Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Improve spray processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

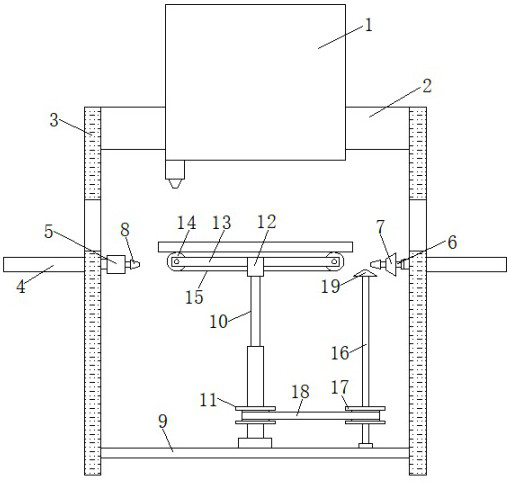

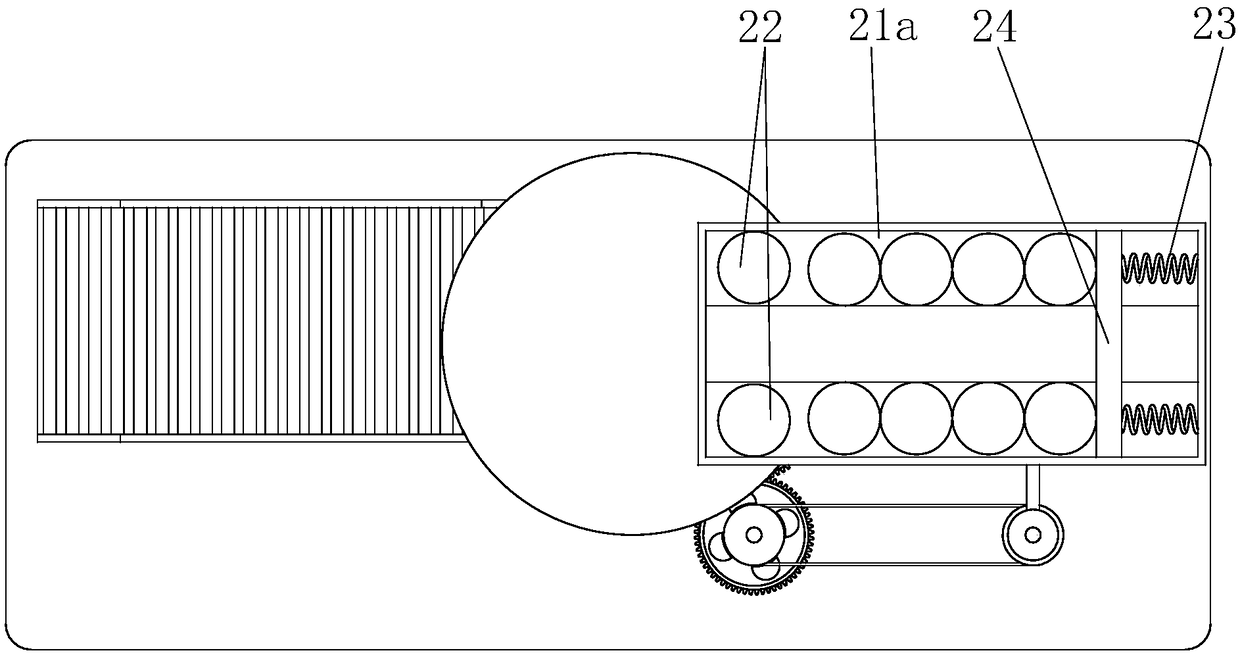

Paint spraying surface drying treatment process

PendingCN112295867ALabor savingImprove processing efficiencyPretreated surfacesCleaning using gasesElectric machineryWheel drive

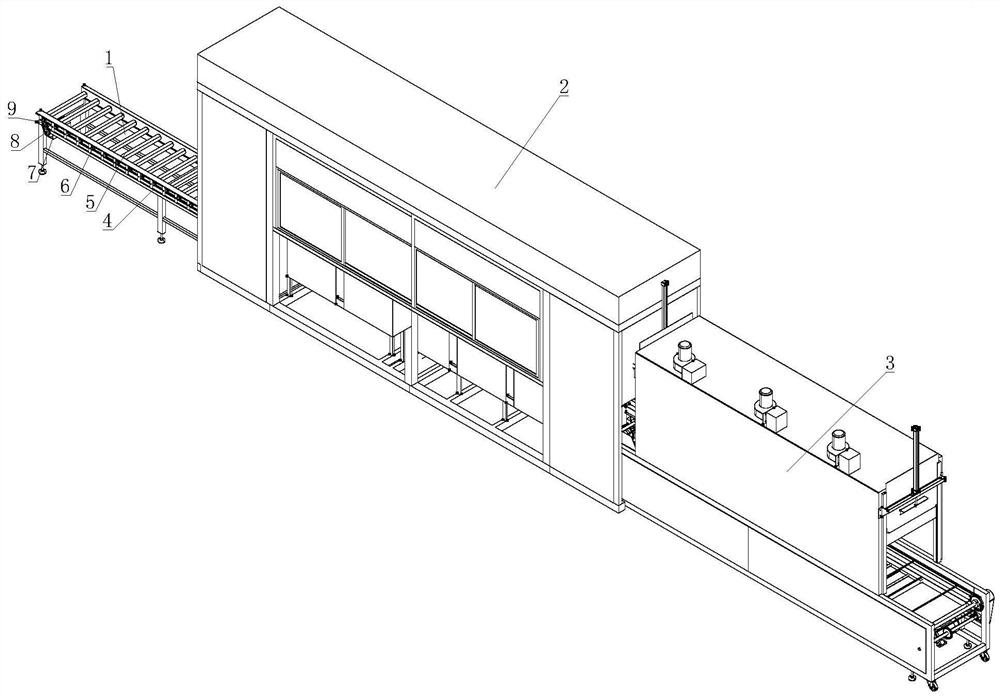

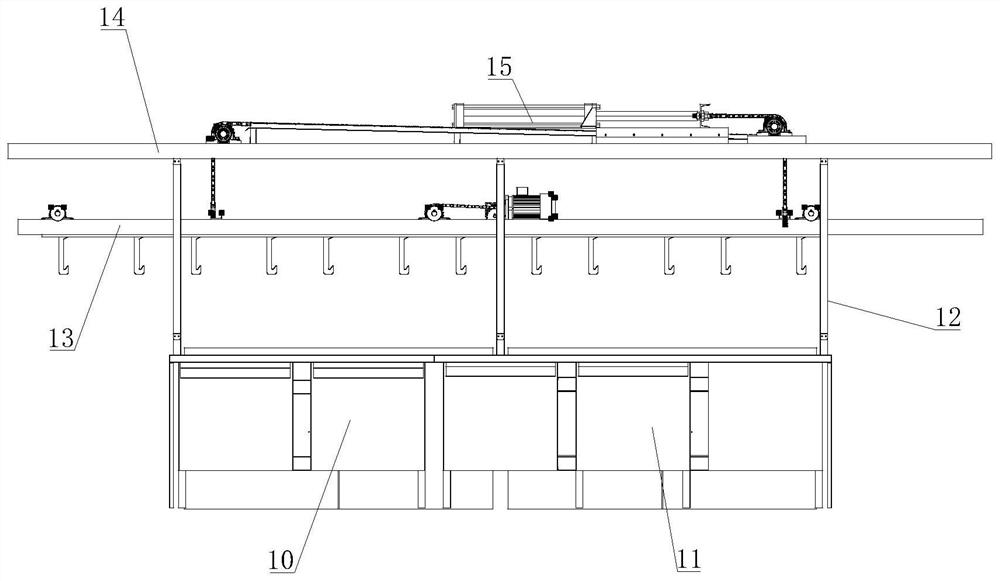

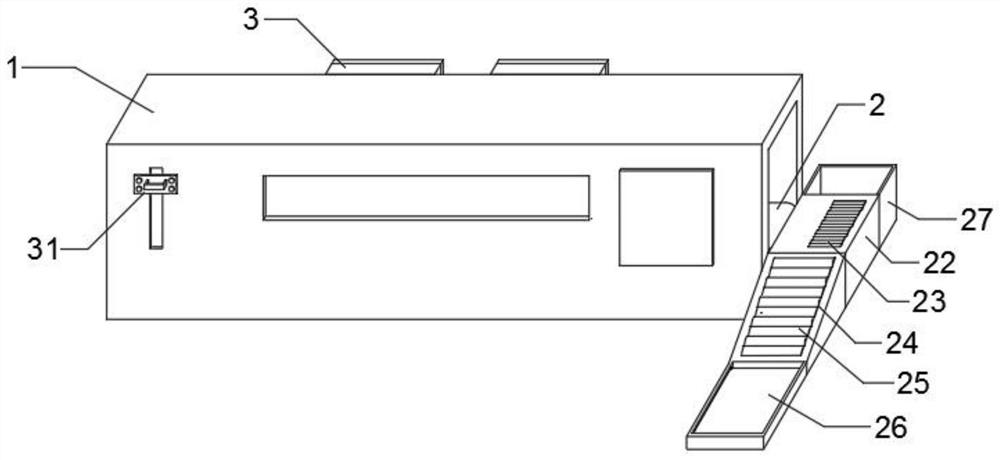

The invention discloses a paint spraying surface drying treatment process. The process is applied to a spraying drying device, and specifically comprises the following steps of 1, a part to be subjected to paint spraying is put on a conveying assembly, a driving belt wheel is driven to rotate by a first motor installed on the conveying assembly, the driving belt wheel drives a driven belt wheel and a conveying roller connected with the driven belt wheel to rotate through a transmission belt, the conveying roller connected with the driven belt wheel drives other conveying rollers to rotate through chains to convey the part, and the part is conveyed into a cleaning and spraying assembly. Cleaning and paint spraying of the part are integrated, the technological process steps of part sprayingmachining are effectively reduced, use of equipment is reduced through integrated cleaning and spraying, the production and machining cost is reduced, automatic grabbing and placing of the part are achieved through automatic horizontal and lifting movement, and the spraying machining efficiency of the part is further improved.

