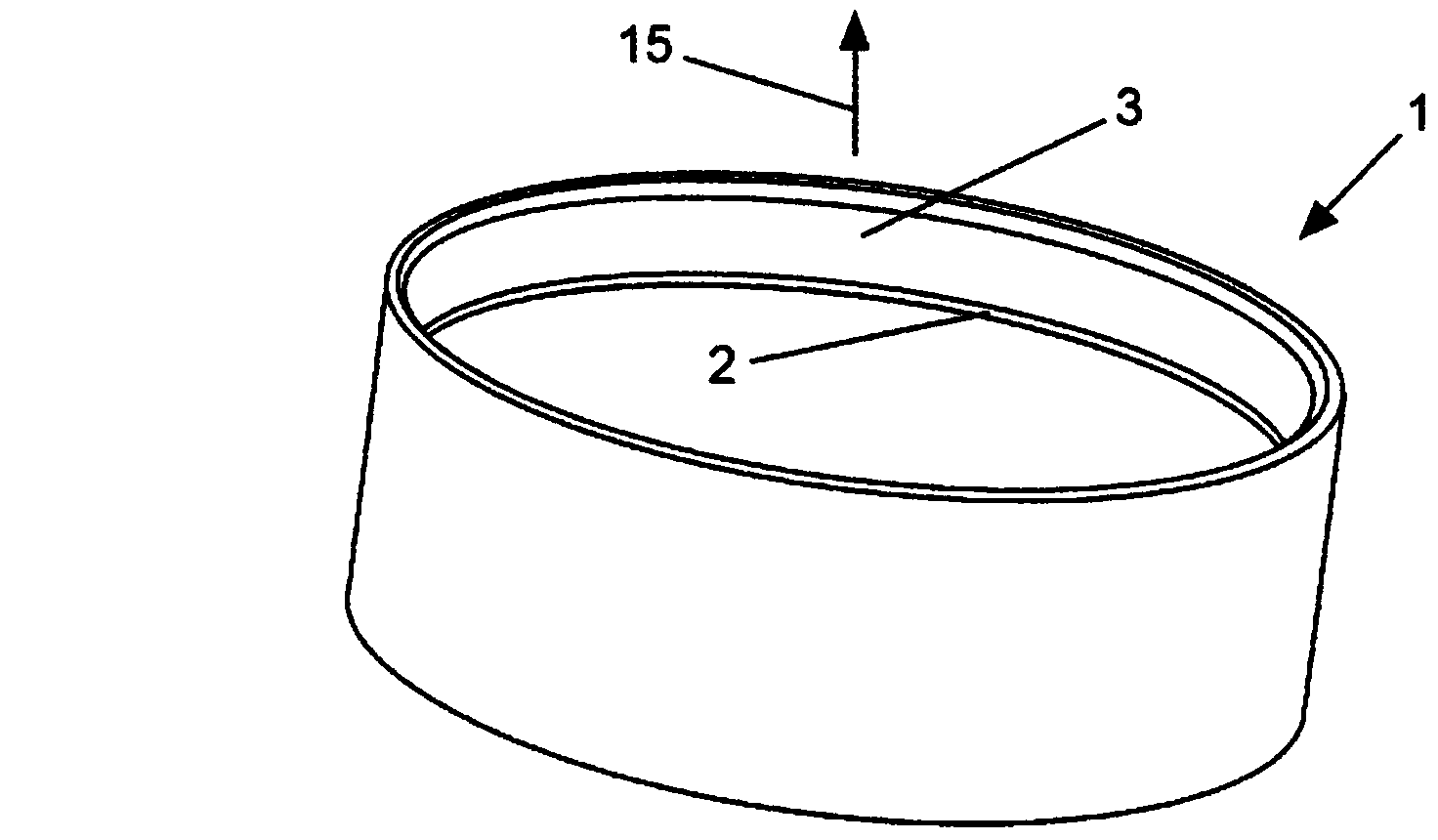

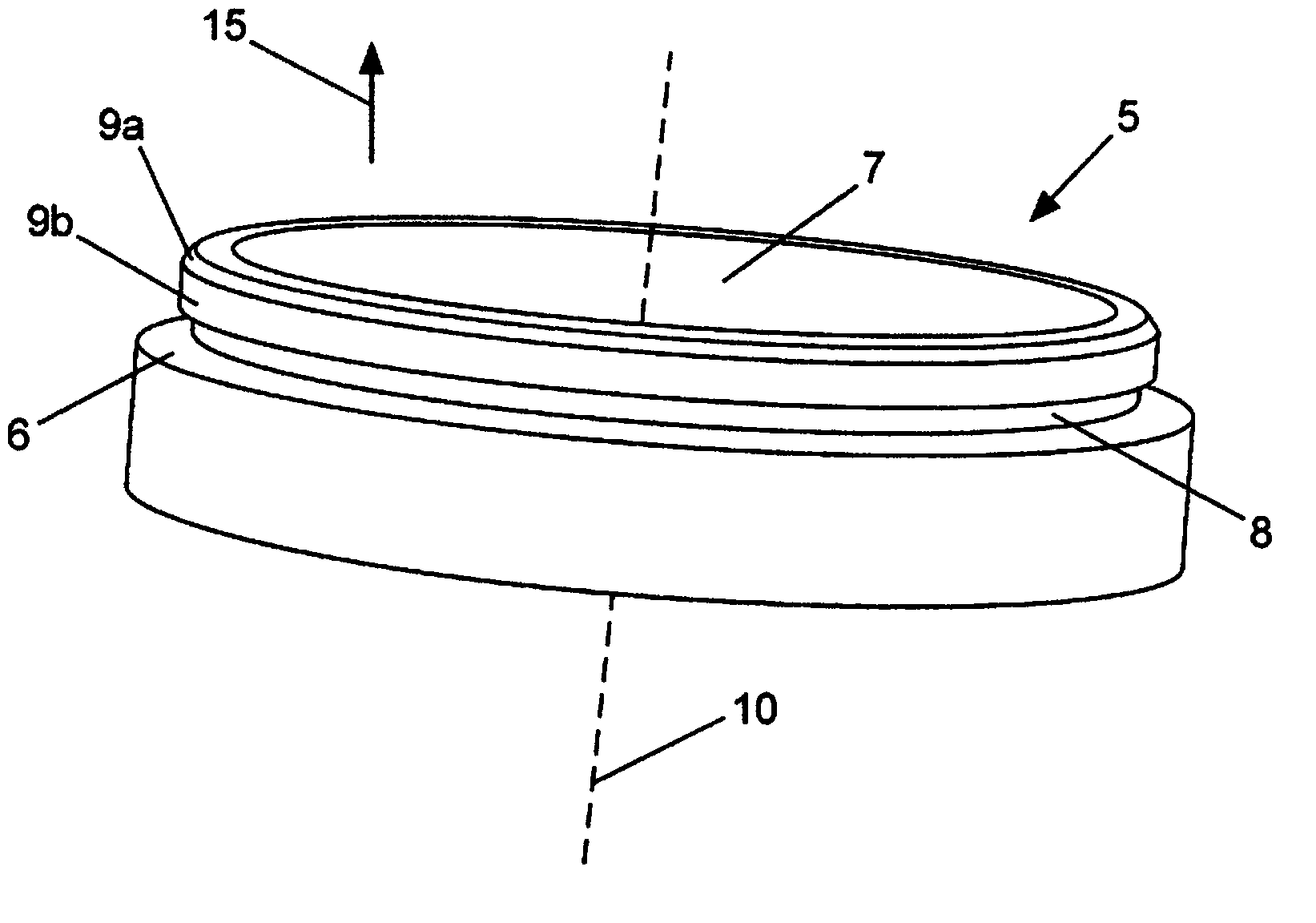

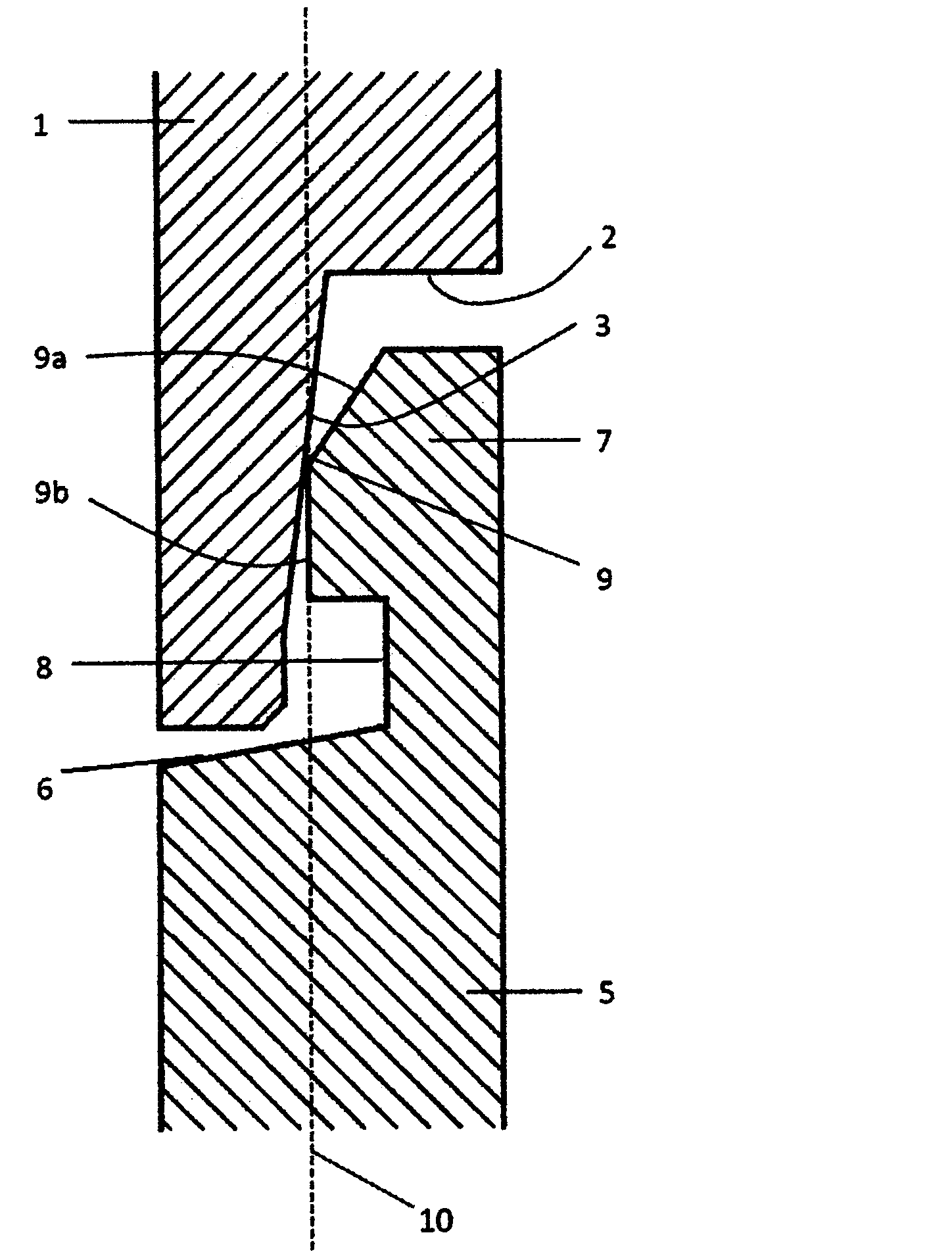

Plug connector housing

ActiveCN103518291AGood shielding propertiesCoupling device detailsContact members penetrating/cutting insulation/cable strandsEngineeringCorrosion

The invention relates to a plug connector housing consisting of at least one housing upper part (1) and at least one housing lower part (5) which together form a plug connector housing. The housing upper part (1) and the housing lower part (5) each have a contact surface (3, 9a, 9b), said contact surfaces (3, 9a, 9b) being at least partly in contact with each other when the housing upper part (1) and the housing lower part (5) are connected to each other. The housing upper part (1) and the housing lower part (5) are made of an electrically conductive material, said housing upper part (1) and lower part (5) having a surface coating that protects against corrosion for example, and the contact between the two contact surfaces (3, 9a, 9b) is formed along an edge (9).

Owner:HARTING ELECTRIC GMBH & CO KG

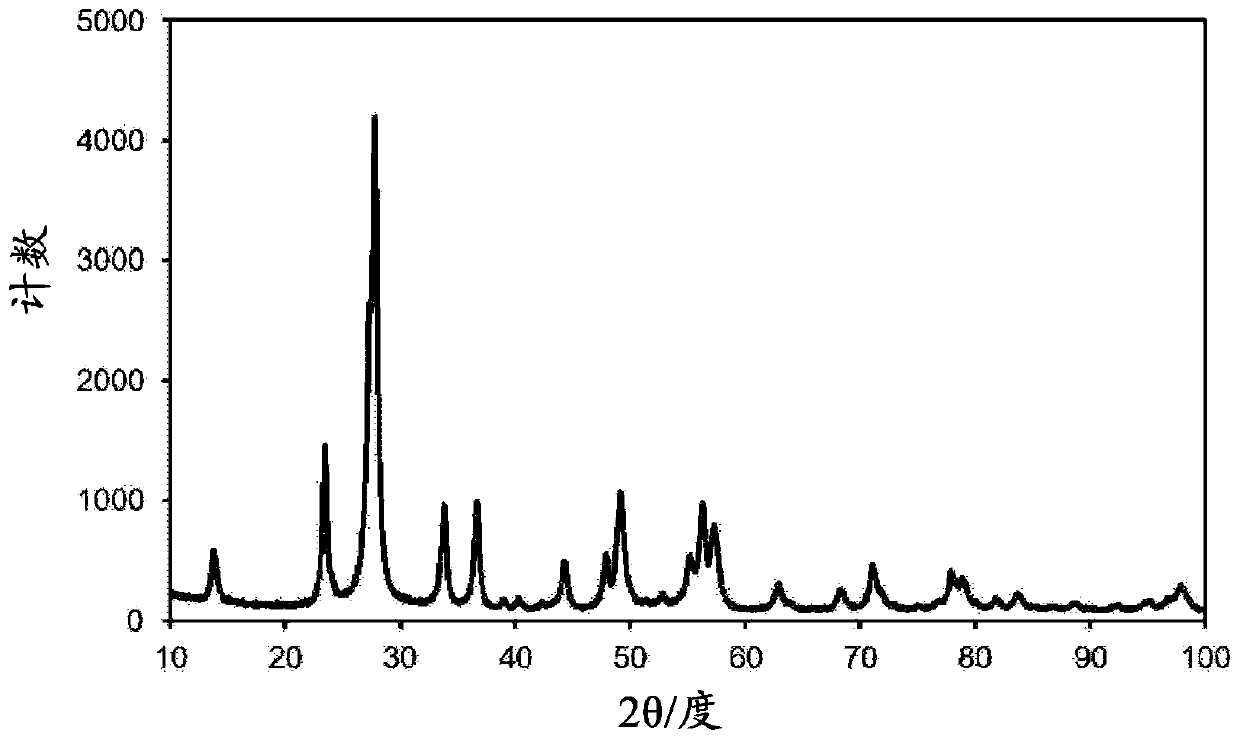

Near-infrared-shielding ultrafine particle dispersion body, near-infrared-shielding intermediate film, near-infrared-shielding laminated structure, and production method for near-infrared-shielding ultrafine particle dispersion body

ActiveCN110662817AWith transparencyGood shielding propertiesOther chemical processesTungsten oxides/hydroxidesInfraredChemistry

Provided is a near-infrared-shielding ultrafine particle dispersion body or the like that has an excellent near-infrared-shielding function, a low haze value, excellent design properties, and inhibited color tone change and blue haze phenomenon in outdoor use, and that is obtained by using near-infrared-shielding ultrafine particles which are transparent in a visible light region, have excellent near-infrared-shielding characteristics, and are produced with high productivity. Provided is a near-infrared-shielding ultrafine particle dispersion body or the like which is a dispersion of ultrafineparticles having near-infrared-shielding characteristics in a solid medium, wherein the ultrafine particles are composite tungsten oxide ultrafine particles (A) represented by general formula MxWyOz,the ratio value of the top intensity of the XRD peak of the composite tungsten oxide ultrafine particles (A) with respect to the XRD peak intensity, defined as 1, of the (220) plane of a silicon powder standard sample is 0.13 or more, the solid medium contains a resin binder (B) and a weather resistance improver (C), and the weather resistance improver (C) contains at least one selected from benzotriazole-based UV absorbents, triazine-based UV absorbents, and benzophenone-based UV absorbents.

