Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117results about How to "Resistance to penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

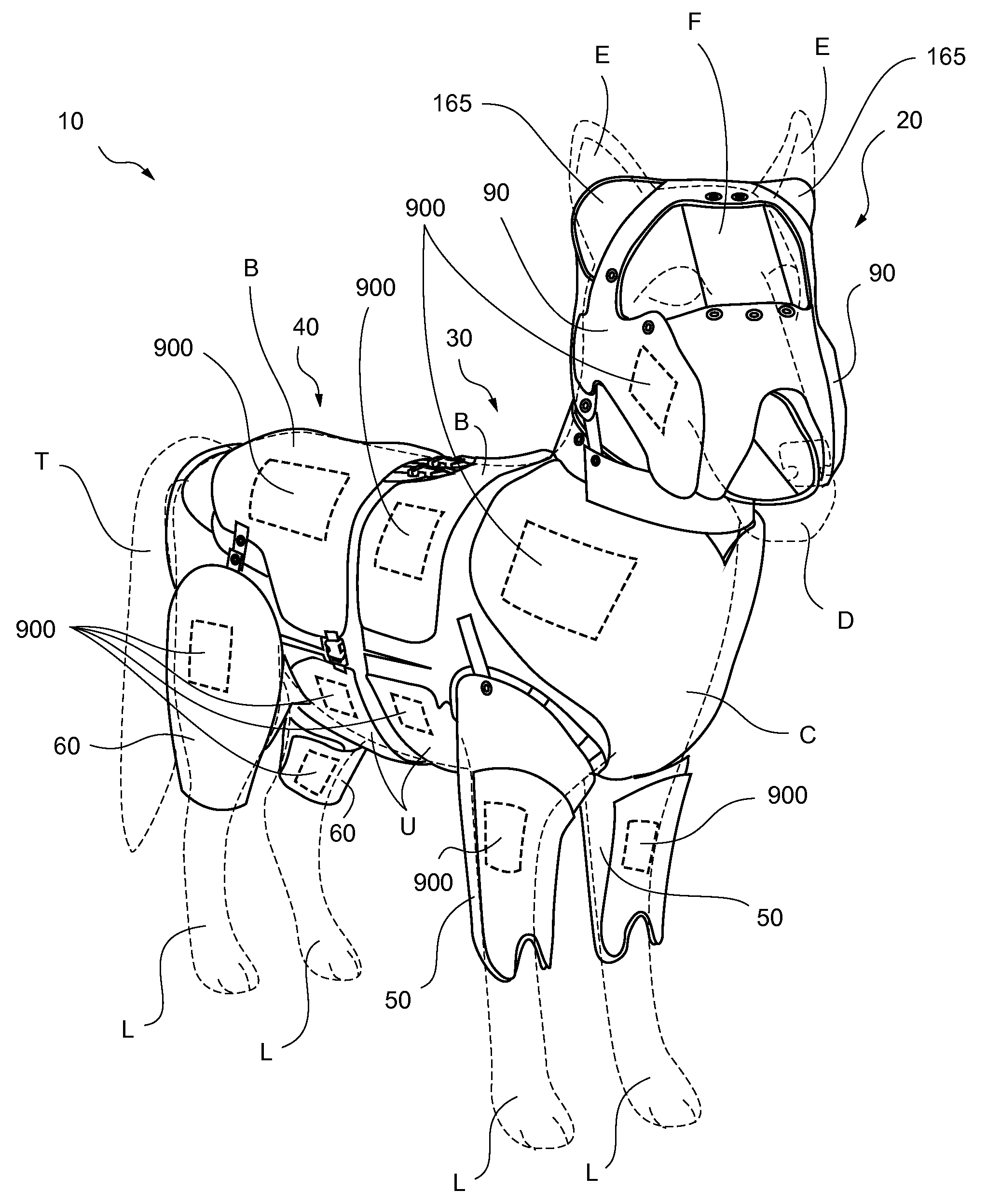

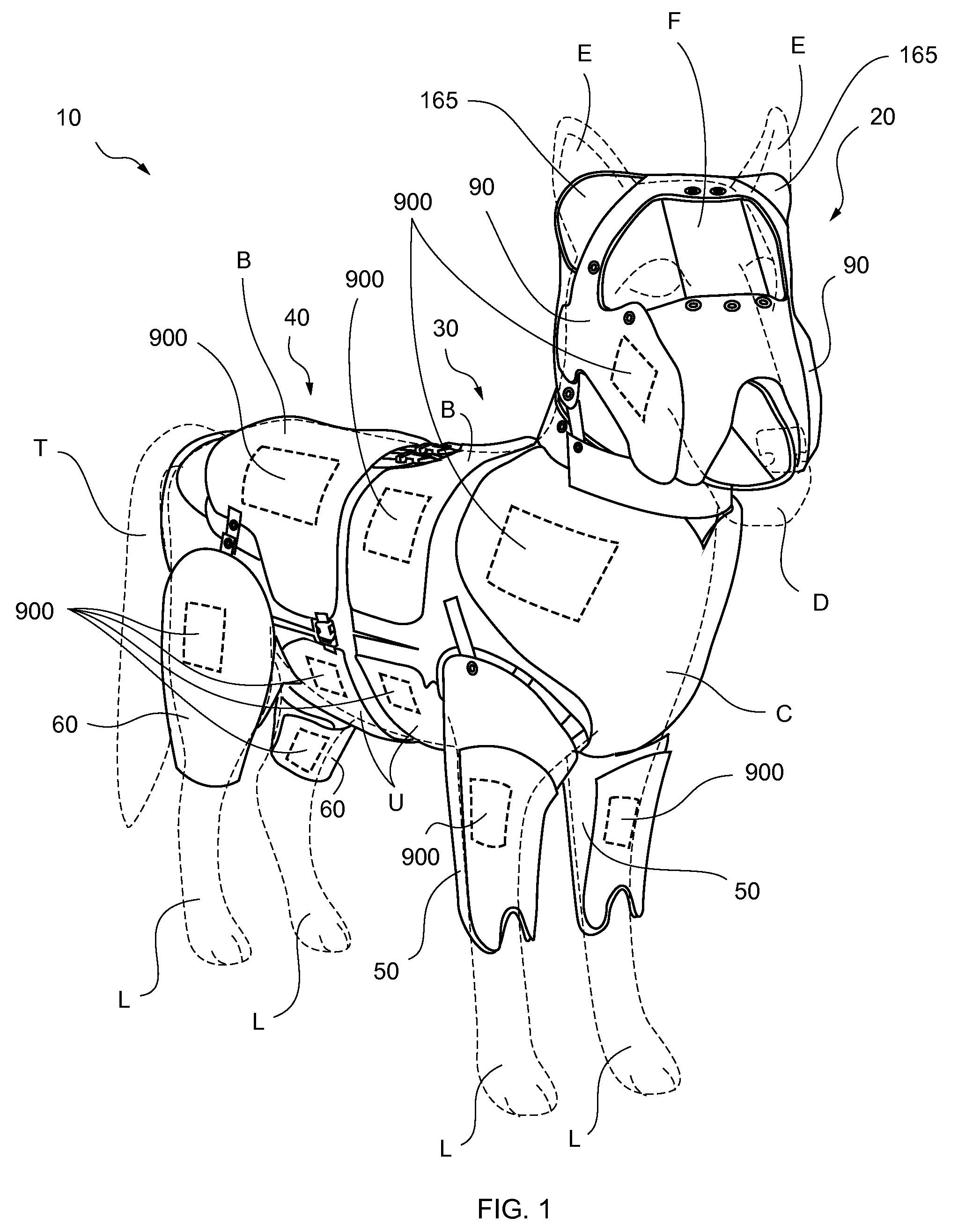

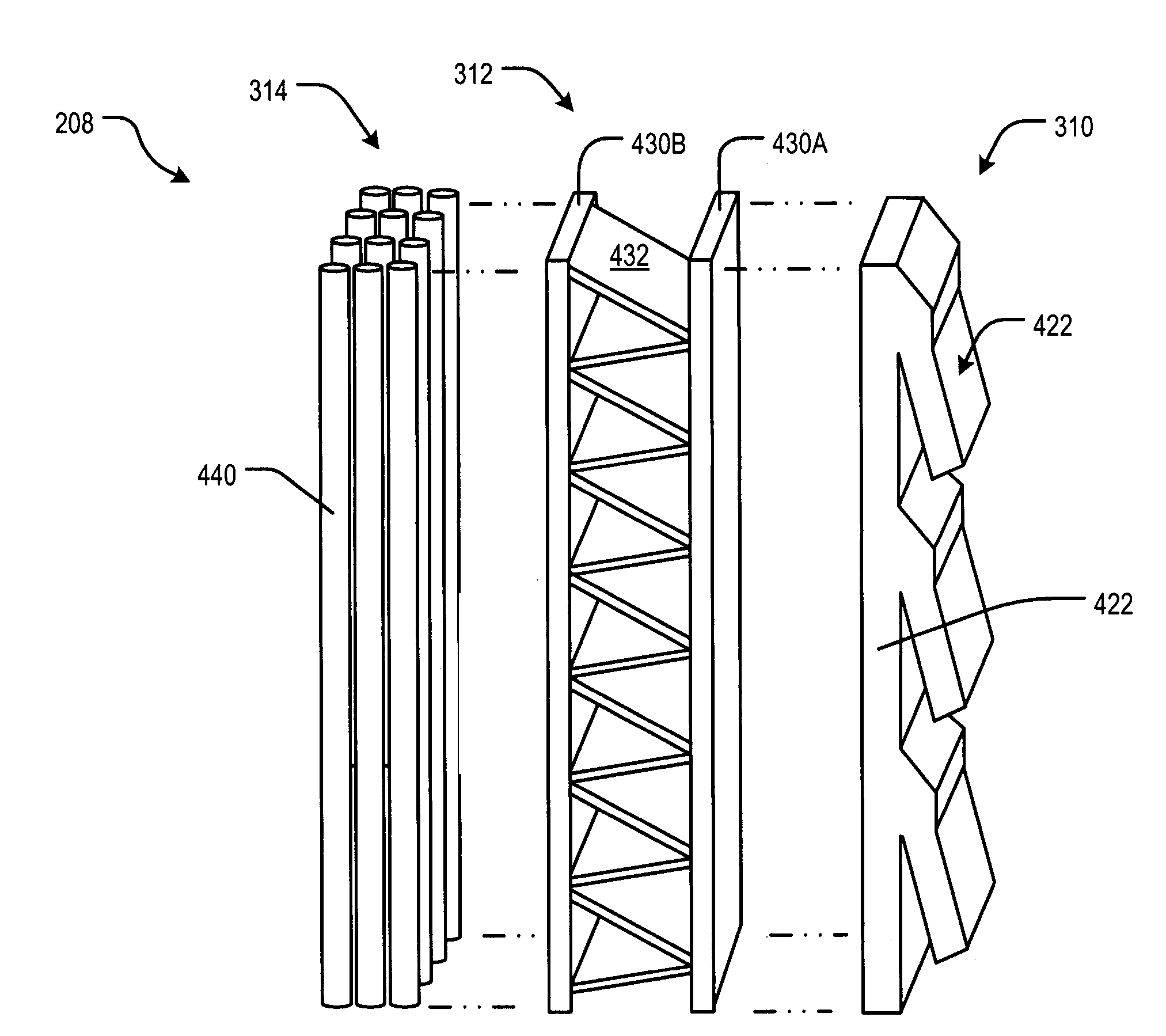

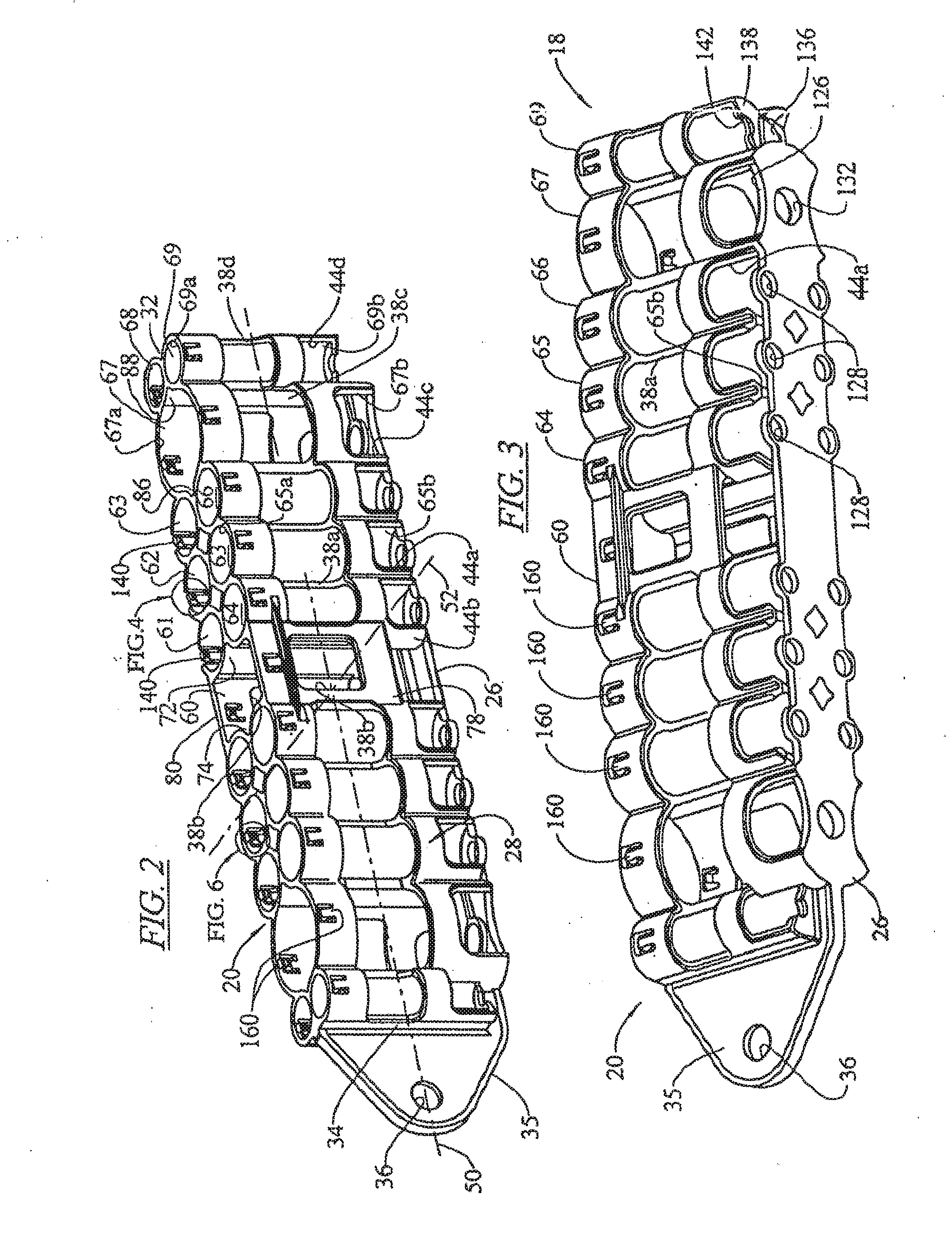

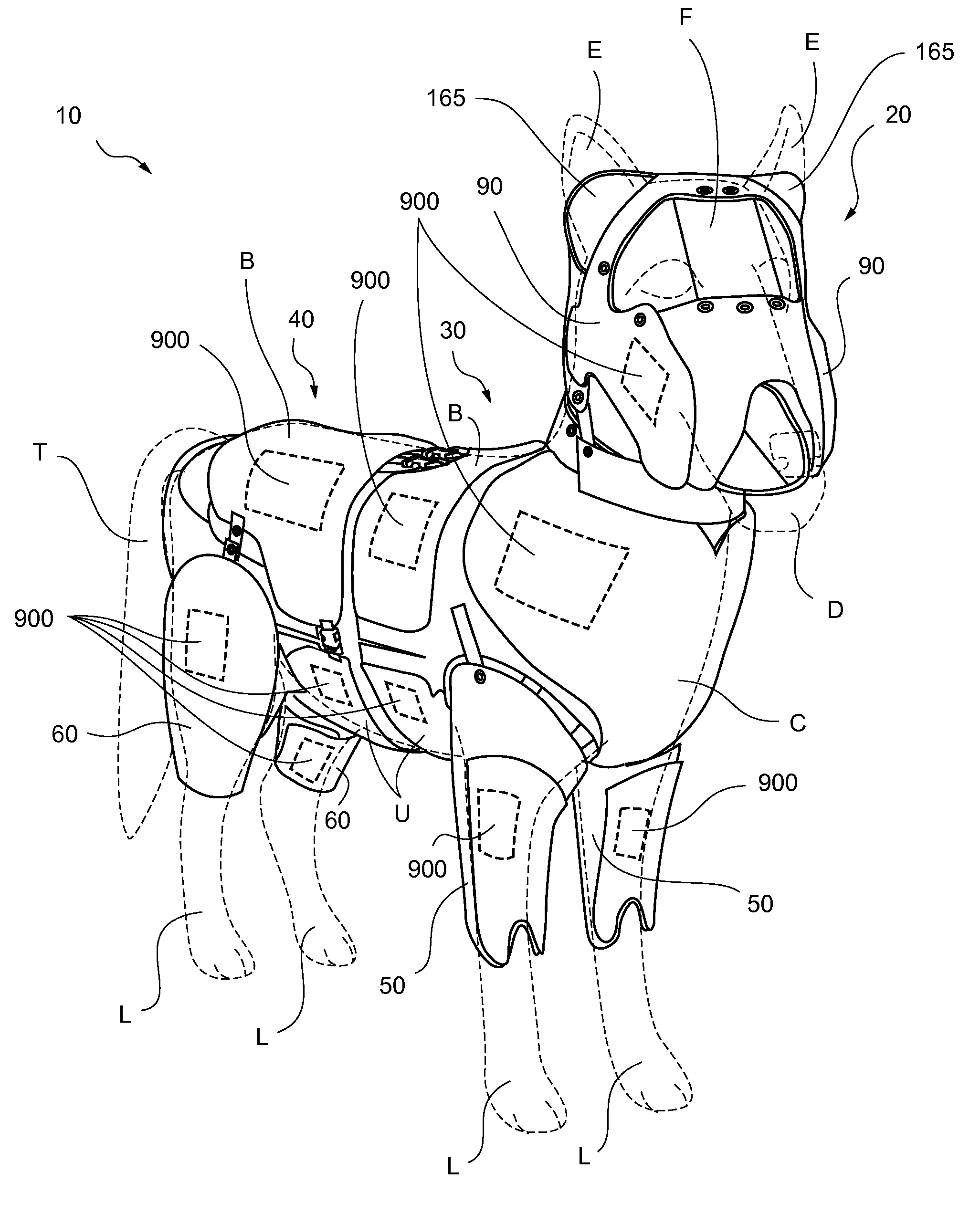

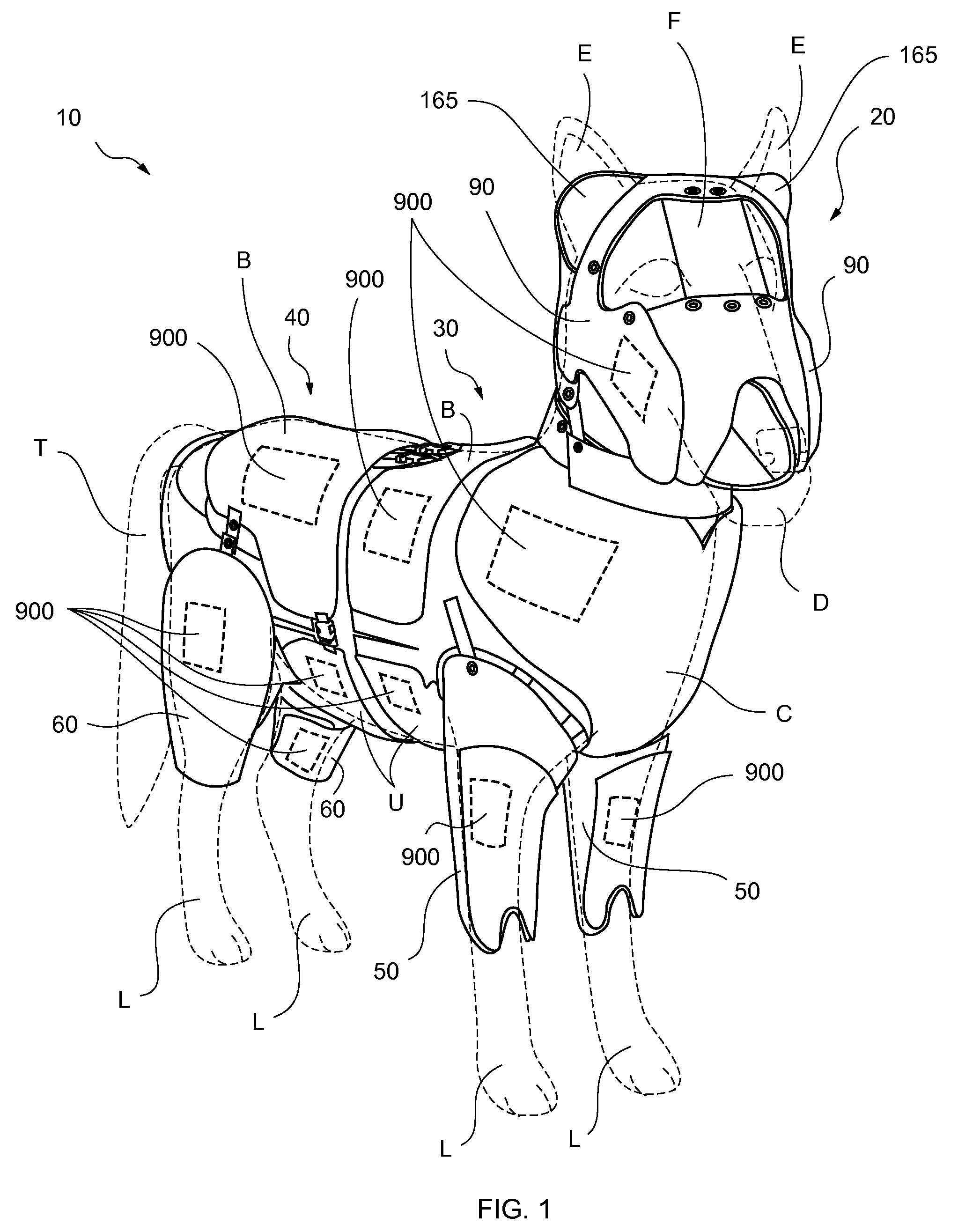

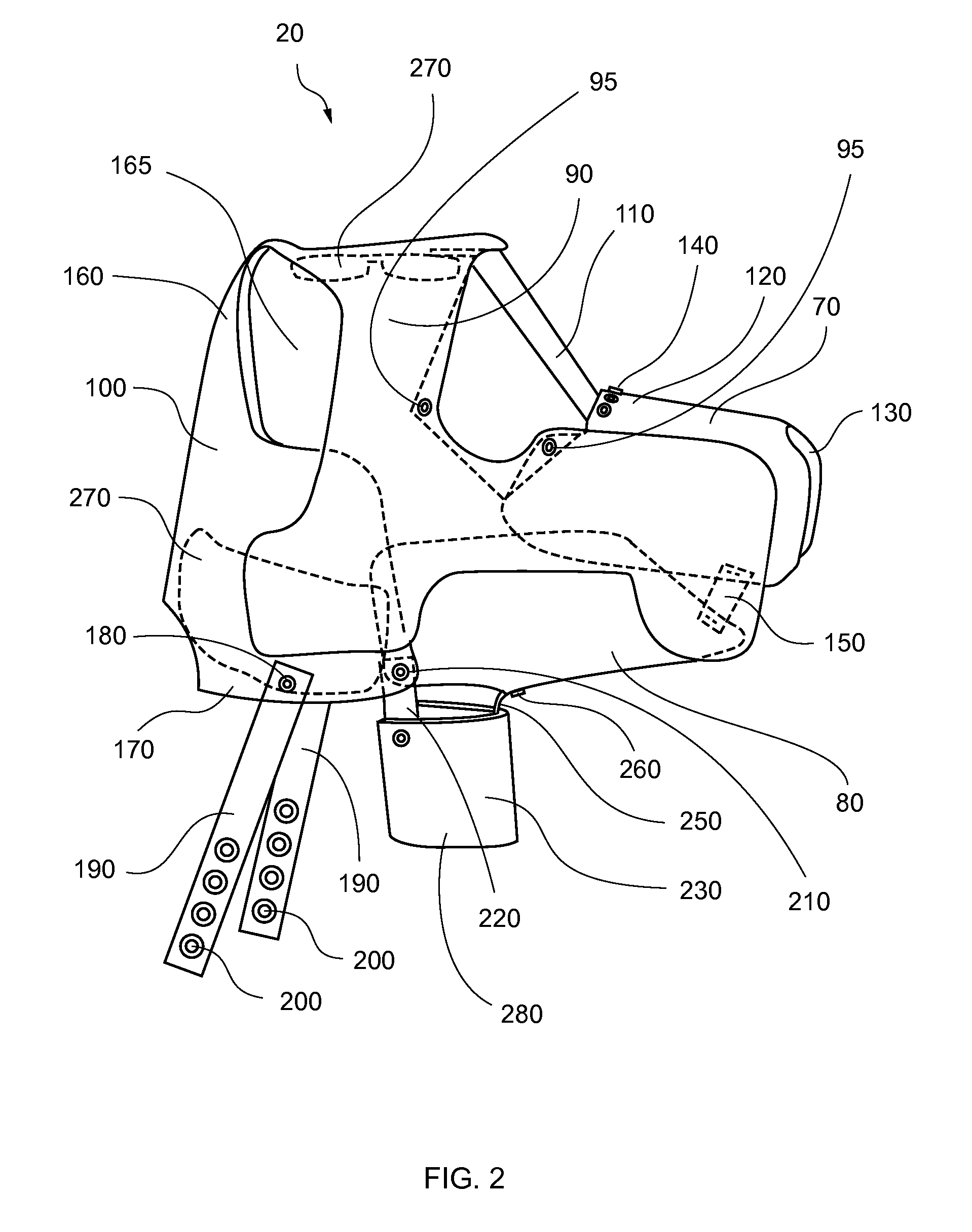

Canine protective suit and method of use thereof

InactiveUS20100043725A1Easy to replaceResistance to penetrationProtection coversUpholsteryEngineeringLower body

A canine protective suit comprising a face mask, a upper body protector and a lower body protector, wherein the face mask is removably secured to the upper body protector, and wherein the lower body protector is removably secured to the upper body protector. The upper body protector comprises elastic bands, wherein the elastic bands secure at least two front leg panels. Similarly, the lower body protector comprises elastic bands, wherein the elastic bands secure at least two back leg panels. To use, a canine's two front legs are placed into the two front leg panels as the upper body protector is placed on the canine. Similarly, the canine's rear legs are inserted into the back leg panels as the lower body protector is installed on the canine. The face mask is then disposed on the canine's face and secured to the upper body protector.

Owner:HALL CHRISTOPHER

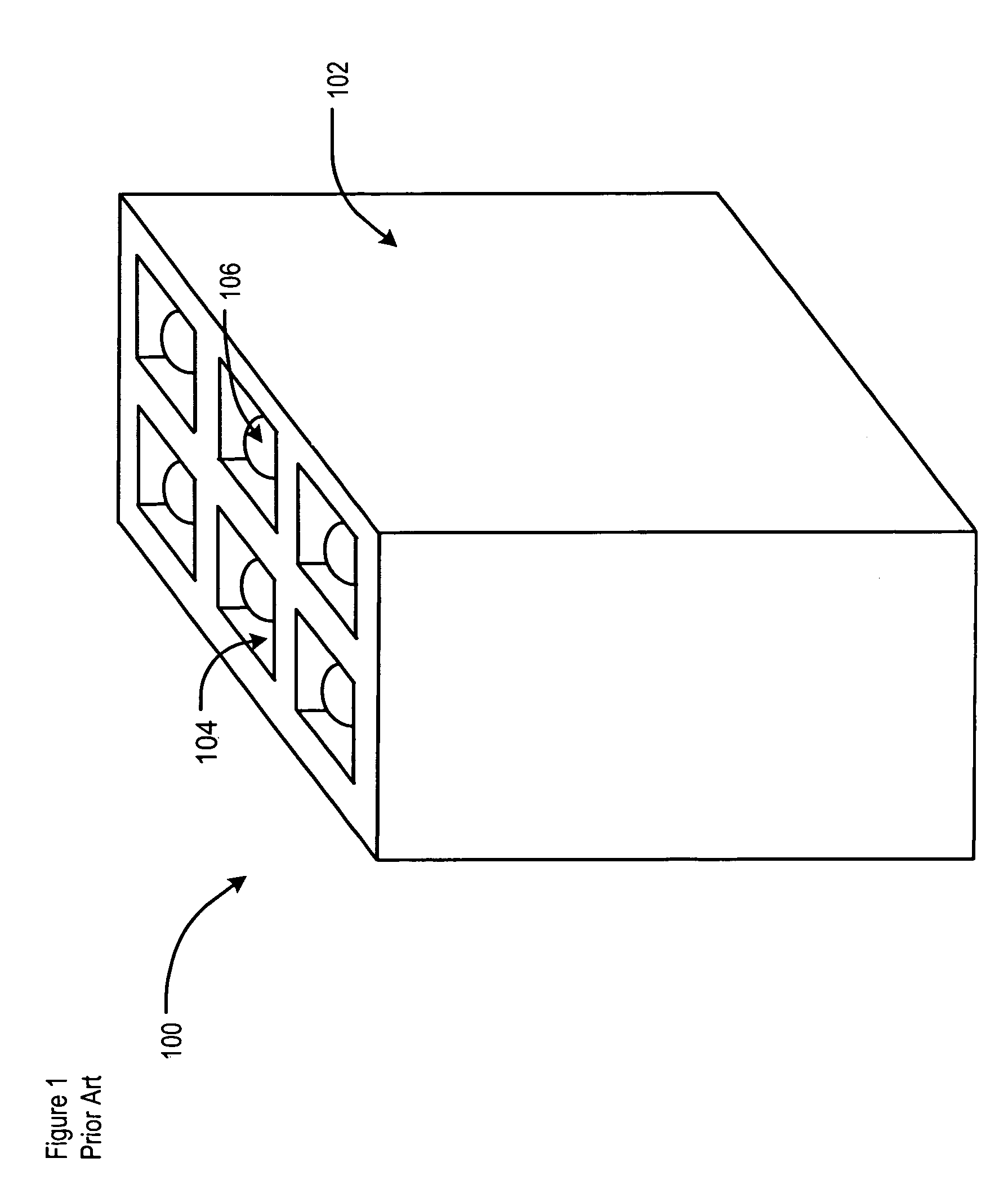

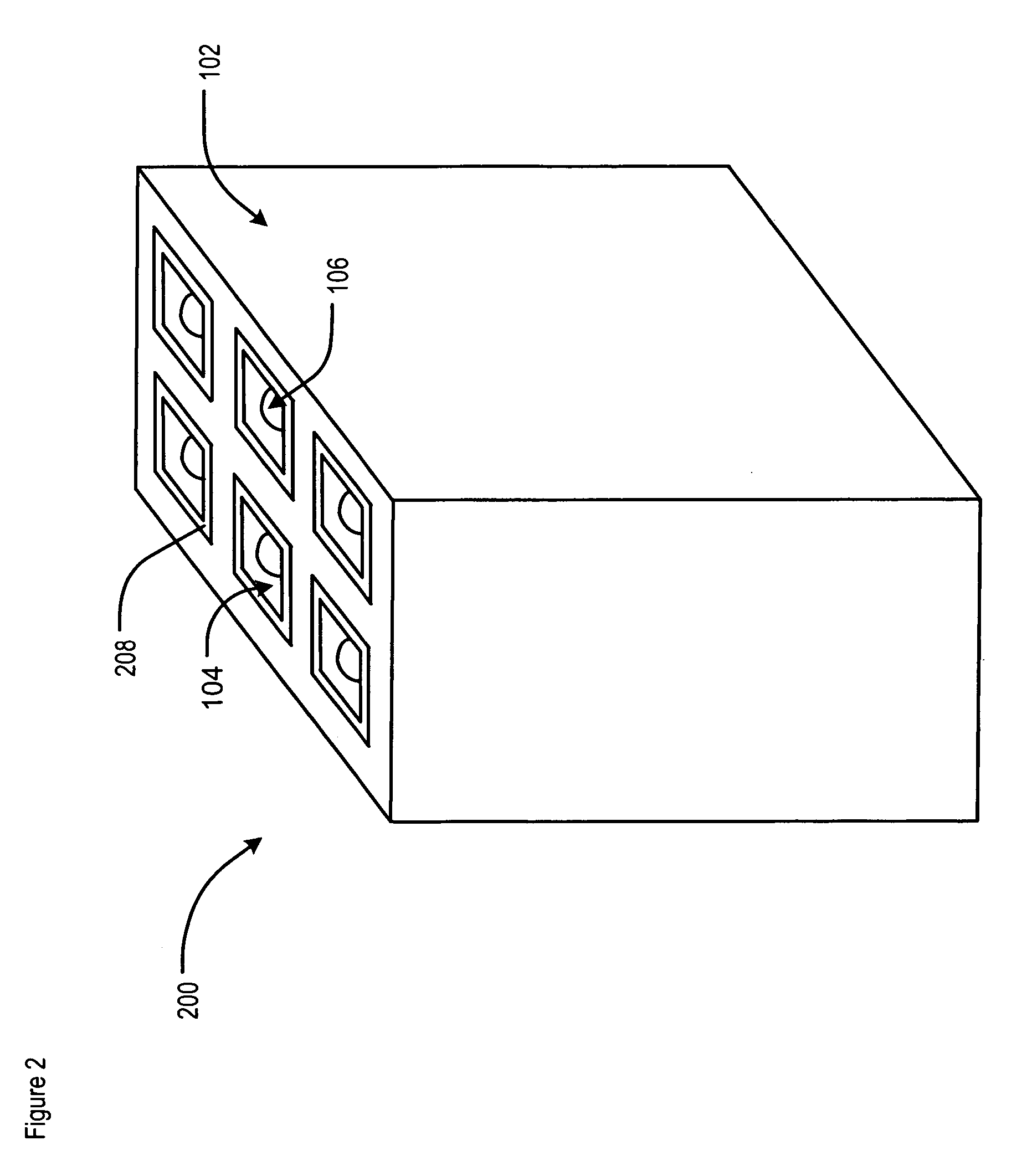

Apparatus comprising armor

InactiveUS7406909B2Limited effectReduce the possibilityAmmunition storageBlastingSilicone GelsEngineering

An armor that is used, for example, in multi-cell missile launchers is disclosed. In some embodiments, the armor includes three layers. The inner-most layer undergoes explosive welding when exposed to a pressure wave from an explosion. An intermediate layer in-elastically deforms when exposed to the explosion. The third and outer-most layer includes a plurality of elongated, pressurized tubes that contain fire retardant, among other chemicals. Silicone gel is interposed between the tubes.