Owner:HEFEI NANFANG AUTO PARTS

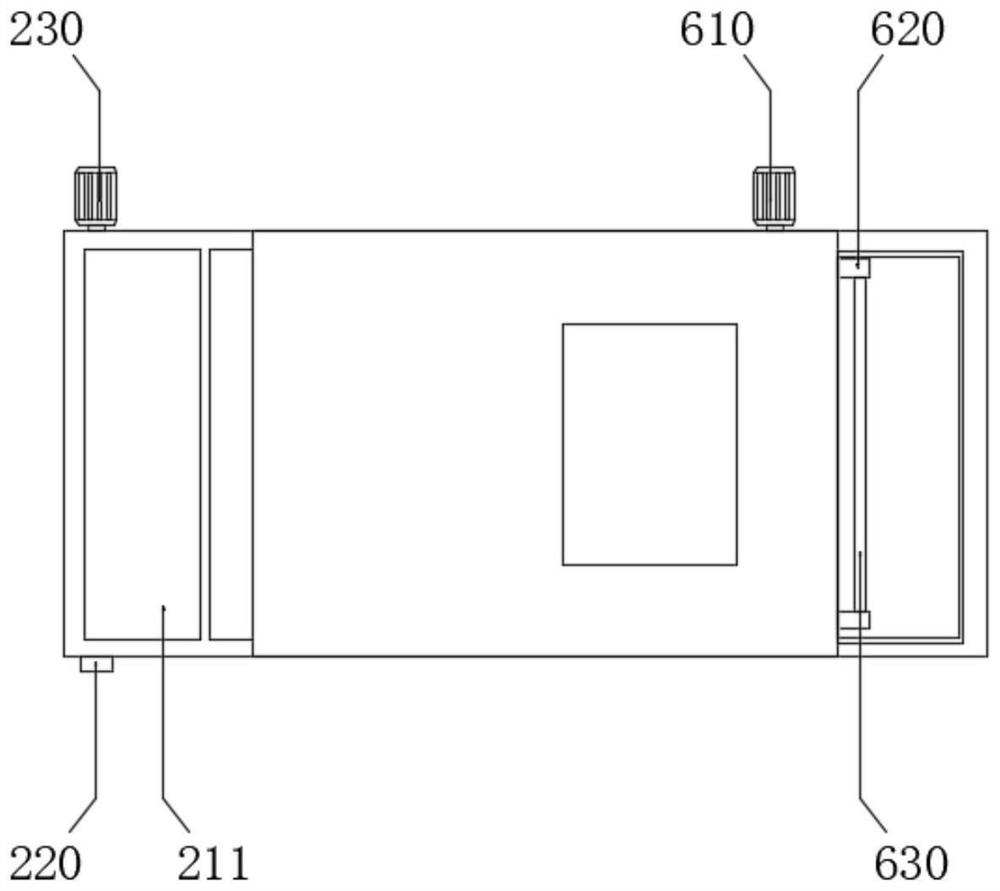

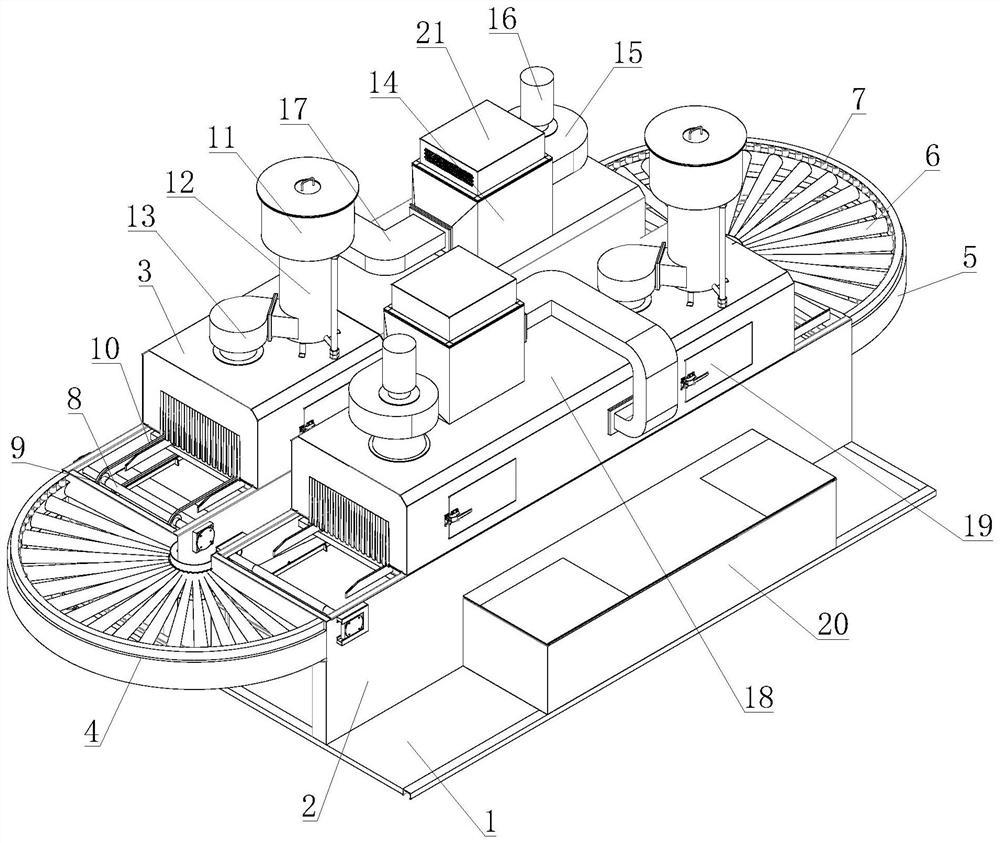

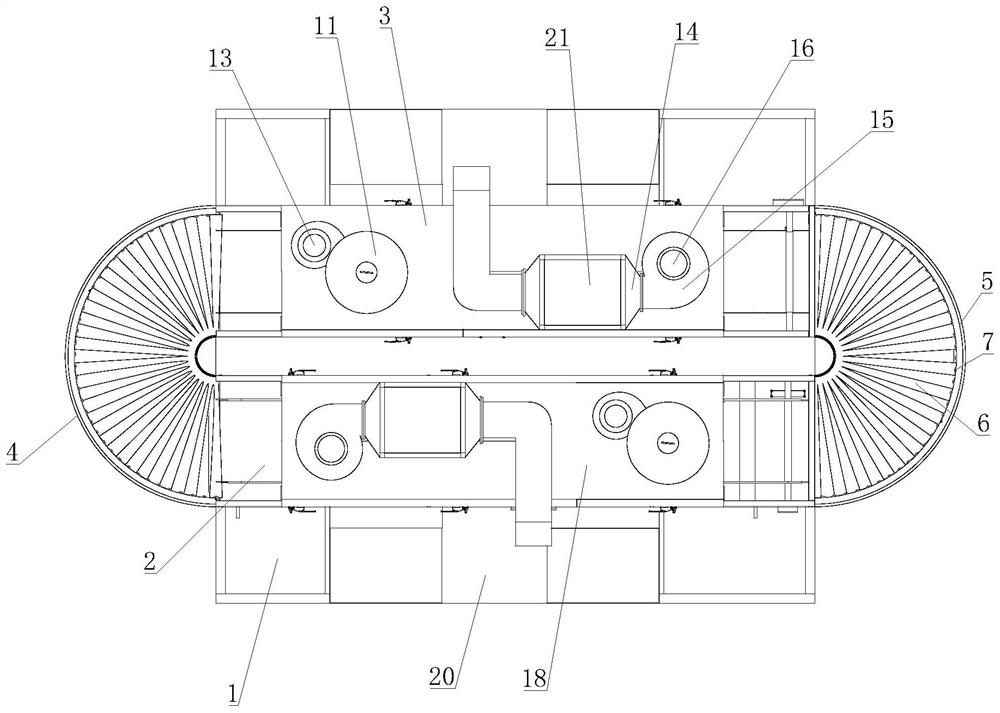

Shell machining process for communication equipment

ActiveCN112718346AImprove spray processing efficiencyAchieve steeringPretreated surfacesCoatingsNumerical controlDry machining