Owner:SUMITOMO METAL MINING CO LTD

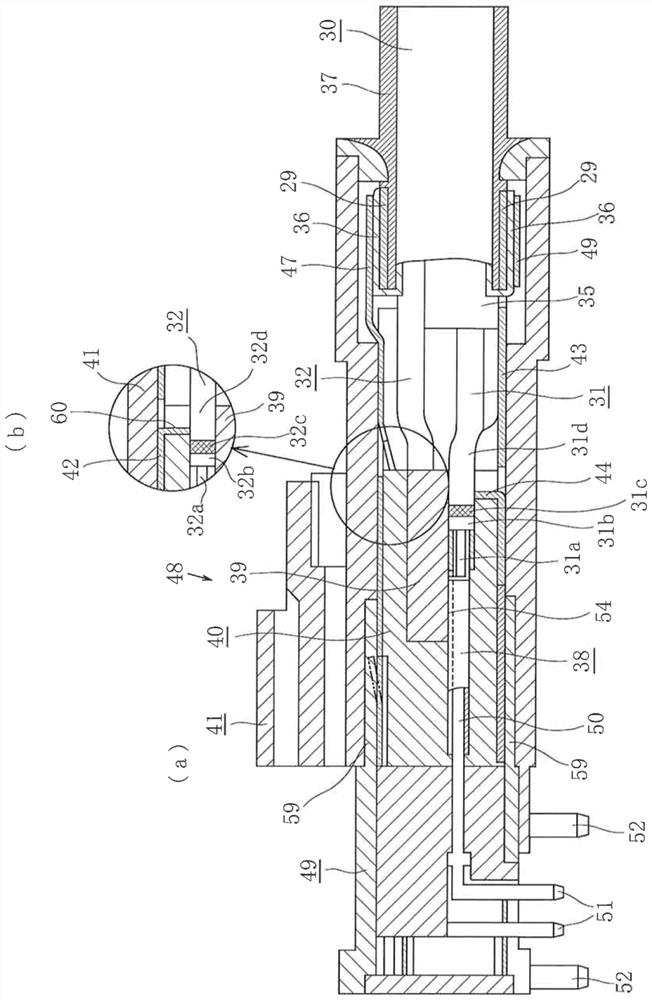

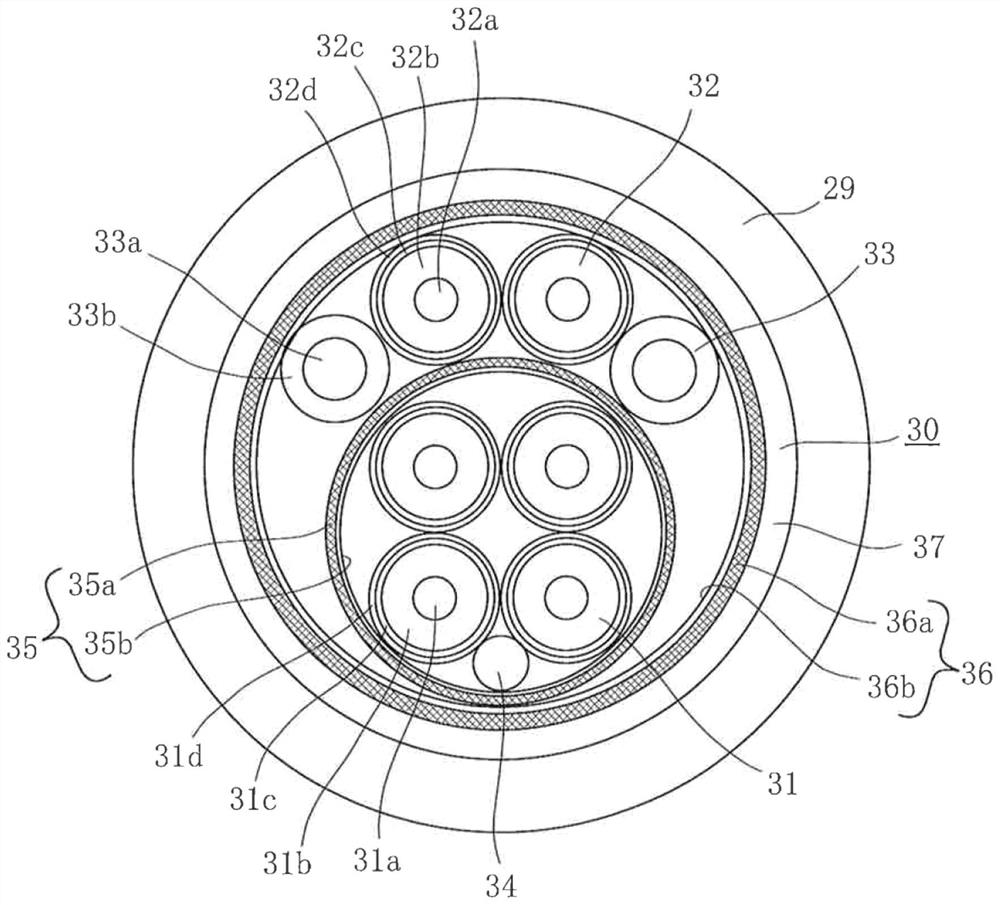

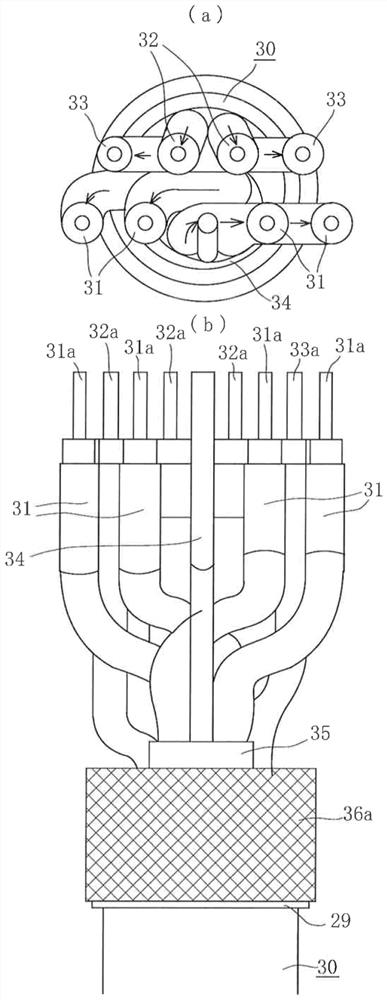

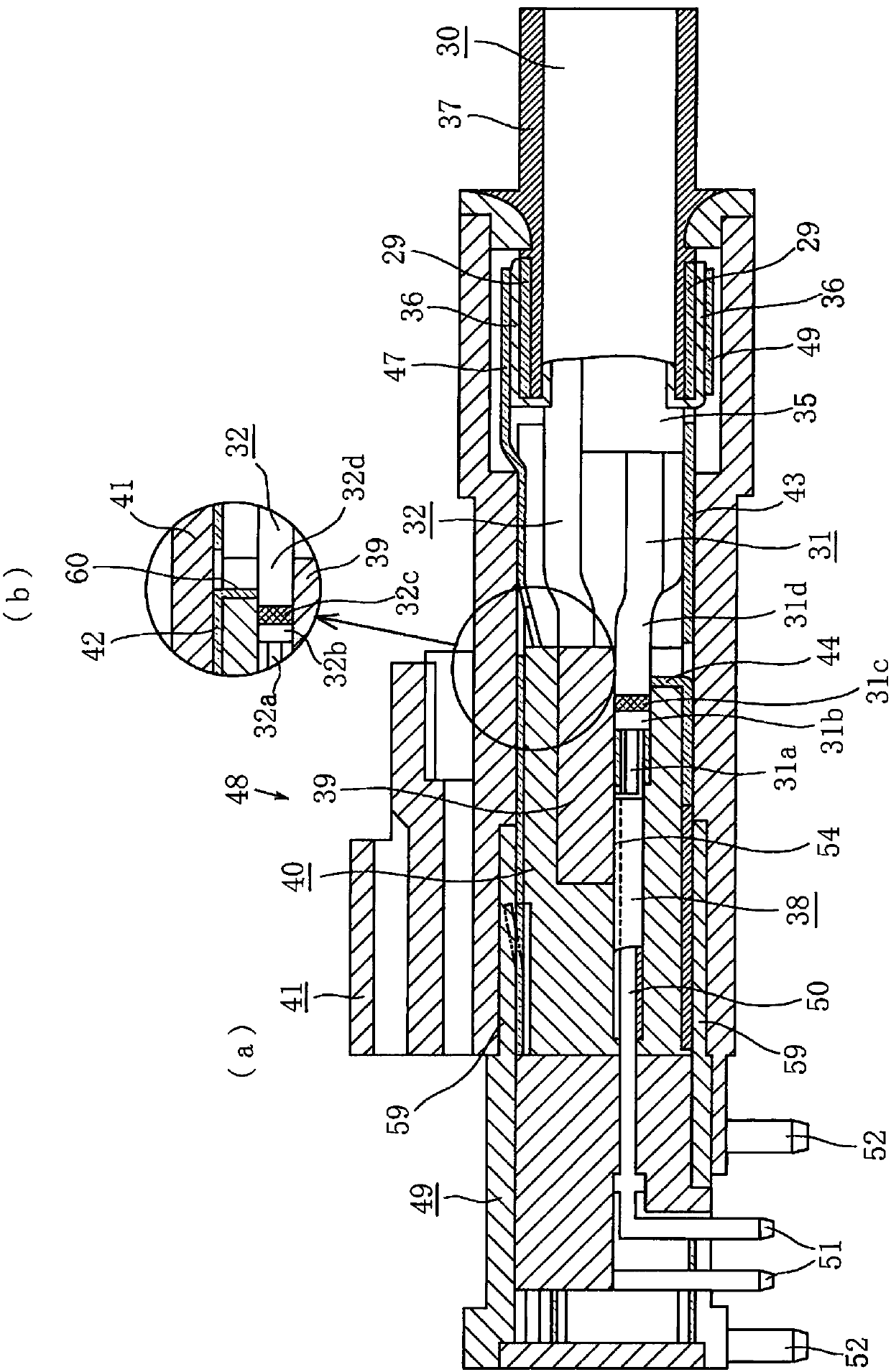

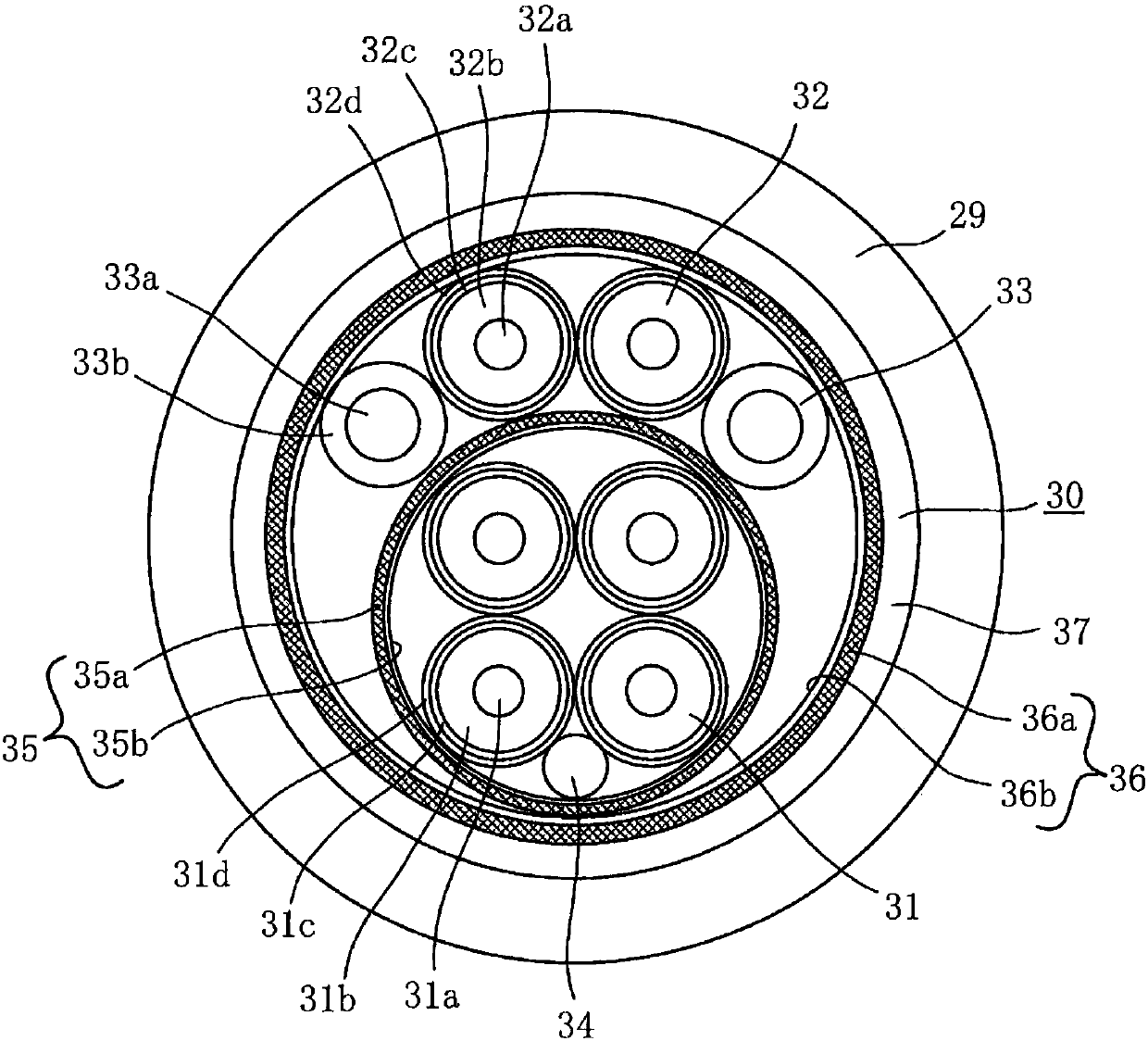

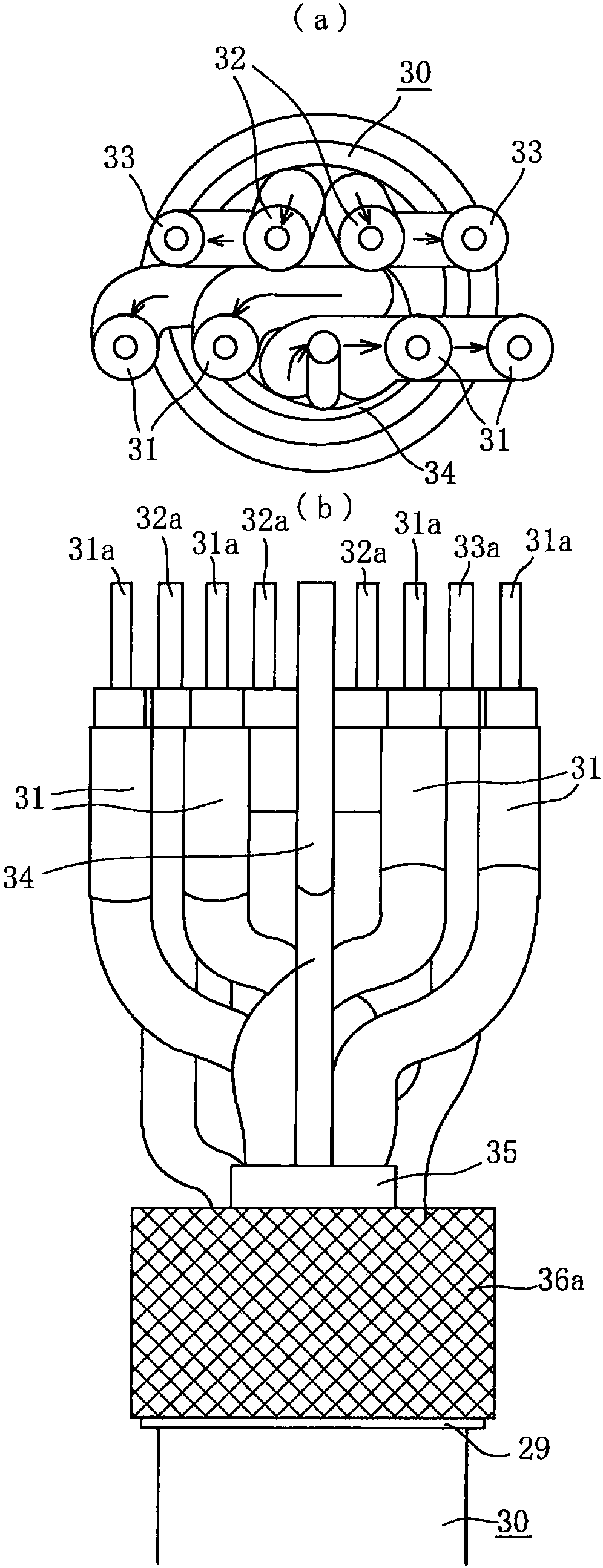

Shielded connector and its connection method

ActiveCN109524848BGood shielding propertiesEasy to achieve impedance matchingCoupling device detailsTwo-part coupling devicesElectrical conductorElectrical connection

The present invention suppresses as much as possible the impedance mismatch that causes the connection operation between the shielded single core wire and the connection terminal that is performed by removing the shield portion at the end. The shielding connector removes the shielding part (36) of the end of the shielding wire (30) to expose a plurality of shielding single core wires (31 and / or 32), and connects the connecting terminal (38) to each shielding part (36) exposed. The conductor at the top of the single core wire (31 and / or 