Method for producing precise foundry sand from high-aluminum coal ash

A high-aluminum fly ash and precision casting technology, which is applied in the field of waste resource utilization, can solve problems such as low thermal expansion rate, and achieve the effects of low water absorption rate, wide source and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

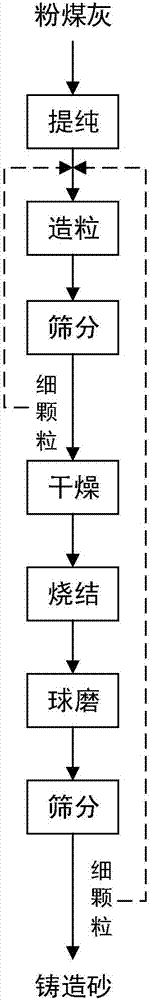

[0073] The method for producing precision casting sand by utilizing high alumina fly ash comprises the following steps:

[0074] The high alumina fly ash is purified according to the process of acid activation-desiliconization-dilute pickling. The acid activation conditions are: acid concentration 250g / L, activation temperature 70°C, activation time 2h, activation liquid-solid ratio 5mL / g; desiliconization conditions: alkali concentration 180g / L, desiliconization temperature 90°C, desiliconization time 60min, desiliconization liquid-solid ratio 5mL / g; dilute pickling conditions: washing temperature 60°C, washing time 50min , the mass ratio of the first washing liquid to the second solid is 3. The mass percent content of prepared alumina is 65%, ω[(Na, K) 2 O] is 0.5% high-purity fly ash powder, granulated in the swing granulator, and then sieved in the sieving machine, the particles greater than 10 meshes are the primary particles, and the fine particles are granulated in a ...

Embodiment 2

[0076] The method for producing precision casting sand by utilizing high alumina fly ash comprises the following steps:

[0077] The high alumina fly ash is purified according to the process of acid activation-desiliconization-dilute pickling. The acid activation conditions are: acid concentration 260g / L, activation temperature 90°C, activation time 2h, activation liquid-solid ratio 4mL / g; desiliconization conditions: alkali concentration 200g / L, desiliconization temperature 90°C, desiliconization time 70min, desiliconization liquid-solid ratio 5mL / g; dilute pickling conditions: washing temperature 70°C, washing time 40min , the mass ratio of the first washing liquid to the second solid is 3. The mass percent content of prepared alumina is 68%, ω[(Na, K) 2 O] is 0.5% high-purity fly ash powder, granulated in the swing granulator, and then sieved in the sieving machine, the particles greater than 10 meshes are the primary particles, and the fine particles are granulated in a ...

Embodiment 3

[0079] The method for producing precision casting sand by utilizing high alumina fly ash comprises the following steps:

[0080]The high alumina fly ash is purified according to the process of acid activation-desiliconization-dilute pickling. The acid activation conditions are: acid concentration 270g / L, activation temperature 85°C, activation time 2h, activation liquid-solid ratio 4mL / g; desiliconization conditions: alkali concentration 200g / L, desiliconization temperature 95°C, desiliconization time 70min, desiliconization liquid-solid ratio 5mL / g; dilute pickling conditions: washing temperature 80°C, washing time 40min , the mass ratio of the first washing liquid to the second solid is 4. The mass percent content of prepared alumina is 66%, ω[(Na, K) 2 O] is 0.45% high-purity fly ash powder, granulated in the swing granulator, and then sieved in the sieving machine, the particles greater than 10 meshes are the primary particles, and the fine particles are granulated in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com