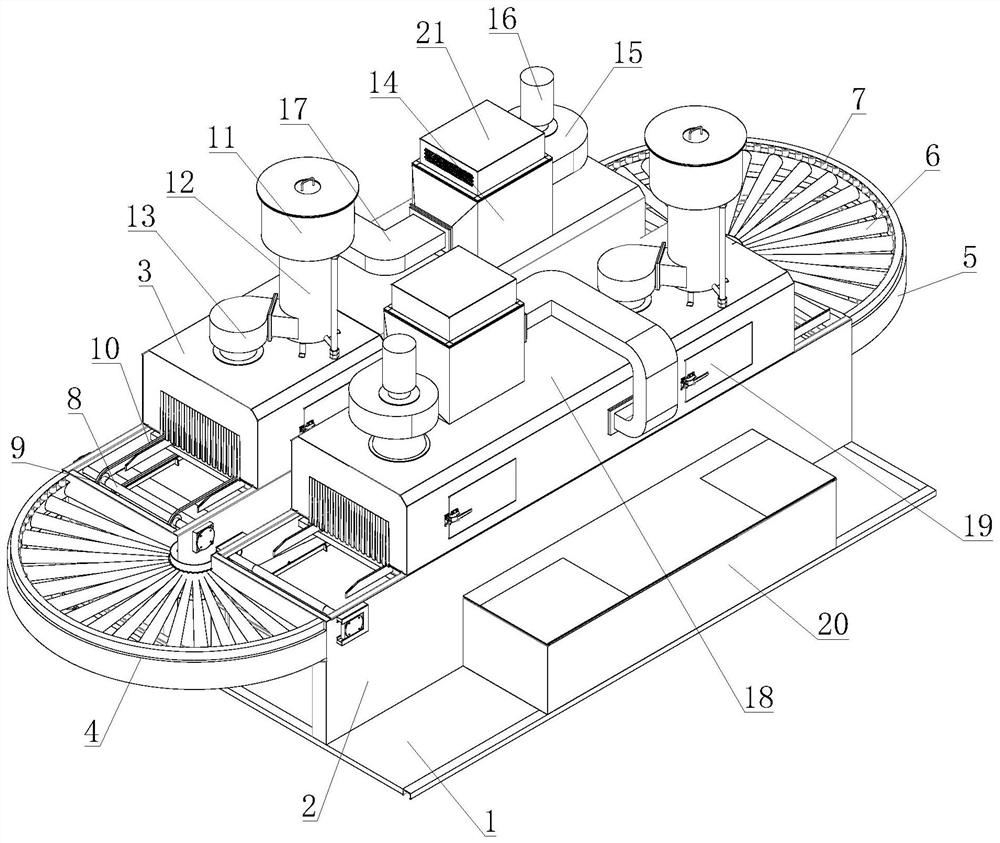

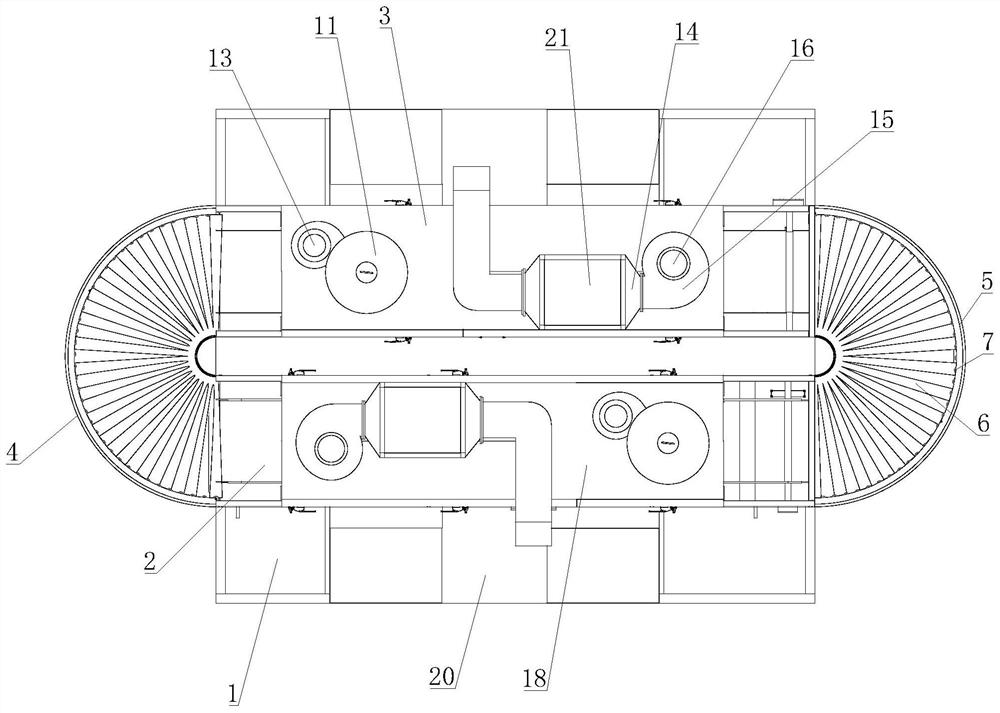

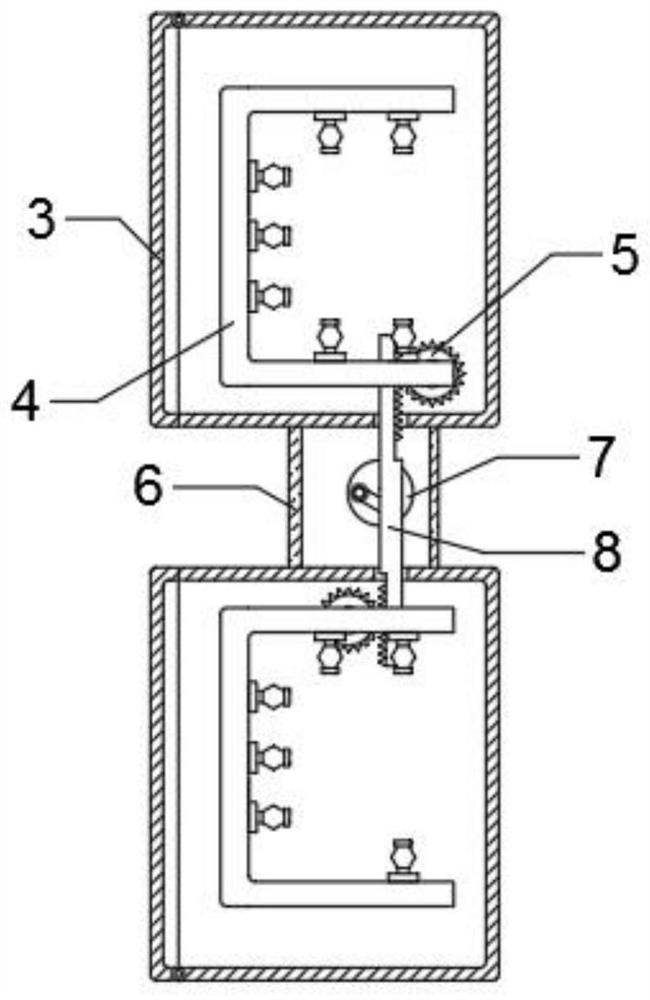

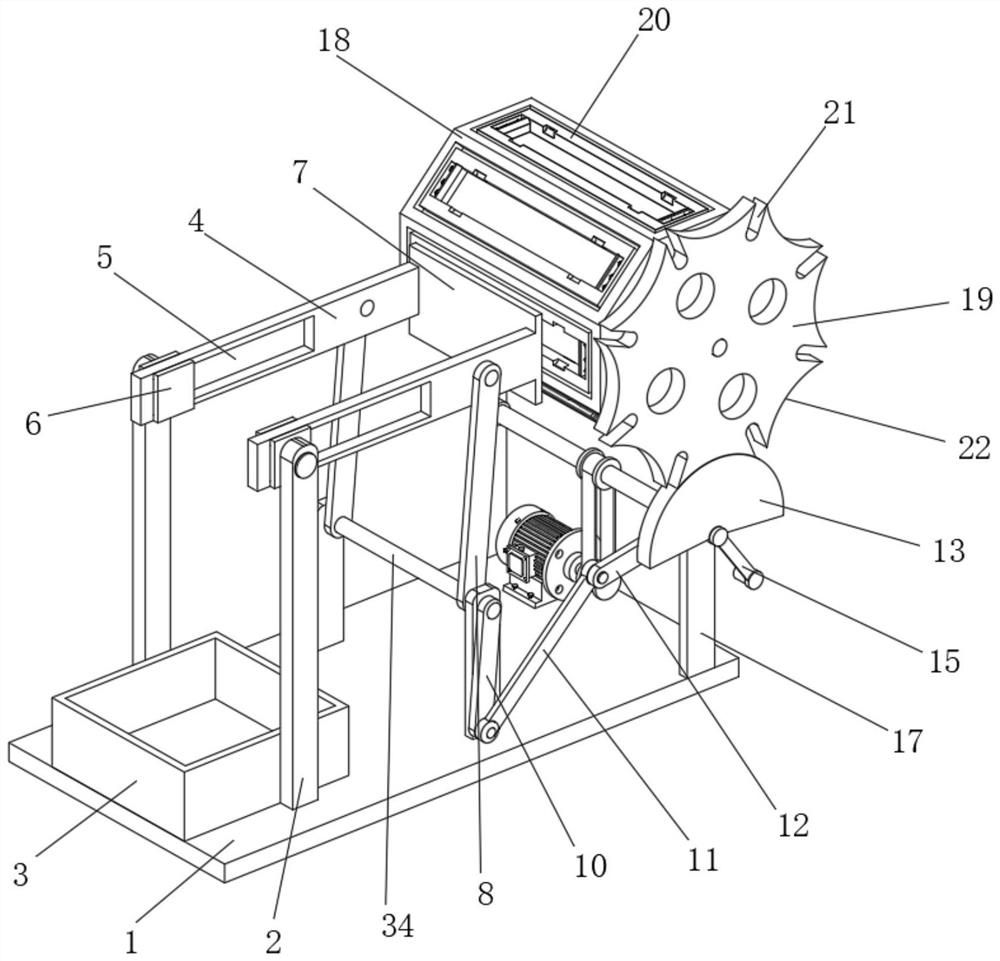

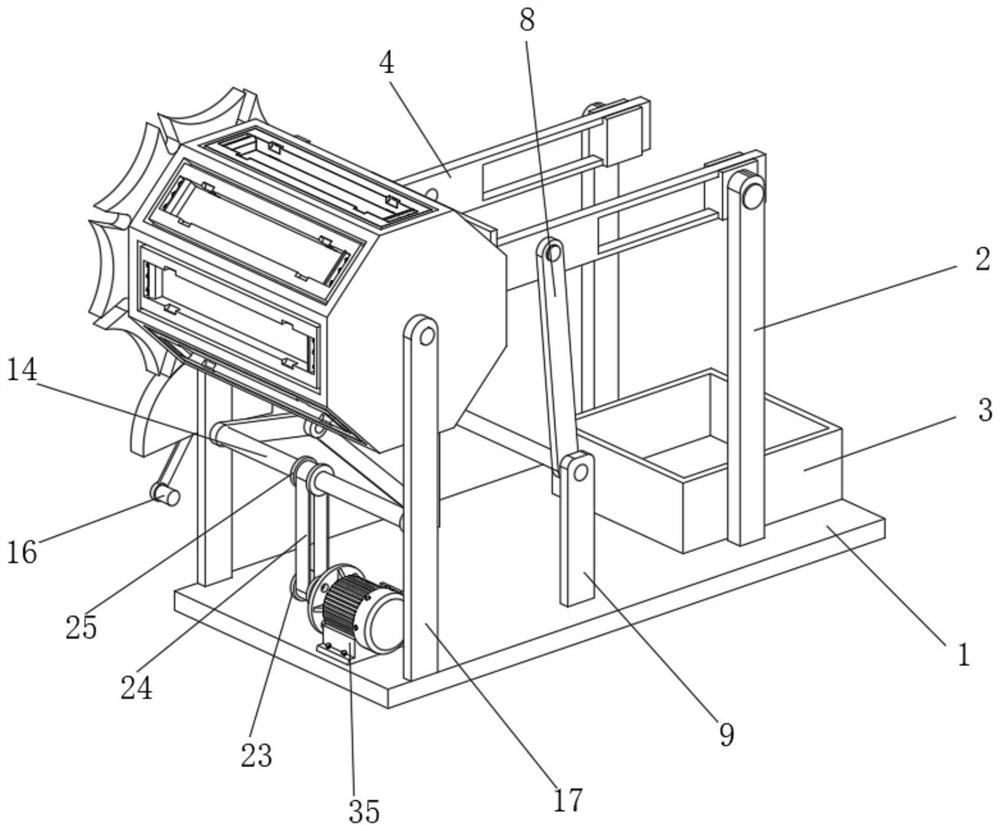

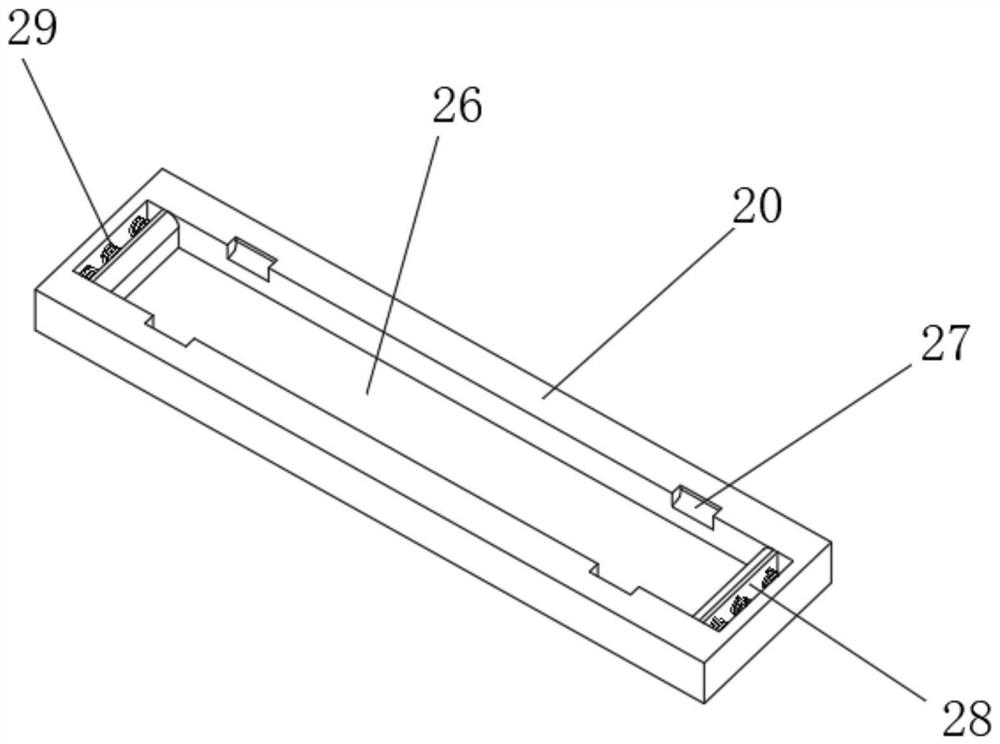

The invention discloses a shell machining process for communication equipment. The shell machining process specifically comprises the following steps: 1, forming a communication equipment shell body through injection molding or casting; 2, placing the communication equipment shell body on a numerical control machine tool to be ground and drilled to obtain a formed shell body; and 3, putting the formed shell body into spraying and drying equipment to be subjected to spraying and drying machining, wherein firstly, the formed shell body is conveyed to a conveying roller of a first arc-shaped frame, and the formed shell body is conveyed into a first drying and spraying box through the conveying roller on the first arc-shaped frame. According to the shell machining process, an overturning assembly is arranged to conduct automatic overturning on shell spraying, automatic overturning and steering of the shell are achieved through an overturning and steering mechanism, comprehensive and uniform spraying treatment is conducted on different positions of the surface of the shell, and a drying mechanism is arranged in a box body to conduct timely drying treatment on the sprayed surface, so that the spraying quality is ensured while the machining efficiency is improved.

