Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Good sand resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alcohol-group coating for V-method casting and preparation method thereof

The invention discloses an alcohol-group coating for V-method casting, wherein the coating is powdery or granulous and is formed by blending 100 parts of fire-resistant powder and 10-14 parts of composite sizing agent by weight. Meanwhile, the invention further discloses a method for preparing the alcohol-group coating for V-method casting. Compared with the prior art, the costing disclosed by the invention is powdery or granulous, so that the advantages of convenience and safety in transportation are achieved; the packaging cost is low because barrels are not required for package; the transportation cost is low because the phenomenon of sediment hardening does not occur during the transportation so as not to result in material scrap; meanwhile, the coating further has the advantages that the adhesion and bond strength of a coating layer is high, the capability of resisting metal fluid machinery and thermal shock is strong, the drying time is short, the production efficiency is high, and the sand cohesiveness resistance is excellent.

Owner:NINGBO CANGHAI NEW MATERIALS DEV

Magnesium aluminium spinel powder alcohol-based coating for heavy section steel castings and preparation method thereof

The invention discloses a magnesium aluminum spinel powder alcohol-based coating for heavy section steel castings, and relates to a casting coating. The alcohol-based coating comprises the following components in percentage by weight: 55 to 60 percent of magnesium aluminium spinel powder, 0.5 to 1.2 percent of binder, 0.11 to 0.18 percent of suspended thickening agent, 1.1 to 1.8 percent of suspending agent, 2.7 to 4.2 percent of fluxing agent, and the balance of organic solvent. In the magnesium aluminum spinel powder alcohol-based coating, the particle size of the magnesium aluminum spinel powder is between 270 and 320, and Al2O3 is more than or equal to 78 percent. The magnesium aluminum spinel powder is synthesized by electric smelting technology, has the characteristics of low expansion and high smelting point, and meets the requirement of serving as refractory aggregate of the coating for the steel castings; and the magnesium aluminum spinel powder has obvious price and resource advantages than zircon powder.

Owner:CHINA YITUO GROUP

Environment-friendly alcohol group ceramic casting coating

ActiveCN104439049AGood sintering peeling propertiesImprove peeling effectFoundry mouldsFoundry coresSolventAluminium

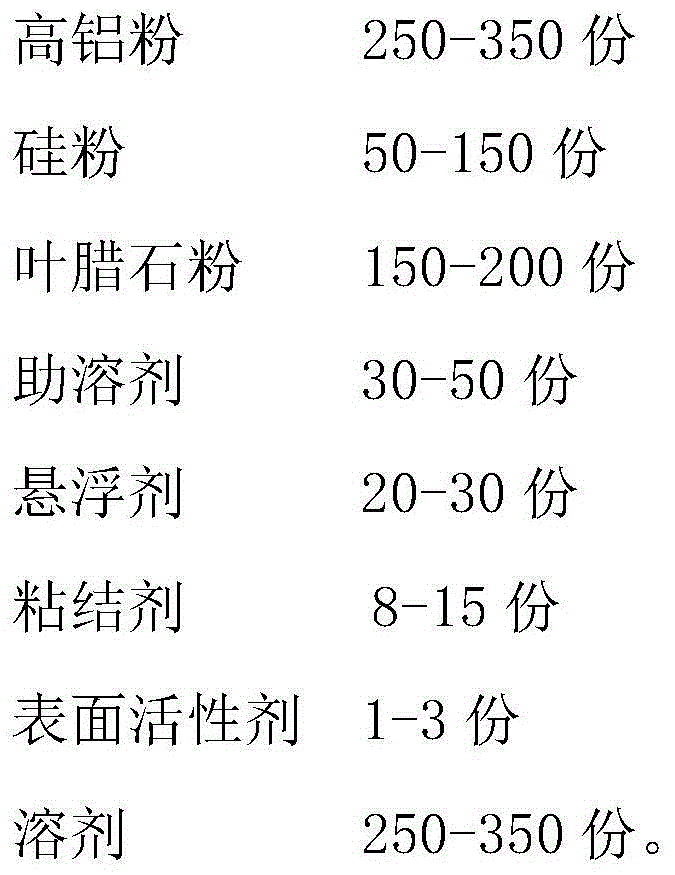

The invention provides an environment-friendly alcohol group ceramic casting coating. The environment-friendly alcohol group ceramic casting coating comprises, by weight, 250-350 parts of high-alumina powder, 50-150 parts of silica powder, 150-200 parts of pyrophillite powder, 30-50 parts of cosolvent, 20-30 parts of suspending agents, 8-15 parts of binding agents, 1-3 parts of surfactant and 250-350 parts of solvent. The environment-friendly alcohol group ceramic casting coating overcomes the defects in the prior art and is high in refractoriness, good in sintering stripping effect, low in price and excellent in comprehensive performance.

Owner:TIANJIN NINGKANG TECH

Cast steel alcohol-based paint, as well as preparation and application method thereof

ActiveCN103769530AHigh strengthExcellent resistance to moisture absorptionFoundry mouldsFoundry coresPolyvinyl alcoholSolvent

Owner:SHANGHAI ZONGHUA IND

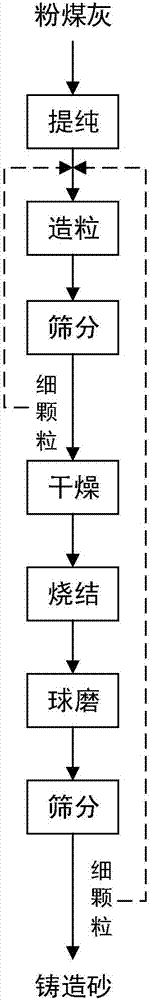

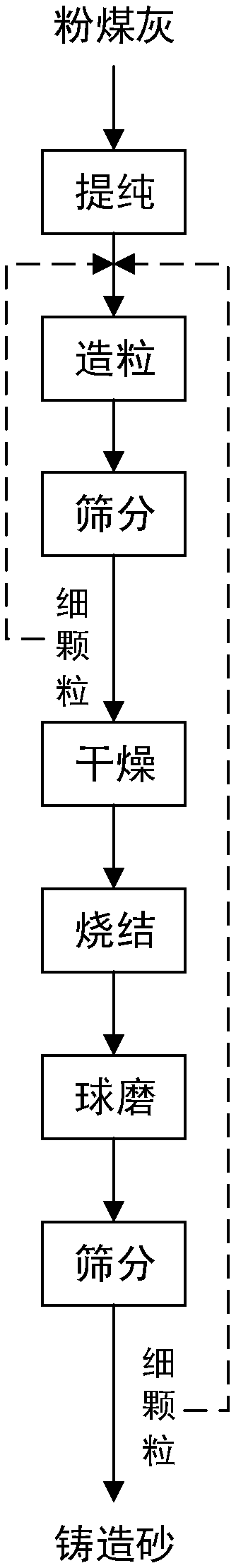

Method for producing precise foundry sand from high-aluminum coal ash

ActiveCN107199310AHigh refractorinessImprove liquidityFoundry mouldsMould handling/dressing devicesFoundryAcid washing

