Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109results about How to "Facilitate automatic processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

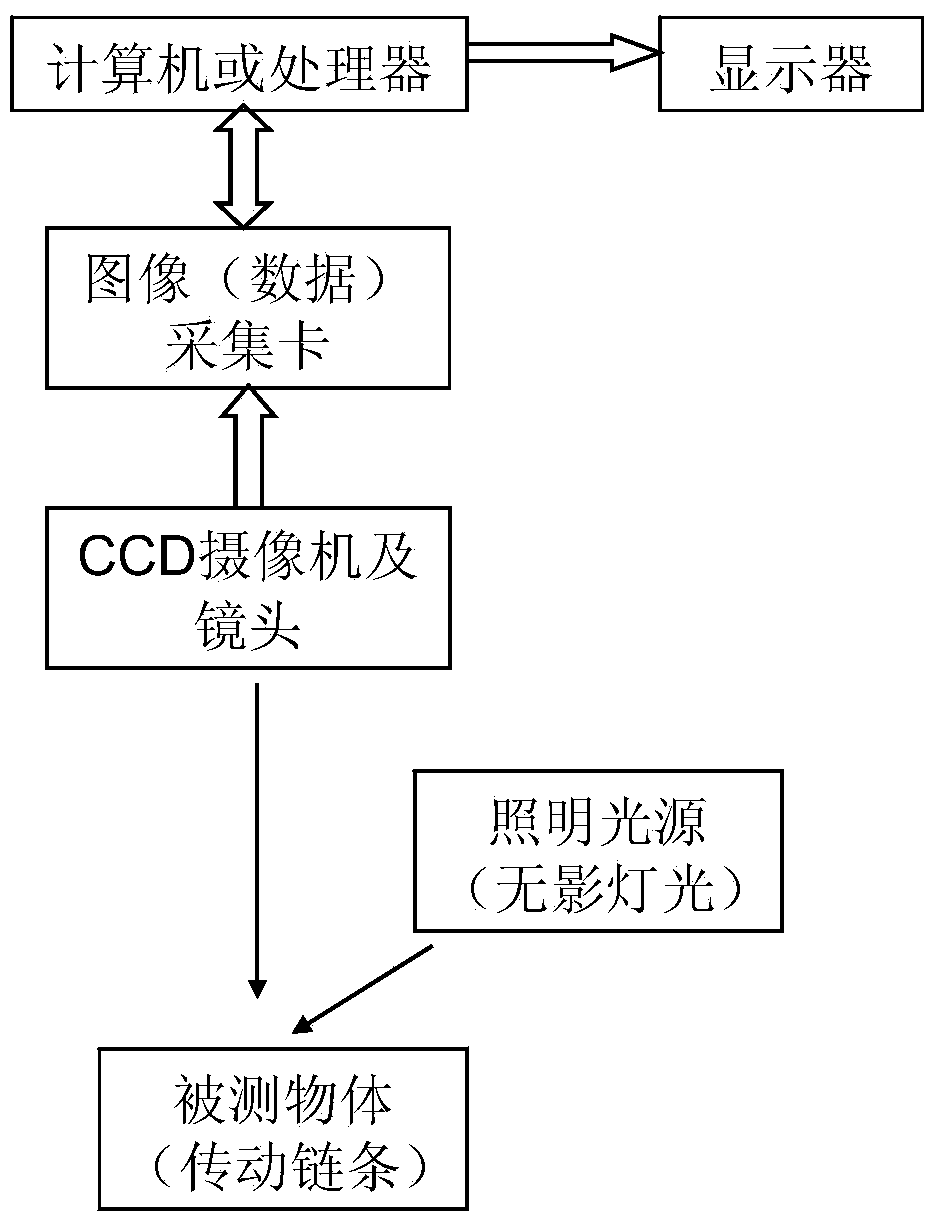

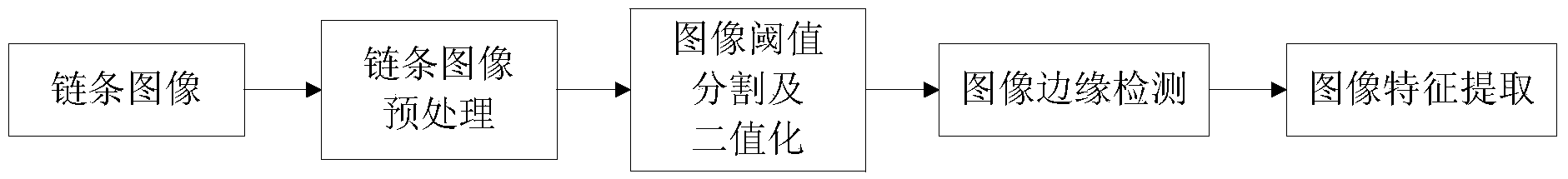

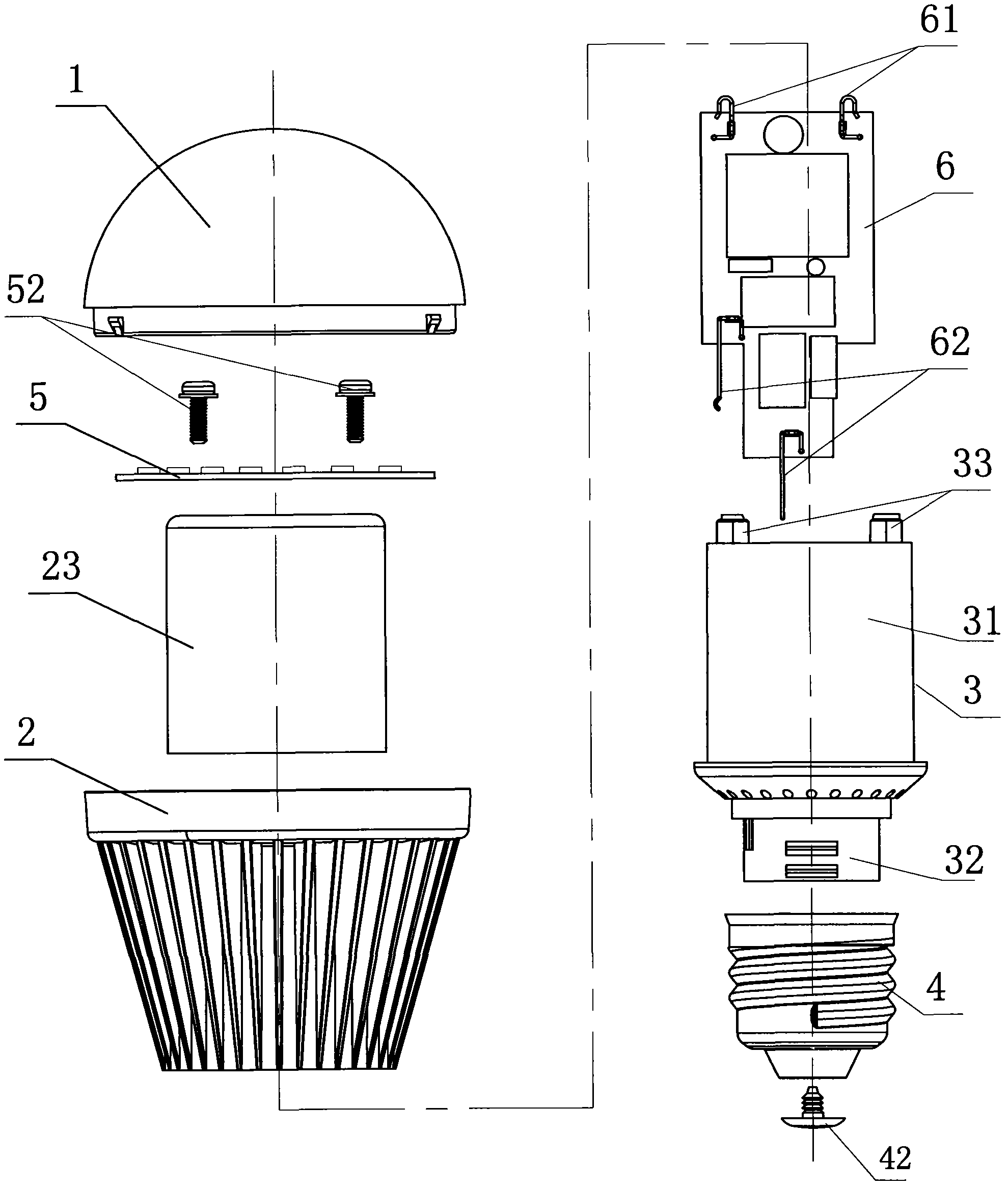

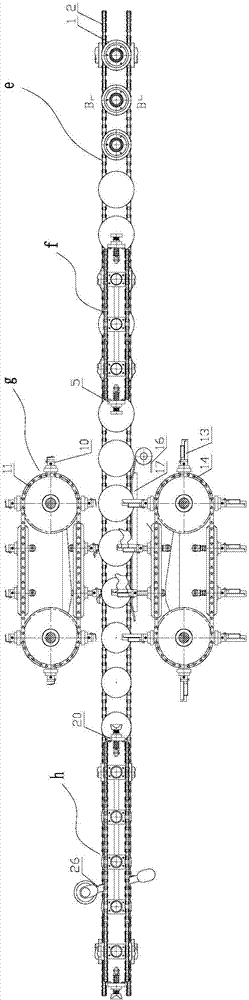

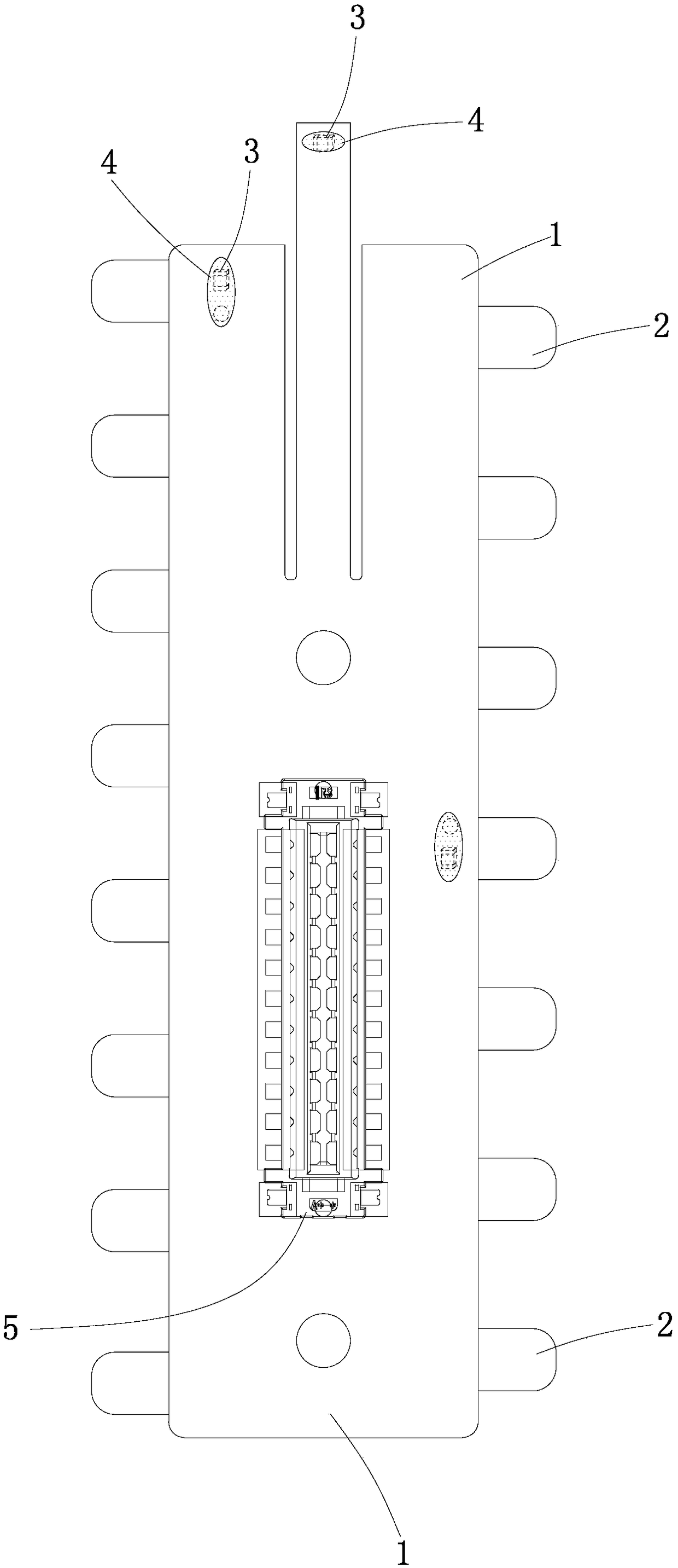

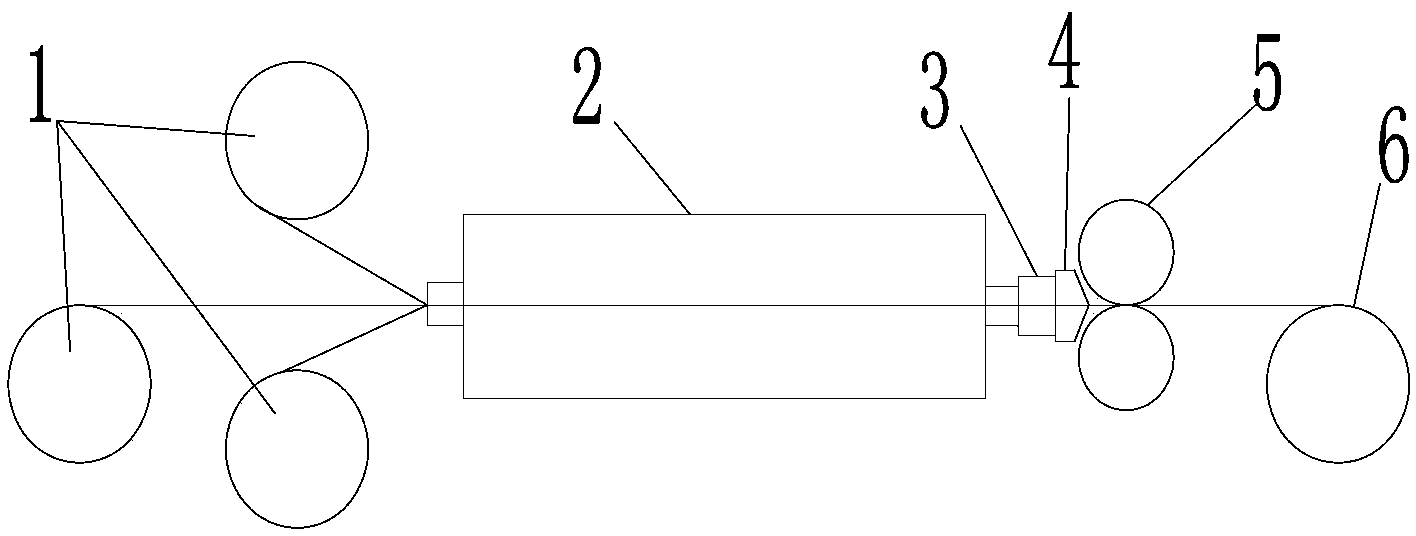

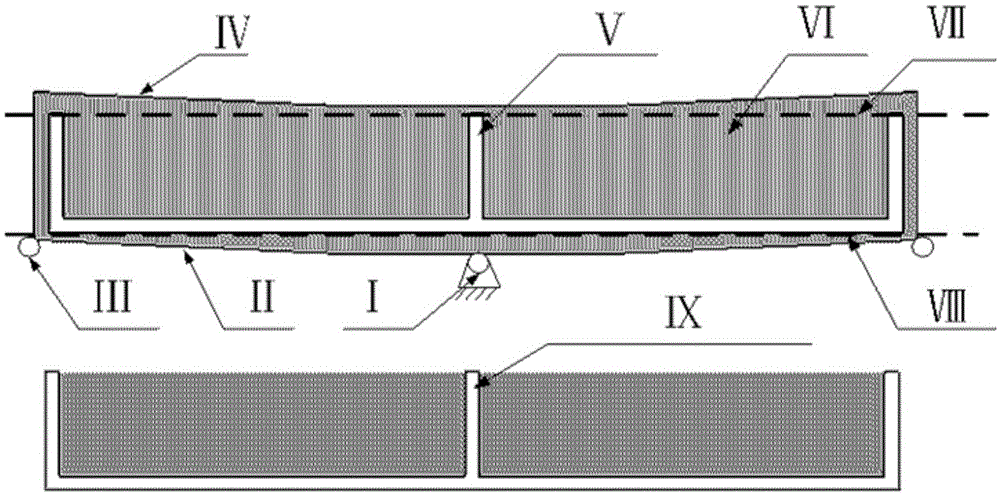

Transmission chain quality detection system based on machine vision

InactiveCN103454285ABright enoughImprove flexibilityOptically investigating flaws/contaminationUsing optical meansImaging processingMachine vision

The invention discloses a transmission chain quality detection system based on machine vision. The transmission chain quality detection system comprises a to-be-detected transmission chain, a lighting source, a CCD (Charge Coupled Device) camera and a lens, an image processing unit, a computer and a display, wherein the CCD camera is used for focusing an image of the to-be-detected transmission chain to a CCD chip through the lens, the image forms a video signal (an image signal) after being filtered and amplified to be output to the image processing unit, and the image processing unit is used for transmitting the image to a computer storage for processing; the computer completes analysis, image processing and storage of acquired data and image information to obtain a quality parameter of the to-be-detected transmission chain, and the obtained quality parameter is compared with a calibrated parameter so that decision and control are completed, and the function of automatic identification is further realized. According to the transmission chain quality detection system based on machine vision, the detection processing speed is greatly increased, the labor intensity is reduced; the length of the transmission chain which can be detected by one transmission chain quality detection system within 1 second reaches about above 4m.

