Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Ensure conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

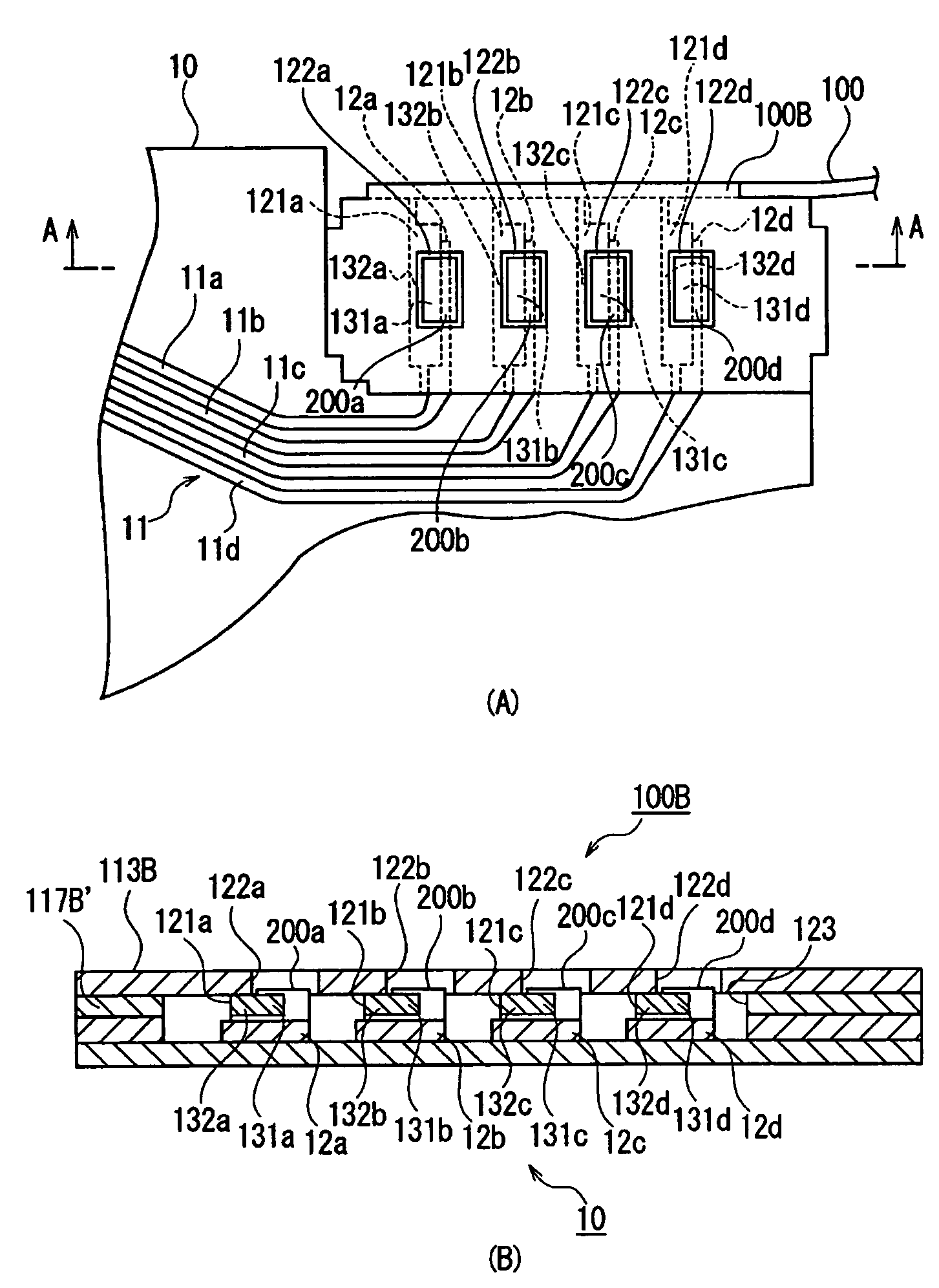

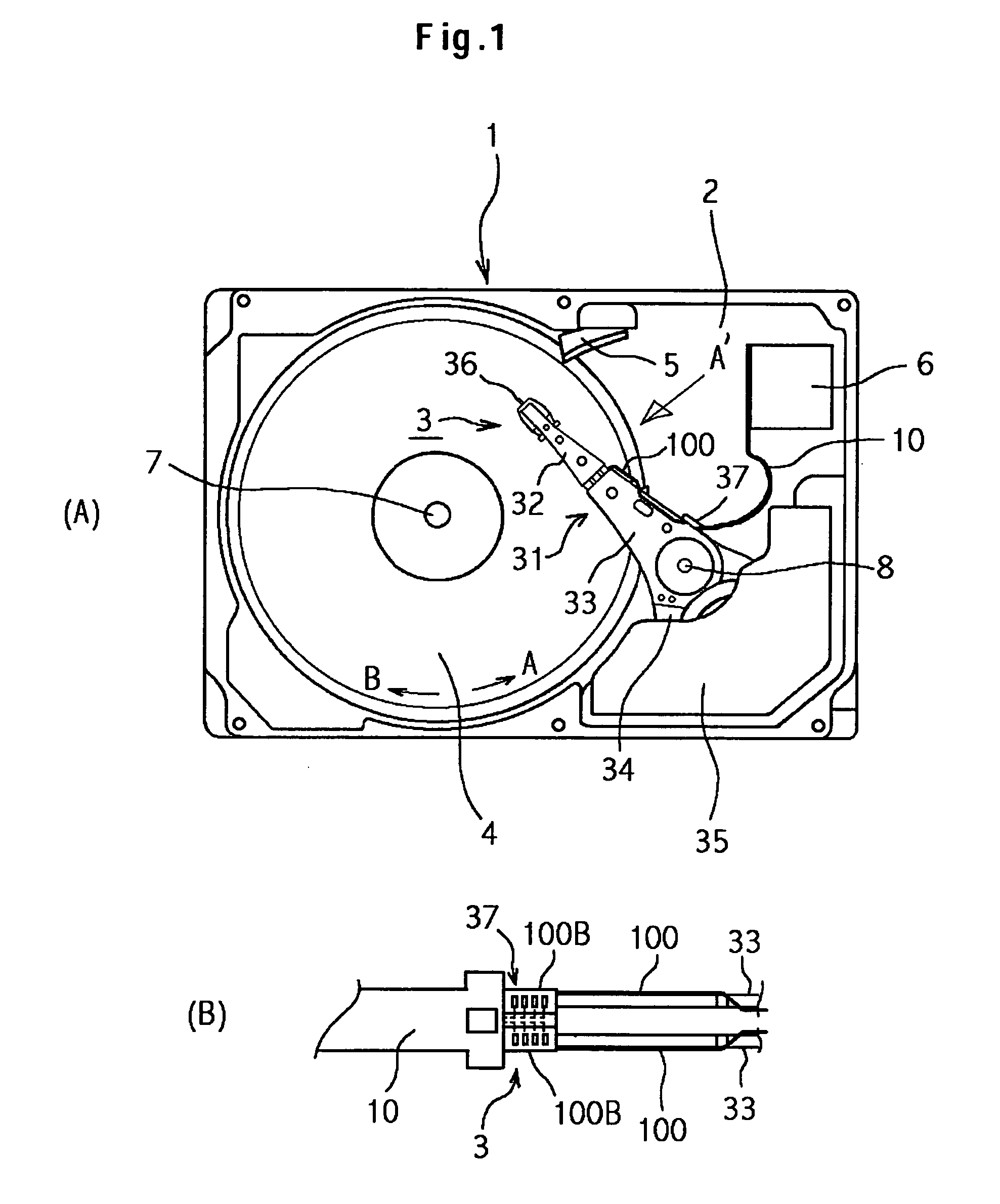

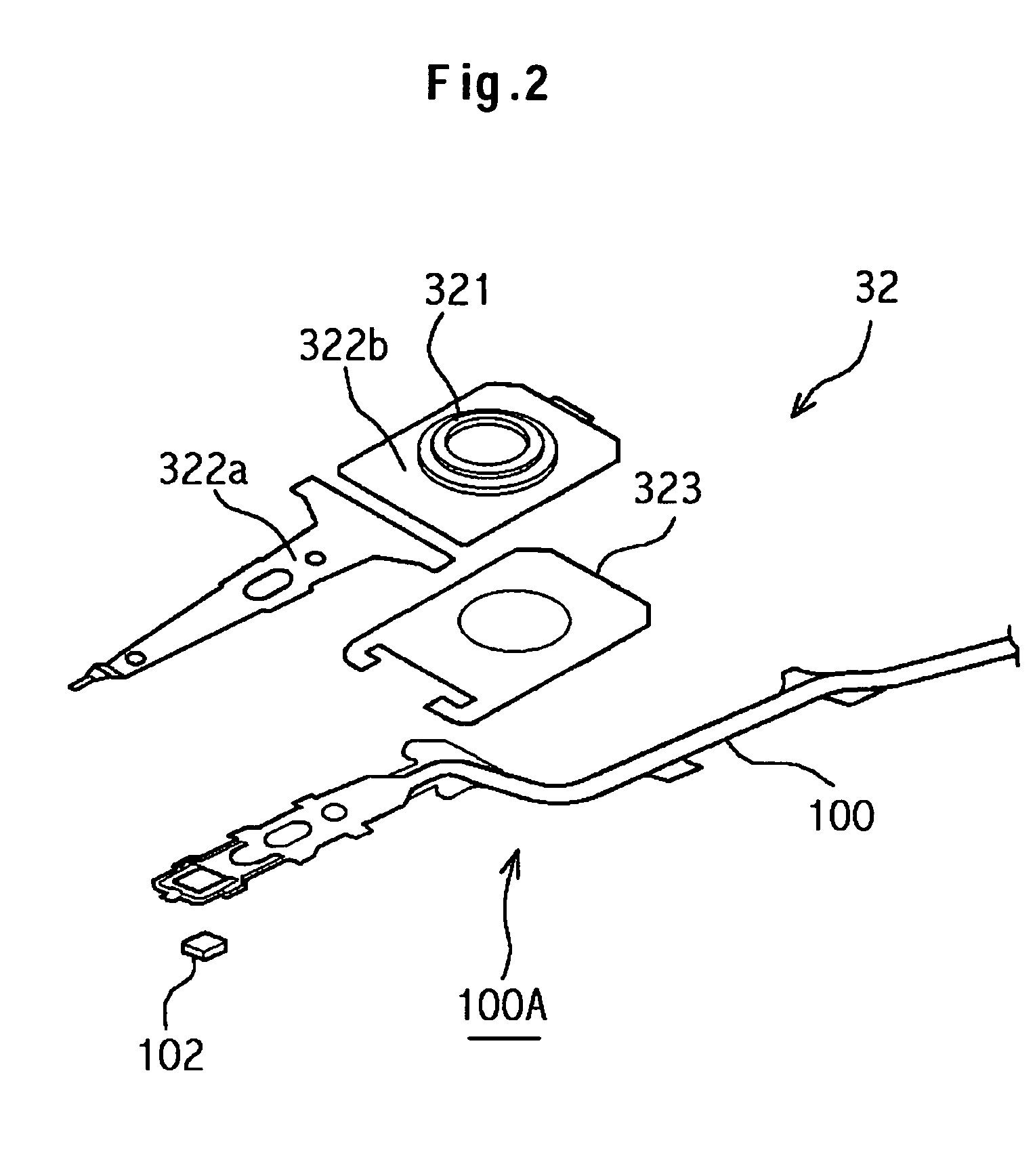

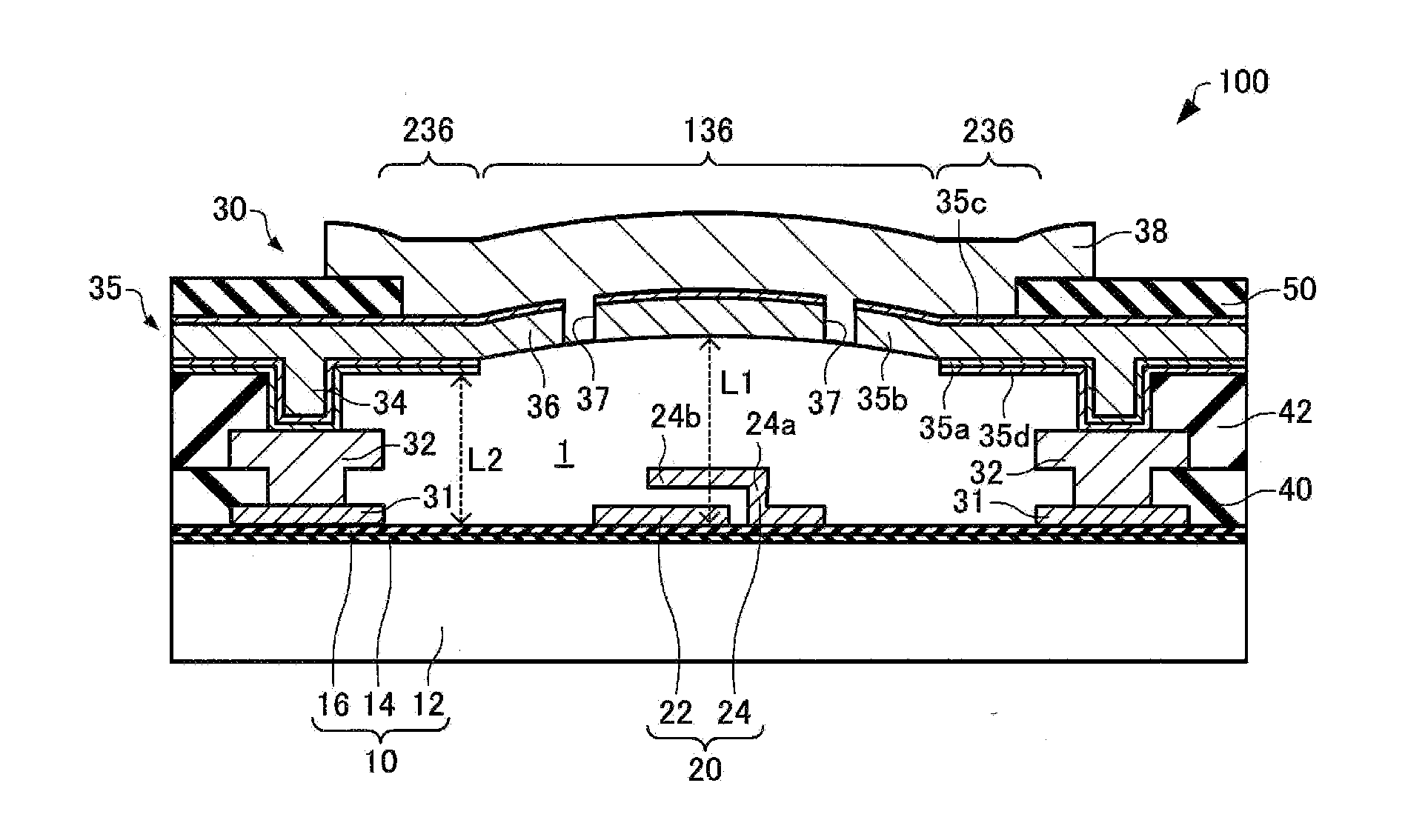

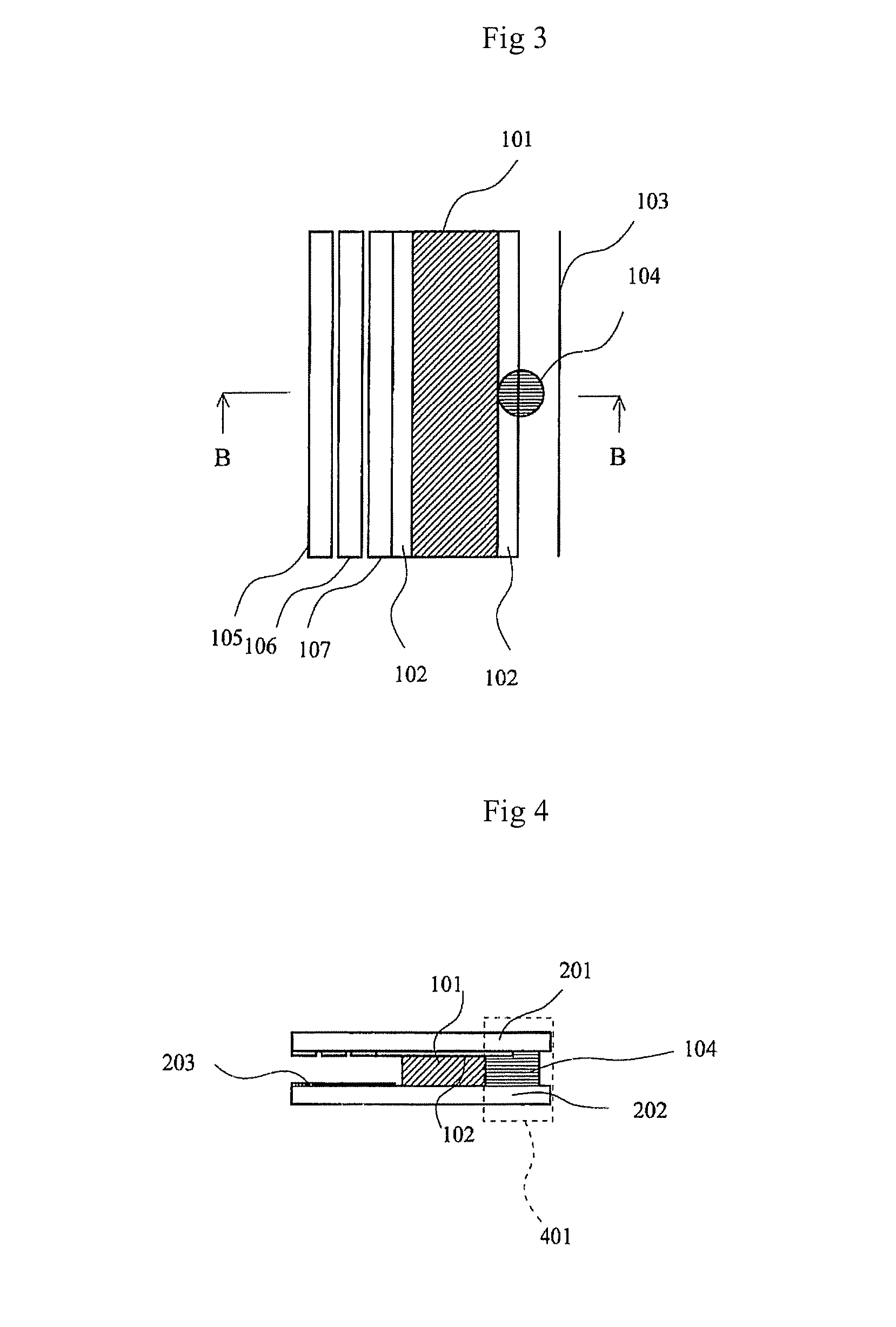

Magnetic disk drive, wiring connection structure and terminal structure

InactiveUS7372669B2Avoid crackingEasy to solvePrinted circuit aspectsRecord information storageElectrical conductorFlexible electronics