The invention provides a method for producing precise foundry sand from high-aluminum coal ash. The method comprises the following steps of: purifying high-aluminum coal ash, pelletizing, drying, roasting and post-treating the purified high-aluminum coal ash to obtain the precise foundry sand, wherein the step of purifying the precise foundry sand adopts an acid activation-alkali desilicication-diluted acid washing process. The precise foundry sand obtained by the method has the advantages of good mobility, high refractoriness, high strength, a low thermal expansion coefficient, good sand sticking resistance, solves the raw material problem in a production process of the precise foundry sand, successfully treats industrial solid waste, achieves the purpose of changing waste into things of value, and has a good economic and social value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

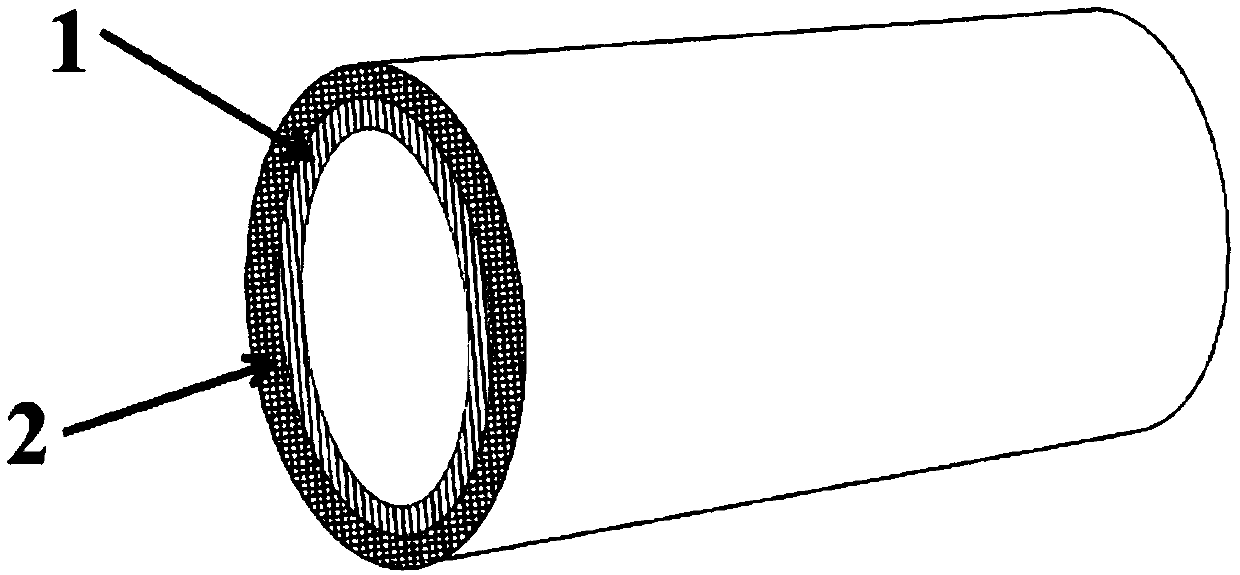

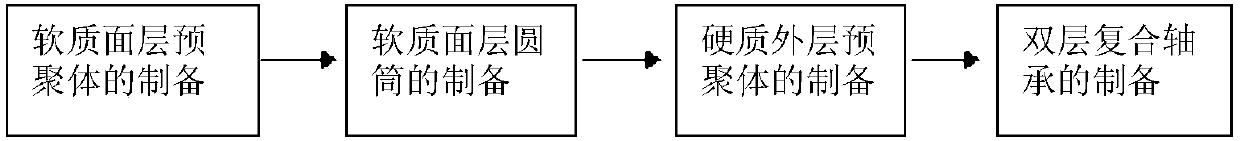

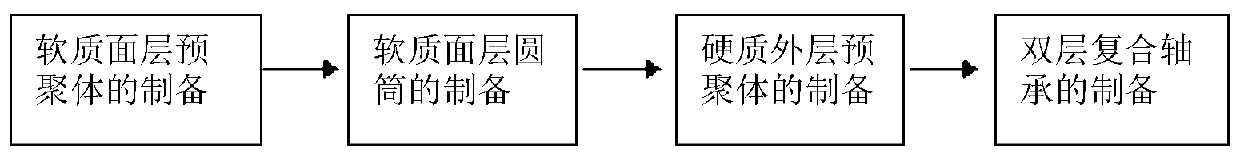

Preparation method of polyurethane composite bearing of double-layer structure

ActiveCN107725601APlay a supporting roleImprove impact resistanceShaftsBearing componentsSurface layerCylinder mold

The invention discloses a preparation method of a polyurethane composite bearing of a double-layer structure and belongs to the technical field of sliding bearings. The polyurethane composite bearingis composed of a hard polyurethane outer layer (2) achieving the supporting and bearing effects and a soft polyurethane surface layer (1) with the self-lubricating and anti-abrasion functions. Firstly, a cylinder mold is adopted, the soft surface layer is cast through a centrifugal casting method, and the outer surface of the surface layer is ground, cleaned, dried, and then coated with an adhesion agent to serve as a mold core; and then the hard outer layer is cast on the outer surface of the surface layer, and the bearing is formed by adhering and composing the layers through the adhesion agent. According to the preparation method of the polyurethane composite bearing of the double-layer structure, the bearing has the technical characteristics of being high in bearing, capable of achieving water-breaking operation within a short time, resistant to silt, easy to machine, low in cost and the like, and the domestic market vacancy is made up; and a composite material integrally has the excellent properties of being resistant to changing of the high and low temperature and hydrolysis and the like, the service life is long, and the polyurethane composite bearing can be widely applied to the rotary or swing sliding portions of water pumps, propeller stern bearings, rudder bearings and the like.

Owner:BEIHUA UNIV

Production technique of sand-type water based paint for casting

ActiveCN102773405ARaw materials are uniqueUnique process methodFoundry mouldsFoundry coresWater basedSuspending Agents

The invention relates to a manufacturing method in a production technique of paint for casting, in particular to a production technique of sand-type water based paint for casting, wherein the sand-type water based paint belongs to a casting accessory. The production technique comprises the following steps of: adding water, tributyl phosphate and CMC (carboxy methylated cellulose) in a dissolving pot firstly, stirring uniformly, dissolving the materials completely; filtering insoluble materials by a filter screen; adding water, sodium benzoate, a sodium base bentonite suspending agent, acetic acid and reducing glue in a stirring kettle, starting up electric stirring; slowly adding white corundum, sodium lignin sulfonate and water in the stirring kettle, stirring for 15-20min; adding water on the basis of the dilution situation, wherein the baum degree of the paint is higher than 95 after being stirred uniformly; transferring the paint prepared by the steps in a colloid mill, continuously milling for 2h, discharging and packaging into barrels to obtain the paint. The invention provides the novel production technique of the sand-type water based paint for casting, which has the following characteristics of environment friendliness, high coating strength and excellent painting property.