Owner:NANJING NORMAL UNIVERSITY

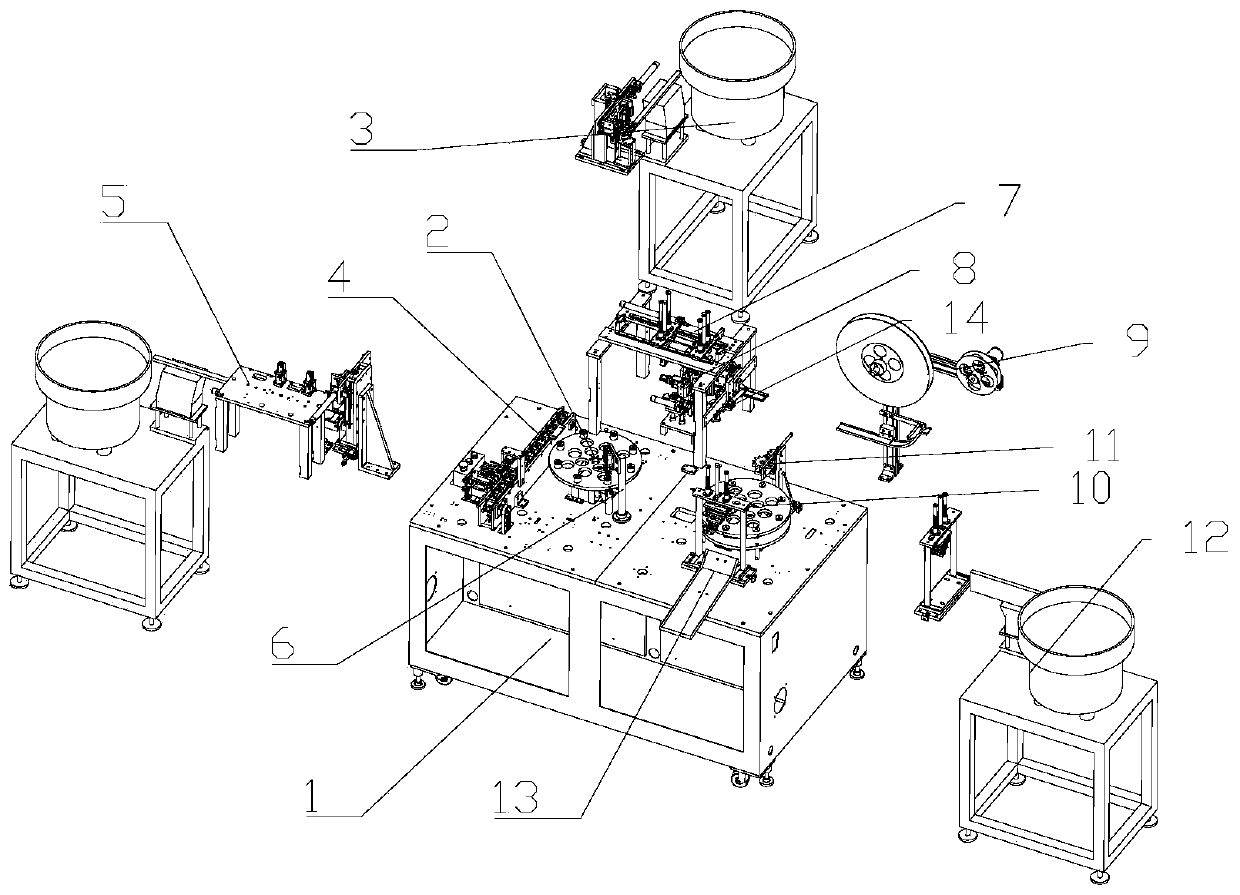

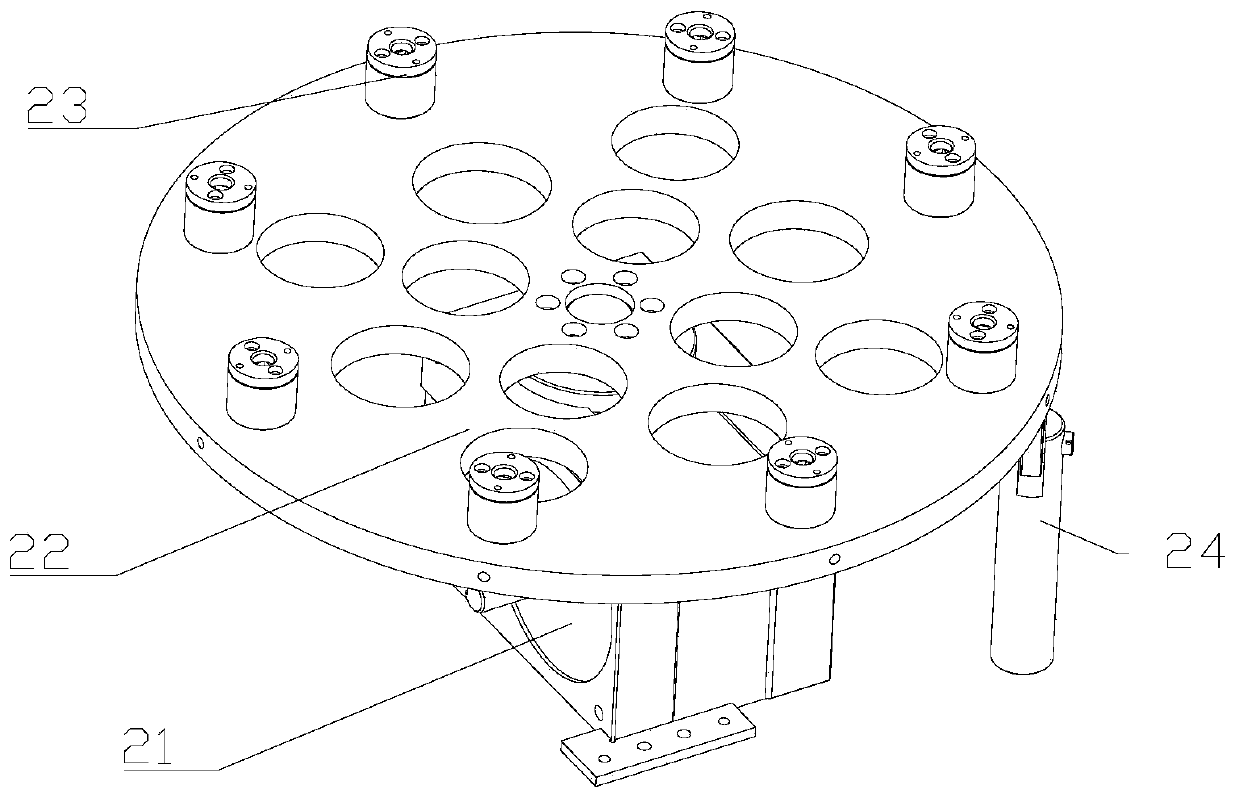

Electronic antenna and full automatic assembling method and production system thereof

The invention relates to the field of communication equipment manufacturing. An electronic antenna full automatic assembling method sequentially comprises the following steps that rotation piece feeding is conducted, specifically, a rotation piece is fed to a first rotary disc device through a rotation piece feeding device; an antenna core and an sma connector are assembled into a core body, specifically, the antenna core and the sma connector are fed and assembled through an antenna core feeding transferring device and an sma connector feeding assembling device, the connector is fixed, and the antenna core is inserted into the connector; the rotation piece and the core body are pressed, specifically, pressing is conducted through a pressing device; copper sheet assembling is conducted, specifically, a carrying device carries a product into a copper sheet pressing device to be assembled; and protection bar assembling is conducted, specifically, a protection bar is fed by an antenna protection bar feeding device, and then, final product assembling is conducted through a protection bar assembling device. An electronic antenna full automatic assembling production system adopted the technical scheme is high in automation degree, working efficiency and finished product percent of pass.

Owner:王朝火

A realization method of paging datatable control customized based on struts2 technology

InactiveCN102262539AFacilitate automatic processingImprove efficiencySpecific program execution arrangementsPagingDatabase

The invention discloses a realization method of a self-defined pagination dataTable control based on struts2 technology, which is characterized in that it comprises the following steps: 1. Create a standard XML format tld tag file through a text creation module; 2. Use the JSP page dataTable control; 3. The data queried by the server is encapsulated into a data list by the encapsulation module; 4. When the server parses the page referencing the dataTable control; 5. After the parsing is completed, the JSP page will automatically reference the CSS style file of the dataTable control, Control the style of the output content, and at the same time refer to the JS file to perform Ajax request processing for data paging, and realize partial redrawing of the page to improve the execution efficiency of the system. The implementation method is very convenient and efficient, and makes the automatic processing of data more convenient and more efficient.

Owner:SHENZHEN CLOU ELECTRONICS

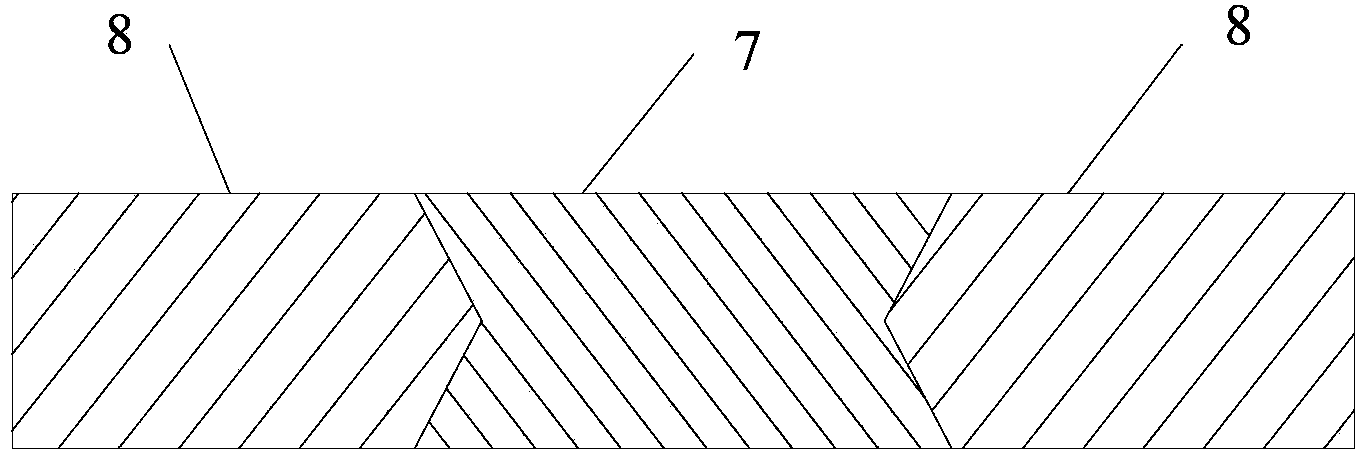

Method for preparing through-type composite strip embedded with silver copper

ActiveCN102896150AHigh bonding strengthIncrease productivityMetal rolling arrangementsIngotUltimate tensile strength

The application discloses a method for preparing a through-type composite strip embedded with silver copper. The method comprises the steps of: extruding silver and copper ingots into profiled strips according to a design shape, respectively cleaning the surfaces of the profiled silver strip and the purchased profiled copper strip, removing a greasy dirt, an impurity and oxide on the surface; mutually embedding the silver strip and the copper strip into a whole; reinforcing and welding two heads to prepare a pre-composite material; continuously rolling and hot rolling to form a silver copper composite material from the pre-composite material under a complete-atmosphere protection state; dragging and receiving materials by a receiving machine, and then annealing in a diffusion manner, rolling and cutting to obtain the product. The method disclosed by the application is high in bonding strength, low in demand on manufacturing device, easy to process, long in length of strip, and convenient to automatically process, and manufacturing on a large scale can be carried out, thus, the cost is greatly reduced.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

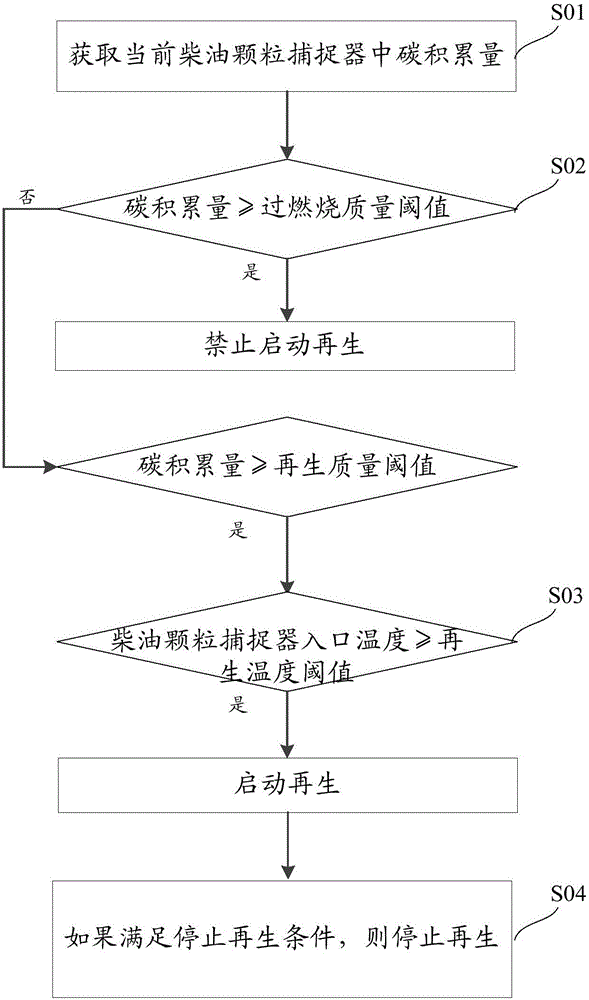

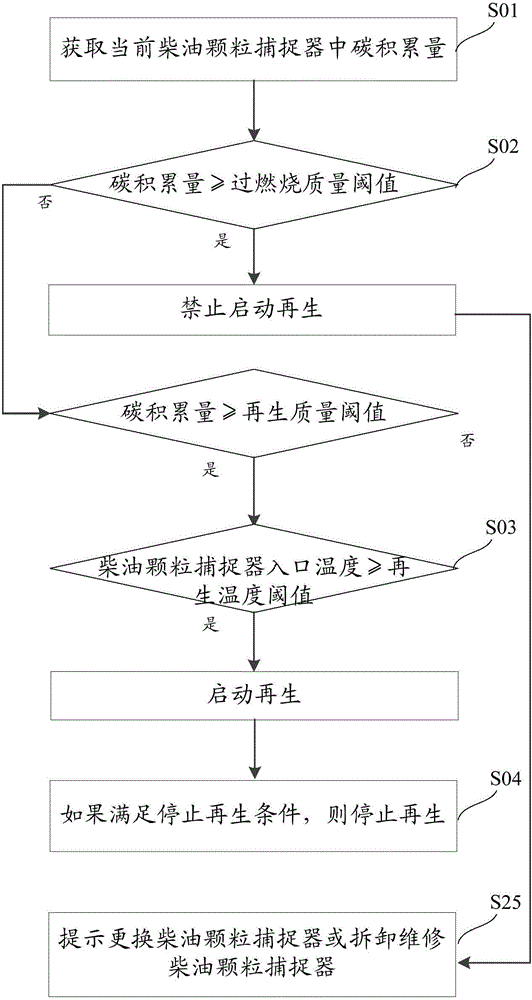

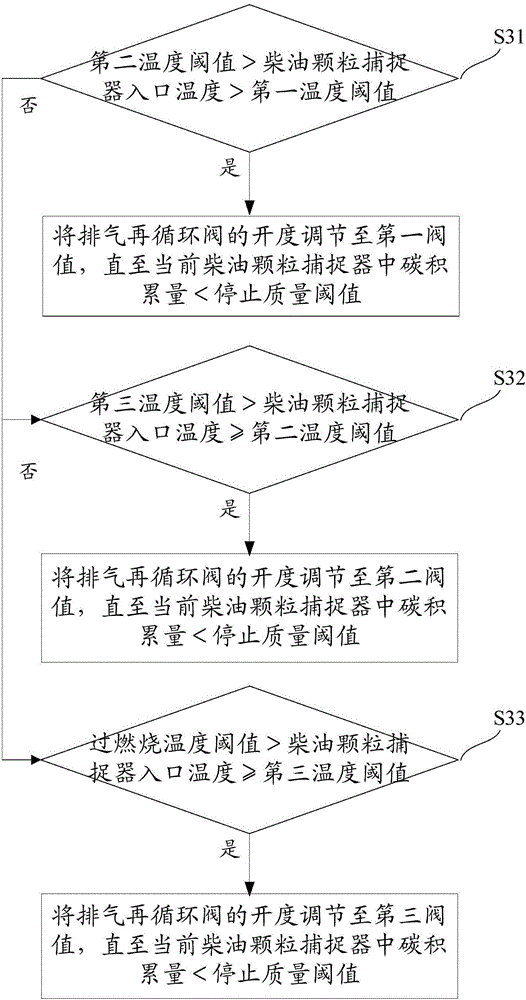

Method and system for preventing over-combustion of diesel particle catcher

ActiveCN106401720AAvoid over-burning situationsAvoid Overburning SituationsInternal combustion piston enginesExhaust apparatusCombustionLow speed

The invention discloses a method and a system for preventing over-combustion of a diesel particle catcher. The method comprises the steps that a carbon accumulation amount in the current diesel particle catcher is acquired; whether the carbon accumulation amount is larger than or equal to an over-combustion mass threshold or not is determined, and if yes, regeneration starting is forbidden; if not, whether the carbon accumulation amount is larger than or equal to a regeneration mass threshold or not is determined; when the carbon accumulation amount is larger than or equal to the regeneration mass threshold, whether the inlet temperature of the diesel particle catcher is larger than or equal to a regeneration temperature threshold or not is determined, and if yes, regeneration is started; and during a regeneration process, if a regeneration stopping condition is met, regeneration is stopped. By utilizing the method and the system, the problem of the diesel particle catcher in the prior art that over-combustion easily happens or excessive carbon particles in the diesel particle catcher cannot be effectively cleared off because a vehicle is at working conditions of idling and low-speed driving for a long term can be solved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