Owner:ANHUI FEIKAI ELECTRONICS TECH CO LTD

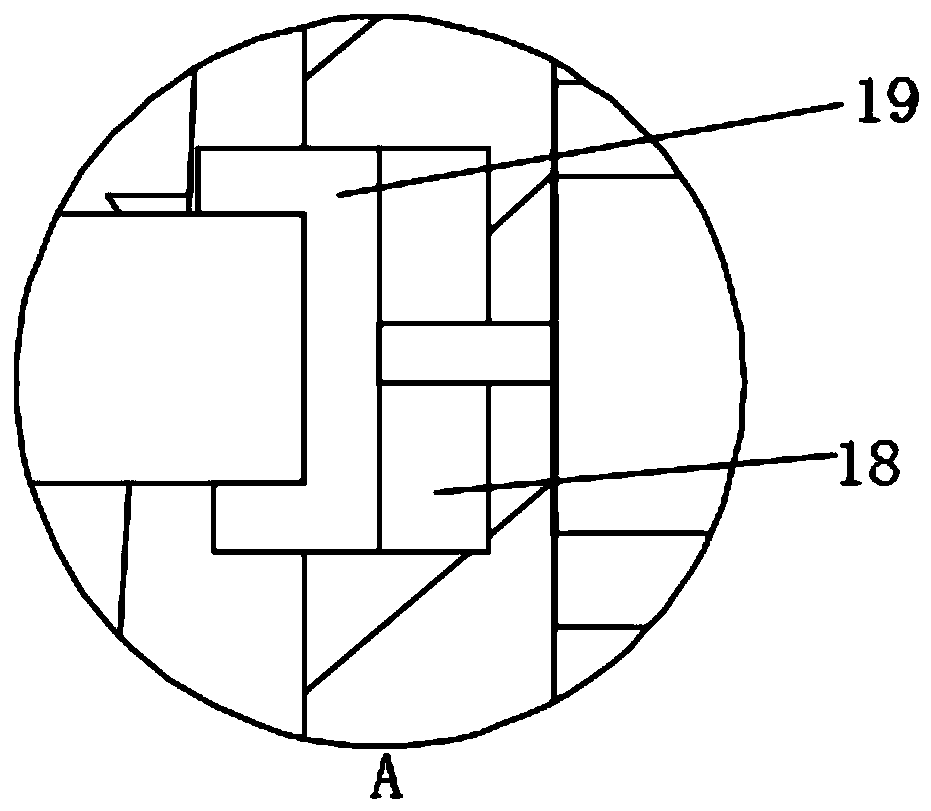

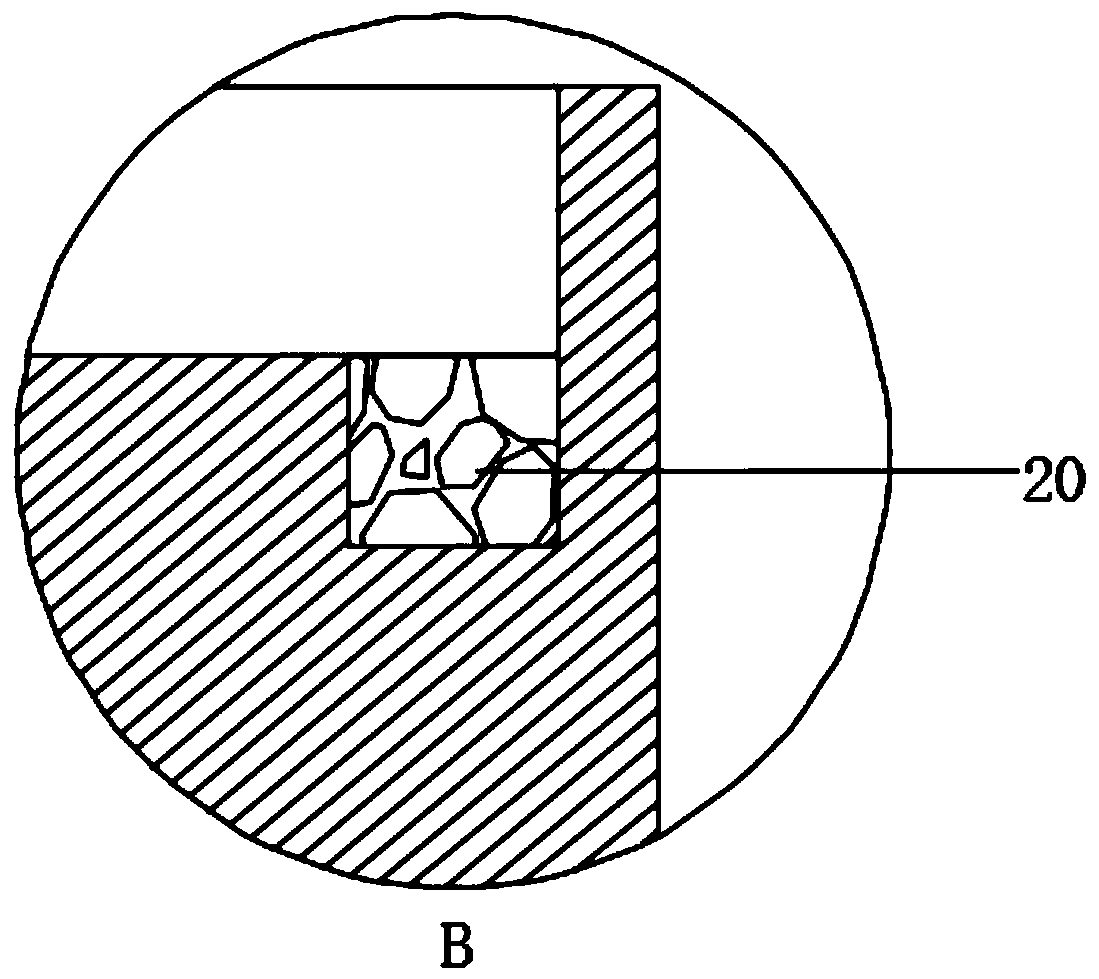

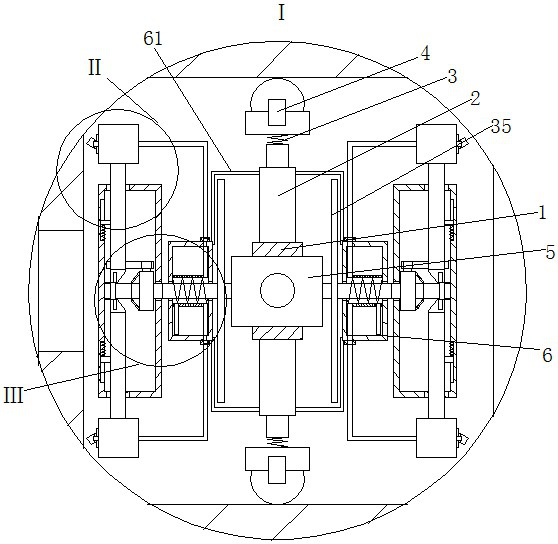

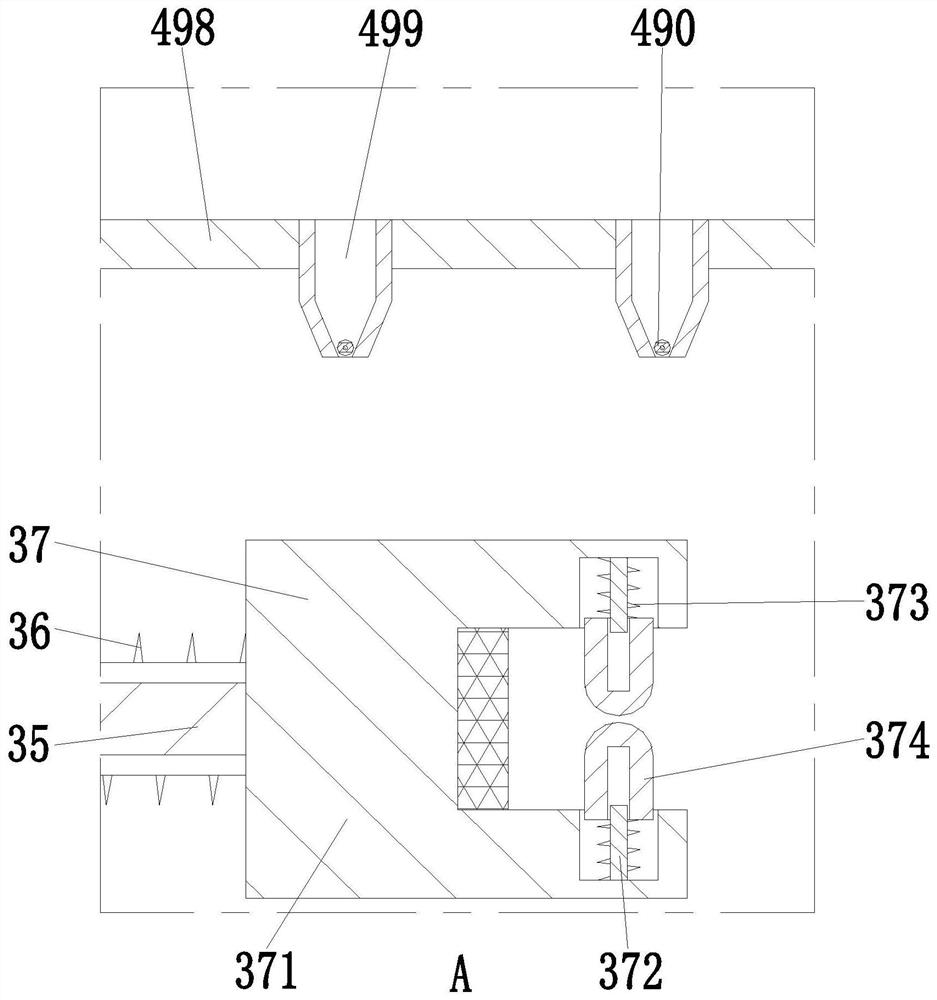

Protection device based on sandblast spray coating of casing installation edge spigots

ActiveCN110496727AEasy loading and unloadingEasy clampingSpraying apparatusAbrasive machine appurtenancesRotation flapProtection mechanism

The invention discloses a protection device based on sandblast spray coating of casing installation edge spigots. The protection device based on the sandblast spray coating of the casing installationedge spigots comprises a protection mechanism and a loading and unloading mechanism, wherein the protection mechanism is composed of a fixed bottom seat, a first rotation cavity, a rotation motor, a first belt pulley, a first rotation shaft, a second belt pulley, a rotation plate, a bottom baffle, a first support pillar, a fixed installing seat, an electric telescopic rod, a second support pillar,fixed clamp grooves, a protection barrel, a clamping air cylinder, resetting clamp grooves, fixed clamp plates, a first electromagnet, a driving case, a switching motor, a driving worm, a driving worm wheel and a switching shaft. The protection device based on the sandblast spray coating of the casing installation edge spigots avoids manual clamping, is convenient and quick, saves trouble and labor, can enable a casing to rotate through the rotation motor so as to perform spray coating on the casing in work due to the fact that the rotation motor and the switching motor are arranged, improvesprocessing efficiency of the spray coating, and cannot influence normal use of a non-spraying face of the casing and achieves an adequate protection function for the casing in the sandblast spray coating process.