Owner:共享新材料(山东)有限公司

Pouring technology for marine propeller

InactiveCN105817587AGood sand resistanceReduce the amount addedMelt-holding vesselsFoundry mouldsStart timePropeller

The invention discloses a pouring process for a marine propeller, which solves the problem that air bubbles are easily formed on the surface of the propeller due to the simple pouring process. The key points of the technical scheme are the following steps: determining the opening time of the blast furnace; preparing the sprue cup; and preparing the pouring ladle; Pouring operation; the inspector records the pouring temperature, pouring time, pouring sequence and the pouring status of each product during the entire pouring process, so that the propeller cast by this process has a firm texture, a smooth surface, and no air bubbles inside. Effect.

Owner:TAIZHOU JIAOJIANG YONGGU SHIP PROPELLER FACTORY

Alcohol-based coating for large castings and preparation method of alcohol-based coating

ActiveCN107971455AImprove technical performanceImprove uniformityFoundry mouldsFoundry coresSodium BentoniteNuclear power

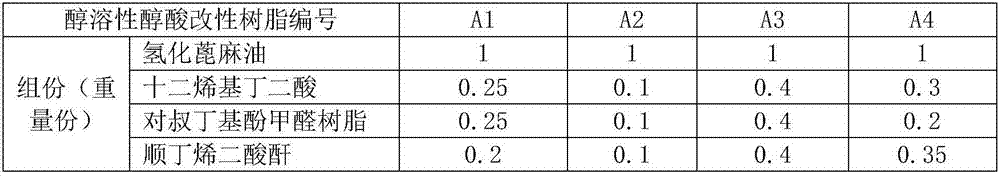

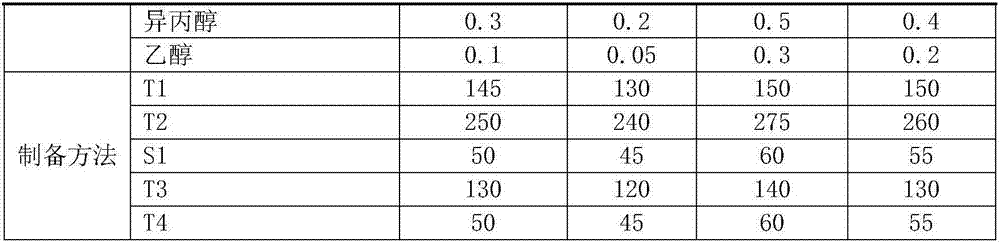

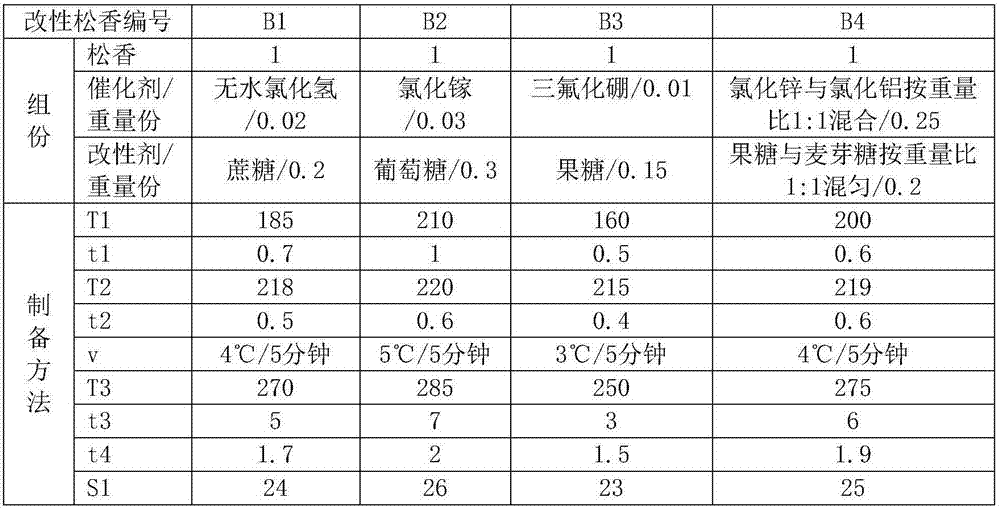

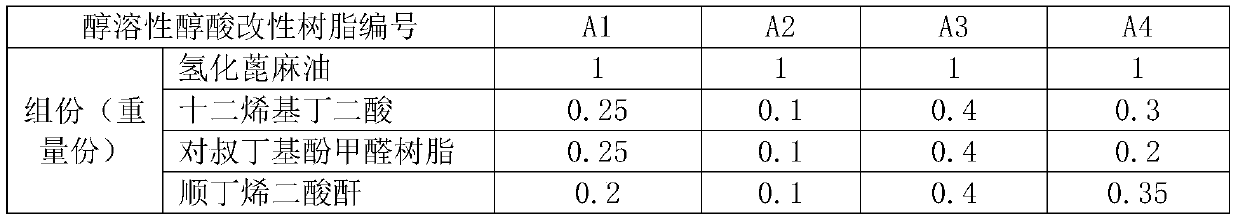

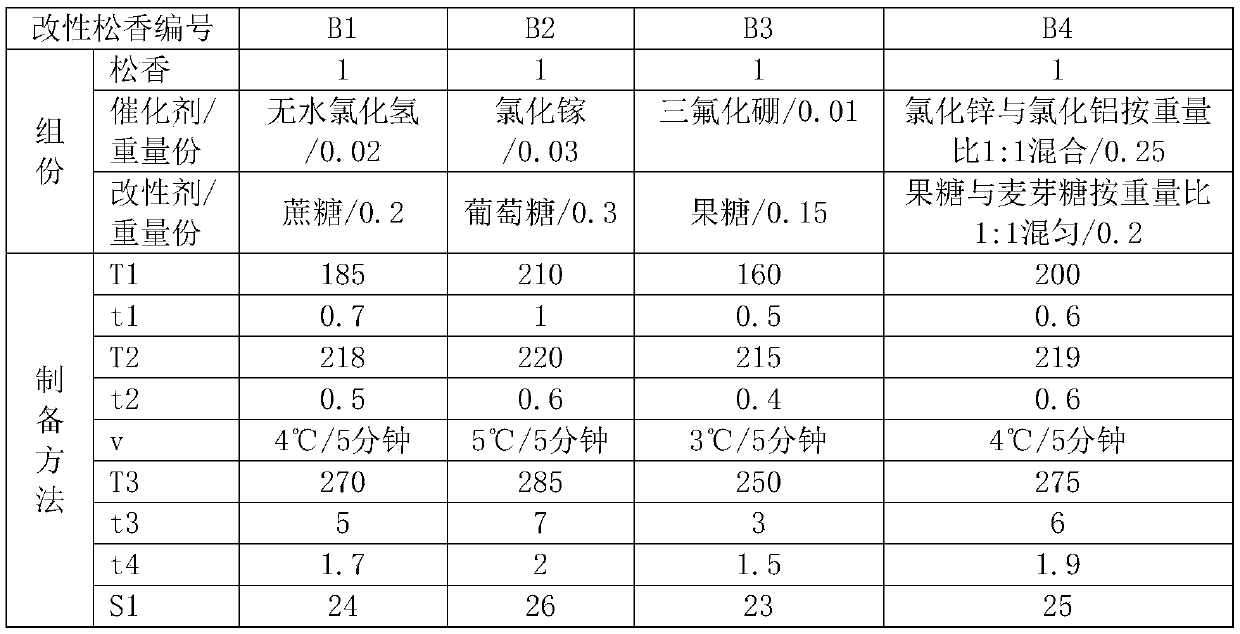

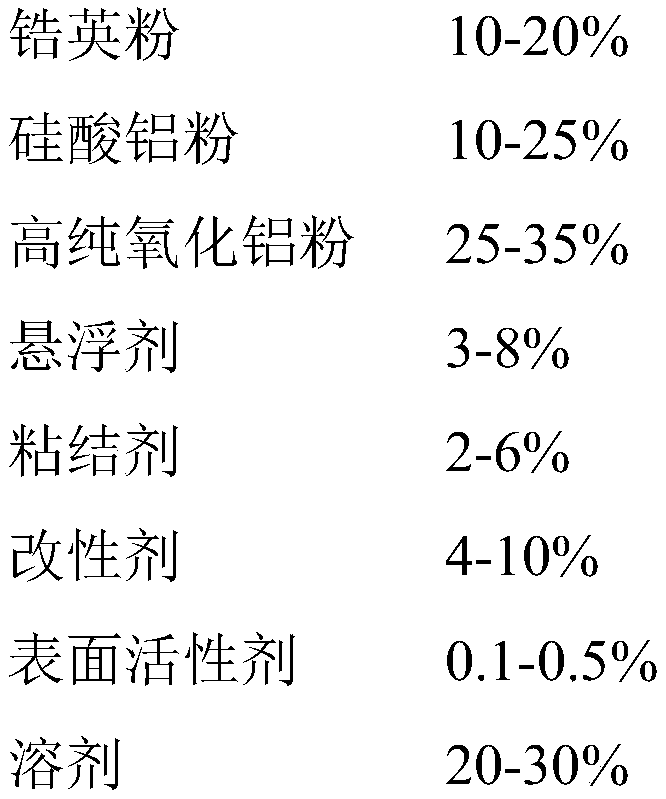

The invention relates to alcohol-based coating for large castings and a preparation method of the alcohol-based coating, in particular to casting coating for large nuclear power steel castings for basic phenolic resin sand molding production, and belongs to the field of casting coating. The casting coating is prepared from modified zirconium powder, lithium-based bentonite paste, magnesium aluminum silicate paste, alcohol soluble alky acid modified resin, modified rosin, low-viscosity polyvinyl butyral resin and carrier liquid. As for the coating, the suspension property (24 hours) is larger than 98%, the adhesive force is level 1, the gas volume is smaller than 10 ml / g, the solid content is larger than 73%, the coating abrasion performance is 0.06 g, and no burnt-on sand exists on the surfaces of the nuclear power castings of 200 tons of molten steel or above.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Formula of water-based dip-coating coating special for precoated sand

ActiveCN108246968ASuperior Light FastnessPrevents veining defectsFoundry mouldsFoundry coresBrown iron oxideAluminum magnesium silicate

The invention provides a formula of a water-based dip-coating coating special for precoated sand. The formula comprises refractory aggregate, a bonding agent, a suspending agent, a surface active agent and a carrier. The refractory aggregate comprises mullite, iron oxide red, kunzite and ball clay powder. The bonding agent comprises polyvinyl alcohol and silica gel. The suspending agent compriseslithium-based bentonite and aluminum-magnesium silicate. The surface active