32) keeps the connecting terminal (38) by the inner casing (39), and wraps the inner casing (39) and the shielding unit with the shielding shell (42). The core wire is fixed to the end of the shielded wire (30) through the fixing piece (47) integrated with the shielding shell (42), wherein the shielding member of the connector is arranged on the shielding shell (42) (43), electrically connecting the shielding member (43) of the connector to the exposed single-core wire shielding portion of the shielded single-core wire (31 and / or 32).

Owner:SMK CO LTD

Layered structure providing shielding characteristics

InactiveUS20050175854A1Low costInexpensively appliedLiquid surface applicatorsMagnetic/electric field screeningMetal alloyLayered structure

The invention relates to a layered structure comprising a plastic substrate, at least one intermediate metallic layer on top of this plastic substrate and a metal or metal alloy layer on top of this intermediate metallic layer. The metal or metal alloy layer is applied from the melt of a metal or metal alloy. The invention further relates to a method of manufacturing such a layered structure.

Owner:NV BEKAERT SA

Conductive coating material and production method for shielded package using conductive coating material

ActiveUS20200299524A1Ensure conductivityImprove shielding effectLocalised screeningSemiconductor/solid-state device detailsConductive coatingFirming agent

A conductive coating material is disclosed including at least (A) 100 parts by mass of a binder component including a solid epoxy resin that is a solid at normal temperature and a liquid epoxy resin that is a liquid at normal temperature, (B) 500 to 1800 parts by mass of metal particles that have a tap density of 5.3 to 6.5 g / cm3 with respect to 100 parts by mass of the binder component (A), (C) 0.3 to 40 parts by mass of a curing agent that contains at least one imidazole type curing agent with respect to 100 parts by mass of the binder component (A), and (D) 150 to 600 parts by mass of a solvent with respect to 100 parts by mass of the binder component (A).

