Sand-burning-resistant water-based expendable pattern coating for gray iron casting and application and preparation method thereof

A lost foam and coating technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of unsatisfactory heat resistance, sticky sand, pores, impurities, and long post-treatment process time, and achieve the appearance quality Good, fast drying, good sintering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

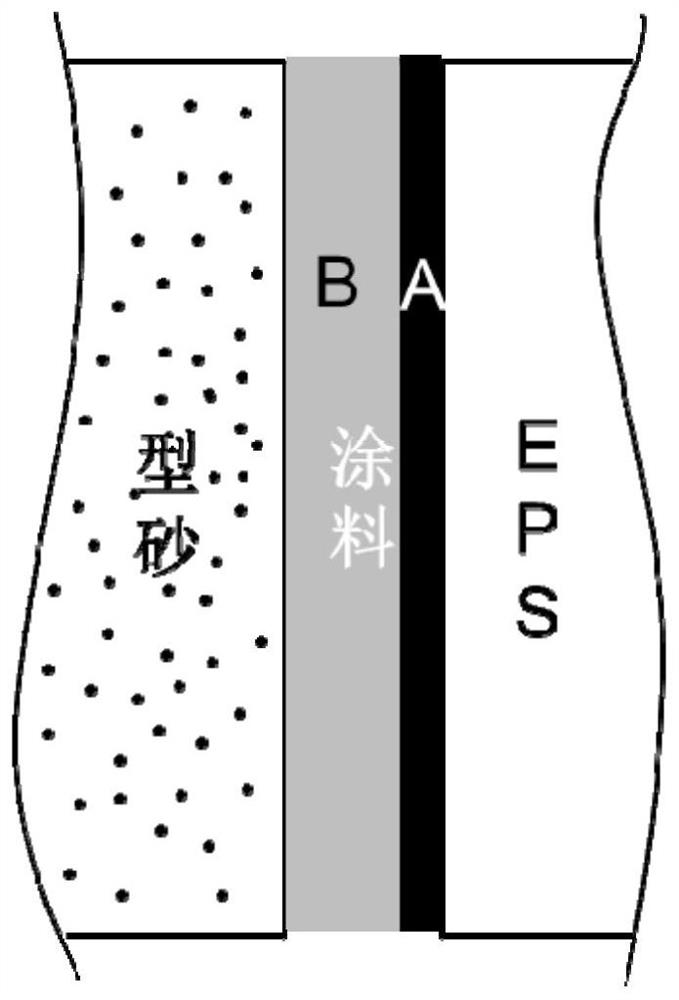

Image

Examples

Embodiment 1

[0059] This embodiment discloses a lost foam coating to improve the precision and quality of casting and avoid the above-mentioned technical problems in view of the phenomena such as sticky sand, pores and impurities that are prone to occur in the gray iron casting process.

[0060] Specifically, a gray iron casting anti-sand sticking water-based lost foam coating disclosed in this embodiment includes the following components in terms of mass:

[0061] 30-40 parts of 100-mesh flake graphite with 90% carbon content, 80-90 parts of 200-mesh mullite, 3-9 parts of light-burned magnesium oxide, 3-5 parts of sodium bentonite, and 10% PVA concentration 9 to 19 parts of glue, 22 to 26 parts of alkaline silica sol with an active ingredient ratio of 30%, 6 to 8 parts of aluminum dihydrogen phosphate, 1 to 3 parts of redispersible white rubber powder, and an active ingredient ratio of 48% 7-10 parts of styrene-acrylic emulsion, 0.3-0.6 parts of JFC penetrant, and 100-160 parts of water. ...

Embodiment 2

[0064] In this example, the formulation of the lost foam coating disclosed in Example 1 is refined, and the following specific and feasible scheme is adopted, which includes the following components in terms of mass:

[0065] 36 parts of 100-mesh flake graphite with 90% carbon content, 84 parts of 200-mesh M45 mullite, 5 parts of light-burned magnesia, 3.2 parts of sodium bentonite, 10 parts of PVA thick gum with an active ingredient ratio of 10%, the ratio of active ingredients 24 parts of 30% alkaline silica sol, 7.2 parts of aluminum dihydrogen phosphate, 2.4 parts of redispersible white rubber powder, 9.6 parts of styrene-acrylic emulsion with an active ingredient ratio of 48%, 0.5 parts of JFC penetrant, and 0.5 parts of washing powder part, 100 parts of water.

[0066] In this embodiment, washing powder is added, and washing powder is used as a surfactant.

[0067] According to the lost foam coating disclosed in this example, the test pouring experiment is carried out. ...

Embodiment 3

[0074] This embodiment refines the formulation of the lost foam coating disclosed in Example 1, adopts the following specific and feasible scheme, and includes the following components in terms of mass:

[0075] 36 parts of 100 mesh flake graphite with 90% carbon content, 84 parts of 200 mesh mullite, 5 parts of light-burned magnesia, 3.5 parts of sodium bentonite, 14 parts of PVA thick glue with an active ingredient ratio of 10%, and the effective ingredient ratio is 24 parts of 30% alkaline silica sol, 7.2 parts of aluminum dihydrogen phosphate, 2.4 parts of redispersible white rubber powder, 9.6 parts of styrene-acrylic emulsion with an active ingredient ratio of 48%, 0.5 part of JFC penetrant, and 0.5 part of washing powder , 130 parts of water. In this scheme, the number of PVA thick glue is increased, and water is added to dissolve it. The advantage of this setting is that the inorganic binder is added, the hardness increases after drying, the high temperature resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com