agent comprises a water-based antifoaming agent, a wetting agent and a penetrant. By means of the water-based coating prepared through the formula, the surface quality of sand cores cast through the precoated sand is obviously improved, and the surfaces of the sand cores are smooth and low in roughness; and meanwhile the wetting agent is added into the formula, the surface tension of the coating can be reduced, and the adhesive force of the water-based coating can be improved.

Owner:TIANJIN NINGKANG TECH

Alcohol-group coating for V-method casting and preparation method thereof

ActiveCN102527928BImprove adhesion strengthHigh bonding strengthFoundry mouldsFoundry coresDrying timeBond strength

The invention discloses an alcohol-group coating for V-method casting, wherein the coating is powdery or granulous and is formed by blending 100 parts of fire-resistant powder and 10-14 parts of composite sizing agent by weight. Meanwhile, the invention further discloses a method for preparing the alcohol-group coating for V-method casting. Compared with the prior art, the costing disclosed by the invention is powdery or granulous, so that the advantages of convenience and safety in transportation are achieved; the packaging cost is low because barrels are not required for package; the transportation cost is low because the phenomenon of sediment hardening does not occur during the transportation so as not to result in material scrap; meanwhile, the coating further has the advantages that the adhesion and bond strength of a coating layer is high, the capability of resisting metal fluid machinery and thermal shock is strong, the drying time is short, the production efficiency is high, and the sand cohesiveness resistance is excellent.

Owner:NINGBO CANGHAI NEW MATERIALS DEV

Casting paint for surface of lead-acid storage battery cast welding machine

InactiveCN107855460AHigh temperature strengthImprove insulation performanceFoundry mouldsFoundry coresAlloySolvent

The invention relates to the technical field of lead-acid storage battery manufacturing, and discloses casting paint for the surface of a lead-acid storage battery cast welding machine. A component framework of conventional high-temperature alloy is broken through, the thermodynamic stability of a generated phase is good, the problems of wetting, interface reaction and the like between a welding phase and a welding surface do not exist, and various properties such as the melting point, the melting temperature range (intensity, toughness and creep resistance), physical and chemical properties (conductivity, oxidation resistance and corrosion resistance) and the like are remarkably improved compared with those of an existing welding method. The anti-fatigue performance is excellent, cleaningis not needed after welding, cleaning with freon is avoided, cleaning equipment and solvents can be saved, the environmental pollution is reduced, and the cost is appropriate.