Owner:TATSUTA ELECTRICWIRE & CABLE

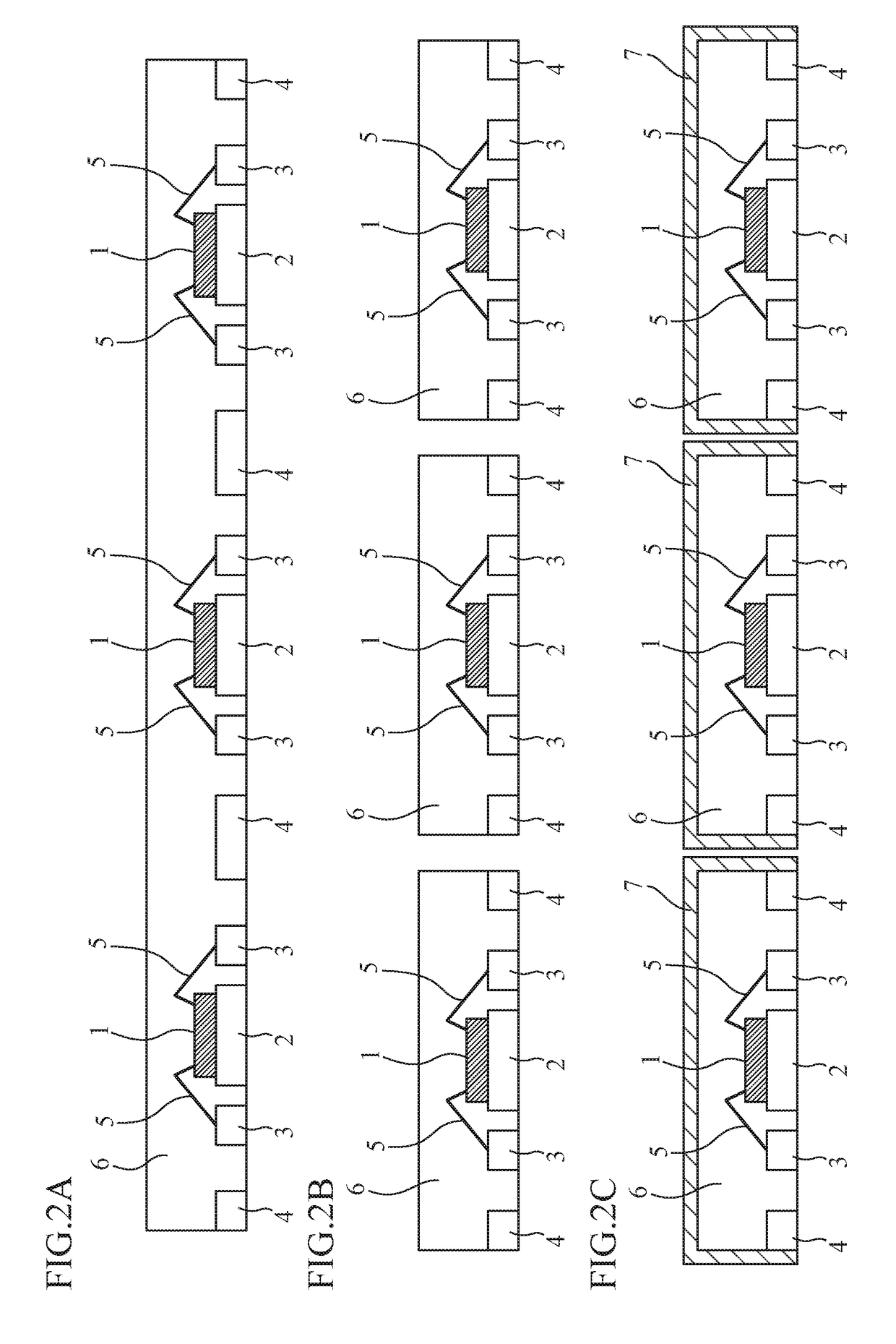

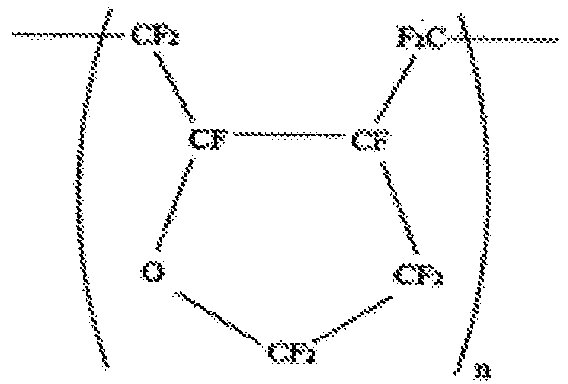

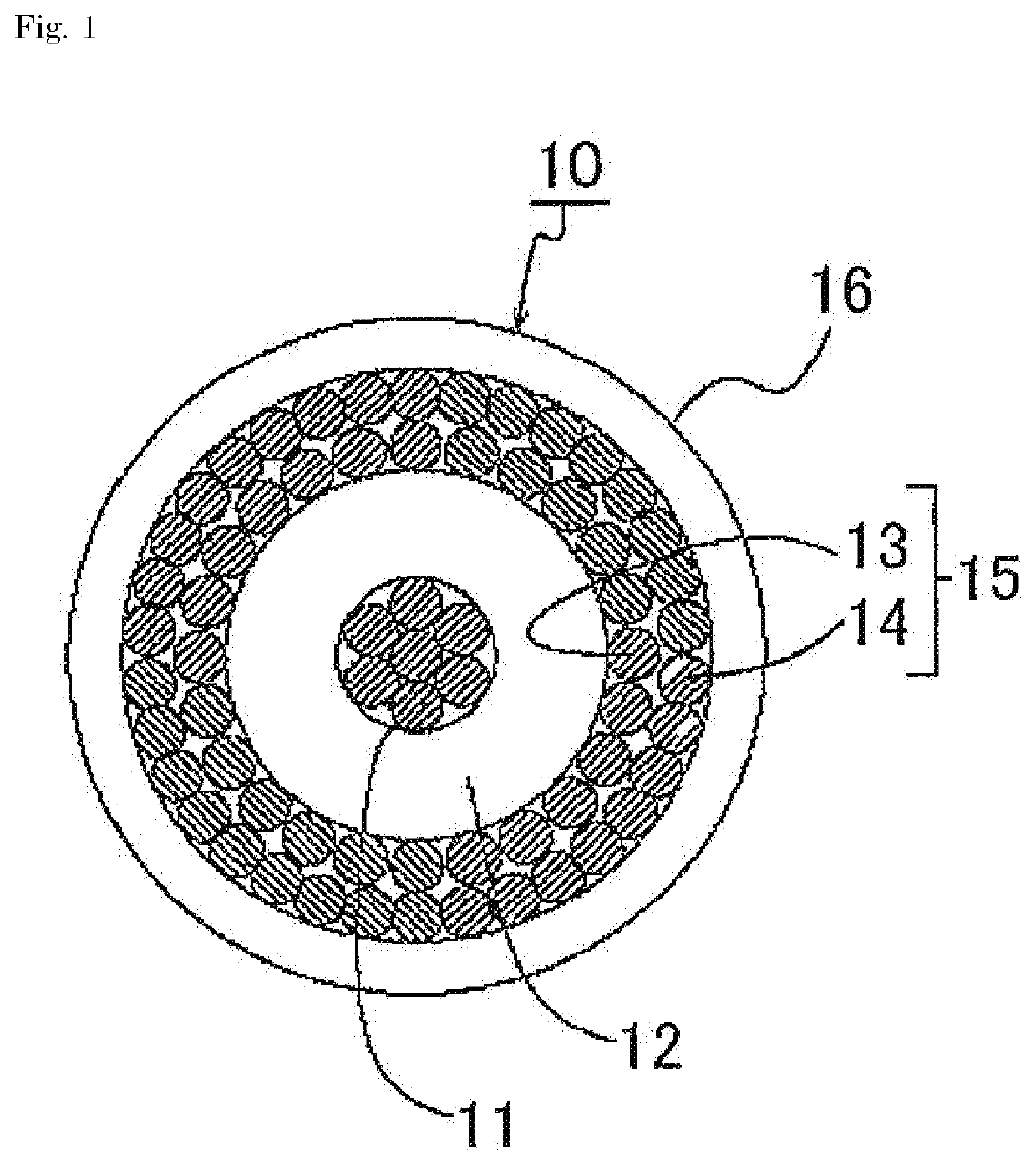

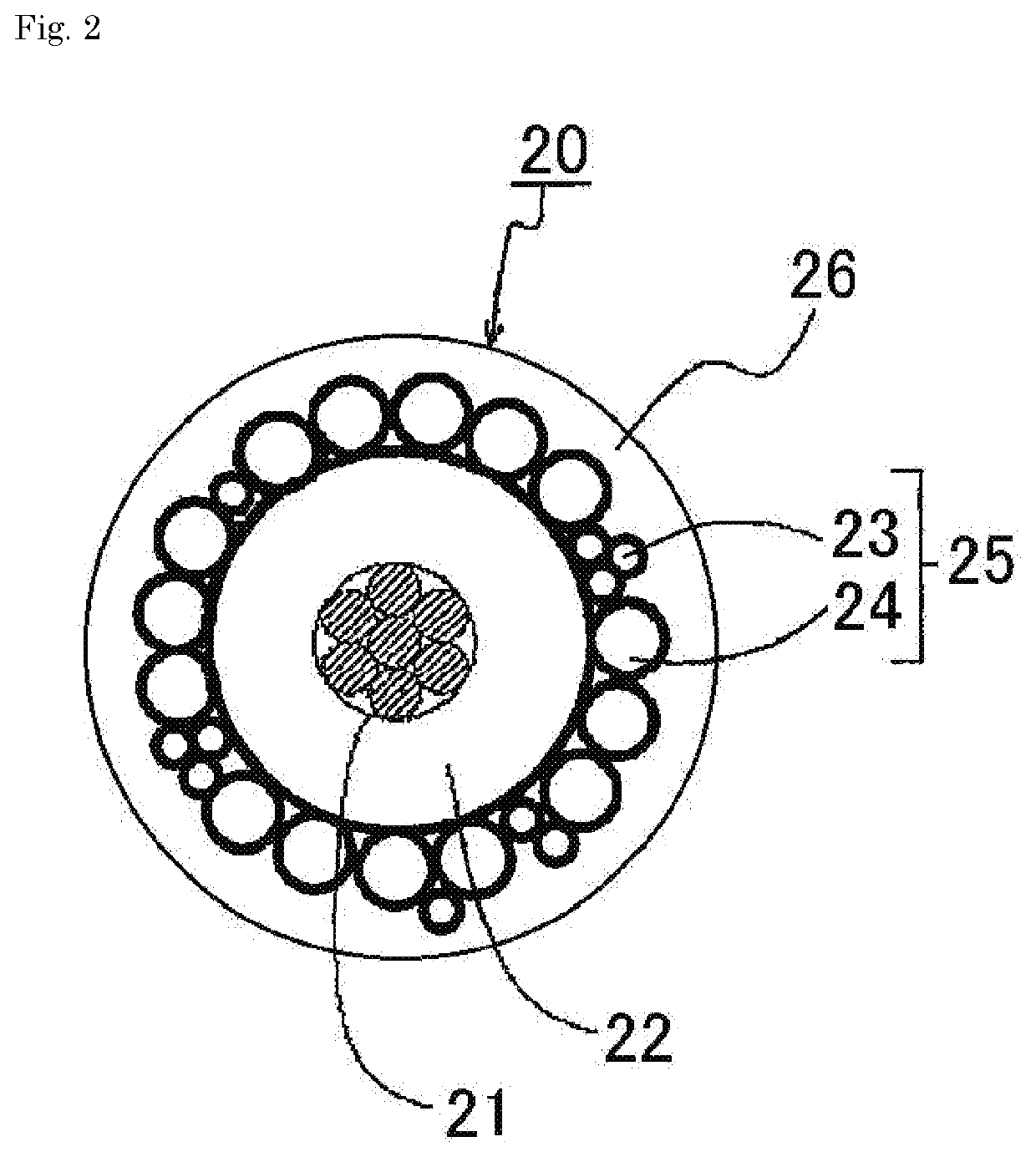

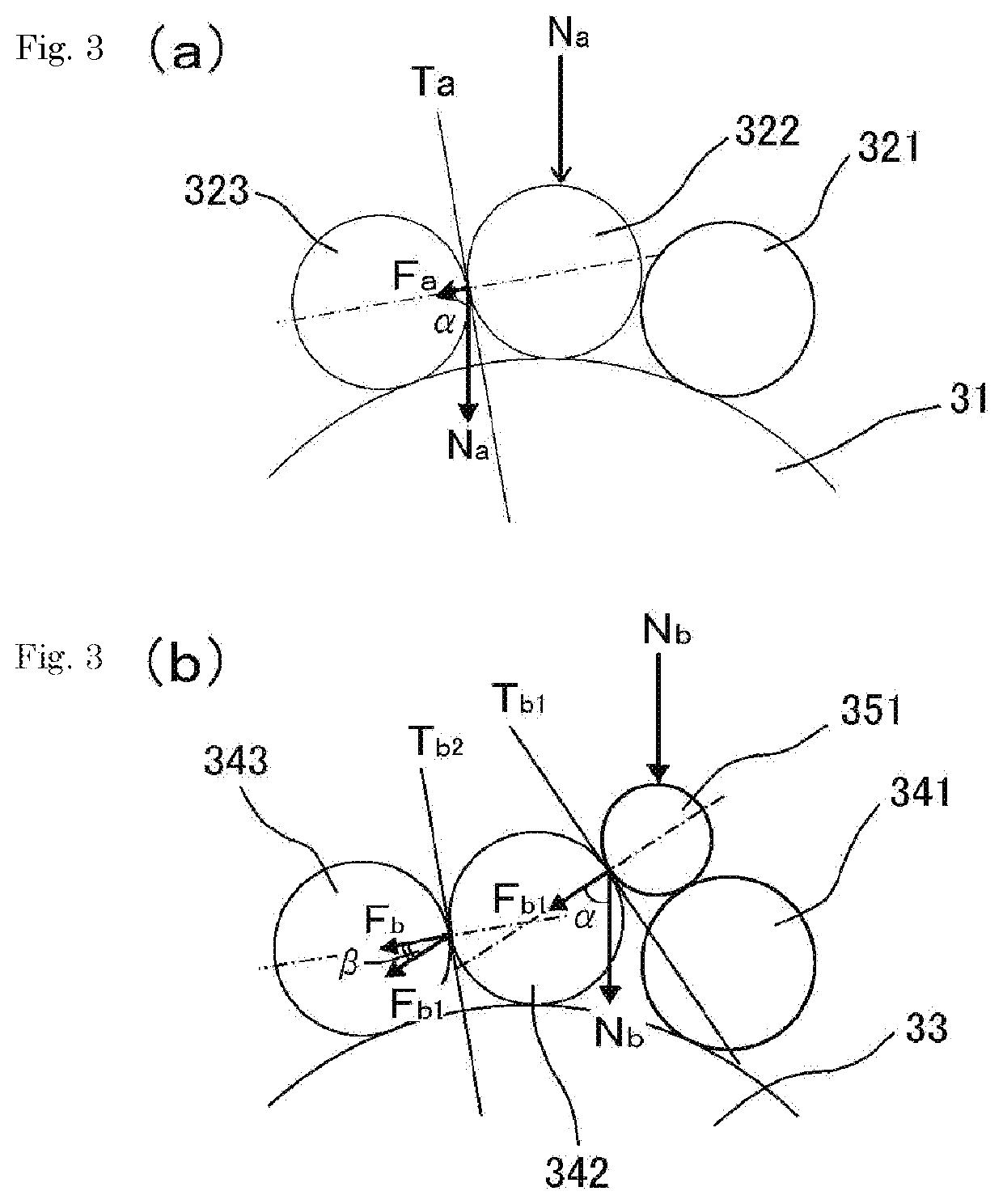

Coaxial cable

ActiveUS10825583B2Small outer diameterGood shielding propertiesCable conductor constructionCoaxial cableStructural engineering

The present invention relates to a coaxial cable, and particularly to a small-diameter coaxial cable for use in frequency bands of 100 MHz or more. The present invention addresses the problem of providing a coaxial cable which has excellent flexibility, a small outer diameter, and excellent shielding characteristics. The problem is solved by a coaxial cable having an outer conductor which is formed by mixing and laterally winding strands in the same direction, the strands having an outer diameter difference of not less than 10% between a large-diameter strand having a maximum outer diameter and a small-diameter strand having a minimum outer diameter.

Owner:JUNKOSHA

Voltage controlled oscillator small in reduction of inductance and Q

InactiveCN100472938CGood shielding propertiesMiniaturizationPrinted circuit aspectsHigh frequency circuit adaptationsHigh current densityElectrical conductor

There is provided a voltage controlled oscillator having a favorable shield characteristic between a strip line and a wiring pattern and being small in reduction of inductance and Q. The voltage controlled oscillator comprises a circuit board having a laminate of a plurality of insulating plates (2), a wiring pattern (3) formed on a surface of the circuit board (1), an electronic part (8) mounted on the surface of the circuit board (1), a resonance strip line (5) provided on an inner layer of the circuit board (1), and a ground pattern (7) formed