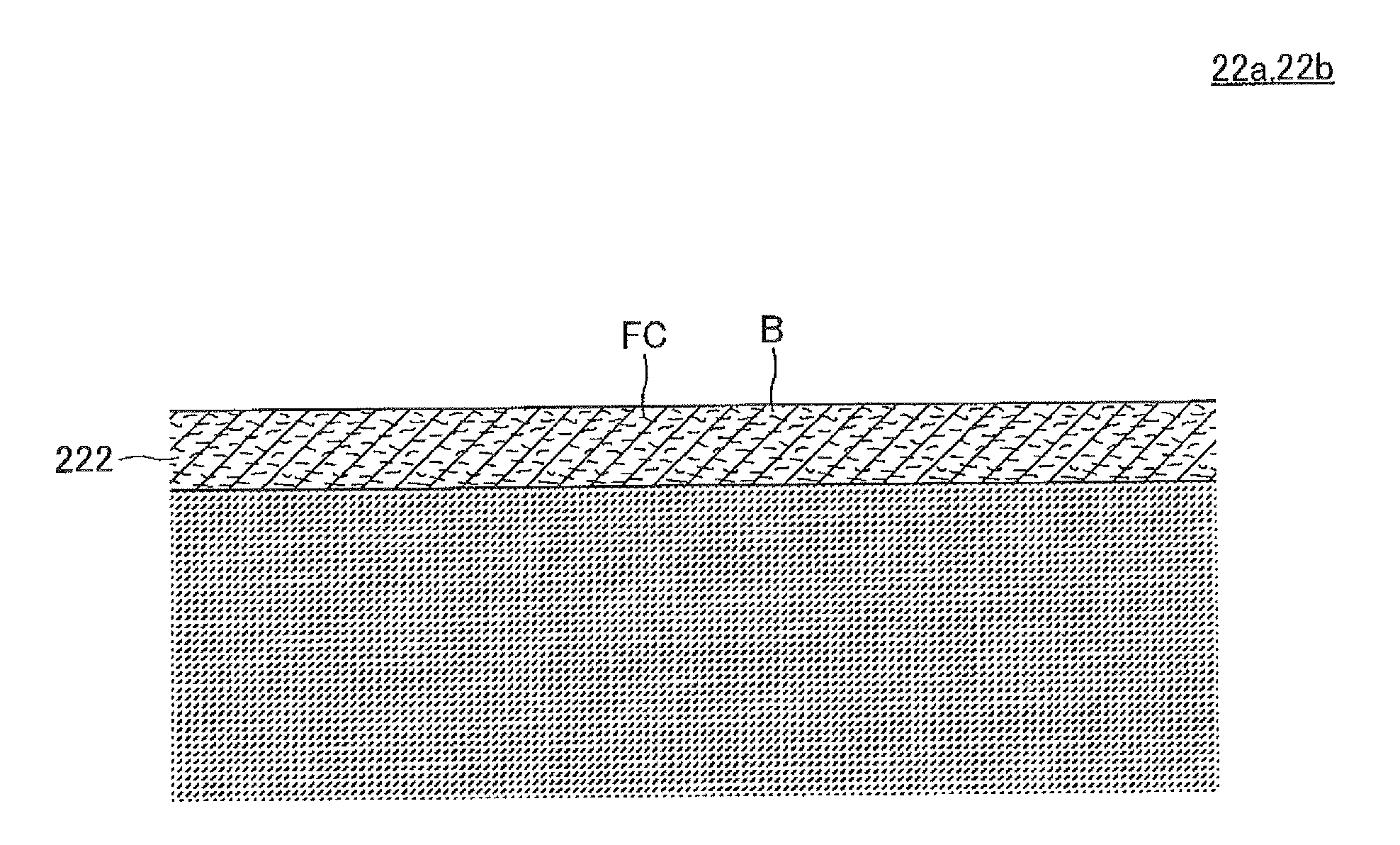

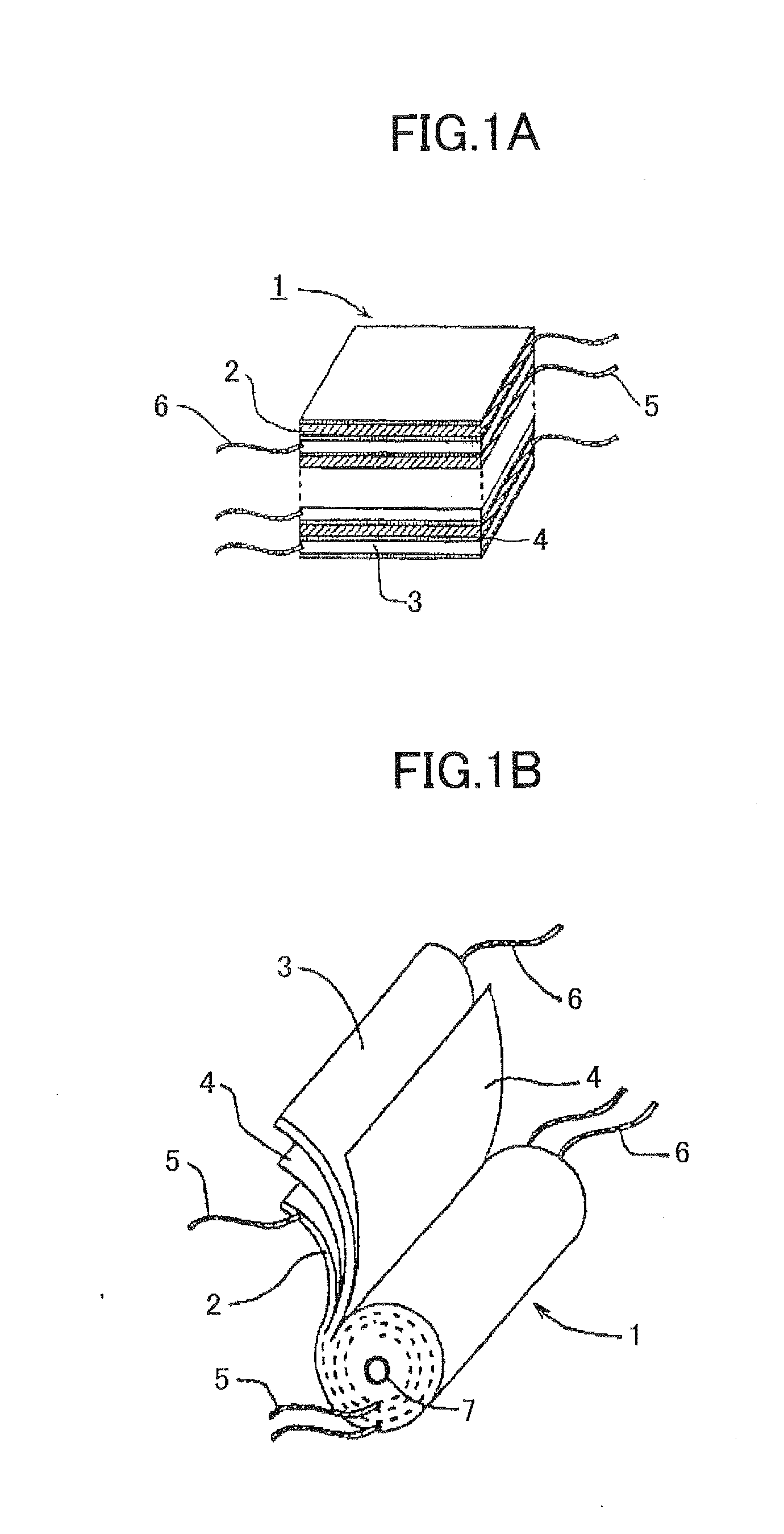

Terminals of a flexible printed circuit board and terminals of a wiring trace in a head suspension assembly are to be connected with each other by soldering without causing a soldering defect. In an embodiment, a terminal structure of a multi-connector in a wiring trace which includes an insulating layer and a conductor pattern portion formed on a surface of the insulating layer is provided with exposed portions of terminals exposed from apertures formed in part of the insulating layer and is also provided with lining portions adjacent to the exposed portions in a longitudinal direction of the conductor pattern portion and bonded to the insulating layer. Even if terminals of the multi-connector are cracked when soldered, not only conductivity is ensured, but also it is possible to strengthen the terminals, because the lining portions of the terminals are bonded to the insulating layer.

Owner:WESTERN DIGITAL TECH INC

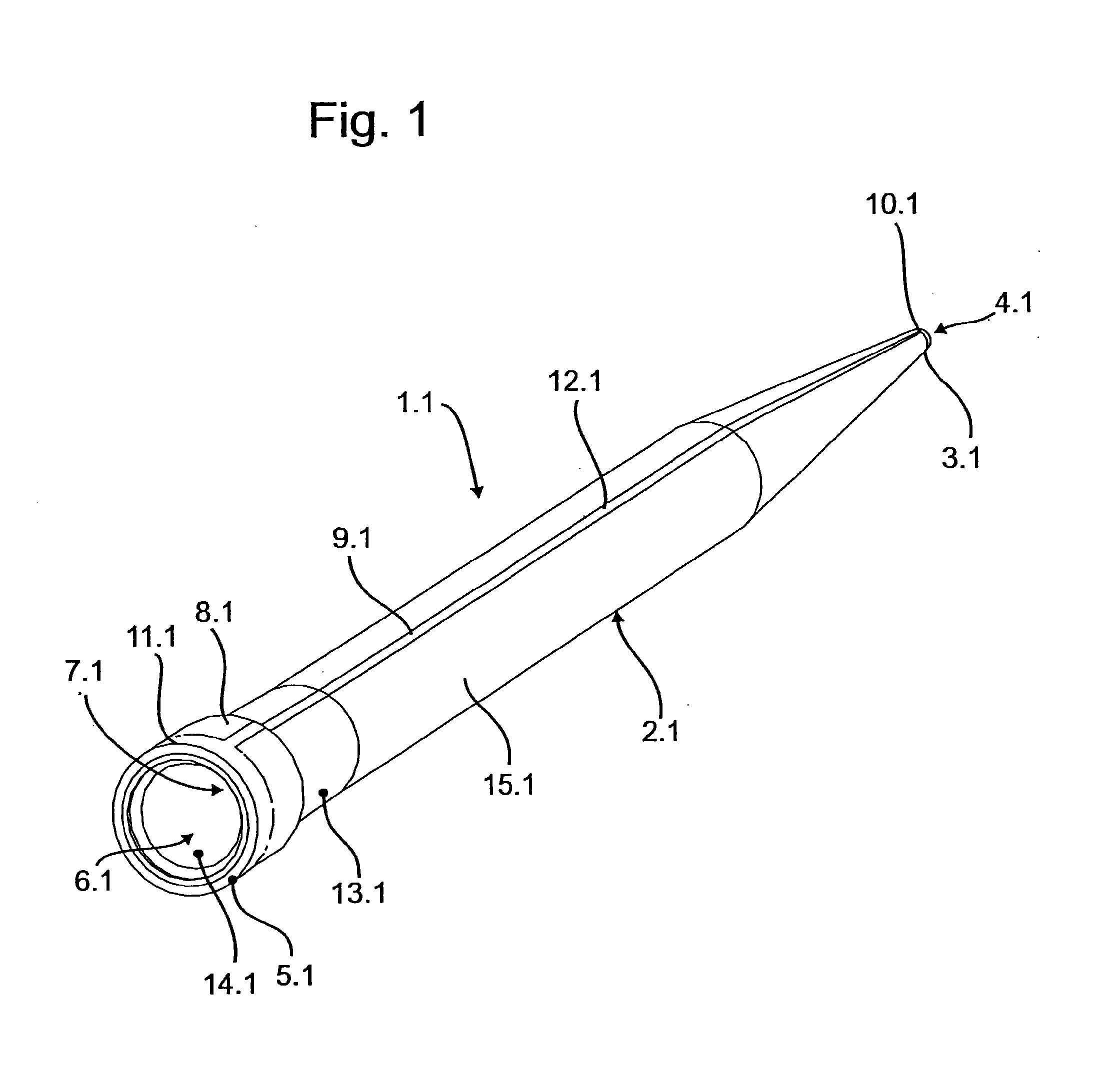

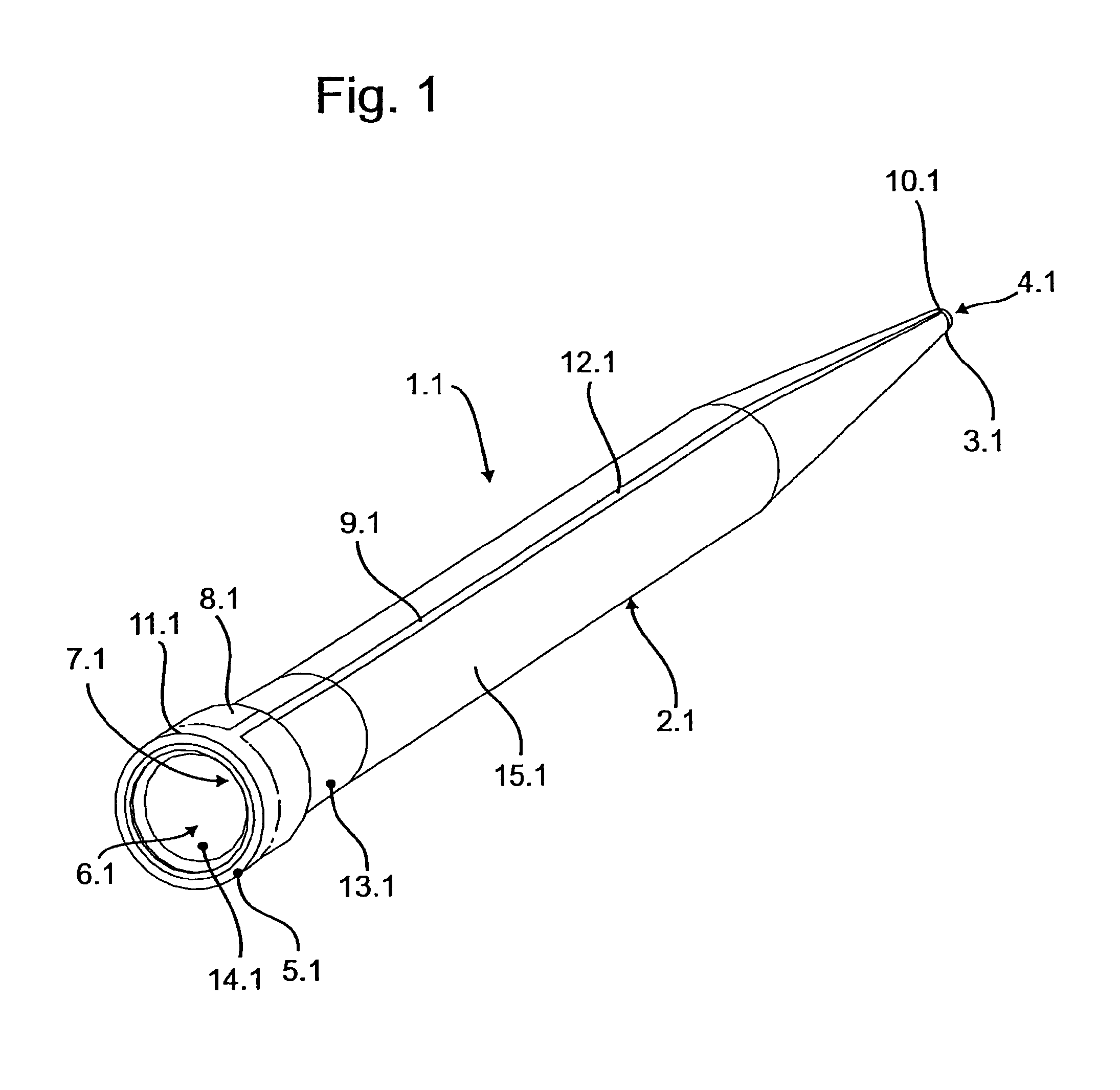

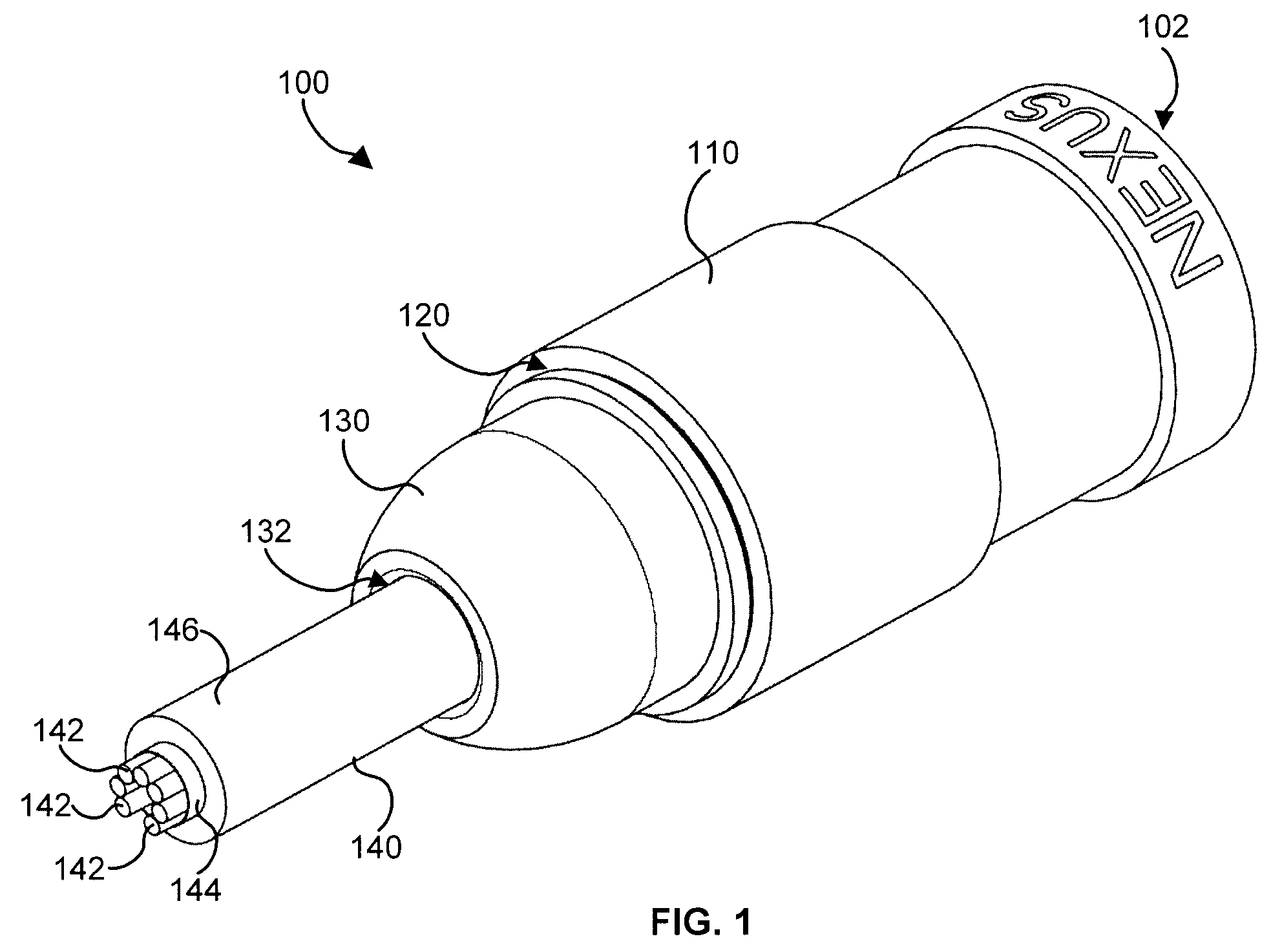

Electrically Conductive Pipette Tip

ActiveUS20130136672A1More flow resistancePrevent of distortionBurettes/pipettesLevel indicatorsPipetteEngineering

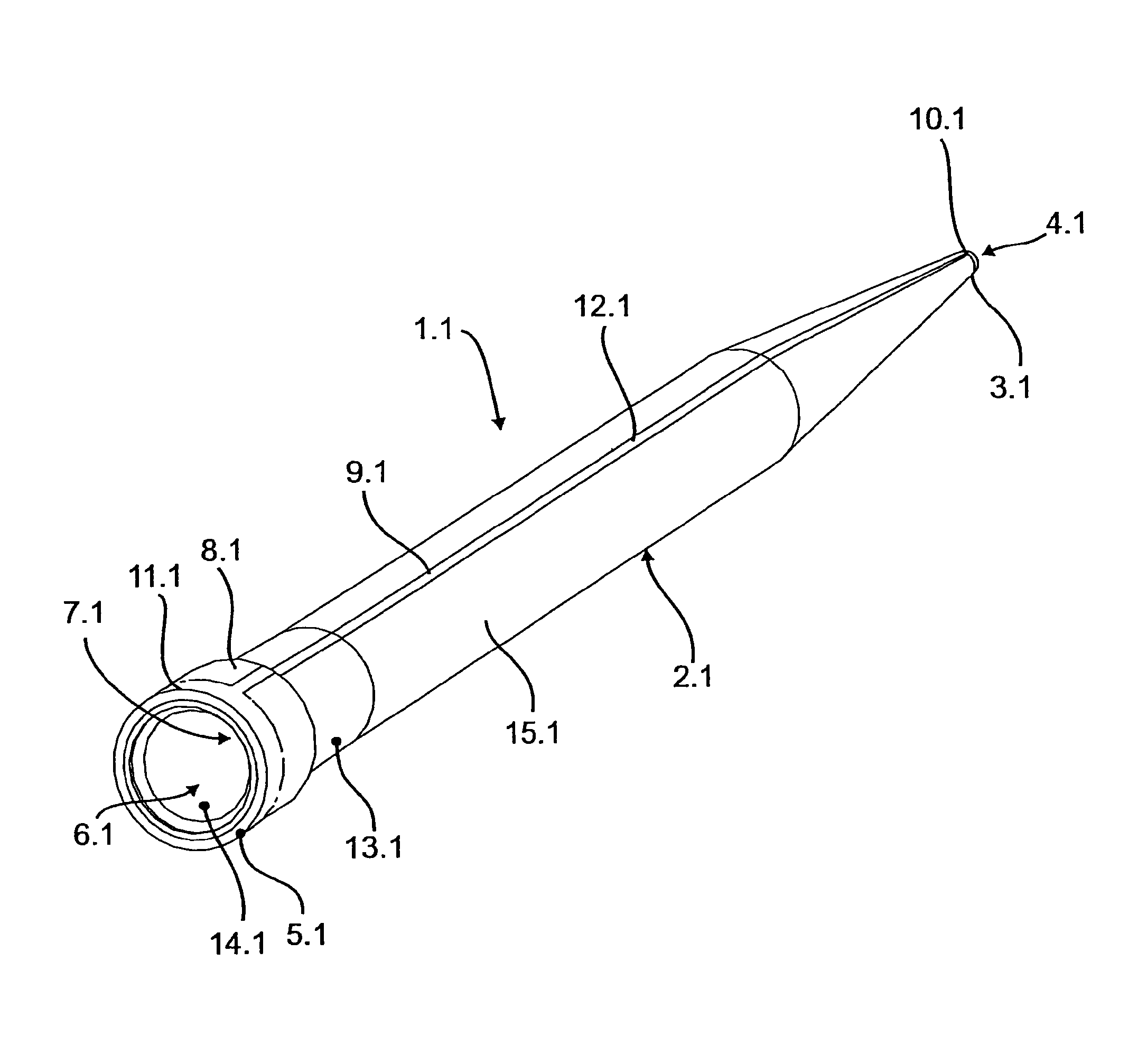

An electrically conductive pipette tip having an elongated tubular body that has a bottom opening at the bottom end for the passage of liquid, and a top opening at the top end for the passage of air, and a passageway between the bottom opening and the top opening, wherein the body has at least one electrically-conductive region extending from the bottom opening to the top opening, and at least one transparent region consisting of plastic that extends from the passageway to the outside of the body.

Owner:EPPENDORF SE

Cathode active material for lithium secondary battery

ActiveUS20120264021A1Good rate characteristicsReduction in capacityAlkaline accumulator electrodesNon-aqueous electrolyte accumulator electrodesEngineeringLithium-ion battery

Provided is a cathode active material for a lithium secondary battery, which can achieve both of excellent rate characteristic and practically sufficient durability (cycle characteristic) in the lithium secondary battery. The cathode active material for a lithium secondary battery includes therein pores. A particle or film of the cathode active material for a lithium secondary battery has formed therein a large number of pores. The inner wall of each of such pores is coated with a conductive film.