Owner:蚌埠市华鼎机械科技有限公司

Coating additive and preparation method and using method thereof

The invention relates to a coating additive. The coating additive is prepared from the following components in percentage by weight: 12-18% of aluminium-magnesium silicate, 2-5% of white carbon black,0.5-0.8% of PVB, 4-7% of phenolic resin powder, 3-5% of maleated rosin powder, 4-8% of attapulgite, 1-2% of sodium hexametaphosphate, 4-8% of organobentonite, 10-15% of spodumene, 15-20% of mica powder, 15-20% of anhydrous sodium sulphate and 6-10% of a dispersing agent. A preparation method of the coating additive comprises the following steps that all the components are mixed according to the weight percentage, stirring is conducted for 10-15 minutes by a spiral rod stirrer, and after even stirring, the powdery coating additive is obtained; and during using, aggregate and a solvent only need to be added into the coating additive, stirring is conducted for at least 20 min by a high-speed dispersion machine, and thus the coating additive can be applied. Compared with the prior art, the coating additive is easy to produce and convenient to package and transport, and all aspects of performance of casting coating made of the coating additive is superior.

Owner:SHANGHAI ZONGHUA IND

High-aluminium vanadine moulding sand, and its preparing method

This invention relates to a high bauxite molding sand and its preparation method composed of a high bauxite, high Al powder, 85% rare H3PO4 solution and bentonite, in which, the high bauxite and the Al powder are the main materials, 85% rare H3PO4 is a bond matched with suitable bentonite in the following weight percentage: high bauxite: 55-75, high Al powder 25-40, 85% rare H3PO4 solution 5-15 and bentonite 2-5. The preparation method includes: dry-mixing the bauxite and the Al power in a sand grinding machine, then adding the H3PO4 steadily to mix them in wet, finally adding bentonite to be mixed and taken out for standby and the mixed sand should be used within 12 hours for avoiding hardened.

Owner:中国一重集团有限公司

Alcohol-based coating for large castings and preparation method thereof

ActiveCN107971455BImprove technical performanceImprove uniformityFoundry mouldsFoundry coresNuclear powerAluminum silicate

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

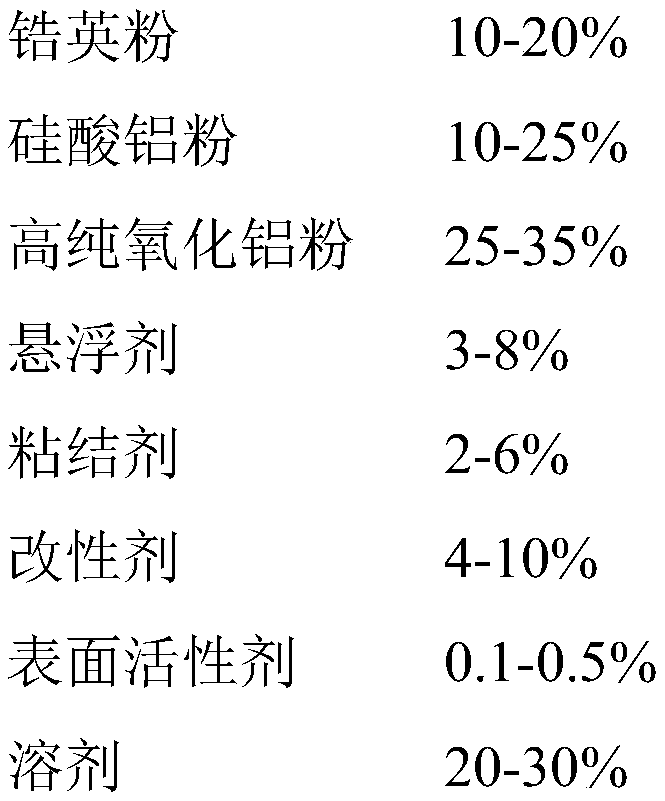

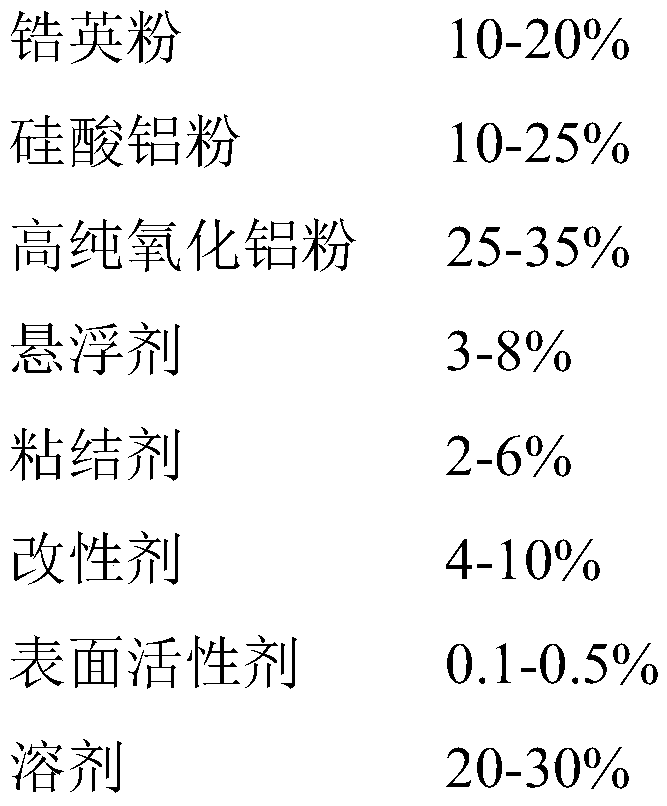

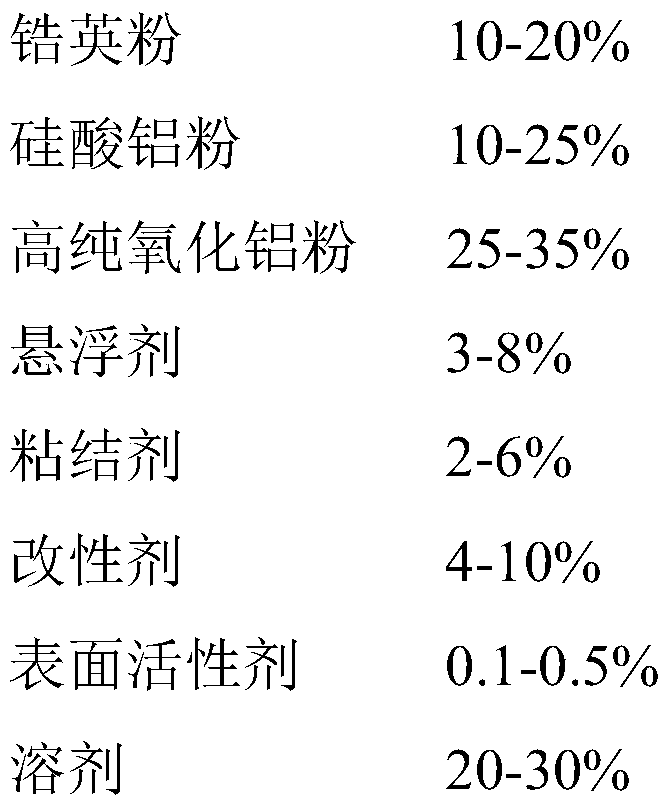

Compound environment-friendly paint suitable for high-chromium white cast iron and preparation method thereof

