A drilling structure construction method that can increase the amount of uranium pumping and injection in ground leaching

An in-situ leaching uranium mining and construction method technology, which is applied to drilling equipment and methods, drill pipes, drill pipes, etc., can solve the problems of high labor intensity for well cleaning, low drilling well completion rate, and poor sediment resistance, and achieve Low labor intensity for well washing, high drilling rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

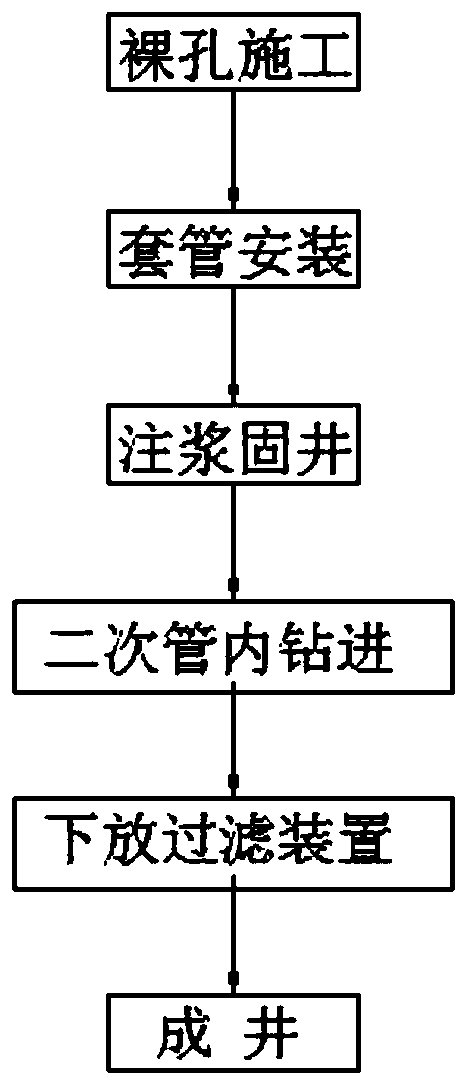

[0033] like Figure 1-2 A drilling structure construction method that can increase the amount of injection liquid for uranium extraction by in-situ leaching is shown, comprising the following steps:

[0034] (a) Carry out drilling of open hole 2, installation of casing 1 and grouting and cementing 3, wherein the drilling diameter of open hole 2 is 150-220 mm, and the drilling depth of open hole 2 is from the surface to the bottom of the sedimentation pipe;

[0035] (b) A casing protection device is installed on the drill pipe to limit the position of the drill pipe so that it is centered during the drilling of the drill bit to reduce casing wear; the casing protection device is a hollow tubular structure made of nylon , the inner diameter of the casing protection device matches the outer diameter of the drill pipe, the wall thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com