Shielded connector and connection method

A connector and shielding technology, applied in the direction of connection, two-part connection device, and components of the connection device, etc., can solve problems such as heightening, impedance mismatch, etc., and achieve improved shielding characteristics, easy impedance matching, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

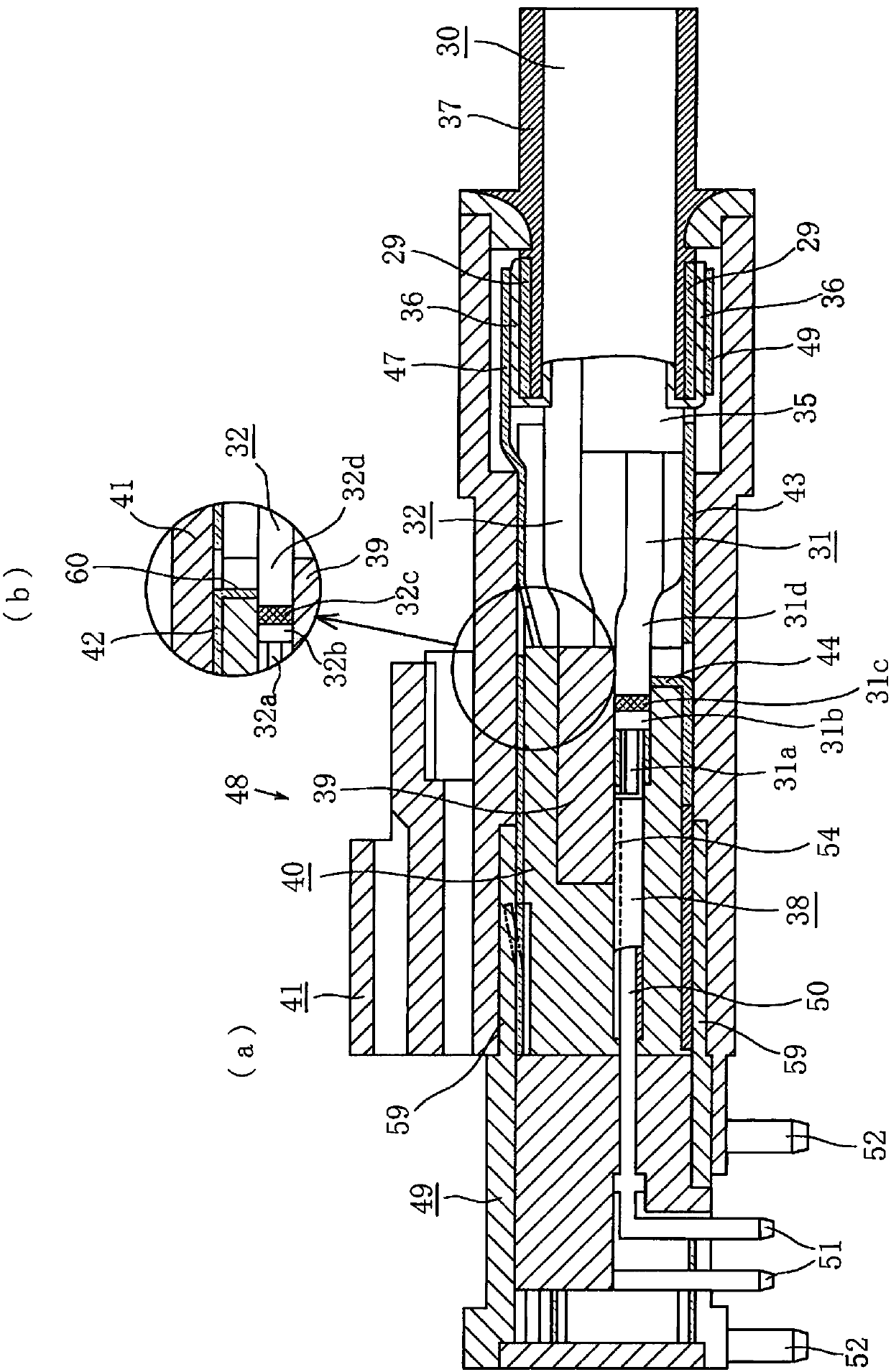

[0047] Hereinafter, Embodiment 1 of the present invention will be described based on the drawings.