on an inner layer of the circuit board (1) which is disposed between the wiring pattern (3) and the strip line (5). Further, an opening (7a) in the ground pattern (7) faces the vicinity including a portion having a high current density in the strip line (5). Thus, reductions of inductance and Q are small. In addition, a portion of the strip line (5) is shielded by means of the ground pattern (7) with respect to the wiring pattern (3). As a result, a voltage controlled oscillator having a favorable shield characteristic can be obtained.

Owner:ALPS ALPINE CO LTD

Shielded connector and connection method

ActiveCN109524848AGood shielding propertiesEasy to achieve impedance matchingCoupling device detailsTwo-part coupling devicesElectrical conductorElectrical impedance

The present invention suppresses, as much as possible, the impedance mismatch that causes the connection operation of a shielded single core wire and a connection terminal with a shielding portion ofa removal end portion. A shield connector is formed such that an electrical wire shield portion at an end of an electrical shield wire (30) is removed to expose a plurality of single shield wires (31and / or 32); connection terminals (38) are each connected to the conductor at an end of each exposed single shield wire (31 and / or 32); the connection terminals (38) are held in an inner housing (39);the inner housing (39) and the single shield wires (31 and / or 32) are sheathed with a shield shell (42); and an attachment piece (47) integrated with the shield shell (42) is fixedly attached to an end of the electrical shield wire (31 and / or 32). The shield shell (42) is provided with a connector shield member, and the connector shield member is electrically connected to single wire shield portions of the exposed single shield wires (31 and / or 32).