Owner:NGK INSULATORS LTD

Electrically conductive pipette tip

ActiveUS9346045B2Economically manufacturedEnsure conductivityMachines/enginesBurettes/pipettesPipetteEngineering

An electrically conductive pipette tip having an elongated tubular body that has a bottom opening at the bottom end for the passage of liquid, and a top opening at the top end for the passage of air, and a passageway between the bottom opening and the top opening, wherein the body has at least one electrically-conductive region extending from the bottom opening to the top opening, and at least one transparent region consisting of plastic that extends from the passageway to the outside of the body.

Owner:EPPENDORF SE

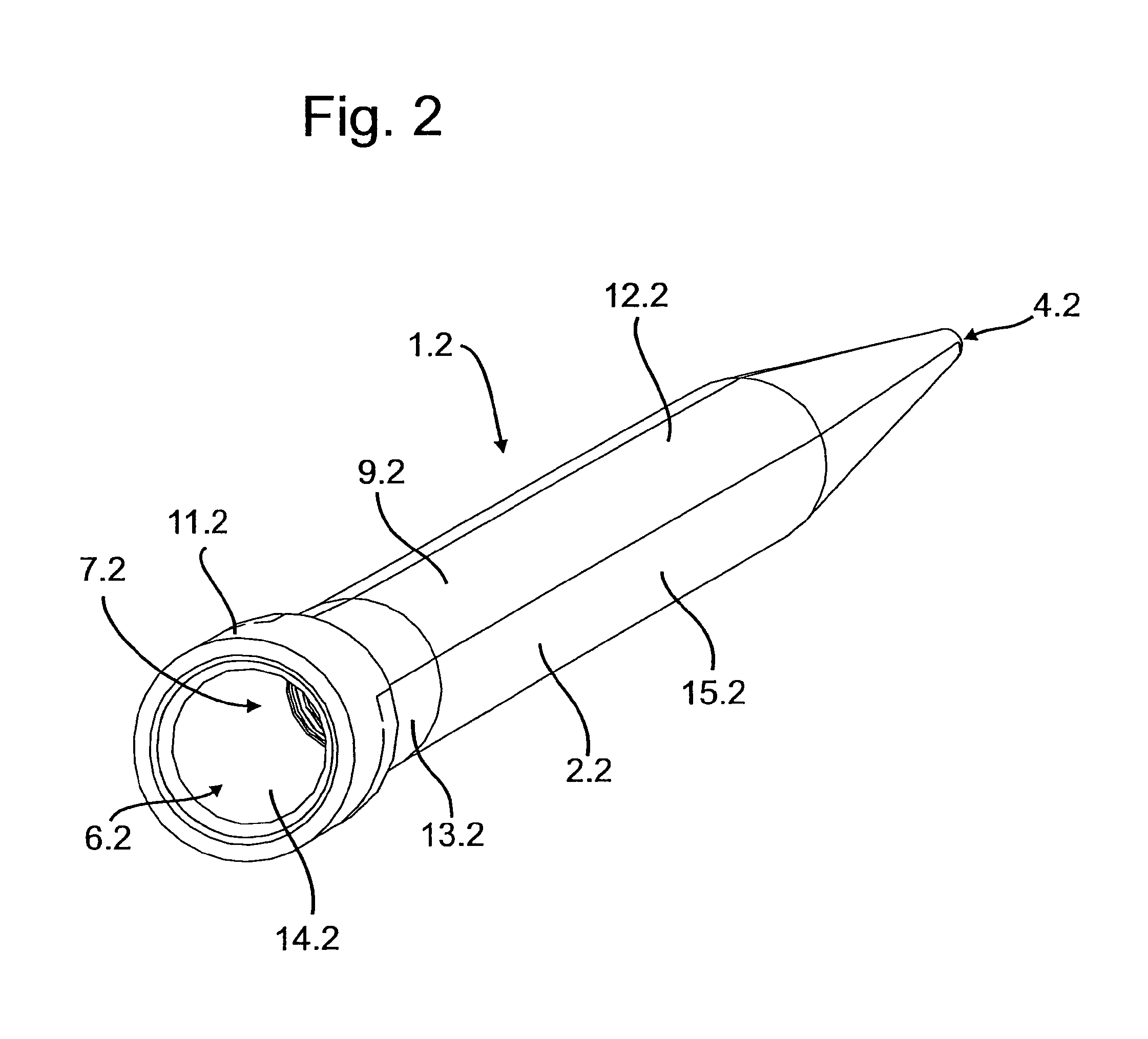

Circuit connecting material, film-like circuit connecting material using the circuit connecting material, structure for connecting circuit member, and method for connecting circuit member

InactiveUS20120138868A1Excellent reliabilityEnsure conductivityMaterial nanotechnologyNanoinformaticsEngineeringElectrical connection

The circuit connecting material of the invention is situated between mutually opposing circuit electrodes, and provides electrical connection between the electrodes in the pressing direction when the mutually opposing circuit electrodes are pressed, the circuit connecting material comprising anisotropic conductive particles wherein conductive fine particles are dispersed in an organic insulating material.

Owner:HITACHI CHEM CO LTD

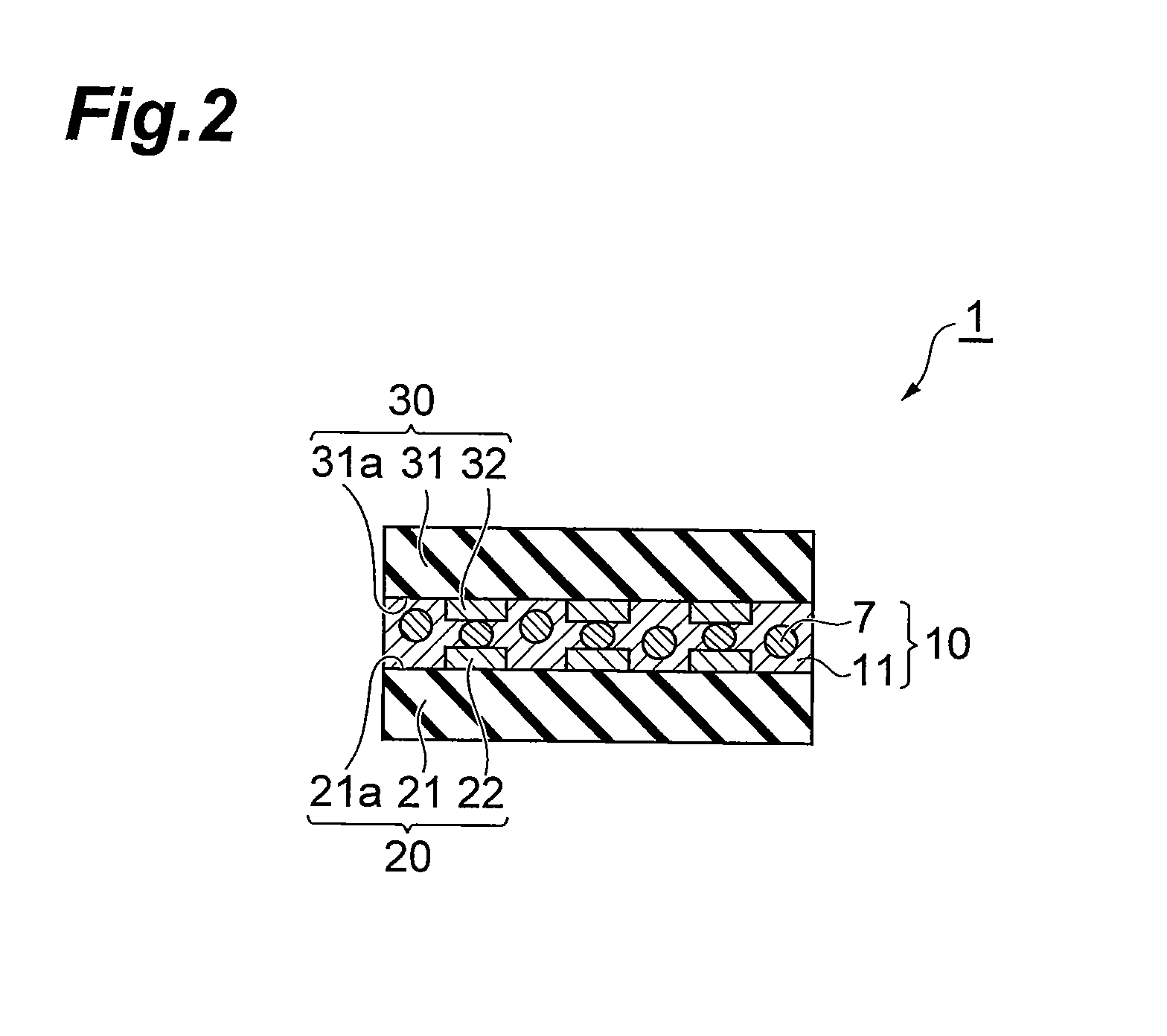

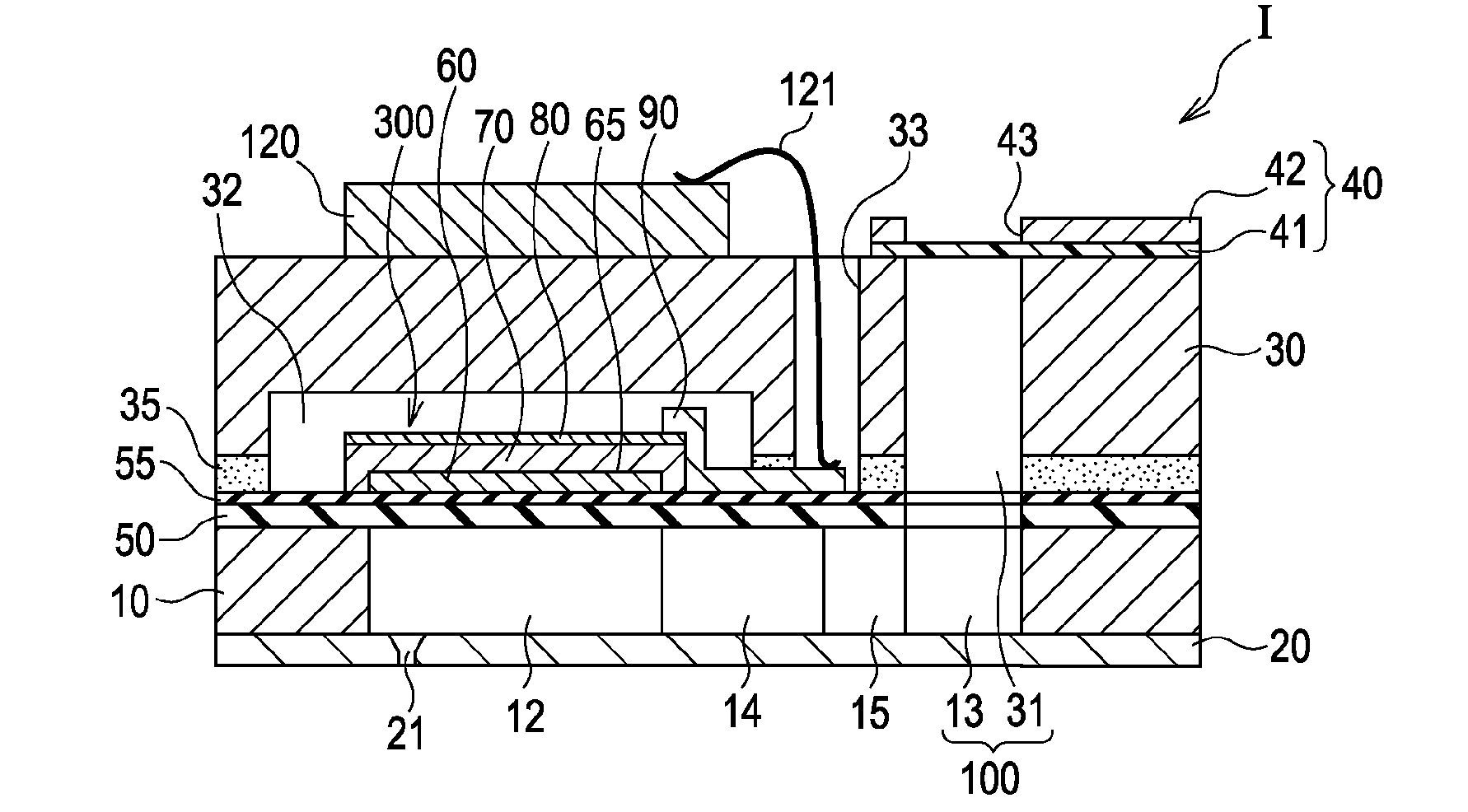

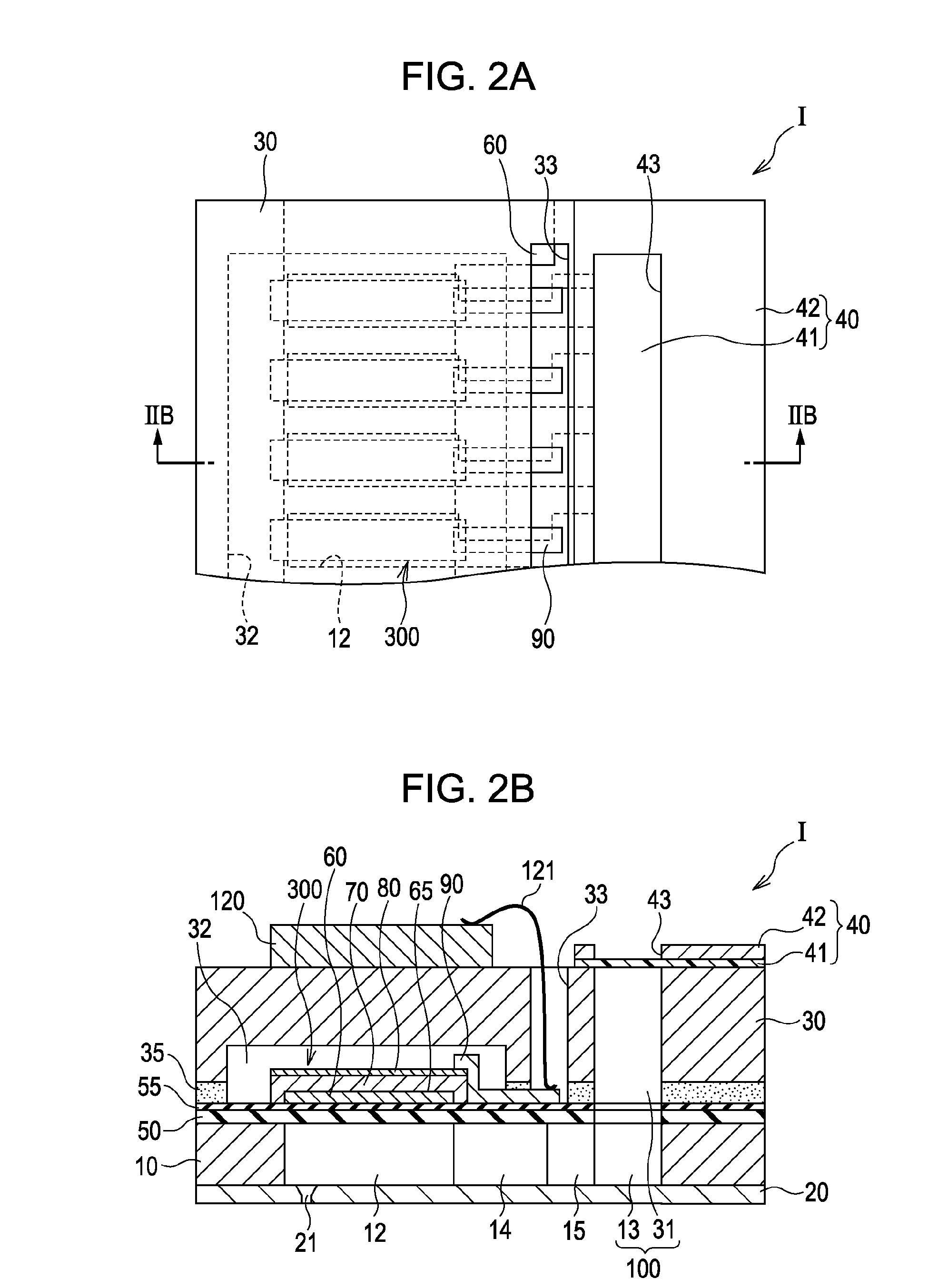

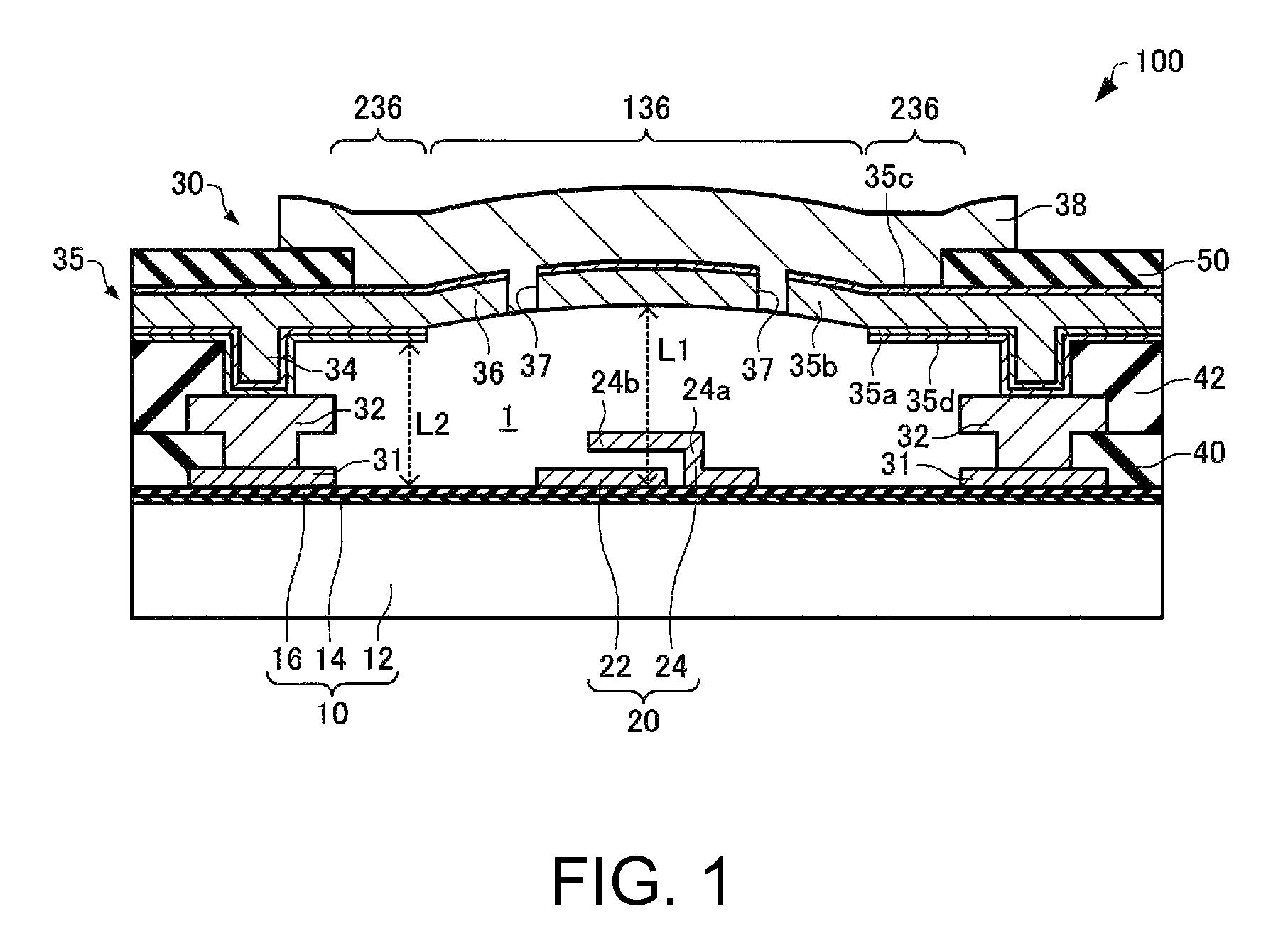

Electronic device and method for manufacturing electronic device

InactiveUS20120104593A1Improve reliabilityHighly reliable electronic deviceImpedence networksSemiconductor/solid-state device detailsEngineering

Owner:SEIKO EPSON CORP

Cathode active material for lithium secondary battery

ActiveUS8815445B2Easy to shapeImprove featuresElectrode carriers/collectorsActive material electrodesEngineeringLithium-ion battery

Owner:NGK INSULATORS LTD

Magnetic disk drive, wiring connection structure and terminal structure

InactiveUS20060034018A1Avoid crackingEasy to solvePrinted circuit aspectsRecord information storageElectrical conductorEngineering

Terminals of a flexible printed circuit board and terminals of a wiring trace in a head suspension assembly are to be connected with each other by soldering without causing a soldering defect. In an embodiment, a terminal structure of a multi-connector in a wiring trace which includes an insulating layer and a conductor pattern portion formed on a surface of the insulating layer is provided with exposed portions of terminals exposed from apertures formed in part of the insulating layer and is also provided with lining portions adjacent to the exposed portions in a longitudinal direction of the conductor pattern portion and bonded to the insulating layer. Even if terminals of the multi-connector are cracked when soldered, not only conductivity is ensured, but also it is possible to strengthen the terminals, because the lining portions of the terminals are bonded to the insulating layer.

Owner:WESTERN DIGITAL TECH INC

Flat heating element

InactiveUS20070257027A1Probability of fracture is highIncrease the probability of failureHeating element shapesHeat exchanger casingsElectrical conductorEngineering

The present invention pertains to an electric heating element with at least one flat heating resistor to be arranged near a surface to be heated, and at least one electrode that serves to feed a current into the heating resistor and features at least two contact conductor strands that are, at least locally, connected to one another and to the heating resistor, at least in an elongated contacting region. The invention proposes that at least at one location along the electrode and / or the contacting region at which at least one of the contact conductor strands, at least locally, extends parallel to the direction of the electrode, and / or the contacting region, at least one additional contact conductor strand, at least locally, extends at an angle thereto.