ActiveCN109175225AResistance to penetrationGood sintering peelabilityFoundry mouldsFoundry coresEnvironmental resistanceAluminum silicate

The invdention relates to a compound environment-friendly paint suitable for high-chromium white cast iron and a preparation method thereof and belongs to the field of casting. The paint comprises, bymass, 10-20% of zircon powder, 10-25% of aluminum silicate powder, 25-35% of high-purity aluminum oxide, 3-8% of a suspending agent, 2-6% of a binder, 4-10% of a modifying agent, 0.1-0.5% of a surface active agent and 20-30% of solvent. The preparation method of the paint comprises the steps that burdening is carried out according to the above mixing ratio, 80% of the total mass of the solvent isadded to a reaction kettle firstly under the condition of stirring; then the rest of components, except for the solvent, are all added, and the new mixture is stirred for over half an hour by a high-speed dispersion machine; and finally, the baume degree of the rest of the solvent is adjusted till being greater than 90 Be, and accordingly the paint is obtained. The paint has high refractoriness and coating strength, and the casting cost of paint production is effectively reduced.

Owner:XIANGYANG WU ER WU PUMP IND

Quick-drying water-based casting paint for large steel castings and its preparation method

ActiveCN109513878BReduce pollutionReduce health hazardsFoundry mouldsFoundry coresAluminum magnesium silicateEtching

The invention relates to a quick-drying water-based casting coating for large steel castings and a preparation method thereof, and belongs to the technical field of foundry coatings. The quick-dryingwater-based casting coating for the large steel castings comprises the following materials, by mass, 100 parts of modified zircon powder, 1 to 5 parts of lithium-based bentonite paste, 1 to 5 parts ofaluminum magnesium silicate paste, 0.2 to 3 parts of water-soluble modified phenol resin, 0.1 to 1 part of water-soluble modified silicone resin, 0.1 to 0.5 part of the low-viscosity polyvinyl butyral resin and 20 to 40 parts of water. The quick-drying water-based casting coating for the large steel castings is characterized in that the suspension property is higher than or equal to 98% / (24H), the gas generation amount is smaller than 5 ml / g, the solid content is larger than 73%, the coating wear resistance is 0.02 g, coating is smooth without flowing, baking and coating can be repeatedly carried out many times, the baked coating is fully dried, the coating has no defects such as cracks, bubbles, pores and delamination, and the good sand resistant function is achieved during molten steelerosion and etching.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

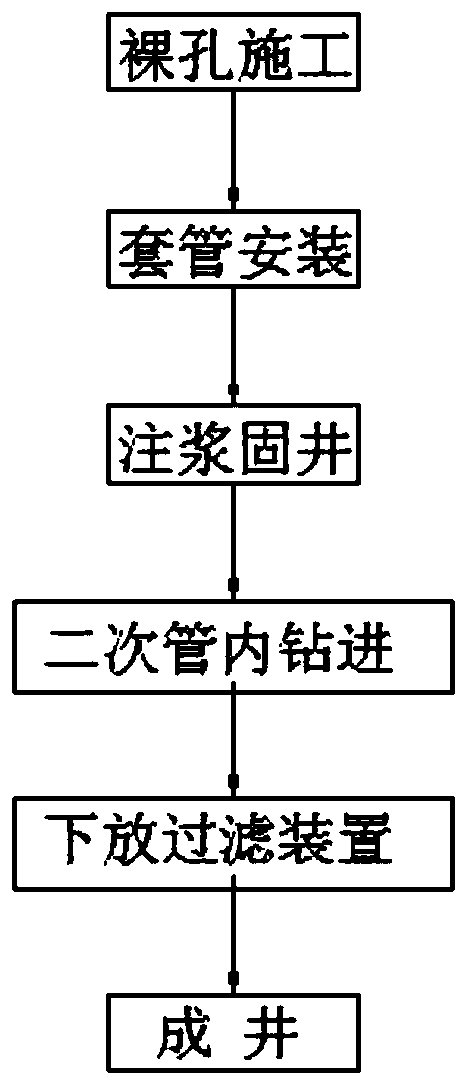

A drilling structure construction method that can increase the amount of uranium pumping and injection in ground leaching

ActiveCN108643827BShort construction periodGood sand resistanceDrilling rodsFluid removalUraniumPetroleum engineering

The invention relates to the field of uranium leaching technology, and specifically discloses a drilling structure construction method capable of increasing the amount of in-situ uranium leaching extraction and injection fluid. The steps comprises the steps that (a) open-hole drilling, sleeve installation and grouting and well cementing are carried out; (b) a sleeve protection device is installedon a drill pipe; (c) a secondary in-pipe drilling drill bit is lowered after fresh drilling fluid is prepared; (d) an ore-containing section is subjected to secondary in-pipe drilling; (e) punching bywater is carried out; and (f) a filtering device is lowered. The method has short construction period, good sediment prevention, high drilling well-completion rate, low well-washing labor intensity,low cost and high construction quality, and the quality improvement, efficiency enhancement and consumption reduction of drilling construction are achieved.

Owner:中核通辽铀业有限责任公司

Magnesium aluminium spinel powder alcohol-based coating for heavy section steel castings and preparation method thereof

Owner:CHINA YITUO GROUP

Alcohol-based coating for cast iron stove and preparation method of alcohol-based coating

The invention discloses an alcohol-based coating for a cast iron stove. The coating comprises, by weight, 30-40 parts of epoxy resin, 10-15 parts of glass fiber, 4-8 parts of borax, 1-3 parts of nanosilicon dioxide, 10-15 parts of binder, 30-40 parts of pentaerythritol and 30-40 parts of isoamyl alcohol. According to the alcohol-based coating, pentaerythritol and isoamyl alcohol are used as mainraw materials, borax and nano silicon dioxide are added to improve the heat resistance of the coating, glass fiber is added to improve the strength of the coating and prevent sand sticking, epoxy resin is added, and the binder is added to improve the fluidity and viscosity of the coating.

