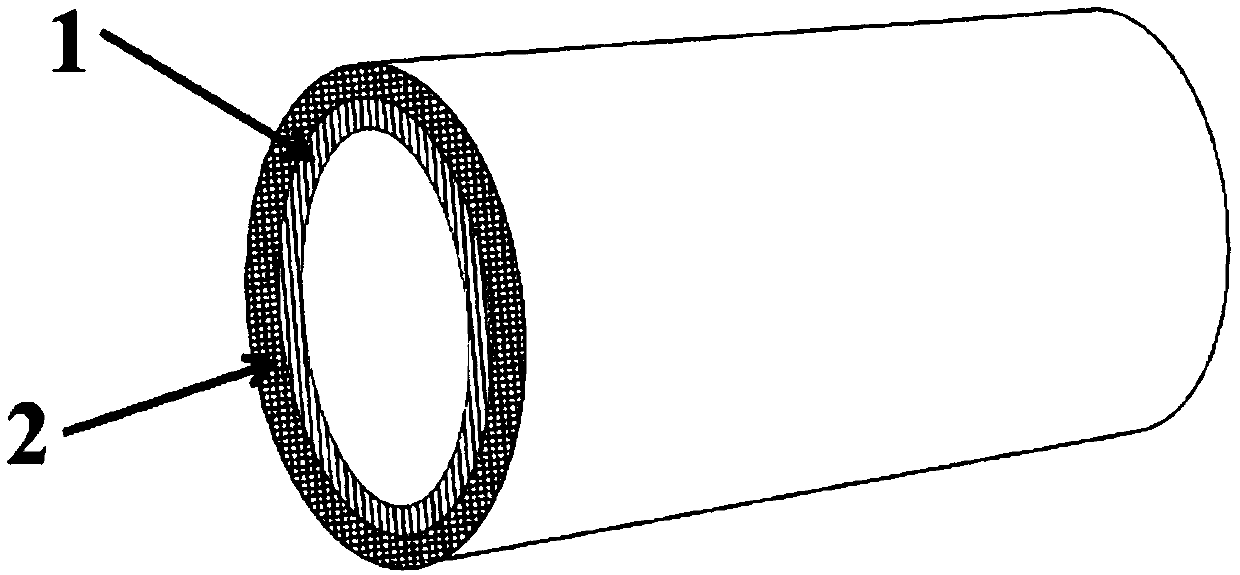

Preparation method of polyurethane composite bearing of double-layer structure

A technology of composite bearing and double-layer structure, applied in bearings, bearing components, shafts and bearings, etc., can solve the problems of complex overall process, low yield, expensive molds, etc., achieve simple process, improve wear resistance, and facilitate processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

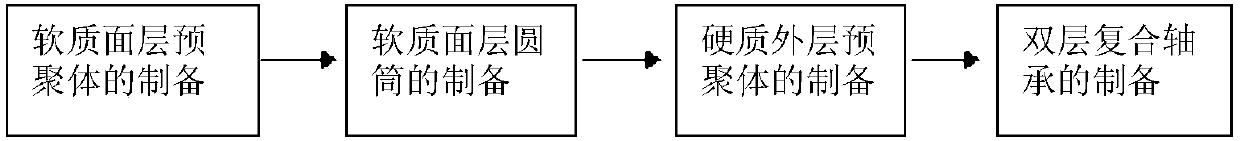

[0031]Preparation of soft surface layer prepolymer: heat 2000 grams of polytetrahydrofuran ether glycol with a molecular weight of 2000 to 110 degrees in a stainless steel reaction kettle with a closed structure, and carry out vacuum dehydration. The vacuum degree is <1000Pa, and the dehydration time is 3 hour; the dehydrated polytetrahydrofuran ether glycol is cooled to 60 degrees, and then slowly added to a stainless steel reactor containing 350g of toluene diisocyanate, stirring under a nitrogen atmosphere to keep the reaction temperature at 70 degrees, after 1 hour of reaction , add 300 grams of anti-wear additive polytetrafluoroethylene micropowder, and then stir and react for 30 minutes, then vacuum defoam while cooling down to obtain a soft surface layer polyurethane prepolymer, and transfer it to the A material tank of the pouring machine , and at the same time, the chain extender 1,4-butanediol is installed in the material tank B of the pouring machine for standby.

...

Embodiment 2

[0036] Preparation of soft surface layer prepolymer: heat 2000 grams of polycaprolactone diol with a molecular weight of 2000 to 110 degrees in a stainless steel reaction kettle with a closed structure, and carry out vacuum dehydration. The vacuum degree is <1000Pa, and the dehydration time is It was 3 hours; the dehydrated polycaprolactone diol was cooled to 60 degrees, and then slowly added into a stainless steel reactor containing 320 grams of p-phenylene diisocyanate, stirring under a nitrogen atmosphere to keep the reaction temperature at 70 After reacting for 1 hour, add 300 grams of wear-resistant additive ultra-high molecular weight polyethylene micropowder, stir and react for 30 minutes, and vacuum defoaming while cooling down to obtain a soft surface layer polyurethane prepolymer, and transfer to The material tank A of the pouring machine is equipped with the chain extender 1,3-butanediol in the B material tank of the pouring machine at the same time, for standby.

...

Embodiment 3

[0041] Preparation of soft surface layer prepolymer: heat 2000 grams of polypropylene oxide ether diol with a molecular weight of 2000 to 110 degrees in a stainless steel reaction kettle with a closed structure, and carry out vacuum dehydration. The vacuum degree is <1000Pa, and the dehydration time is 3 hours; then slowly add 420 grams of 1,5-naphthalene diisocyanate into the stainless steel reactor, stir under nitrogen atmosphere to keep the reaction temperature at 130 degrees, after 10 minutes of reaction, add 300 grams of wear-resistant Auxiliary molybdenum disulfide, start to cool down, while cooling down to 70 degrees, vacuum defoaming at the same time, to obtain soft surface layer polyurethane prepolymer, and transfer it to the A material tank of the pouring machine, and at the same time in the B material tank of the pouring machine Equipped with chain extender 1,3-butanediol, ready for use.

[0042] Preparation of the soft surface layer cylinder: adjust the ratio of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com