Owner:GENTHERM GMBH

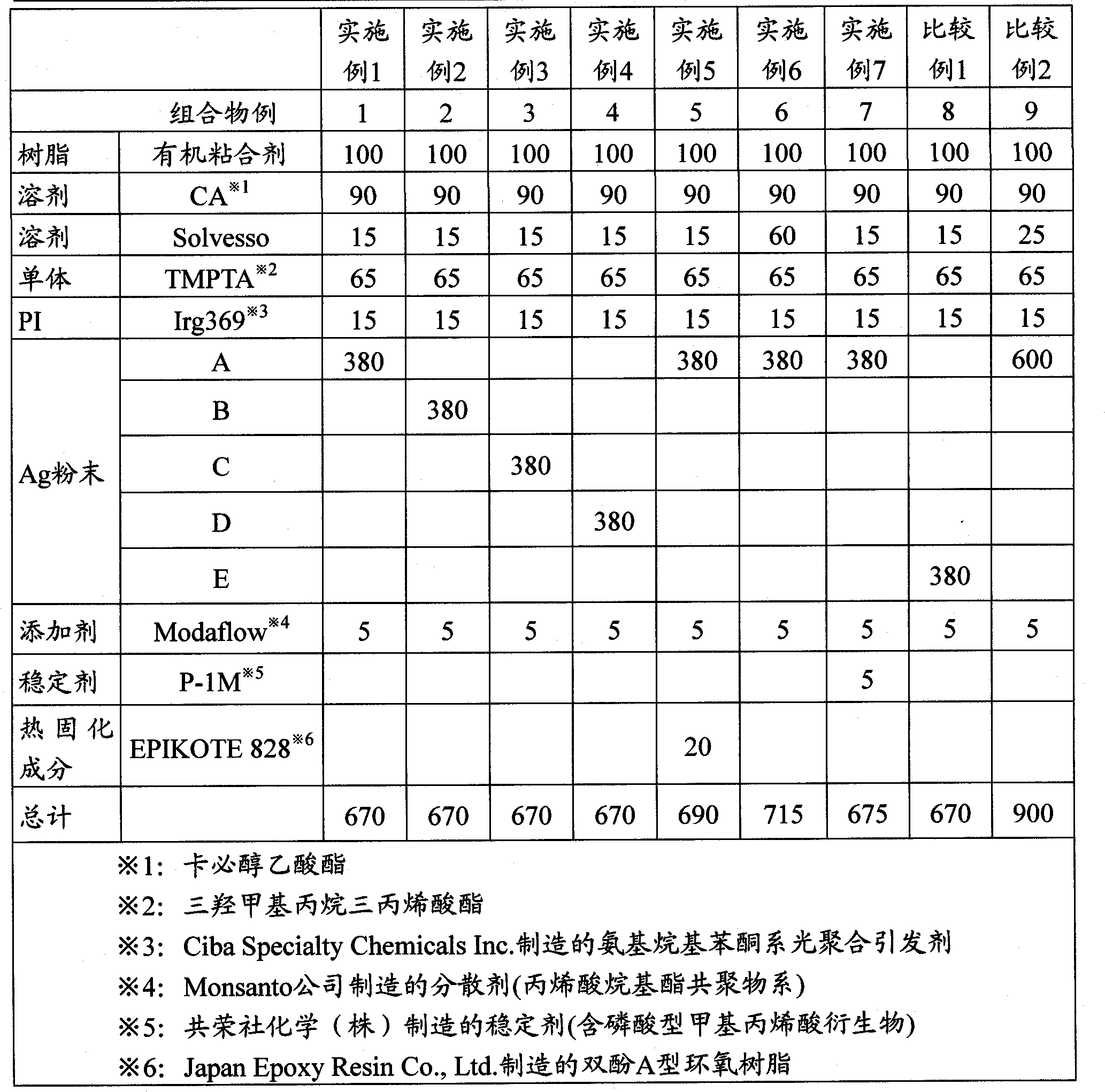

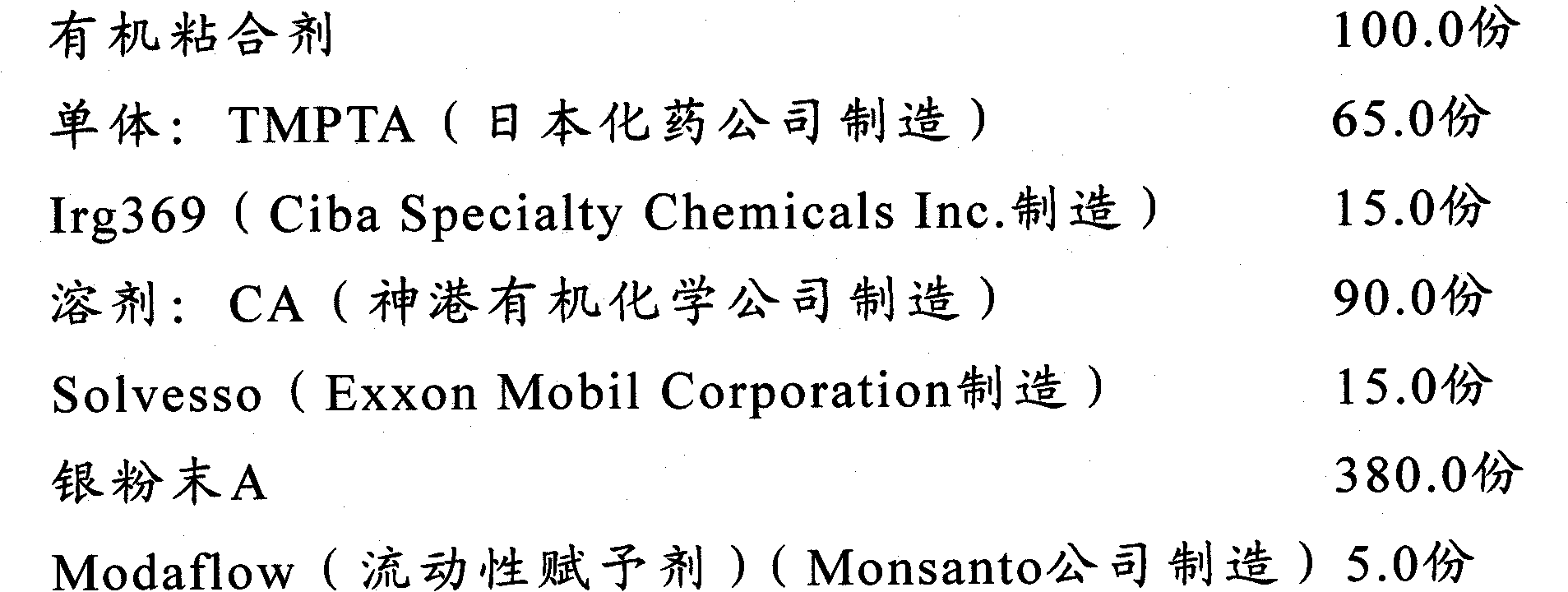

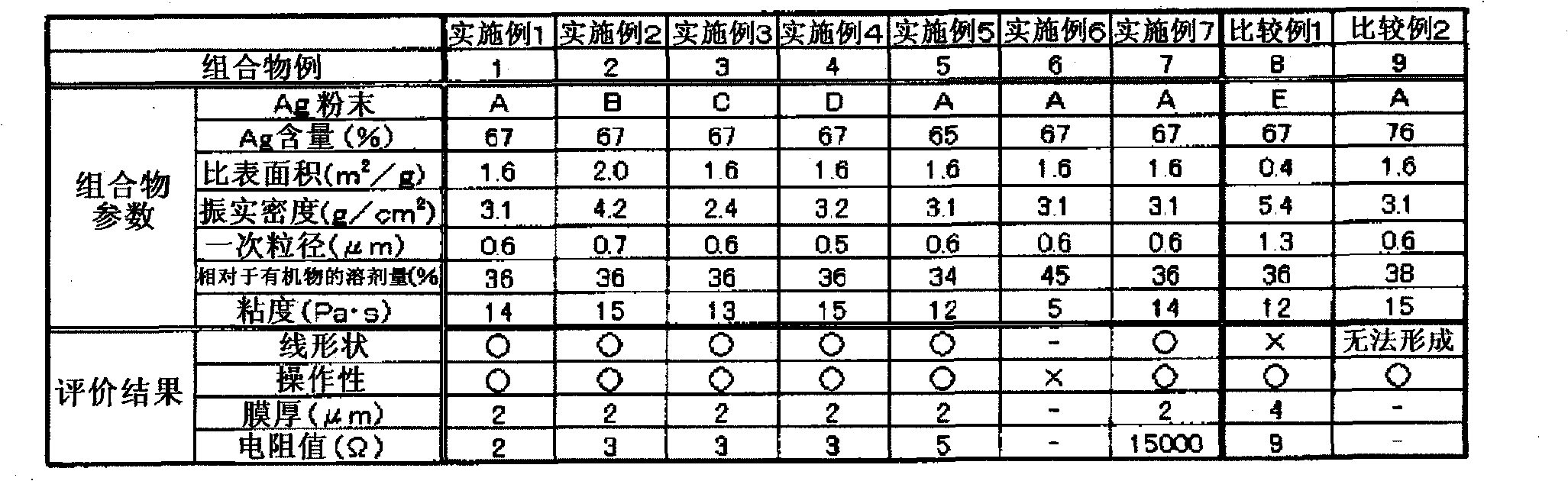

Photosensitive electrically conductive paste and electrode pattern

ActiveCN102365690AAchieve high precisionAchieve thin filmPhotodevelopable thick filmNon-conductive material with dispersed conductive materialOrganic solventMetallurgy

Provided is a photosensitive electrically conductive paste containing silver powder, organic binder, photopolymerizable monomer, photopolymerization initiator and organic solvent. The silver powder, having a primary particle diameter of not more than 1.0 [mu]m, a specific surface area from 1.5 m2 / g to 2.0 m2 / g and a tap density from 2.0 to 5.0 g / cm3, is included in an amount of less than 70 mass%of the electrically conductive paste excluding the organic solvent.

Owner:TAIYO INK MFG

Conductive adhesive for screen printing, joined body of inorganic material, and method for producing same

ActiveUS20150282330A1Improve conductivityImprove productivityPrinted circuit assemblingNon-macromolecular adhesive additivesAdhesiveMetal colloids

The present invention relates to a conductive adhesive for screen printing containing metal colloid particles (A) containing metal nanoparticles (A1) and a protective colloid (A2) containing an organic compound having a carboxyl group and a polymer dispersant having a carboxyl group, a viscosity modifier (B) having an amide bond and / or a urea bond, and a dispersion solvent (C).

Owner:MITSUBOSHI BELTING LTD

Anisotropic conductive particles

InactiveUS20120097902A1Ensure conductivityNon-insulated conductorsPrinted circuit aspectsOptoelectronicsAnisotropy

Owner:HITACHI CHEM CO LTD

Flap Type Nano/Micro Mechanical Device and Fabrication Method Thereof

InactiveUS20070279140A1Limit thickness of dielectric layerEnsure conductivityWave amplification devicesImpedence networksCMOSCapacitance

A μ-flap type nano / micro mechanical device with a lower electrode 1,1a, 1b, an upper electrode layer 2, an dielectric layer 3 arranged between the lower electrode 1,1a,1b and the upper layer 2, such that the dielectric layer 3 and said upper electrode layer—2 form a layered body 4, the layered body 4 comprising a horizontal recess 5 in a side portion of the dielectric layer 3, and an overhanging portion 6 of reduced thickness over the recess 5 that forms a gap 5a; such that the overhanging portion 6 forms a μ-flap 6a which extends over the gap 5a. The device is a capacitative-based device in which the mechanical motion can be measured at room temperature and without monolithic integration thereof with an integrated circuit but that can be easily integrated with complementary metal oxide semiconductor (CMOS) circuitry.

