Alcohol-based coating for large castings and preparation method thereof

A technology for large-scale castings and coatings, applied in casting molding equipment, coatings, cores, etc., can solve problems such as high cost and difficult to meet actual needs, easy hardening of refractory aggregates, poor brushing performance, etc., to achieve good sand resistance Functional, not easy to delaminate, not easy to harden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

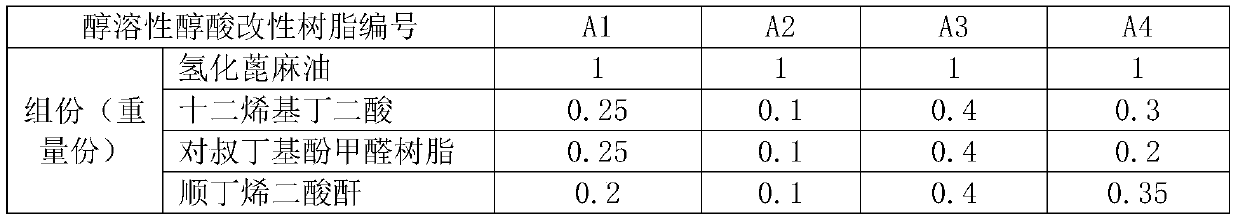

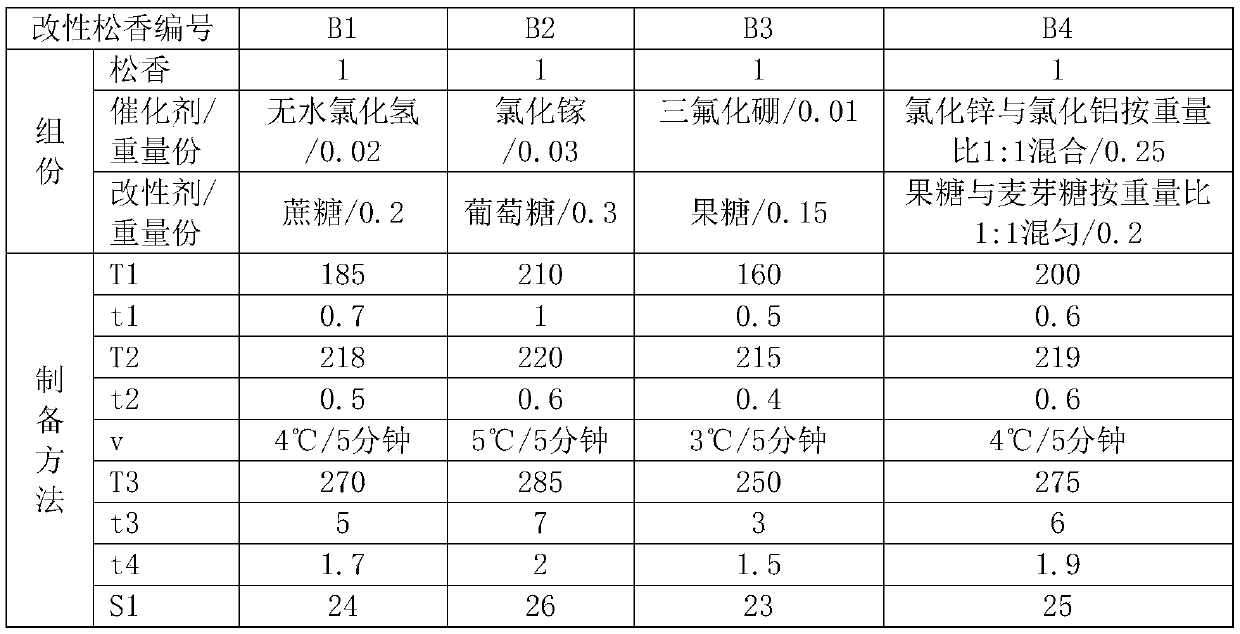

[0037] The preparation method of modified rosin is as follows: add 1 part of rosin to the reaction kettle and heat up to 160-210°C, and after maintaining for 0.5-1.0 hours, use anhydrous hydrogen chloride, zinc chloride, aluminum chloride, gallium chloride and trifluoro At least one of boron chloride is used as a catalyst, and the amount of catalyst added is 0.01 to 0.03 times of the weight of rosin, and at least one of sucrose, glucose, fructose and maltose is added in an amount of 0.15 to 0.3 times of the weight of rosin. Mix well, keep warm at 215-220°C for 0.4-0.6 hours, then raise the temperature to 250-285°C at a speed of 3-5°C / 5 minutes, keep warm for 3-7 hours, dehydrate under reduced pressure for 1.5-2.0 hours, wait for the acid value to drop To 23 ~ 26mgKOH / g, softening point ≥ 130 ° C, cooled and discharged to obtain modified rosin.

[0038] Low-viscosity polyvinyl butyral resin: its degree of polymerization is 300-400; molecular weight is 18×10 4 ~27×10 4 / mole,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com