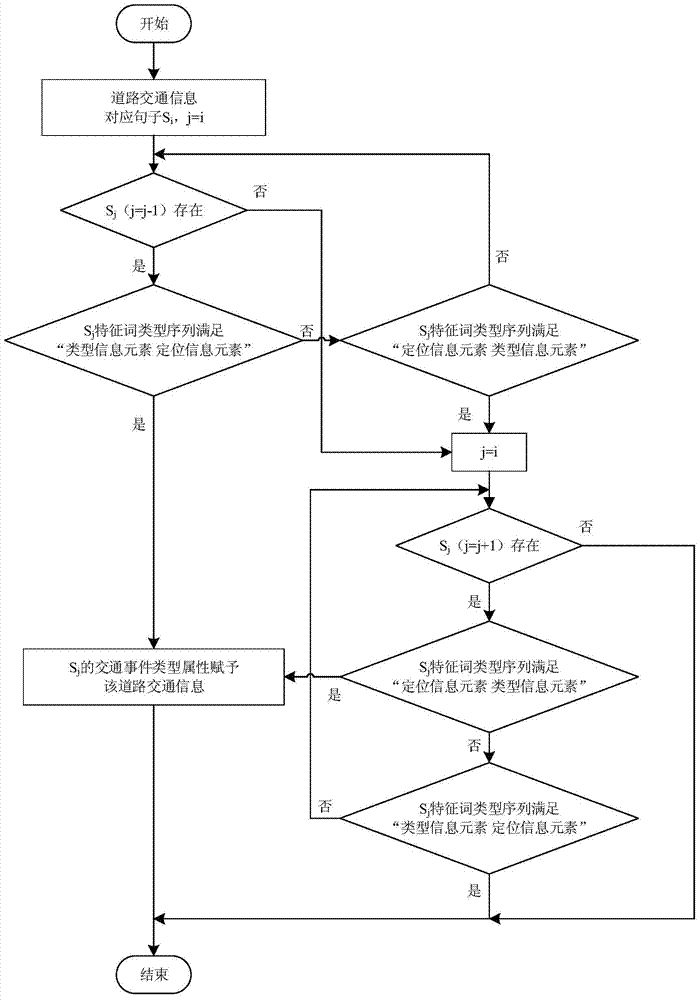

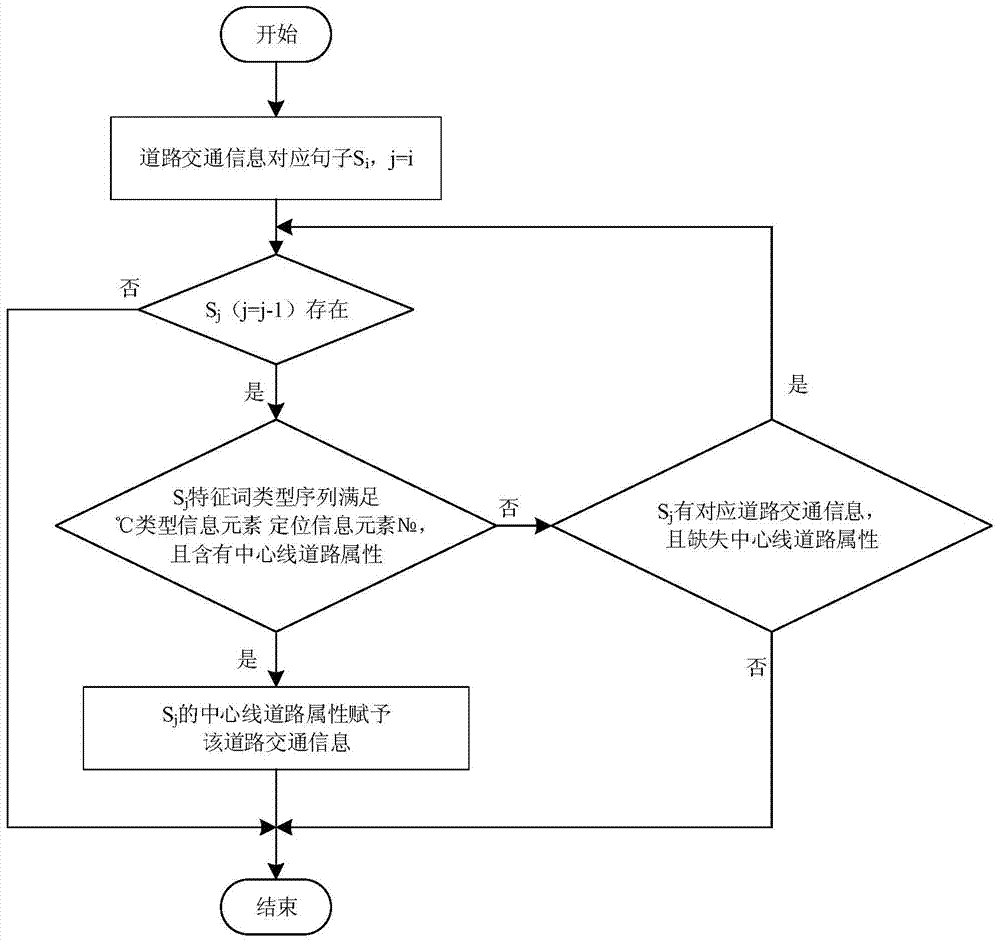

Method for extracting road traffic information from Internet unstructured text

InactiveCN103886080AFacilitate automatic processingUnstructured textual data retrievalNatural language data processingTime informationThe Internet

The invention provides a method for extracting road traffic information from an Internet unstructured text. The method comprises the steps of defining a data structure of the road traffic information and a description feature word type of the road traffic information, expanding a few manually-established basic extraction modes to obtain an extraction mode bank, generating a feature word type sequence after the input Internet unstructured text is preprocessed, obtaining a matched extraction mode of the input text according to the similarity of the feature word type sequence, utilizing the matching extraction mode for extracting a positioning information element and a type information element of the road traffic information from the Internet unstructured text, utilizing a regular expression and a judgment rule for extracting a time information element from the input text, and obtaining the road traffic information through the combination of the positioning information element, the type information element and the time information element. By the means of the method for extracting the road traffic information from the Internet unstructured text, real-time processing can be carried out on the unstructured text collected from the Internet, the road traffic information can be extracted, and the traffic information collecting means are enriched.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

Electromagnet clamping, positioning, and rotating mechanism used for auto spare part board

InactiveCN108466839AFacilitate automatic processingGood effectConveyorsMetal working apparatusEngineeringSpare part

The invention discloses an electromagnet clamping, positioning, and rotating mechanism used for auto spare part boards. The mechanism comprises a rack. Two sides of a top plate top surface of the rackare fixedly provided with movable supporting plates. Two ends of a horizontal screw are hinged with the two movable supporting plates. The outer side wall of one of the movable supporting plates is fixedly provided with a moving motor. An output shaft of the moving motor is a spline shaft. The spline shaft is inserted in a spline hole on one end of the horizontal screw. A vertical supporting plate is screwed in the horizontal screw. The lower part of the left side wall of the vertical supporting plate is fixedly provided with a drive servo motor. An output shaft of the drive servo motor passes through the vertical supporting plate and is fixedly provided with a driving gear. The upper part of the vertical supporting plate is hinged with a rotating shaft. The right end of the rotating shaft extends out of the vertical supporting plate and is fixedly provided with a clamping plate. The rotating shaft is fixedly provided with a transmission gear. The electromagnet clamping, positioning,and rotating mechanism can automatically clamp an auto spare part board and automatically turn over the auto spare part board, providing convenience for subsequent equipment to grab the auto spare part board and perform automated processing. The mechanism is good in effect and high in efficiency.

Owner:DONGGUAN SHENGRONG AUTOMATION TECH CO LTD

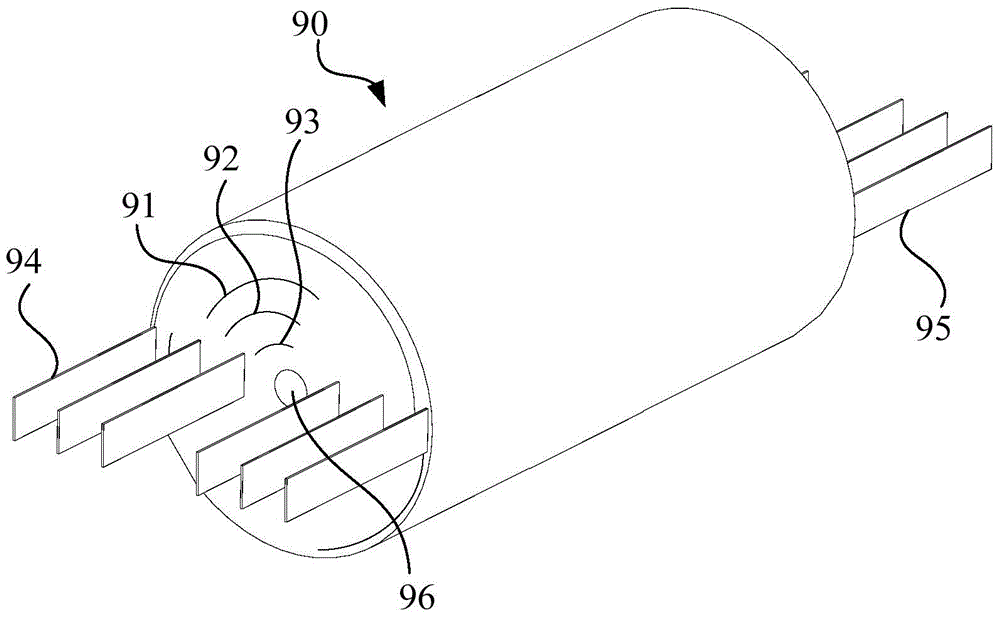

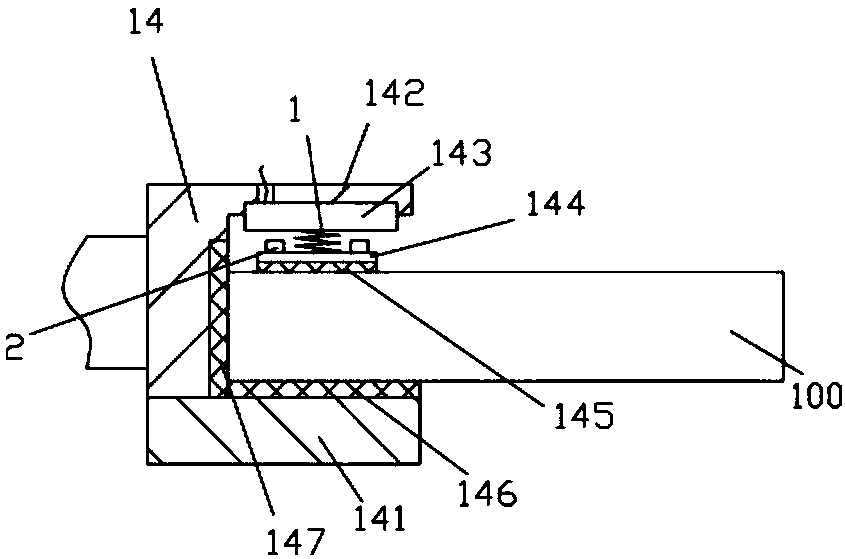

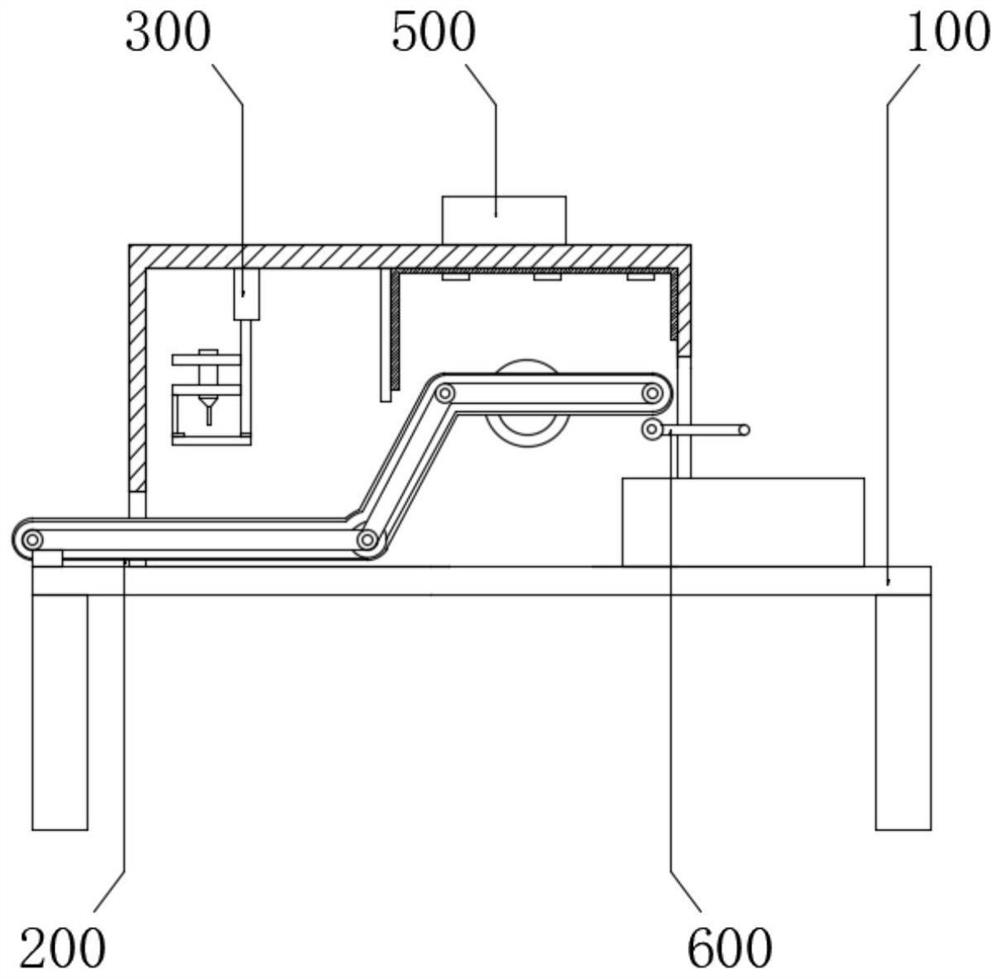

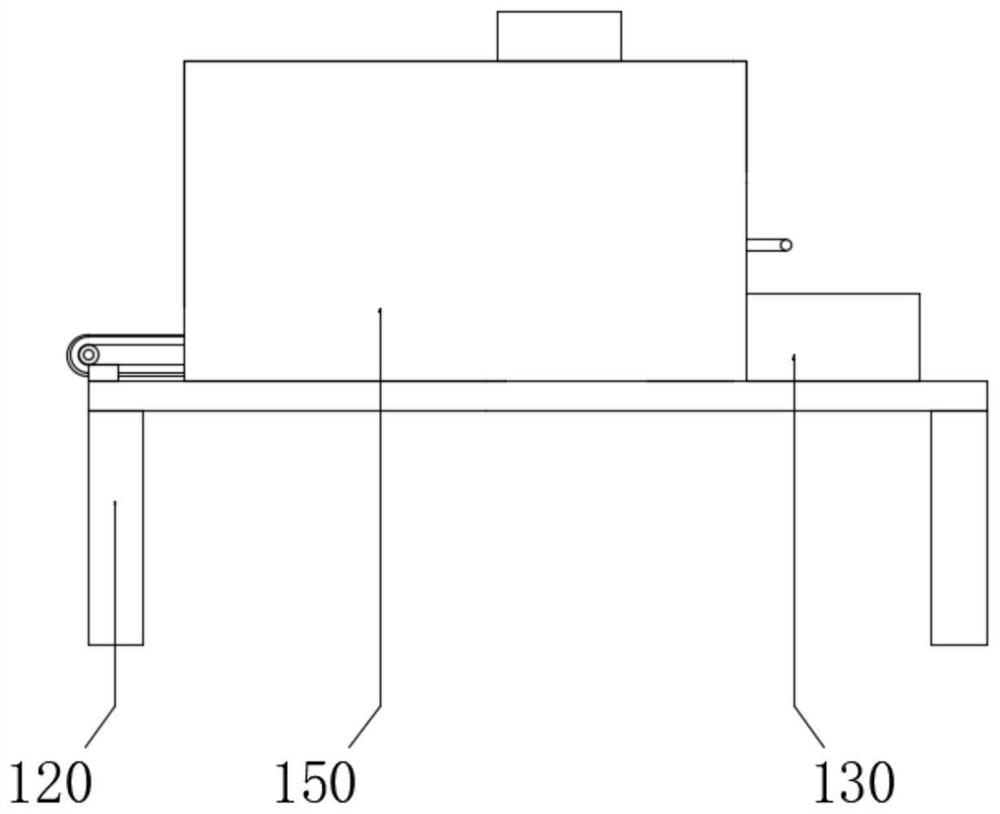

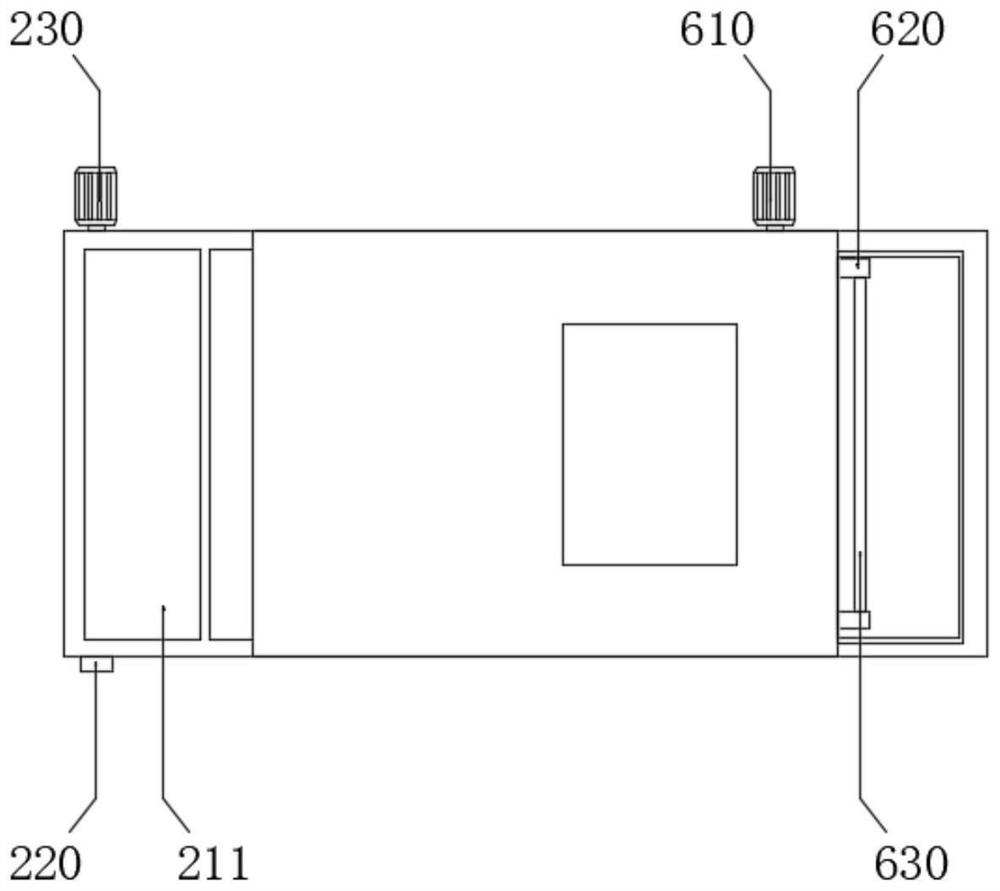

Cell delivery mechanism

InactiveCN104787552AAccurate transmission positioningFacilitate automatic processingFinal product manufactureSecondary cells manufactureEngineeringAssembly line

The invention relates to a cell delivery mechanism which is used for delivering cells of batteries for subsequent processing on an assembly line. The cell delivery mechanism comprises a first delivery frame, a second delivery frame, a first power source and a second power source, wherein processing stations used for bearing the cells are arranged on the first delivery frame and the second delivery frame, the first power source is connected with the second delivery frame and is used for driving the second delivery frame opposite to the first delivery frame in the direction parallel with the delivery plane of the cells, and the second power source is connected with the second delivery frame and is used for driving the second delivery frame opposite to the first delivery frame in the direction perpendicular to the delivery plane of the cells. The corresponding processing stations are arranged on the first delivery frame and the second delivery frame, the second delivery frame moves opposite to the first delivery frame in two different directions, and therefore the cells are moved to next adjacent processing stations of the downstream in sequence. The cell delivery mechanism is accurate in delivery positioning, facilitates automatic processing of the wound cells, and is simple in delivery structure and easy to achieve.