Owner:WUJIANG GERUIFU HARDWARE

Environment-friendly cast iron stove paint and preparation method thereof

InactiveCN109666341AHigh refractorinessGood sand resistanceFireproof paintsStarch coatingsBarium oxideCast iron

The invention discloses an environment-friendly cast iron stove paint. The environment-friendly cast iron stove paint is composed of raw materials including, by weight part, 30-40 parts of acrylic acid, 1-5 parts of sorbitan monooleate, 2-8 parts of lanthanum oxide, 2-8 parts of barium oxide, 10-15 parts of quartz powder, 3-6 parts of green tea powder, 3-6 parts of modified starch, 3-6 parts of carboxymethyl cellulose, 20-30 parts of ethyl alcohol and 40-60 parts of water. The environment-friendly cast iron stove paint is environmentally friendly in raw materials, high in refractoriness and good in sand adhesion resistance and stripping effects, achieves a casing removal rate of 94% before castings are shot-cast, reduces cleaning costs and working hours and further greatly reduces the labor intensity of aftertreatment workers.

Owner:WUJIANG GERUIFU HARDWARE

Alcohol based ceramic casting coating

ActiveCN104439049BGood peeling effectStripping helpsFoundry mouldsFoundry coresAlcoholSuspending Agents

Owner:TIANJIN NINGKANG TECH

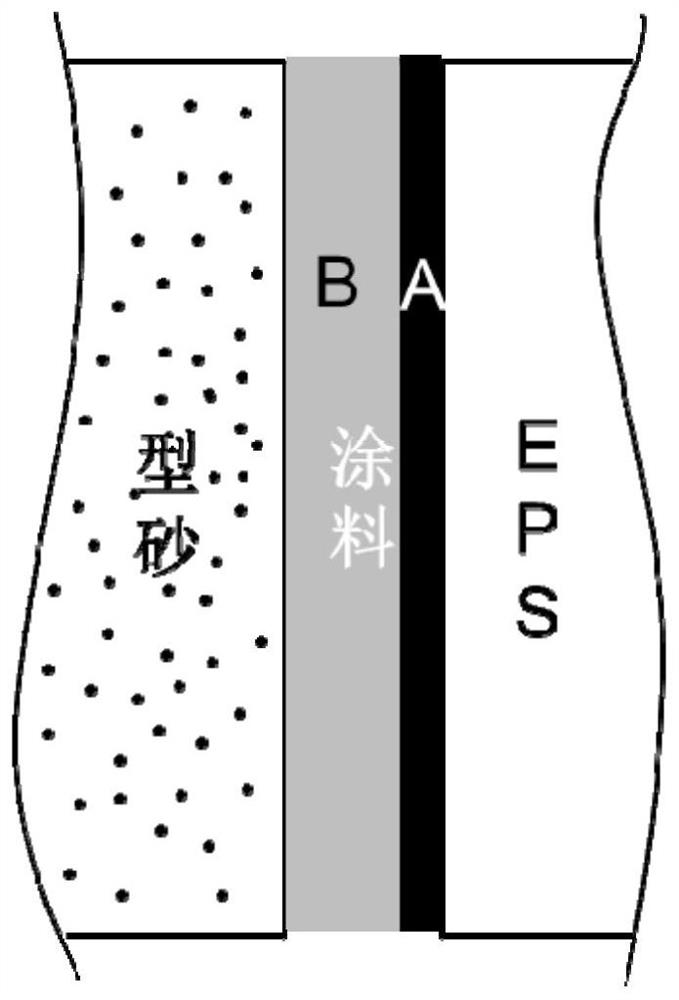

Sand-burning-resistant water-based expendable pattern coating for gray iron casting and application and preparation method thereof

The invention relates to the technical field of expendable pattern casting, and specifically, to a sand-burning-resistant water-based expendable pattern coating for gray iron casting and application and a preparation method of the coating. According to the coating, flaky graphite, mullite, and light calcined magnesia are organically matched, so that the coating is difficult to penetrate through bycontinuous high-temperature molten iron. By optimizing resin and an auxiliary, the coating is high in drying speed under an oven-drying condition of 70 to 85 DEG C, and can also be smoothly operatedin a severe environment; and by utilizing the light calcined magnesia and the flaky graphite, the coating can be easily peeled off from the surface of a cast piece after being poured, the cast piece is good in appearance quality, the later fire treatment is not needed, and the casting time is greatly saved. White rubber powder, styrene-acrylate resin, and two inorganic adhesives are utilized, so that the hardness of the coating is improved, a model is difficult to damage, and the coating is difficult to permeate under the scouring of the molten iron. By utilizing a JFC penetrating agent and asurfactant, the adhesiveness of the coating and EPS foam is good, the bareness is difficult in a brushing process, an air hole can be guaranteed in the surface of the dried coating, and the air permeability of the coating is guaranteed.

Owner:四川省宜宾普什集团有限公司 +1

Alcohol-based paint for cast steel and method for preparing and using same

ActiveCN103769530BHigh strengthExcellent resistance to moisture absorptionFoundry mouldsFoundry coresAlcoholNaphtha

The invention discloses a cast steel alcohol-based paint, as well as a preparation and application method thereof. The cast steel alcohol-based paint comprises the following components: 12-18 wt% of ethyl alcohol, 4.5-8 wt% of isopropanol, 0.4-2.5 wt% of black rosin, 0.35-3 wt% of solvent naphtha, 0.9-2.5 wt% of aluminium-magnesium silicate, 0.5-2.6 wt% of phenolic resin, 0.05-0.5 wt% of poval, 0.1-1 wt% of white carbon black, 0.15-2.5 wt% of attapulgite, 40-60 wt% of zircon powder, 10-25 wt% of fused alumina zirconia powder, 0.1-0.5 wt% of kunzite, 0.8-2.5 wt% of ludox and 0.5-3.5 wt% of pyrophyllite powder. The specific preparation and application method are shown in the specification. The cast steel alcohol-based paint has the following benefits: the refractoriness is high, sintering is easy, and the sand burning resistance is good; in addition, the solid content is high, the suspension property is good, the gas content is low and excellent thixotropic property is realized; moreover, after a coating is hardened, the strength is high, and the hygroscopicity resistance is good.