Owner:LOCKHEED MARTIN CORP

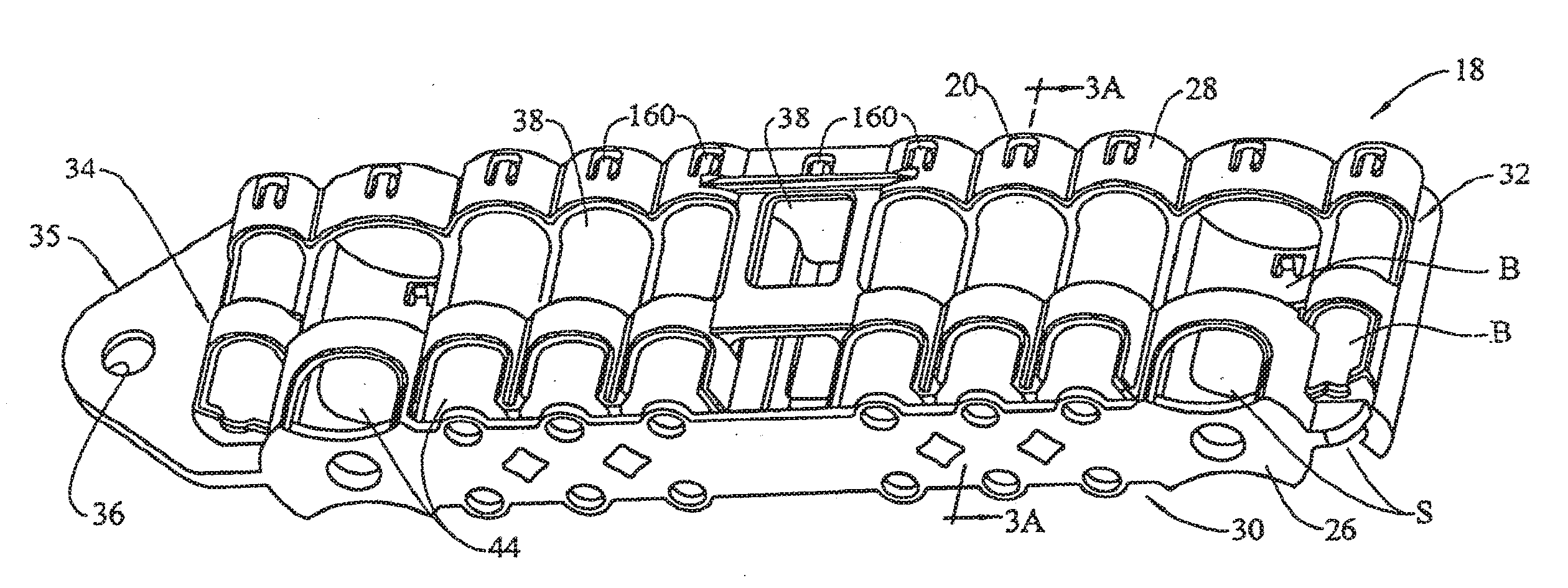

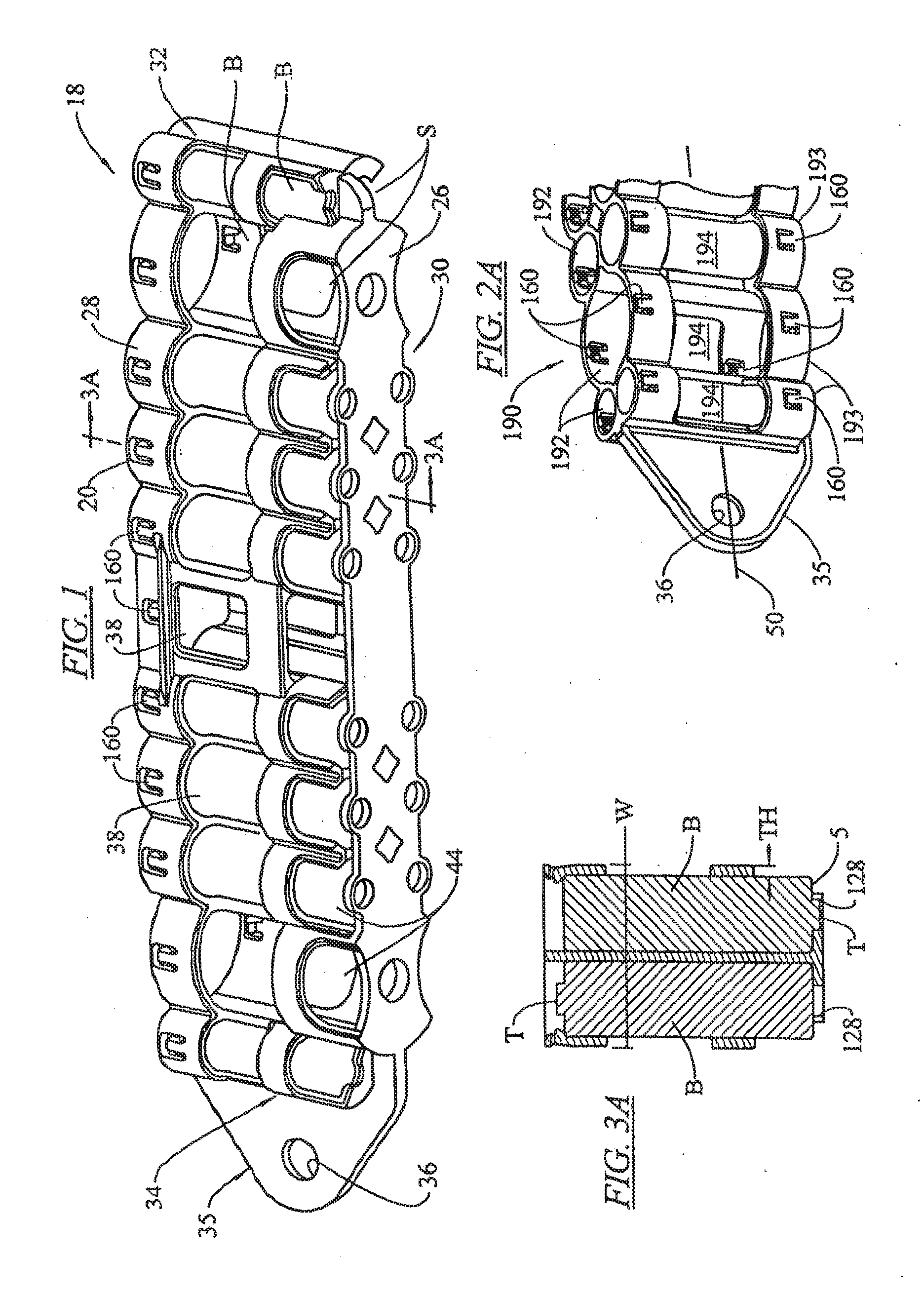

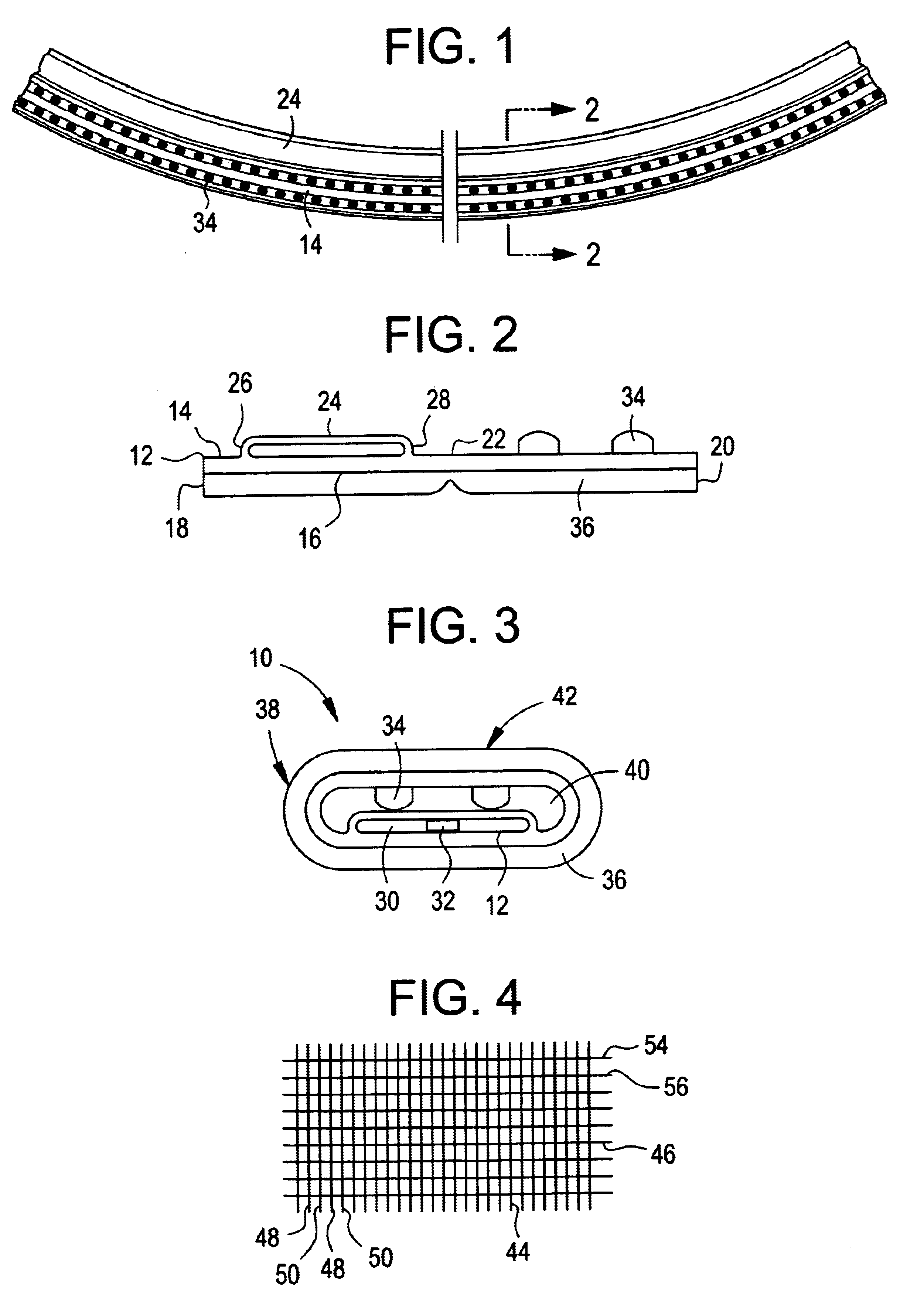

Wearable protective system having protective elements

InactiveUS6911247B2Resistance to penetrationLayered productsWoven fabricsProtective systemPliability

A protective covering system having high-flexibility and low areal density characteristics. In one aspect of the invention, the protective system includes a plurality of metallic staples or wire elements secured to multi-layer matrix including woven fibers, the layers being oriented at cross angles to provide a grid-like pattern of protective elements. In one aspect of the invention, protective elements provide a coverage area of less than 90% and as little as 40% of total surface area. In one aspect of the invention, protective elements may be mechanically secured to a matrix by a puncture and crimp process. In another, wire elements may be attached or woven into one or more matrix layers.

Owner:WARWICK MILLS INC

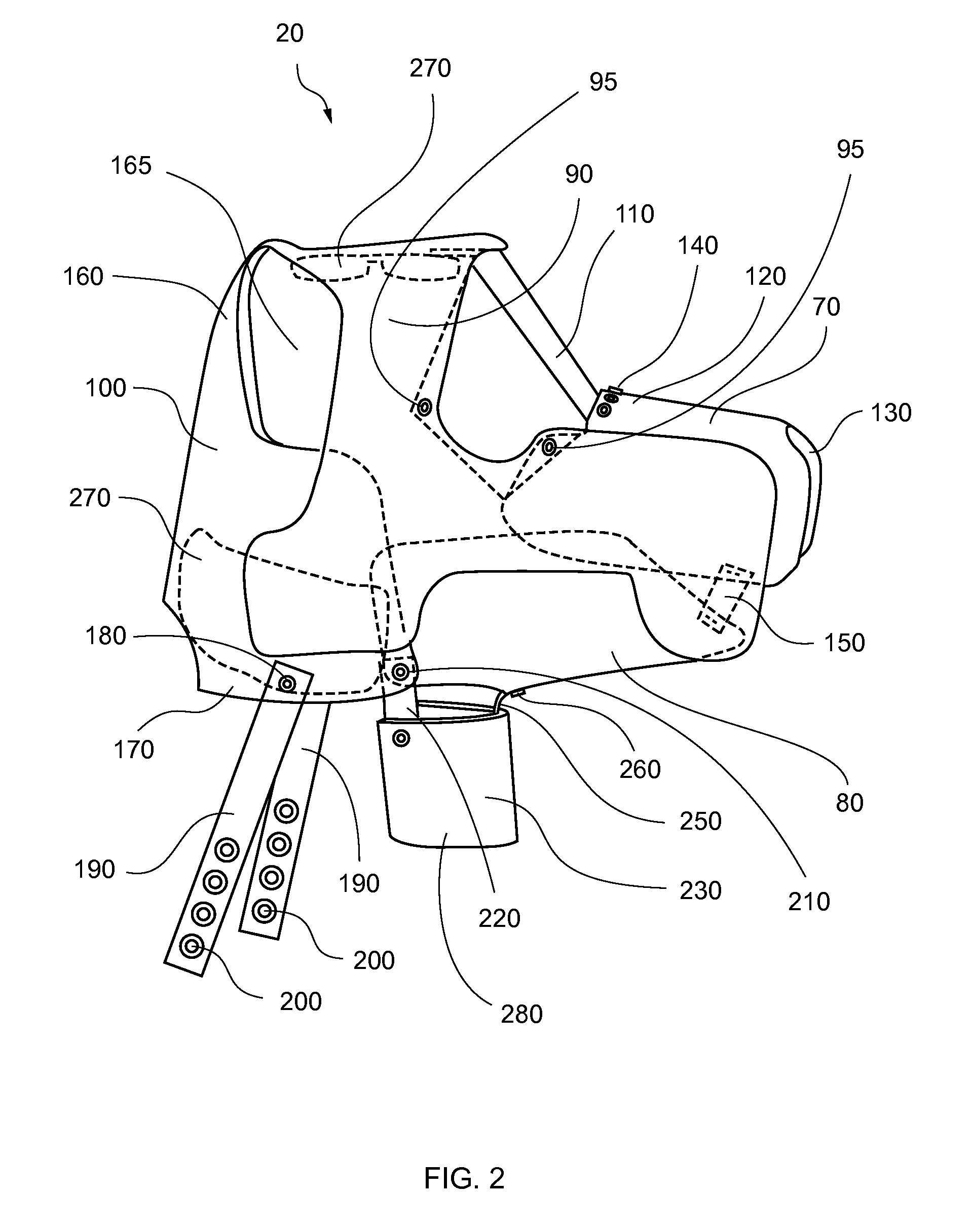

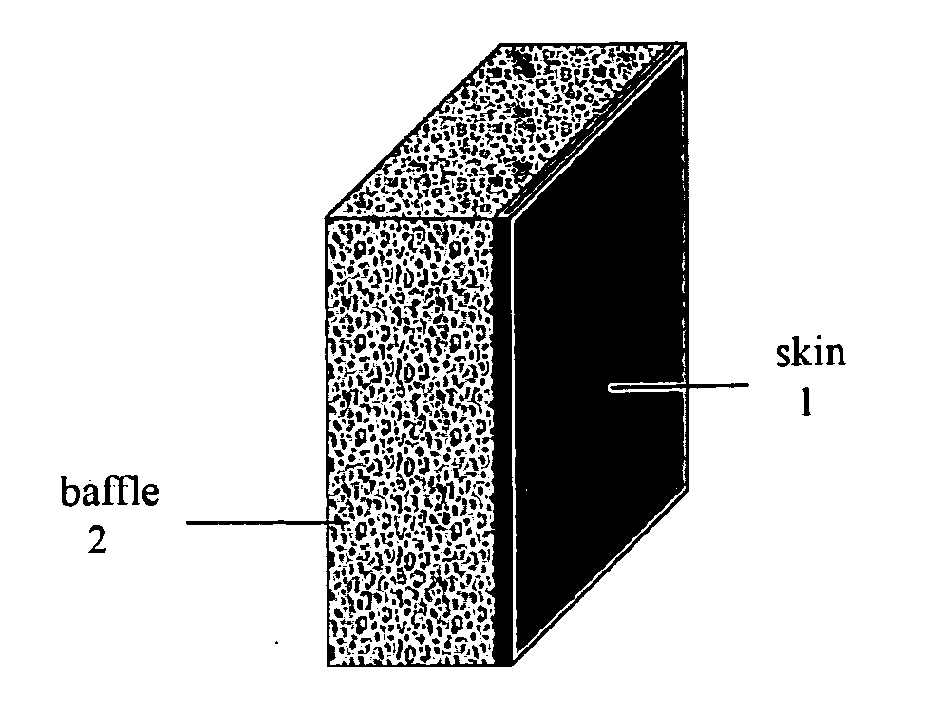

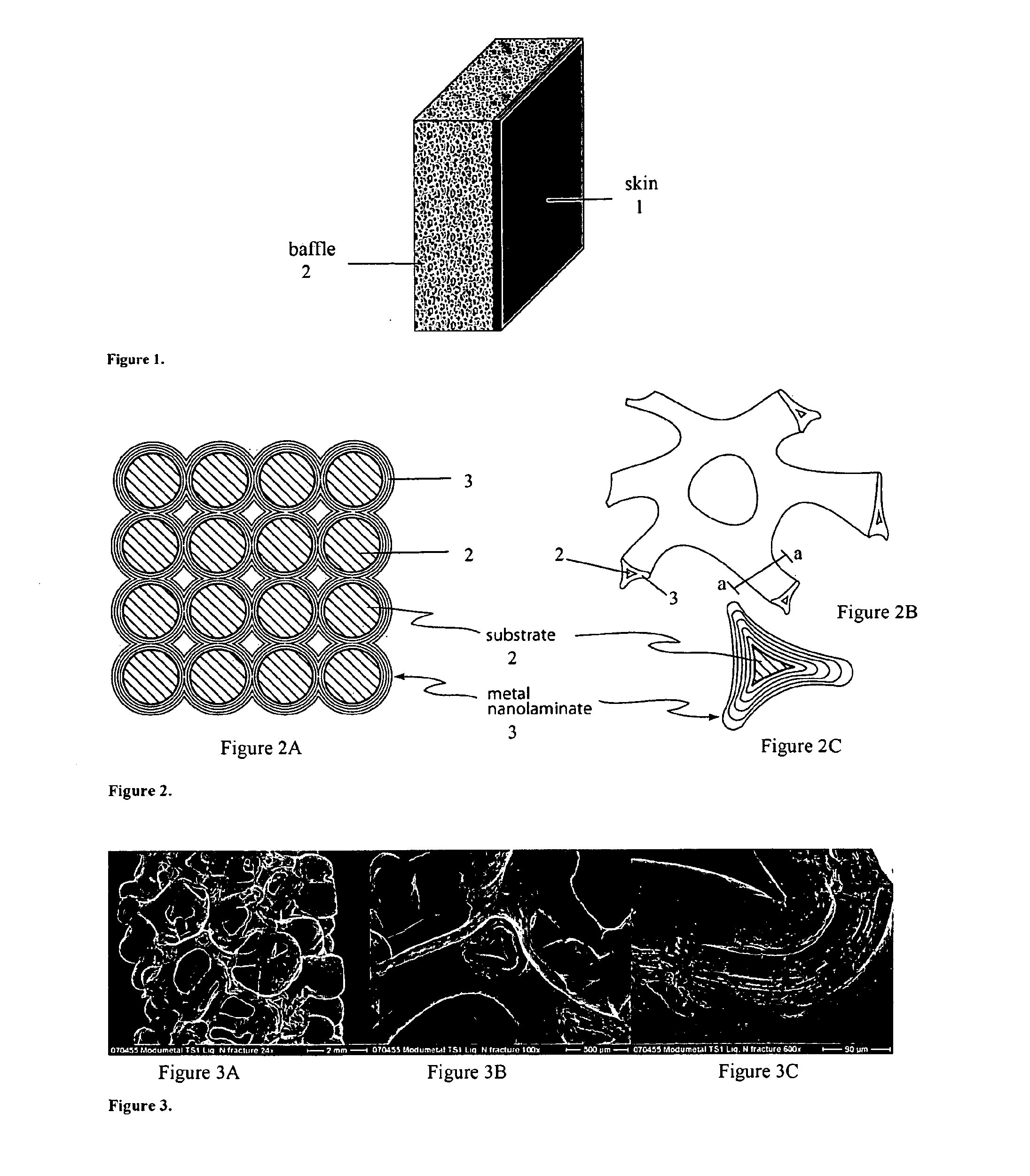

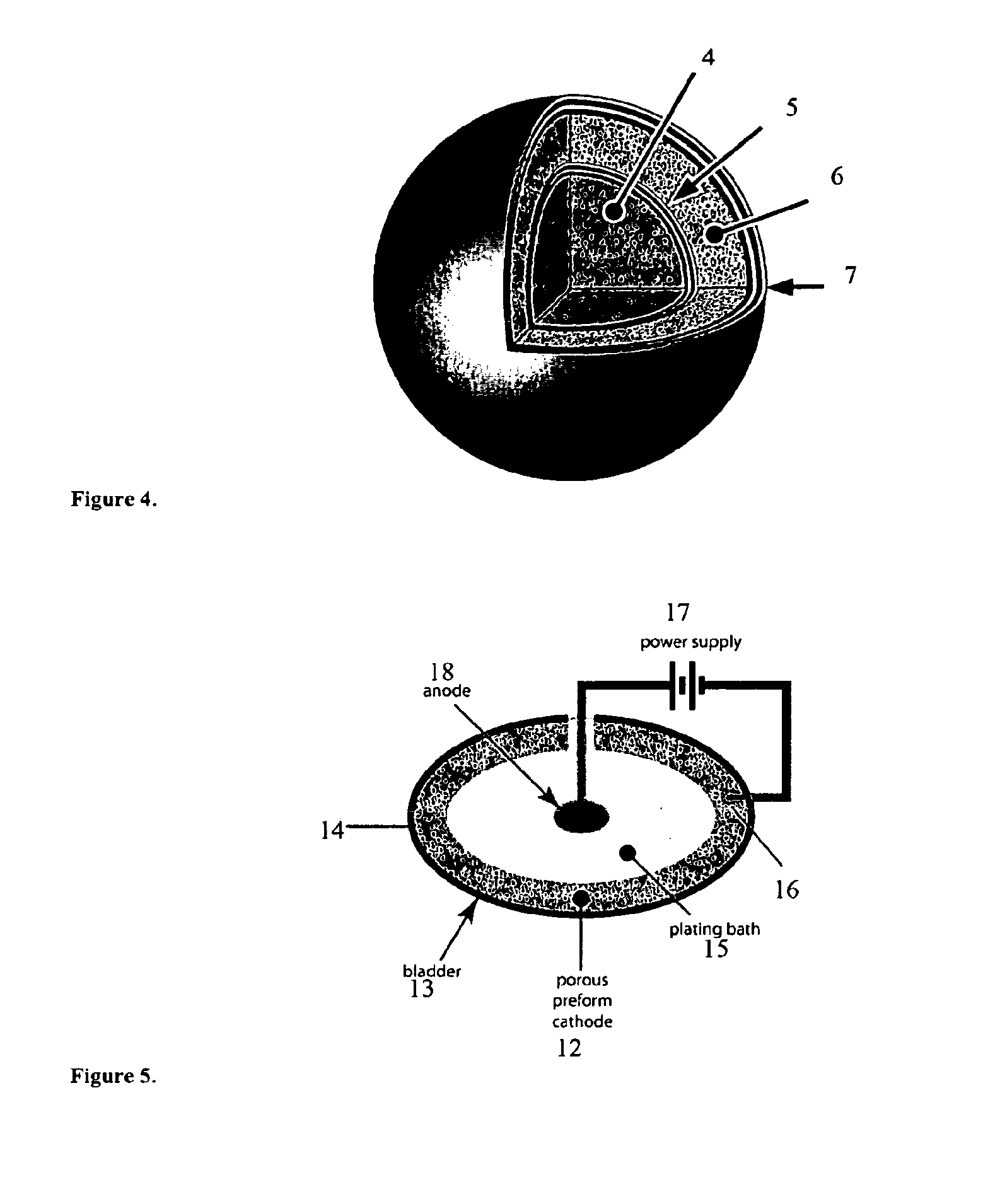

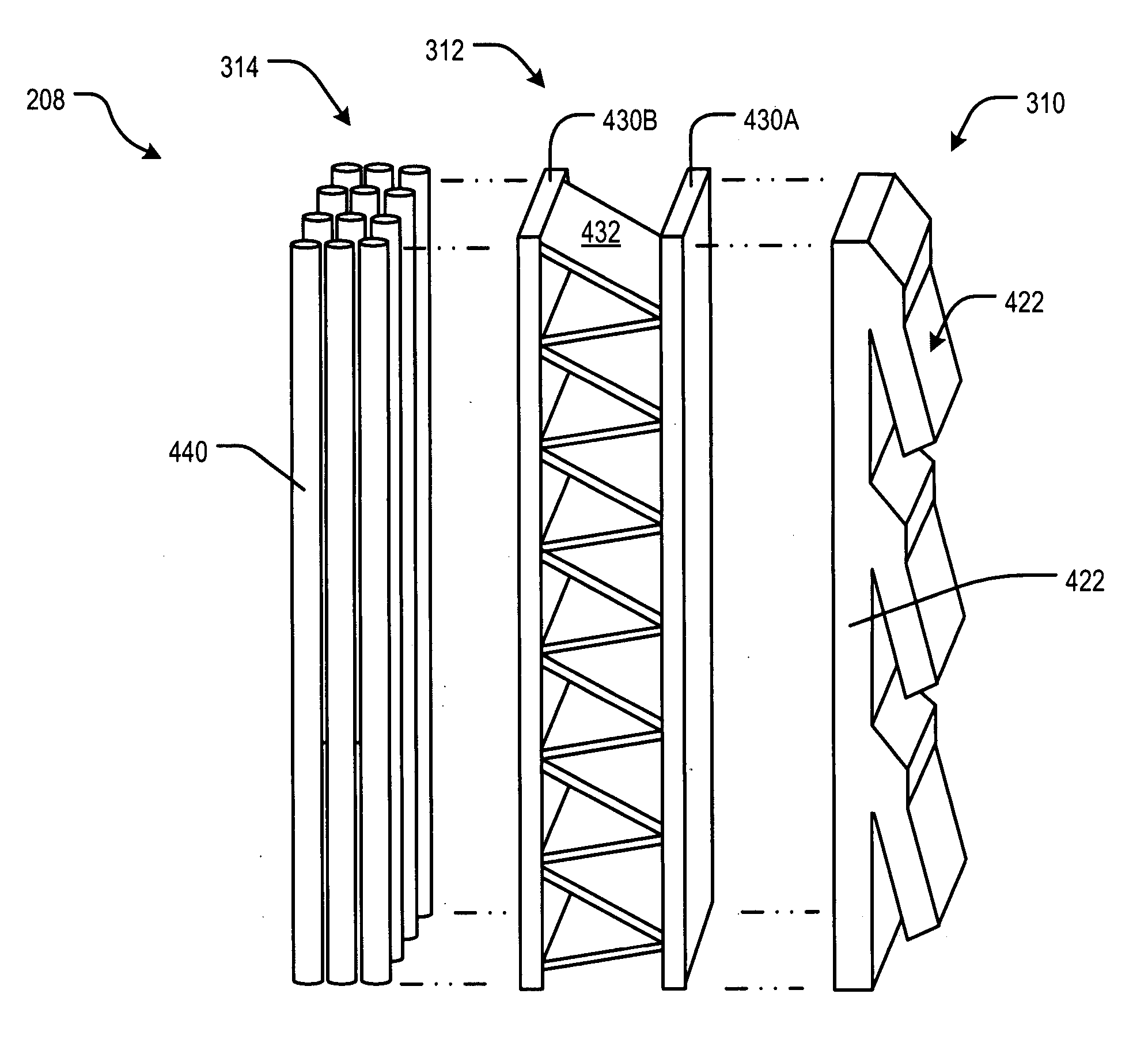

Nanolaminate-reinforced metal composite tank material and design for storage of flammable and combustible fluids

ActiveUS20110186582A1Raise the ratioGreat vehicle traveling distanceElectrolytic coatingsLarge containersFuel tankVoid space

An improved fuel tank and method of forming a fuel tank utilize reinforced porous metal composite materials. In one embodiment, the composite material includes a fully dense, fluid-impermeable skin (1) combined with a porous metal baffle (2). The skin (1) and baffle (2) may be formed as a single monolithic system via electrodeposition of a nanolaminate material into at least a portion of open, accessible void space within a porous preform (e.g., a metal foam preform) and on the exterior surface of the preform to form the fluid-impermeable skin (1).