Owner:SHENZHEN YINGHE TECH

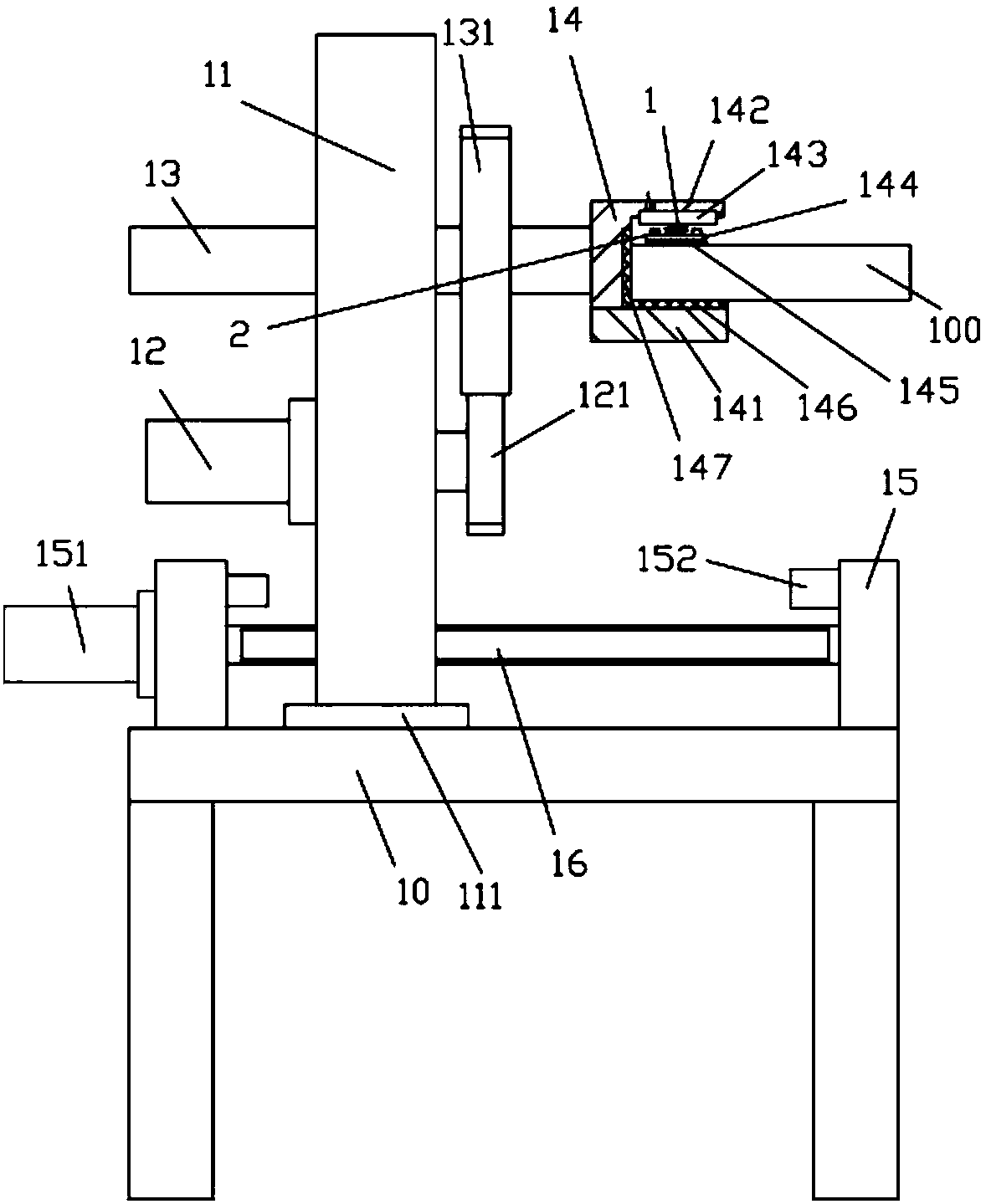

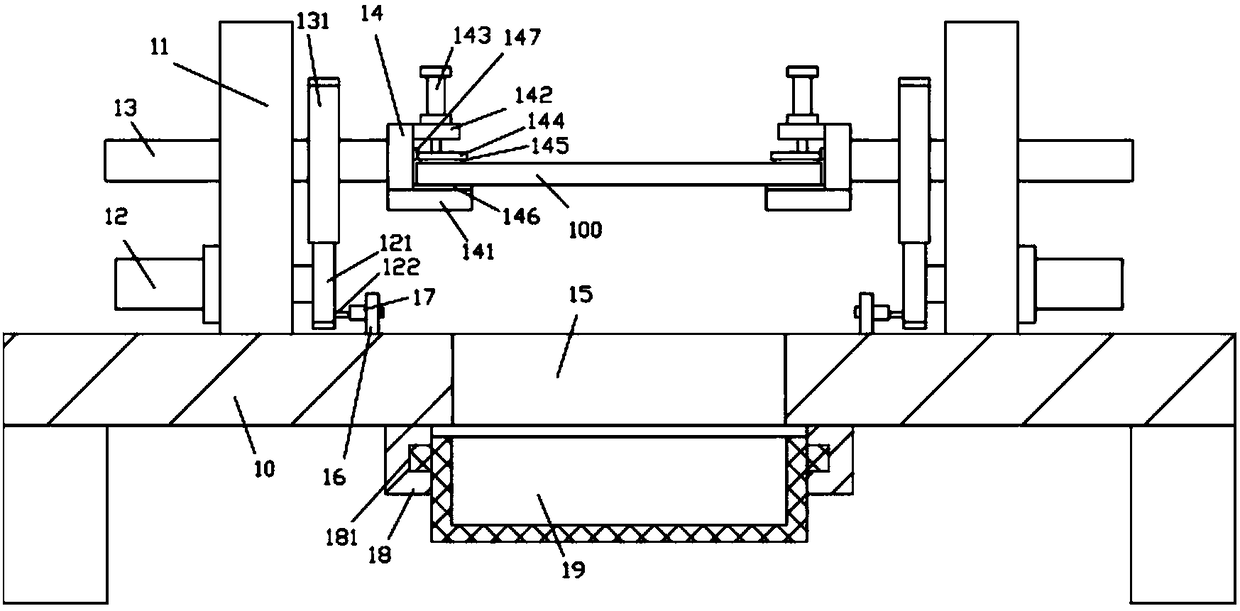

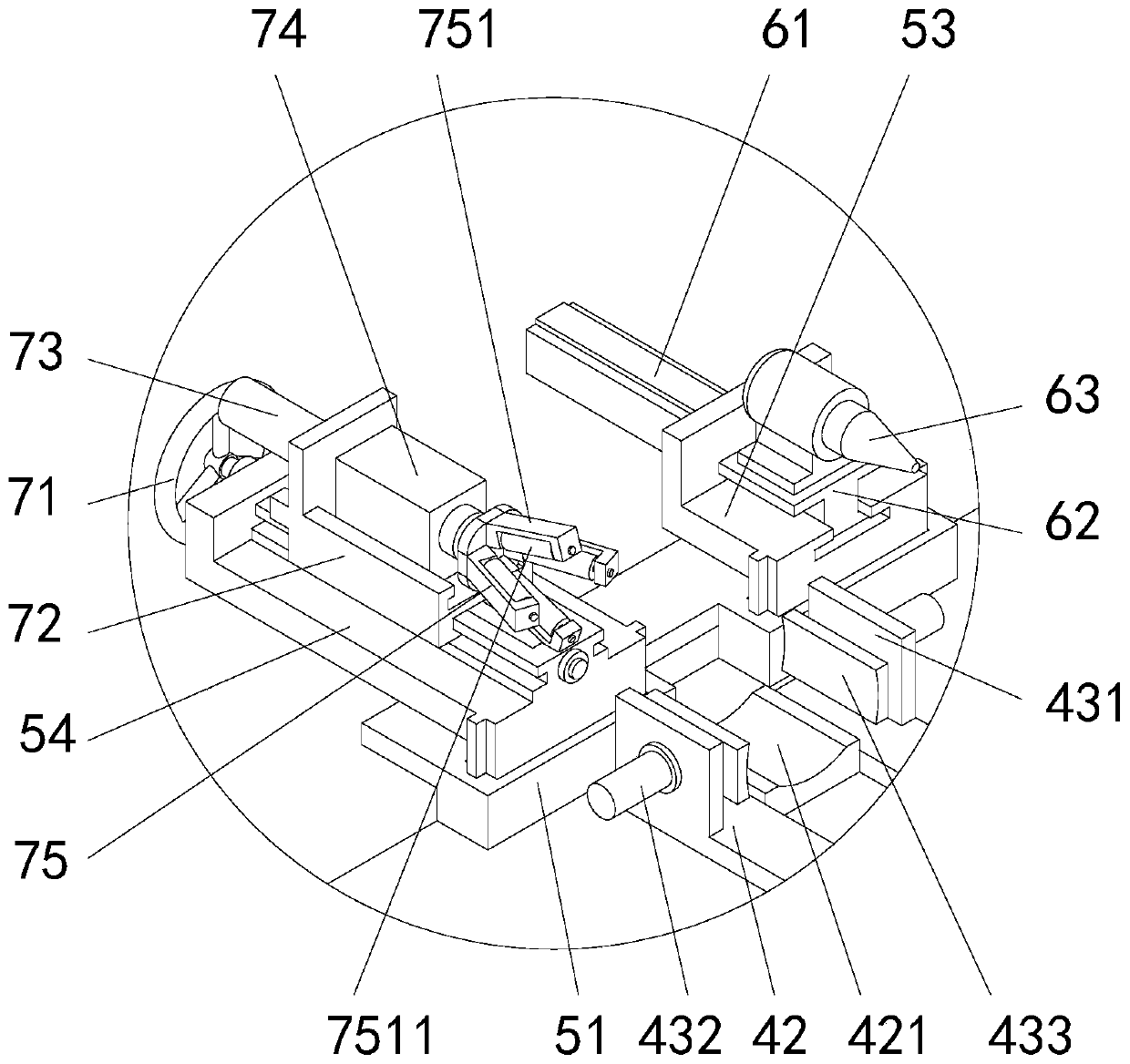

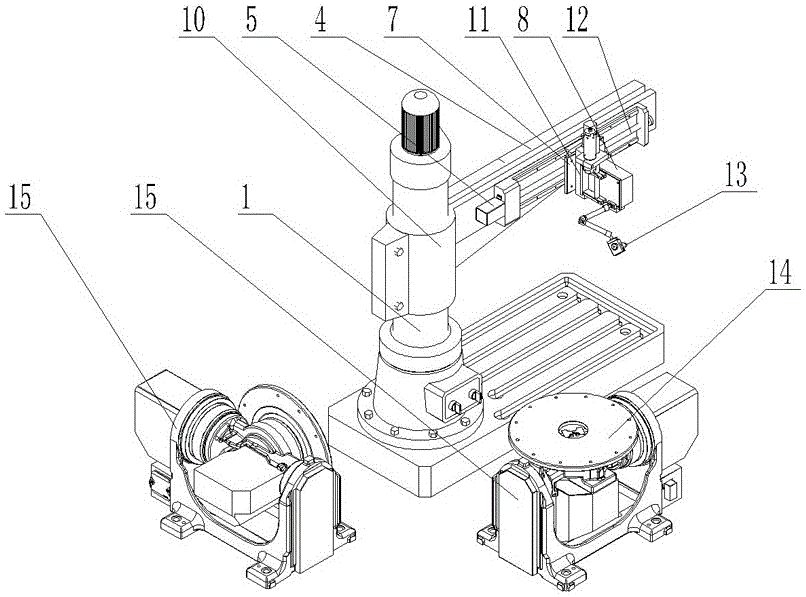

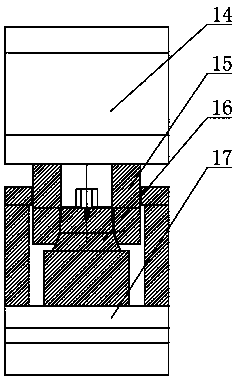

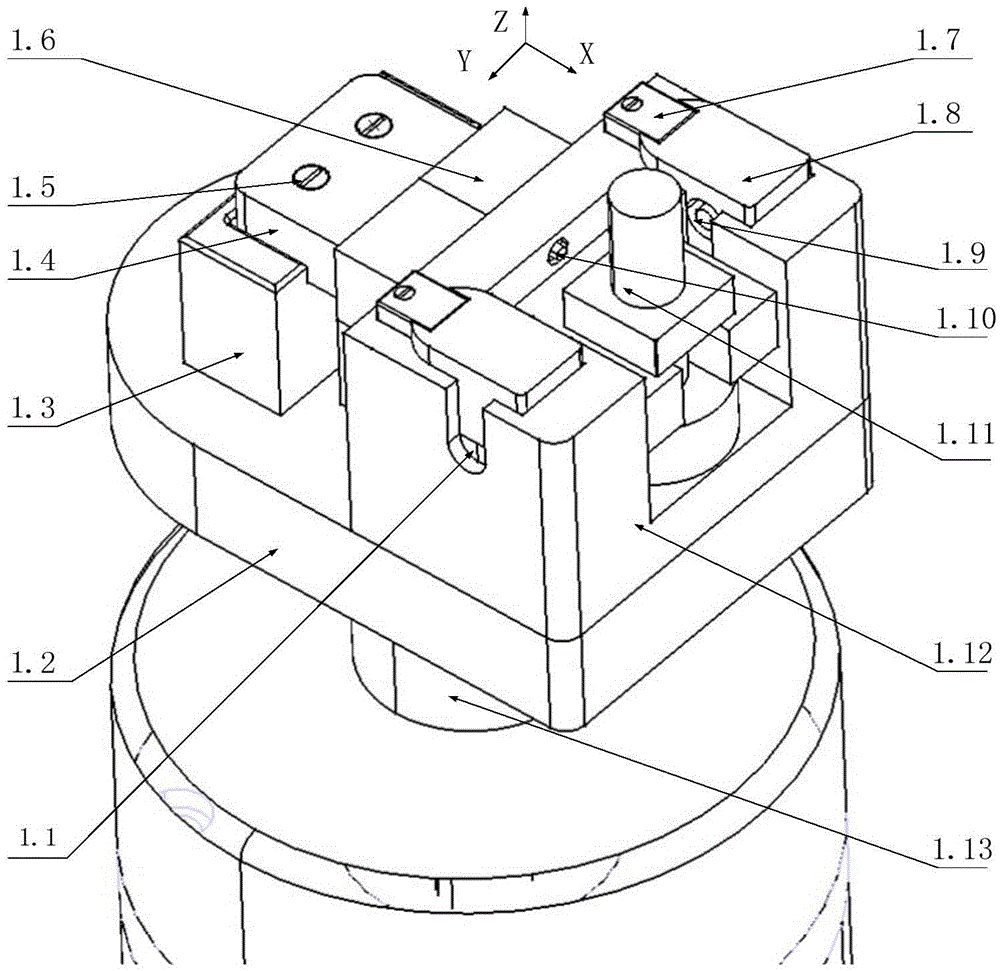

Low-stress self-adaptive machining method and process equipment

ActiveCN104625785AReduce distortionReduce stressMeasurement/indication equipmentsPositioning apparatusScrapSelf adaptive

The invention discloses a low-stress self-adaptive machining method and process equipment. According to the method, the clamping state of a part is automatically adjusted according to deformation caused by release of residual stress after a certain material of the part is removed, the part can release deformation fully in the machining process, and deformation is small after the part is unloaded. To realize the machining method, the invention provides self-adaptive clamping and monitoring equipment. The equipment adjusts the space position of a clamping point in a self-adaptive mode according to deformation of the part on the premise of ensuring clamping force of a certain degree, and stress and a displacement value of the clamping point are monitored through a force sensor and a displacement sensor. It is ensured that deformation of the part is small after clamping is removed, the out-of-tolerance and scrap problems caused by deformation of the machined part are solved, and the automation and intelligent of clamping are achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

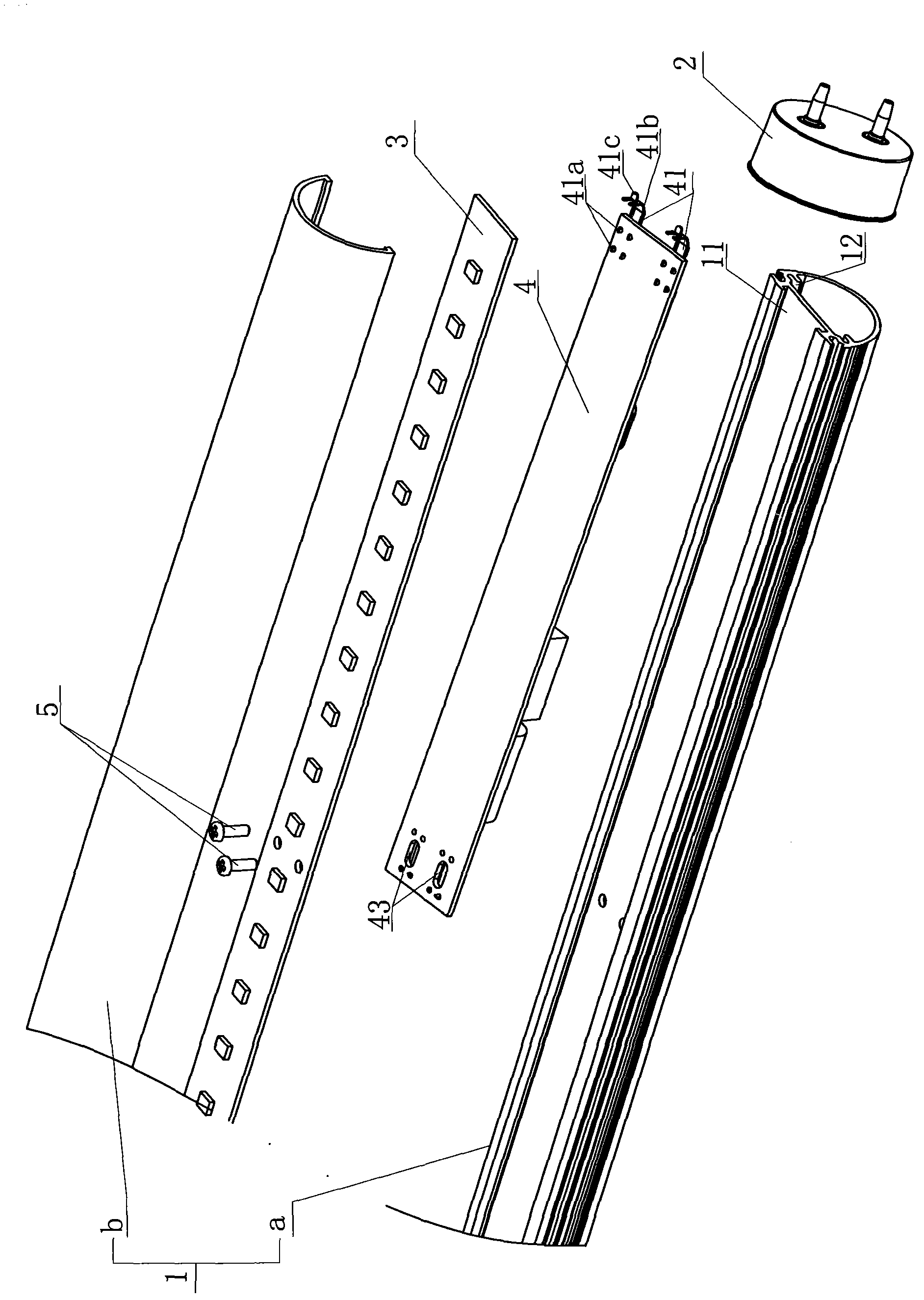

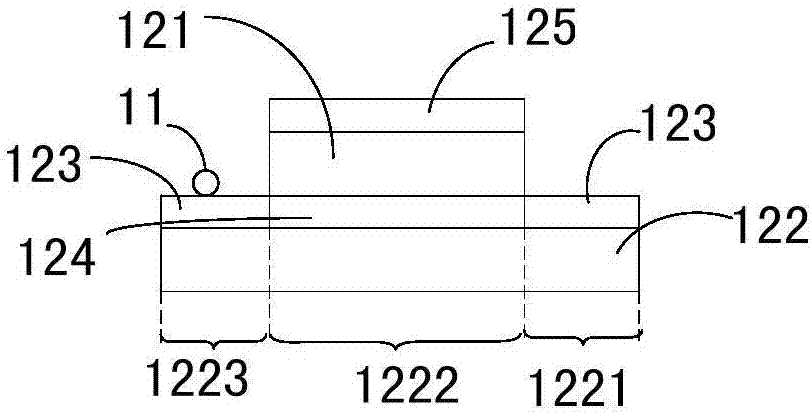

Automatically-produced light-emitting diode (LED) lamp tube

ActiveCN103216759ASimplifies wiring routingAchieve electrical connectionPoint-like light sourceElectric circuit arrangementsElectricityPower circuits