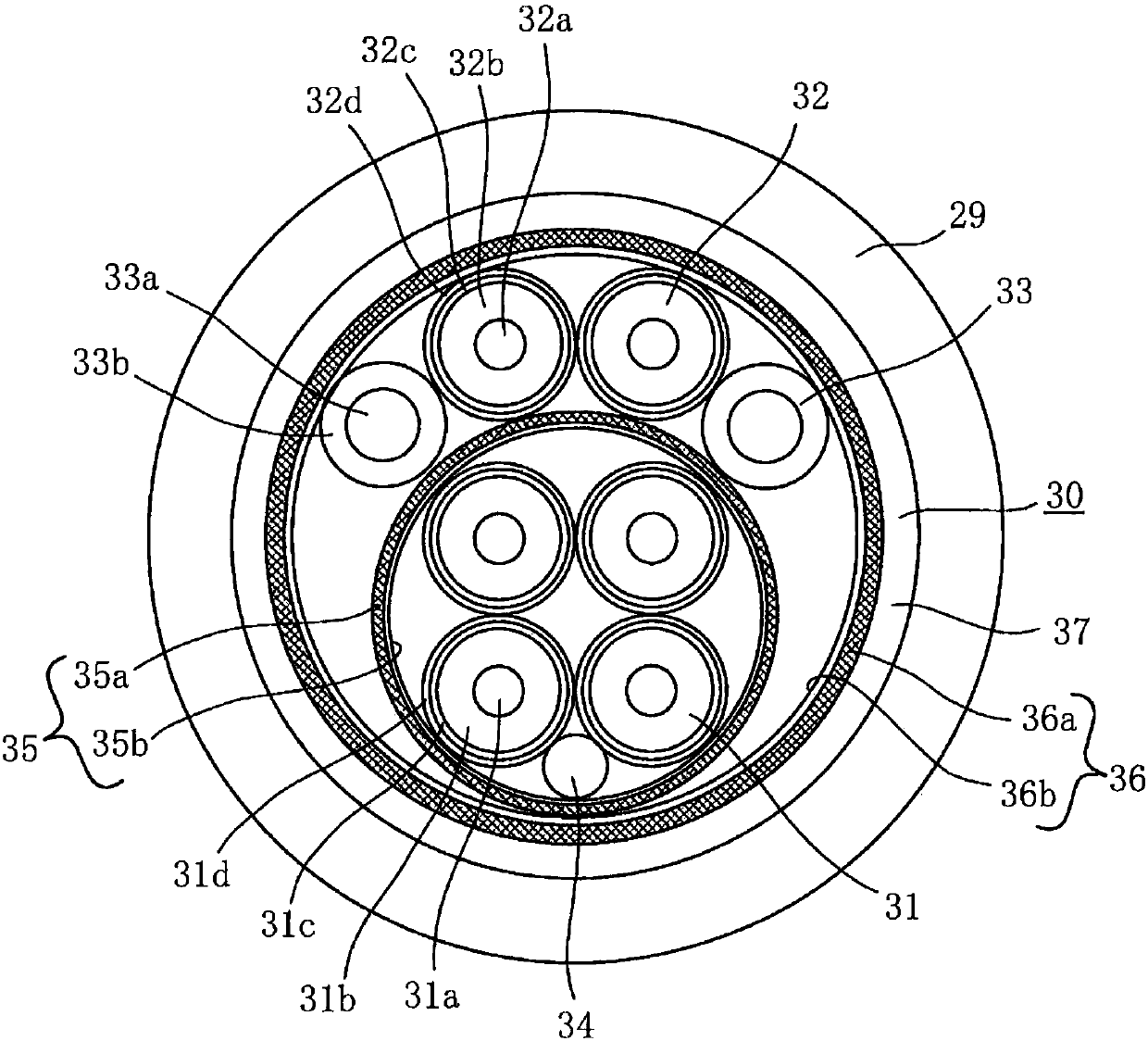

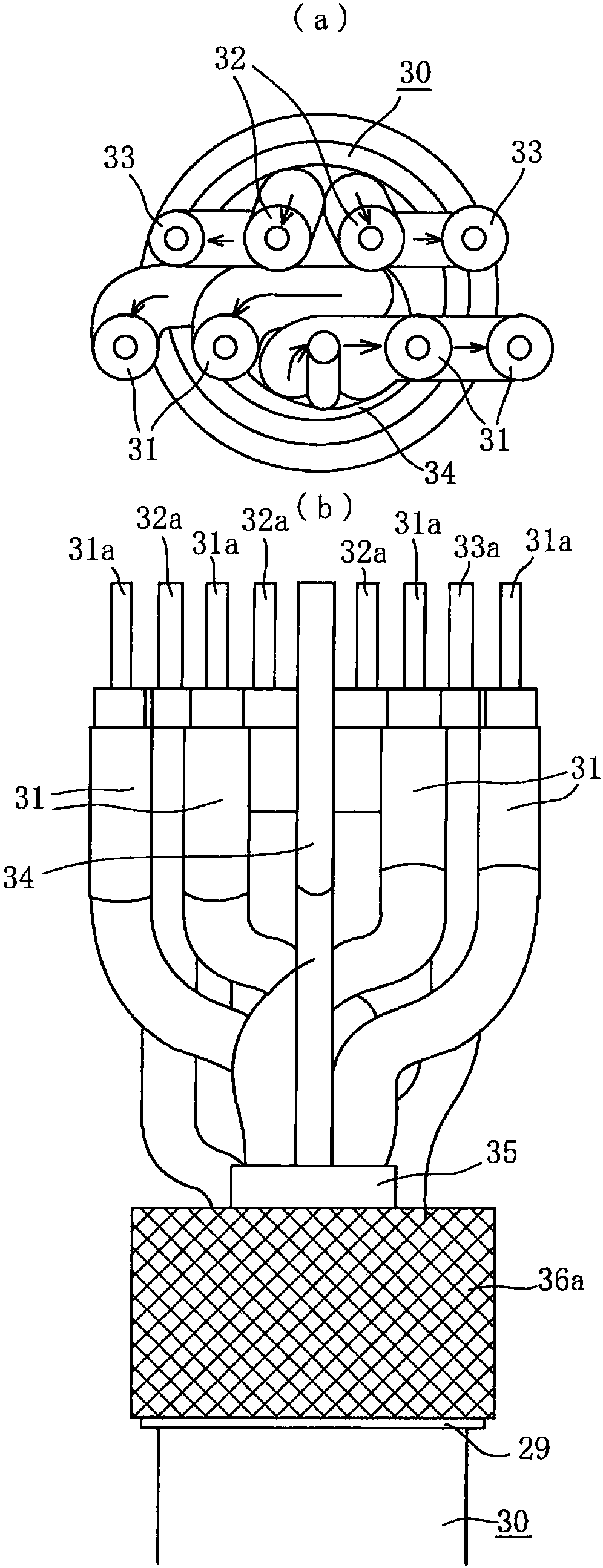

[0048] figure 2 An 8-core composite shielded electric wire 30 used in the shielded connector of the present invention and its connection method is shown. The composite shielded electric wire 30 in this example has six shielded single-core wires, among which four shielded single-core wires 31 are high-speed wires used in differential signal transmission and the like, and two shielded single-core wires 32 include medium-speed wires. This composite shielded electric wire 30 also includes two power supply wires 33 and one drain wire 34 .

[0049] The central conductor 31a of the four high-speed wires 31 is covered by an insulator 31b, and the outer periphery is covered by a single-core wire shield including a horizontally wound shield 31c and an aluminum strip 31d. Similarly, the two medium-speed wires 32 The central conductor 32a is covered with an insulator 32b, and the outer ...

Embodiment 2

[0066] In the above-described embodiment, the high-speed wire 31 for differential signal transmission is provided with the slit 44 to achieve impedance matching over the entire area of the exposed portion, but the same configuration may be adopted for the medium-speed wire 32 . Thus, if figure 1As shown in (b), a part of the shielding shell 42 is grooved downward to form a cut-and-raised piece 60 of the shielding member of the connector, and the cut-and-raised piece 60 is pressed on the medium-speed wire 32 including the horizontally wound shielding portion 32c and The single-core wire shielding portion of the aluminum tape 32d thereby achieves impedance matching over the entire area of the exposed portion of the medium-speed wire 32 and enhances the shielding effect.

[0067] In said embodiment, for the connection of the single-core wire shielding portion of the high-speed wire 31 and the cut-and-raised piece 44 and / or the connection of the single-core wire shielded port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com