Owner:MODUMETAL LLC

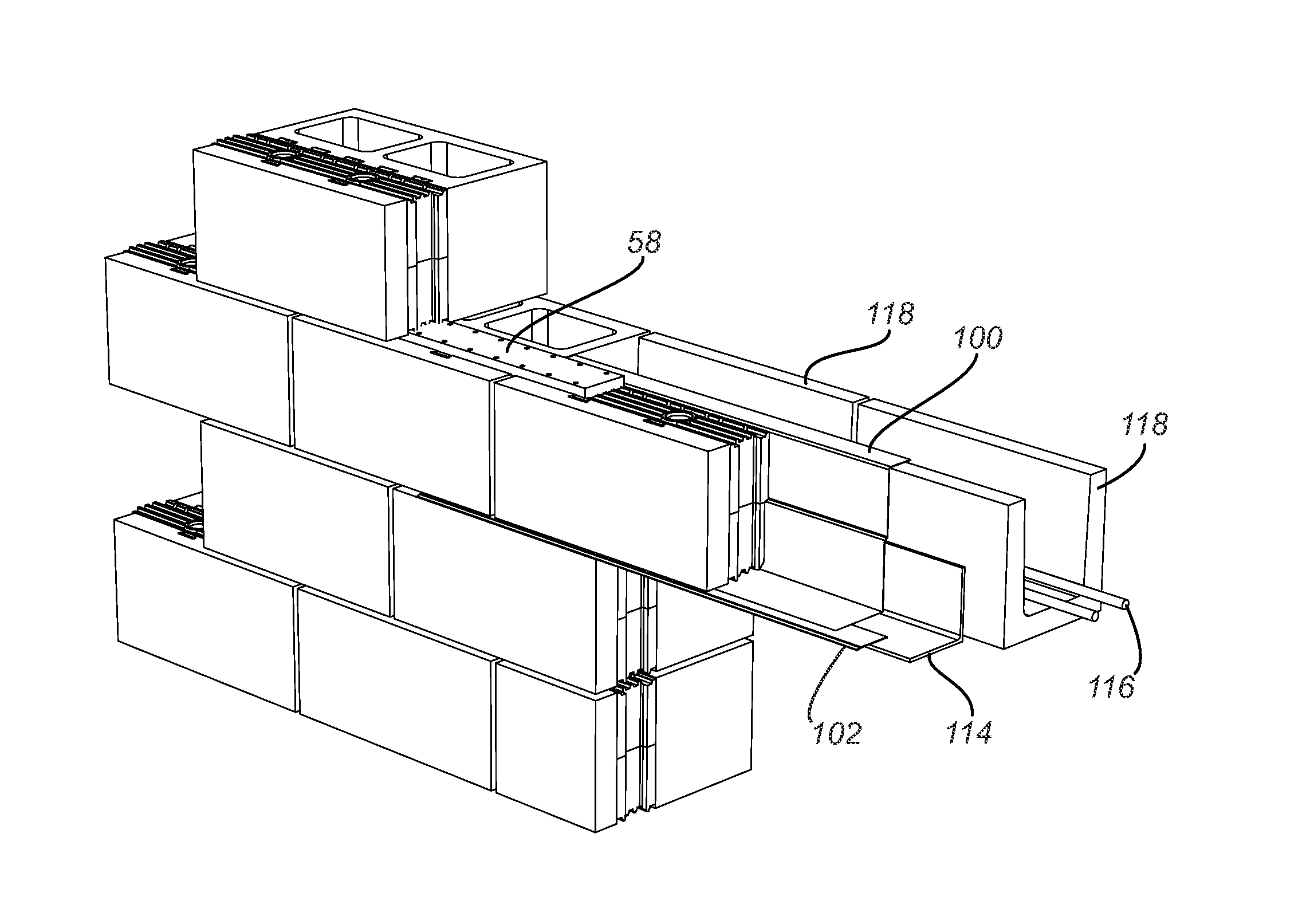

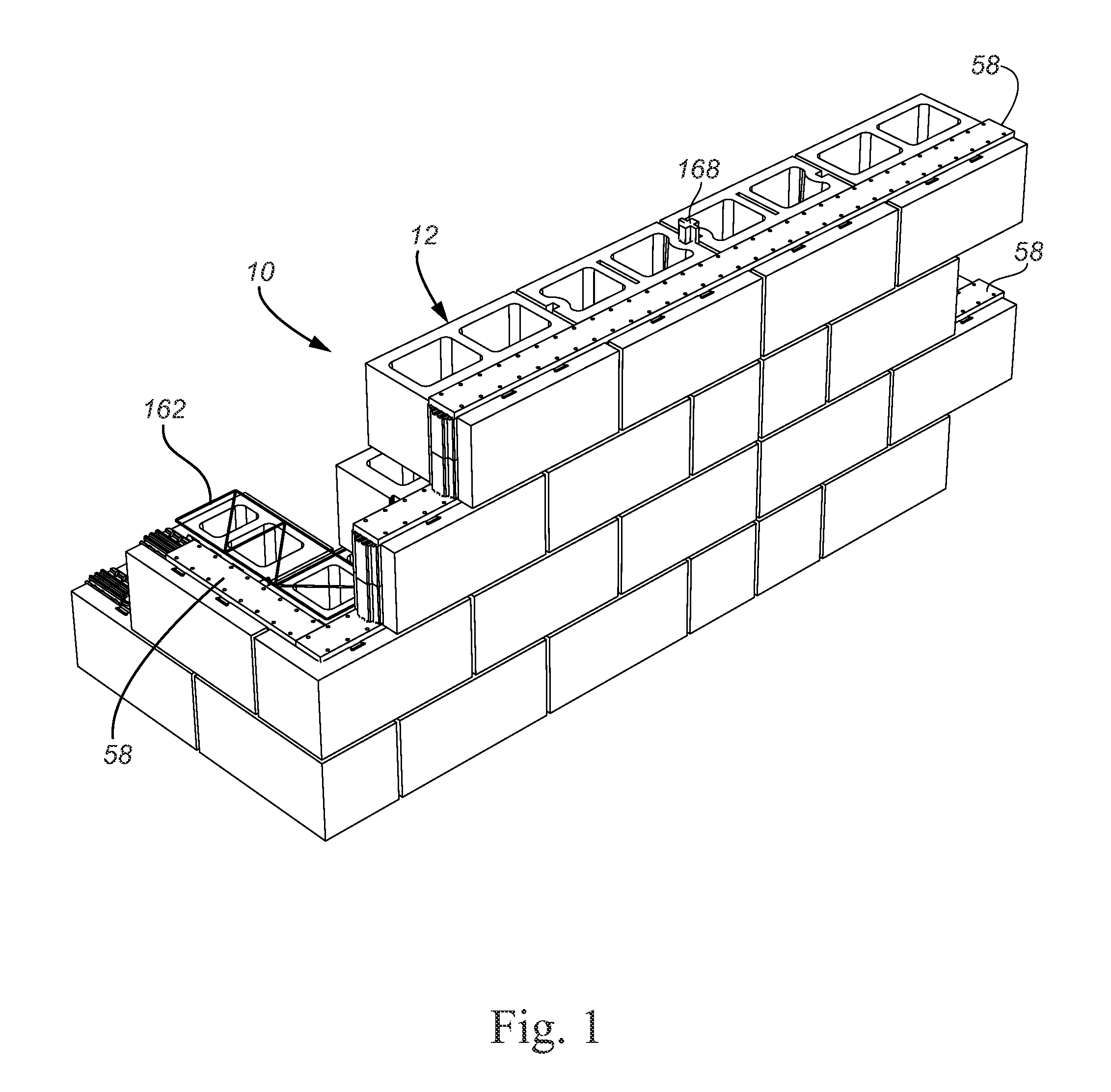

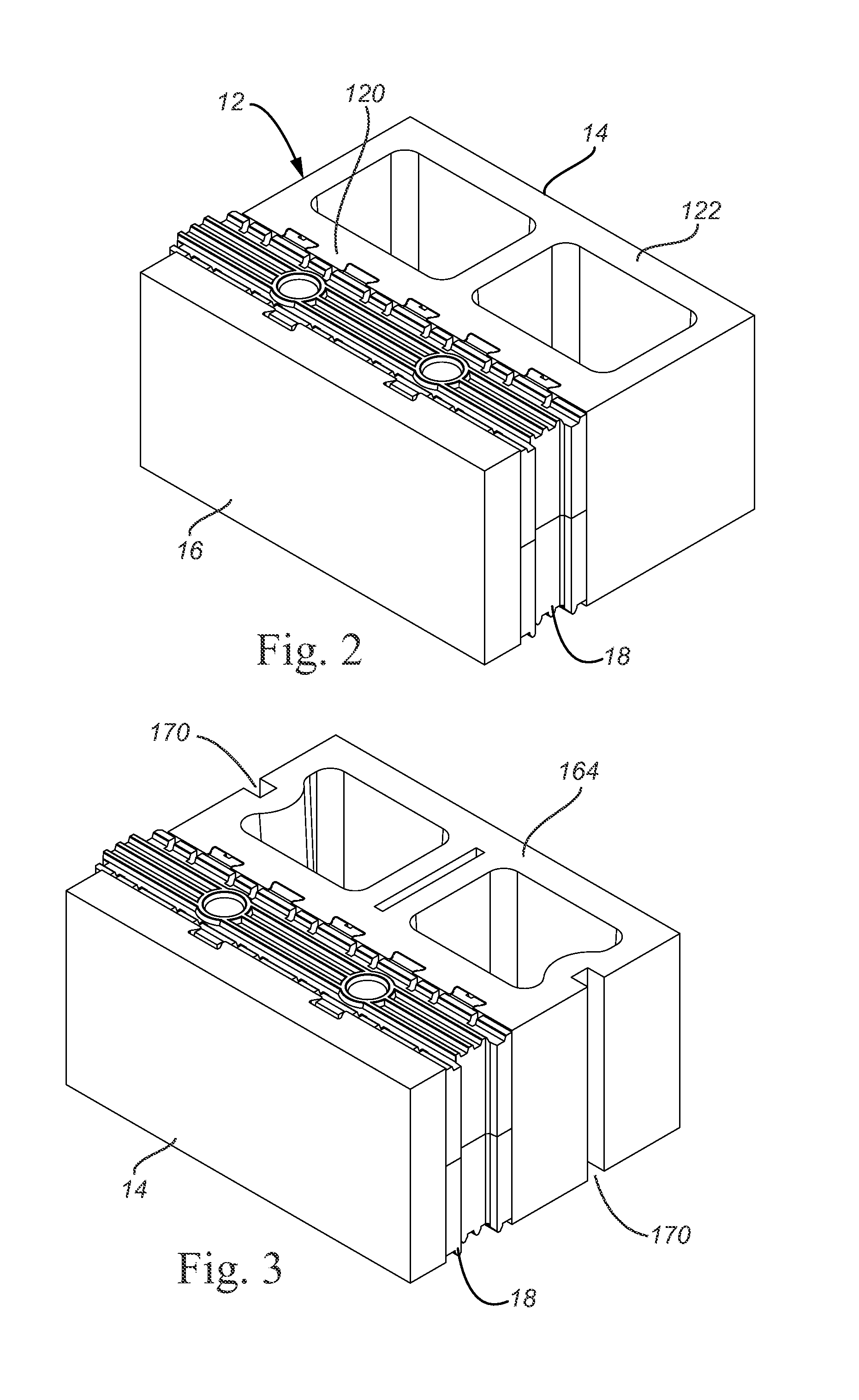

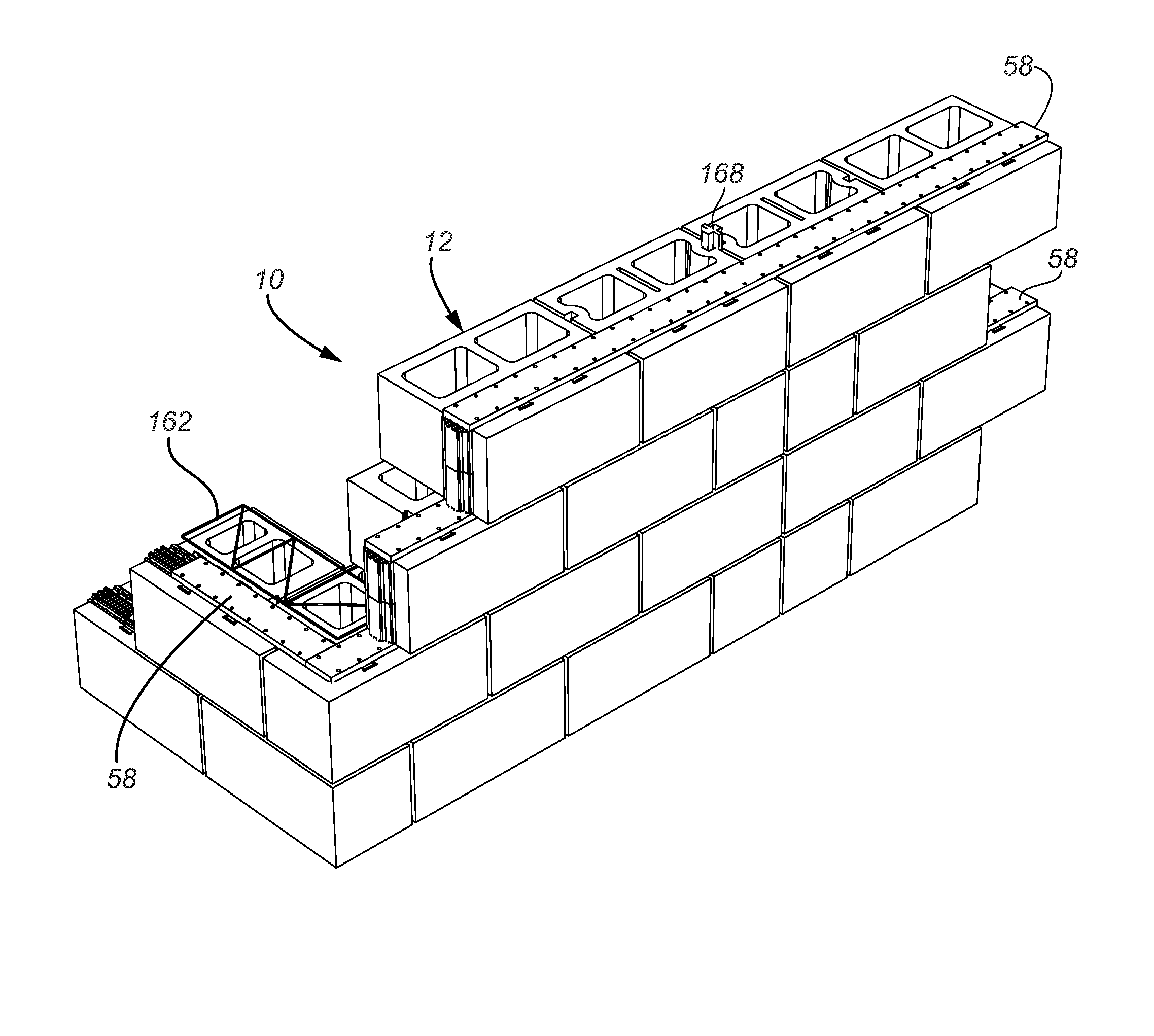

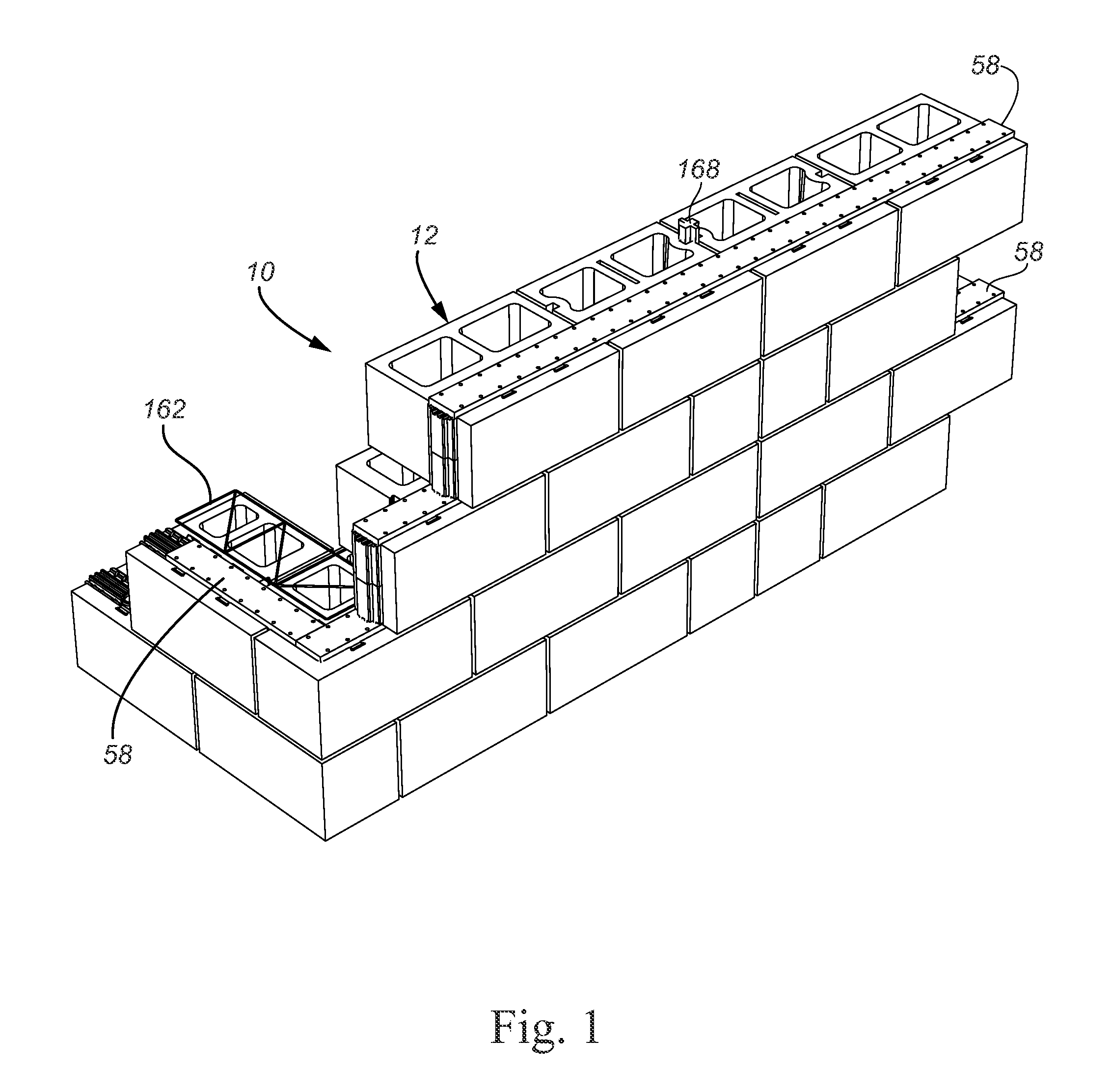

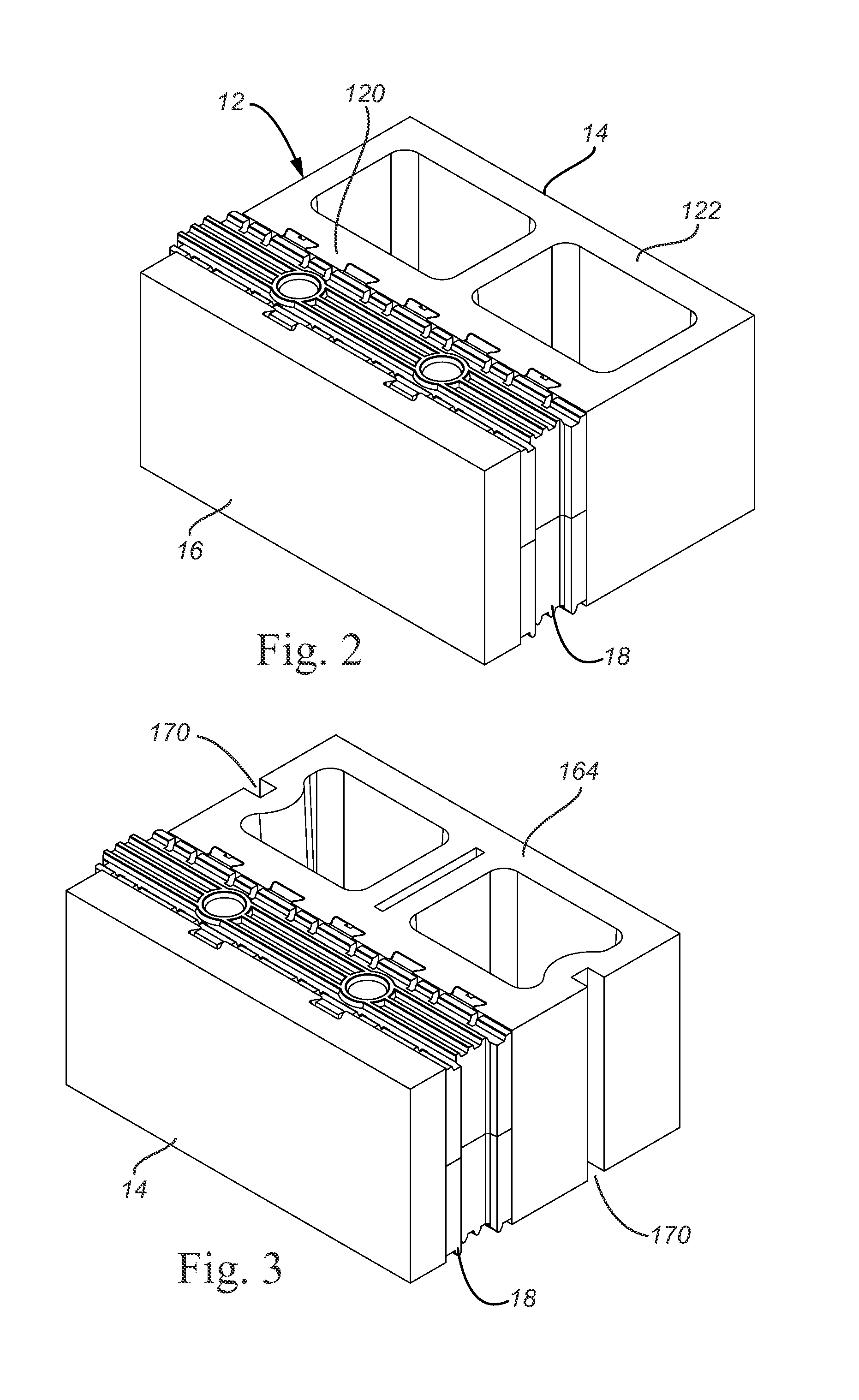

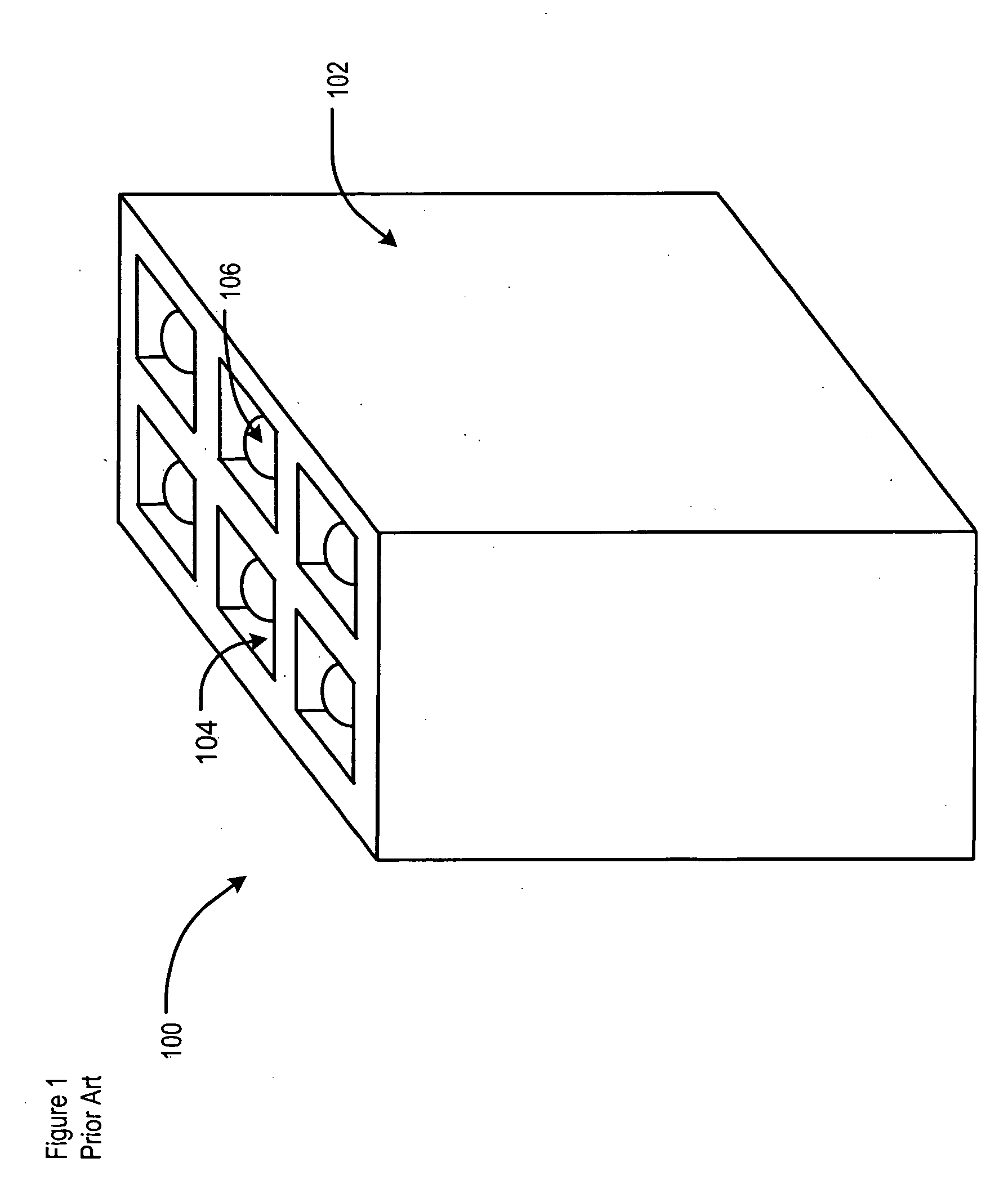

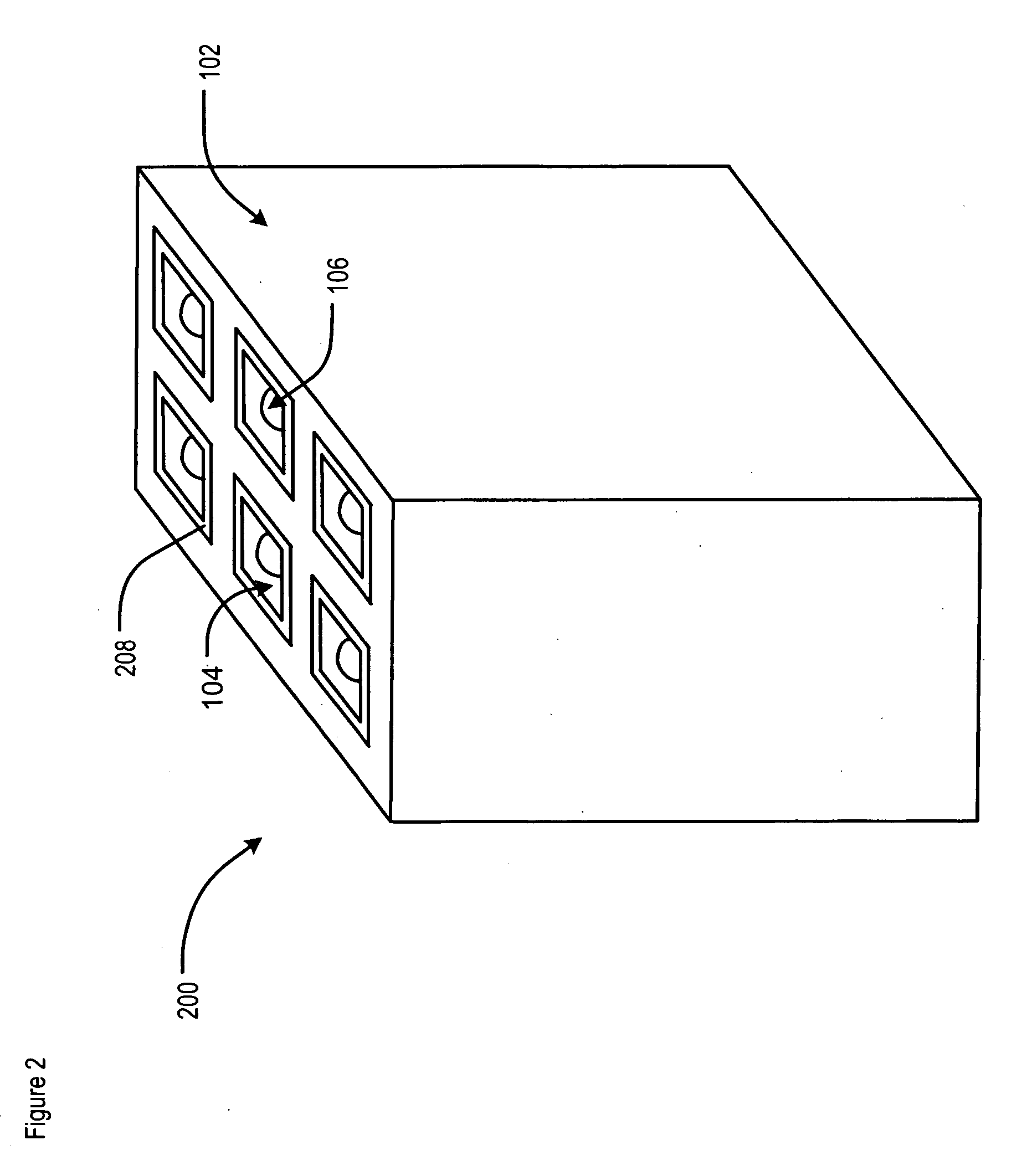

Insulated concrete masonry system

ActiveUS20140260029A1Strong and inexpensiveAvoid thermal bridgeStrutsConstruction materialStructural engineering

A insulated masonry wall system having insulation blocks between structural and face blocks to provide structures that are strong, inexpensive, avoid thermal bridges, and resist transmission of heat. The walls are attractive and versatile, and an enormous variety of decorative face members may be utilized. The face blocks are attached to the structural blocks to prevent facing materials from falling even if fire destroys the insulation blocks between the structural blocks and the facing. The system resists water penetration and effectively drains water that does penetrate any portion of the system.