Owner:SMK CO LTD

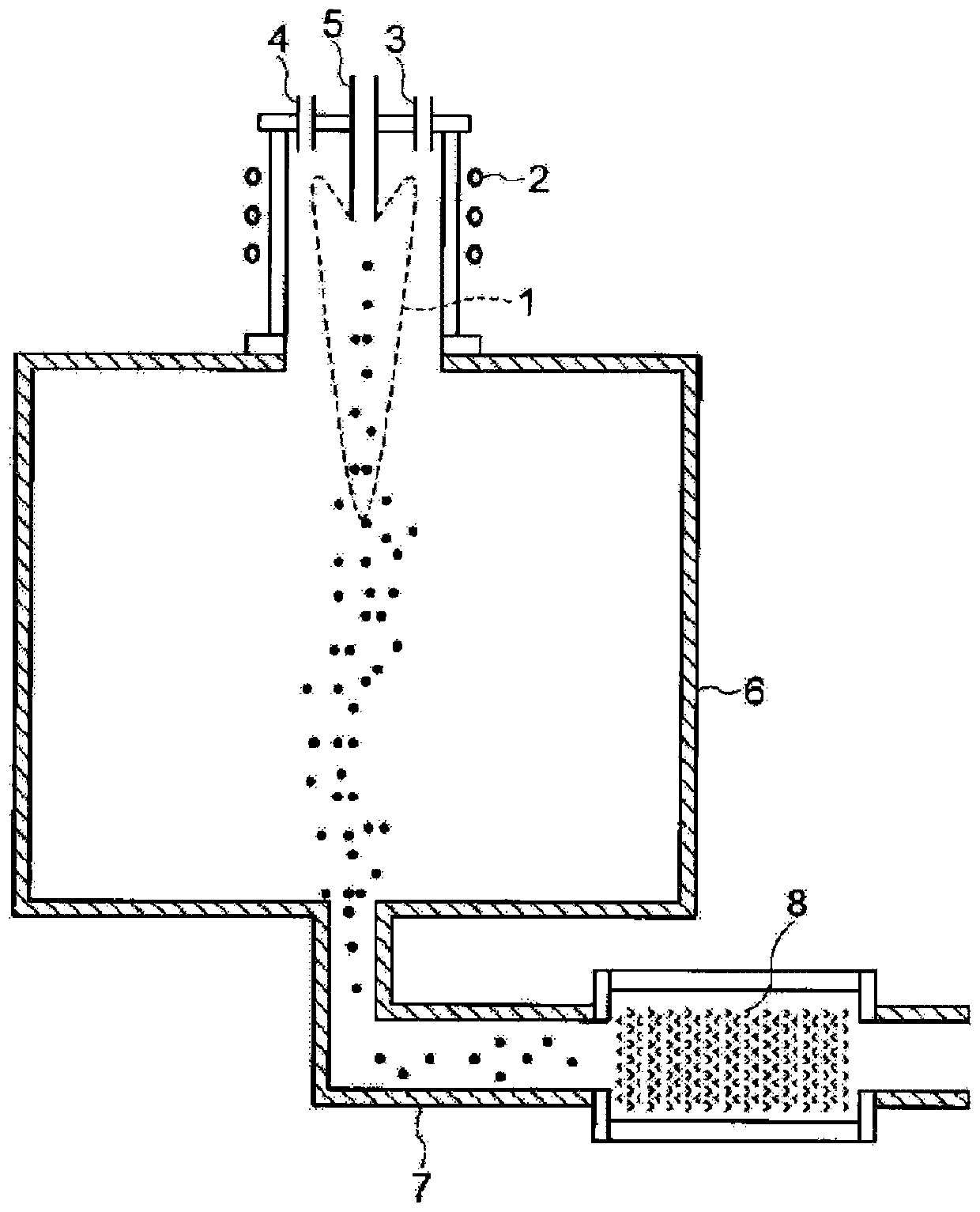

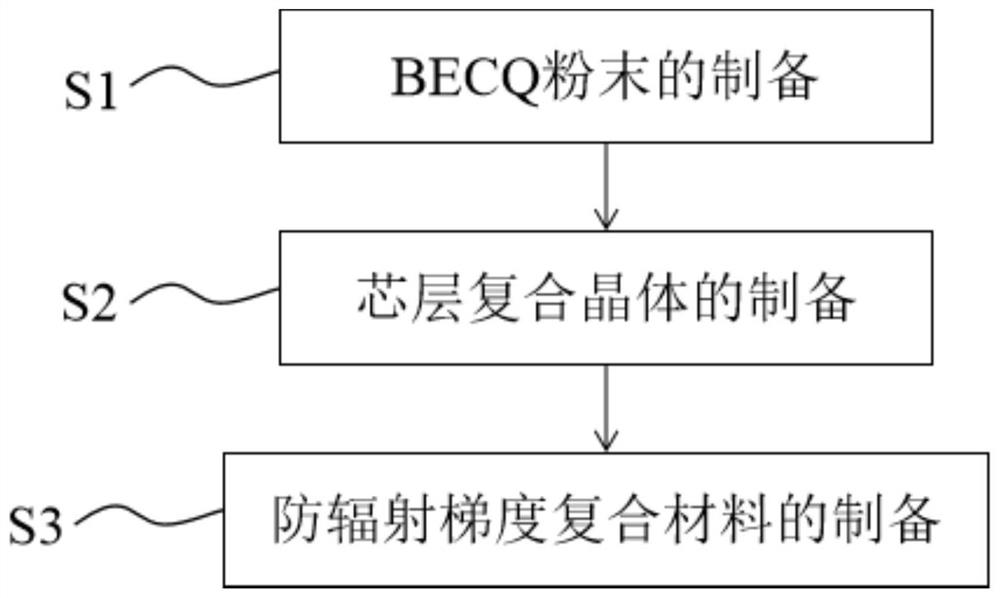

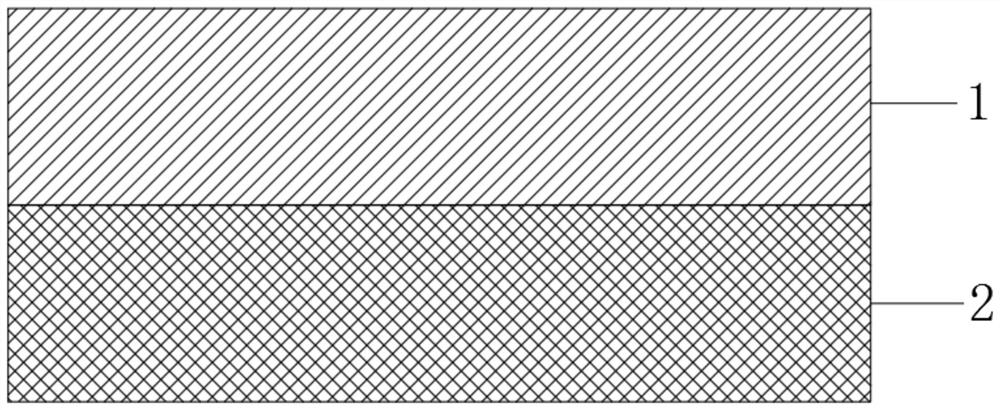

A kind of radiation protection gradient composite material and its preparation method and application

ActiveCN112895621BEffective shieldingGood shielding propertiesPolycrystalline material growthLayered productsPolyethylene glycolRadiation rays

The invention belongs to the technical field of composite materials, and particularly relates to a radiation protection gradient composite material and a preparation method and application thereof. In parts by weight, the radiation protection gradient composite material includes the following components: 30-40 parts of core layer composite crystals, 35-50 parts of BECQ powder, and 20-35 parts of polyethylene glycol. The radiation protection gradient composite material includes an inner layer of BECQ powder and an outer layer of a core layer composite crystal. The radiation protection gradient composite material of the present invention is based on the BECQ powder, and then adds a core layer composite crystal layer, and the main component of the core layer composite crystal layer is MoO 3 Crystal, the crystal has good shielding properties. The outer core layer composite crystal can absorb and attenuate radiation rays, and the inner layer BECQ powder further attenuates and absorbs attenuating radiation rays. The synergistic effect between the two can effectively shield Radiation rays, therefore, have certain application prospects in the field of materials.

Owner:武汉市莎卡娜尔科技有限公司

Near-infrared absorption dye and absorption layer

ActiveCN111665583AGood shielding propertiesImprove reliabilityOptical filtersPhotometryInfraredCarbamate

Owner:AGC INC

Layered structure providing shielding characteristics

InactiveUS7026060B2Improve shielding effectEasy to transformLiquid surface applicatorsMagnetic/electric field screeningMetal alloyLayered structure

The invention relates to a layered structure comprising a plastic substrate, at least one intermediate metallic layer on top of this plastic substrate and a metal or metal alloy layer on top of this intermediate metallic layer. The metal or metal alloy layer is applied from the melt of a metal or metal alloy. The invention further relates to a method of manufacturing such a layered structure.

Owner:NV BEKAERT SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com