Owner:SEIKO EPSON CORP

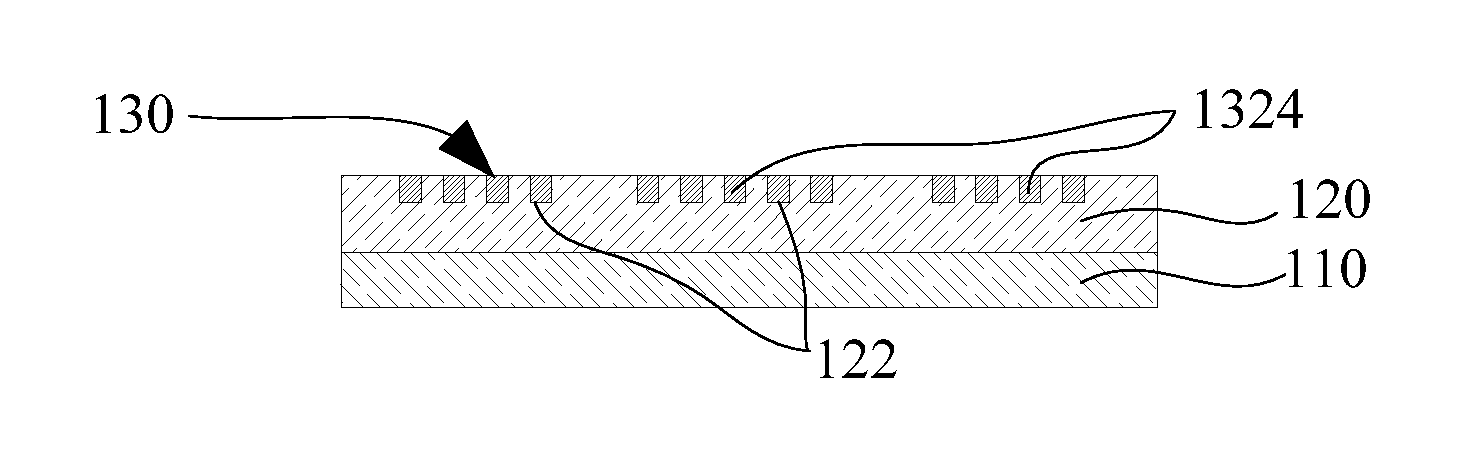

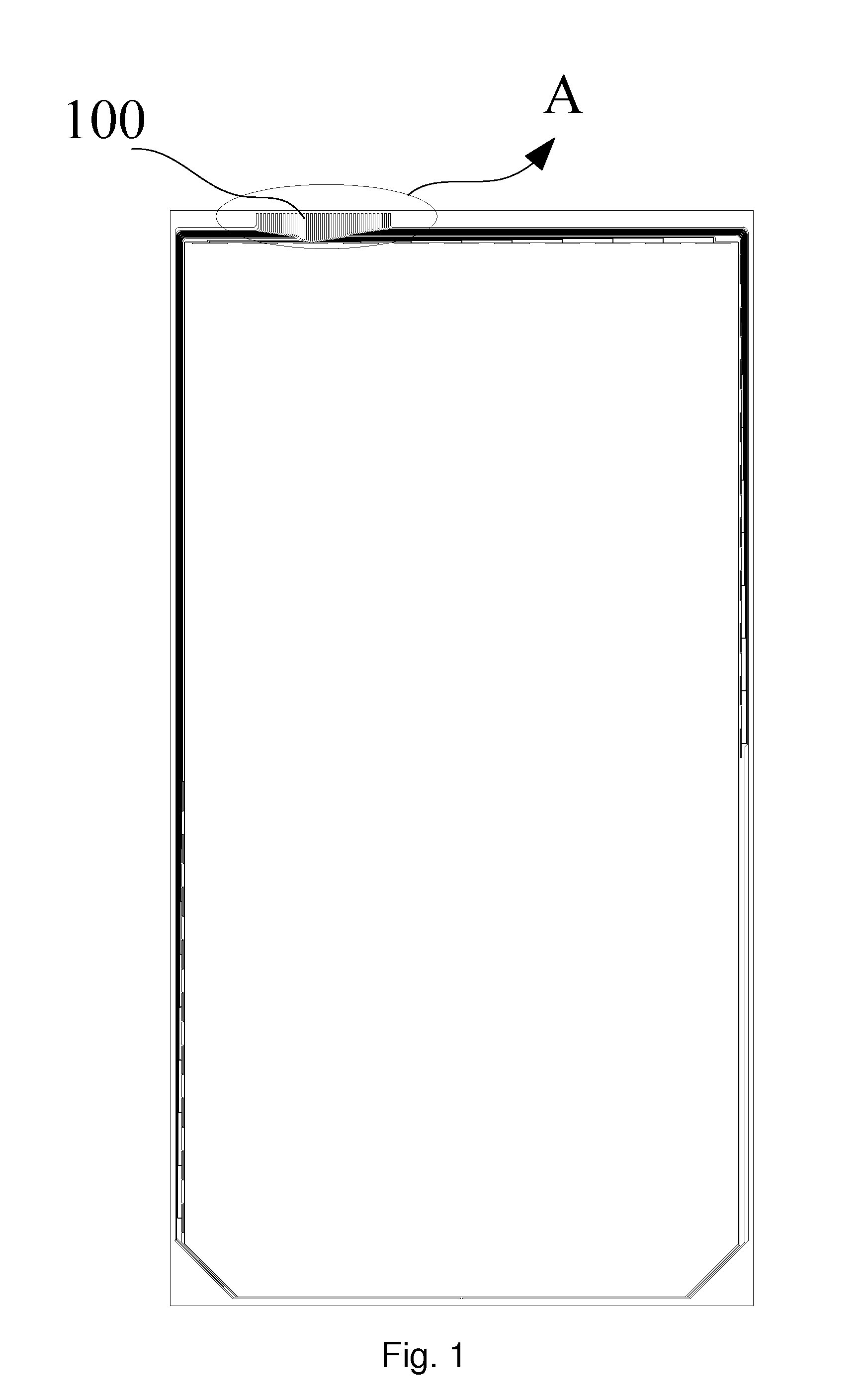

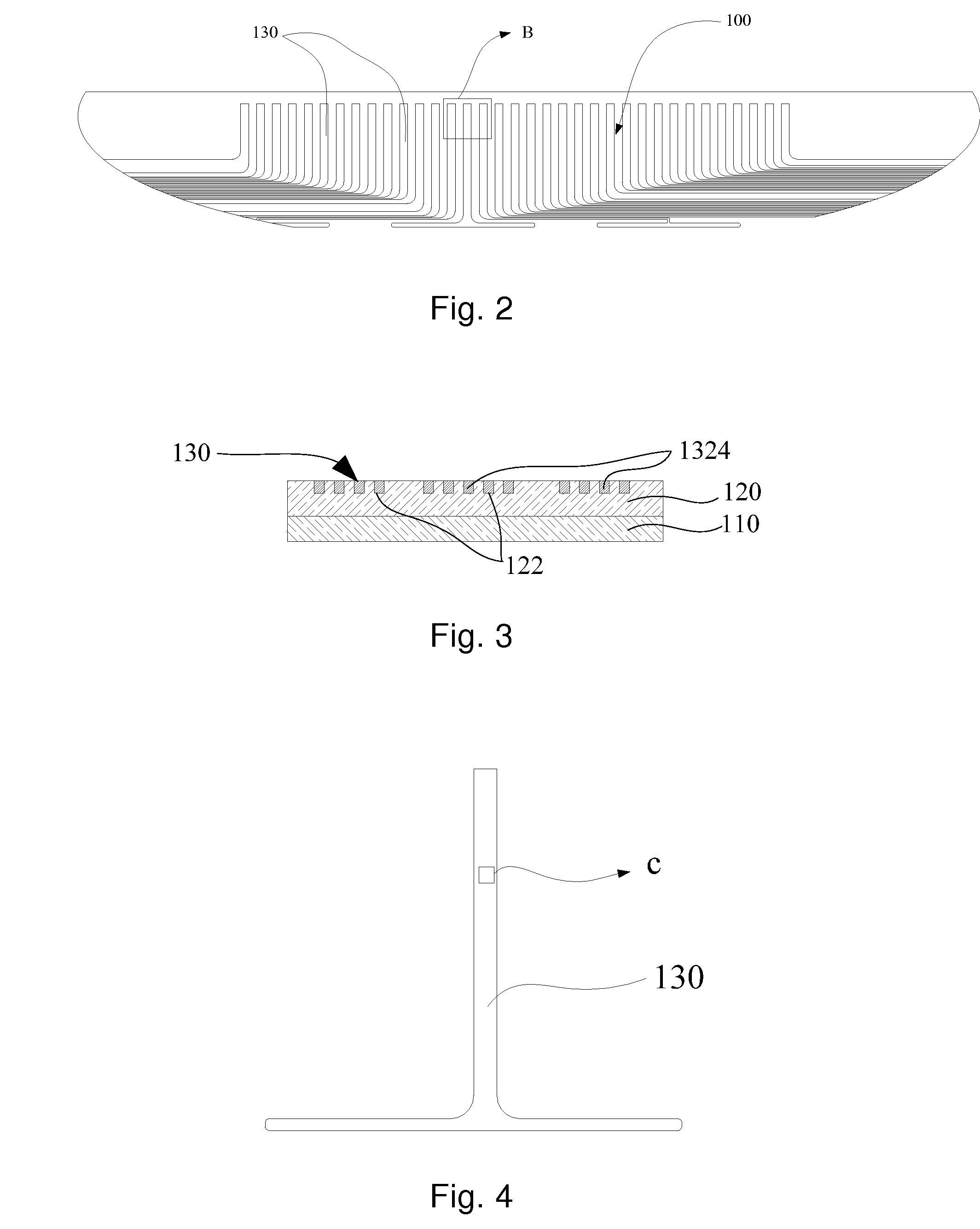

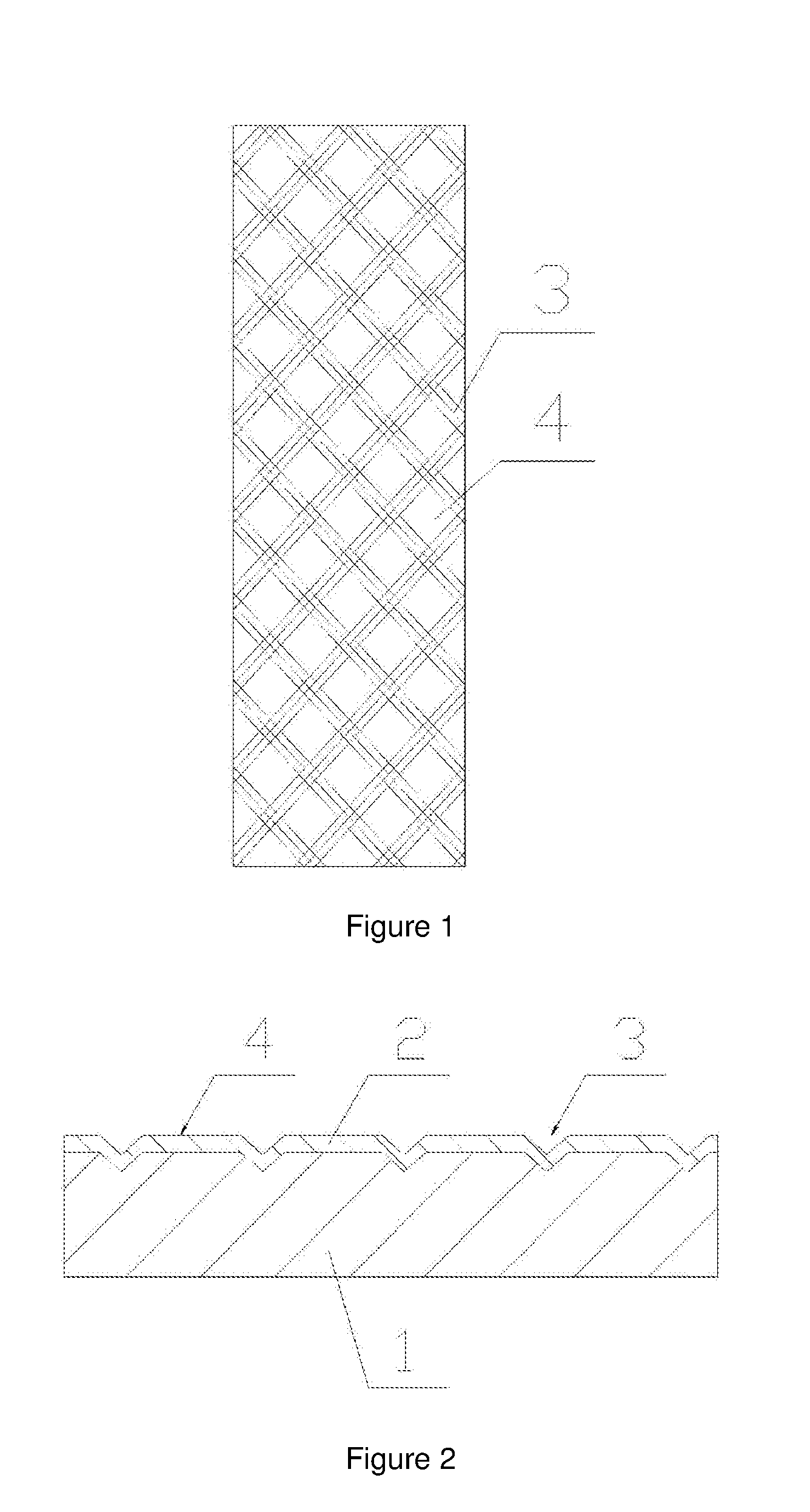

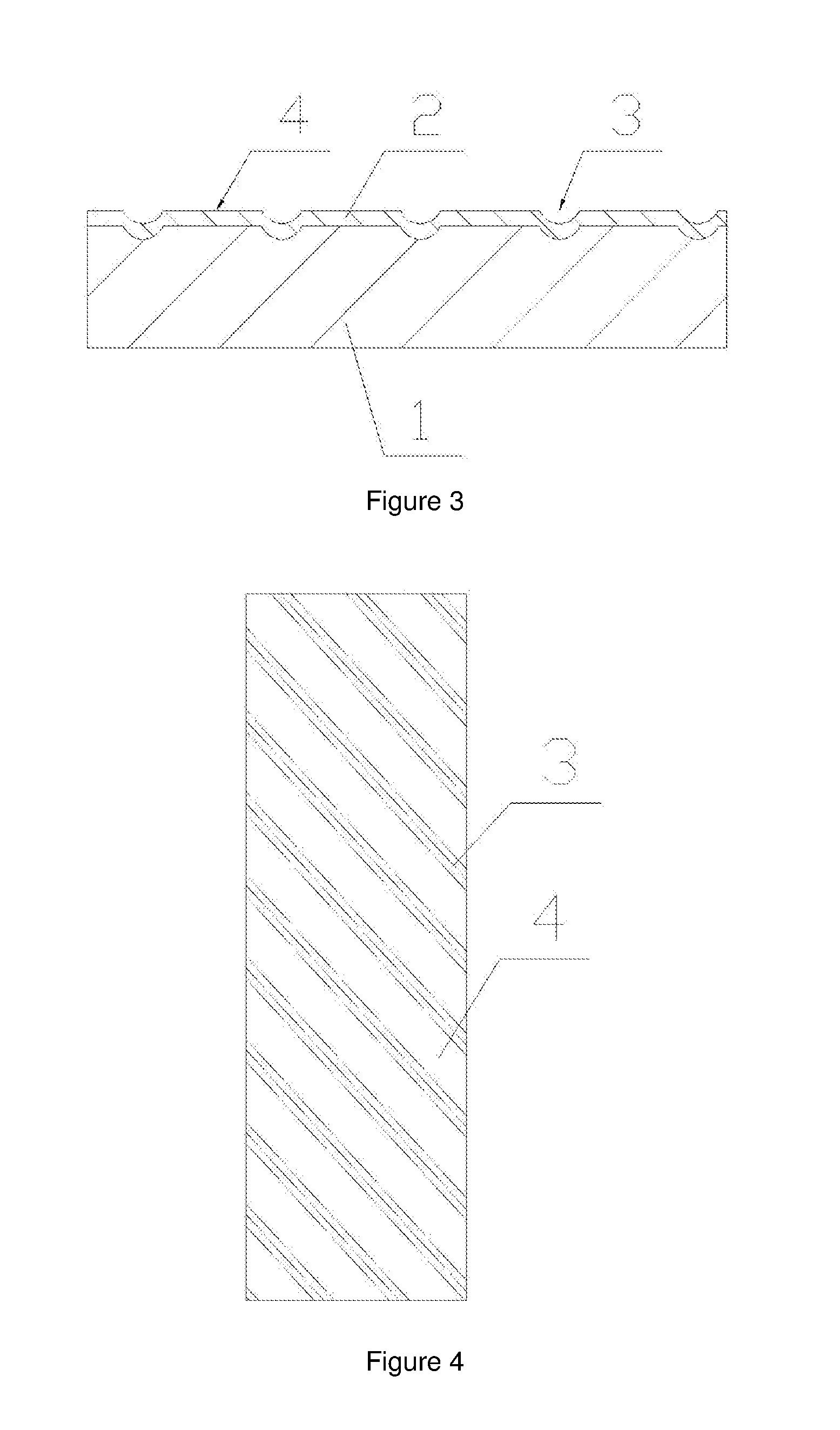

Gold finger and touch screen

ActiveUS20140290991A1Easy to fall offEnsure conductivityTransparent dielectricsPrinted circuit manufactureAnisotropic conductive adhesiveEngineering

A gold finger, includes a substrate, an embossable adhesive layer and a plurality of wires. The gold finger is achieved through adhering an embossable adhesive layer to a side of the substrate, providing grid-shaped grooves on a side of the embossable adhesive layer away from the substrate, embedding conductive grids of the wires in the grooves to form the wires. The gold finger is disposed on a sensing component, the wires of the gold finger are electrically connected with a circuit board through an anisotropic conductive adhesive. The contact area of the wire and the embossable adhesive layer is increased through embedding the conductive grid of the wire, which is grid-shaped structure, in the grooves such that the wires are tightly combined to the embossable adhesive layer and not easy to fall off or be scratched. The present invention further provides a touch screen containing the gold finger.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