Owner:OLDCASTLE ARCHITECTURAL

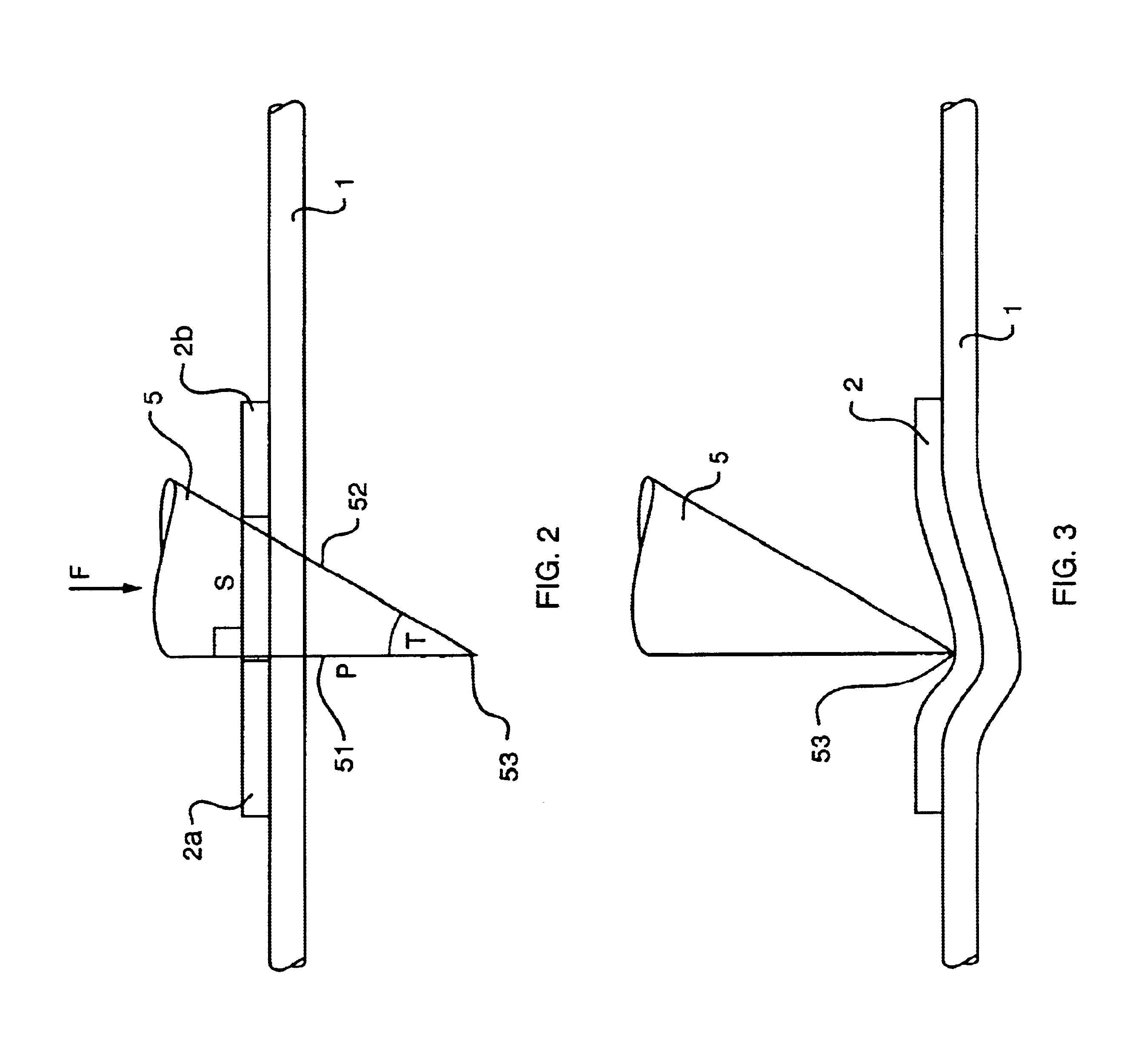

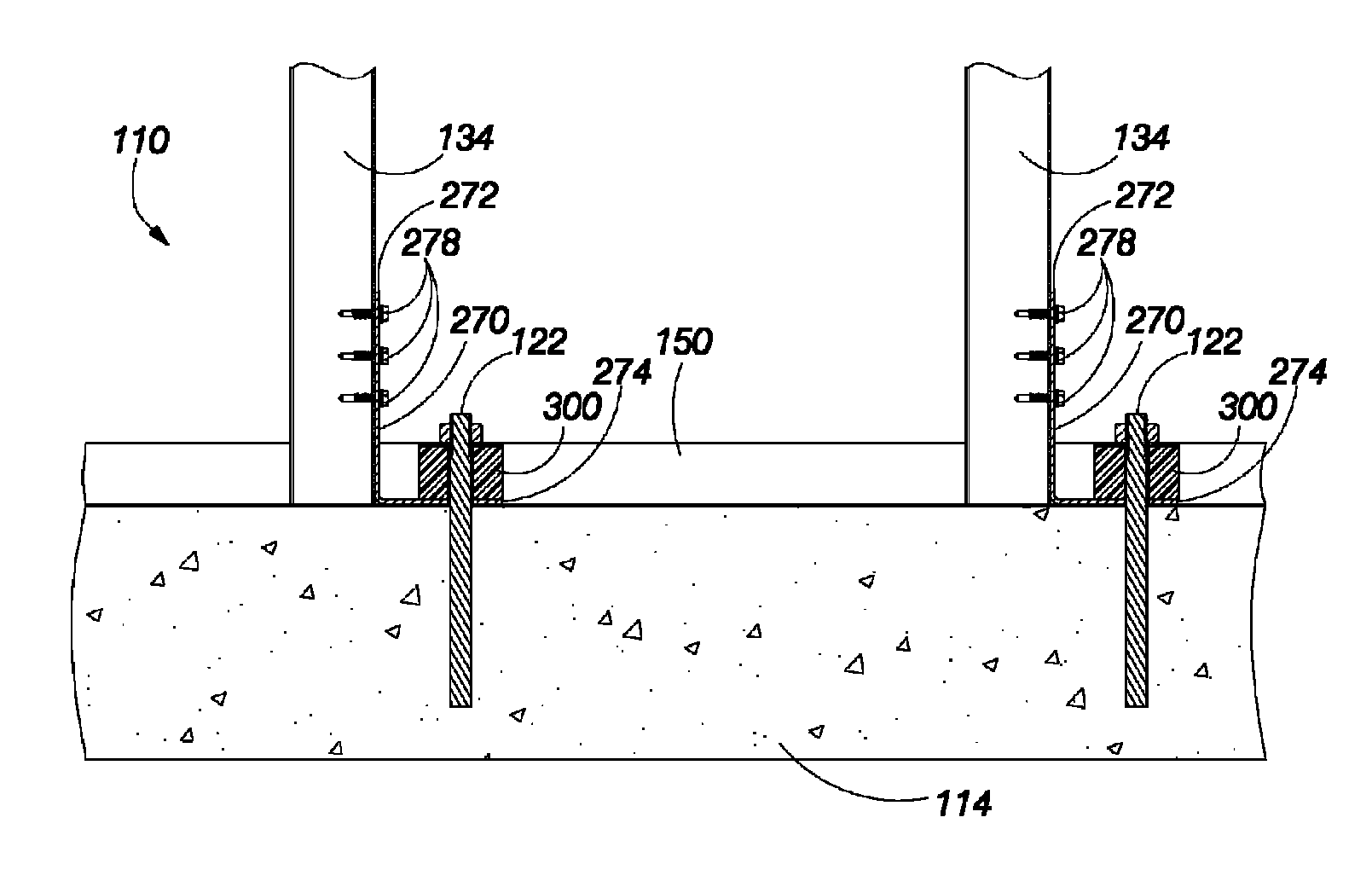

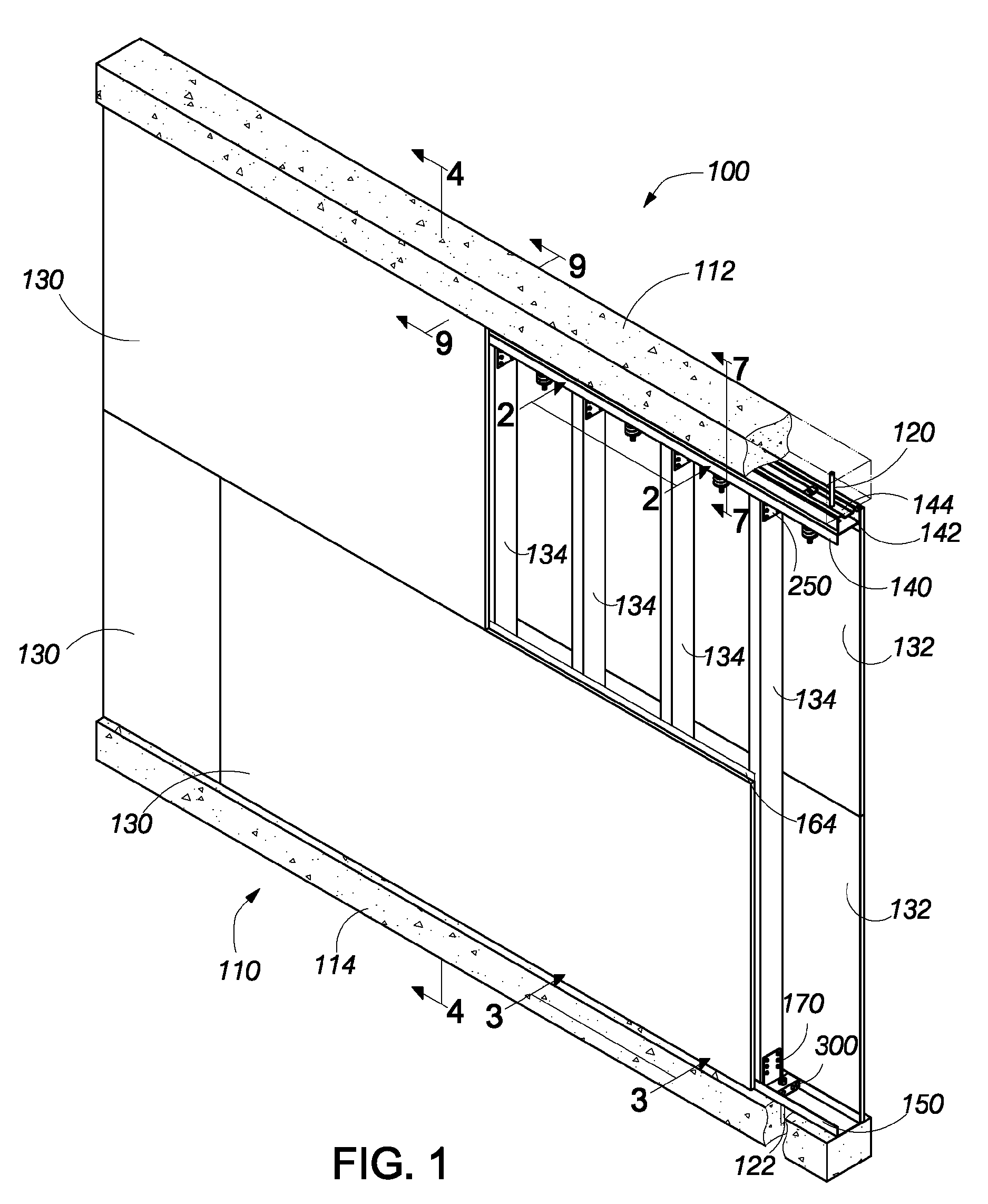

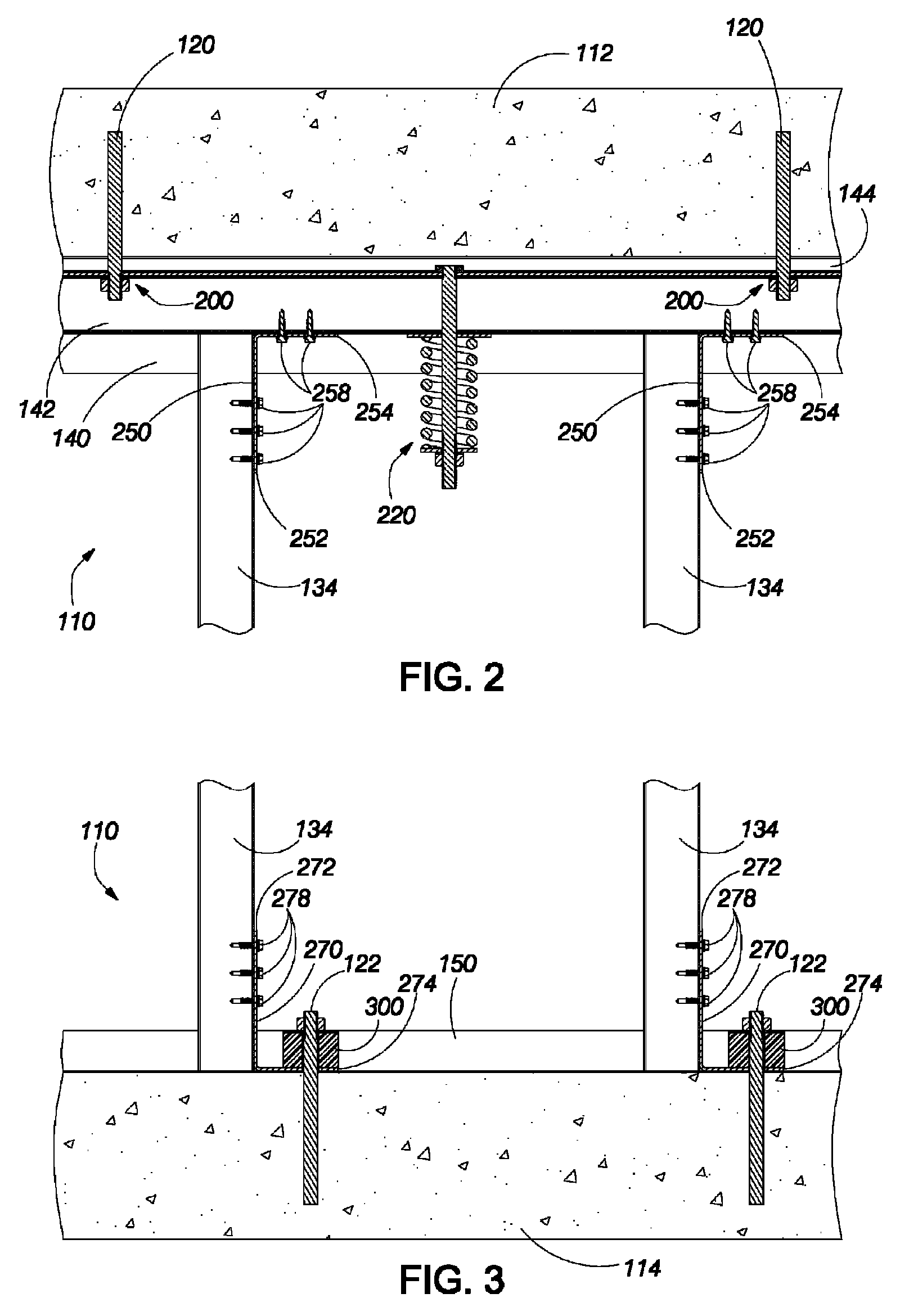

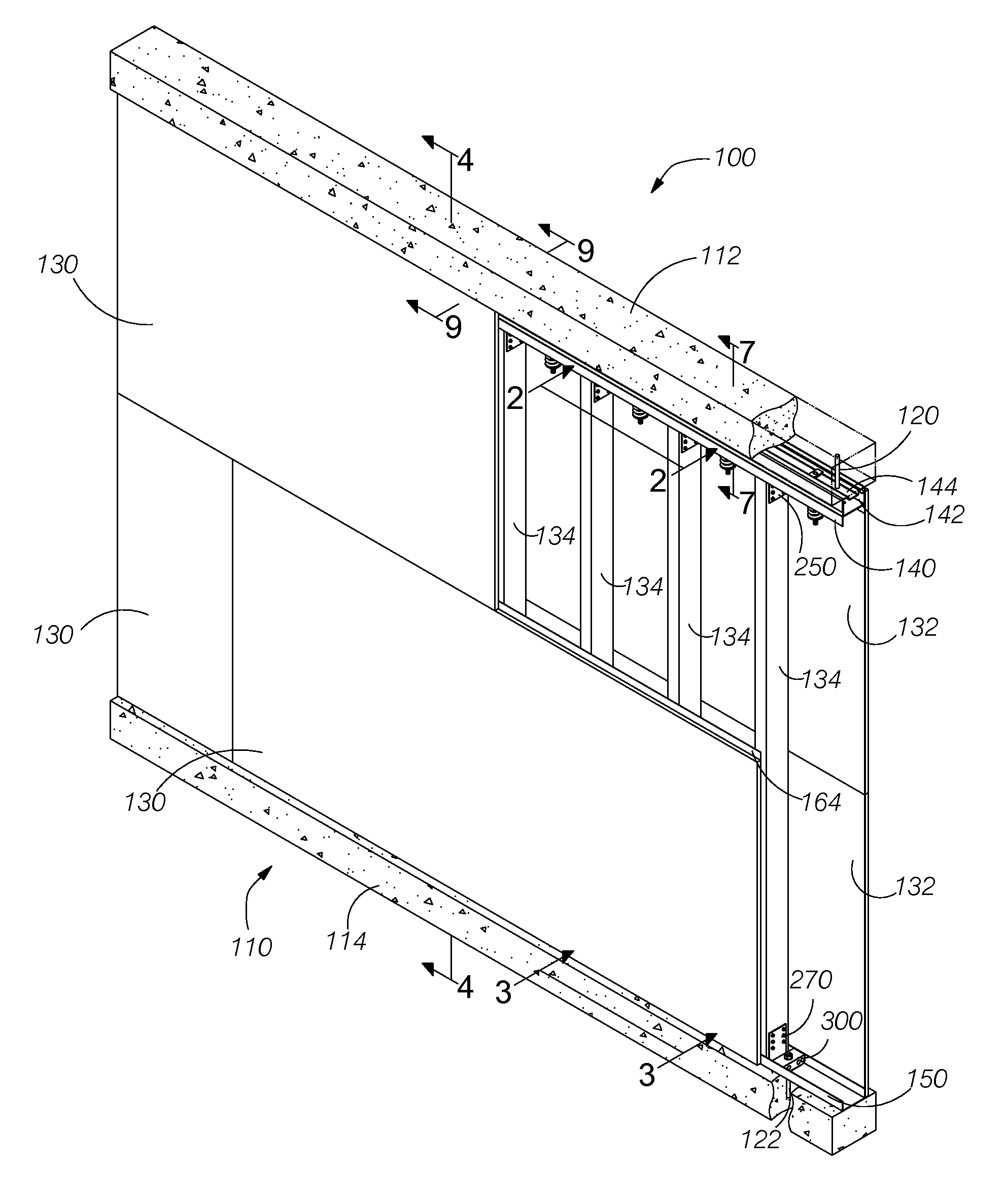

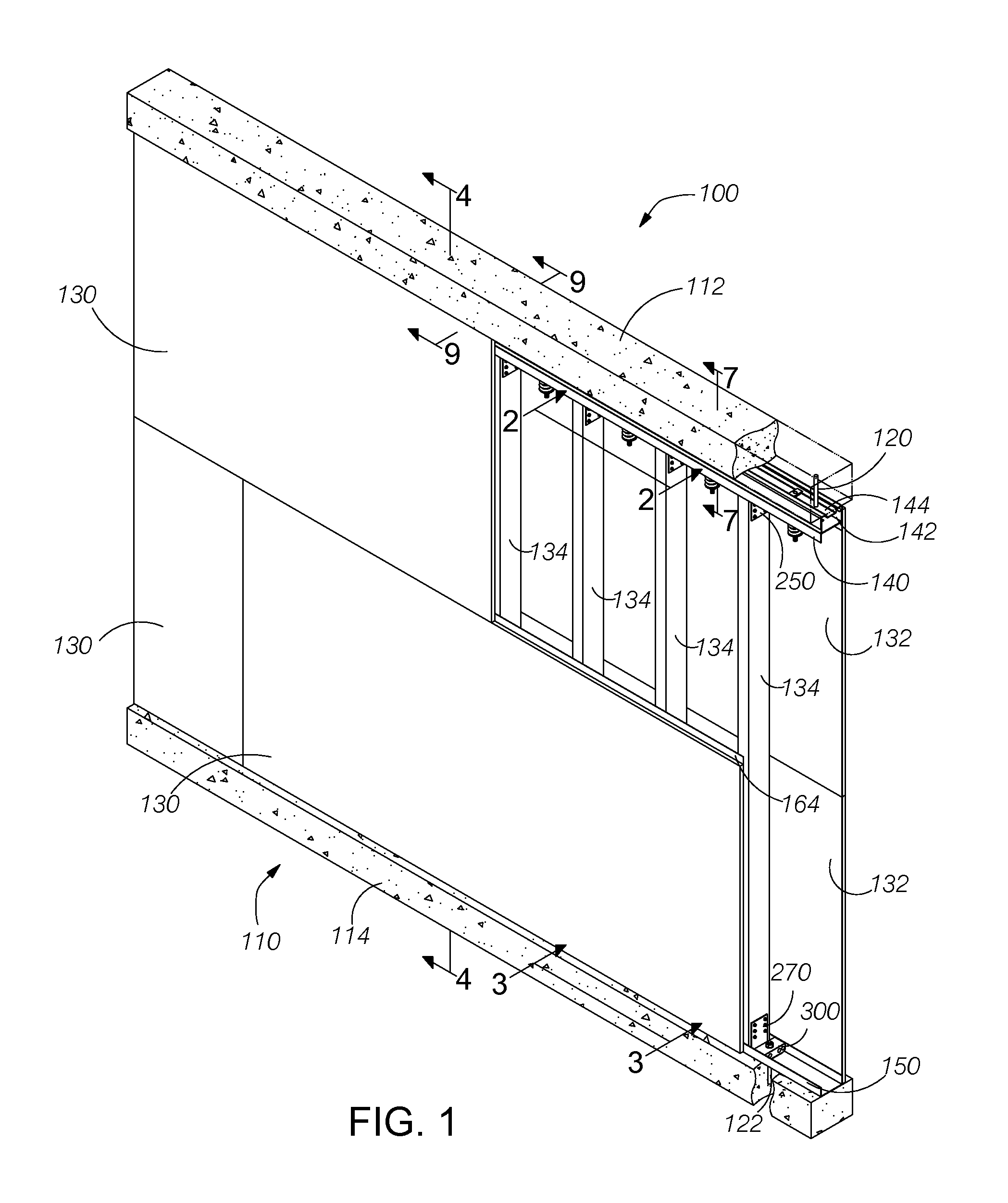

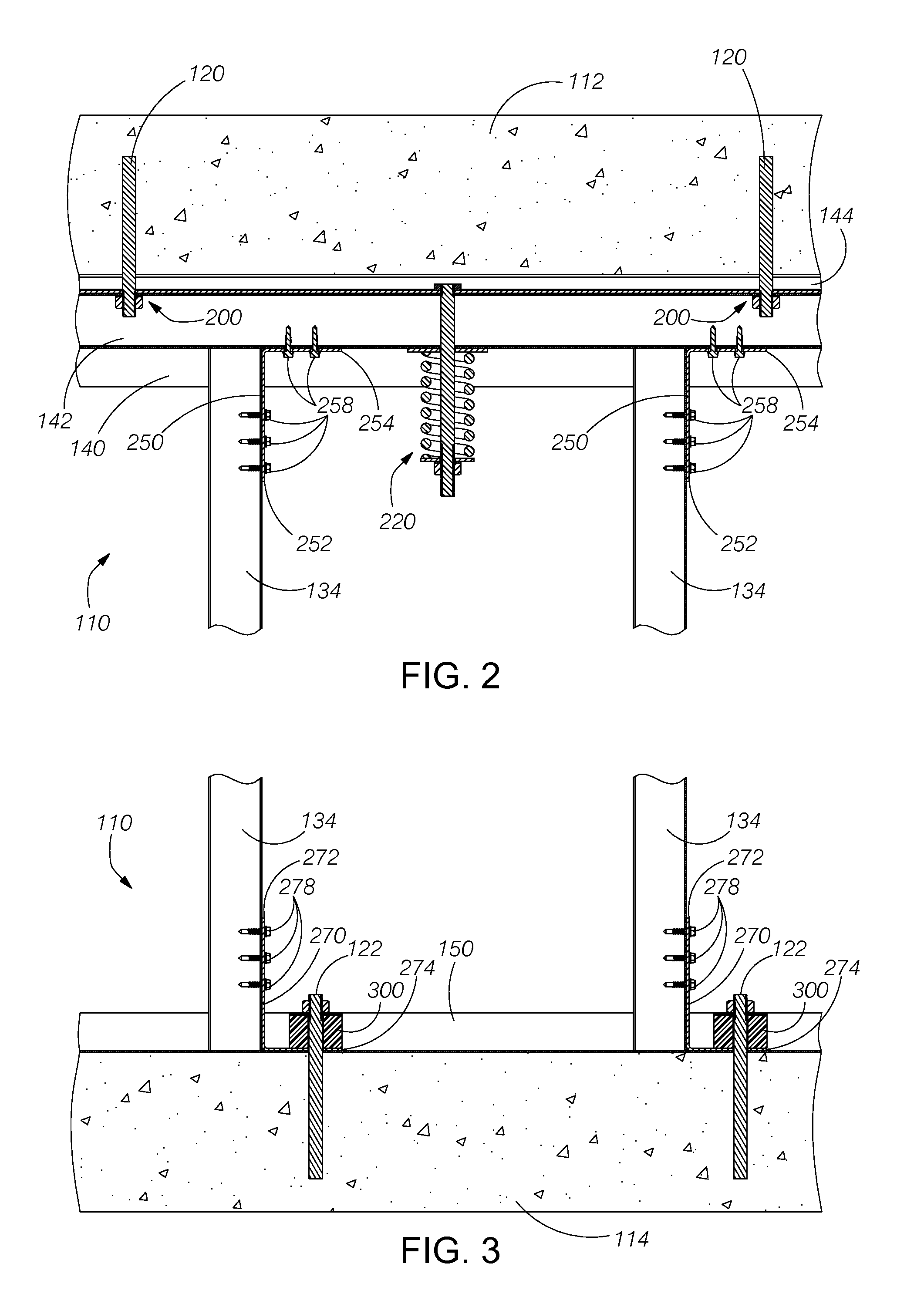

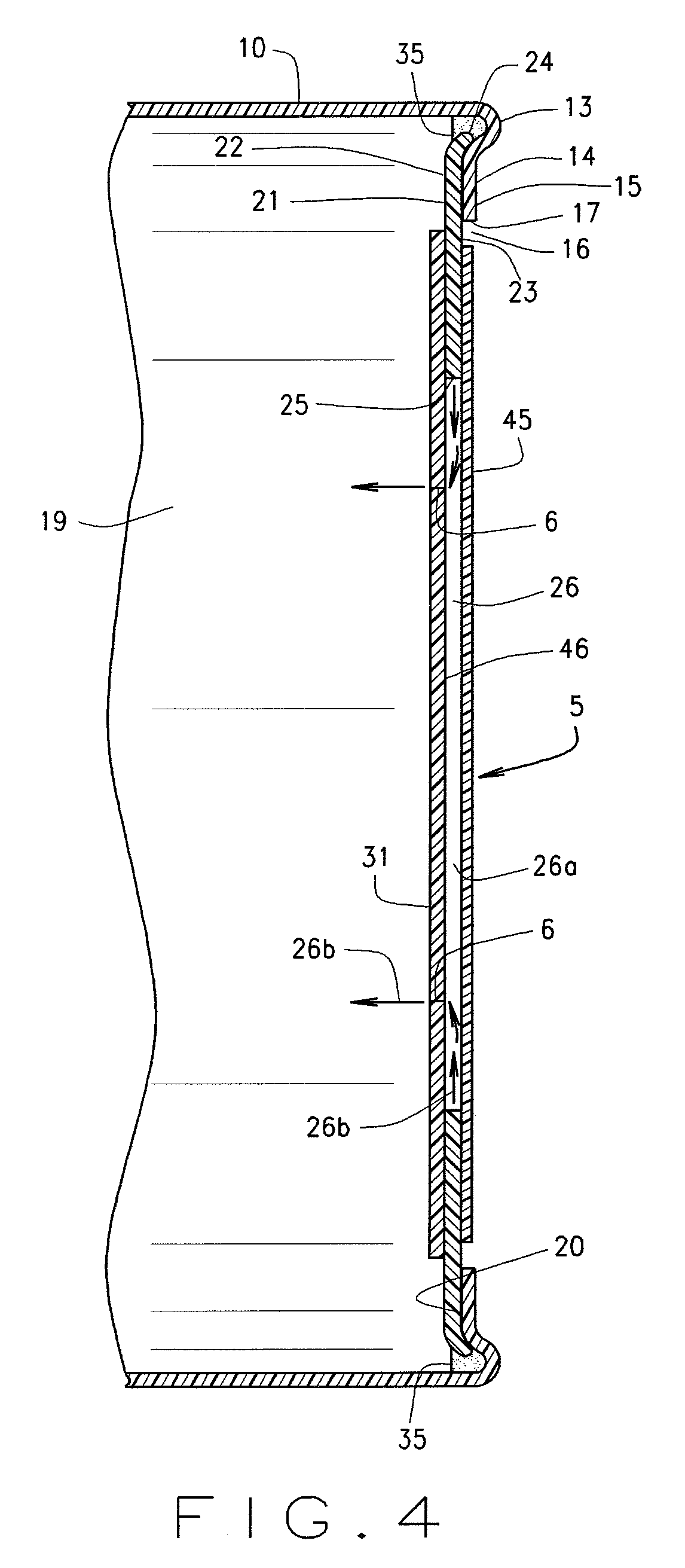

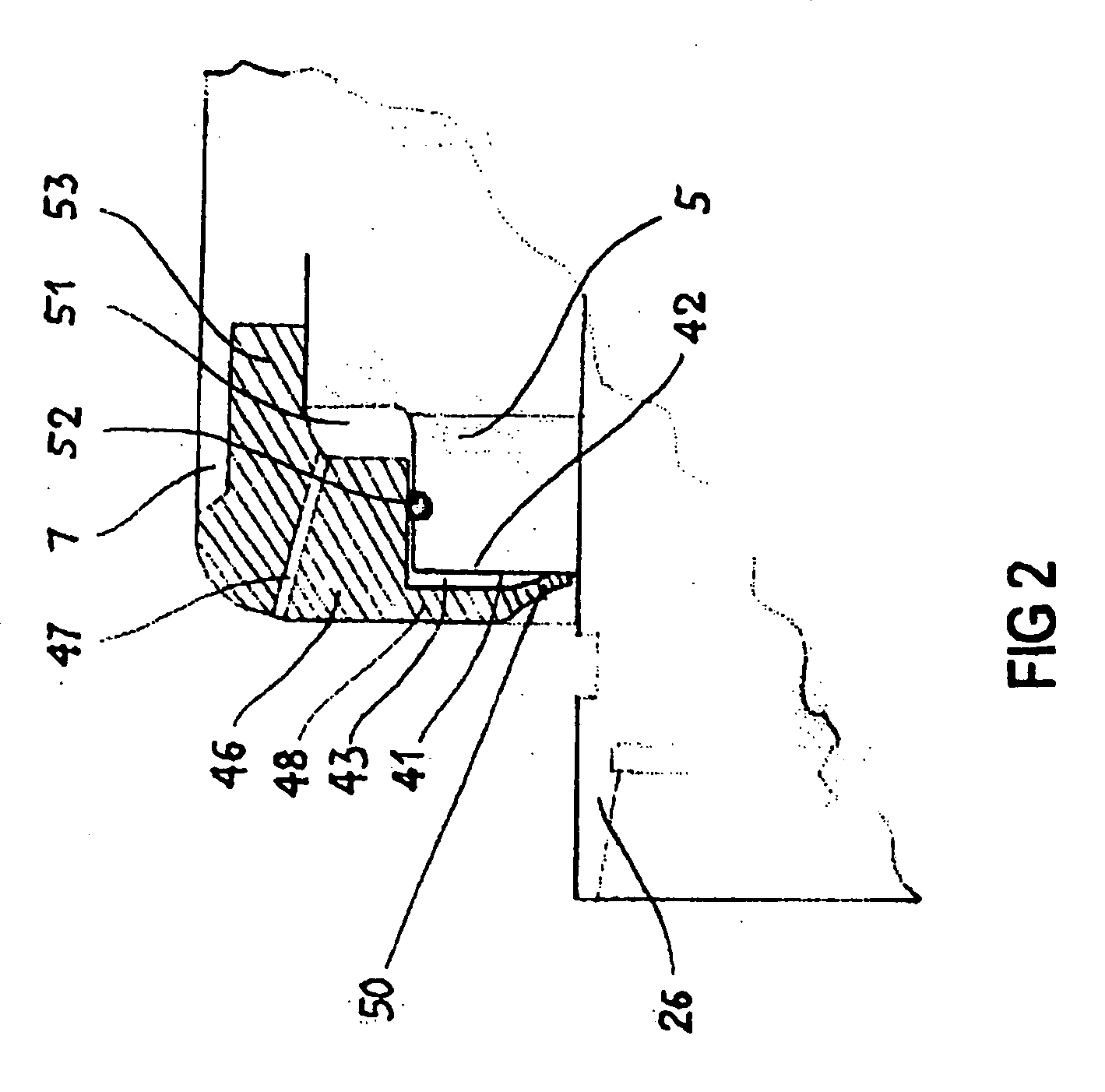

Energy absorbing blast wall for building structure

ActiveUS8079188B2Effective absorptionImprove securityBuilding roofsCeilingsEnergy absorptionWall plate

A wall system protects a building structure from pressure caused by explosive blasts. The wall system includes vertical studs. Outer blast wall panels and inner blast wall panels are secured to the opposing sides of the vertical studs. An upper mounting system is attached to the building structure. An upper mounting system includes a fixed track, a movable mounting track, and an energy absorbing system that flexibly couples the movable mounting track to the fixed track. The upper ends of the vertical studs are attached to movable mounting track. A lower mounting system includes a mounting track that aligns the lower ends of the vertical studs. A respective attachment clip is attached to a lower portion of vertical stud. Each attachment clip is attached to the building structure with an energy absorption pad that resists vertical and lateral movement of lower end of the respective vertical stud.

Owner:SPECIALTY HARDWARE LLC

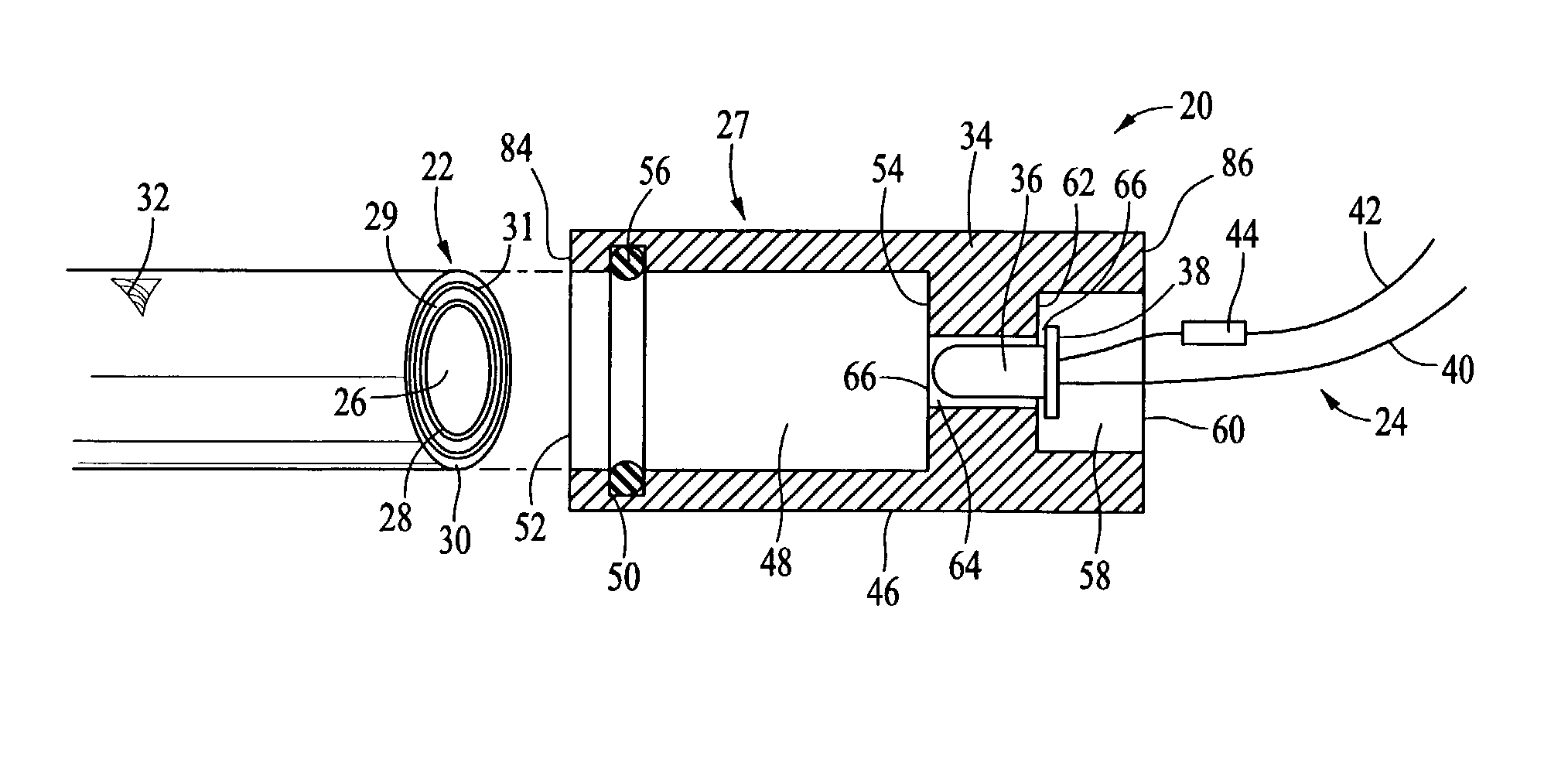

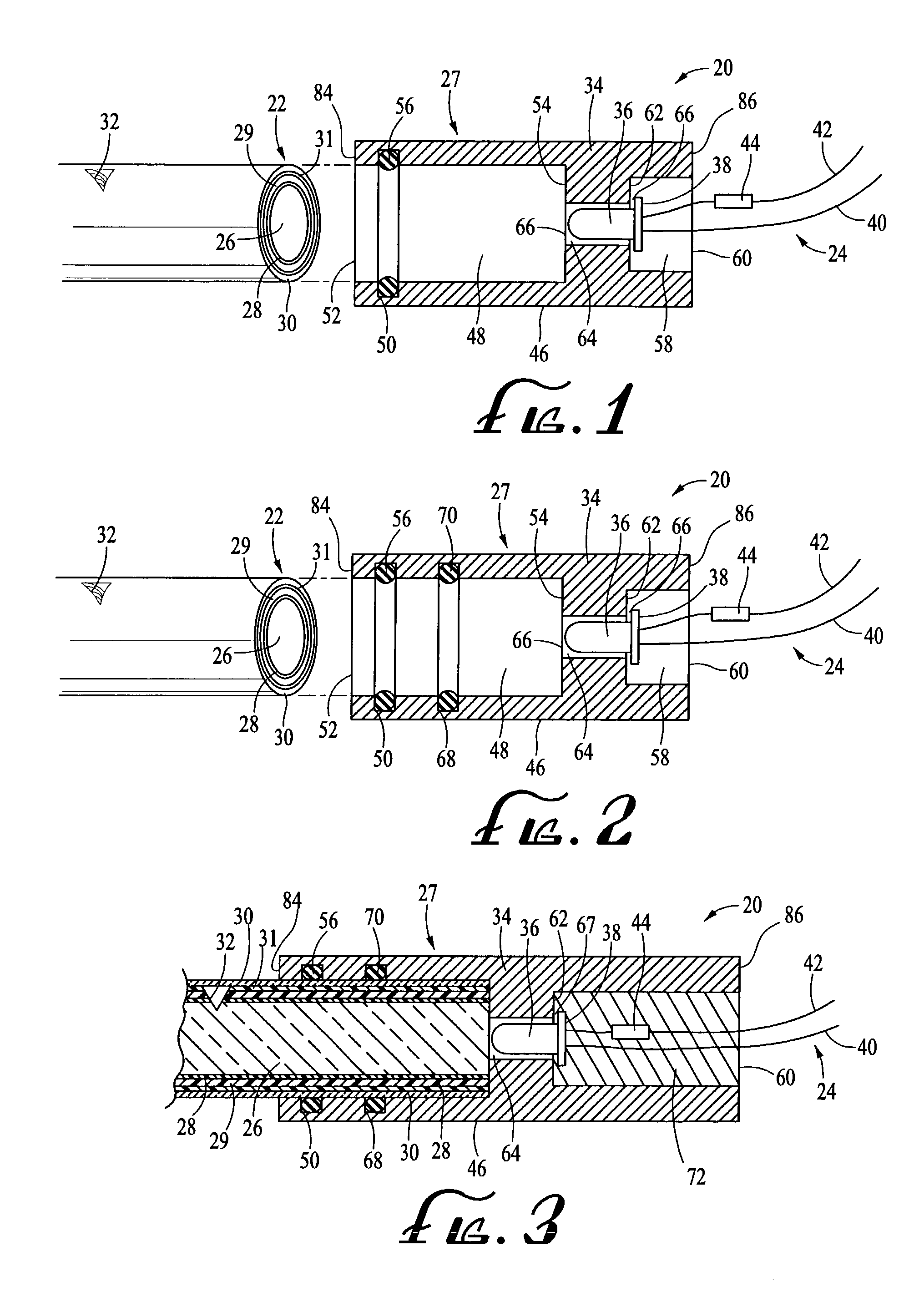

Fiber optic LED light

An LED coupled to a large core plastic optical fiber light guide with a tubular connector having a first bore into which the light guide is inserted, a second bore into which the LED and its attached wires are inserted and a third bore adjacent to the first bore, extending between the first and second bores and into which the LED is positioned so that when illuminated the LED transmits light into the guide with the first bore. The connector includes helical threads formed in the first bore into which the guide is threaded to securely retain the guide within the first bore and which form a seal to prevent contaminants from entering the region in the first bore adjacent the LED. Alternatively, the connector includes one or more internal channels extruding around the inner periphery of the bore and into which one or more O-rings are positioned so that the guide is securely retained within the first bore and that a barrier is formed to prevent contaminants from entering the region in the first bore adjacent the LED. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope of the claims.

Owner:LUMENYTE INT

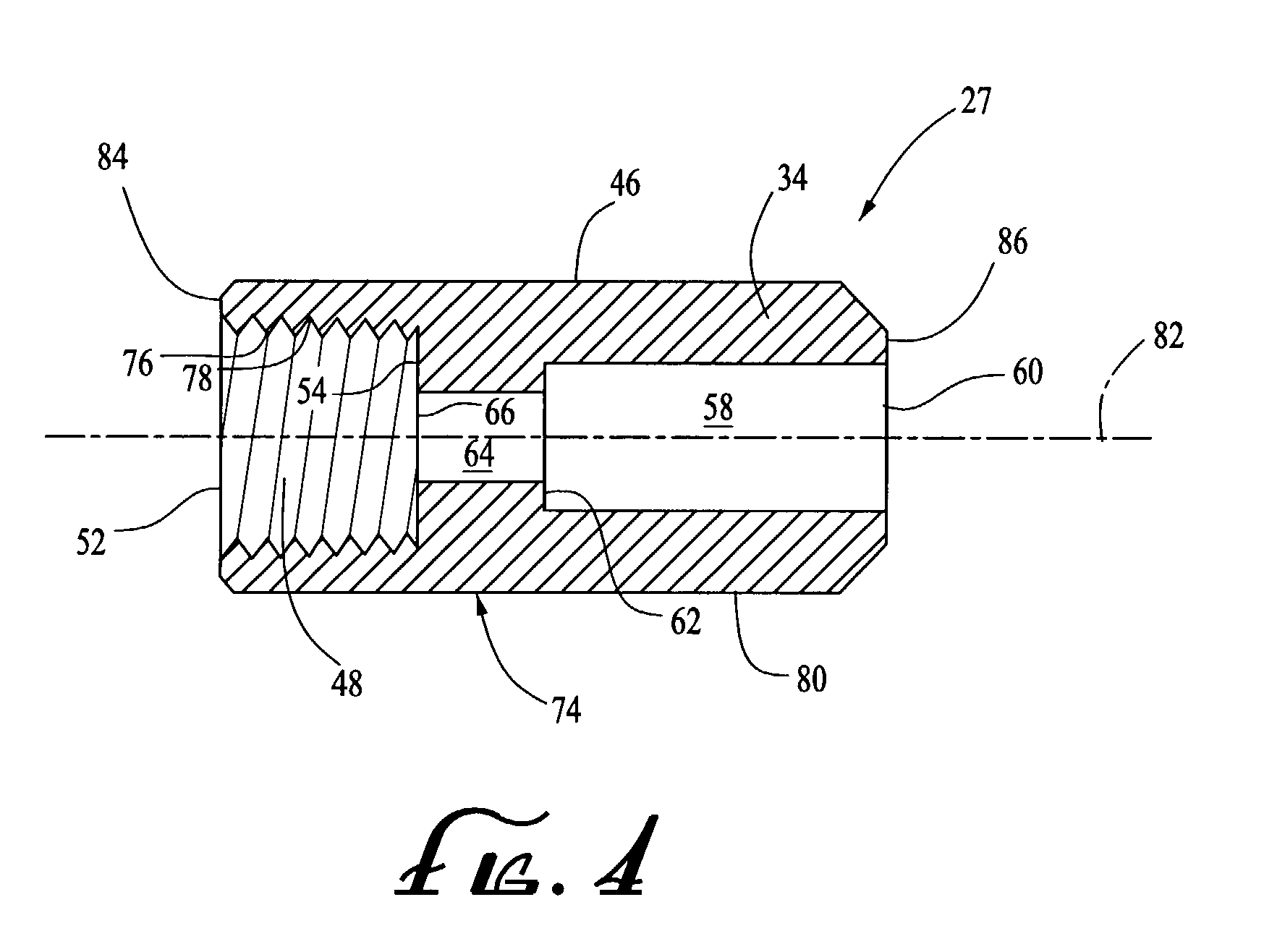

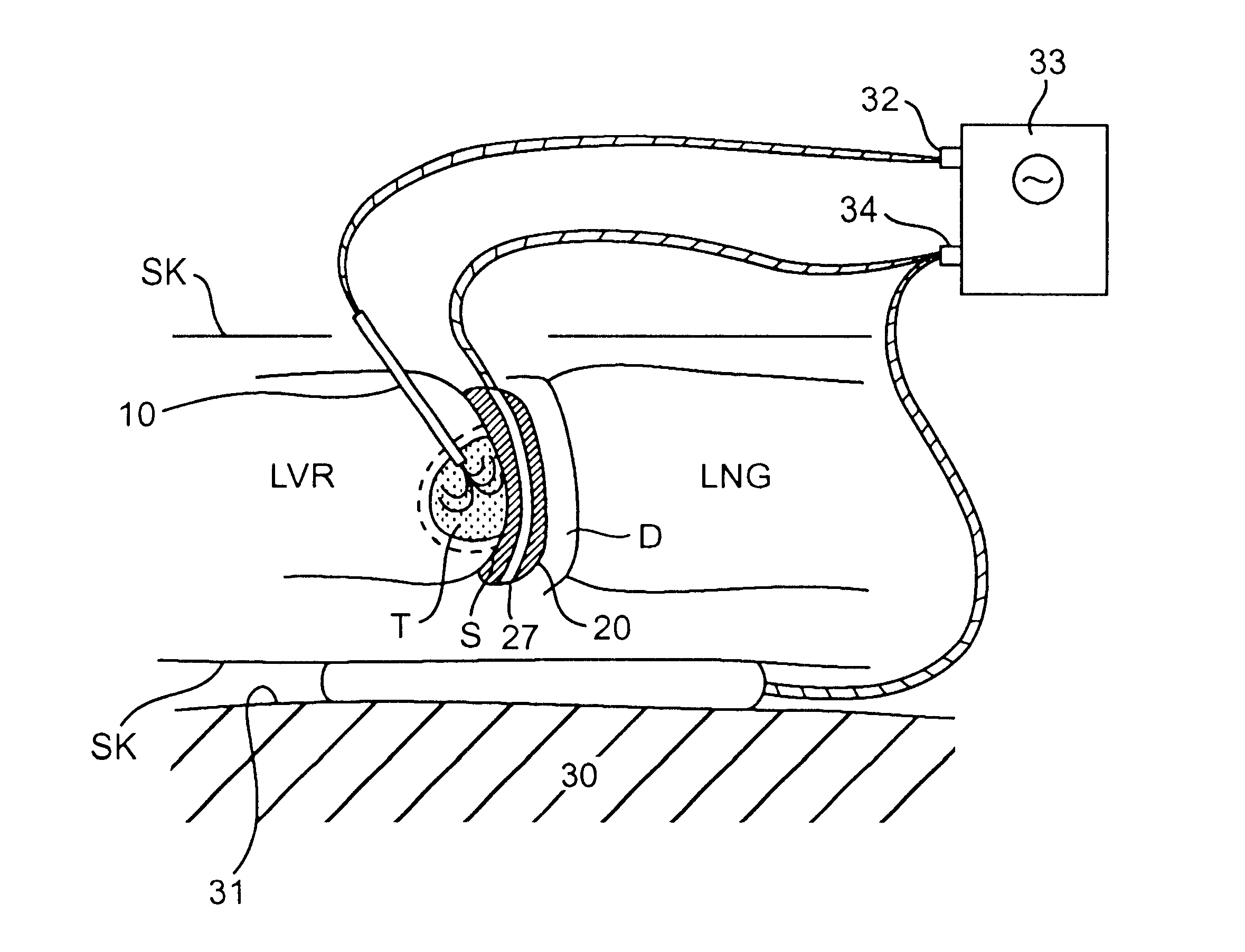

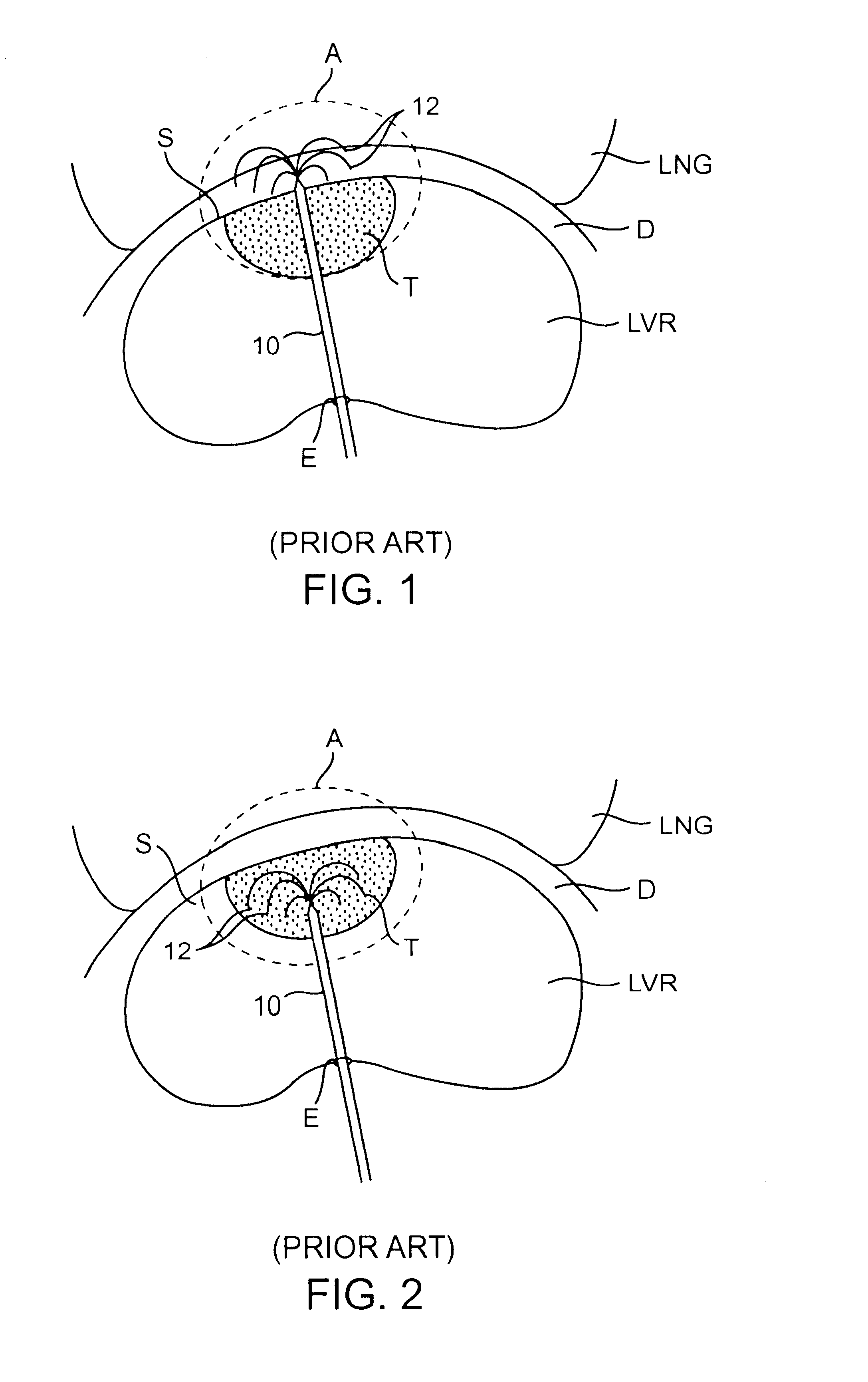

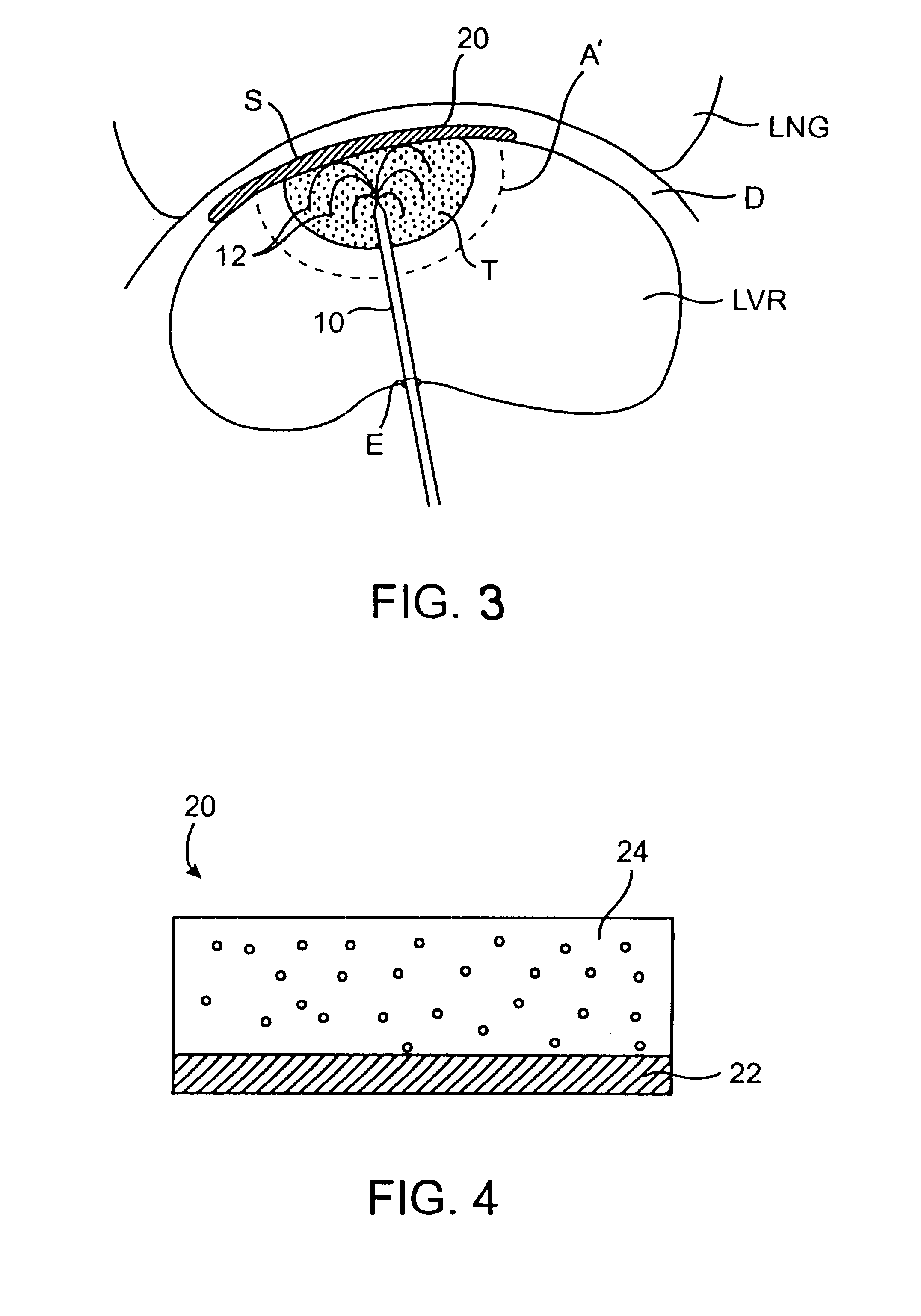

Apparatus and method for shielding tissue during tumor ablation

InactiveUS6471695B1Resistance to penetrationHigh proportionElectrotherapyDiagnostic recording/measuringAbnormal tissue growthTherapeutic effect