Owner:永嘉县纳海川科技有限公司

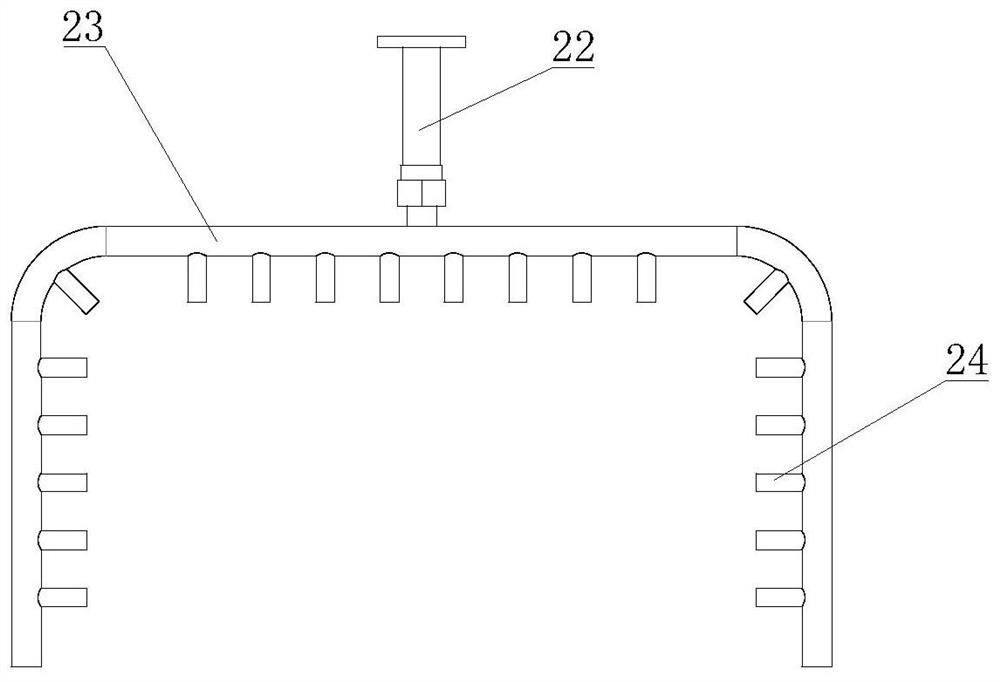

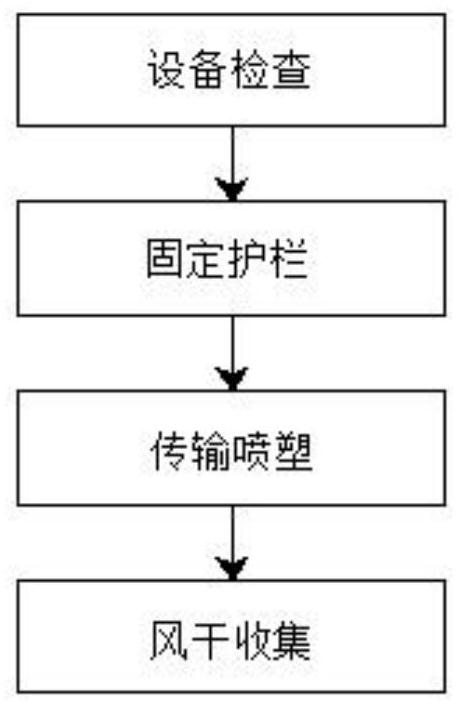

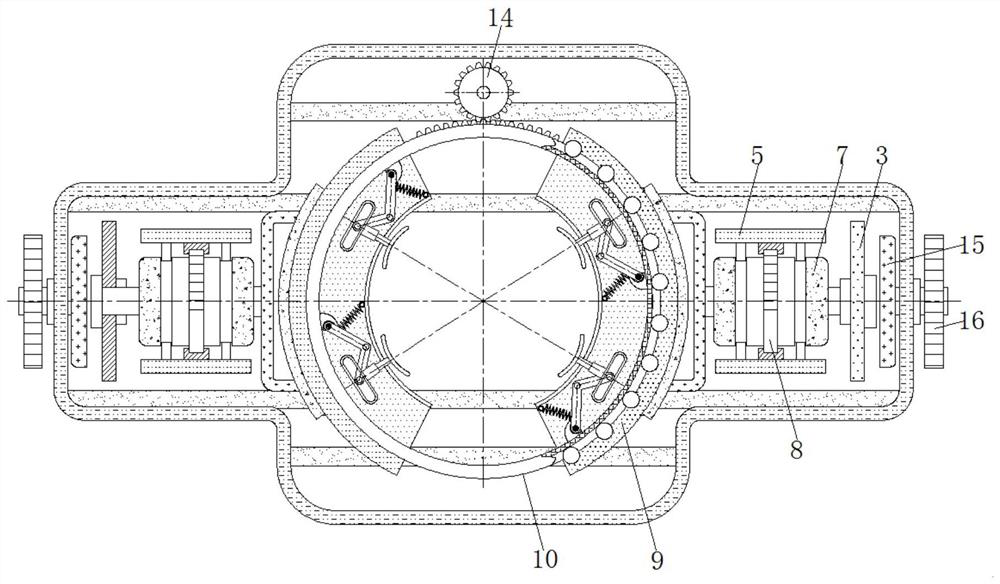

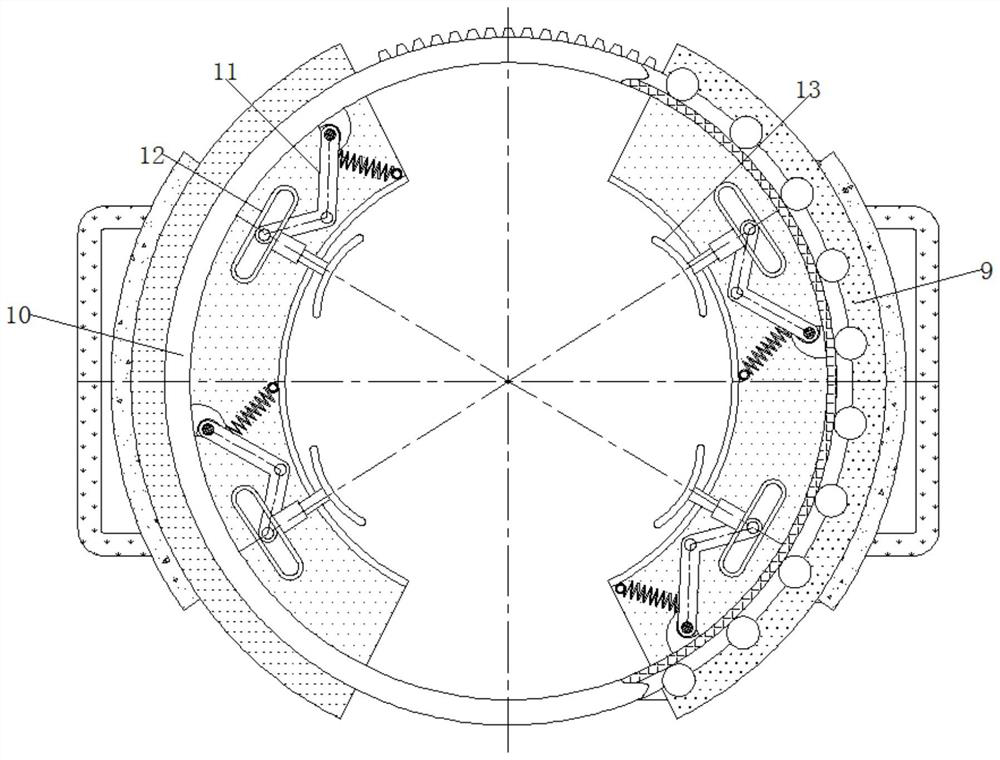

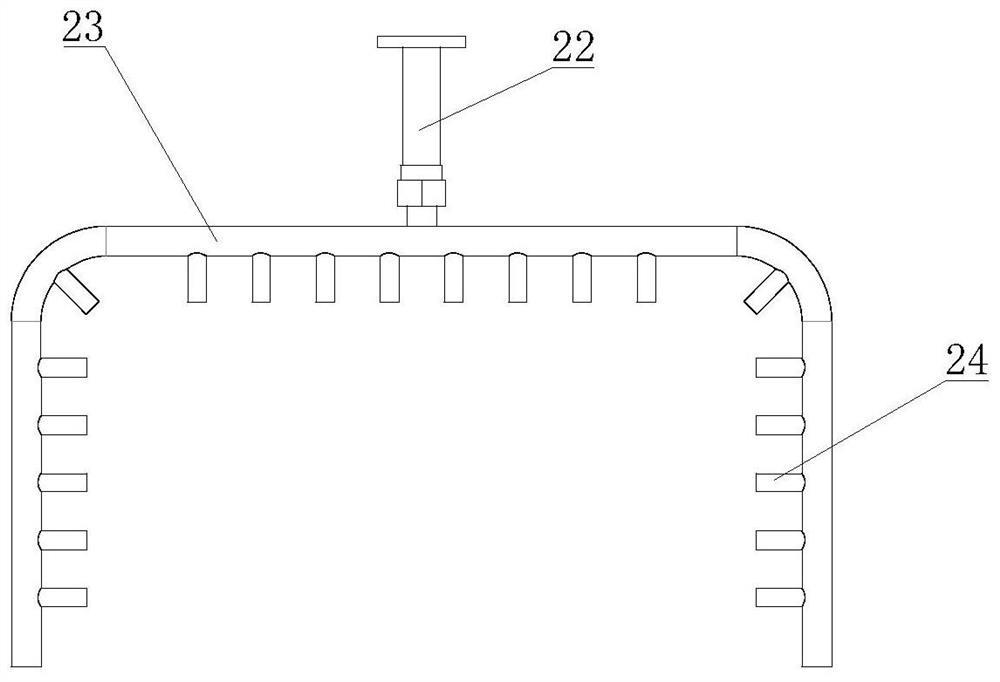

Guardrail surface plastic spraying process

InactiveCN111871655AImprove the effectImprove automationLiquid surface applicatorsSpraying apparatusElectric machineryManufacturing engineering

The invention relates to the field of guardrail manufacturing, in particular to a guardrail surface plastic spraying process. The process uses a guardrail plastic spraying device, the guardrail plastic spraying device comprises a main body, a conveying groove of an annular structure is formed in the main body, first sliding grooves of an annular structure are symmetrically formed in the inner wallof the conveying groove, and tooth grooves are formed in the first sliding grooves. A plurality of moving gears are symmetrically inserted into the tooth grooves, the moving gears are engaged with the tooth grooves, a plurality of first motors are symmetrically arranged in the first sliding grooves, the first motors and the moving gears are symmetrically arranged, and the output ends of the firstmotors penetrate through the first sliding grooves to be fixedly installed on the moving gears; and fixing rods are arranged at the ends, away from the moving gears, of the first motors, and one endsof the fixing rods are inserted into the first sliding grooves and fixedly installed on the first motors. All-dimensional uniform and stable plastic spraying can be conducted on a metal guardrail, the plastic spraying effect is improved, and the process is suitable for popularization.

Owner:张盼盼

Lifting type anti-rust paint spraying equipment for cylindrical parts

ActiveCN111744696AFull sprayConvenient spray processingLiquid spraying apparatusElectric machineryEngineering

The invention discloses lifting type anti-rust paint spraying equipment for cylindrical parts, and relates to the technical field of cylindrical part processing. The problems that existing cylindricalpart spraying equipment needs to drive a circular part to rotate twice to complete spraying processing of a single cylindrical part, then a certain time difference exists when the two faces of the cylindrical part are sprayed, so that the spraying quality and effect of paint are affected, operation is inconvenient, and the spraying efficiency is low are solved. The lifting type anti-rust paint spraying equipment for the cylindrical parts comprises supports, a sliding plate, rolling shafts, a supporting frame, a supporting plate, a driving motor and the like; and the sliding plate is fixedly installed on the two supports, a round hole is formed in one end of the sliding plate, and the plurality of rolling shafts are rotationally installed on the sliding plate. According to the lifting typeanti-rust paint spraying equipment, through cooperative work of a lifting mechanism and a paint spraying mechanism, paint spraying processing can be conducted on the cylindrical parts located on a supporting disc, and the supporting disc can drive the cylindrical parts to rotate, so that paint spraying is more uniform and comprehensive.