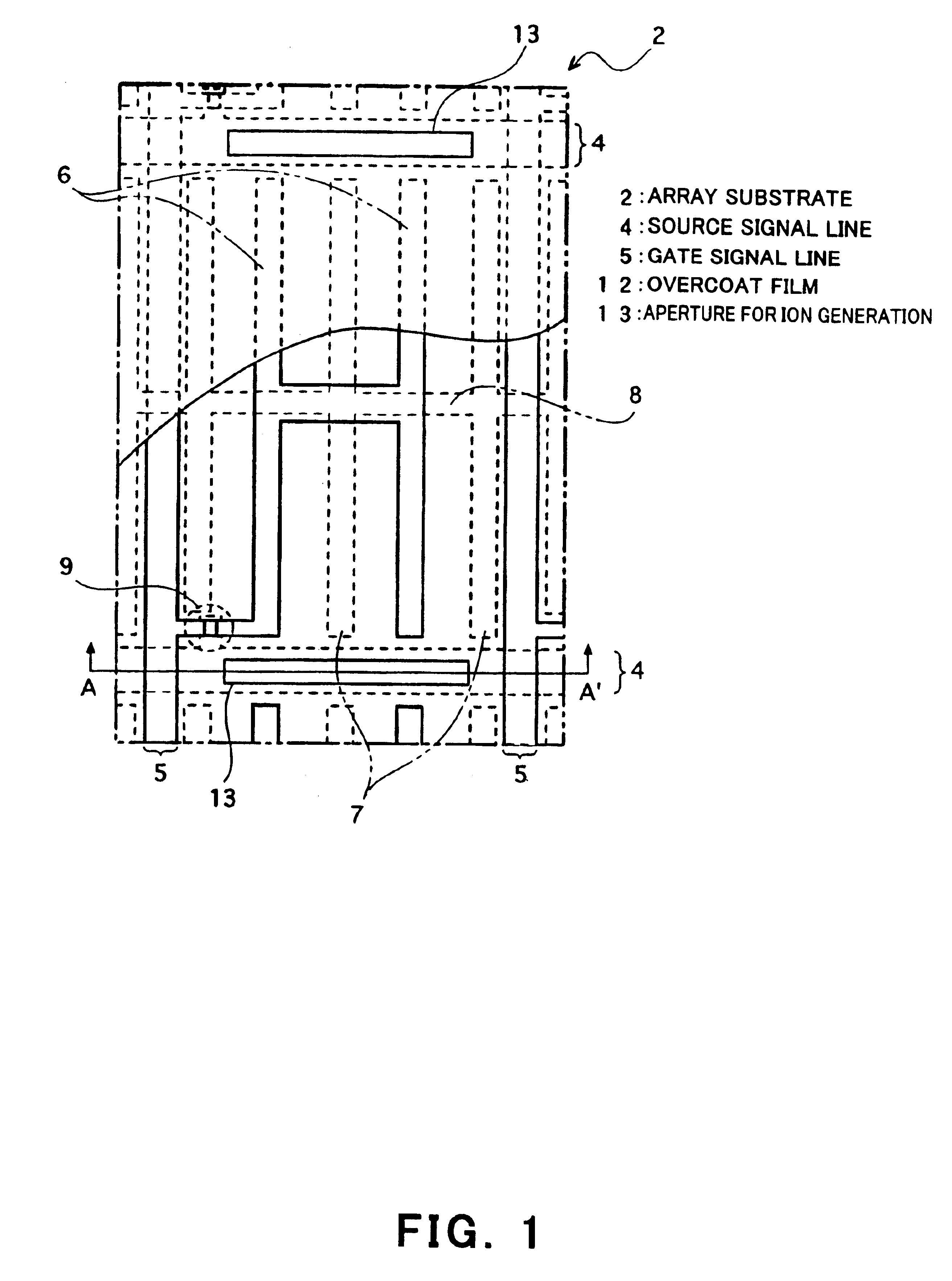

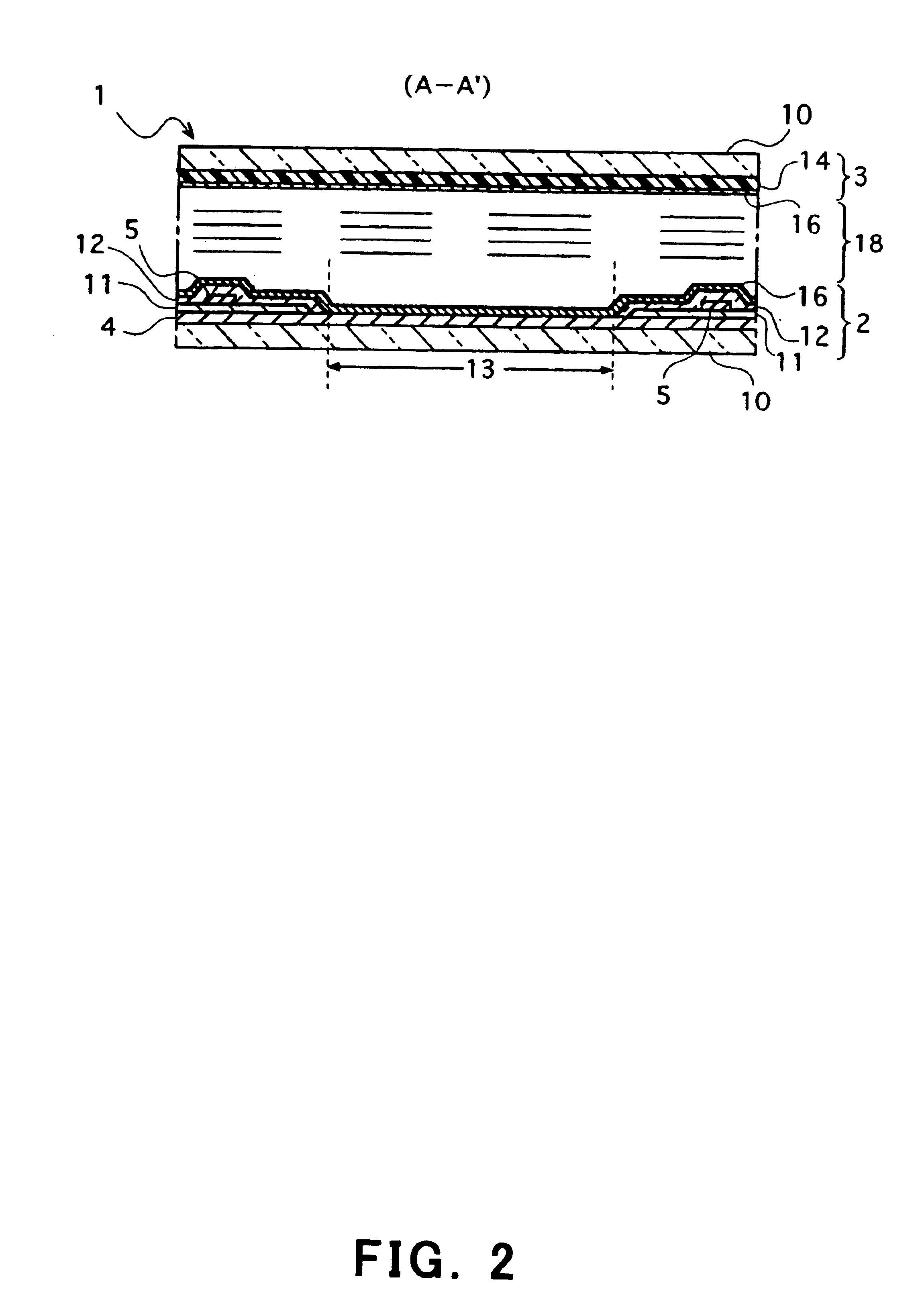

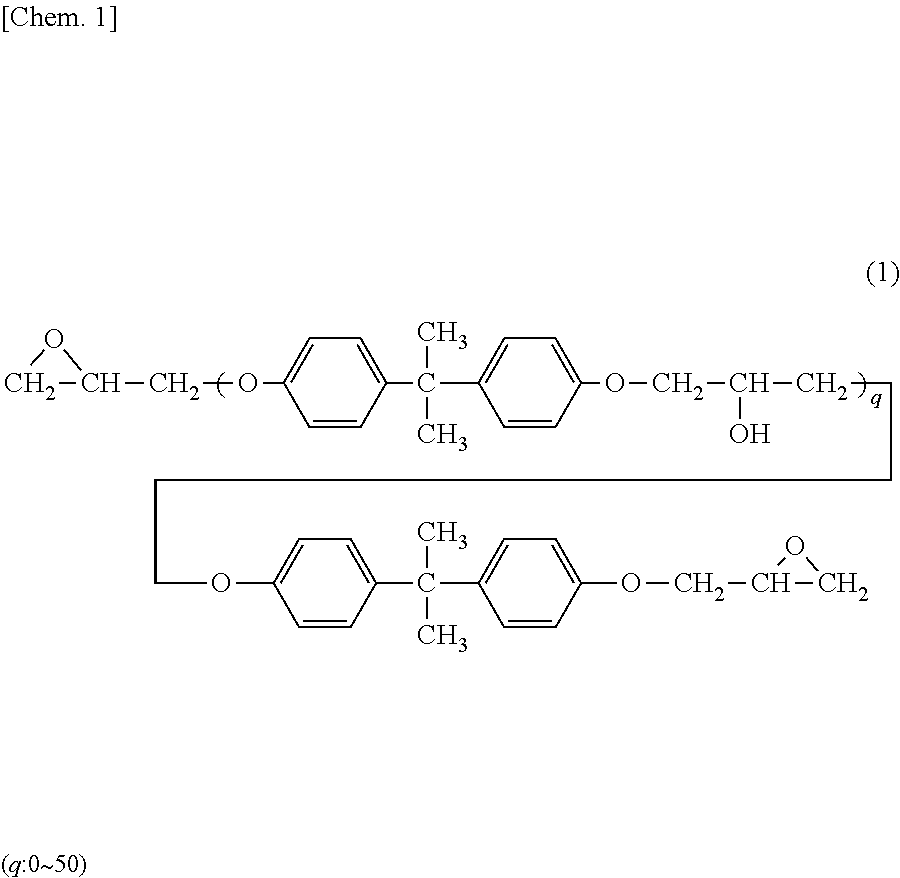

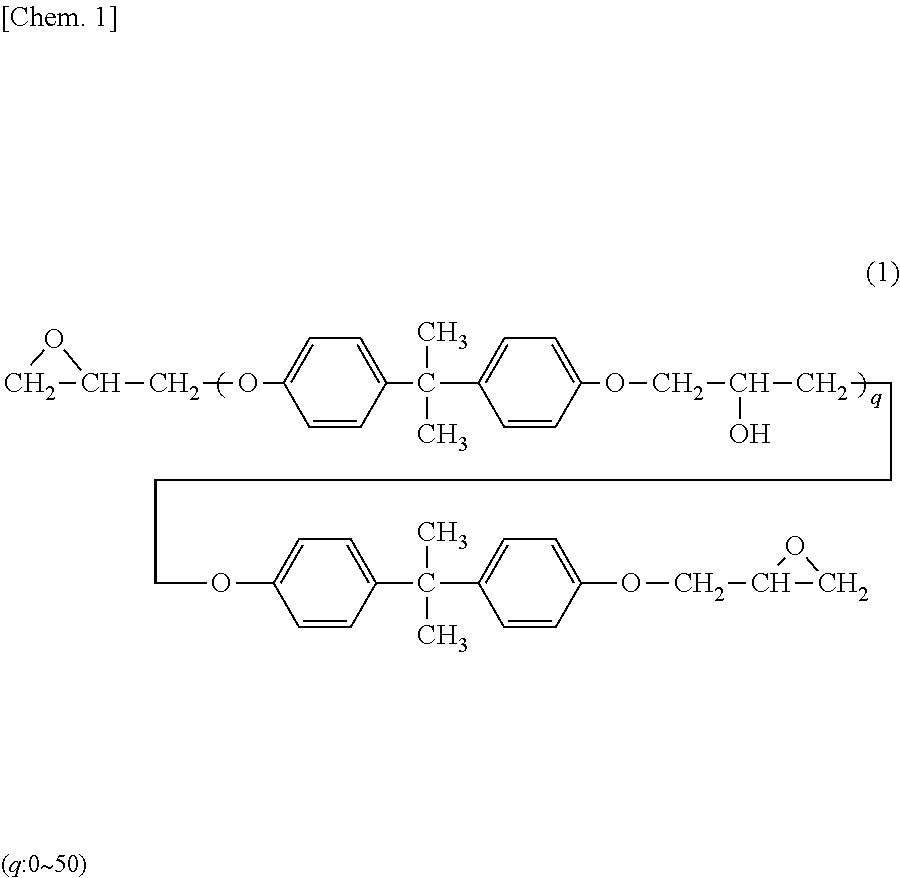

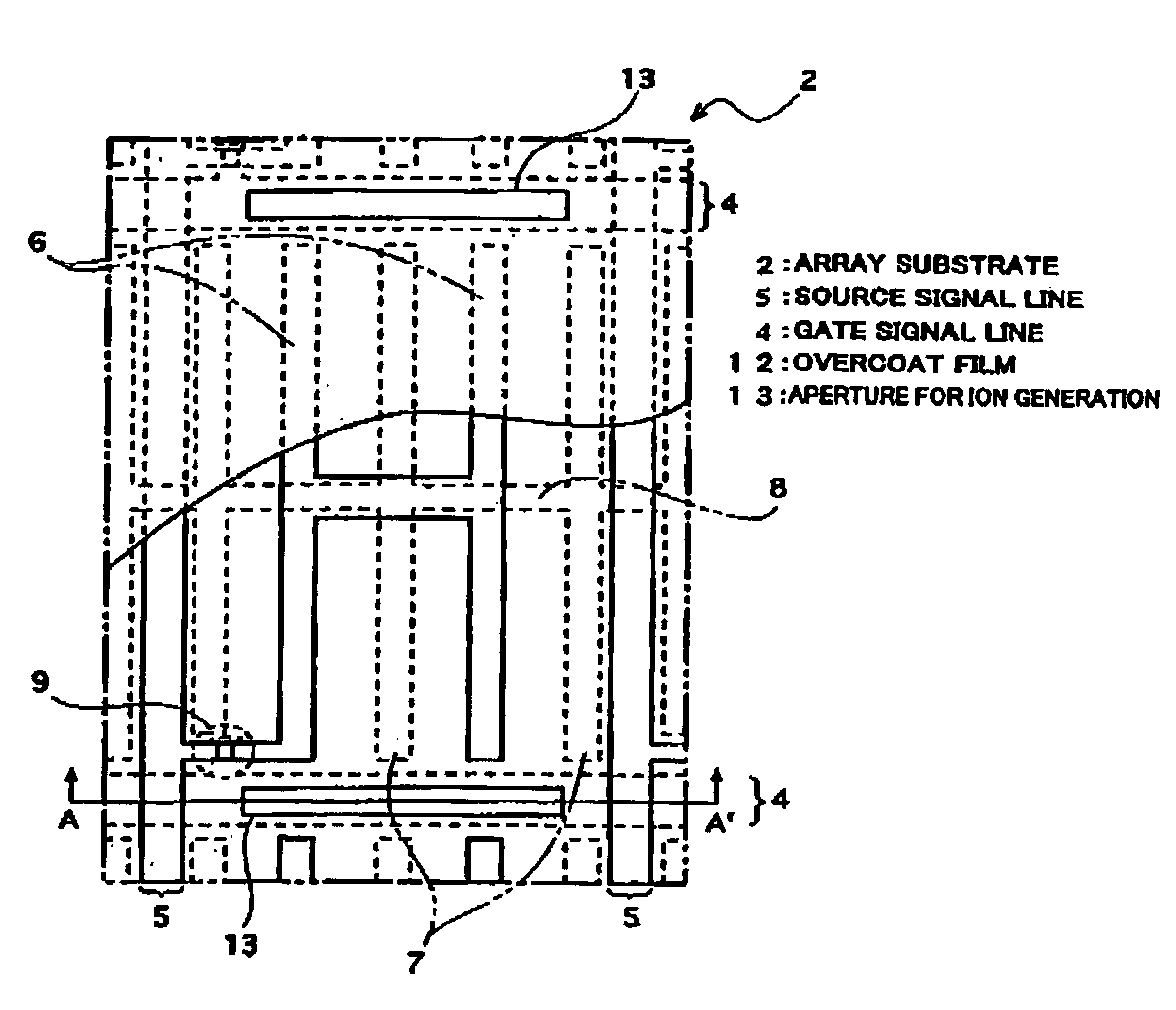

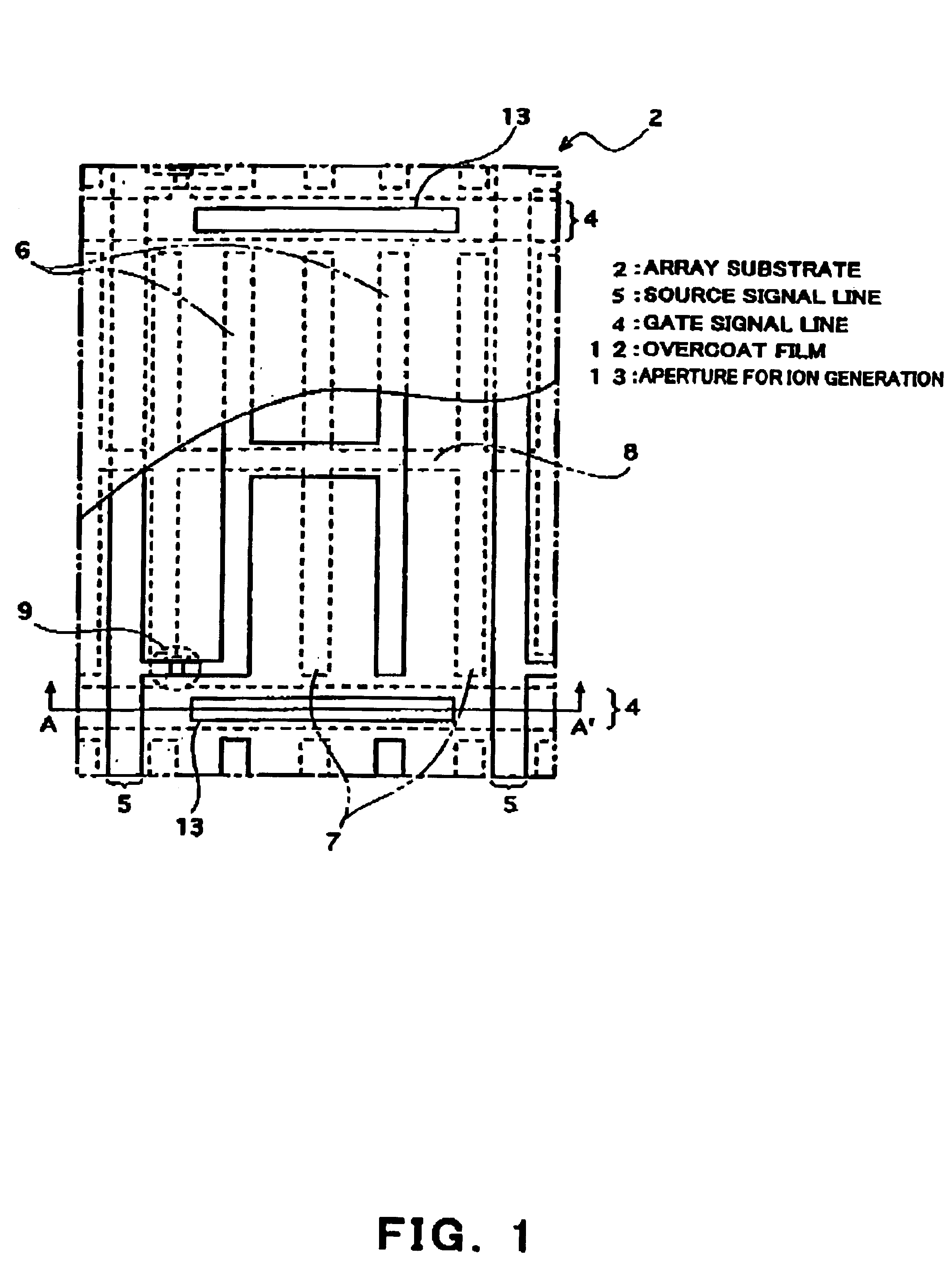

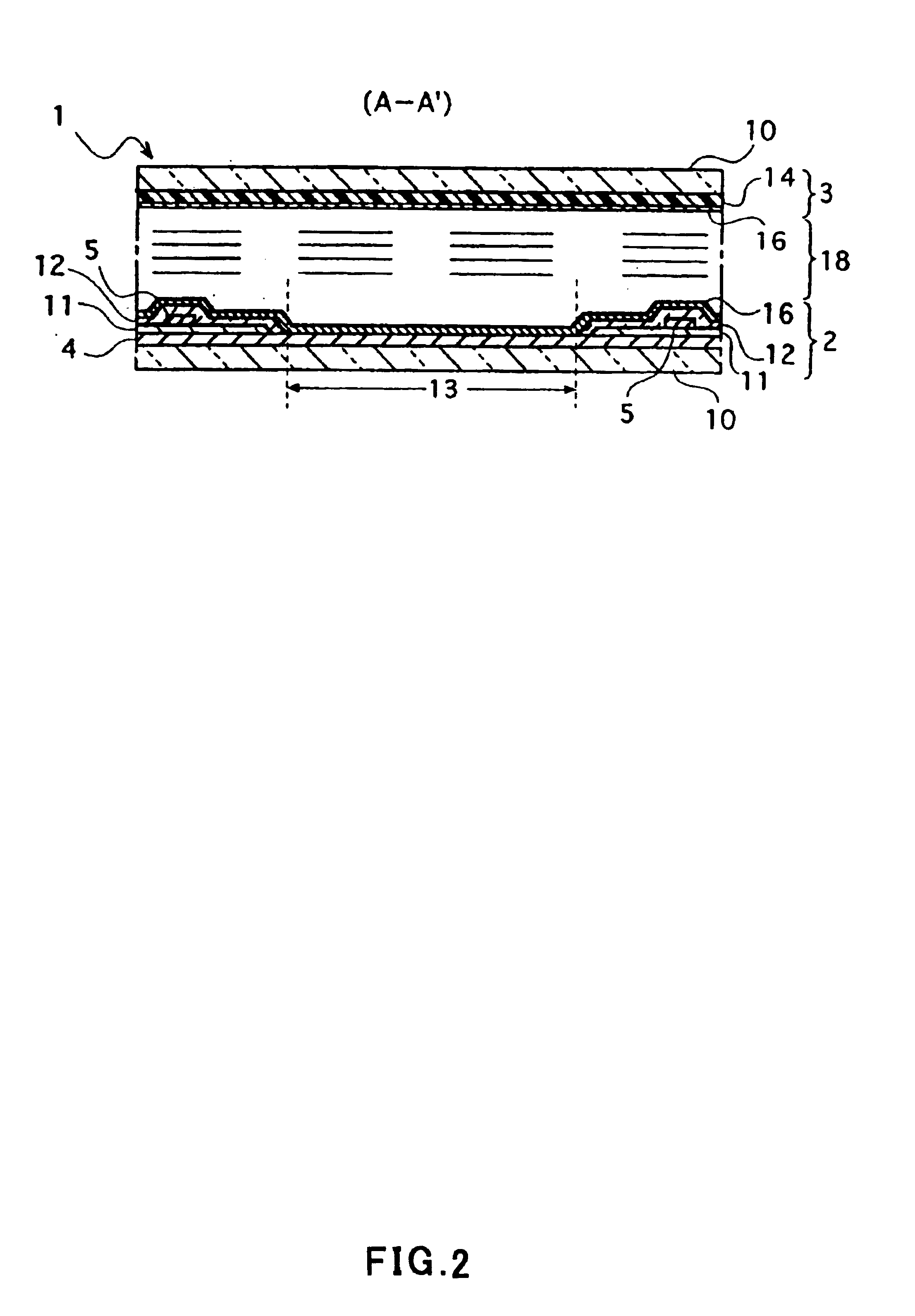

Liquid crystal screen display

InactiveUS6906769B2Avoid unevennessSatisfactory imageThin material handlingNon-linear opticsLiquid-crystal displayIon distribution

Owner:BISHOP DISPLAY TECH LLC

Zinc-based metal coated steel sheet

ActiveUS20130302637A1Improve adhesionImprove corrosion resistancePretreated surfacesAnti-corrosive paintsHydrogenEmulsion

A surface treatment liquid contains a resin emulsion that contains a cationic urethane resin emulsion and / or a nonionic acrylic resin emulsion, a tetraalkoxysilane, at least one silane coupling agent (c) that contains at least one reactive functional group selected from active hydrogen-containing amino group, an epoxy group, a mercapto group, and a methacryloxy group, a chelating agent (d), a vanadic acid compound (e), a titanium compound (f), and water in a specific ratio. The surface treatment liquid has a pH of 3 to 6. The surface treatment liquid is applied to a surface of a zinc-based metal coated steel sheet and dried by heating to form a first layer. Next, a surface treatment liquid containing an organic resin is applied to a surface of the first layer and dried by heating to form a second layer.

Owner:JFE STEEL CORP

Zinc-based metal coated steel sheet

ActiveUS9127366B2Improve corrosion resistanceInhibit progressPretreated surfacesAnti-corrosive paintsPolymer scienceMeth-