The present invention provides improved methods, systems, and kits for protecting body tissues which are adjacent to tissues undergoing thermal treatment. Thermal treatment is often prescribed for tumors and other disease conditions within body organs and other tissue masses. The methods, systems, and kits are particularly useful for treating tumors which lie at or near the surface of an organ, such as the kidney, pancreas, stomach, spleen, and particularly the liver. One risk of treating such tumors is the possibility of mistargeting the tumor and penetrating a delivery cannula or portions of a treatment device beyond the surface into the adjacent tissues or organs. In the case of radiofrequency or electrosurgical treatment, healthy surrounding tissue may be directly ablated. An additional risk, present even when the tumor is correctly targeted, is the possibility of thermal damage to the surrounding, non-targeted tissue. In radiofrequency or electrosurgical treatment, heat may dissipate into surrounding tissues which are more fragile and heat sensitive than the tissue in the organ being treated, thus causing unwanted tissue damage. These risks and others may be lessened or avoided with the use of an interface shield between the target region and adjacent body tissues to shield surrounding organs and tissue from treatment effects.

Owner:BOSTON SCI SCIMED INC

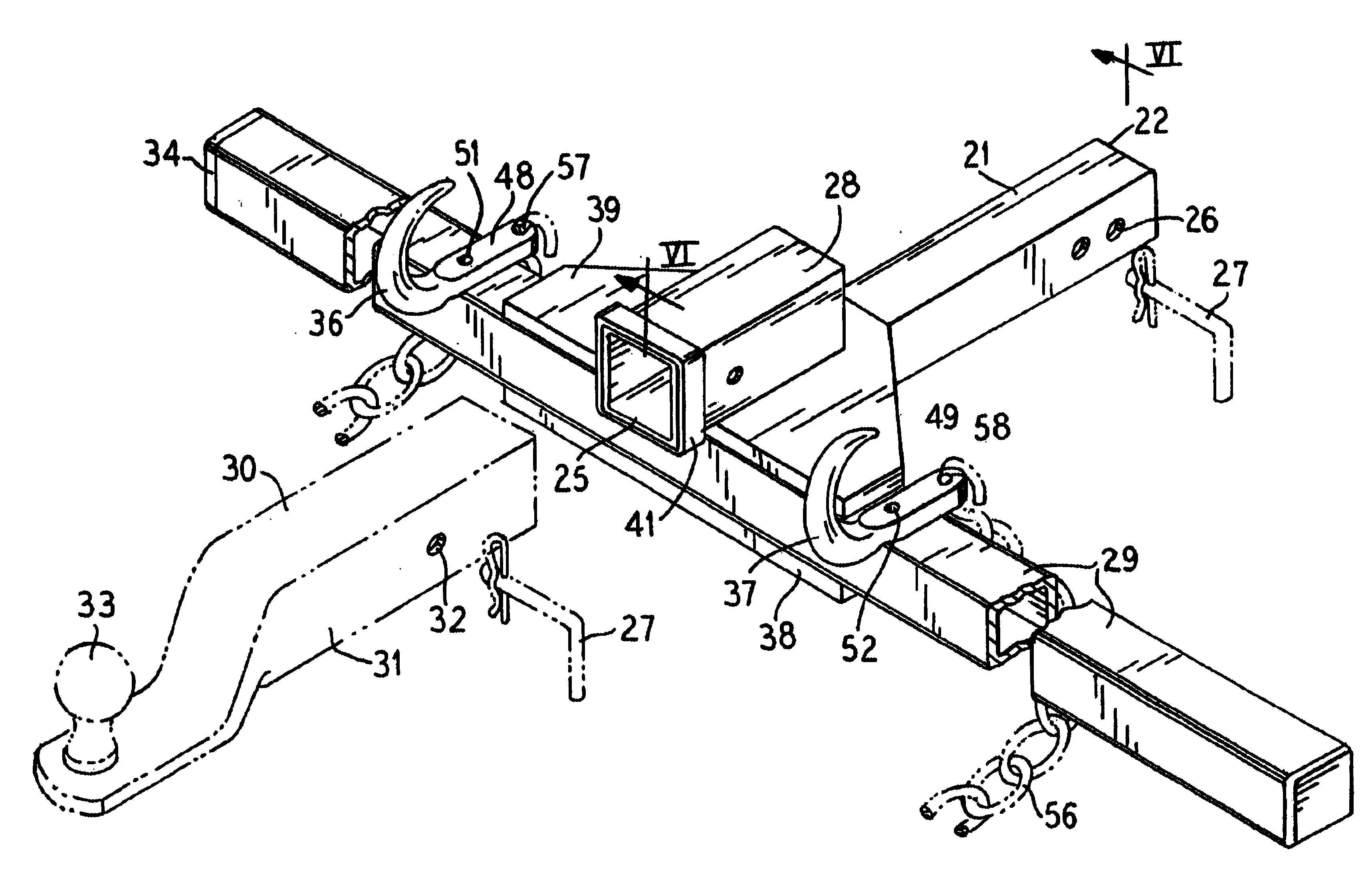

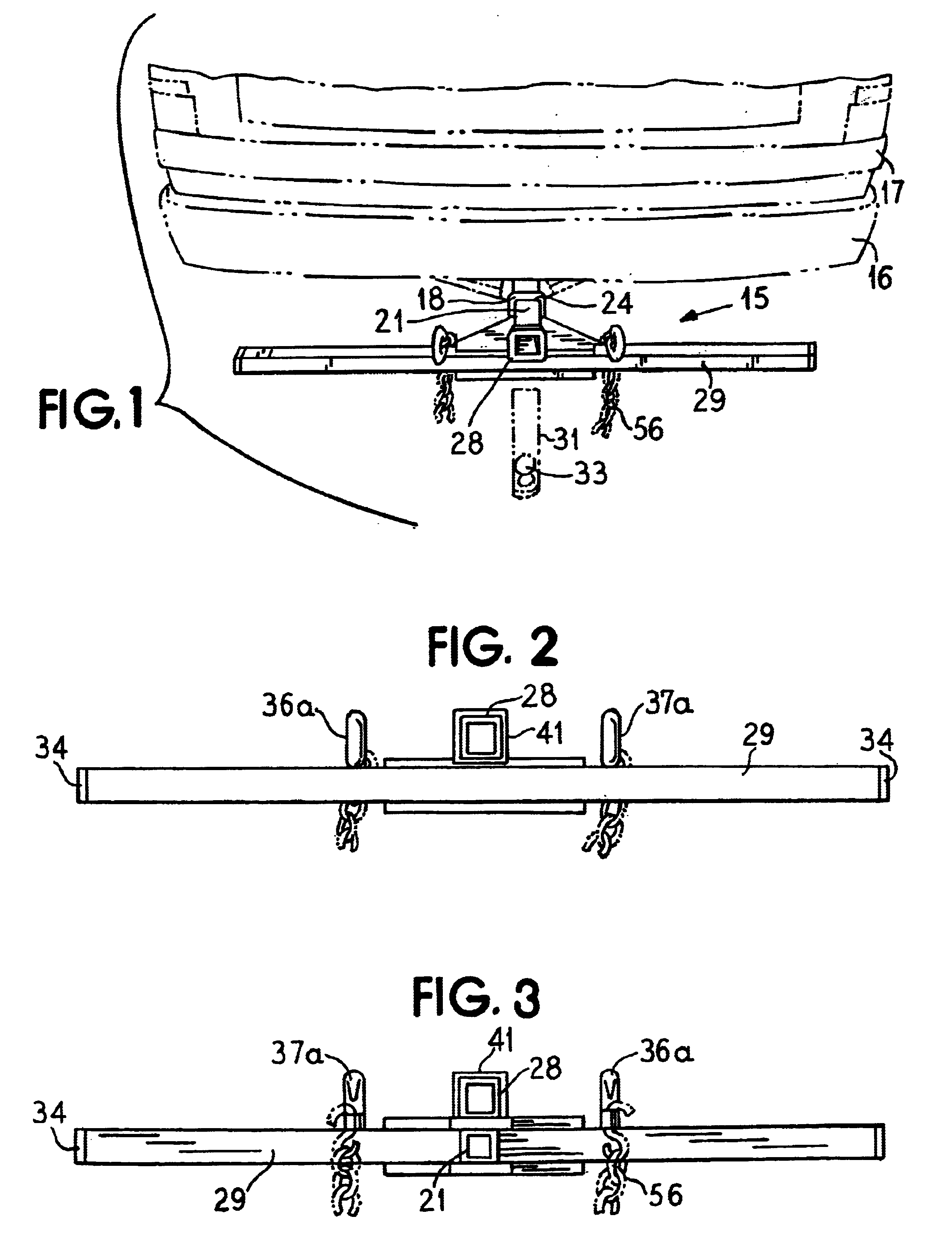

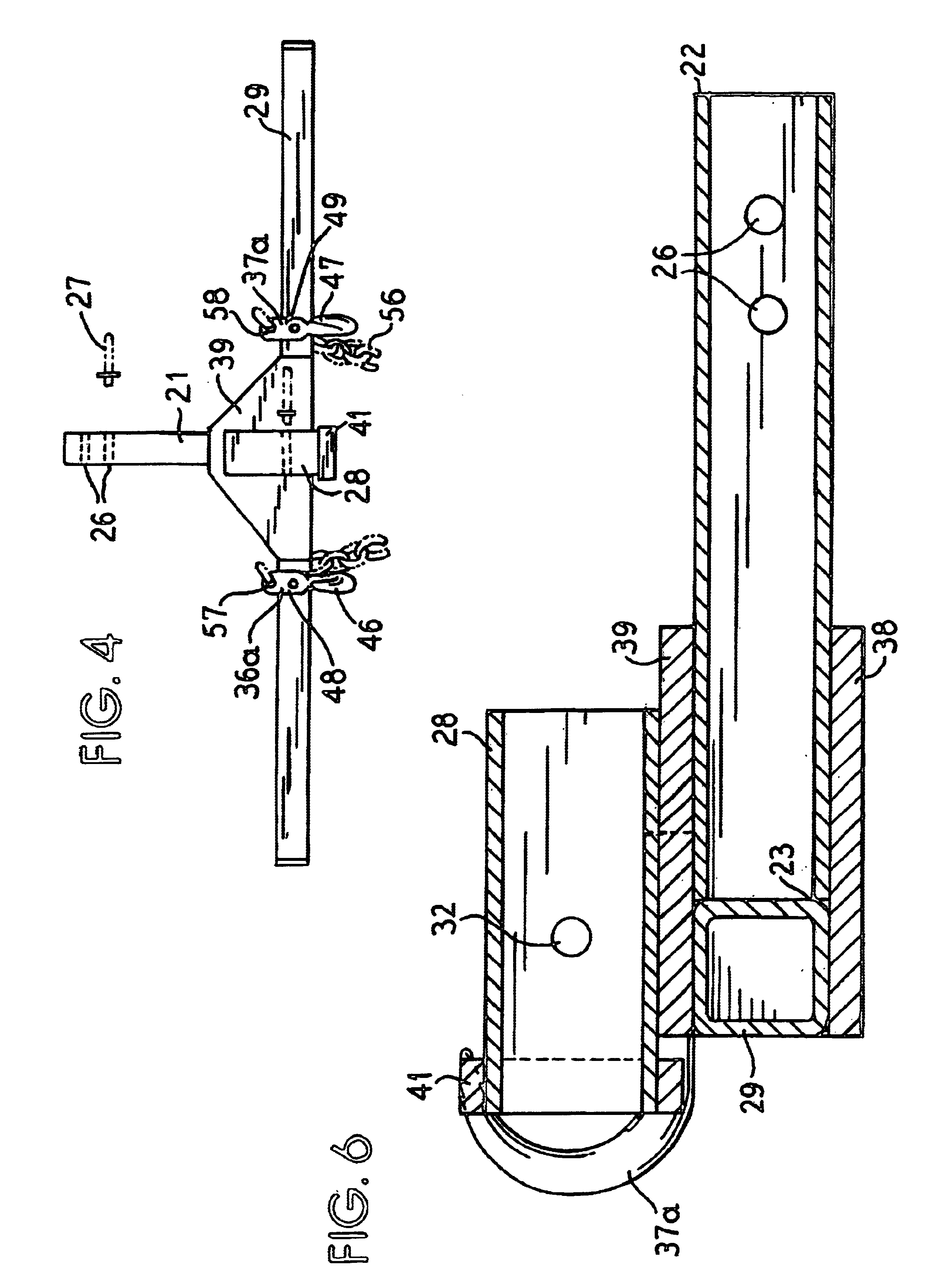

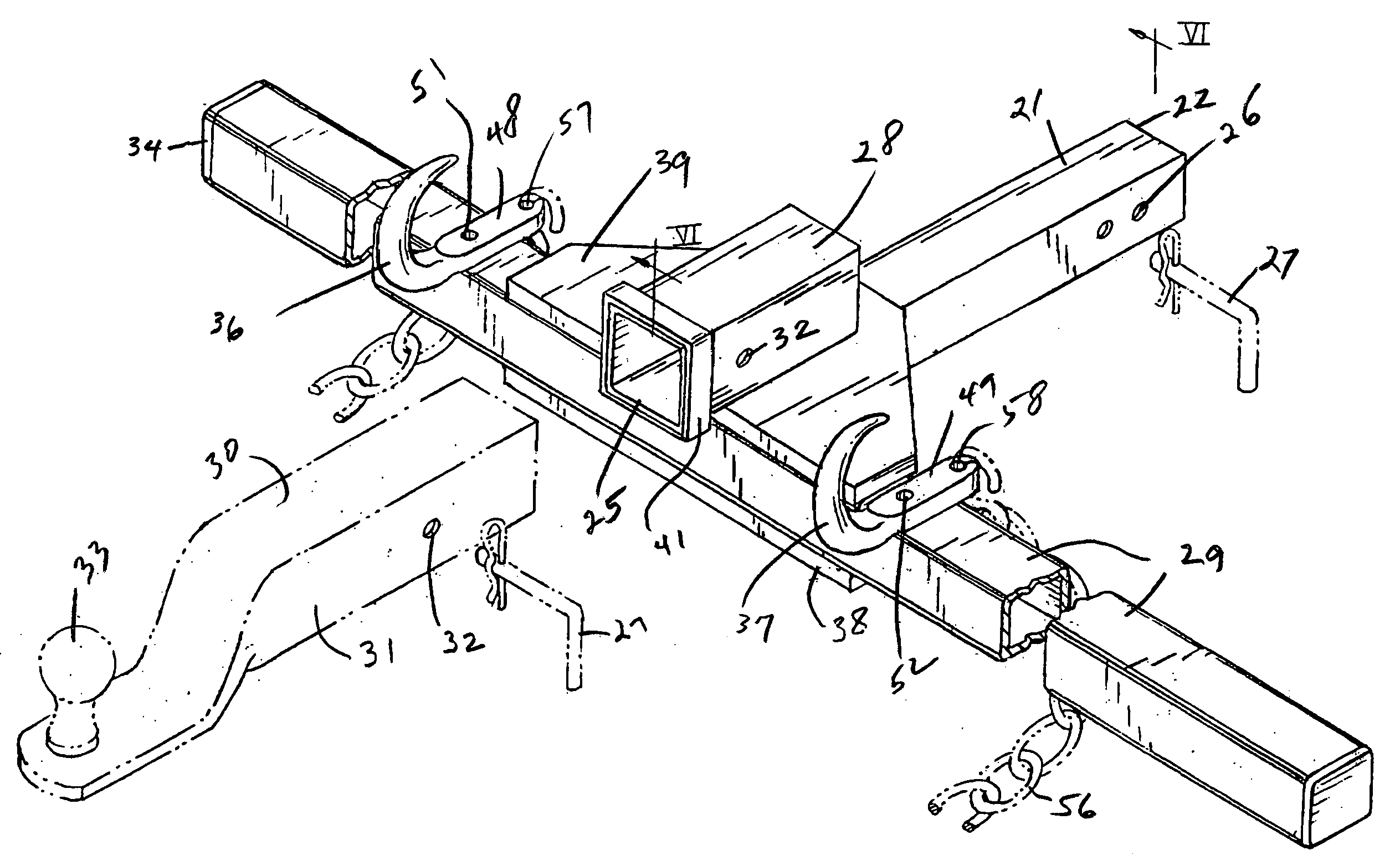

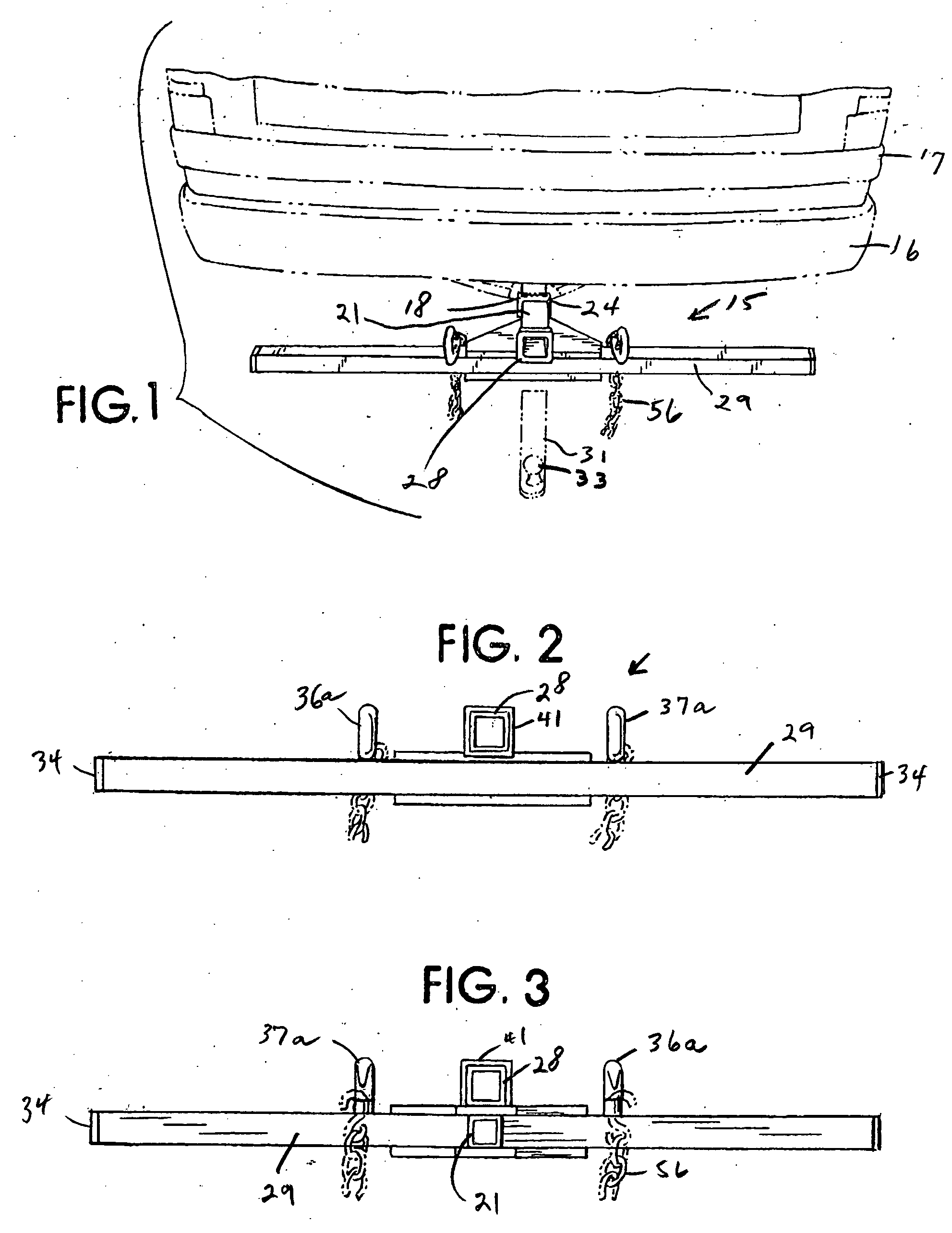

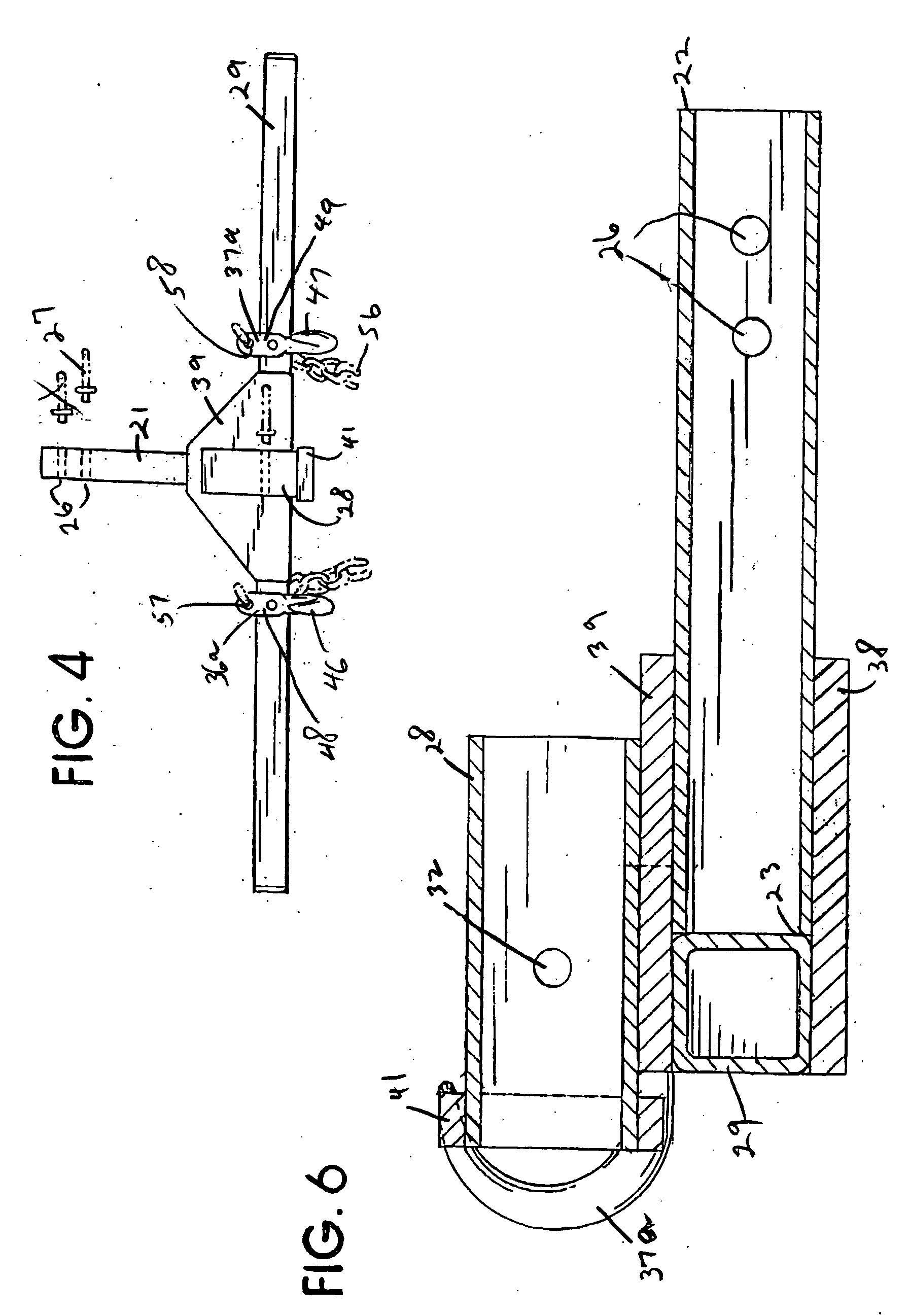

Towing hitch extension

InactiveUS6913277B2Avoids and minimizes damaging effectAvoid shockSupplementary fittingsTowing devicesFront and back endsTowing

A towing hitch extension is provided that is adapted to protect the rear bumper, especially a plastic bumper, of a towing vehicle. The hitch extension includes a tow bar with front ends and rear ends. The front end couples to the rear towing hitch of the towing vehicle. The rear end is mounted to a transversely extending, horizontally oriented, enlongated cross bar medially an also to a trailer hitch receiver hitch receiver that is somewhat above the tow bar. A pair of guard projections, such a pair of tow hooks for example, upstand from the cross bar on either side of the tow bar. Braces, preferably metal plate members, are preferably mounted to the tow bar and the cross bar to strengthen the position of the cross-bar relative to the tow bar.

Owner:MROFKA ROBERT J +1

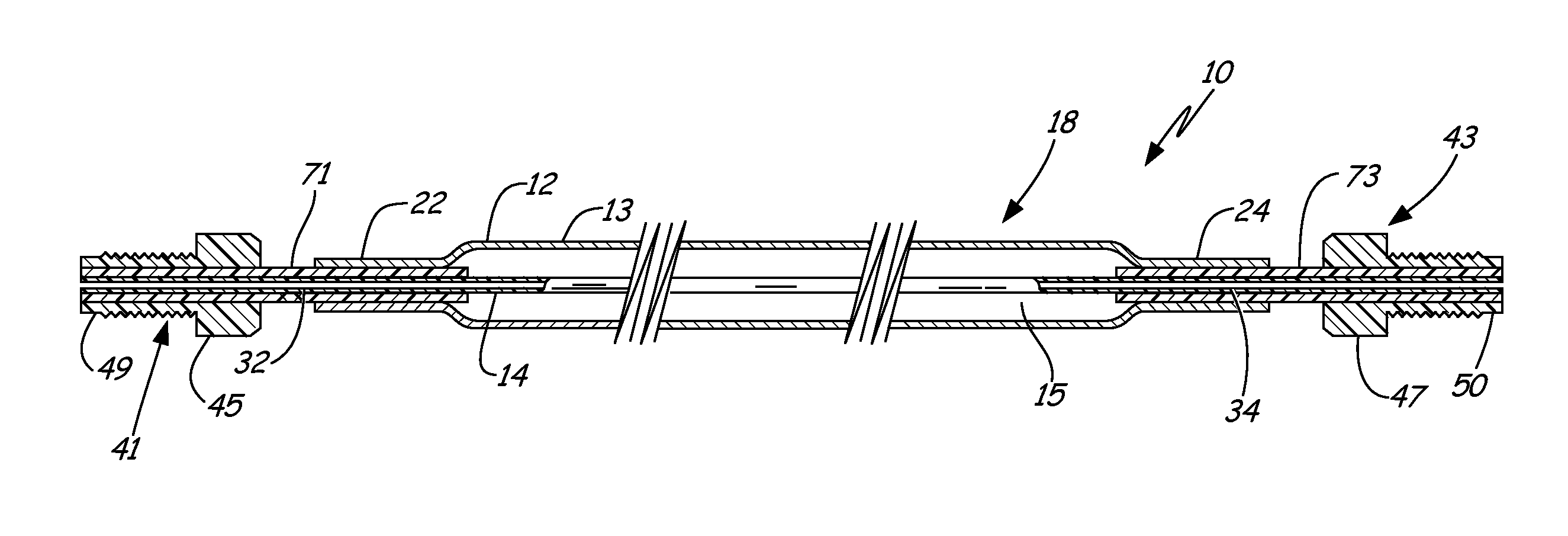

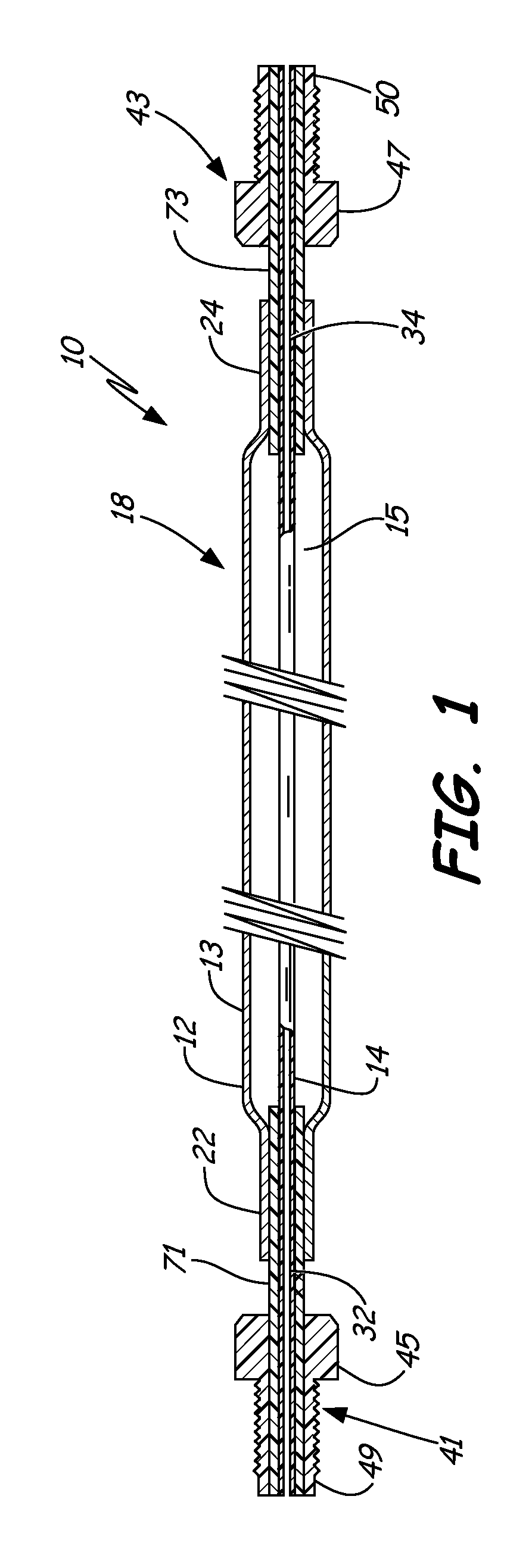

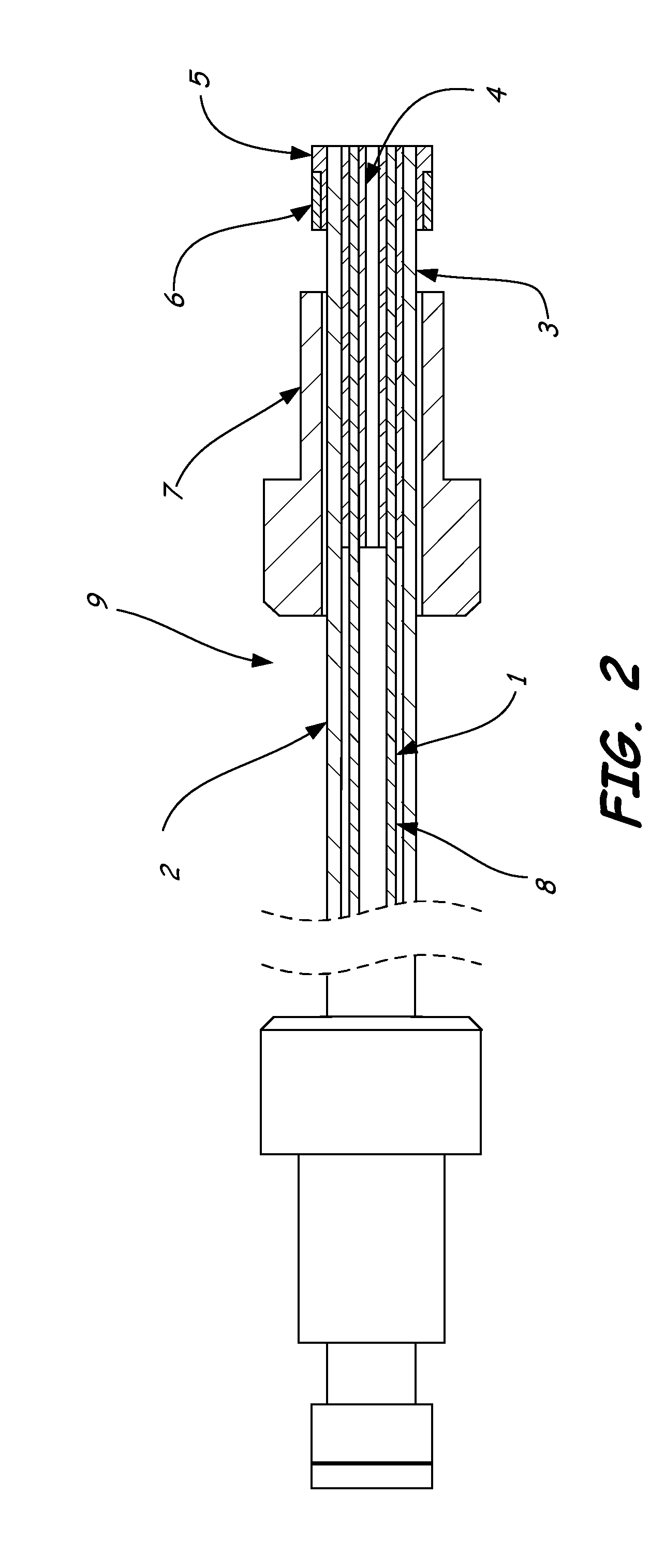

Supersaturated Fluid Degassing

ActiveUS20130061748A1Minimizes condensation potentialFine surfaceMembranesSemi-permeable membranesEngineering

An elongated flow-through degassing apparatus includes an elongated gas permeable outer shell and one or more gas-permeable, liquid-impermeable elongated inner conveyance members extending within the outer shell and at least partially through a chamber defined within the outer shell. The apparatus also includes inlet and outlet junctions for securing the outer shell to the inner conveyance member. The outer shell exhibits a first permeance that is substantially greater than a second permeance of the inner conveyance member. The degassing apparatus may be sufficiently flexible so as to be readily manipulatable into desired configurations.