Owner:SUZHOU YUQIAN INFORMATION TECH CO LTD

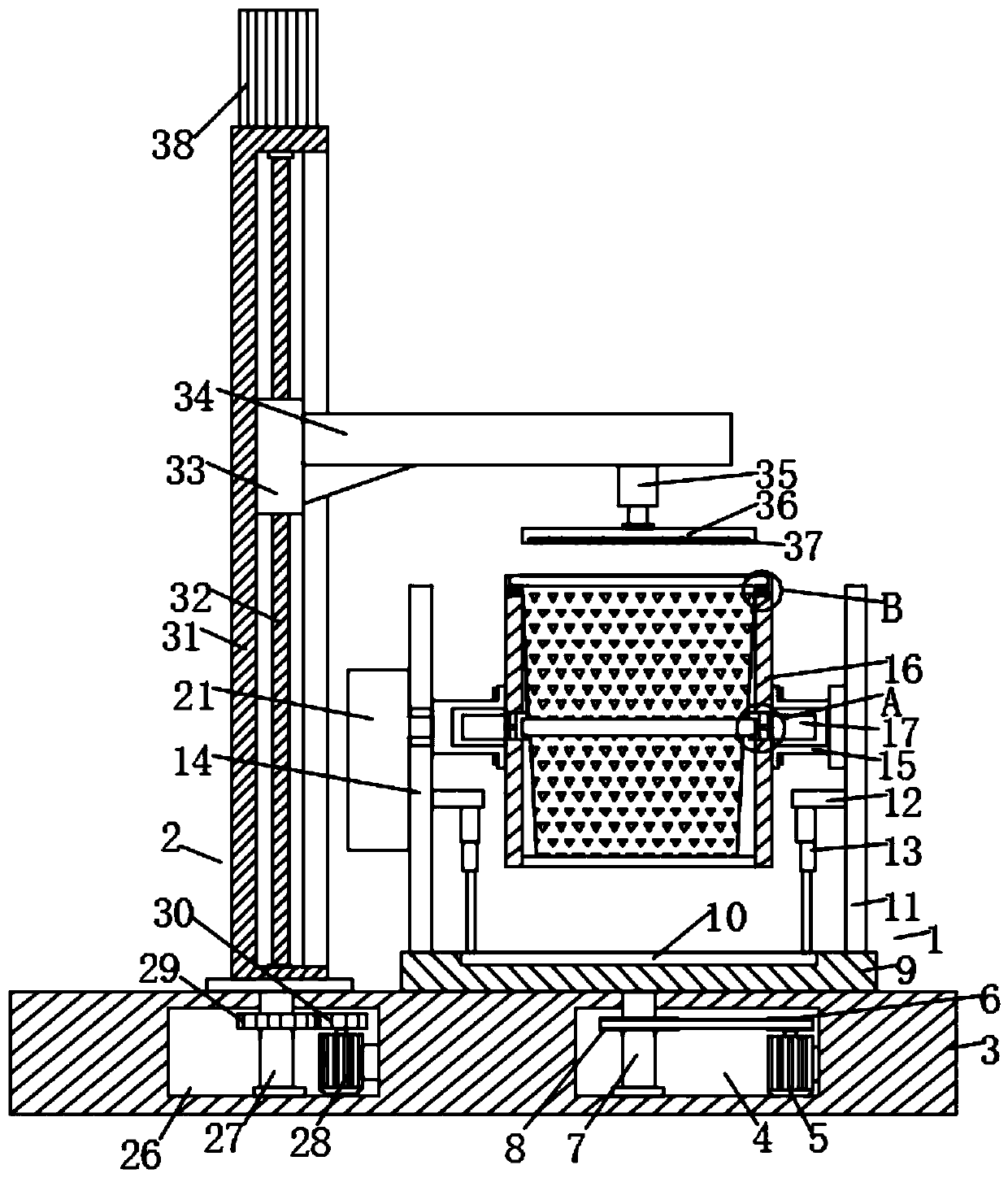

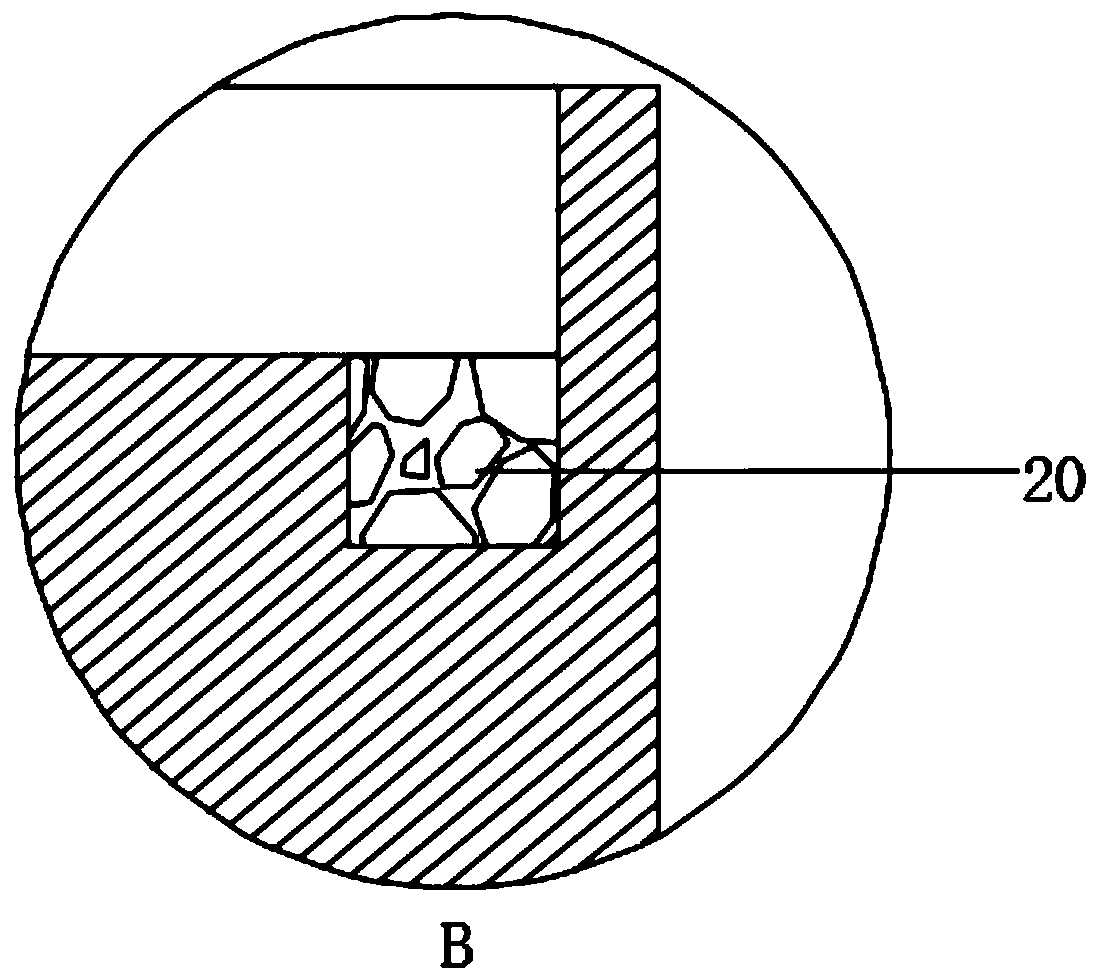

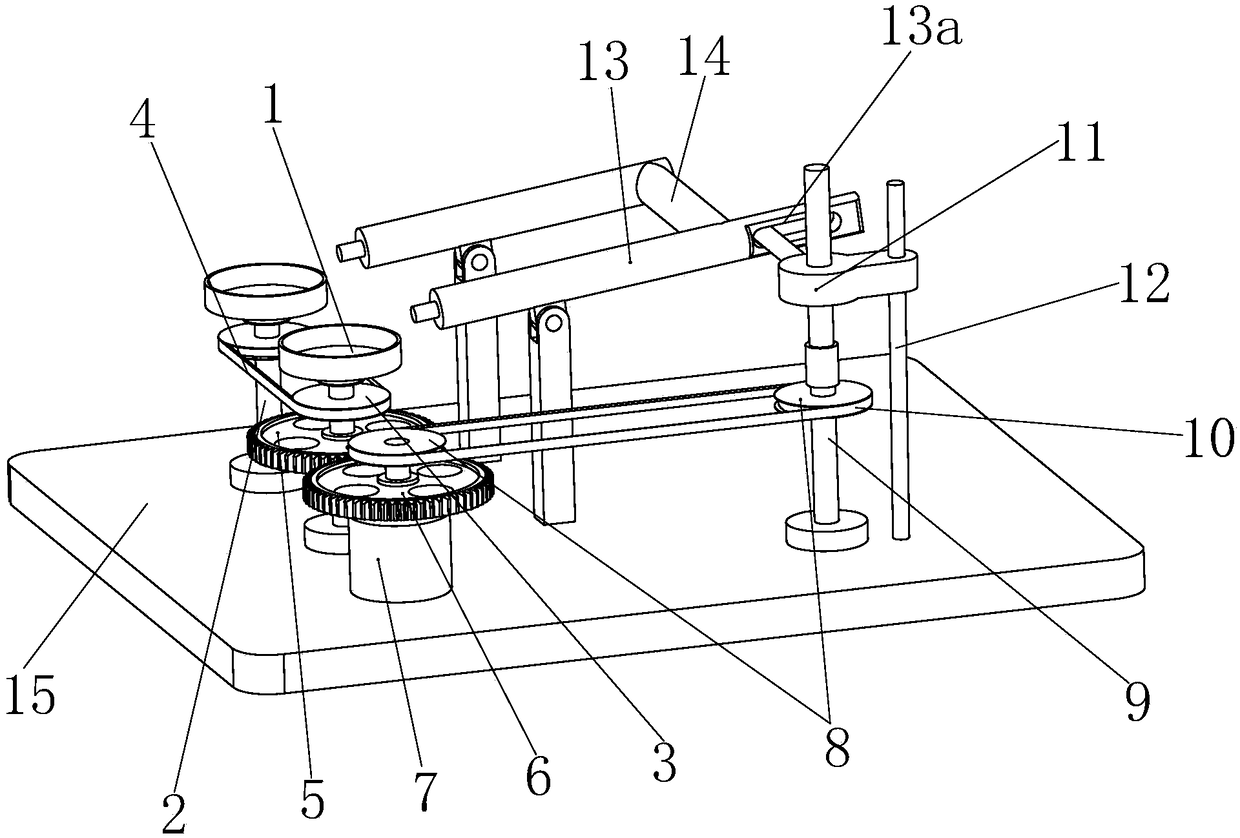

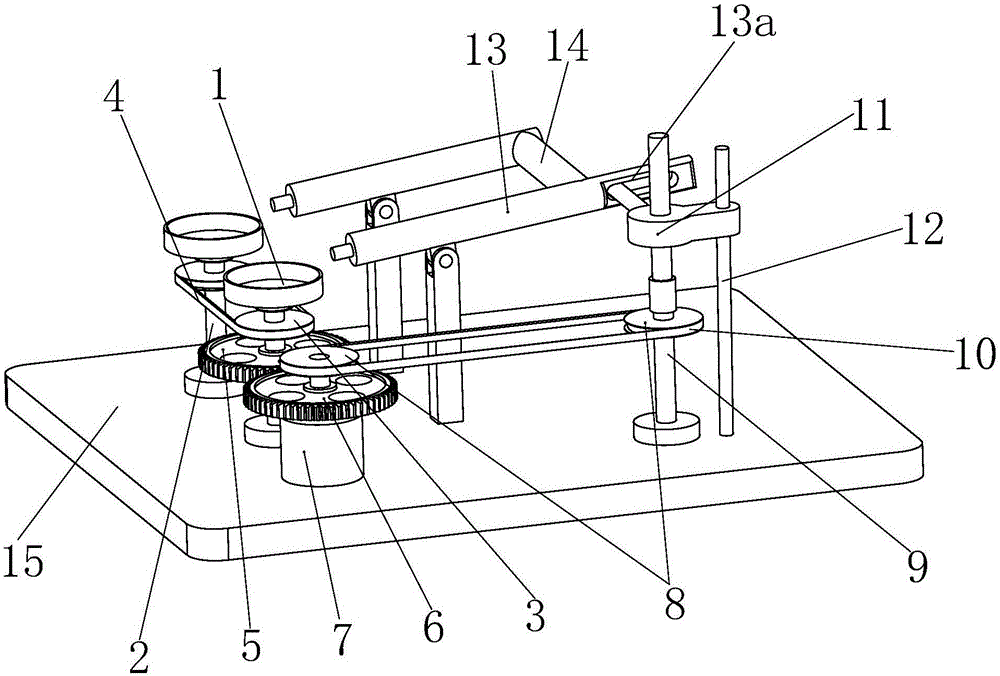

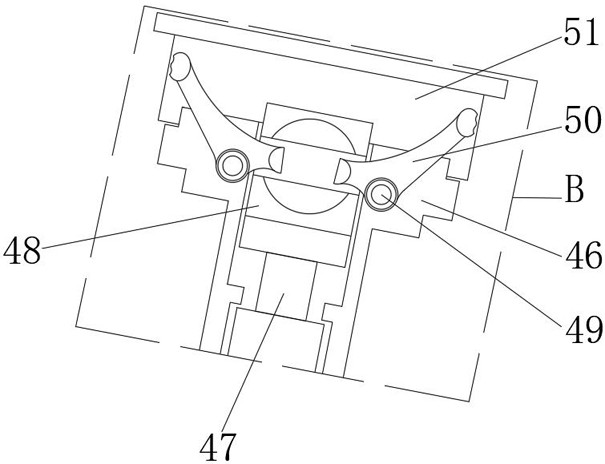

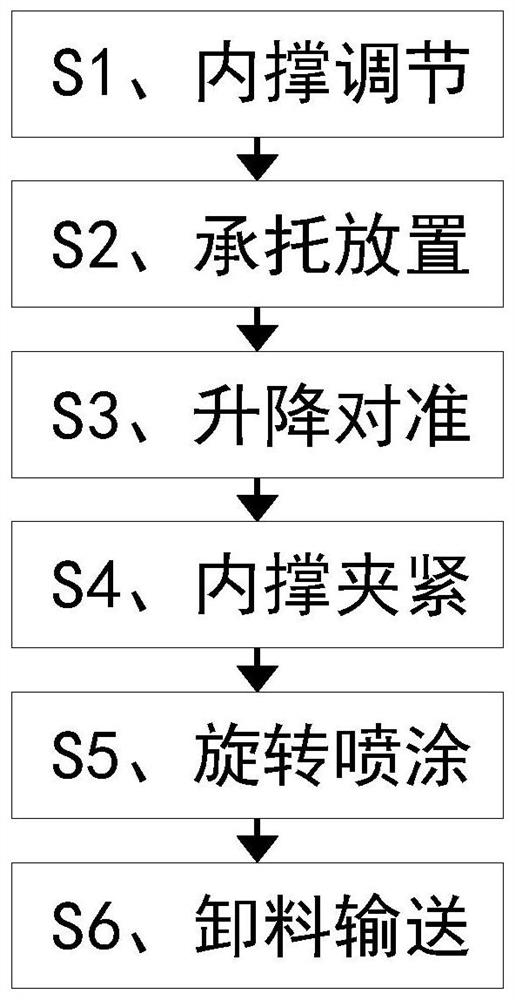

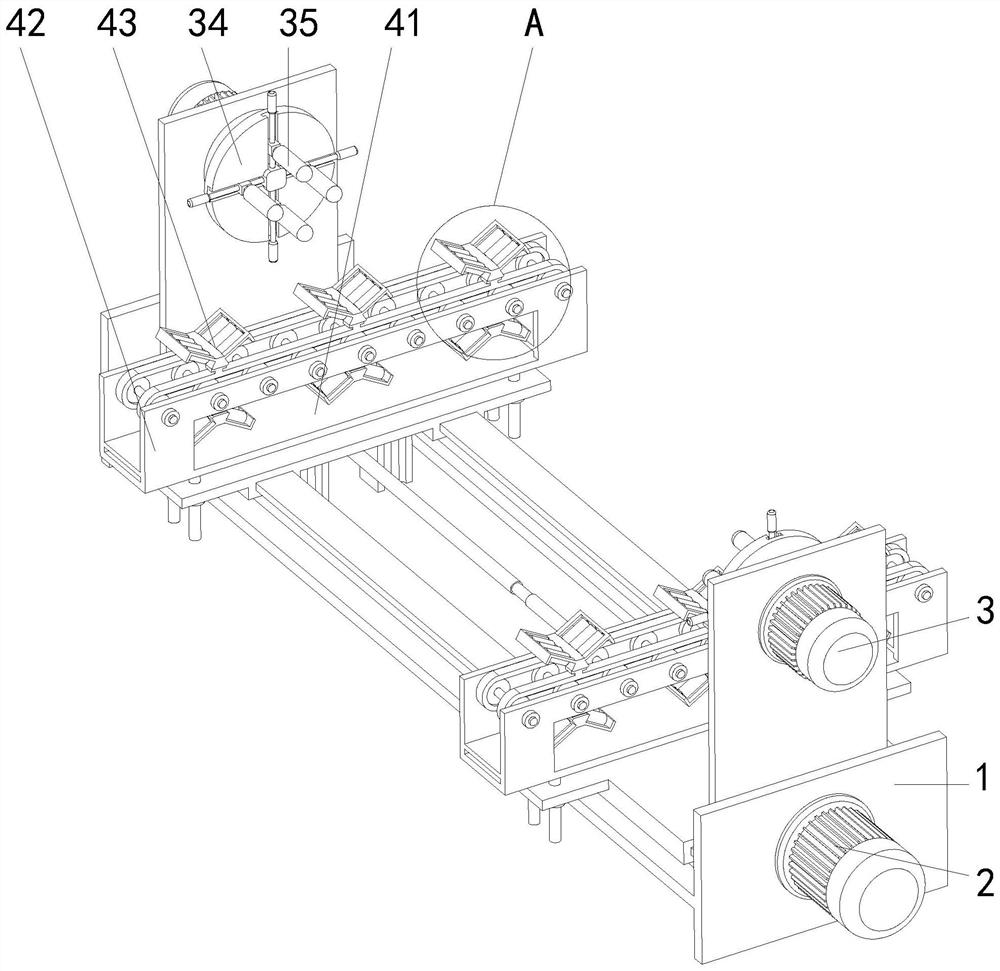