Owner:JFE STEEL CORP

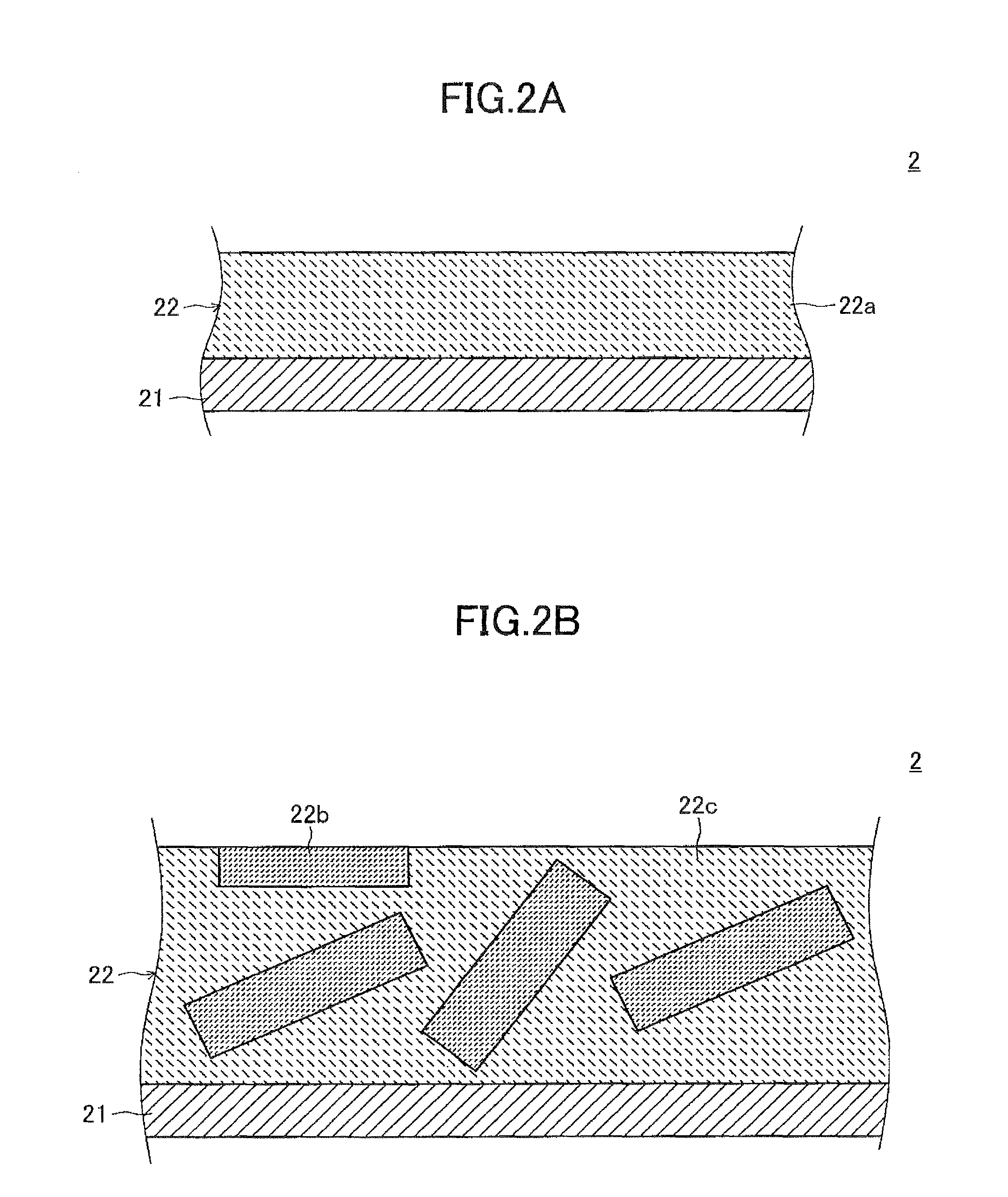

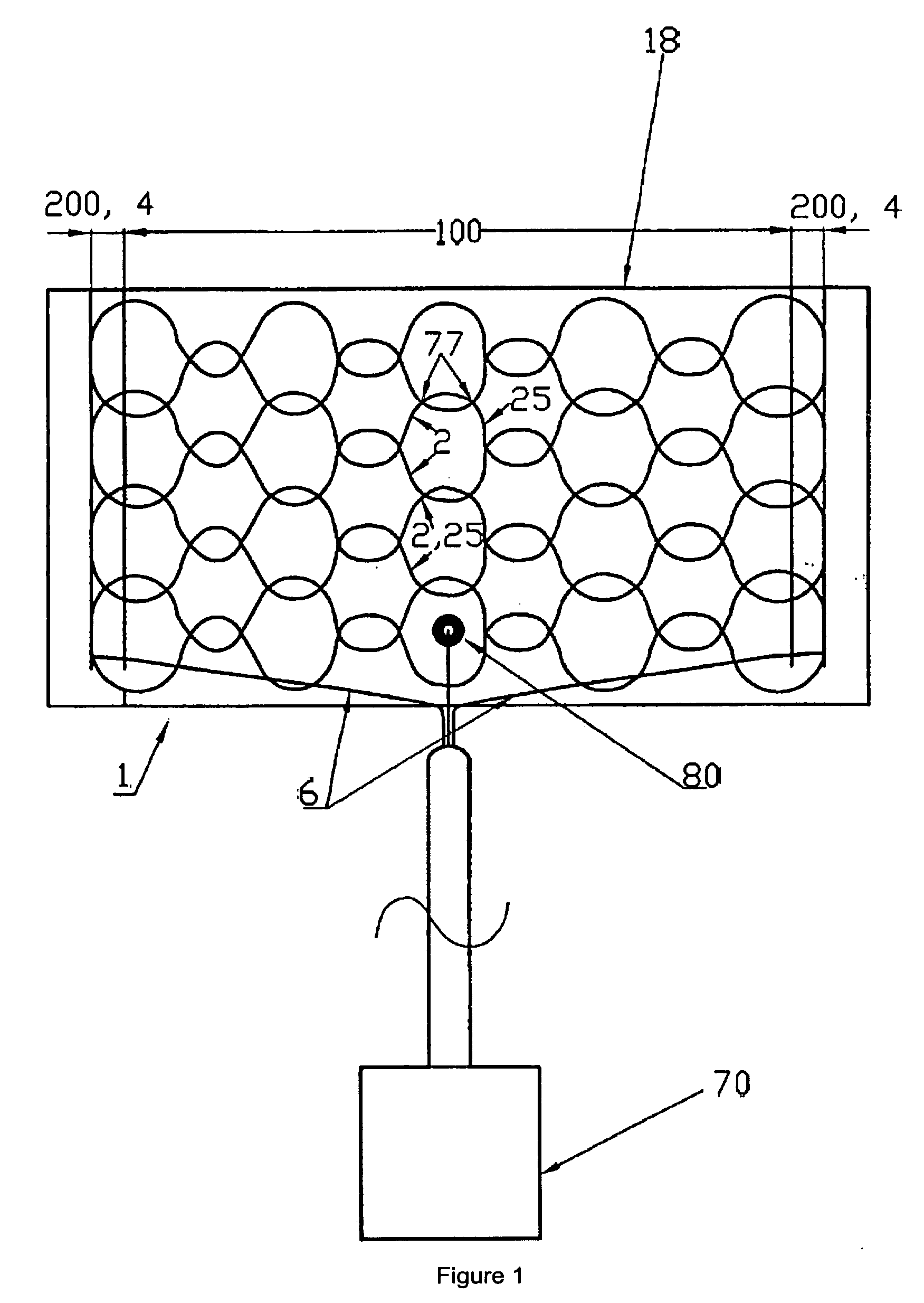

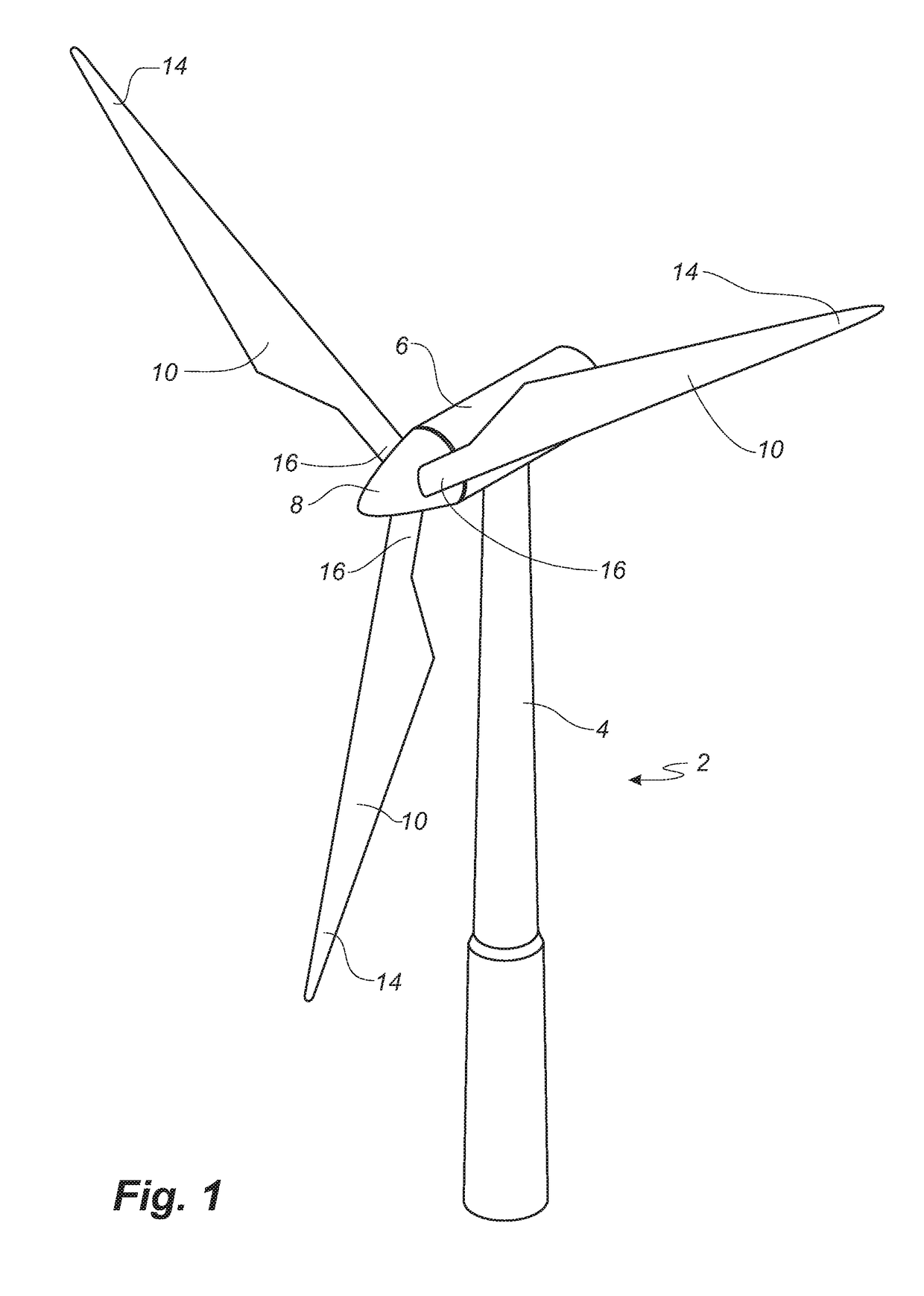

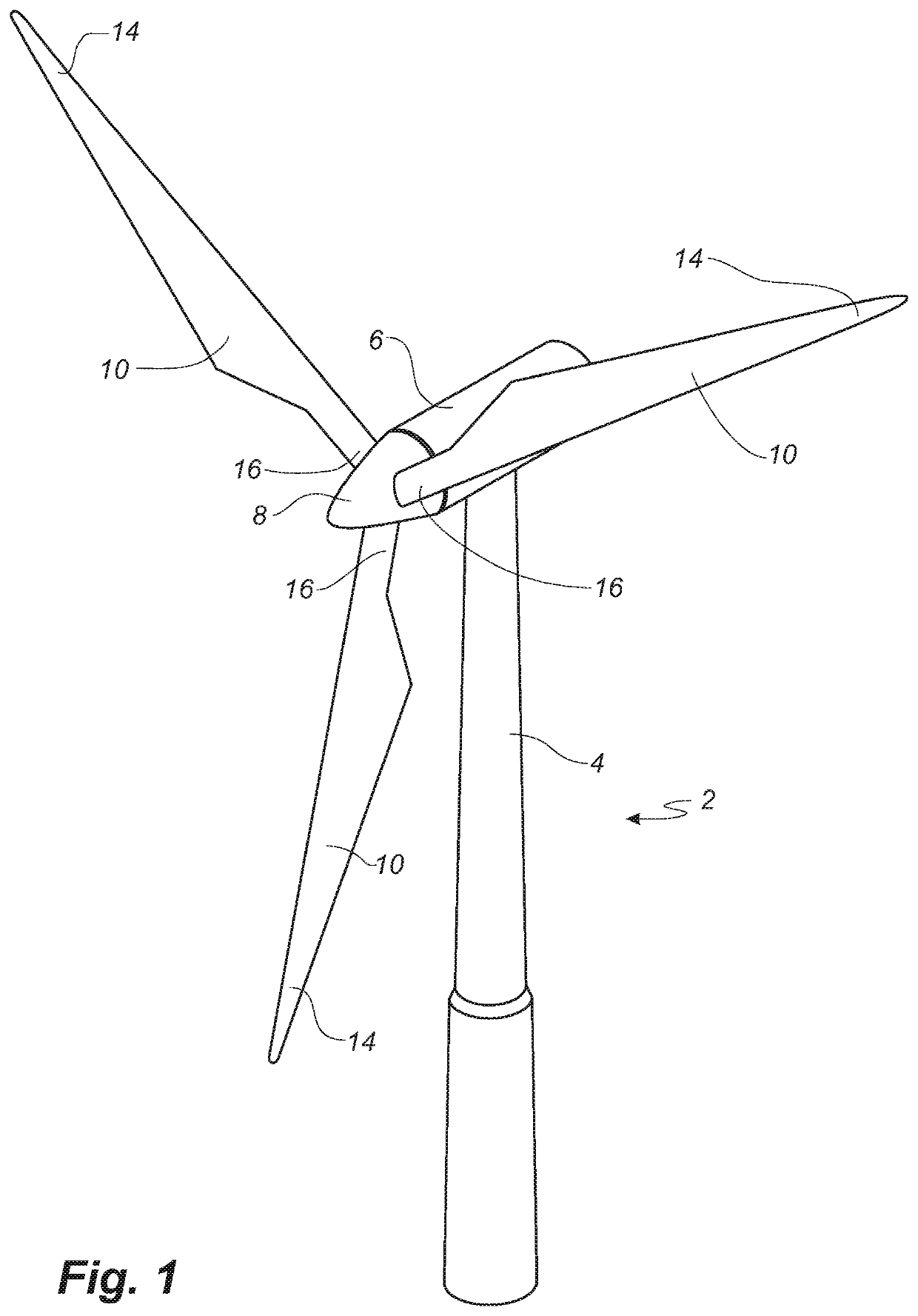

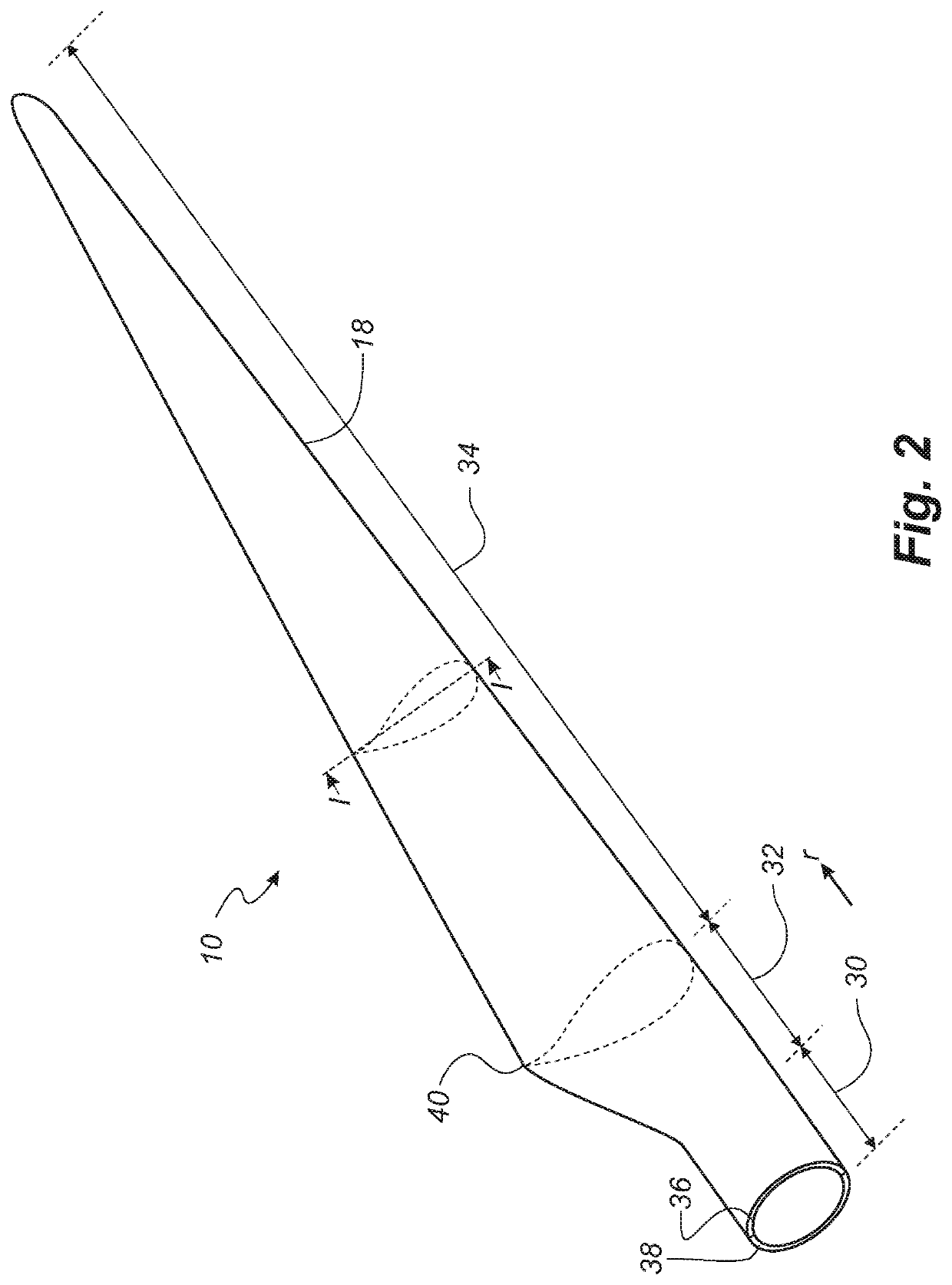

A method of manufacturing a composite laminate structure of a wind turbine blade part and related wind turbine blade part

ActiveUS20190001592A1Provide usageEasy to manufactureFinal product manufactureMachines/enginesTurbine bladeShell molding

A method of manufacturing a composite laminate structure of a wind turbine blade part is performed by resin transfer moulding. The fibre-reinforcement material is impregnated with liquid resin in a mould cavity which includes a rigid mould part having a mould surface defining a surface of the wind turbine blade part. The method includes alternately stacking on the rigid mould part: i) a number of fibre-reinforcement layers including electrically conductive fibres and ii) a flow strip layer in form of a layer of flow strips having a strip width and which are arranged so as to form voids having a void width between two juxtaposed strips. The method includes sealing a second mould part against the rigid mould part in order to form the mould cavity, optionally evacuating the mould cavity, supplying a resin to the mould cavity, and curing the resin to form the composite laminate structure.

Owner:LM WP PATENT HLDG

Liquid crystal screen display

InactiveUS6896940B2Avoid unevennessSatisfactory imageLiquid crystal compositionsThin material handlingLiquid-crystal displayIon distribution

A liquid crystal screen display is disclosed which is capable of restraining occurrence of display unevenness. In the display of the invention, a conductive member to which a negative voltage is applied is placed between a substrate and an alignment layer so as to be in partial contact with the alignment layer. Uneven ion distribution attributable to ion generation within broken or pin hole parts of an overcoat film is restrained, for instance, by exposing gate signal lines etc. to the alignment layer so that ions are intentionally generated in the regions of the liquid crystal layer corresponding to the exposed regions.

Owner:BISHOP DISPLAY TECH LLC

Electrical Connector Assembly and Method for Using the Same

ActiveUS20090227150A1Ensure conductivityElectric discharge tubesCoupling device detailsDistal portionEngineering

An electrical connector including a housing including an opening, a carrier assembly for receiving one or more leads from a wire assembly and extending via the opening, an annular gap between an inside surface of the opening and the carrier assembly, a shell including a hole for receiving the wire assembly, the shell adapted for slideable engagement with the housing in the annular gap, and wherein the slideable engagement between the shell and the housing severs a distal portion of a shield layer of the wire assembly and secures a proximal portion of the shield layer in the annular gap.

Owner:AMPHENOL CORP

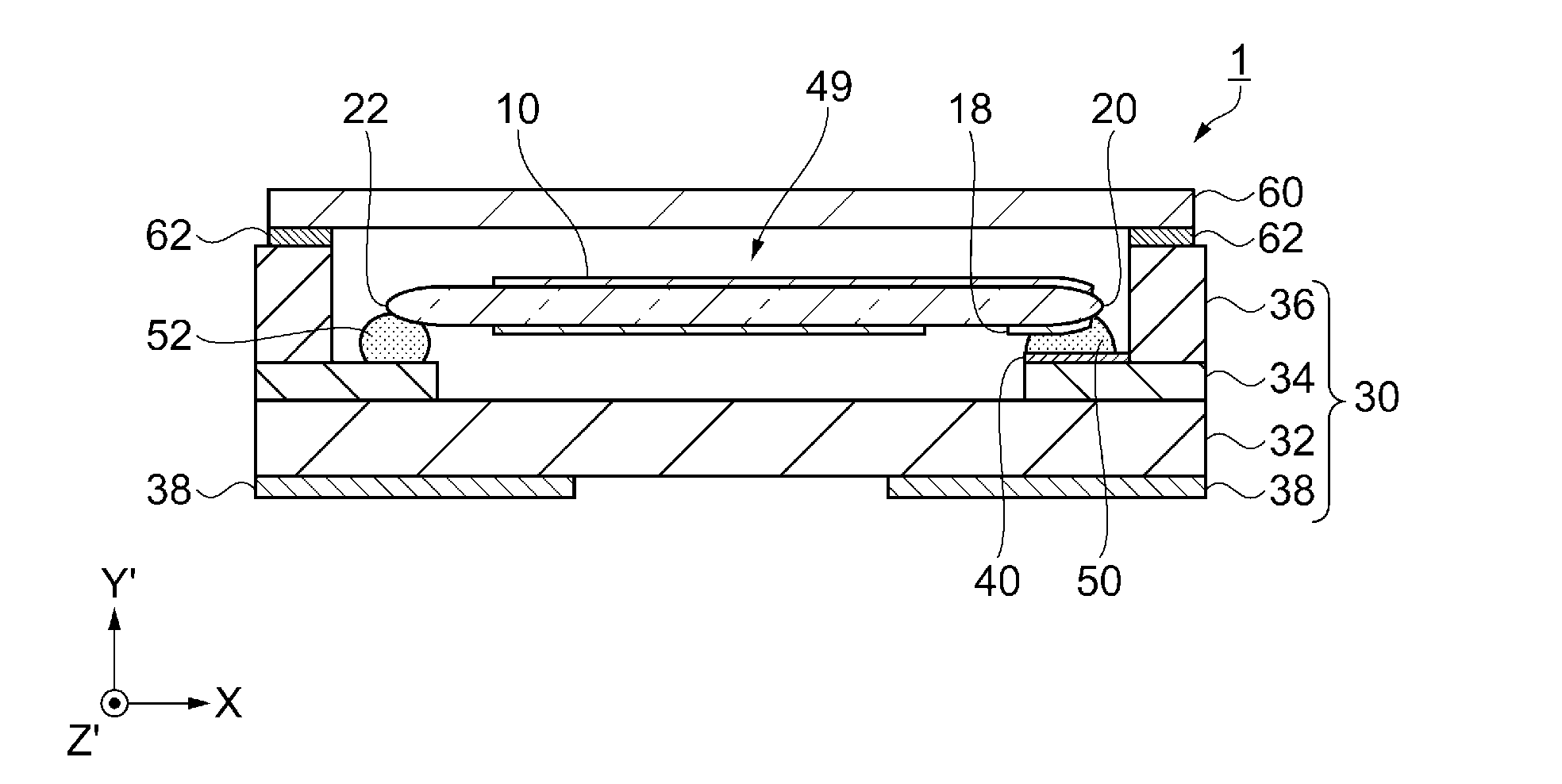

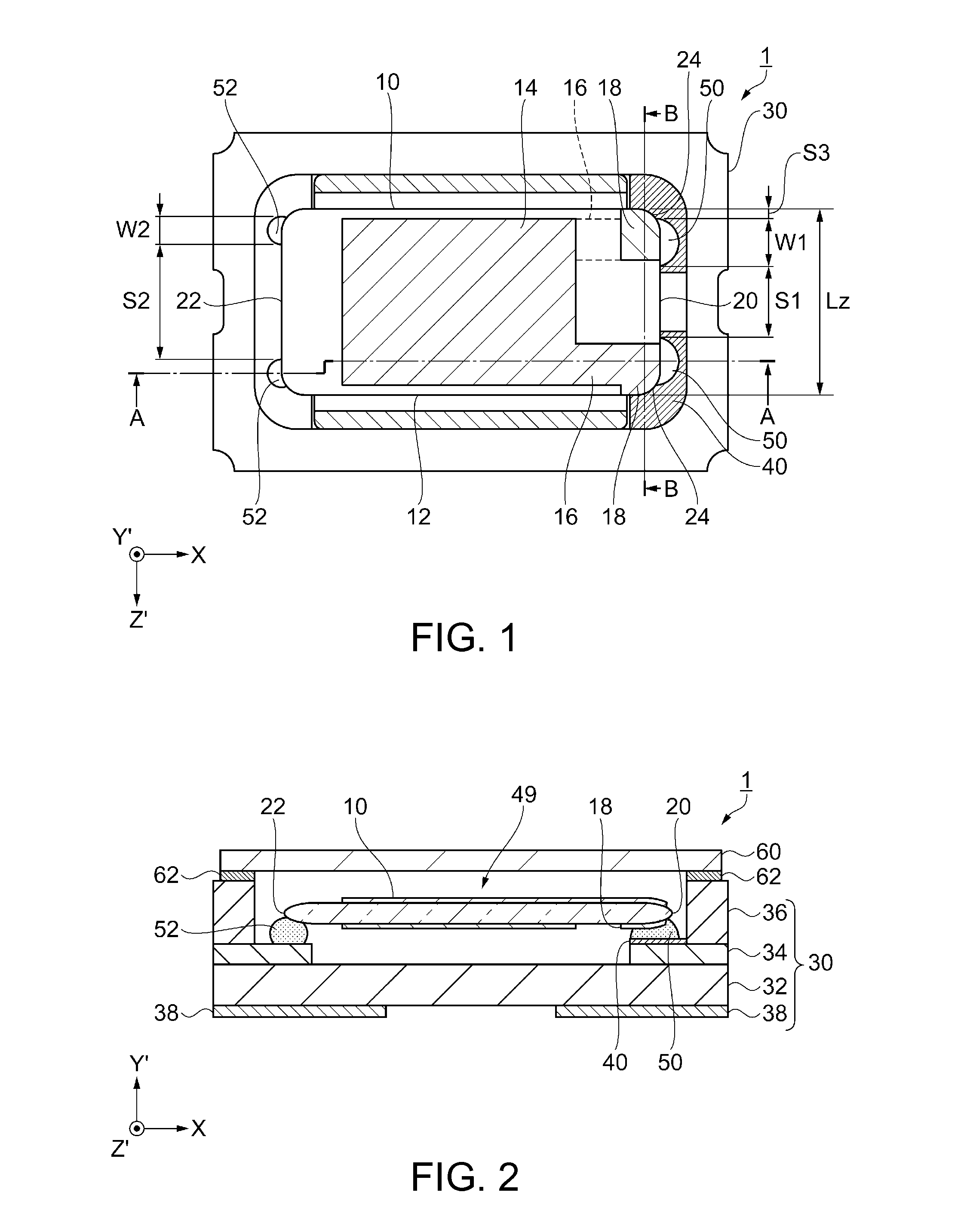

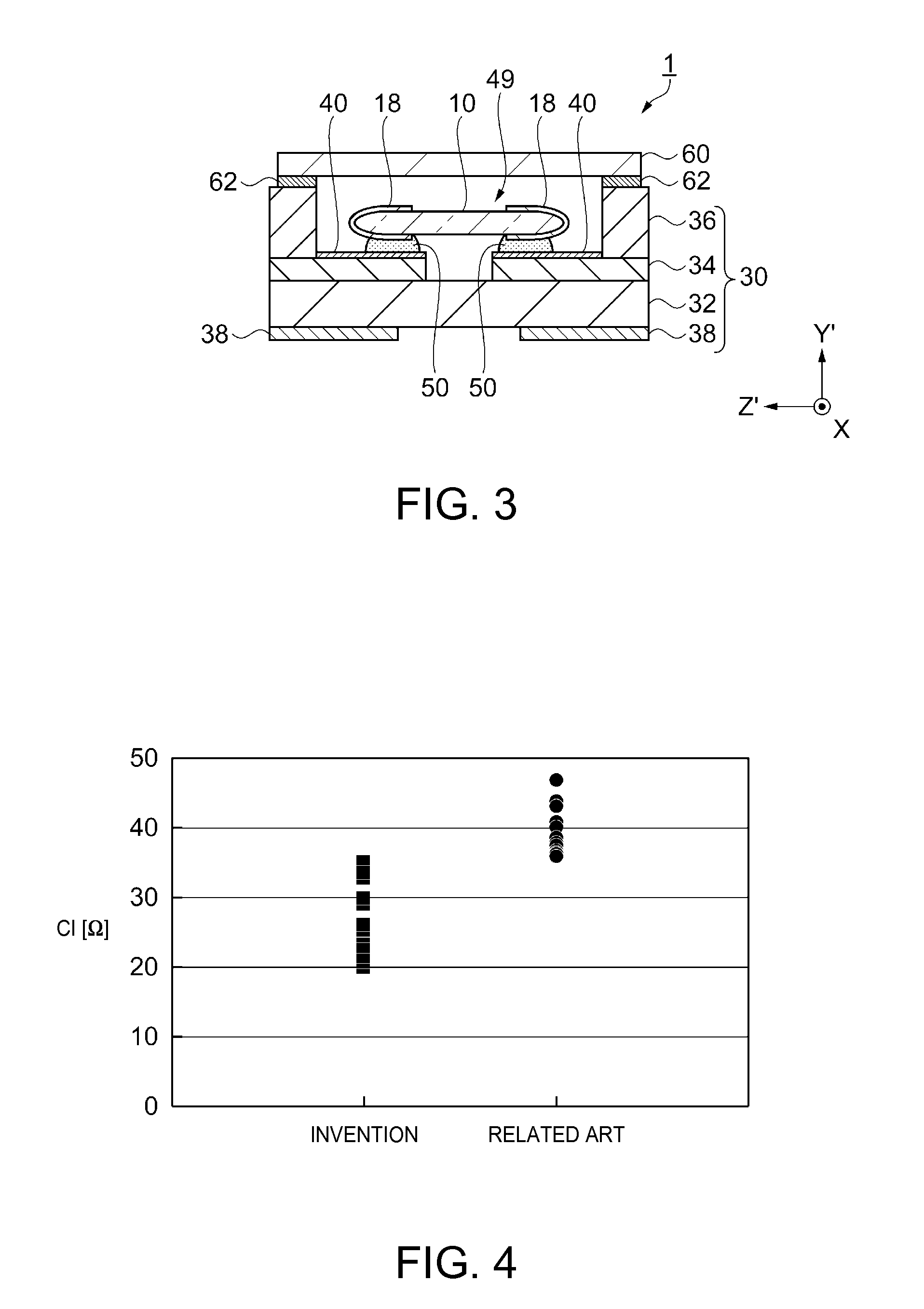

Resonator, oscillator, electronic apparatus, and mobile object

ActiveUS20160099401A1Improve reliabilitySolution value is not highImpedence networksPiezoelectric/electrostriction/magnetostriction machinesResonatorMolecular physics

A resonator includes a resonator element including a substrate gradually increasing in thickness from an outer edge toward a center, excitation electrodes respectively disposed on both principal surfaces of the substrate, and a pair of electrode pads electrically connected to the excitation electrodes, disposed on at least one of the both principal surfaces, and disposed on one end side of the substrate, and a second substrate as a base, the pair of electrode pads are bonded to the second substrate via respective first bonding members, two places of the other end of the substrate on the opposite side to the one end are bonded to the second substrate via respective second bonding members, and a distance S1 between the two first bonding members, and a distance S2 between the two second bonding members fulfill S1<S2.