Owner:IDEX HEALTH & SCI

Battery Holder and Dispensing Package

InactiveUS20160329537A1Sufficient forceResistance to penetrationSmall article dispensingRod article dispensingElectrical batteryEngineering

A battery holding and dispensing device can hold a plurality of batteries, in an assortment of battery sizes. The battery holding and dispensing device includes a frame having a plurality of compartments sized and shaped to each receive a battery of a particular battery size and each having a detent for releasably retaining the battery in the compartment. Each compartment has at least one opening in the bottom and lower side to expose a corner of the battery to allow finger ejection of the battery from the compartment past the detent, and to allow the user to touch the batteries to ascertain battery size by feel. The assortment of batteries held in the frame is preferably pre-selected to correspond to the batteries needed by a particular profession. An arrangement for illuminating the frame is provided.

Owner:TOOLS AVIATION

Water-based asphalt emulsion-based coatings, compositions, manufacture and applications for use

InactiveUS20080028978A1Efficient use ofReduce usageLiquid surface applicatorsOther chemical processesWater basedPolymer modified

The present invention relates generally to water based polymer modified asphalt emulsions, their composition, their manufacture and their uses. For example, there is disclosed a method for coating a structure or surface by applying a polymer modified asphalt emulsion coating to the structure or surface. The coating is preferably applied as a two component spray comprising an aqueous catalyst and an aqueous asphalt emulsion. The aqueous catalyst can employ an aqueous acid, preferably citric acid, but can also use an aqueous catalyst comprising an aqueous solution of calcium chloride. Preferably each of the two components are directed through separate ports on a spray nozzle so that they mix together on the fly external to the nozzle before contacting the surface to be coated. This methodology can be used to sound insulate structures, to encapsulate friable materials, to weather coat a structure, and to create a non-corrosive waterproof monolithic membranes.

Owner:BLACK TUF STUF

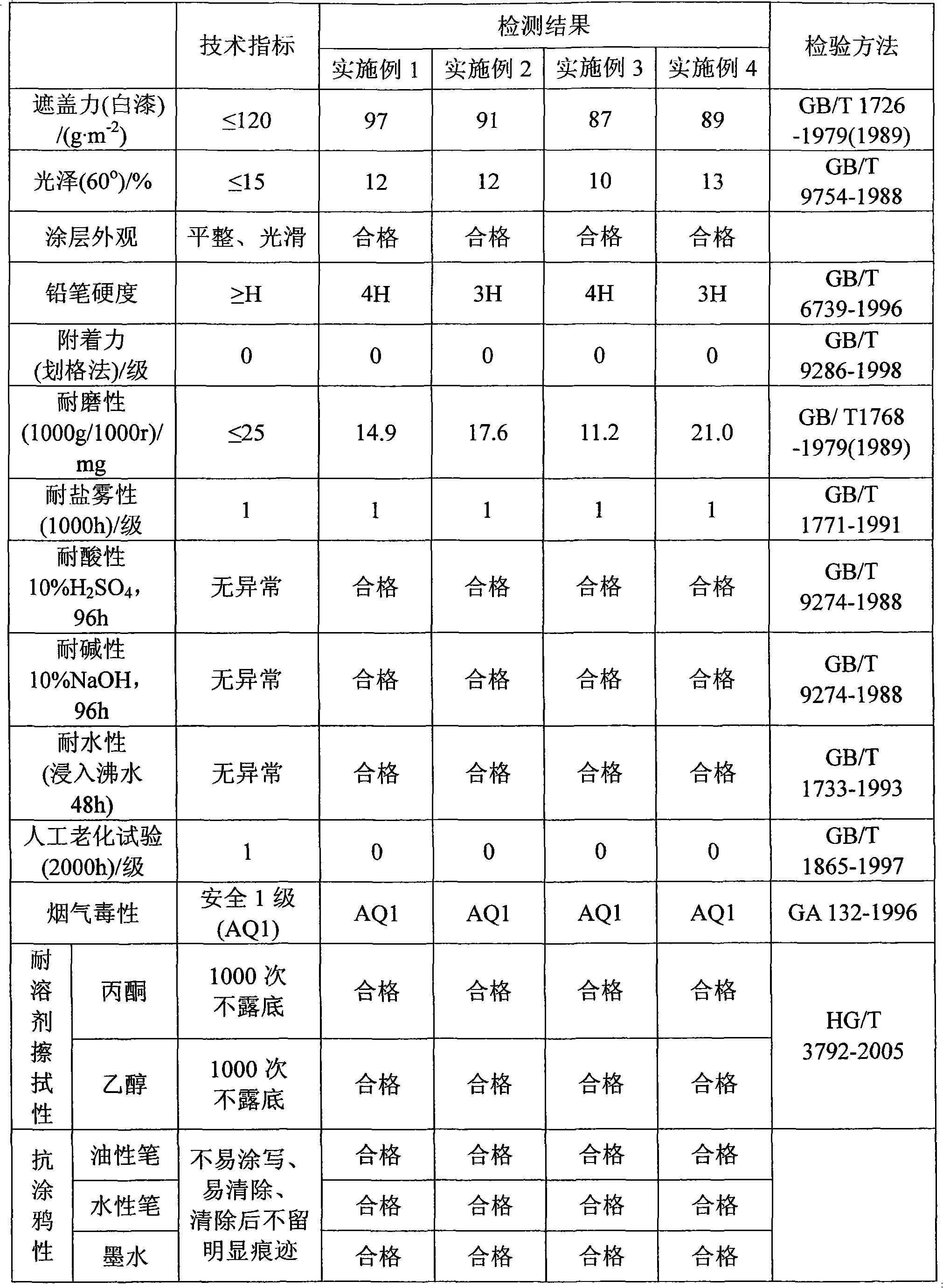

Method for preparing anti-graffiti coating for rail train carriage

InactiveCN101613563AImprove hydrophobicityGood oleophobic effectPolyurea/polyurethane coatingsAcrylic resinLacquer

The invention discloses a method for preparing an anti-graffiti coating for a rail train carriage, wherein the coating is prepared by mixing a component A and a component B. The component A comprises the following components: 21 to 65 portions of hydroxy-fluoro-silicon modified acrylic resin, 15 to 40 portions of pigments and fillers, 1 to 10 portions of auxiliary agent, and 16 to 42 portions of organic solvent; and the component B comprises 20 to 36 portions of polyisocyanate prepolymer. When in use, the components A and B are mixed and stirred evenly according to a mass ratio of 2-7:1, and then the mixture is adjusted to proper viscosity for construction by using a spraying method. The surface of a lacquer film formed by the coating has the advantages of low tensile force, compact structure, high hardness, excellent anti-graffiti performance, abrasion resistance, scrub resistance, corrosion resistance and long service life.

Owner:SOUTHEAST UNIV

Nanolaminate-reinforced metal composite tank material and design for storage of flammable and combustible fluids

ActiveUS9108506B2Raise the ratioIncrease energy densityElectrolytic coatingsLarge containersFuel tankMetal foam

An improved fuel tank and method of forming a fuel tank utilize reinforced porous metal composite materials. In one embodiment, the composite material includes a fully dense, fluid-impermeable skin combined with a porous metal baffle. The skin and baffle may be formed as a single monolithic system via electrodeposition of a nanolaminate material into at least a portion of open, accessible void space within a porous preform (e.g., a metal foam preform) and on the exterior surface of the preform to form the fluid-impermeable skin.

Owner:MODUMETAL LLC

Insulated concrete masonry system

ActiveUS9482003B2Resist transmission of heatStrong and inexpensiveConstruction materialCovering/liningsThermal bridgeStructural engineering

A insulated masonry wall system having insulation blocks between structural and face blocks to provide structures that are strong, inexpensive, avoid thermal bridges, and resist transmission of heat. The walls are attractive and versatile, and an enormous variety of decorative face members may be utilized. The face blocks are attached to the structural blocks to prevent facing materials from falling even if fire destroys the insulation blocks between the structural blocks and the facing. The system resists water penetration and effectively drains water that does penetrate any portion of the system.

Owner:OLDCASTLE ARCHITECTURAL

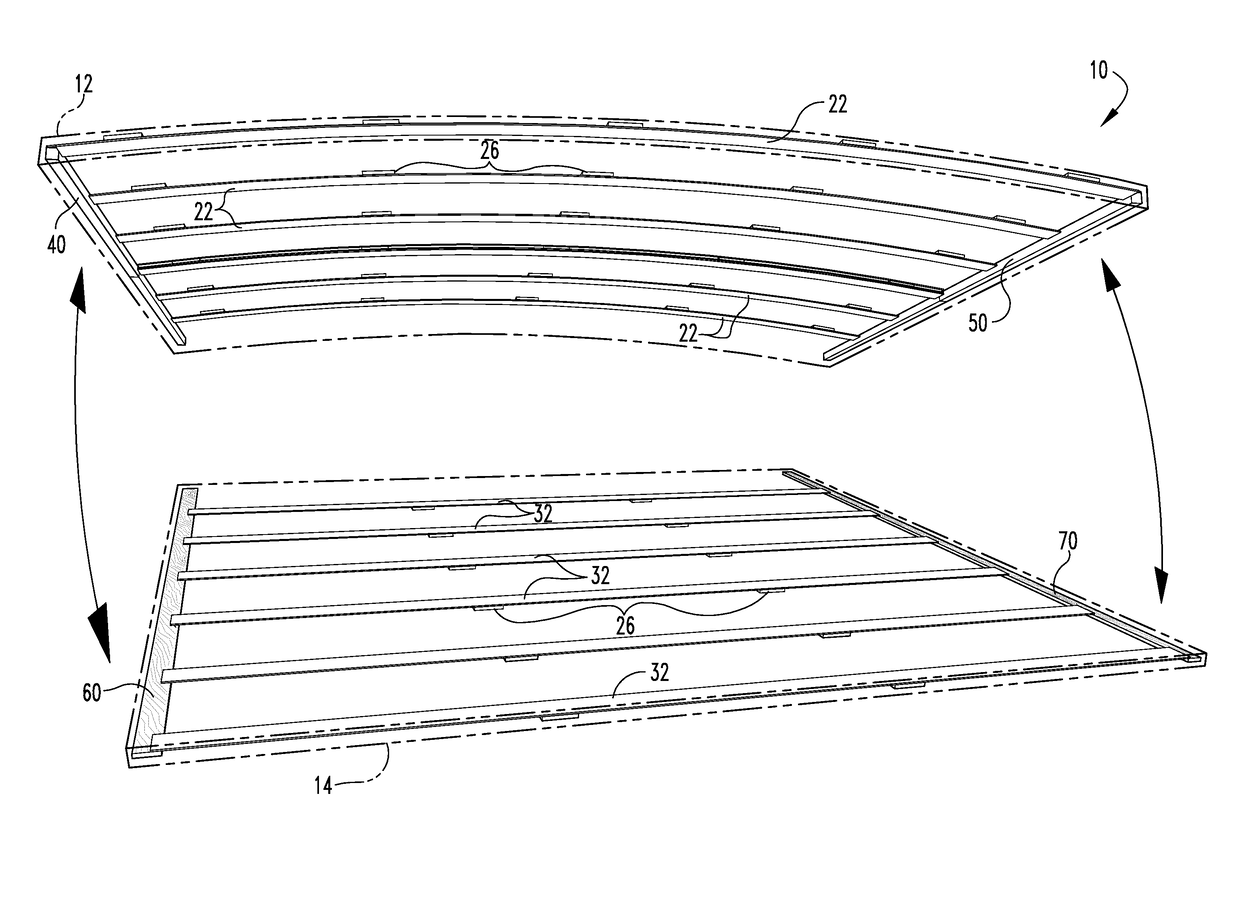

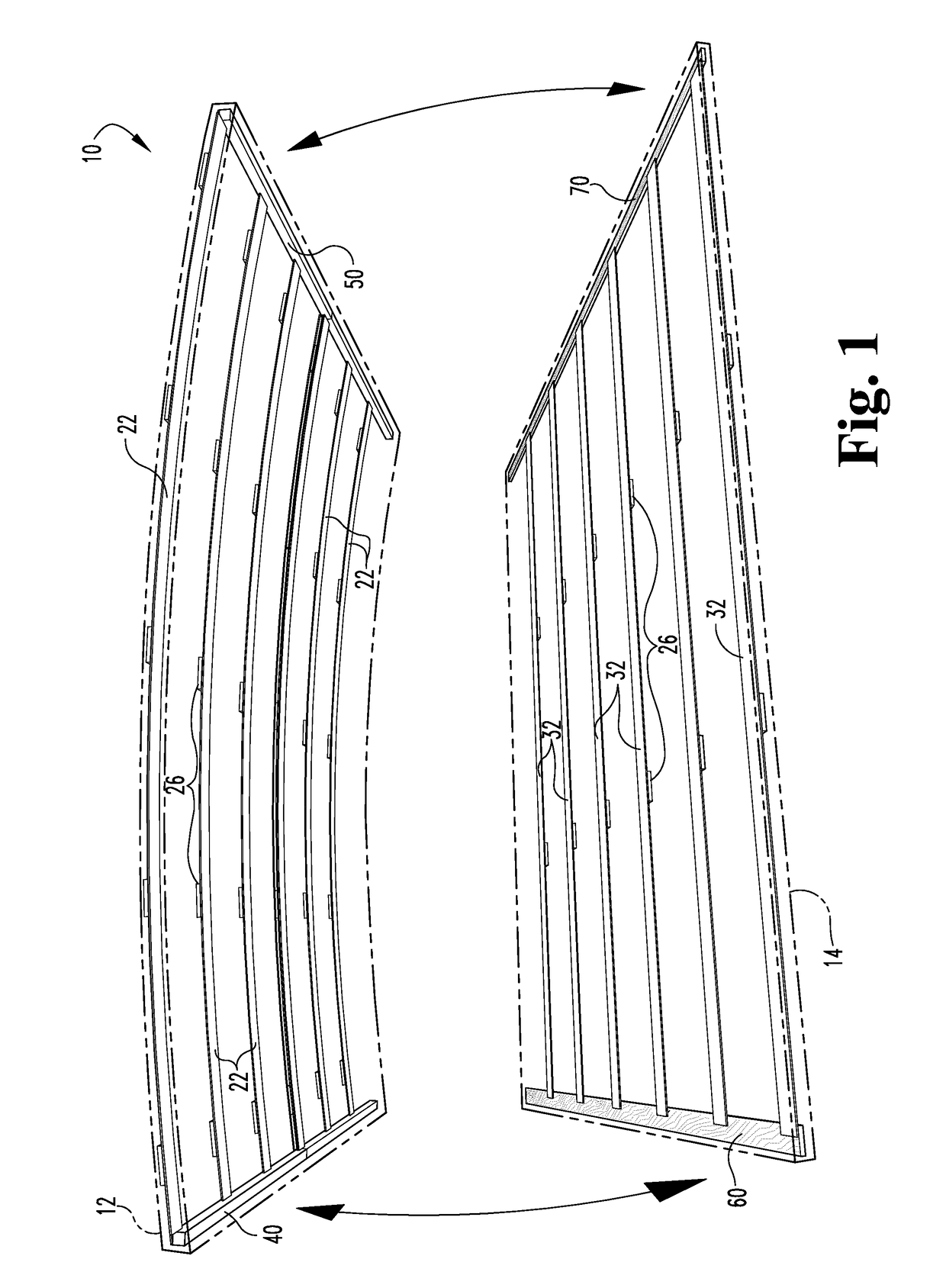

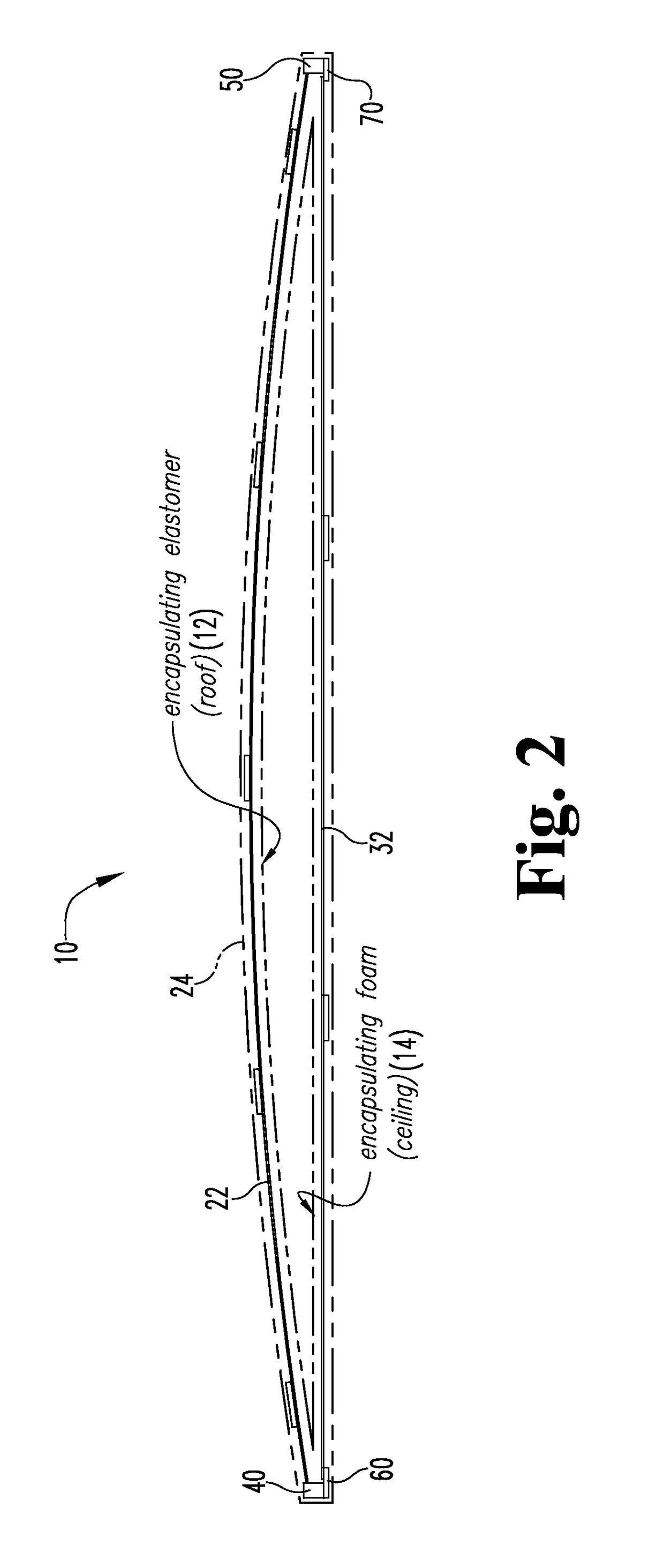

Integral roof/ceiling assembly for vehicles and manufactured housing

ActiveUS9708009B2Easily rolled and sprayedImproves Structural IntegritySuperstructure subunitsDomestic articlesStructural componentManufacturing engineering

The present invention involves a roofing assembly of a plurality of structural components arranged unattached as a frame in a mold. The frame is sprayed with foam and the structural components are encapsulated within the foam.

Owner:THE MACUMBER COMPANY

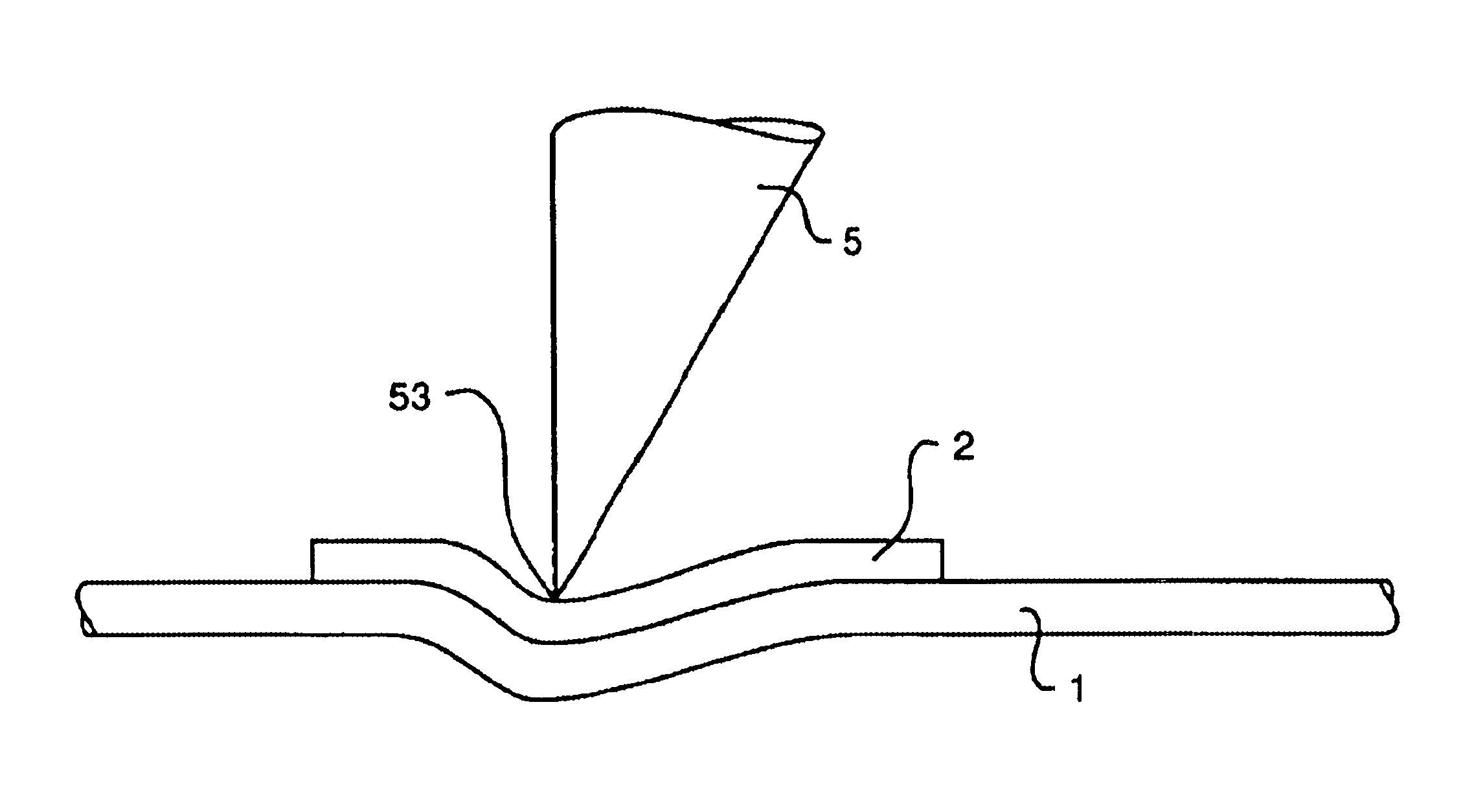

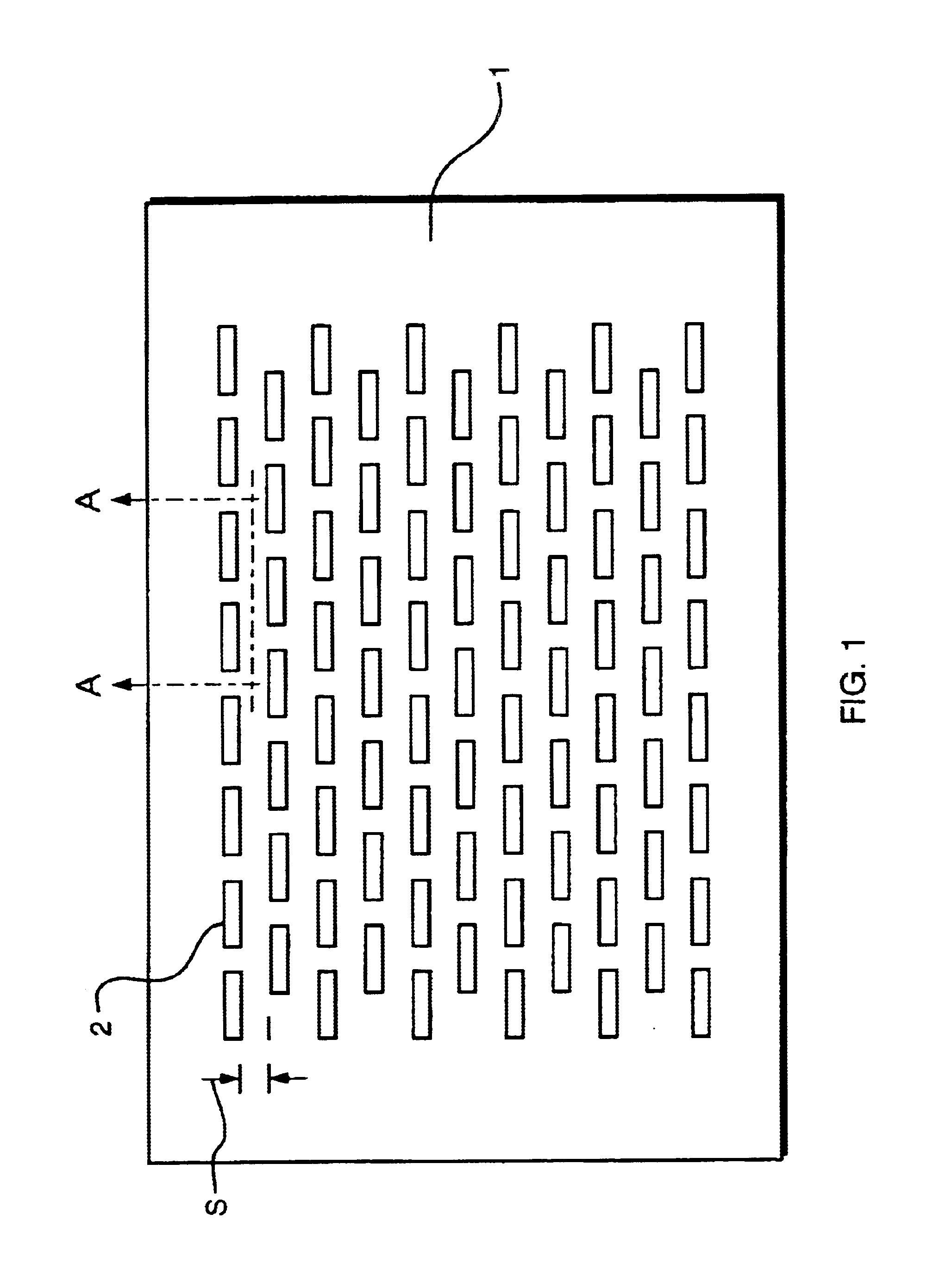

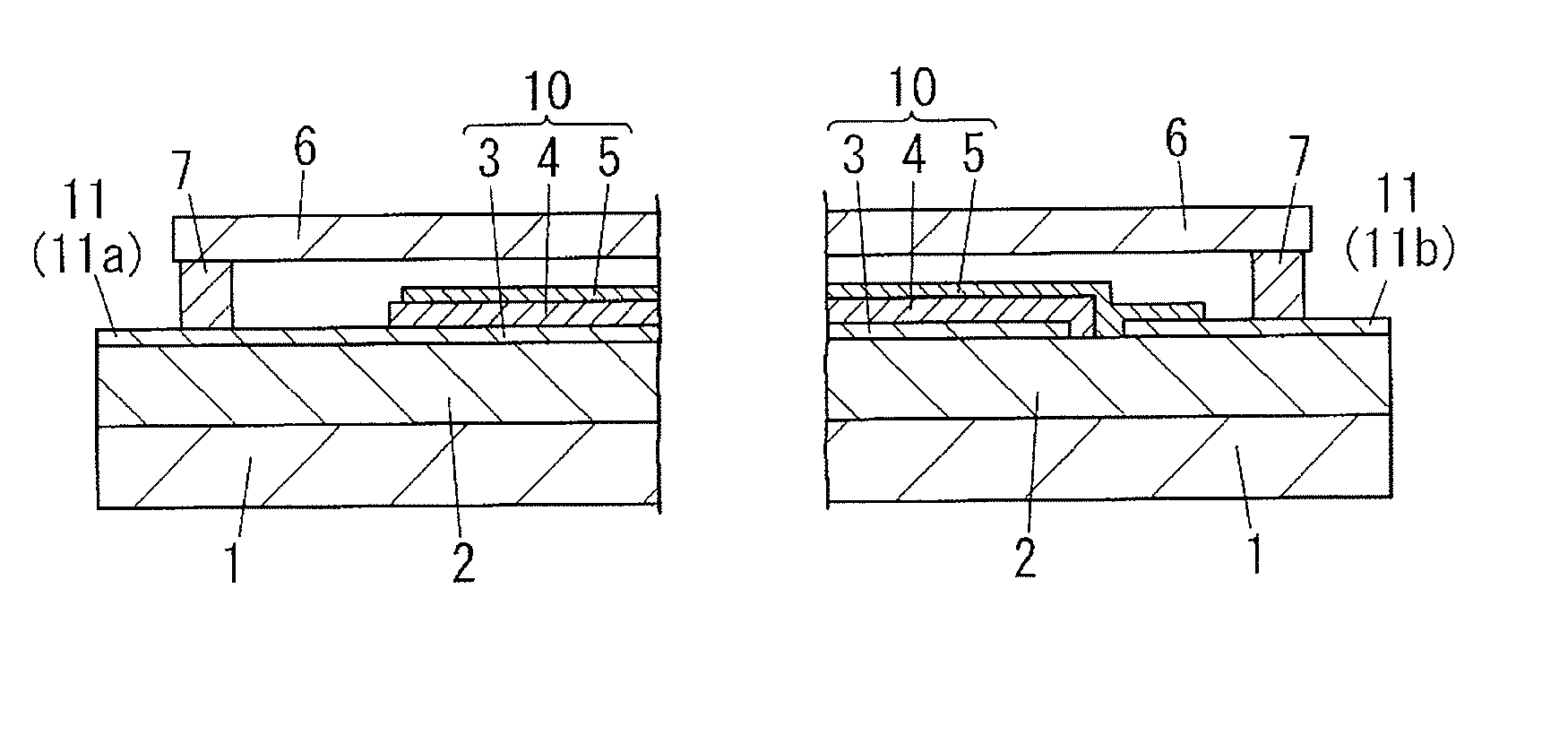

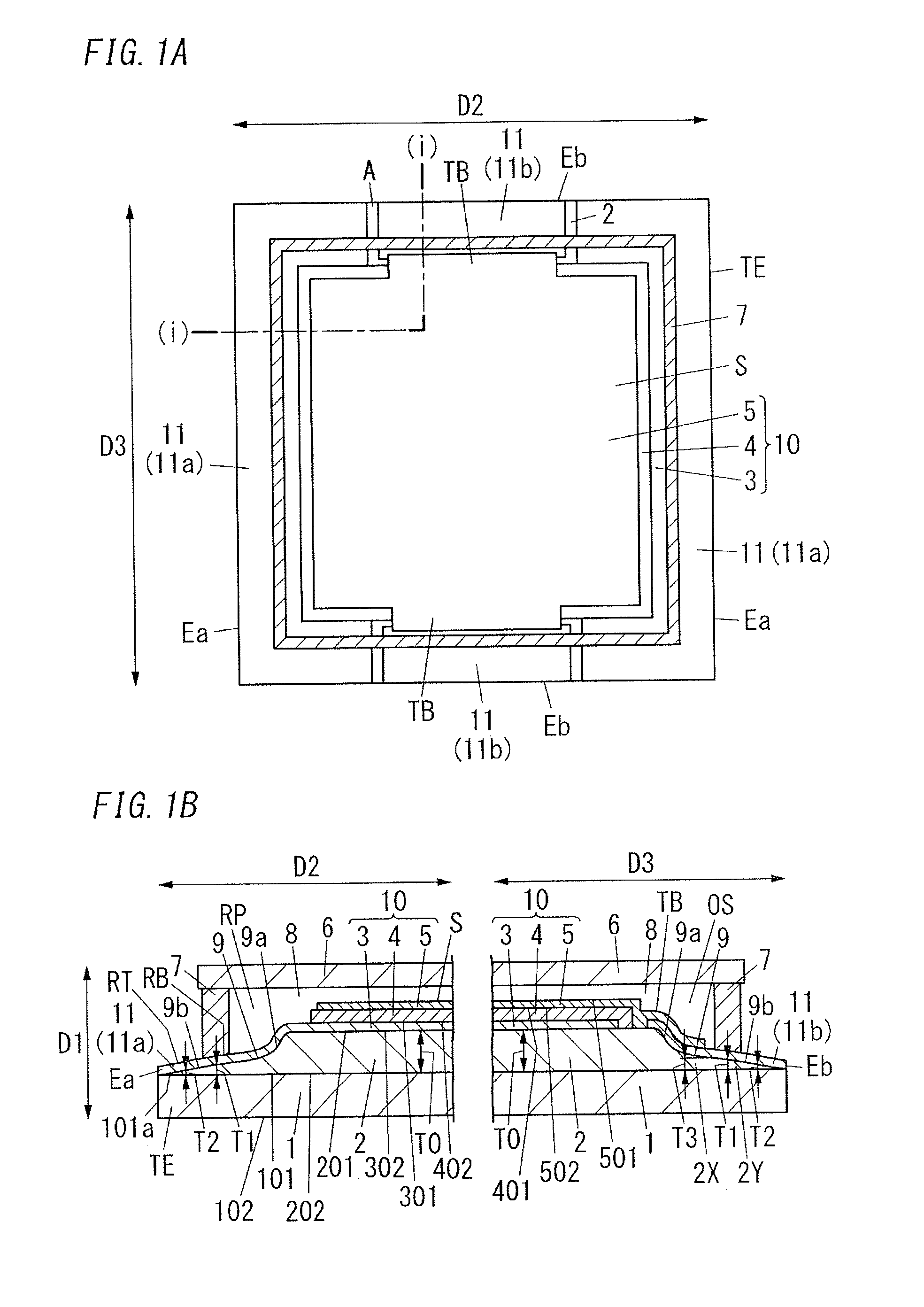

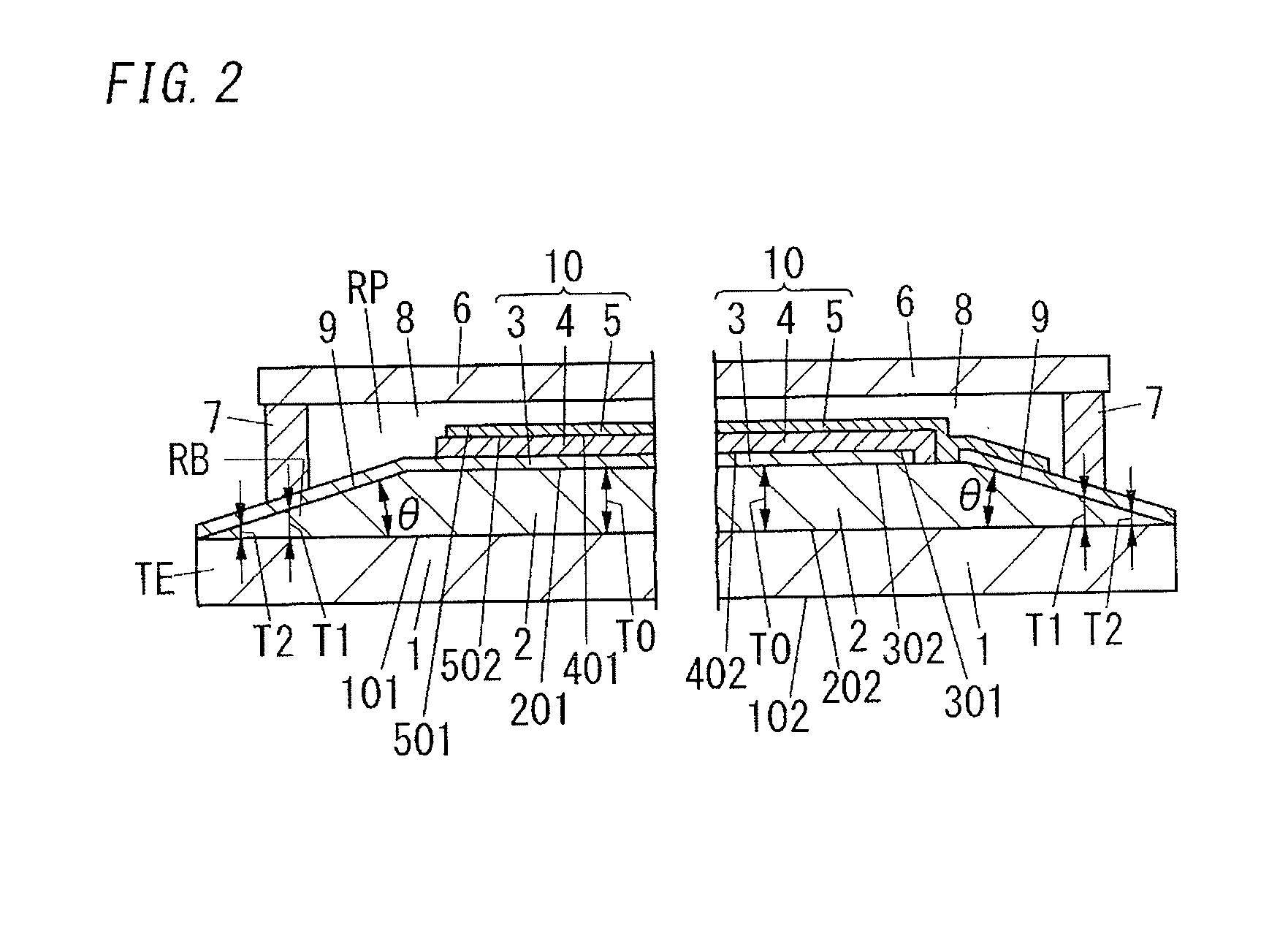

Organic electroluminescent element

InactiveUS20150028317A1Light-outcoupling efficiency can be improvedSuppress water penetrationSolid-state devicesSemiconductor/solid-state device manufacturingOrganic layerOrganic electroluminescence

The organic electroluminescent element has a transparent substrate, a transparent first electrode, an organic layer, a second electrode, and a light-outcoupling layer. The light-outcoupling layer is formed between the transparent substrate and the first electrode. The first electrode, the organic layer and the second electrode constitute an electroluminescent laminate. A covering substrate facing the transparent substrate is adhered to the surface of the transparent substrate via an adhesive sealing portion surrounding the periphery of the electroluminescent laminate. A connection electrode extending outward from inside a surrounded region where the electroluminescent laminate is covered with the covering substrate is formed at least on the surface of the light-outcoupling layer. The average thickness of the light-outcoupling layer in an adhesion region where the adhesive sealing portion is formed is smaller than the thickness in the central region where the electroluminescent laminate is formed.