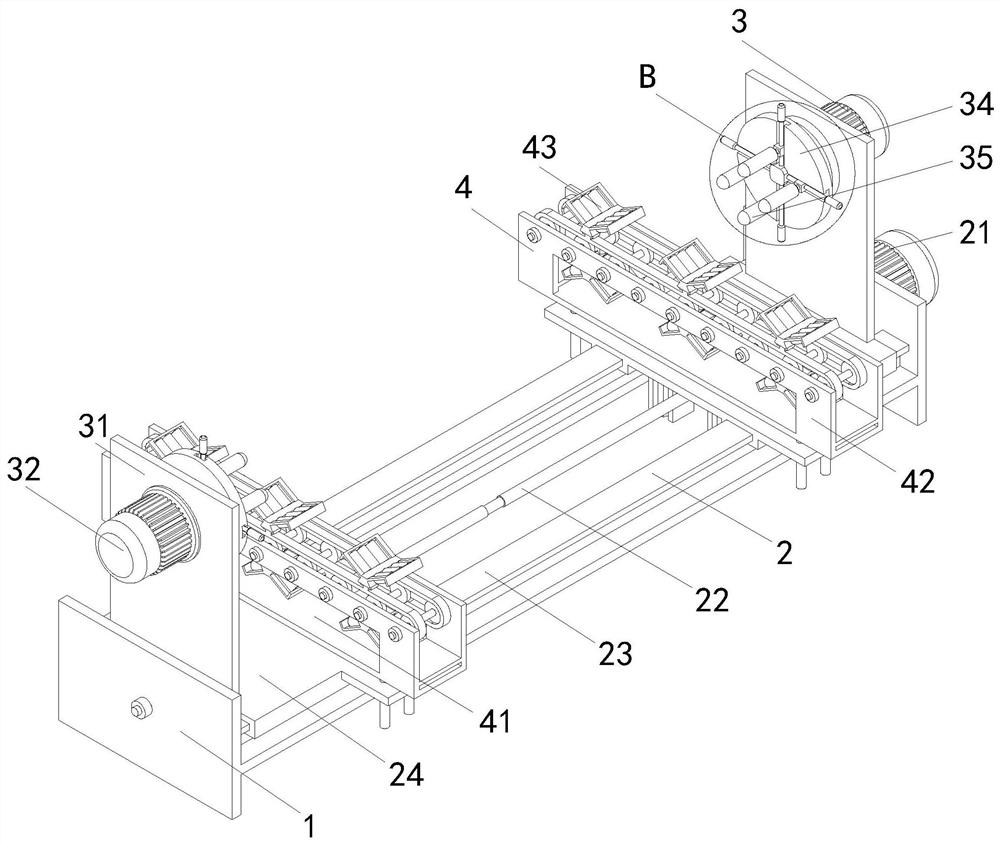

Machining method of plastic-steel profile

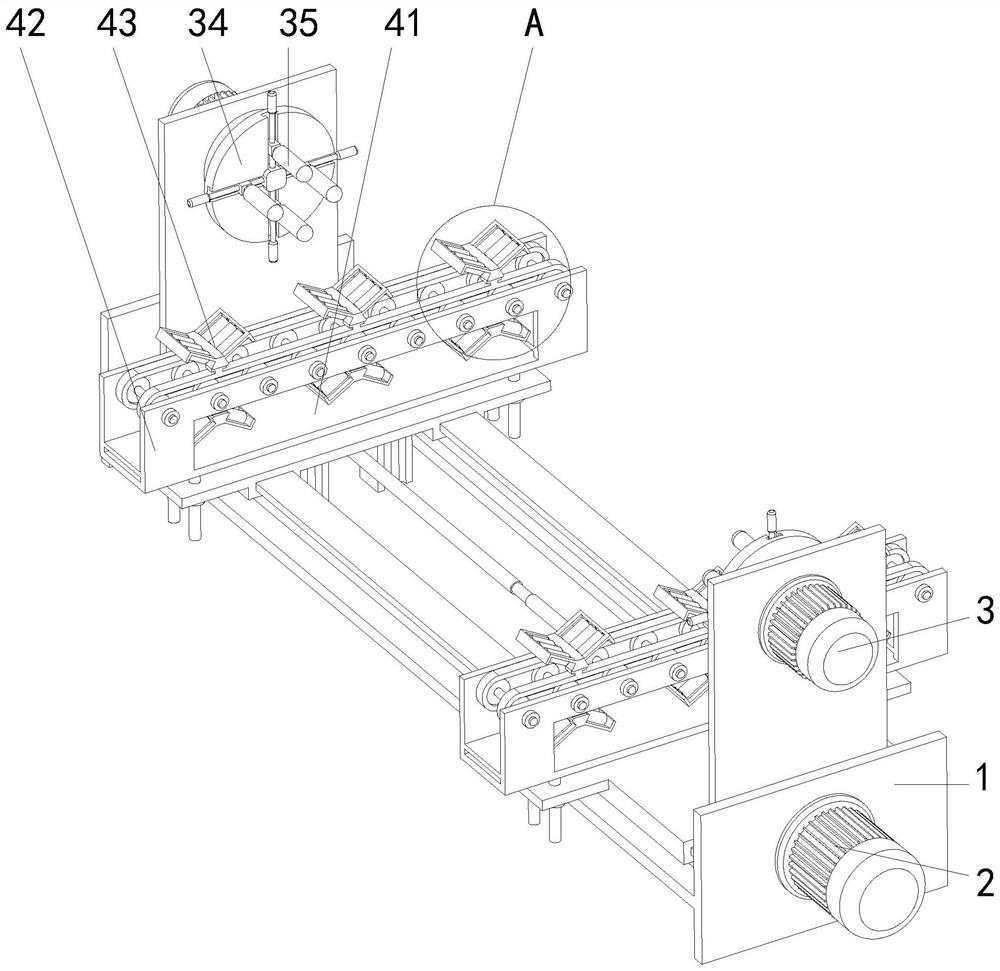

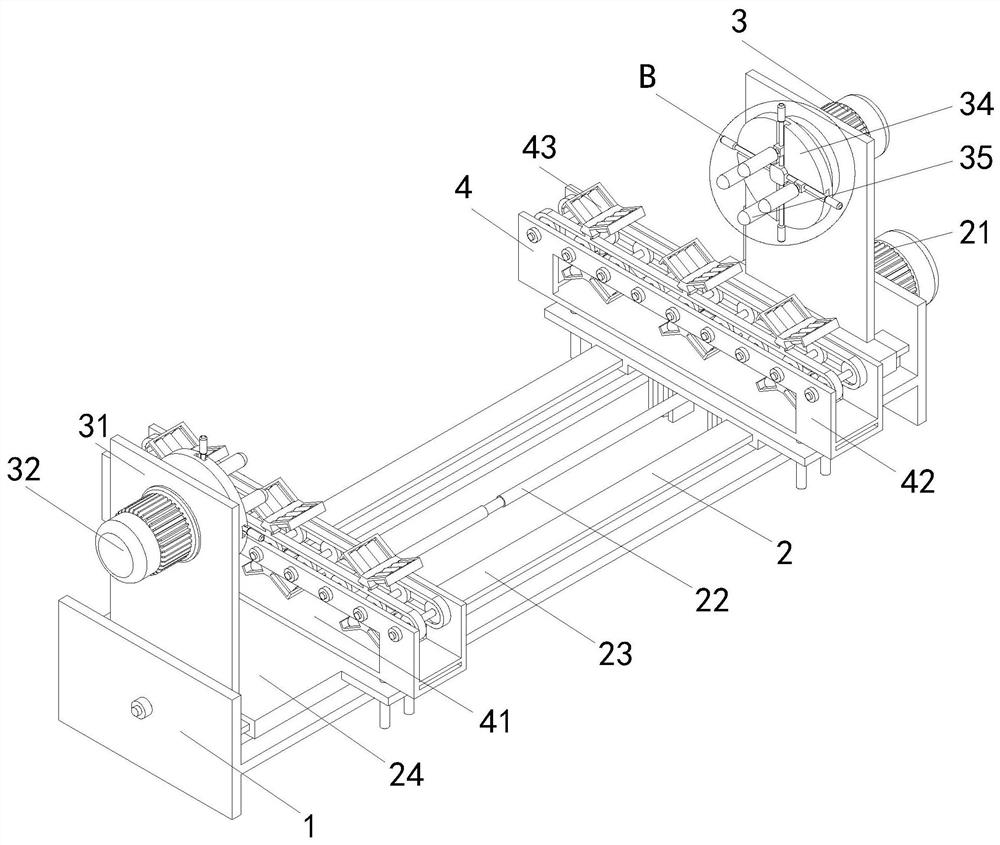

ActiveCN112718319AImprove spray processing efficiencyGuaranteed uniformitySpraying apparatusStructural engineeringMachining process