The invention provides an automatically-produced light-emitting diode (LED) lamp tube which comprises a lamp tube body, lamp bases at two ends of the lamp tube body, a luminous bead circuit board and a power circuit board. The luminous bead circuit board and the power circuit board are arranged in the lamp tube body. An upper plug-in groove and a lower plug-in groove are arranged in a substrate in an upper-lower layered mode in the axial direction. The luminous bead circuit board and the power circuit board are respectively arranged in the upper plug-in groove and the lower plug-in groove in an inserted and layered mode. Electrical input connecting pieces are arranged at one end of the power circuit board, and electrical output connecting pieces are arranged at the other end of the power circuit board. Electrode connecting pieces are arranged at the inner end of one lamp base and are connected with the electrical input connecting pieces in a plug-in mode. Conductive screws are arranged on the board surface of the luminous bead circuit board and are electrically connected with the electrical output connecting pieces. The automatically-produced LED lamp tube is simplified in connecting wire distribution, achieves technical effects of stable electricity conduction, and is suitable for automated production of LED ball lamps.

Owner:OUTRACE TECH

Automobile battery cover overturning mechanism

InactiveCN108502499AFacilitate automatic processingGood effectConveyor partsAutomotive batteryElectric machinery

The invention discloses an automobile battery cover overturning mechanism which comprises a rack. Vertical supporting plates are fixed to the two sides of the top face of a top plate of the rack, driving servo motors are fixed to the lower portions of the outer side walls of the two vertical supporting plates, output shafts of the driving servo motors penetrate the vertical supporting plates and are fixedly provided with driving gears, rotating shafts are hinged to the upper portions of the vertical supporting plates, the inner ends of the rotating shafts extend out of the inner side walls ofthe vertical supporting plates and are fixedly provided with clamping plates, transmission gears are fixed into the inner ends of the rotating shafts, the transmission gears are meshed with the corresponding driving gears, lower extending plates are fixed to the bottom faces of the two clamping plates, upper supporting plates are fixed to the upper portions of the opposite wall faces of the two clamping plate, clamping air cylinders are fixed to the top faces of the upper supporting plates, push rods of the clamping air cylinders penetrate the upper supporting plates and are fixedly provided with compression plates, and the compression plates correspond to the lower extending plates up and down. By means of the automobile battery cover overturning mechanism, automatic overturning of an automobile battery cover can be achieved, the follow-up equipment grabbing is facilitated, automatic machining is carried out, and the effect of the mechanism is good.

Owner:DONGGUAN SHENGRONG AUTOMATION TECH CO LTD

Light-emitting diode (LED) ball lamp in automatic production

InactiveCN103216760AImprove cooling effectUsability will not be affected by heatPoint-like light sourceElectric circuit arrangementsElectricityEngineering

The invention discloses a light-emitting diode (LED) ball lamp in automatic production. The LED ball lamp comprises a hollow lamp body and an LED light source in the lamp body, wherein a lens, a radiating lamp cup, a connecting base and a lamp head are sequentially connected to form the lamp body. The LED light source comprises a luminous lamp bead circuit board and a power source circuit board. A locating column is arranged in the connecting base, and a locating groove is vertically formed along the side edge of the locating column. The power source circuit board is located in the locating groove. Two electrical output connecting pieces which are located with the locating column are arranged at the upper portion of the power source circuit board. Two electrical input connecting pieces are arranged in the middle and at the lower portion of the power source circuit board respectively. The luminous lamp bead circuit board is located on the locating column and is provided with corresponding conductive bolts which are electrically connected with the electrical output connecting pieces. The electrical input connecting piece in the middle is arranged between the connecting base and a connecting position of the lamp head in an inserted mode. The electrical input connecting piece at the lower portion is arranged at the bottom of the lamp head in an inserted mode and is fastened through pivots. The LED ball lamp can simplify arrangement of connecting wires, achieves a technical effect of stable electric conduction and is suitable for the automatic production.

Owner:OUTRACE TECH

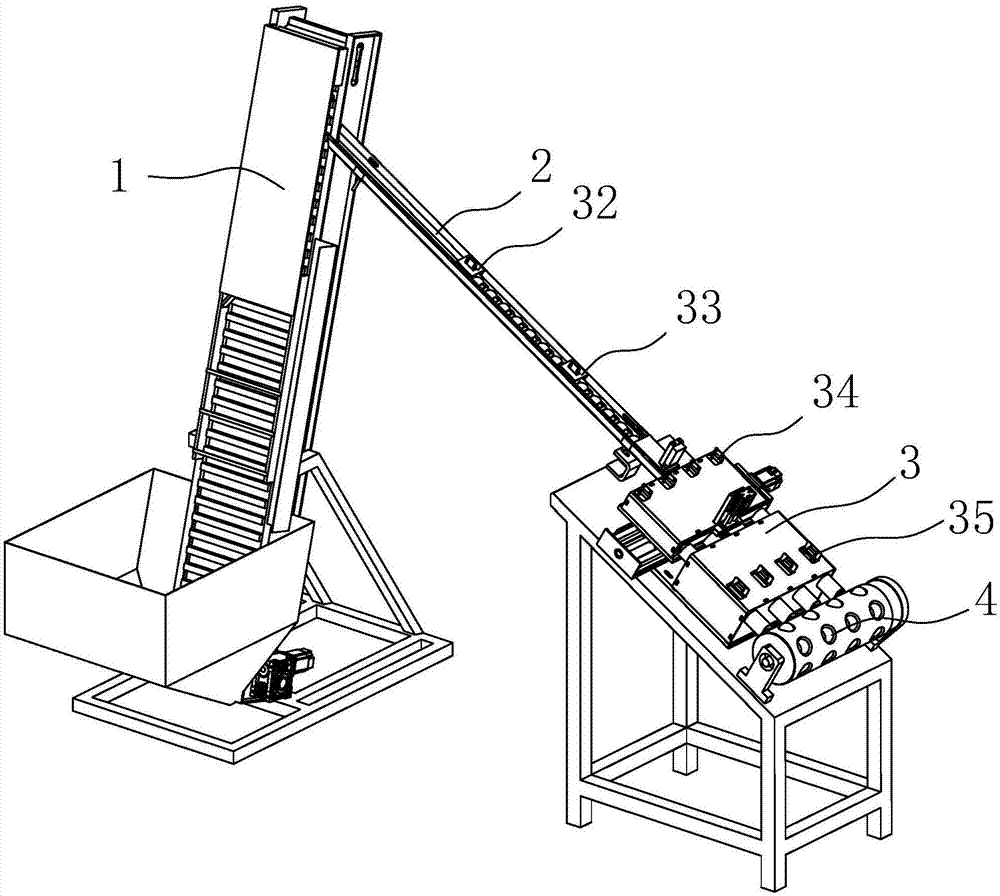

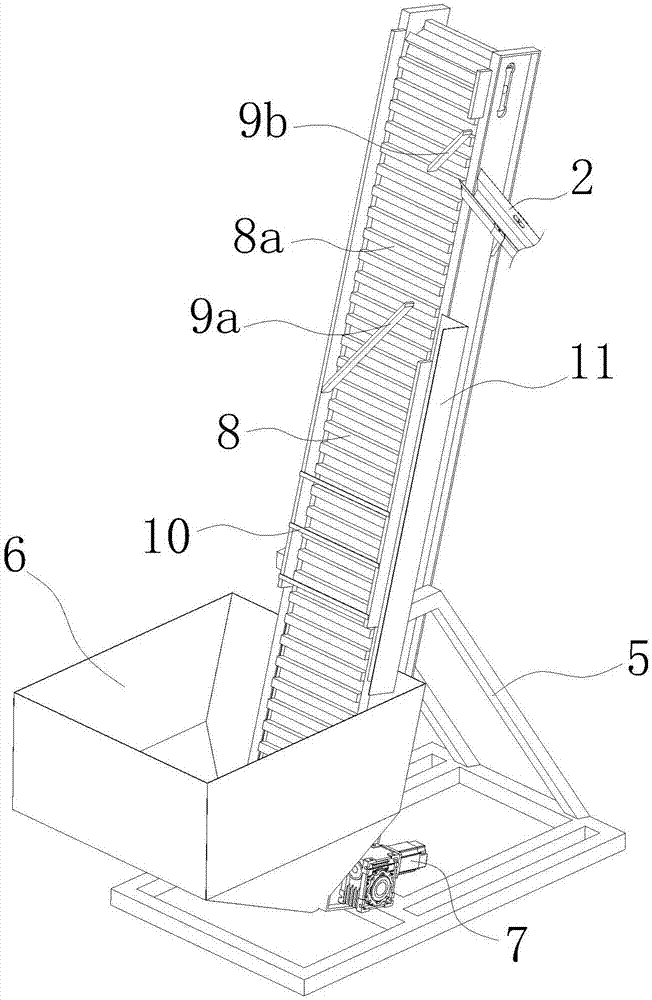

Wine bottle cap feeding machine

PendingCN107284994AReasonable structural designHigh degree of automationConveyorsControl devices for conveyorsControl systemWine bottle

The invention relates to a wine bottle cap feeding machine. The wine bottle cap feeding machine comprises a belt type material fetcher, an overturning and uprighting mechanism, a multi-channel type storage material supplying device and a roller type feeder, wherein the belt type material fetcher is used for arranging wine bottle caps to be in one-by-one transverse arrangement, then conveying and sorting the wine bottle caps to be in single-column vertical arrangement and then conducting outputting; the overturning and uprighting mechanism is connected with the output end of the belt type material fetcher so that the wine bottle caps in one-by-one transverse arrangement can be obtained, and after ball heads of the wine bottle caps are overturned to be in the direction that the ball heads of the wine bottle caps face upwards, the wine bottle caps are sequentially stacked and output; the multi-channel type storage material supplying device is mounted at the output end of the overturning and uprighting mechanism; and the roller type feeder is mounted at the output end of the multi-channel type storage material supplying device. The wine bottle cap feeding machine further comprises a control system, wherein the control system is connected with the belt type material fetcher, the overturning and uprighting mechanism, the multi-channel type storage material supplying device and the roller type feeder. The wine bottle cap feeding machine is reasonable in structural design and high in automation degree; the overturning and uprighting mechanism is adopted, and the wine bottle caps can be overturned to be in uniform posture and orientation to be supplied; by means of cooperation between multiple storage channels and the roller type feeder, simultaneous output of the multiple wine bottle caps is achieved; and batch material supply is achieved.

Owner:WUHU HUIYING AUTOMATIC EQUIP CO LTD

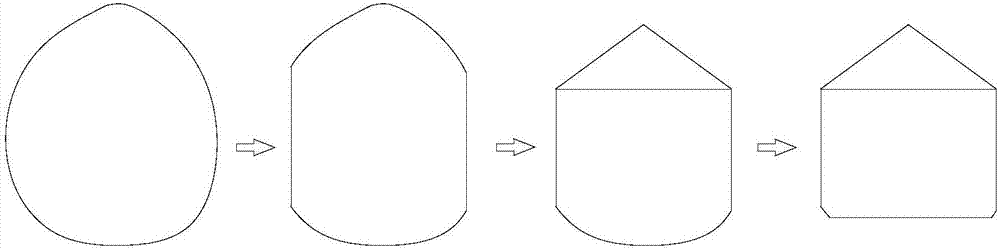

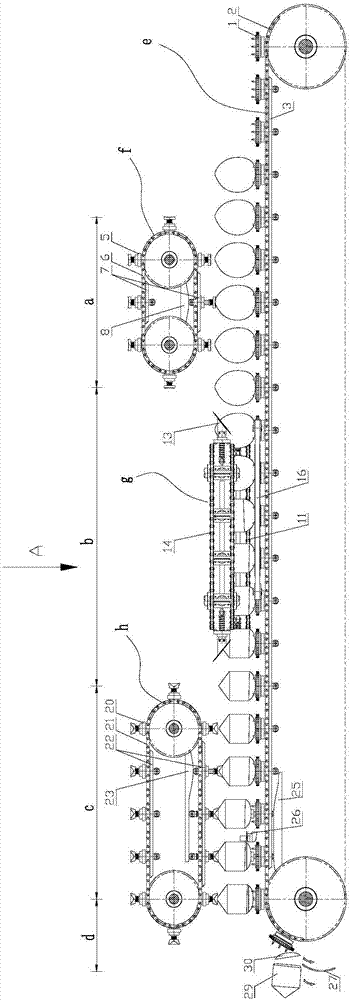

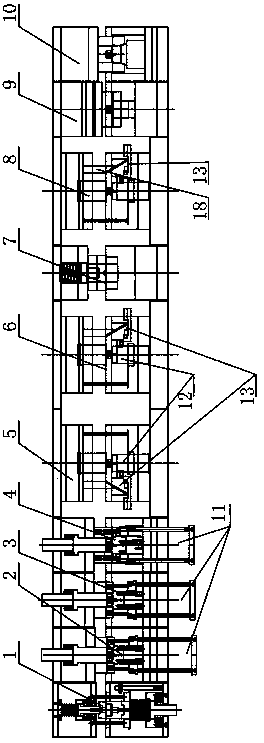

Online continuous tender coconut cutting and forming equipment and method

InactiveCN107097284ARealization of continuous cuttingAdapt to mass productionMetal working apparatusHigh volume manufacturingEngineering

The invention discloses online continuous tender coconut cutting and forming equipment and a method. The equipment comprises a positioning and conveying device, a coconut body pressing device, a coconut body cutting device and an end cutting device. The positioning and conveying device comprises conveying chains and a plurality of positioning disc mechanisms, all the positioning disc mechanisms are distributed on the conveying chains at an equal interval, and each positioning disc mechanism is correspondingly provided with a tender coconut; and the coconut body pressing device, the coconut body cutting device and the end cutting device are sequentially arranged above the conveying chains, the coconut body pressing device and the end cutting device are arranged on the tender coconuts, and the coconut body cutting device is arranged on the two sides of the tender coconuts. The method comprises the steps that the tender coconuts are conveyed continuously through the positioning and conveying mechanism and pressed and locked through the coconut body pressing device; then, the outer-side cylindrical faces and top conical faces of the tender coconuts are cut and formed through the coconut cutting device; and finally, the bottom ends of the tender coconuts are cut through the end cutting device to form tender coconut products. By means of the online continuous tender coconut cutting and forming equipment and the method, manual operation can be replaced, continuous cutting and forming of the tender coconut products are achieved, and the equipment and the method are suitable for mass production of the tender coconut products.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