Owner:SEIKO EPSON CORP

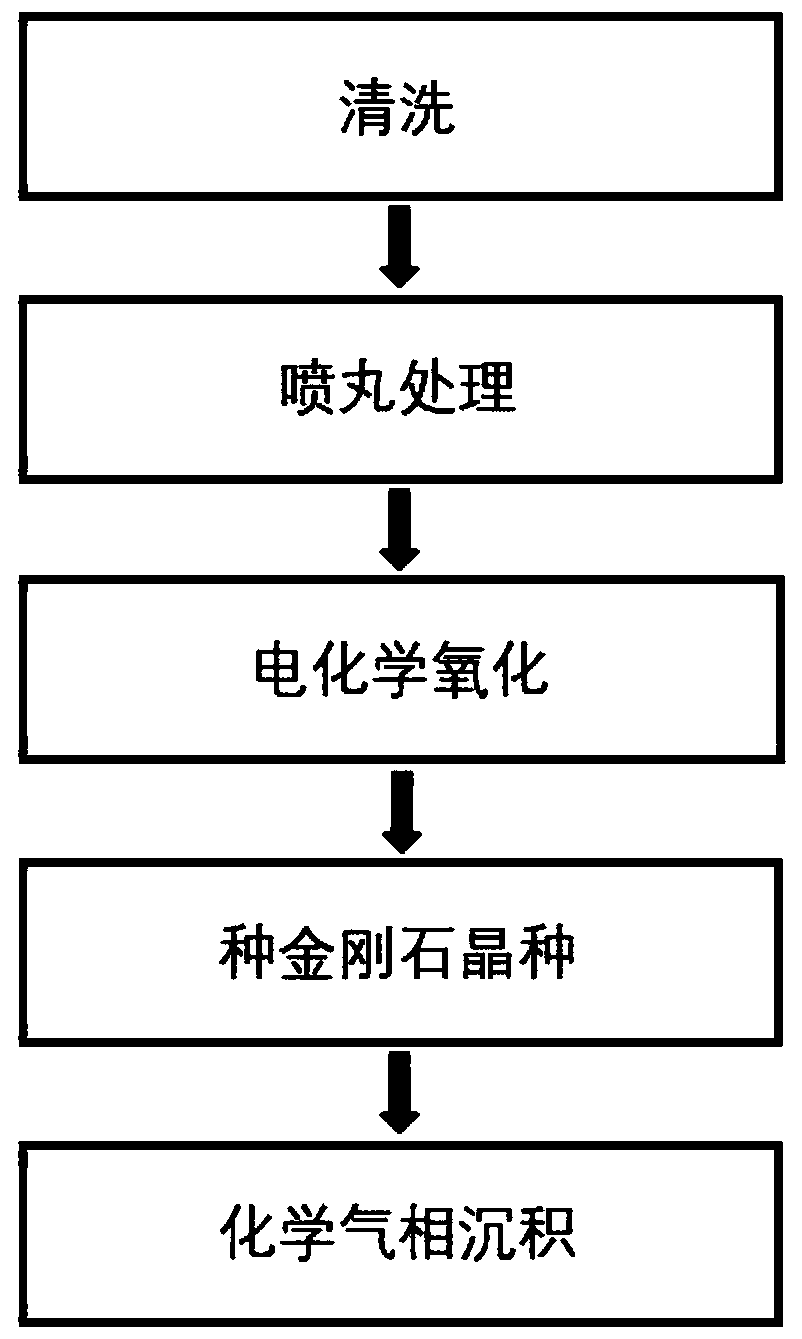

Preparation process of high-quality titanium-based boron-doped diamond film electrode

InactiveCN110184586AImprove macro roughnessImprove thermal expansion coefficient matchingSurface reaction electrolytic coatingChemical vapor deposition coatingDiamond electrodesDiamond crystal

The invention discloses a preparation process of a high-quality titanium-based boron-doped diamond film electrode. The preparation process of the high-quality titanium-based boron-doped diamond film electrode comprises the following concrete steps of (1) cleaning: cleaning a substrate; (2) shot blasting: using a shot blasting machine for shot blasting the cleaned substrate; (3) electrochemically oxidizing: infiltrating the shot-blasted substrate in an electrolytic tank, and oxidizing; (4) planting a diamond crystal seed: infiltrating the oxidized substrate into a boron-doped diamond crystal seed solution; and (5) carrying out chemical vapor deposition (CVD): placing the substrate planted with the diamond crystal seed in a hot wire CVD chamber. According to the preparation process of the high-quality titanium-based boron-doped diamond film electrode, the production cost of the diamond electrode is greatly reduced, a binding force between a diamond film and the titanium substrate is improved, the service life is prolonged, the preparation process is simple, and the mass production efficiency is improved at the same time.

Owner:莫兰

Liquid ejecting head, liquid ejecting apparatus, and piezoelectric element

ActiveUS20100007706A1Increased durabilityAvoid layeringPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusStress relievingEngineering

A liquid ejecting head includes a pressure generating chamber communicating with a nozzle opening, and a piezoelectric element generating a pressure change in the pressure generating chamber. In this liquid ejecting head, the piezoelectric element includes a first electrode, a piezoelectric layer provided above the first electrode, and a second electrode provided above the piezoelectric layer at a side opposite to the first electrode. The first electrode has a diffusion-preventing layer containing iridium oxide as a primary component, and the diffusion-preventing layer has stress relieving holes that pass through in the thickness direction thereof and that is filled with a material other than iridium oxide.

Owner:SEIKO EPSON CORP

Conductive foam for fingerprint identification

PendingCN108040456ALose weightReduce compressionShielding materialsSynthetic resin layered productsFiberPolyester

The invention discloses conductive foam for fingerprint identification. The conductive foam comprises foam serving as a core, wherein conductive fibers are arranged outside the foam to serve as a coating layer; the foam density is 10-50kg / m<2>; the conductive fibers comprise a polyester fiber base material, conductive layers formed by nickel, copper and nickel are sequentially arranged on one sideof the polyester fiber base material, and the other side of the polyester fiber base material is connected with the foam; and conductive two-sided adhesive is arranged on one side or two opposite sides of the outer side of the conductive fibers when the conductive fibers coat the foam. According to the conductive foam, the foam having the density of 10-50kg / m<2> is selected as a core, the compressing force can be effectively reduced; and in the structure of the conductive fibers, the conductive layers formed by nickel, copper and nickel are arranged on the polyester fibers, so that the conductive fibers with the structure have an extremely low gram weight which is 30-50g / m<2> and extremely low resistance which is less than 0.05ohms / inch<2>, so that the conductive foam has extremely low compressing force, relatively small resistance and extremely high pressing sensitivity, and is suitable for fingerprint identification.

Owner:昆山汉品电子有限公司

Electronic device covered by multiple layers and method for manufacturing electronic device

InactiveUS8796845B2Highly reliable electronic deviceImprove reliabilityImpedence networksSemiconductor/solid-state device detailsEngineeringElectron

Owner:SEIKO EPSON CORP

Liquid crystal panel for liquid crystal display device and the manufacture method of the same

InactiveUS20080178997A1Improve yield rateEfficient use ofLaminationLamination apparatusLiquid-crystal displayConductive materials

The invention discloses a liquid crystal panel used for liquid crystal display device and a method for manufacturing the same. The object of the invention is to provide a liquid crystal panel having the following structure in order to utilize effectively the peripheral portion of the liquid crystal panel: in a liquid crystal panel which is formed by sandwiching the liquid crystal between a TFT substrate configured with the pixels in a matrix shape and a CF substrate configured with the color filter and sealing the peripheral area with a seal material, the seal material is completely overlappingly disposed on the BM of the CF substrate, and in order to electrically connect said TFT substrate and said CF substrate, a conductive material is adjoined at the outer side of said seal material and is configured to overlap the BM completely, and a structure in which said BM only projects outwardly at the portion, where said conductive material is disposed, is formed. Wherein said conductive material comprises electric transfer isolation component with the electric transfer film disposed on the surface of the isolation component. Therefore, the reduction of the yield rate, which is caused by black matrix being cut off when the cut off line shifts slightly during cutting the substrate, can be decreased while the peripheral portion of the liquid crystal panel substrate is utilized effectively.

Owner:INFOVISION OPTOELECTRONICS HLDG LTD

Method of manufacturing a composite laminate structure of a wind turbine blade part and related wind turbine blade part

ActiveUS10723089B2Provide usageEasy to manufactureMachines/enginesEngine componentsTurbine bladeComposite laminates

Owner:LM WP PATENT HLDG

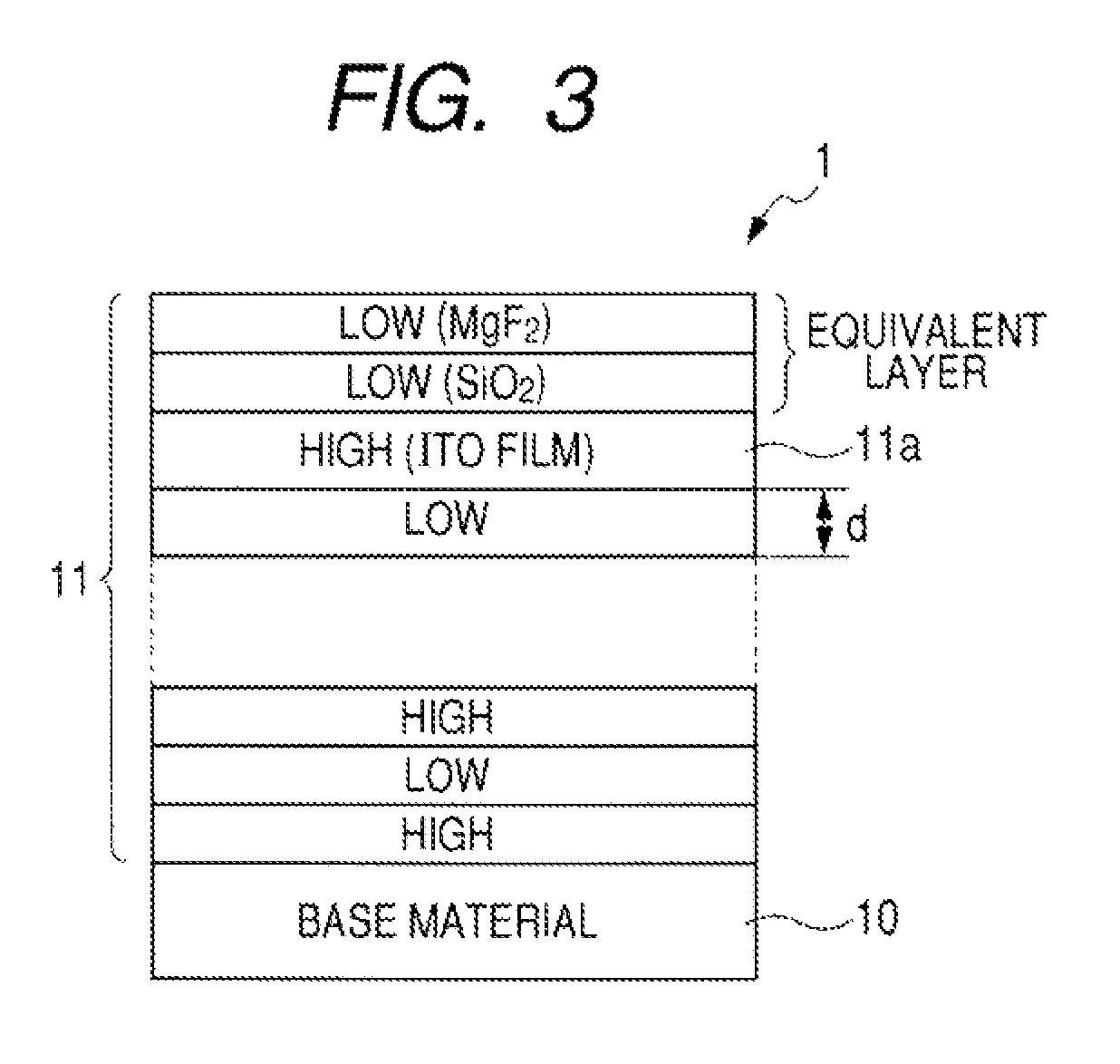

Optical low-pass filter

ActiveUS8437084B2Effectively prevent attachmentCost containmentTelevision system detailsMirrorsBand-pass filterConductive materials

On the light-entering surface side of a base material 10, a coating layer 11 in which a high-refractive layer and a low-refractive layer are sequentially disposed alternately on one on the other is provided for blocking infrared radiation. One of the high-refractive layers is configured by an ITO film 11a so that the conductivity is increased on the surface of the coating layer. Herein, in view of preventing, to a further extent, the attachment of dirt and dust by providing the conductivity to the surface of the coating layer, it is desirable if the outermost high-refractive layer is made of a transparent conductive material. Moreover, it is desirable if the total layer thickness is 140 nm or smaller for the refractive layers formed outside of the high-refractive layer made of the transparent conductive material.

Owner:SONY CORP

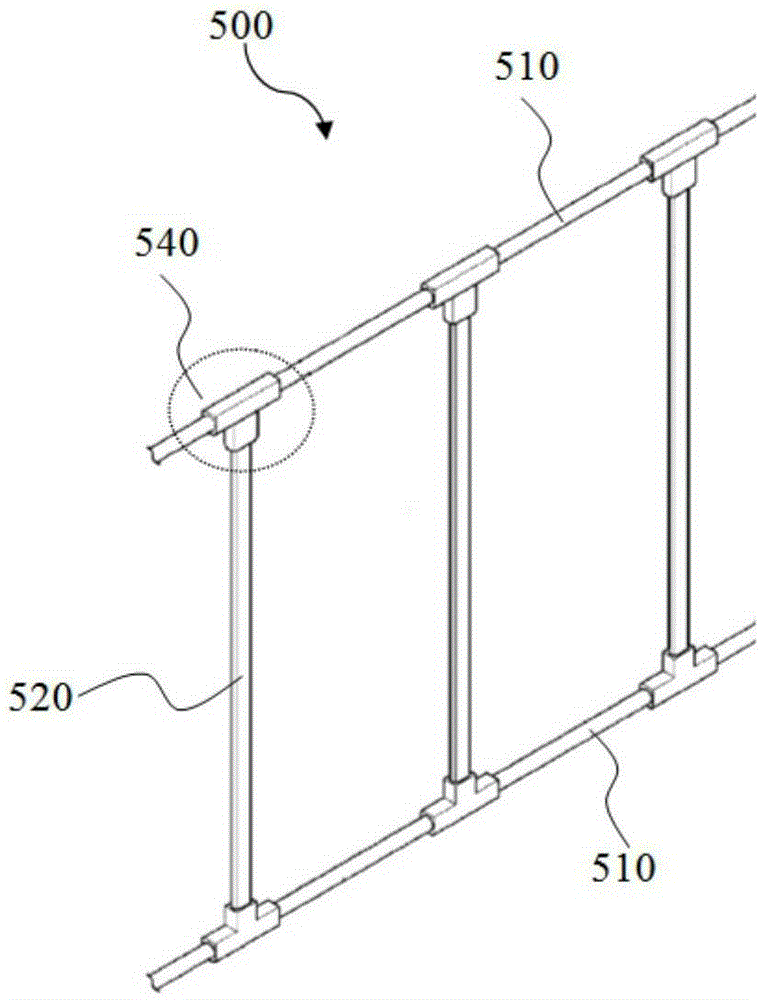

Photovoltaic interconnect wire

ActiveUS20160336471A1Minimize loss current collection efficiencyEnsure conductivityWelding/cutting media/materialsPhotovoltaic energy generationSolar cellBattery bank

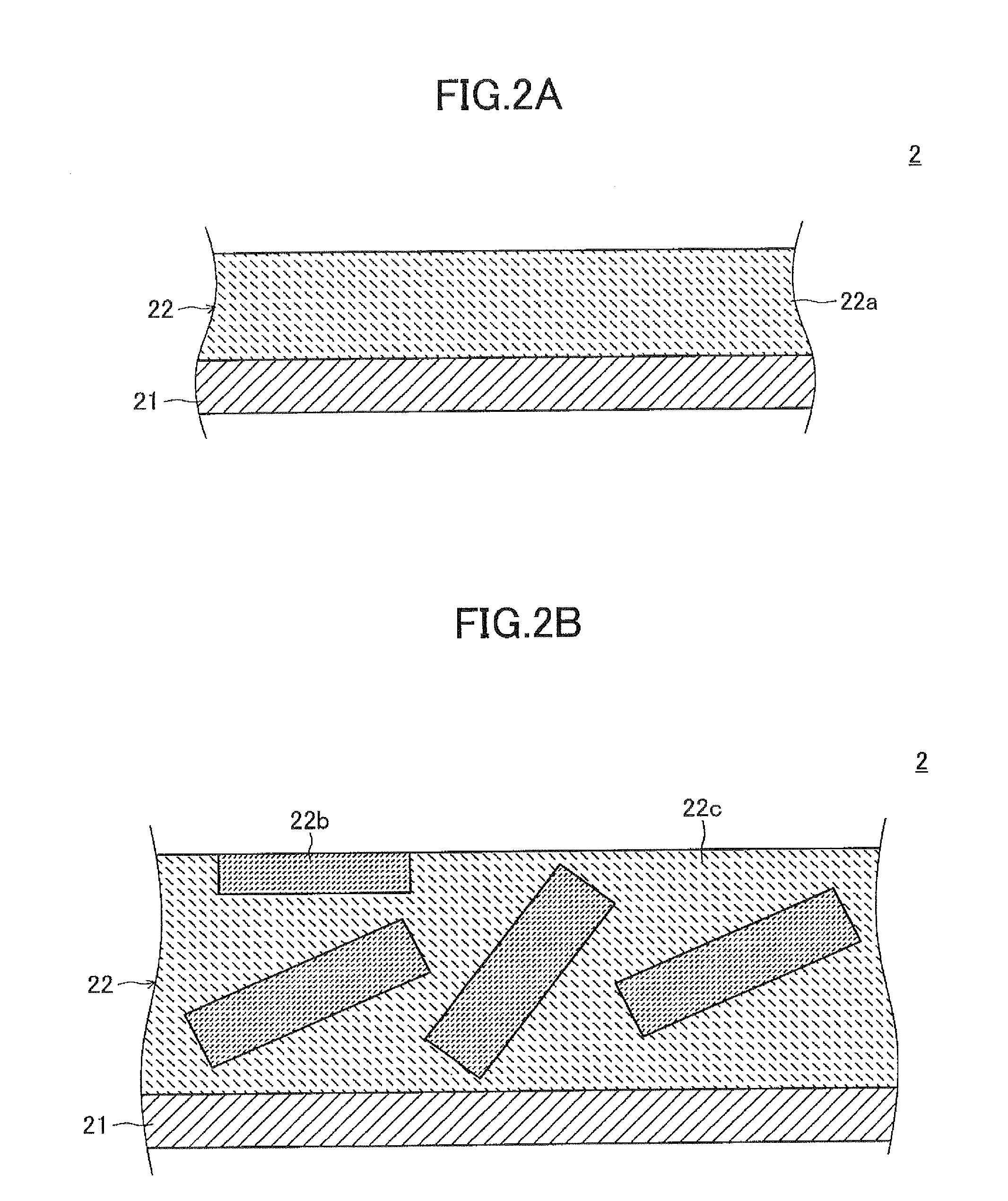

A photovoltaic interconnect wire includes a conductive base strip with grooves provided thereon, and the grooves are linear and / or curved strip-shaped grooves (3) arranged obliquely to a longitudinal direction of the conductive base strip. An inclination angle of 15° to 75° is present between each linear strip-shaped groove and the longitudinal direction of the conductive base strip, and between a tangent line of any point on the curve of a curved-shaped groove and the longitudinal direction of the conductive base strip. The photovoltaic soldering strip increases an output power of a solar cell assembly by increasing the total reflection proportion. It also ensures soldering fastness by adjusting flat regions of the base strip. Effective cross section loss of the conductive base strip is reduced by adjusting the angle of each groove, so as to minimize the confluence efficiency loss of the soldering strip.

Owner:FUNDANT JIANGSU ADVANCED MATERIALS CO LTD

Carbon thermal rail production line and carbon thermal rail production method

InactiveCN105423404AIncrease productivityLow costLighting and heating apparatusElectric heating systemProduction lineControl system

The invention relates to a carbon thermal rail production line and a carbon thermal rail production method. The carbon thermal rail production line comprises a bookbinding system, a connector packaging system and a control system, wherein the bookbinding system is used for bookbinding power lines and carbon rods in a carbon thermal rail; the connector sealing system is connected with the bookbinding system, and is used for packaging the connection parts between the power lines and the carbon rods in the carbon thermal rail; and the control system is connected with the bookbinding system and the connector packaging system and controls the bookbinding system and the connector packaging system. The carbon thermal rail production line can complete the bookbinding and connector packaging of at least 500 carbon rods and power lines per hour, so that the production efficiency of the carbon thermal rail can be improved greatly, and the cost is reduced.

Owner:北京中科联众科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com