Owner:PANASONIC CORP

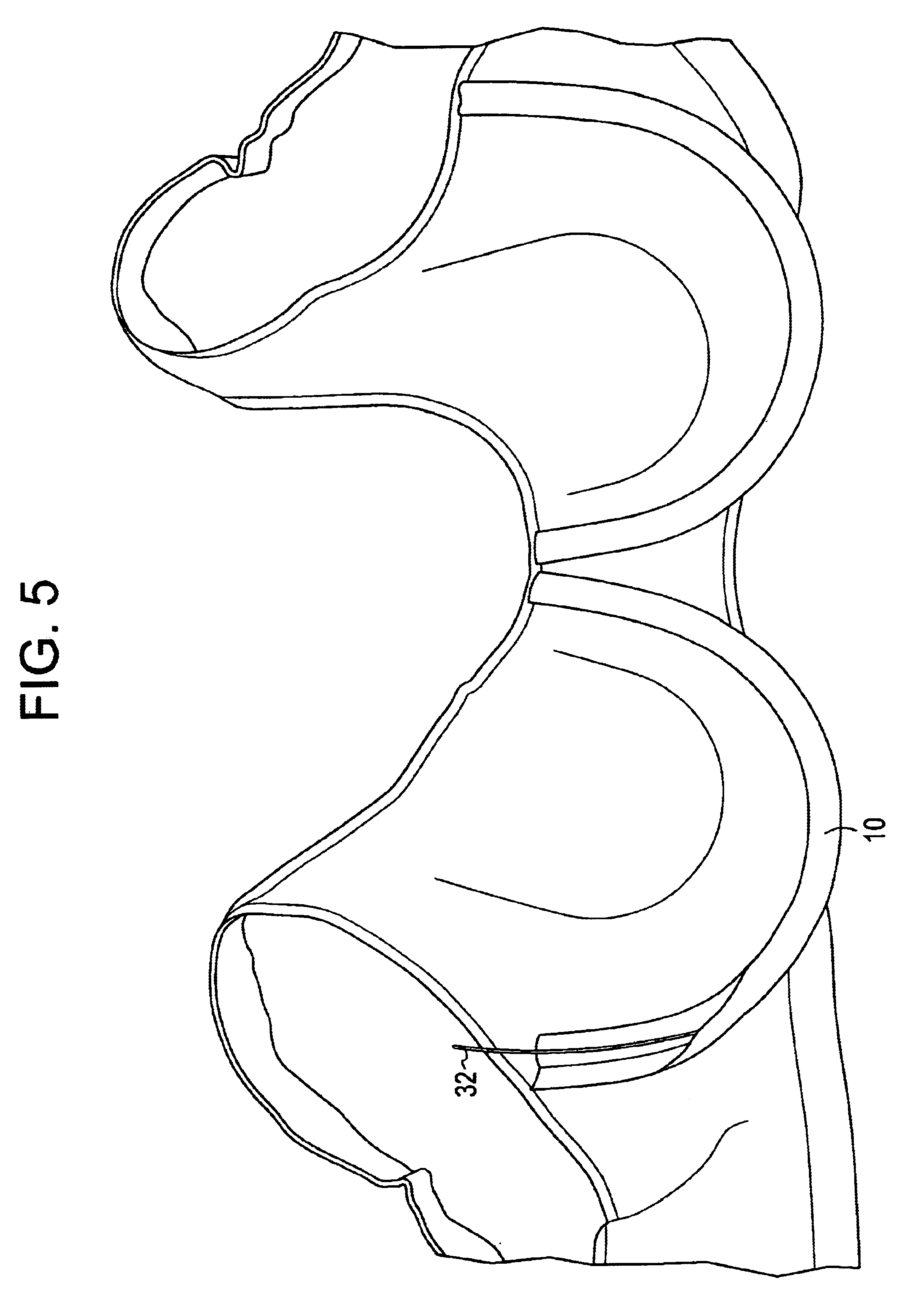

Safety bubble cushion bra-sheath

InactiveUS6857934B2Simple and comfortable and safe and reliableMore resistant to piercingGarmentsBrassieresEngineeringMiddle line

A bra sheath comprising a sheath-body and a plurality of lugs attached to the inner surface of an elongated liner. The sheath-body and liner define a tunnel for an underwire. A softness layer is disposed adjacent the liner outer surface. The bra sheath is formed by folding the liner and softness layer along the medial line to form a longitudinally extending internal cavity. The liner and sheath-body are comprised of woven fabrics including interlocking warp and weft threads. At least some of the threads are comprised of heat fusible materials that are melted during processing to bond the woven fabric of the liner and sheath-body.

Owner:FOUR K KNITTERS

Apparatus comprising armor

InactiveUS20070089595A1Limited effectReduce the possibilityAmmunition storageBlastingSilicone GelsEngineering

An armor that is used, for example, in multi-cell missile launchers is disclosed. In some embodiments, the armor includes three layers. The inner-most layer undergoes explosive welding when exposed to a pressure wave from an explosion. An intermediate layer in-elastically deforms when exposed to the explosion. The third and outer-most layer includes a plurality of elongated, pressurized tubes that contain fire retardant, among other chemicals. Silicone gel is interposed between the tubes.

Owner:LOCKHEED MARTIN CORP

Inhibition of rosin crystallization

InactiveUS20040127681A1Prevent spoilagePrevent bacterial growthNatural resin chemical modificationNatural resin purificationCarboxylic acidRosin

The invention relates to the inhibition of crystallization in rosin and rosin-based materials through the use of crystallization inhibitors. More specifically, the crystallization inhibitor is selected from the group consisting of carboxylic acids and the salts of carboxylic acids. The invention also relates to the process of inhibiting crystallization in rosin and rosin-based materials.

Owner:EASTMAN CHEM CO

Energy absorbing blast wall for building structure

InactiveUS20110225915A1Effective absorptionImprove securityCeilingsWallsEnergy absorptionEngineering

A wall system protects a building structure from pressure caused by explosive blasts. The wall system includes vertical studs. Outer blast wall panels and inner blast wall panels are secured to the opposing sides of the vertical studs. An upper mounting system is attached to the building structure. An upper mounting system includes a fixed track, a movable mounting track, and an energy absorbing system that flexibly couples the movable mounting track to the fixed track. The upper ends of the vertical studs are attached to movable mounting track. A lower mounting system includes a mounting track that aligns the lower ends of the vertical studs. The wall are filled with an energy absorbing material. The lower ends of the vertical studs are connected to a lower track.

Owner:SPECIALTY HARDWARE

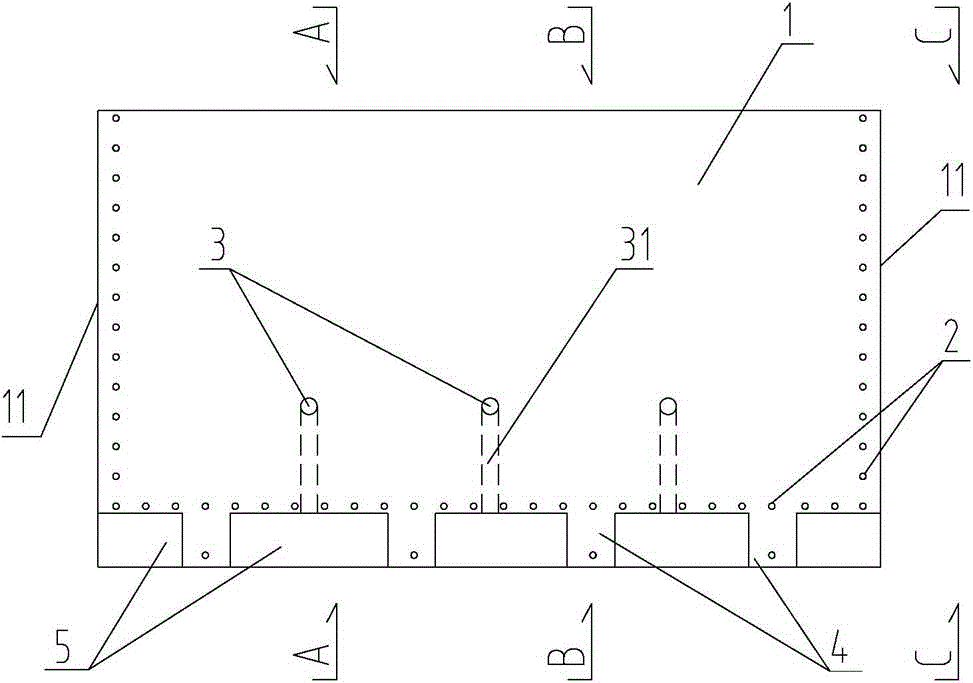

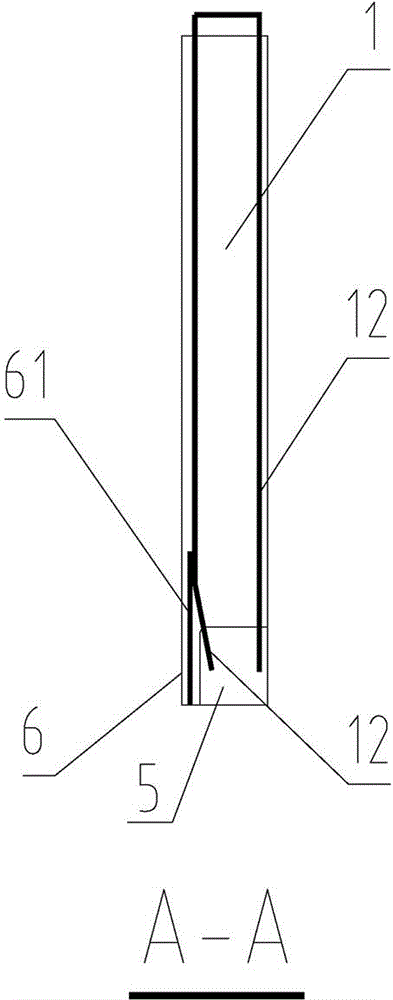

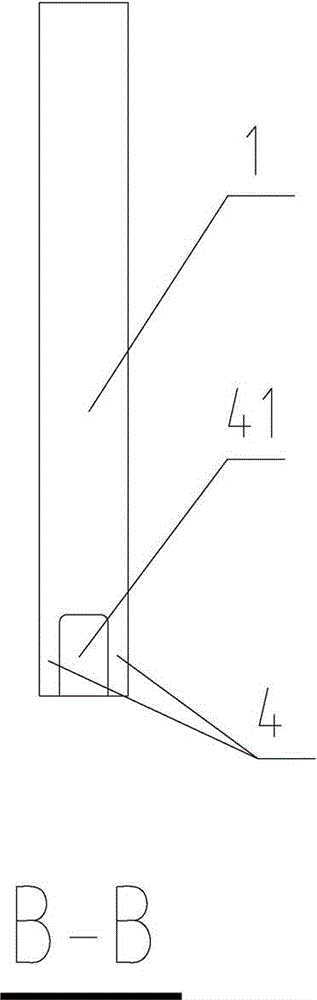

Prefabricated shear wall in cast-in-situ connection mode

ActiveCN105604208AEasy constructionGuaranteed connection qualityConstruction materialWallsRebarThreaded pipe

The invention relates to a prefabricated shear wall in a cast-in-situ connection mode. The prefabricated shear wall comprises a wall, pier heads, bottom upper concave sections and a bottom outer side plate. Side edges are respectively arranged on two sides of the wall, and a groove is formed in the middle of each side edge and is vertically perforated through the wall; wall vertical reinforcing bars are arranged in the wall; the bottom upper concave sections are uniformly distributed at the bottom of the wall; each pier head is arranged between the two corresponding adjacent bottom upper concave sections; air holes are formed in positions above the middles of the bottom upper concave sections; the air holes are communicated with the bottom upper concave sections via pipelines; the thicknesses of the pier heads are identical to the thickness of the wall, and holes are formed in the pier heads; the bottom outer side plate and the wall are integrated with each other, and the bottom outer side plate is positioned on the outer sides of the bottom upper concave sections; internally threaded pipes are embedded in positions close to the side edges of the wall, above the bottom upper concave sections and on the pier heads. The prefabricated shear wall in the cast-in-situ connection mode has the diversified advantages of firm structure, convenience in construction, reliability in connection and the like.

Owner:华汇工程设计集团股份有限公司

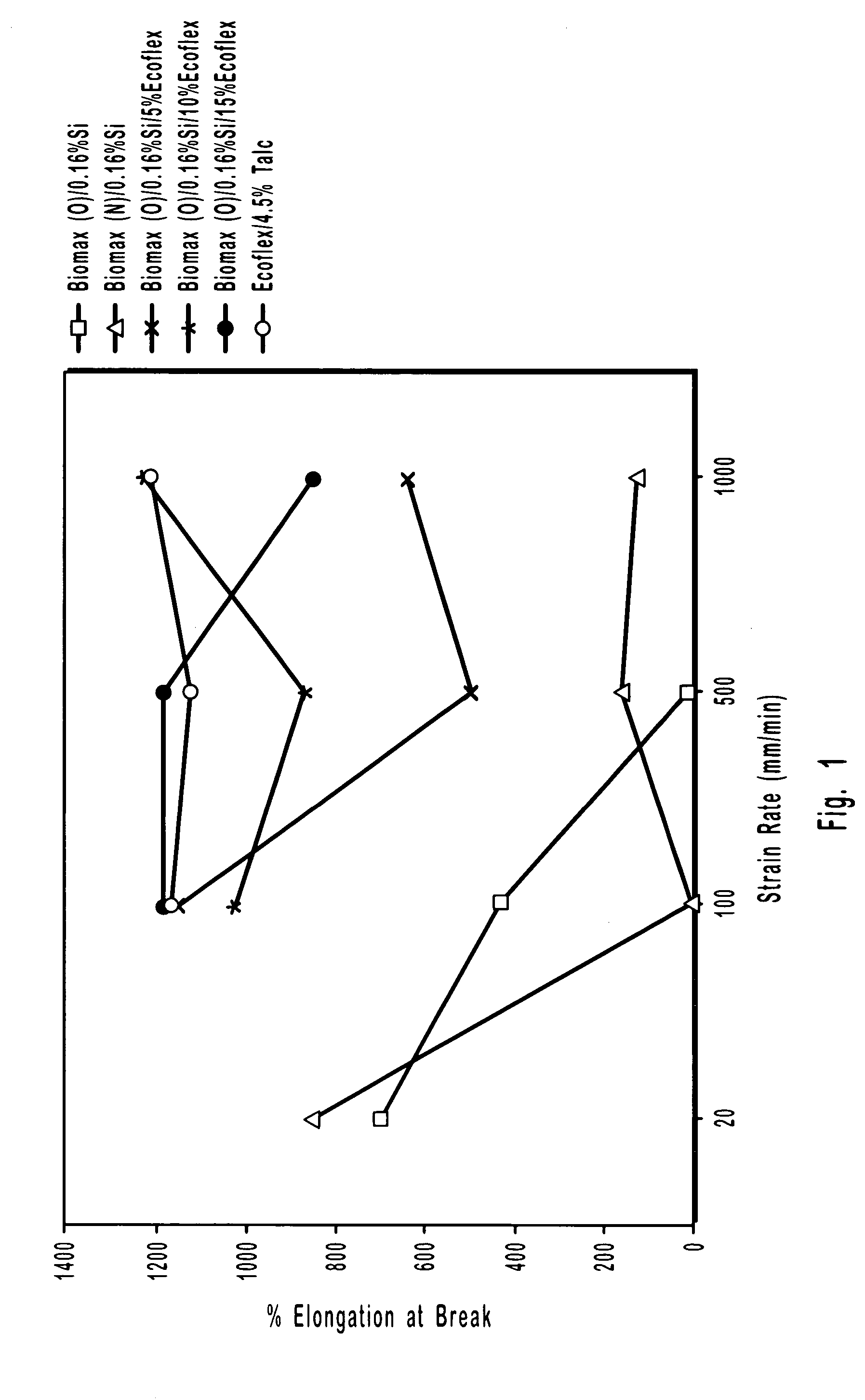

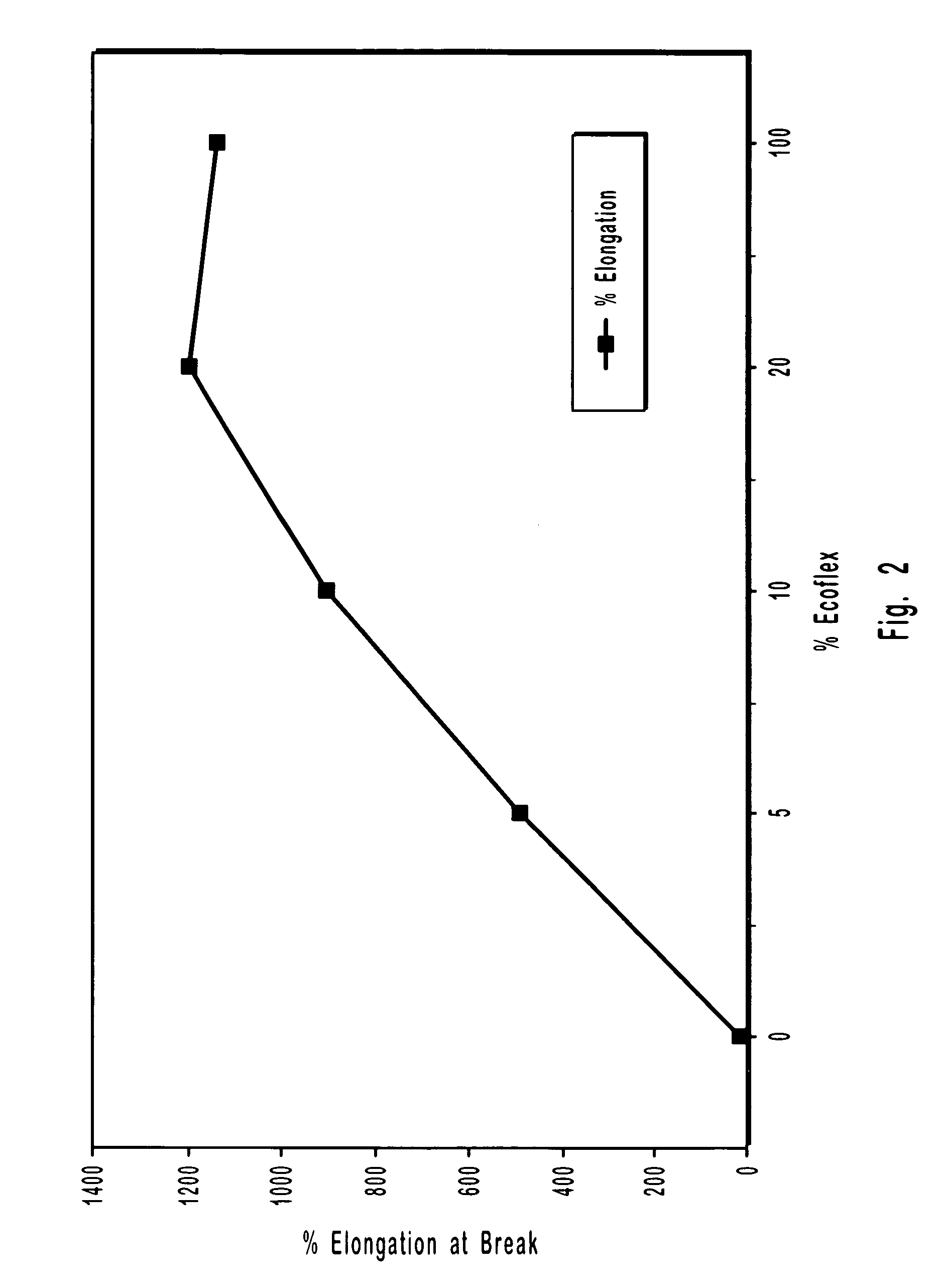

Fibrous sheets coated or impregnated with biodegradable polyhydroxybutyrate polymers or polymer blends

InactiveUS20060240726A1High glass transition temperatureImprove the crystallization processBio-packagingSynthetic resin layered productsVitrificationPolymer science

Fibrous sheets are coated or impregnated with a biodegradable composition to render the sheets more resistant to penetration by liquids. Biodegradable polymer blends suitable for use in coating or impregnating a fibrous sheet can be manufactured from at least one type of polyhydroxybutyrate, optionally in combination with at least one additional biodegradable polymer (e.g., a “hard” biodegradable polymer having a glass transition temperature of at least about 10° C. and / or a “soft” biodegradable polymer having a glass transition temperature less than about 0° C. Sufficient inorganic filler may be included so as to render the treated sheet microwaveable. The biodegradable polymer compositions are especially well-suited for coating or impregnating paper sheets, e.g., 12-15 lb / 3000 ft2 tissue paper to yield food wraps. Food wraps will typically be manufactured to have good “dead-fold” properties so as to remain in a wrapped position and not spring back to an “unwrapped” form.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

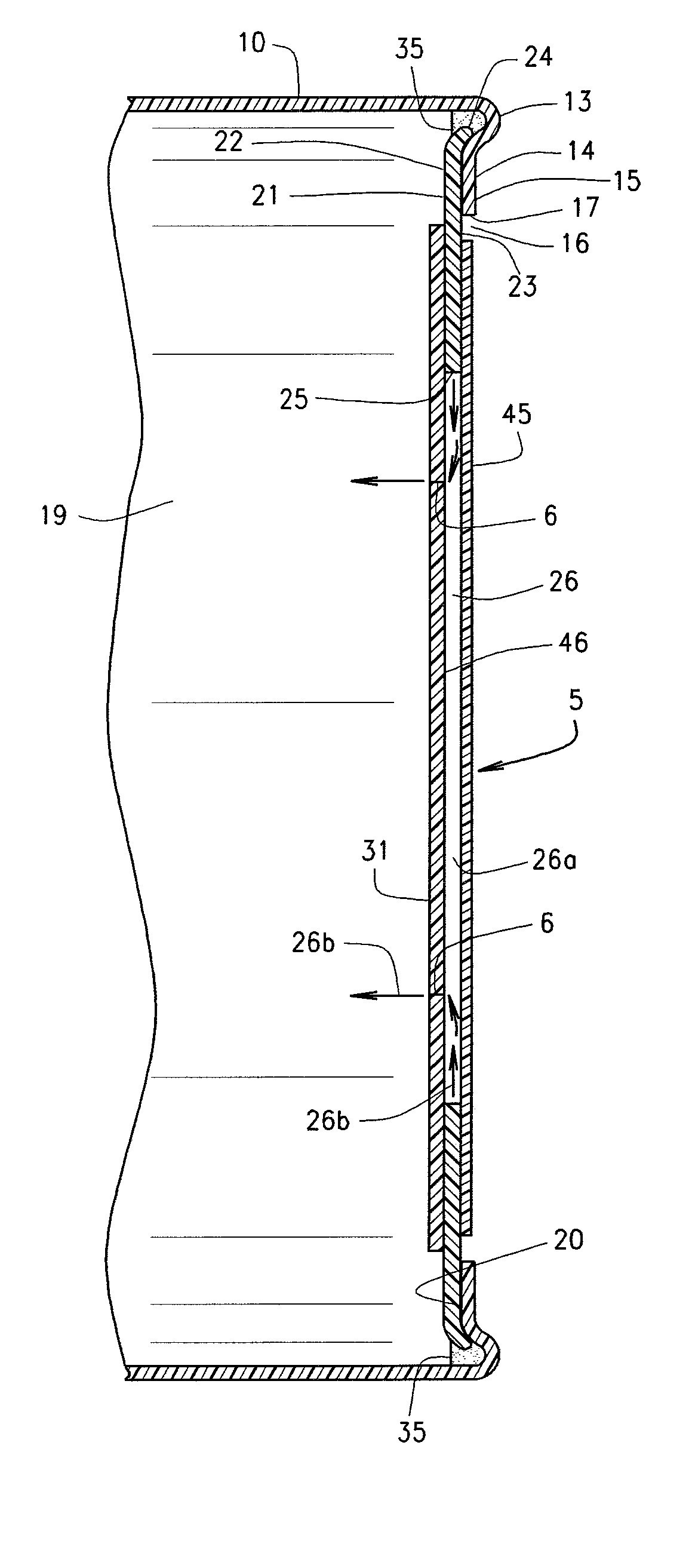

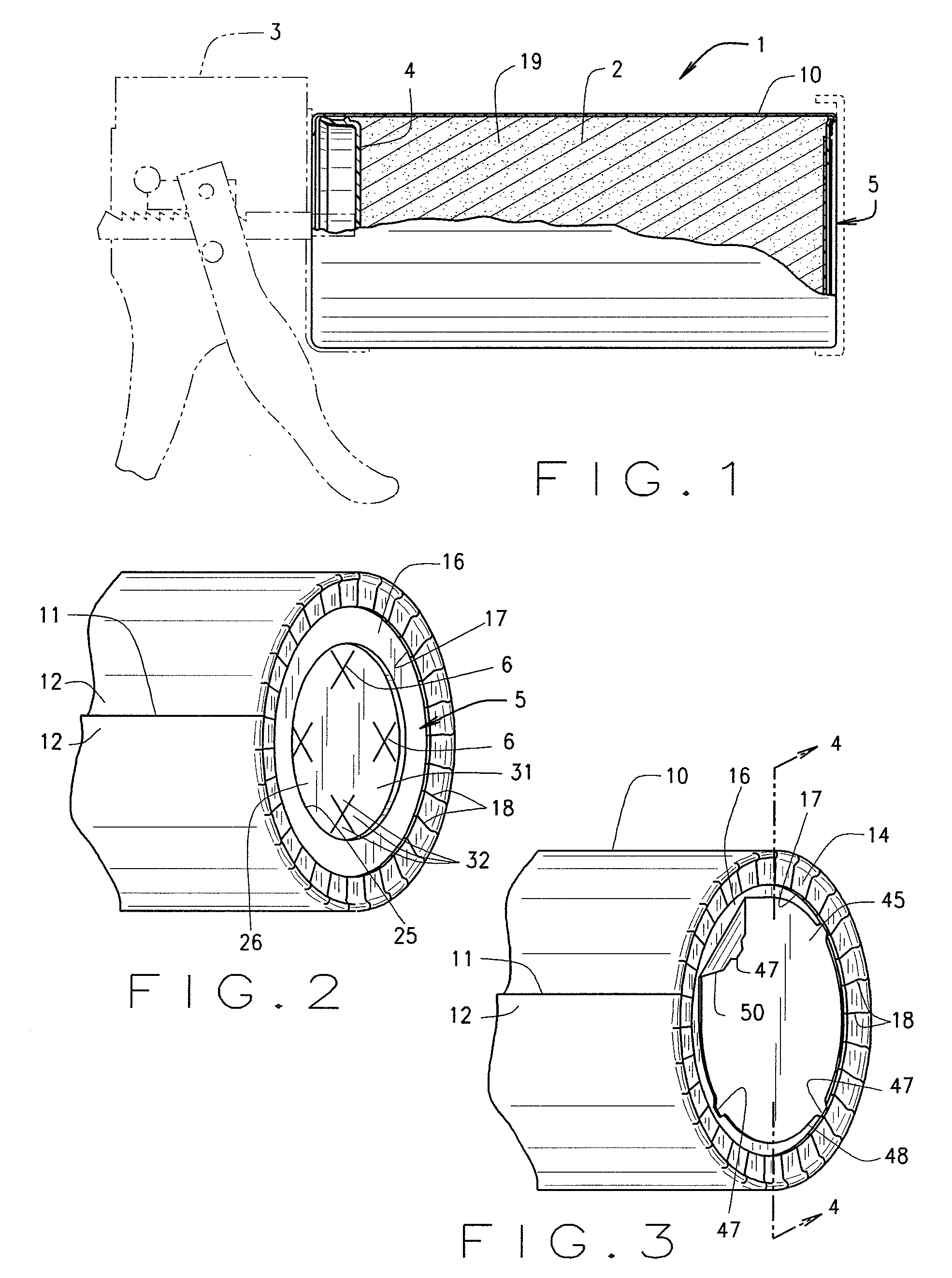

Dispenser for viscous condiments

A dispenser is provided for viscous condiments. The dispenser includes a tubular sidewall having opposite ends. One opposite end is open and can receive a plunger or piston therein for applying force to condiment contained within a compartment inside of the sidewall. The other end of the sidewall includes a dispenser valve assembly comprising a member secured to an inturned flange portion of the sidewall with the flange portion being generally normal to the sidewall. The dispenser valve assembly is suitably secured to the flange portion as by heat sealing to form a composite laminated structure that is resistant to the penetration of liquids from the condiments. A bead of hot melt can be provided to seal an exposed outer edge of the dispenser valve assembly and to seal the dispenser valve assembly to the sidewall. The dispenser valve assembly includes a valve plate having one or more selectively openable discharge openings formed therein that will open and close under the influence of pressure applied to the condiment within the dispenser.