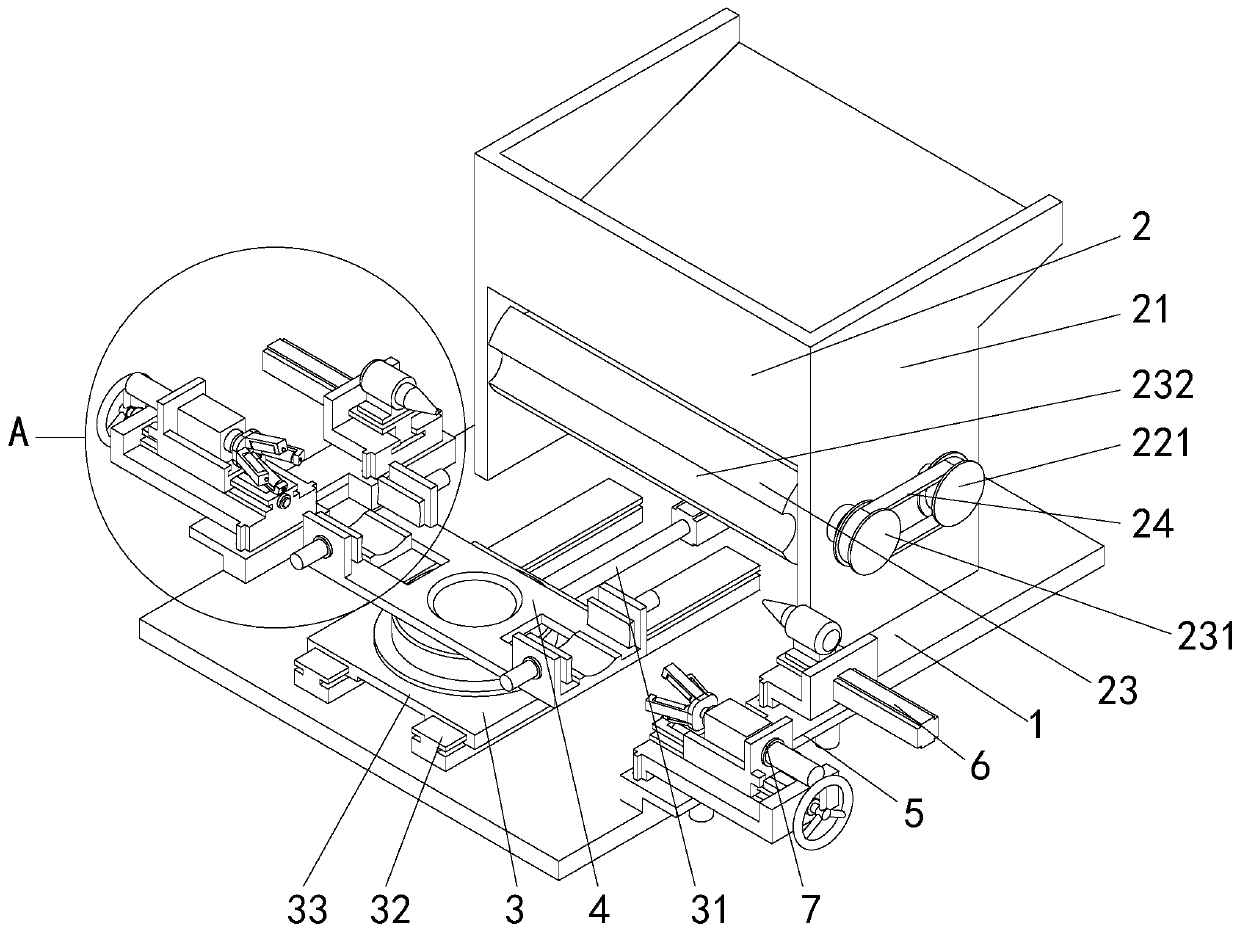

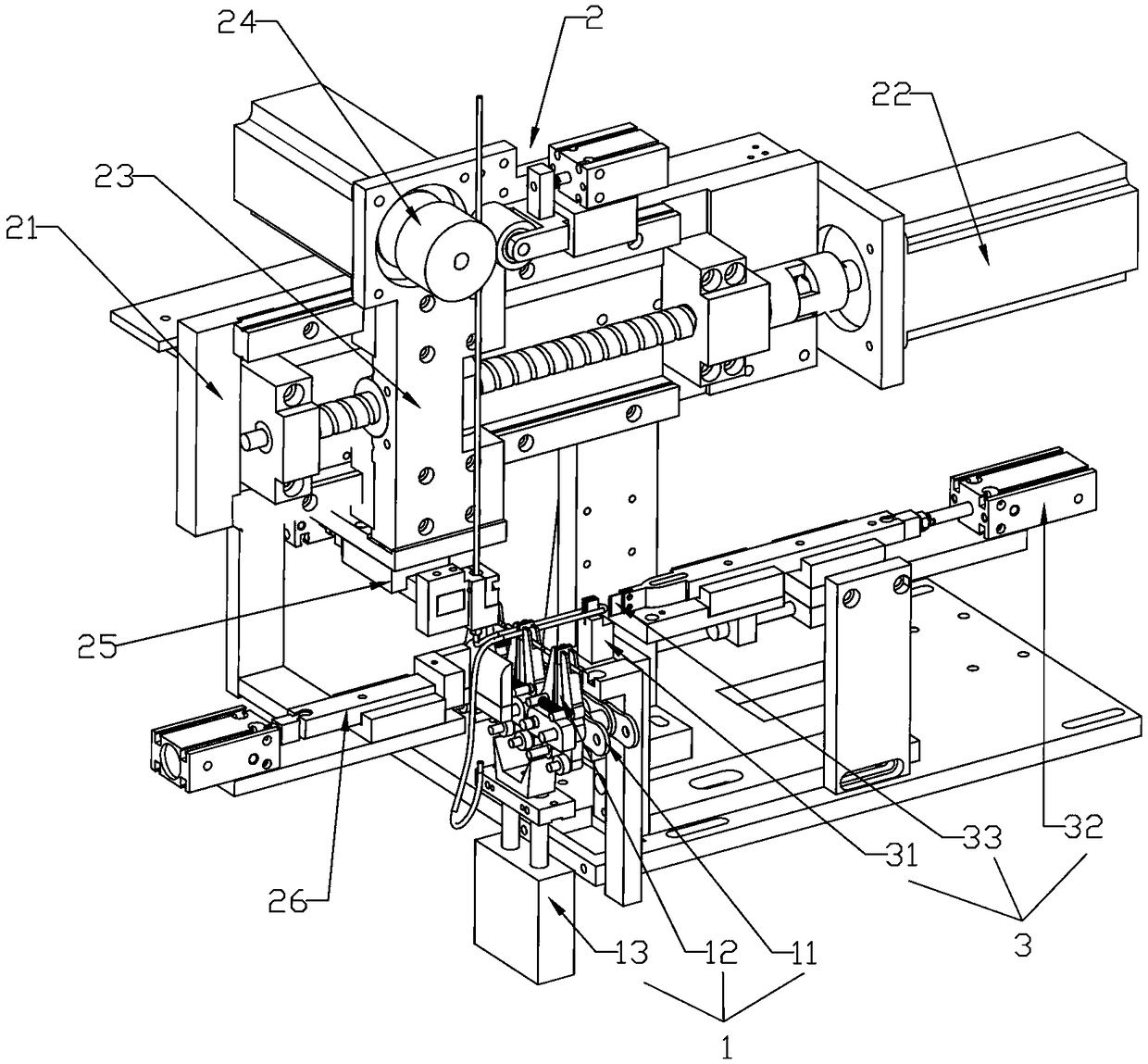

Automatic machining machine for manufacturing steel structure truss through stainless steel pipes

InactiveCN111266472AFacilitate automatic processingHigh degree of automationMetal-working feeding devicesPositioning devicesMachineMirror image

The invention relates to an automatic machining machine for manufacturing a steel structure truss through stainless steel pipes. The automatic machining machine comprises a base, an automatic feedingmechanism arranged on the base, a displacement mechanism arranged on the base, a clamping bearing table arranged on the displacement mechanism and used for bearing and clamping a steel pipe, two fineadjustment mechanisms fixedly installed on the base in a mirror image arrangement mode, two centering mechanisms and two correction mechanisms arranged in a mirror image arrangement mode. According tothe machine, through mutual cooperation of the automatic feeding mechanism, the displacement mechanism, the clamping bearing table, the fine adjustment mechanism, the centering mechanisms and the correcting mechanisms, complete automatic machining operation can be achieved, synchronous forming machining of the two ends of the steel pipe can be achieved, the automation degree is high, and comparedwith a traditional semi-automatic manual machining mode, the efficiency is greatly improved, and the labor intensity is greatly reduced.

Owner:吉林省龙聚山钢结构工程有限公司

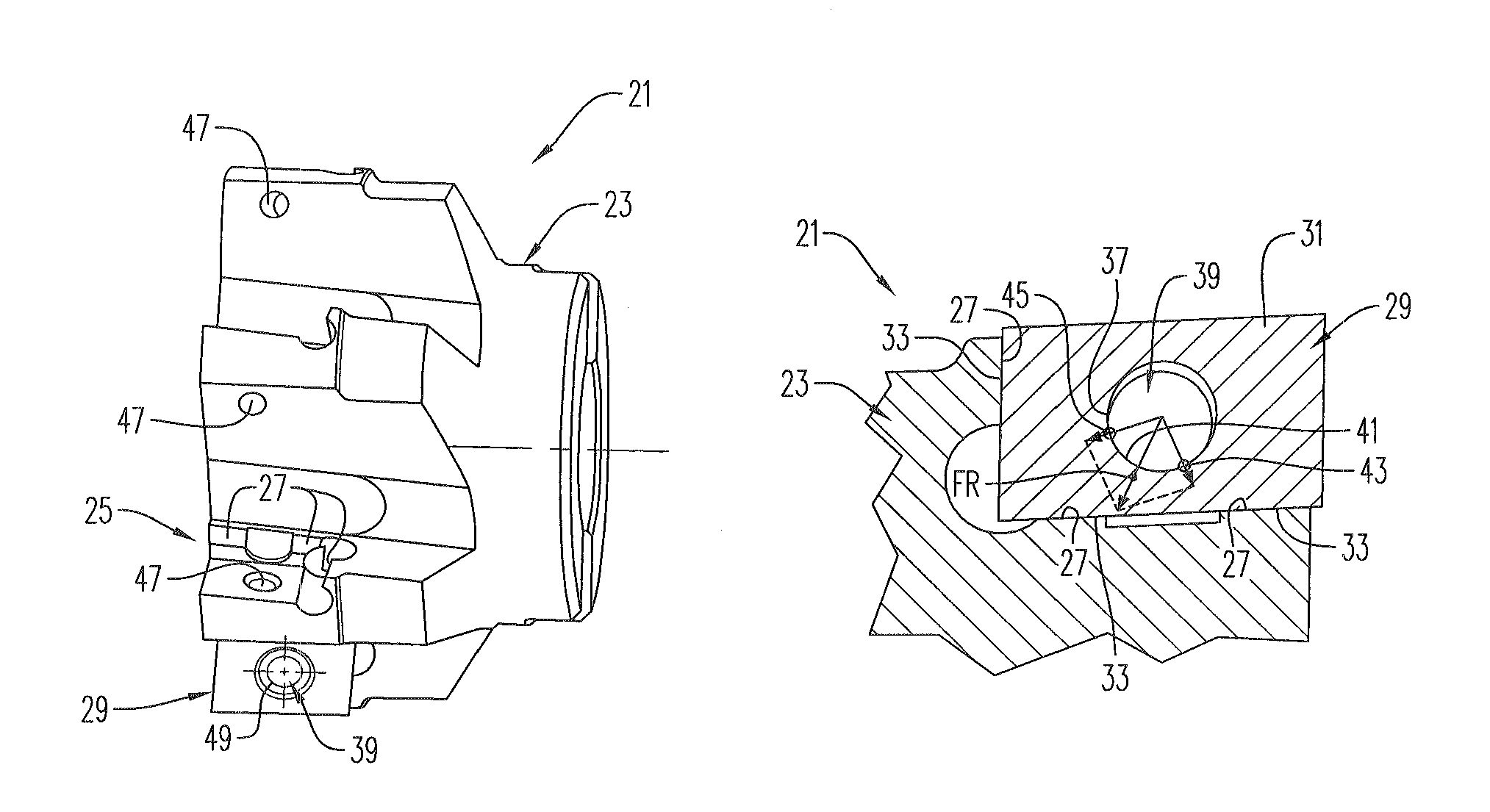

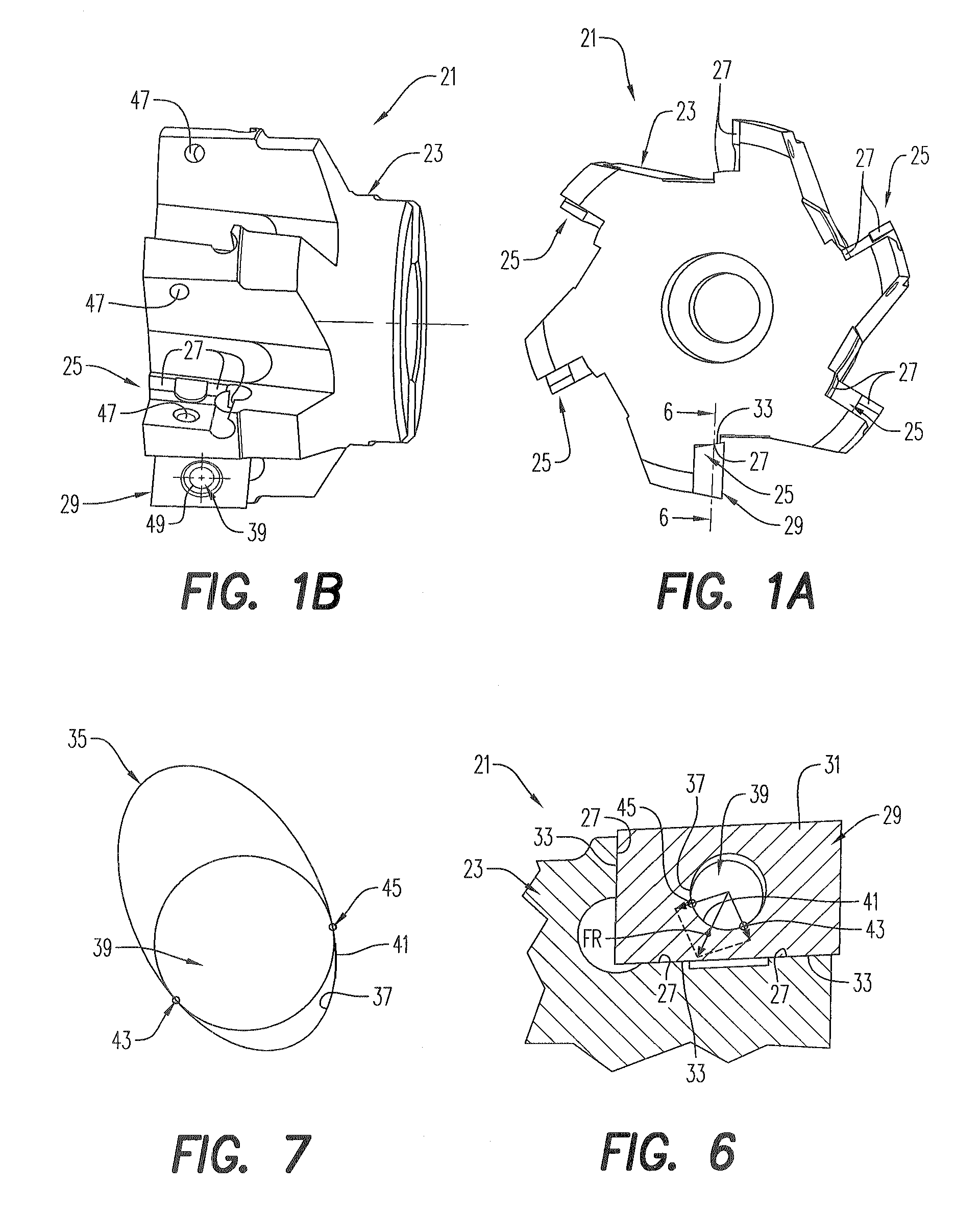

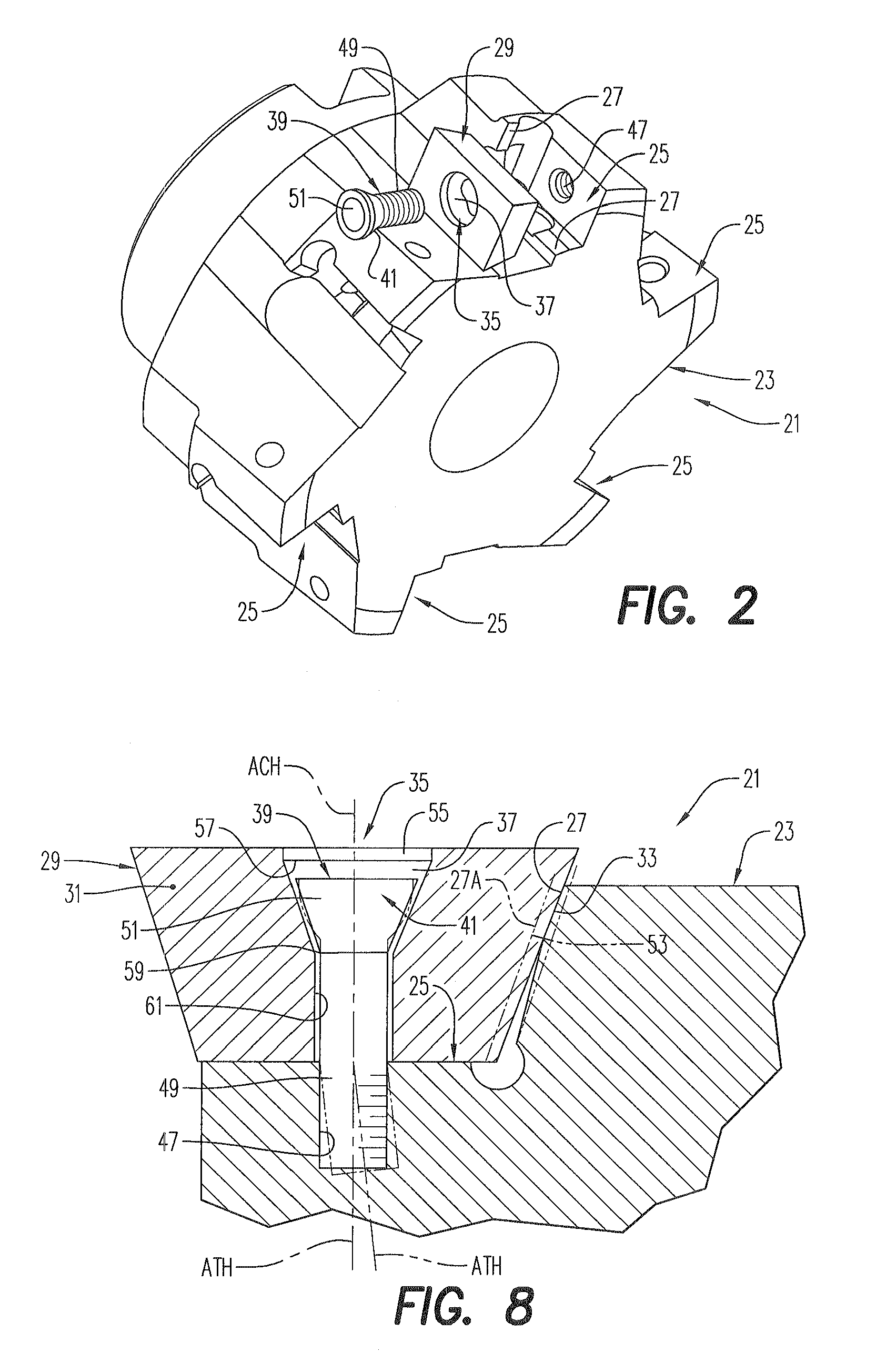

Cutting insert and cutting tool

InactiveUS8408847B2Minimizing any tendencyTrend downTransportation and packagingMilling cuttersAbutmentEngineering

The present invention relates to cutting tools and, more particularly, to cutting tools using clampable cutting inserts. The cutting tool includes a toolholder including at least one insert-receiving pocket, the insert-receiving pocket including at least one side abutment surface. The cutting tool further includes a cutting insert comprising an insert body having at least one insert supporting surface and a clamping hole including a clamping surface defining at least part of a non-circular, substantially elliptical cone. The cutting tool further includes a clamp having a clamp surface adapted to contact the clamping surface at two contact points such that the at least one side abutment surface and the at least one insert supporting surface are secured in a contacting relationship.

Owner:PRAMET TOOLS

Production technology of rigid fuse

InactiveCN1724488AImprove product qualityFacilitate automatic processingFusesDetonatorsDetonatorSoldering

The invention relates to the manufacturing technique for detonators, especially the process for preparing rigid igniting head which comprises the following steps, pressing comb teeth, injection molding, shaping, soldering bridge wires, automatically dipping powder, drying the igniting heads and soldering leg wires. The process can realize production automation, increased production efficiency, and guaranteed quality of products.