Owner:SHANGHAI ZONGHUA IND

Composite environmental protection coating suitable for high chromium white cast iron and preparation method thereof

ActiveCN109175225BImprove thixotropyHigh refractory aggregate contentFoundry mouldsFoundry coresActive agentAluminum silicate

The invention relates to a compound environment-friendly coating suitable for high-chromium white cast iron and a preparation method thereof, belonging to the field of casting. In the coating of the present invention, the mass percentage of each component is: zircon powder: 10-20%; aluminum silicate powder: 10-25%; high-purity alumina powder: 25-35%; suspending agent: 3-8%; Binder: 2-6%; Modifier: 4-10%; Surfactant: 0.1-0.5%; Solvent: 20-30%; The preparation method of the coating of the present invention is formulated according to the above proportioning relationship, and is stirred 80% of the total mass of the solvent is first put into the reaction kettle; then all the remaining ingredients except the solvent are put into the reaction kettle, and the high-speed disperser is used to stir for more than half an hour; finally, the Baume degree is adjusted with the remaining solvent until the Baume When the beauty degree is greater than 90゜Bé, the coating preparation is completed. The coating has high refractoriness and coating strength, and effectively reduces the casting cost of coating production.

Owner:XIANGYANG WU ER WU PUMP IND

A casting paint for the surface of lead-acid battery casting welding machine

InactiveCN107855460BHigh temperature strengthImprove insulation performanceFoundry mouldsFoundry coresSuperalloyUltimate tensile strength

The invention relates to the technical field of lead-acid storage battery manufacturing, and discloses casting paint for the surface of a lead-acid storage battery cast welding machine. A component framework of conventional high-temperature alloy is broken through, the thermodynamic stability of a generated phase is good, the problems of wetting, interface reaction and the like between a welding phase and a welding surface do not exist, and various properties such as the melting point, the melting temperature range (intensity, toughness and creep resistance), physical and chemical properties (conductivity, oxidation resistance and corrosion resistance) and the like are remarkably improved compared with those of an existing welding method. The anti-fatigue performance is excellent, cleaningis not needed after welding, cleaning with freon is avoided, cleaning equipment and solvents can be saved, the environmental pollution is reduced, and the cost is appropriate.

Owner:蚌埠市华鼎机械科技有限公司

A kind of high air permeability alcohol-based lost foam coating and preparation method thereof

InactiveCN107096874BImprove suspension stabilityEasy to dryFoundry mouldsFoundry coresPolyvinyl alcoholActive agent

The invention discloses high-breathability alcohol-based evaporative pattern coating. The high-breathability alcohol-based evaporative pattern coating comprises the following raw materials in percent by mass: 20-40% of an alcohol-based solvent, 40-60% of refractory aggregates, 0.5-5% of polyvinyl formal, 0.5-5% of silica sol, 0.5-5% of a suspending agent, 0.05-0.2% of a surfactant and 0.1-1% of an auxiliary agent, altogether 100%. The invention further discloses a preparation method of the high-breathability alcohol-based evaporative pattern coating. The high-breathability alcohol-based evaporative pattern coating is prepared by mixing the weighed raw materials according to a certain adding sequence and uniformly stirring the raw materials. The high-breathability alcohol-based evaporative pattern coating can achieve a rapid self-drying effect in the case of no drying; when the added polyurethane foam microbeads or foamable polymethyl methacrylate microbeads encounter high temperature in the casting process, liquid metal is gasified and small holes are formed in a coating layer, so that the breathability of the high-breathability alcohol-based evaporative pattern coating is greatly improved; the high-breathability alcohol-based evaporative pattern coating is good in adhesion and sand-sticking resistance.

Owner:HUABAO (TIANJIN) NEW MATERIAL SCI & TECH DEV CO LTD

A method for producing precision casting sand using high-alumina fly ash

ActiveCN107199310BHigh refractorinessImprove liquidityFoundry mouldsMould handling/dressing devicesFoundryAcid washing

The invention provides a method for producing precise foundry sand from high-aluminum coal ash. The method comprises the following steps of: purifying high-aluminum coal ash, pelletizing, drying, roasting and post-treating the purified high-aluminum coal ash to obtain the precise foundry sand, wherein the step of purifying the precise foundry sand adopts an acid activation-alkali desilicication-diluted acid washing process. The precise foundry sand obtained by the method has the advantages of good mobility, high refractoriness, high strength, a low thermal expansion coefficient, good sand sticking resistance, solves the raw material problem in a production process of the precise foundry sand, successfully treats industrial solid waste, achieves the purpose of changing waste into things of value, and has a good economic and social value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of preparation method of double-layer structure polyurethane composite bearing

The invention discloses a preparation method of a polyurethane composite bearing of a double-layer structure and belongs to the technical field of sliding bearings. The polyurethane composite bearingis composed of a hard polyurethane outer layer (2) achieving the supporting and bearing effects and a soft polyurethane surface layer (1) with the self-lubricating and anti-abrasion functions. Firstly, a cylinder mold is adopted, the soft surface layer is cast through a centrifugal casting method, and the outer surface of the surface layer is ground, cleaned, dried, and then coated with an adhesion agent to serve as a mold core; and then the hard outer layer is cast on the outer surface of the surface layer, and the bearing is formed by adhering and composing the layers through the adhesion agent. According to the preparation method of the polyurethane composite bearing of the double-layer structure, the bearing has the technical characteristics of being high in bearing, capable of achieving water-breaking operation within a short time, resistant to silt, easy to machine, low in cost and the like, and the domestic market vacancy is made up; and a composite material integrally has the excellent properties of being resistant to changing of the high and low temperature and hydrolysis and the like, the service life is long, and the polyurethane composite bearing can be widely applied to the rotary or swing sliding portions of water pumps, propeller stern bearings, rudder bearings and the like.

Owner:BEIHUA UNIV

A kind of production process of sand mold water-based paint for foundry

ActiveCN102773405BRaw materials are uniqueUnique process methodFoundry mouldsFoundry coresWater basedSodium Bentonite

The invention relates to a manufacturing method in a production technique of paint for casting, in particular to a production technique of sand-type water based paint for casting, wherein the sand-type water based paint belongs to a casting accessory. The production technique comprises the following steps of: adding water, tributyl phosphate and CMC (carboxy methylated cellulose) in a dissolving pot firstly, stirring uniformly, dissolving the materials completely; filtering insoluble materials by a filter screen; adding water, sodium benzoate, a sodium base bentonite suspending agent, acetic acid and reducing glue in a stirring kettle, starting up electric stirring; slowly adding white corundum, sodium lignin sulfonate and water in the stirring kettle, stirring for 15-20min; adding water on the basis of the dilution situation, wherein the baum degree of the paint is higher than 95 after being stirred uniformly; transferring the paint prepared by the steps in a colloid mill, continuously milling for 2h, discharging and packaging into barrels to obtain the paint. The invention provides the novel production technique of the sand-type water based paint for casting, which has the following characteristics of environment friendliness, high coating strength and excellent painting property.

Owner:共享新材料(山东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com