Owner:HUHTAMAKI INC

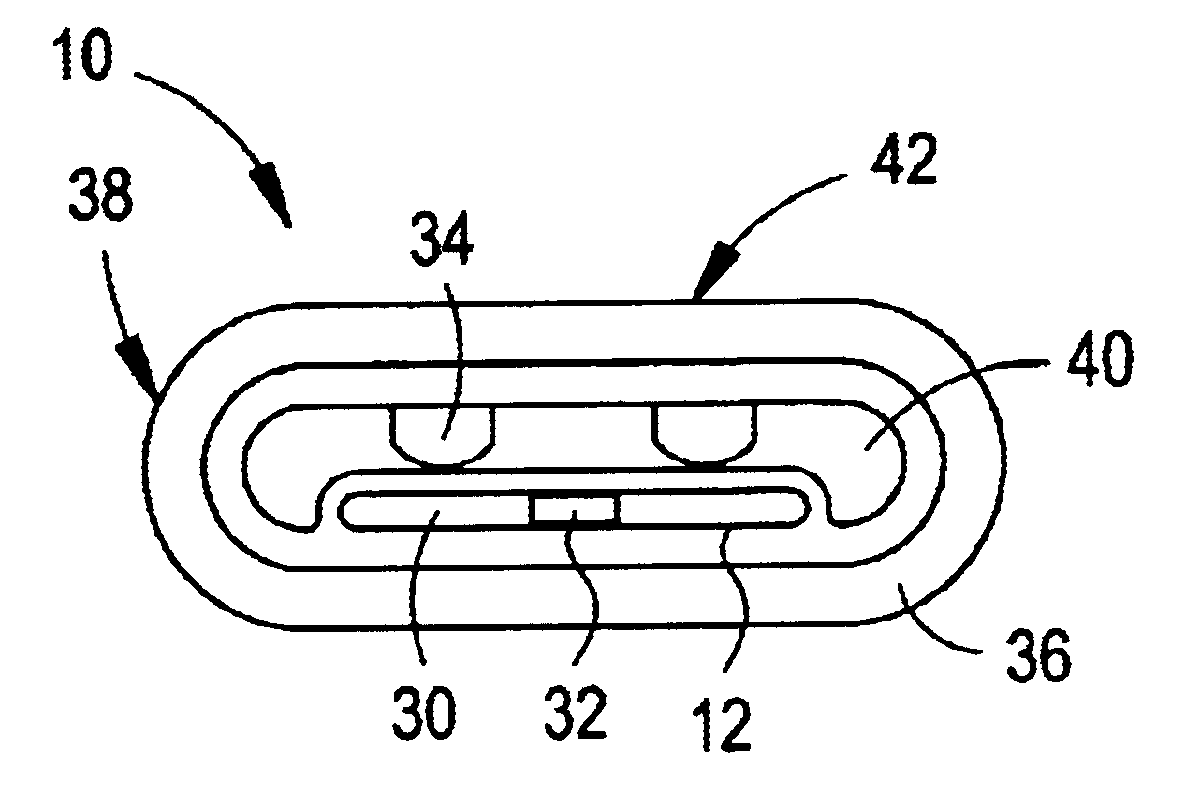

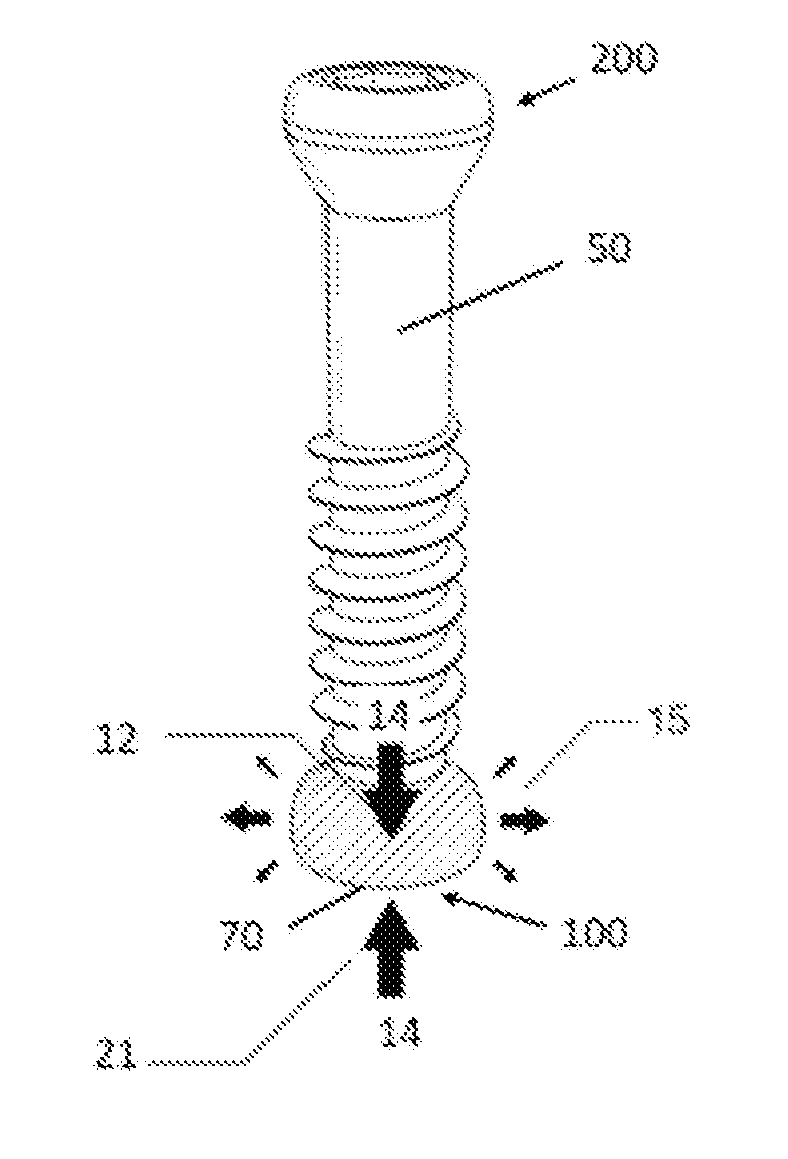

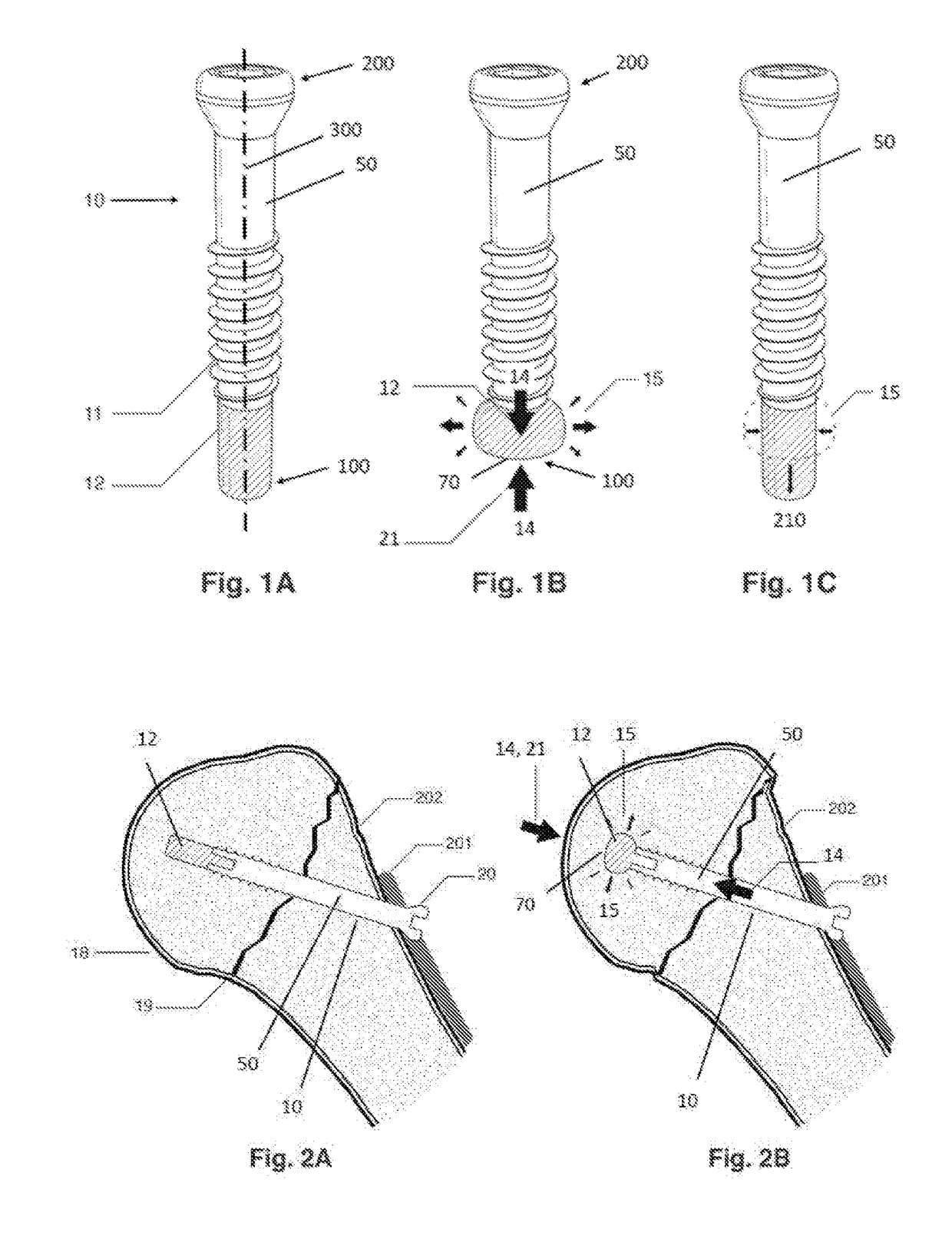

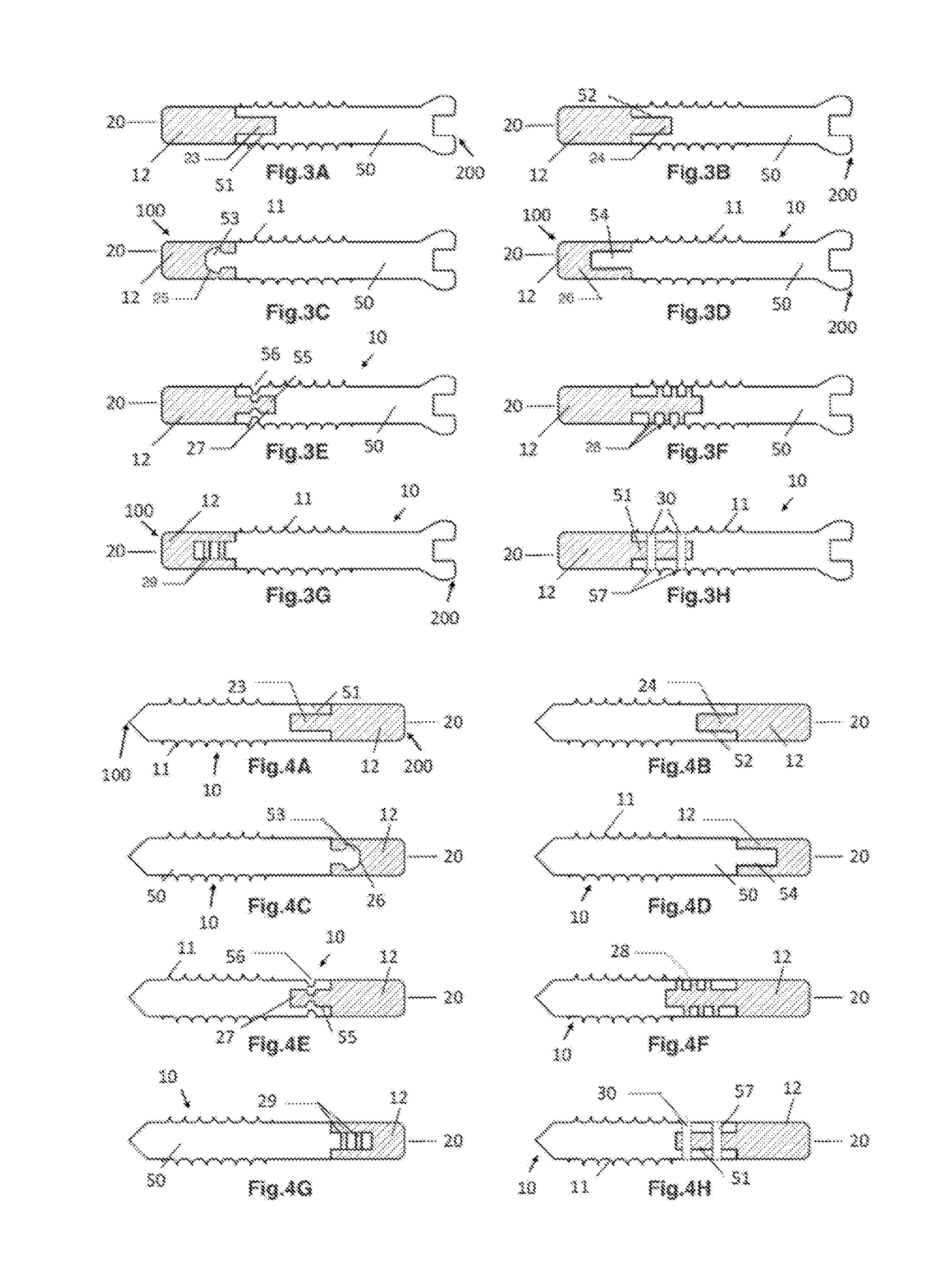

Anti-penetration bone implant device and method

ActiveUS20180085154A1Novel and inexpensive and highly effectiveReduce complicationsSuture equipmentsInternal osteosythesisBone tissueImplanted device

A device for engagement with a bone includes a dynamically expandable tip (12), a dynamically expandable ring (40), or other dynamically expandable insert (60, 62, 401L) that reacts to forces pushing the implant into bone tissue. The tip (12), ring (40) or insert (60, 62, 401L) expands at least normal to the direction of motion, increasing contact area between the surrounding bone tissue and the material and thereby reducing the occurrence of high areas of contact stress in the adjacent bone tissue. The tip (12), ring (40) or insert (60, 62, 401L) translates forces along an axis of motion into lateral frictional forces that can resist penetration into the bone tissue without the need for additional operator or patient interaction. A method of reducing migration of the device for engagement includes the steps of providing the device and inserting the device within bone tissue.

Owner:VERSITECH LTD

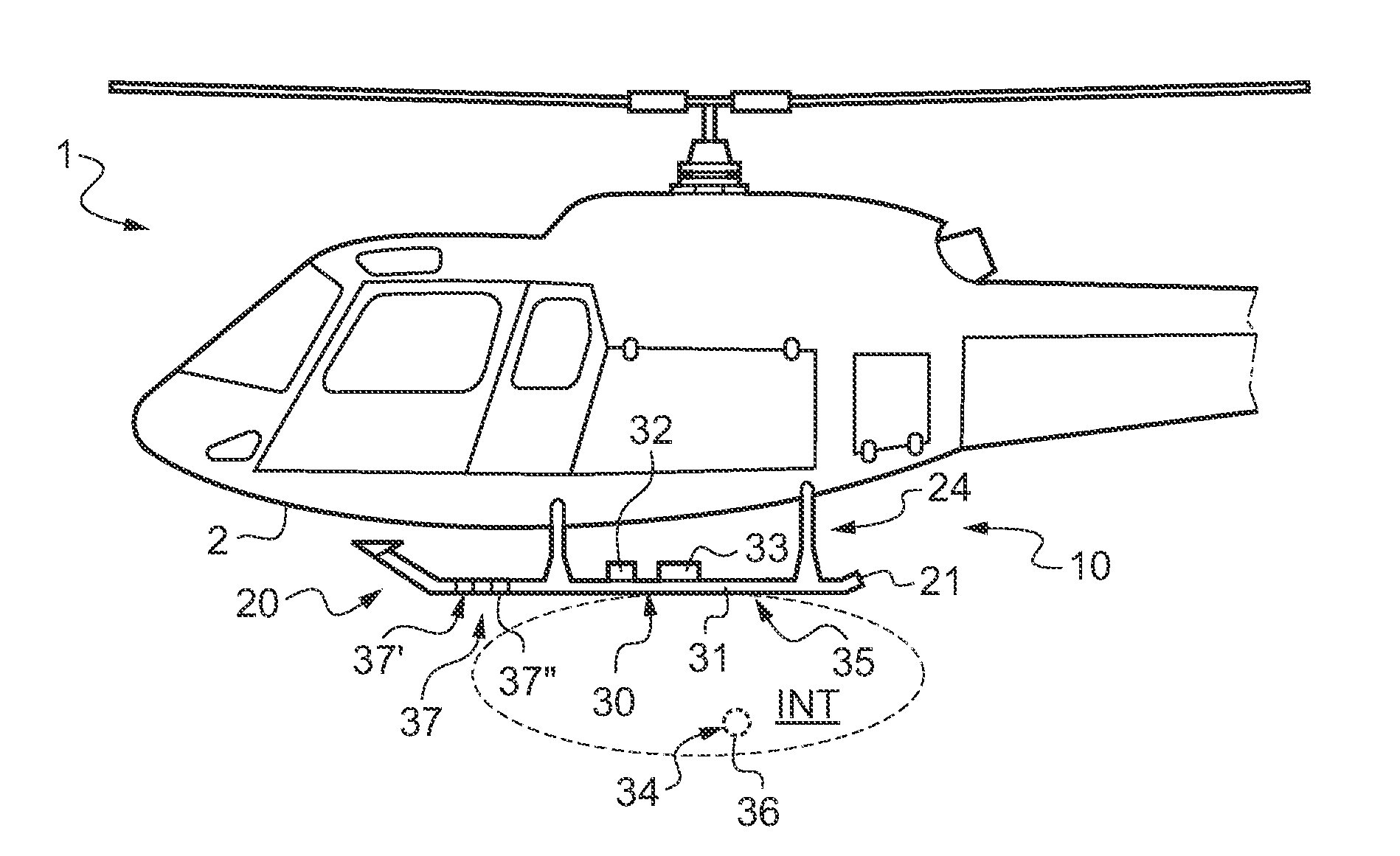

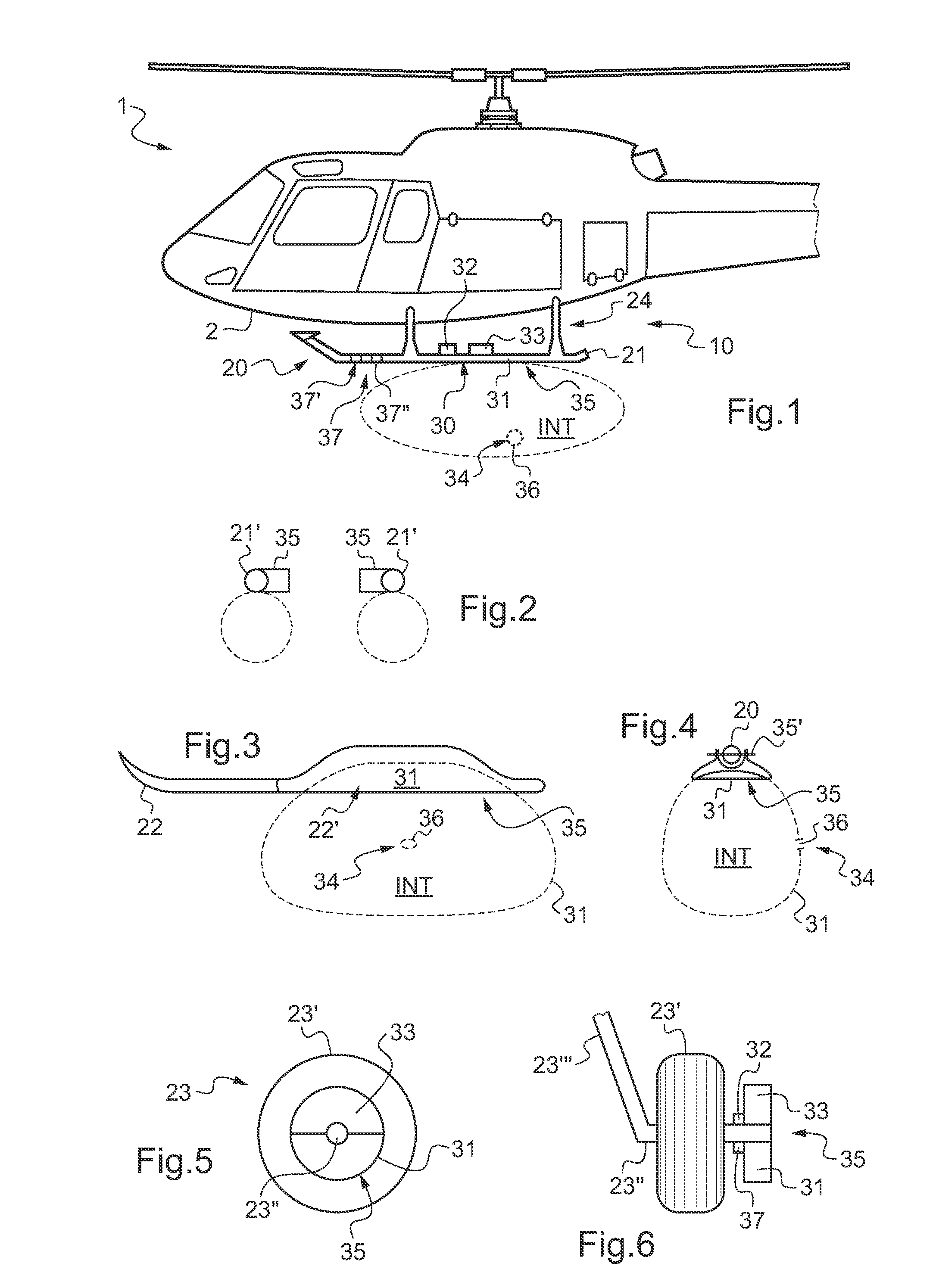

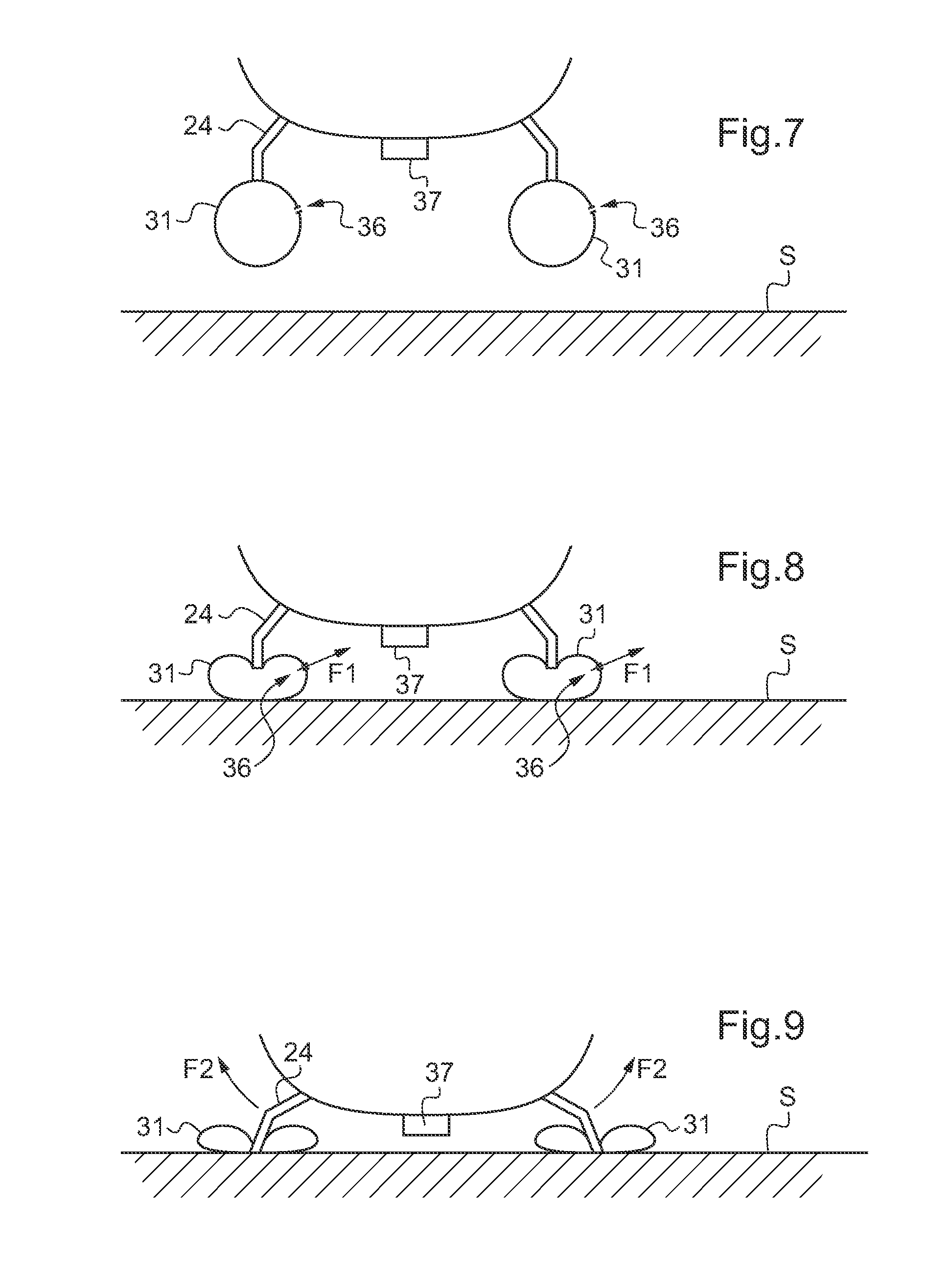

Landing gear provided with energy absorber means, an aircraft provided with said landing gear, and a method of landing

InactiveUS20110260001A1Maximum energy absorptionResistance to penetrationFloatsAirbagsFlight vehicleAircraft landing

Aircraft landing gear (10) provided with at least one contact means (20) for making contact with a contact surface (S). The landing gear includes energy absorber means (30) provided with an inflatable airbag (31) secured to said contact means (20), said energy absorber means (30) being provided with control means (32) and with at least one inflation means (32) for inflating said airbag (31) under the control of said control means (32), said energy absorber means (30) including adjuster means (34) for adjusting the pressure that exists inside (INT) said airbag (31).

Owner:EUROCOPTER

Towing hitch extension

InactiveUS20050006874A1Avoids and minimizes damage effectEffectively useRail and road vehiclesSupplementary fittingsEngineeringTowing

A towing hitch extension is provided that is adapted to protect the rear bumper, especially a plastic bumper, of a towing vehicle. The hitch extension includes a tow bar with front ends and rear ends. The front end couples to the rear towing hitch of the towing vehicle. The rear end is mounted to a transversely extending, horizontally oriented, enlongated cross bar medially an also to a trailer hitch receiver hitch receiver that is somewhat above the tow bar. A pair of guard projections, such a pair of tow hooks for example, upstand from the cross bar on either side of the tow bar. Braces, preferably metal plate members, are preferably mounted to the tow bar and the cross bar to strengthen the position of the cross-bar relative to the tow bar.

Owner:MROFKA ROBERT J +1

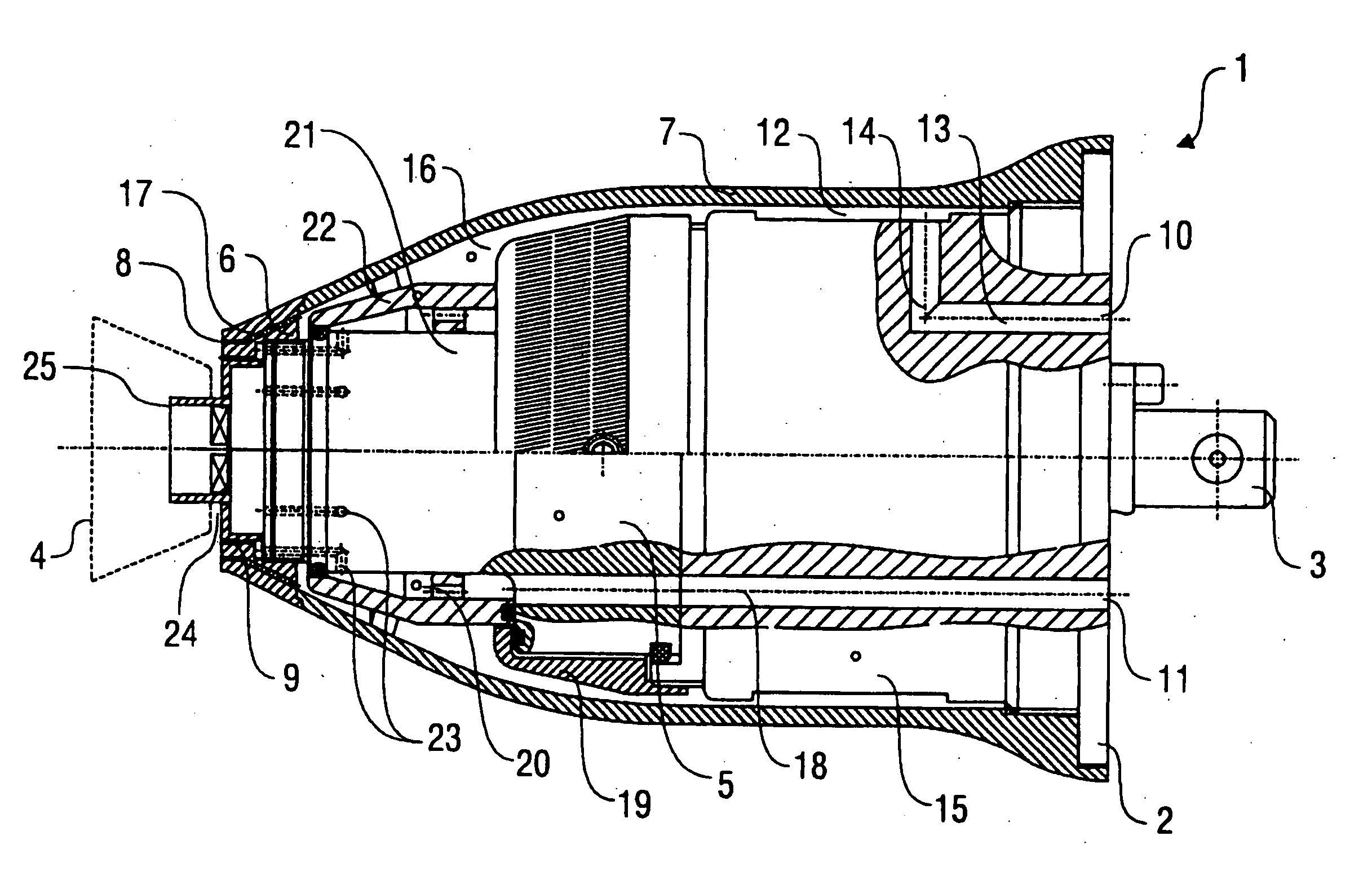

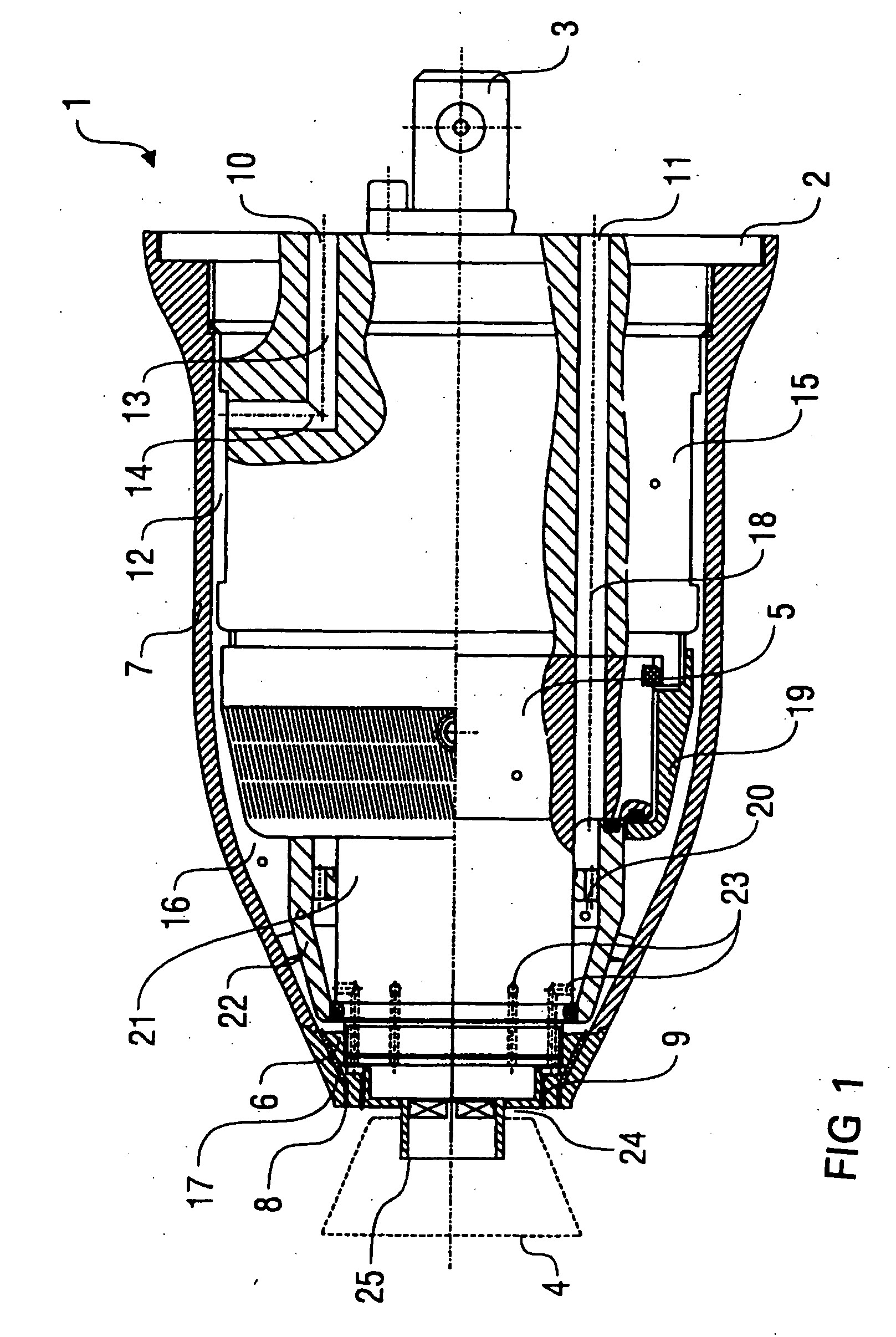

Rotary atomizer component

InactiveUS20060219816A1Reduce vacuumResistance to penetrationMovable spraying apparatusSpray nozzlesMechanical engineeringEngineering

A rotary atomizer component, such as for a steering air ring or bell cup for a rotary atomizer with at least one steering air jet for delivering steering air (or controlled air) and a rotary bearing shaft where, in axial direction between the bell cup and the steering air jet, a circumferential annular gap is located. A shaft cover in form of a bushing covers the bearing shaft, when mounted, at least partially in the annular gap area between the bell cup and the steering air jet. In addition, the annular gap space between the front surface of the bearing unit and the internal surface facing it axially or any other front element of the atomizer is sealed in a radial way internally against the externally accessible area of the shaft. The sealing element provided for this purpose is located along the internal circumference of the air-steering rings or front element and able to be attached to the front surface of the bearing unit in a way that it is elastically deformable.

Owner:DURR SYST INC

Canine protective suit and method of use thereof

InactiveUS8015948B2Easy to replaceResistance to penetrationProtection coversUpholsteryEngineeringFace shield

A canine protective suit comprising a face mask, a upper body protector and a lower body protector, wherein the face mask is removably secured to the upper body protector, and wherein the lower body protector is removably secured to the upper body protector. The upper body protector comprises elastic bands, wherein the elastic bands secure at least two front leg panels. Similarly, the lower body protector comprises elastic bands, wherein the elastic bands secure at least two back leg panels. To use, a canine's two front legs are placed into the two front leg panels as the upper body protector is placed on the canine. Similarly, the canine's rear legs are inserted into the back leg panels as the lower body protector is installed on the canine. The face mask is then disposed on the canine's face and secured to the upper body protector.

Owner:HALL CHRISTOPHER

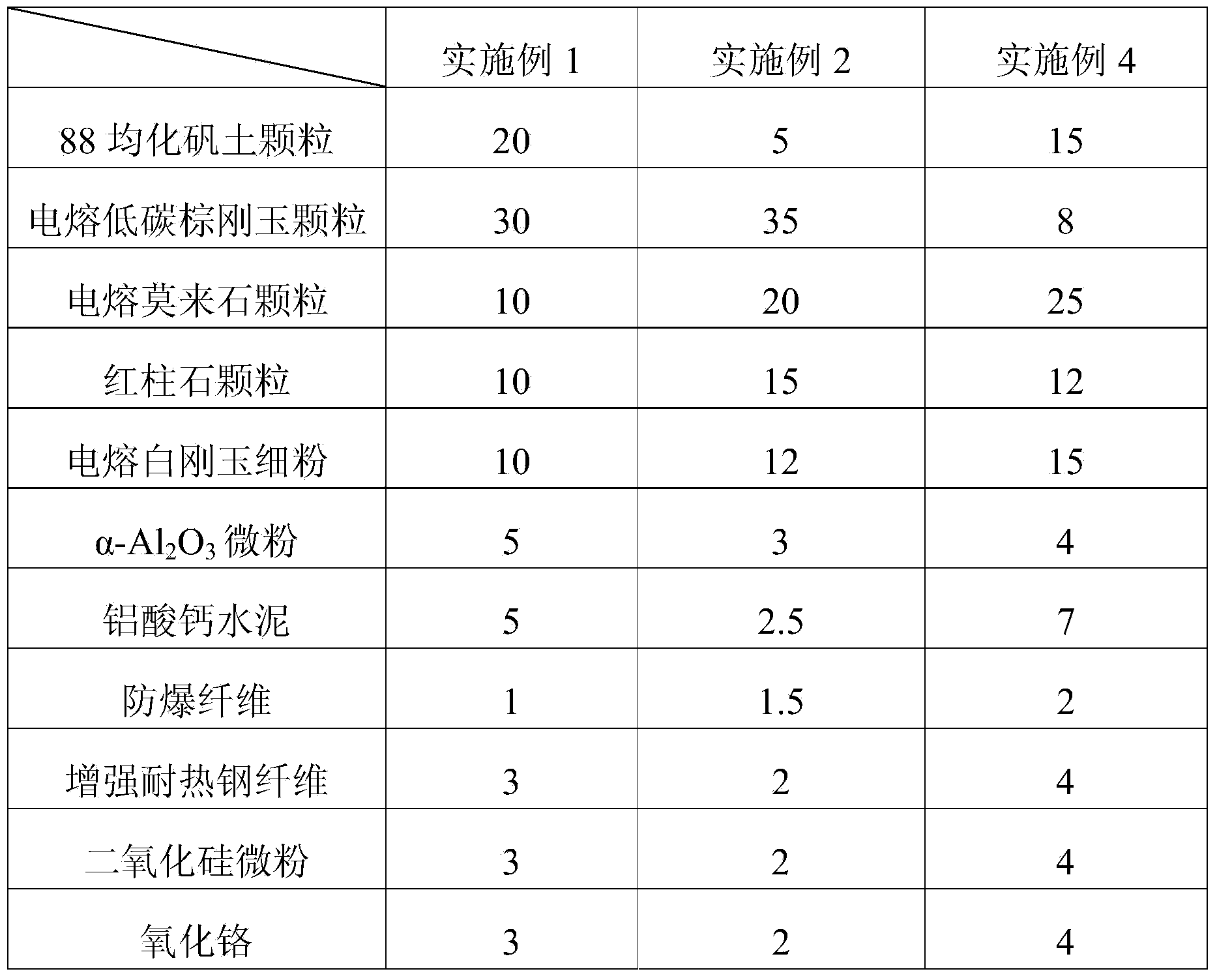

Alumina electric furnace cover and preparation method thereof

The invention aims to provide an alumina electric furnace cover, which is high in thermal shock resistance, density and iron slag erosion resistance and long in service life. The alumina electric furnace cover comprises the following components in percentage by weight: 5 to 20 percent of 88 homogenized alumina particles, 8 to 35 percent of electrofused low-carbon brown aluminum oxide particles, 10 to 25 percent of electrofused mullite particles, 10 to 15 percent of andalusite particles, 10 to 15 percent of electrofused white corundum fine powder, 3 to 5 percent of alpha-Al2O3 micro powder, 2.5 to 7 percent of calcium aluminate cement, 1 to 2 percent of explosion-proof fibers, 2 to 4 percent of reinforced heat-resistant steel fibers, 2 to 4 percent of silicon dioxide micro powder and 2 to 5 percent of chromium oxide. A preparation method comprises the following steps of uniformly mixing the electrofused white corundum fine powder, the alpha-Al2O3 micro powder, the silicon dioxide micro powder and the explosion-proof fibers; adding the electrofused mullite particles and the andalusite particles, stirring the mixture for at least 3min, adding the other raw materials, and stirring the mixture for at least 8min; adding water and a water reducing agent, performing stirring and casting molding, and performing natural curing, de-molding and drying.

Owner:北京利尔高温材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com