Owner:云南燃一有限责任公司

Height-adjustable automobile battery cover turnover mechanism

InactiveCN108405741AImprove efficiencyFacilitate automatic processingMetal-working feeding devicesPositioning devicesAutomotive batteryEngineering

The invention discloses a height-adjustable automobile battery cover turnover mechanism. The height-adjustable automobile battery cover turnover mechanism comprises a machine frame and a lifting plate; vertical main adjusting plates are fixed on the top surfaces of the left side and the right side of a top plate of the machine frame, and an upper transverse supporting plate is fixedly arranged onthe inner side wall of the top of each vertical main adjusting plate; the bottom ends of vertical screw rods are hinged to the top plate of the machine frame, the top ends of the vertical screw rods are hinged to the upper transverse supporting plates, and the vertical screw rods are close to the inner side walls of the vertical main adjusting plates; and a lifting adjusting motor is fixed on thetop surface of each upper transverse supporting plate, an output shaft of each lifting adjusting motor is a spline shaft, each spline shaft is inserted into a spline hole formed in the top end of thecorresponding vertical screw rod, and the lifting plate is in threaded connection with the two vertical screw rods. According to the height-adjustable automobile battery cover turnover mechanism, automobile battery cover plates can be turned automatically, the high-low positions can be adjusted, and therefore subsequent equipment can conveniently grab the automobile battery cover plates for automatic processing, effect is good, and efficiency is high.

Owner:DONGGUAN SHENGRONG AUTOMATION TECH CO LTD

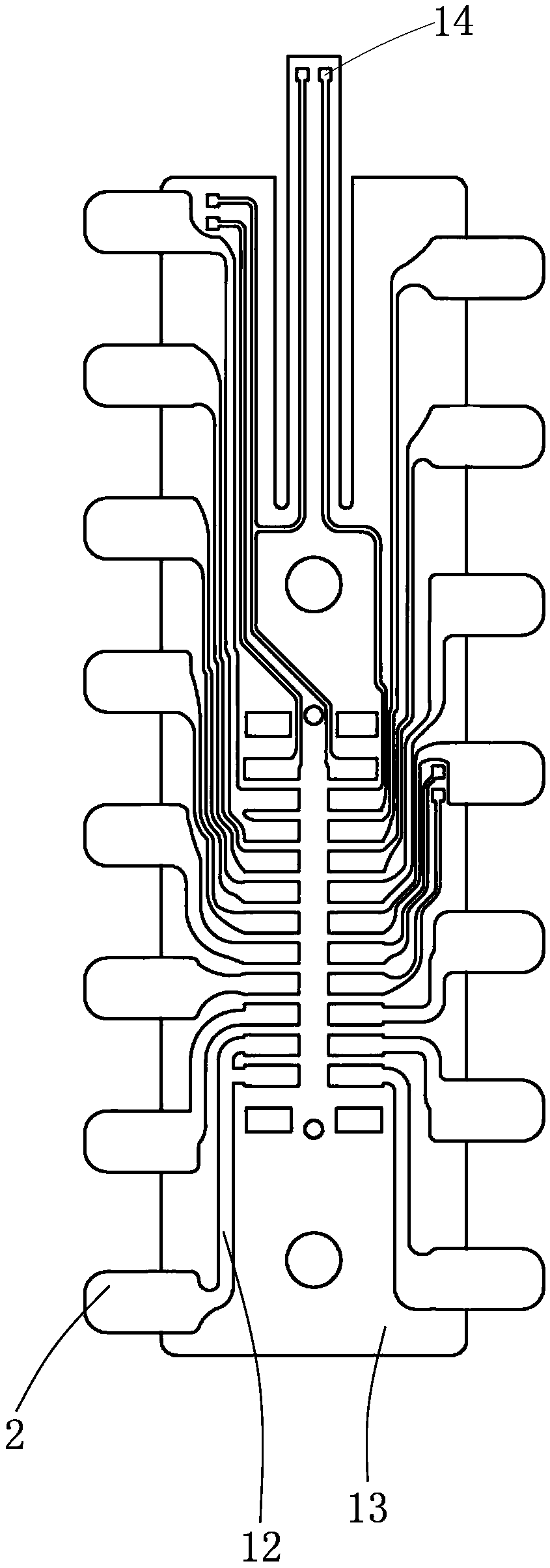

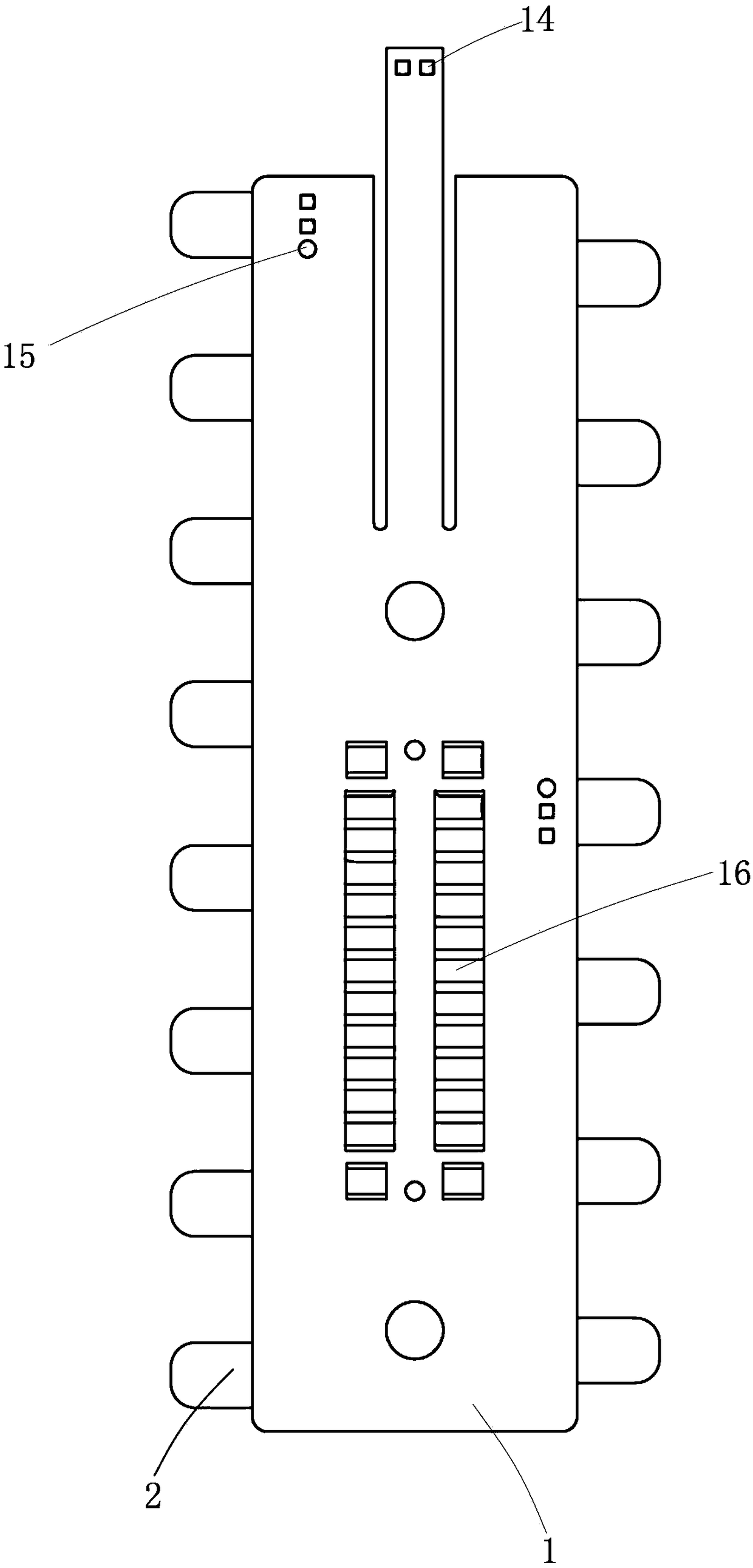

Flexible circuit board

PendingCN109496064AImprove the safety of useExtended service lifePrinted circuit aspectsInspection/indentification of circuitsElectricityHigh voltage igbt

The invention relates to the technical field of circuit boards, and especially relates to a flexible circuit board for detecting a voltage and temperature. The circuit board provided by the inventioncomprises a flexible circuit board body, a connection port, a voltage collecting end and a temperature collecting component, wherein the connecting port, the voltage collecting end and the temperaturecollecting component are disposed on the flexible circuit board body, the voltage collecting end and the temperature collecting component are electrically connected with the connection port through the wires of the flexible circuit board body, and the signals collected by the voltage collecting end and the temperature collecting component are transmitted through the connection port. The circuit board has the advantages of small size, light weight, easy assembly, easy automatic processing, high voltage and temperature collection precision, and can effectively improve the safety and prolong service life of a battery pack.

Owner:XIAMEN BOLION CIRCUIT

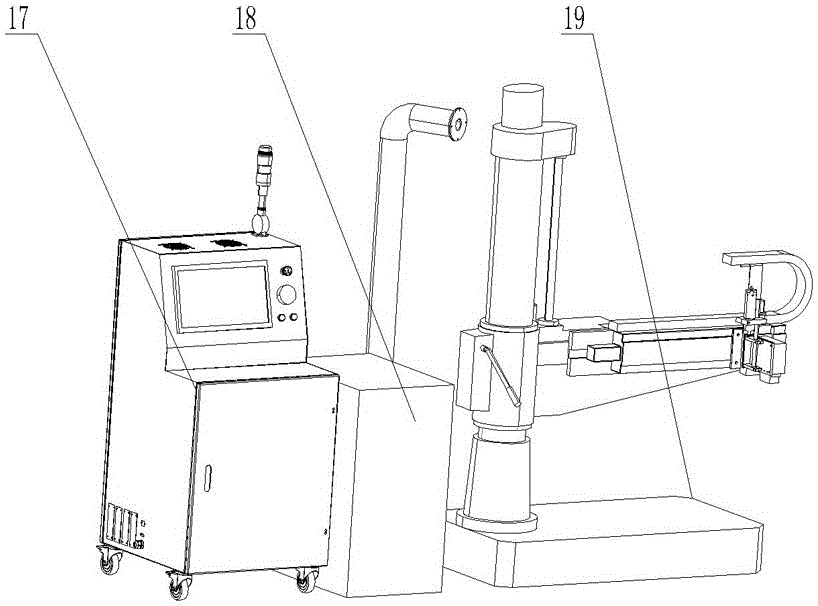

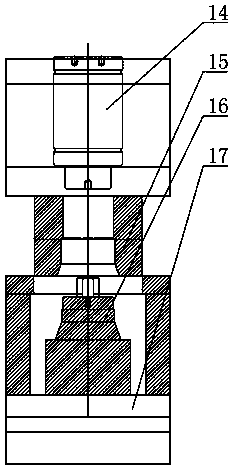

Laser surface strengthening machining device and method for plane type valve sealing surface

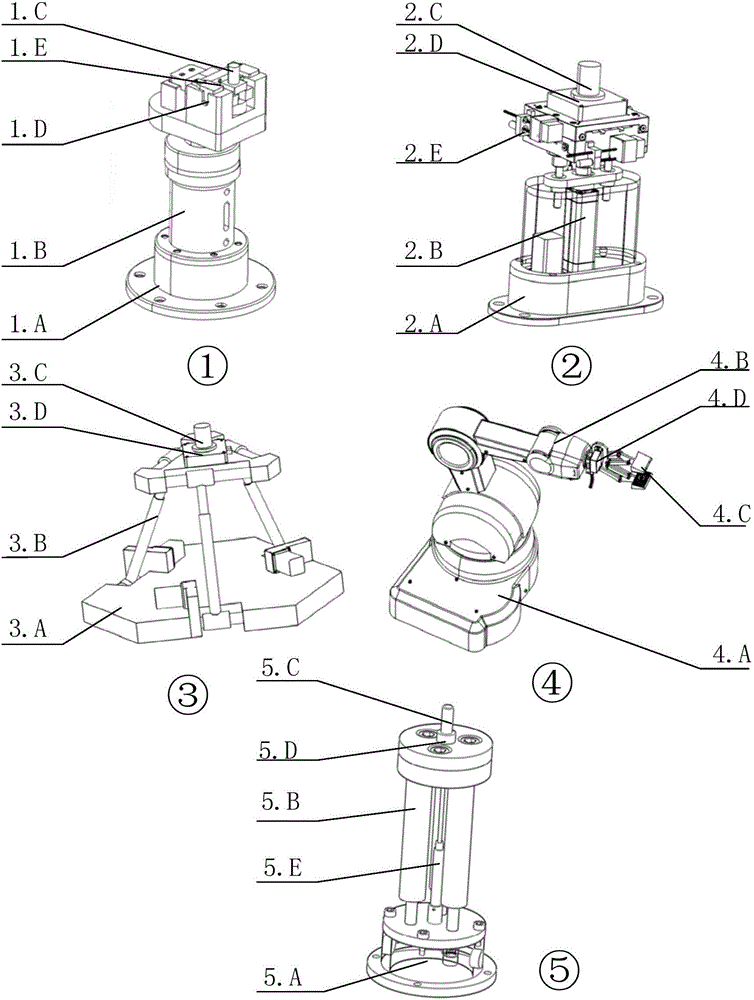

InactiveCN106513995AHigh precisionImprove machining accuracyIncreasing energy efficiencyLaser beam welding apparatusRocker armEngineering

The invention discloses a laser surface strengthening machining device for a plane type valve sealing surface. The machining device is characterized by comprising a control cabinet, a powder feeding device and a laser machining device; a controller is arranged in the control cabinet; the laser machining device is provided with a stand column sleeved with a rocker arm capable of rotating in all directions; a first sliding platform capable of moving horizontally is arranged on the rocker arm; a second sliding platform capable of moving vertically is mounted on the first sliding platform; a laser head and a powder feeding head are arranged on the second sliding platform; the powder feeding head is connected with the powder feeding device; the rocker arm moves vertically on the stand column; the vertical movement of the rocker arm and the vertical movement of the second sliding platform form a double-Z-axis structure; and machining stations are arranged on the periphery of the stand column. The double-Z-axis structure is adopted, the device has the high precision for adjusting the machining position of a machined piece, and the machining process and the preparation process of the device do not interfere with each other, so that the device has the advantages that the machining precision is high, the quality of a machined layer is well controlled, the device is convenient and simple to operate and the like. The invention further discloses a machining method.

Owner:浙江久恒光电科技有限公司

Horizontally adjustable electromagnet type rotary mechanism for plates of automobile components

InactiveCN108529221AFacilitate automatic processingGood effectConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a horizontally adjustable electromagnet type rotary mechanism for plates of automobile components. The horizontally adjustable electromagnet type rotary mechanism comprises a framework. A central rotary shaft is hinged to the middle of a top plate of the framework, the top of the central rotary shaft extends out of the top surface of the top plate of the framework, a rotarysupport plate is fixed to the top of the central rotary shaft, a rotary gear is fixed to the upper portion of the central rotary shaft, a rotary driving motor is fixed to the edge of the bottom surface of the top plate of the framework, an output shaft of the rotary driving motor penetrates the top plate of the framework, a driving rotary gear is fixed to the output shaft of the rotary driving motor and meshes with the rotary gear, a vertical support plate is fixed to the right side of the top surface of the rotary support plate, a driving servo motor is fixed to the lower portion of the leftside wall of the vertical support plate, an output shaft of the driving servo motor penetrates the vertical support plate, and a driving gear is fixed to the output shaft of the driving servo motor.The horizontally adjustable electromagnet type rotary mechanism has the advantages that the horizontally adjustable electromagnet type rotary mechanism can automatically rotate to reach collecting locations, the plates of the automobile components can be automatically clamped, can be automatically turned over, then rotate to reach feeding locations and can be conveniently grabbed by follow-up equipment to be automatically machined, accordingly, good effects can be realized by the horizontally adjustable electromagnet type rotary mechanism, and the horizontally adjustable electromagnet type rotary mechanism is high in efficiency.

Owner:DONGGUAN SHENGRONG AUTOMATION TECH CO LTD

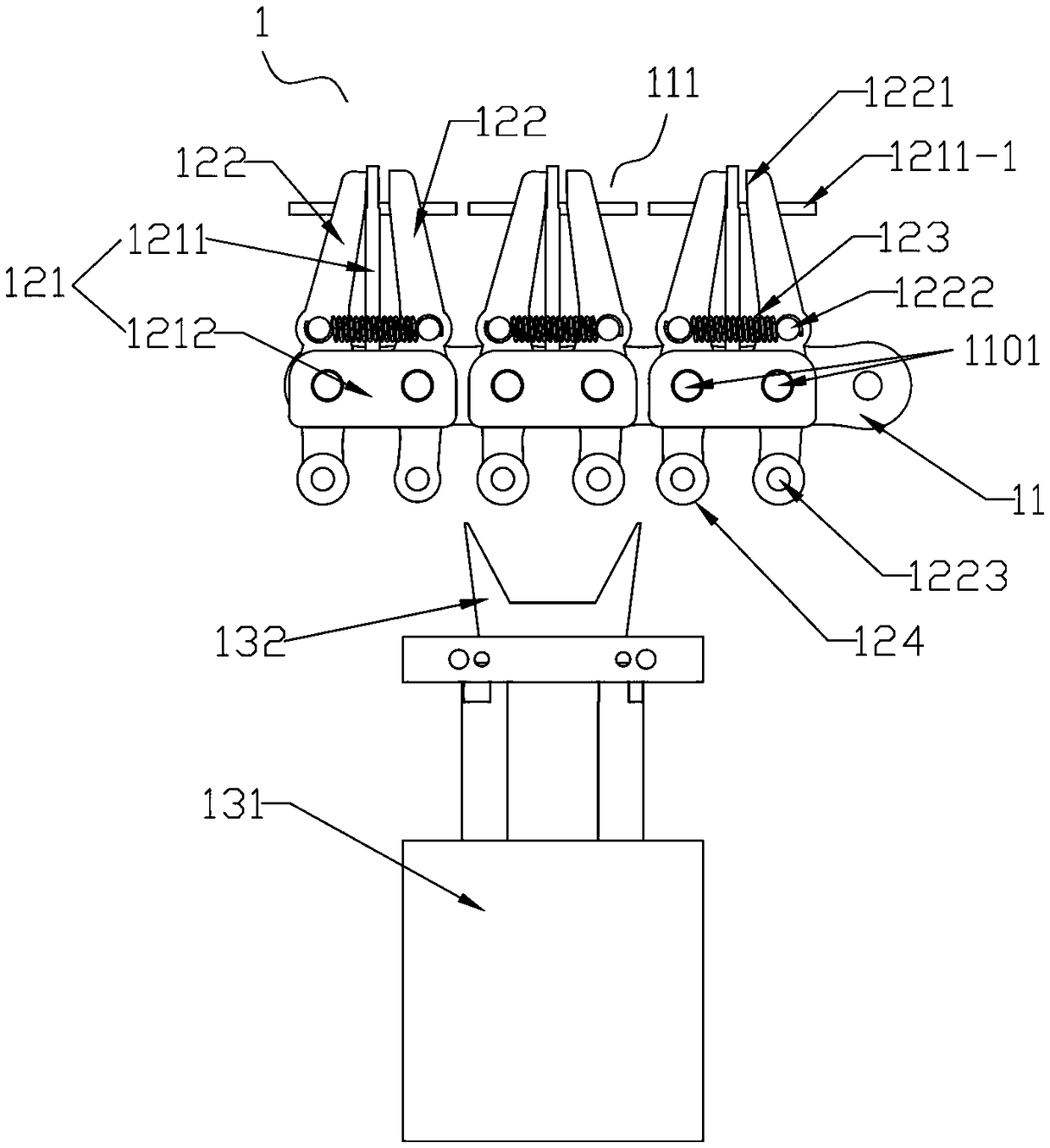

Automatic despooling and wire cutting device

The invention provides an automatic despooling and wire cutting device which comprises a wire clamping and conveying module, a wire feeding module and a wire cutting module. The wire clamping and conveying module comprises a conveyor belt for conveying from back to front, multiple wire clamping devices uniformly distributed on the conveyor belt, and a control device; a wire cutting station is arranged on the conveyor belt; the control device is arranged under the wire cutting station and controls the wire clamping devices to clamp a wire; the wire cutting module comprises a wire winding blockarranged on the right side of the wire cutting station, and a first drive device and a cutter arranged on the right side of the wire winding block; the wire bypasses the wire winding block and is cutoff through the cutter; the wire feeding module comprises a wire feeding assembly, a wire pulling assembly and a wire pressing assembly; and the wire feeding assembly is used for feeding the wire, thewire pulling assembly controls the moving direction of the wire, and the wire pressing assembly fixes one end of a point, so that the wire is conveyed. The automatic despooling and wire cutting device provided by the invention is high in efficiency, high in processing accuracy, capable of automatically despooling and wire cutting, and convenient to continuously process the follow-up steps.

Owner:DONGGUAN CHAOS ELECTRONICS TECH CO LTD

Lock support transferring die structure

The invention relates to a lock support transferring die structure which comprises a rack. A feeding device, a first drawing die, a second drawing die, a sizing pressure foot small die, a first side punching die, a second side punching die, a third side punching die, an edge shearing die, a punching and typing die and a rolling foot small die. A sensor is arranged in the feeding device, the middles of the dies are used for conveying workpieces through conveying belts, clamps for clamping the workpieces are arranged in the middle positions of the sets of dies, and each single set of die structurally comprises an upper die assembly and a lower die assembly. The upper die assemblies are provided with male die assemblies through nitrogen spring material pressing assemblies, lower die seats of the lower die assemblies are installed on female die assemblies matched with the male die assemblies, and the lower die assemblies are further provided with lower air cylinder material jacking assemblies. Machining is easy and convenient, and the working efficiency is improved and is high.

Owner:无锡市振华亿美嘉科技有限公司

Method for preparing through-type composite strip embedded with silver copper

ActiveCN102896150BHigh bonding strengthIncrease productivityMetal rolling arrangementsIngotUltimate tensile strength

The application discloses a method for preparing a through-type composite strip embedded with silver copper. The method comprises the steps of: extruding silver and copper ingots into profiled strips according to a design shape, respectively cleaning the surfaces of the profiled silver strip and the purchased profiled copper strip, removing a greasy dirt, an impurity and oxide on the surface; mutually embedding the silver strip and the copper strip into a whole; reinforcing and welding two heads to prepare a pre-composite material; continuously rolling and hot rolling to form a silver copper composite material from the pre-composite material under a complete-atmosphere protection state; dragging and receiving materials by a receiving machine, and then annealing in a diffusion manner, rolling and cutting to obtain the product. The method disclosed by the application is high in bonding strength, low in demand on manufacturing device, easy to process, long in length of strip, and convenient to automatically process, and manufacturing on a large scale can be carried out, thus, the cost is greatly reduced.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Metal glasses legs with spiral lines

InactiveCN109283699AFacilitate automatic processingWeight increaseNon-optical partsInjection mouldingMachining process

The invention discloses metal glasses legs with spiral lines, and belongs to the field of glasses frame structures. The leg sleeves of general glasses legs are machined through injection molding, so that the machining process is complex; glasses easily slide down along the nose bridge in the wearing process; and the leg sleeves made of plastics are not durable and lack of a design sense, and evencan cause skin allergy. Therefore, the invention provides the metal glasses legs with the spiral lines. Each metal glasses leg comprises a glasses leg body, and further comprises a spiral glasses legsleeve and a spiral locking sleeve; the spiral glasses leg sleeve is connected to the rear end of the glasses leg body in a sleeving mode; and the spiral locking sleeve is located at the tail end of the glasses leg body. According to the metal glasses legs, automatic processing is facilitated; the weight of the rear end of each glasses leg is increased, so that a glasses frame does not easily slide down along the nose bridge when a user wears the glasses; a vacuum galvanized coating material is environment-friendly and durable, and does not easily cause the skin allergy; and the shape is novel.

Owner:SHENZHEN XING HONGFA GLASS FRAME TECH LTD

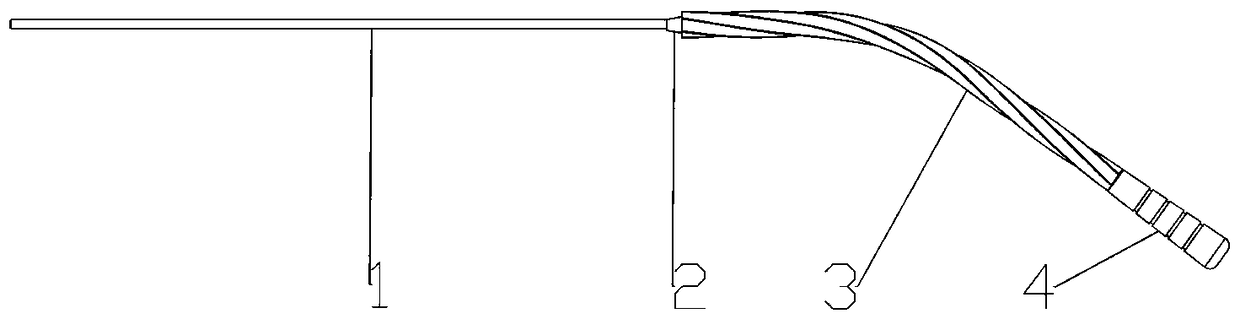

Winding wire, winding and preparation method of winding wire

ActiveCN107123546AFacilitate automatic processingImprove power densityInsulated cablesCoils manufactureConductor CoilElectrical and Electronics engineering

Owner:DELTA ELECTRONICS JIANGSU

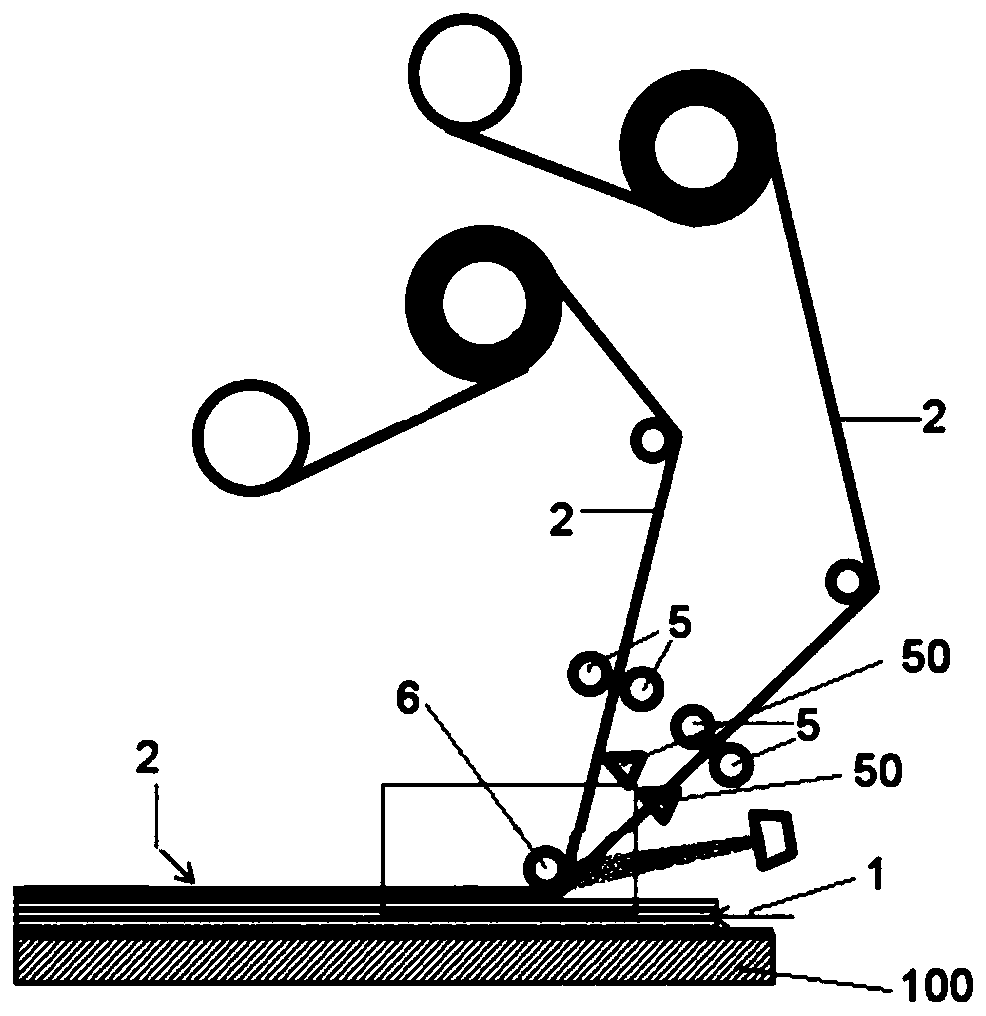

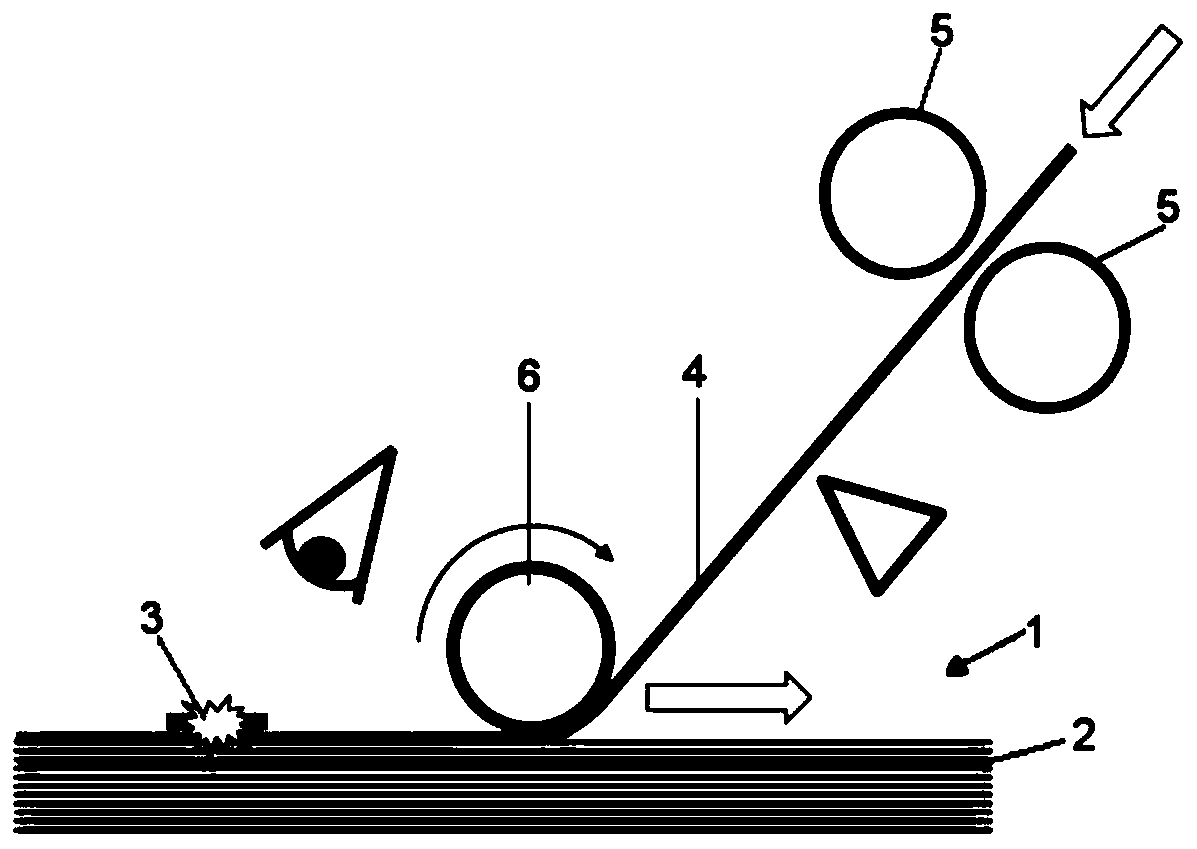

Method and system for reworking composite laminate and automated tape placement machine

PendingCN111070731AFacilitate automatic processingLaying operations are fully automatedLayered productsLaminationComposite materialManufacturing engineering

The invention relates to a method and system for reworking a composite laminate and an automated tape placement machine. In one aspect, a method is provided for reworking a composite laminate (1) comprising a plurality of tapes (2), the method comprising the following steps: detecting the occurrence of a defect (3) on a tape (4) of composite material while the tape (4) is being laid up; continuingthe lay-up of the defective tape (4) until a tape (4) length which surpasses a manufacturing length (L) of the tape (4); catching the part of the defective tape (4) that surpasses the manufacturing length (L) of the tape (4); cutting the defective tape (4) in the part of the defective tape (4) that surpasses the manufacturing length (L) of the tape (4); removing from the laminate (1) the caught defective tape (4) by the catching system, and laying-up a replacement tape (2) in the place of the removed defective tape (4).

Owner:AIRBUS OPERATIONS SL

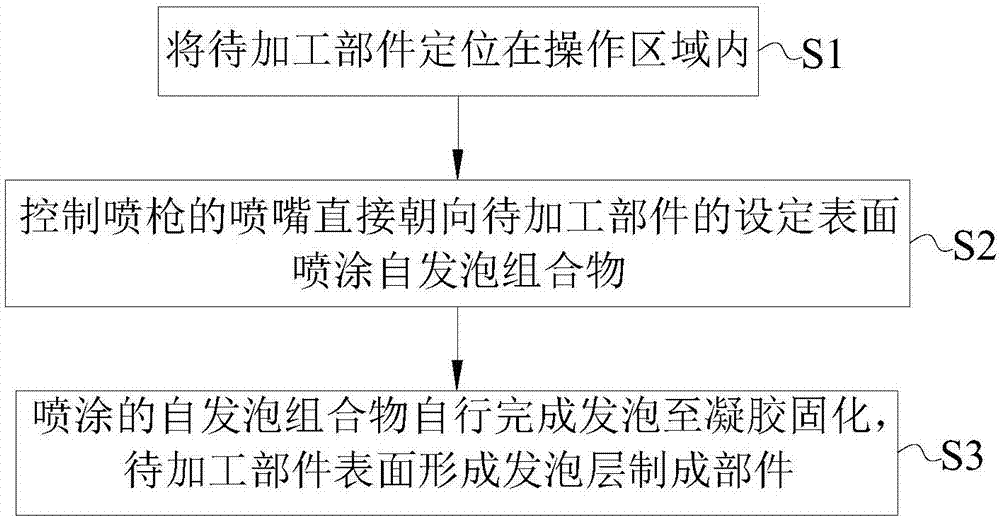

Air-conditioner machining method, self-foaming production system and air-conditioner

The invention discloses an air-conditioner machining method, a self-foaming production system and an air-conditioner. The surface of at least one part of the air-conditioner is provided with a foaming layer formed in the mode that after covering of a self-foaming composition, foaming, gelation and solidification are conducted. The method for machining parts comprises the following machining steps that 1, the to-be-machined parts are positioned in the operation area; 2, a spray nozzle of a spray gun is controlled to directly spray the self-foaming composition towards the set surfaces of the to-be-machined parts; and 3, the sprayed self-foaming composition automatically completes foaming till gelation and solidification are achieved, and the foaming layers are formed on the surfaces of the to-be-machined parts, so that the parts are manufactured. According to the air-conditioner machining method, the foaming layer is adopted to replace a sponge heat insulation layer, so that the machining technique is simpler, the production efficiency is high, and automatic machining is easy to achieve.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Floating clamping adaptive processing method and process equipment

ActiveCN104625785BReduce distortionReduce stressMeasurement/indication equipmentsPositioning apparatusProcess equipmentMachine parts

The invention discloses a low-stress self-adaptive machining method and process equipment. According to the method, the clamping state of a part is automatically adjusted according to deformation caused by release of residual stress after a certain material of the part is removed, the part can release deformation fully in the machining process, and deformation is small after the part is unloaded. To realize the machining method, the invention provides self-adaptive clamping and monitoring equipment. The equipment adjusts the space position of a clamping point in a self-adaptive mode according to deformation of the part on the premise of ensuring clamping force of a certain degree, and stress and a displacement value of the clamping point are monitored through a force sensor and a displacement sensor. It is ensured that deformation of the part is small after clamping is removed, the out-of-tolerance and scrap problems caused by deformation of the machined part are solved, and the automation and intelligent of clamping are achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Garment fabric spraying and drying device and drying method

InactiveCN112718337ASimple and fast operationImprove spray processing efficiencyPretreated surfacesCoatingsIndustrial engineeringAutomatic processing

The invention provides a garment fabric spraying and drying device, and belongs to the technical field of garment processing. The garment fabric spraying and drying device comprises a rack, a conveyor, a spraying mechanism and a drying mechanism. The conveyor is located in a protective cover, the spraying mechanism comprises an electric push rod, a movable frame, a mold plate and a spray head, and the drying mechanism comprises an air heater and an air inlet pipe. During use, fabric is placed on the upper portion of the conveyor, the fabric is conveyed into the protective cover through the conveyor, the electric push rod does telescopic motion, the movable frame fixedly connected to the lower end of the electric push rod moves along with the electric push rod, the mold plate is pressed downwards to the fabric, the spray head sprays pigment, different patterns can be manufactured on the fabric through the mold plate and the spray head, then drying operation is conducted, the air heater blows hot air into the protective cover through the air inlet pipe, and coating on the fabric is dried. According to the device, operation of personnel is simple and convenient, the spraying processing efficiency is improved, and automatic processing is convenient.

Owner:周利剑

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com