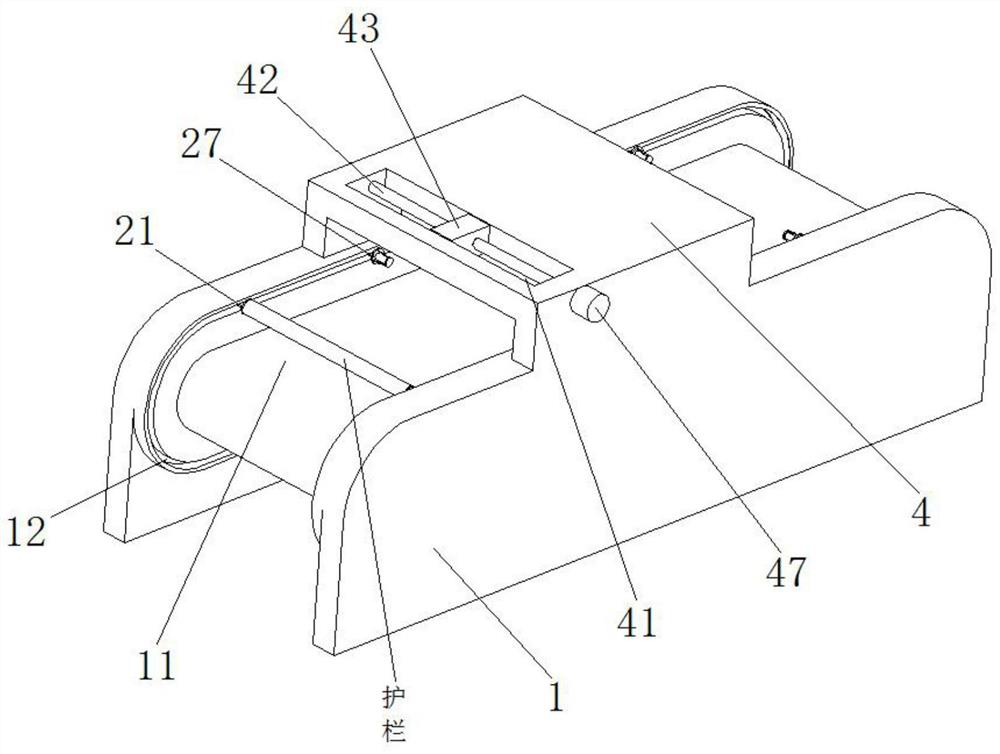

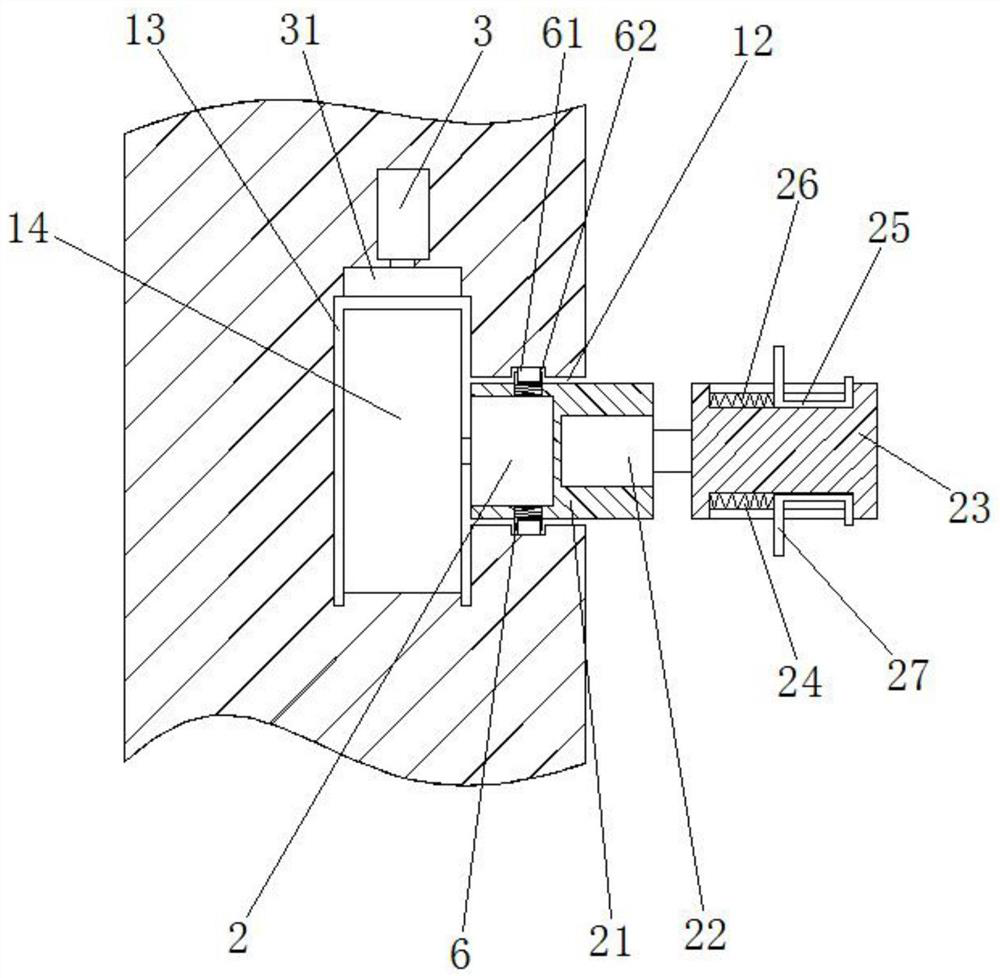

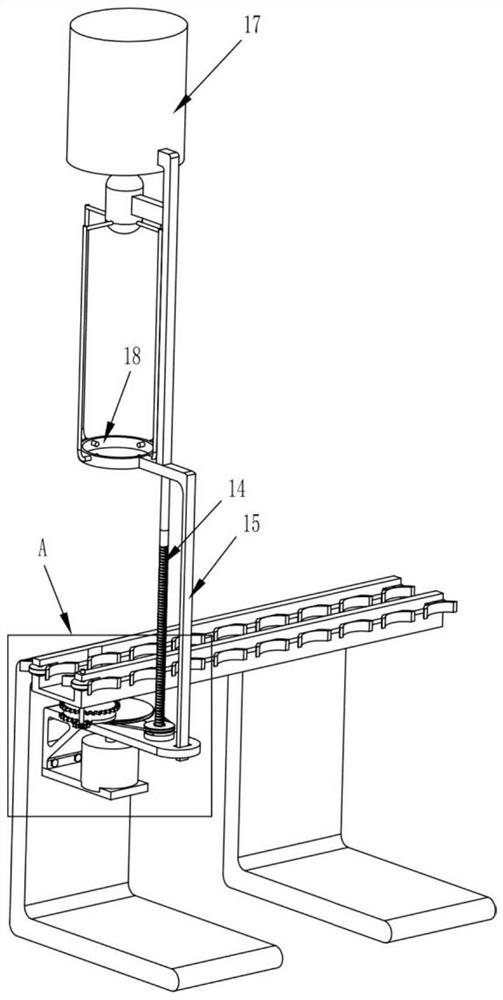

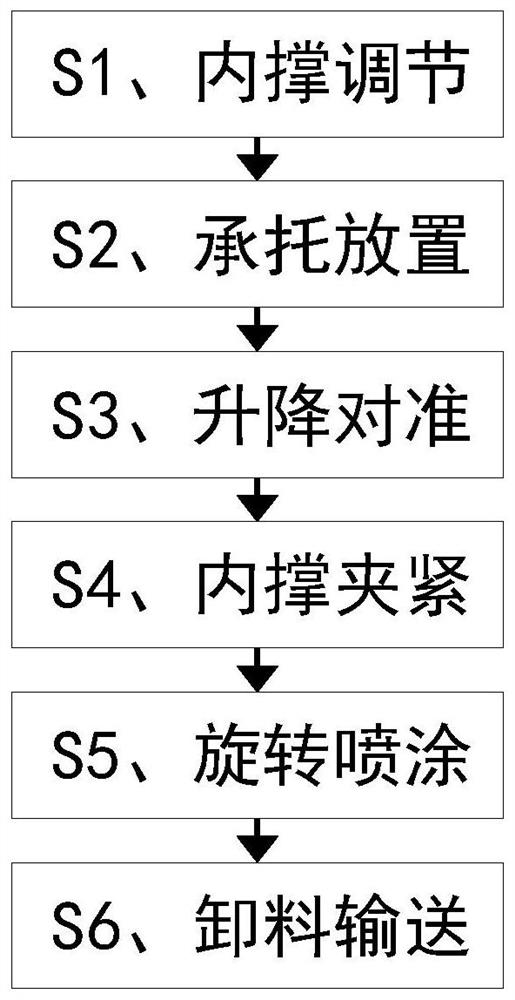

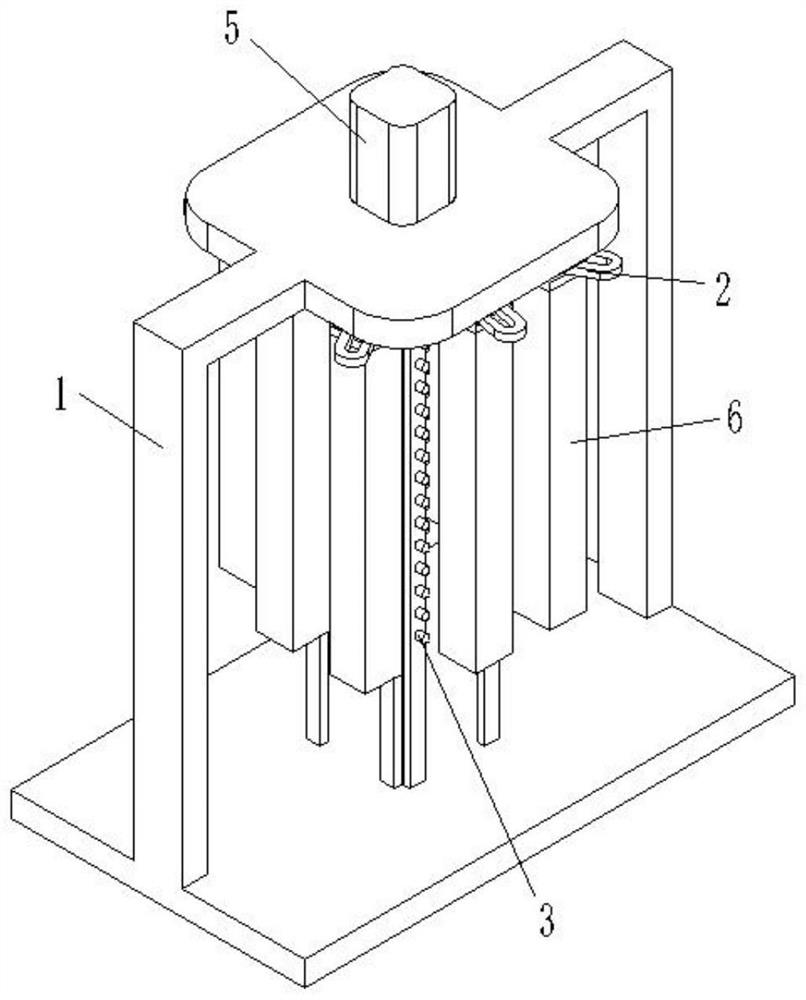

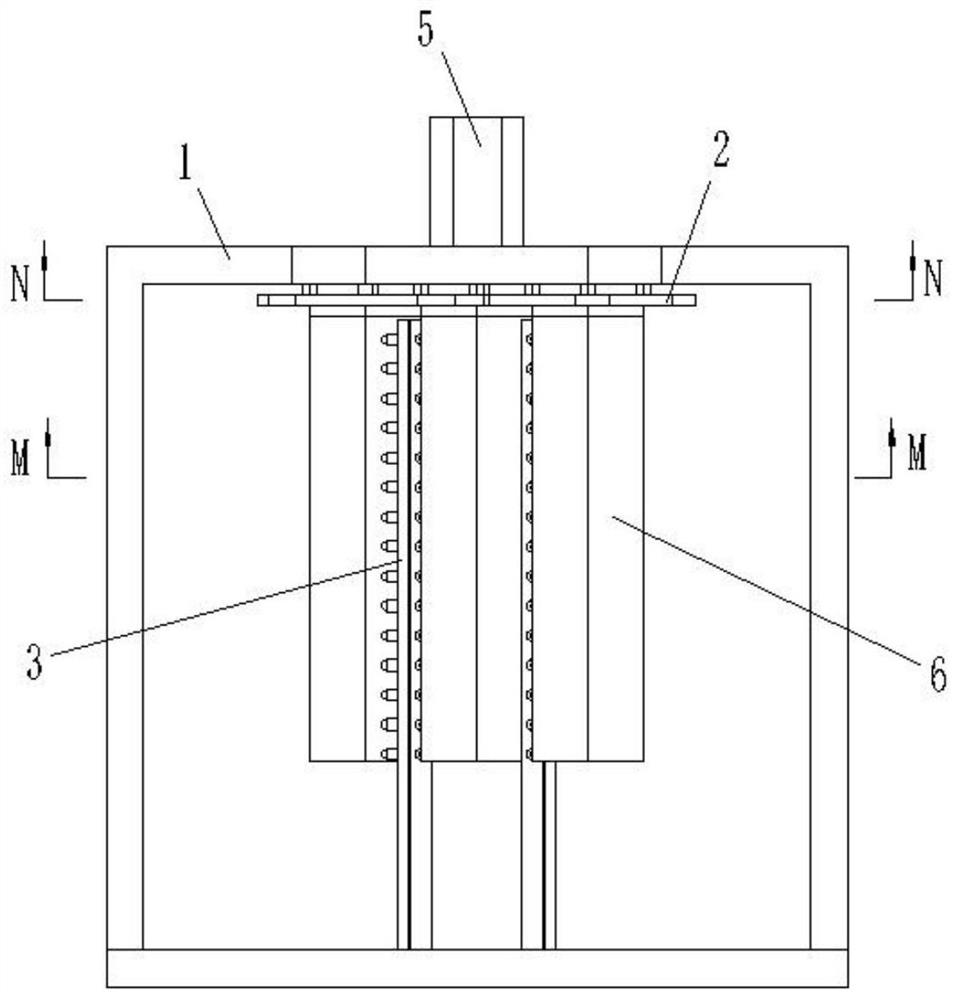

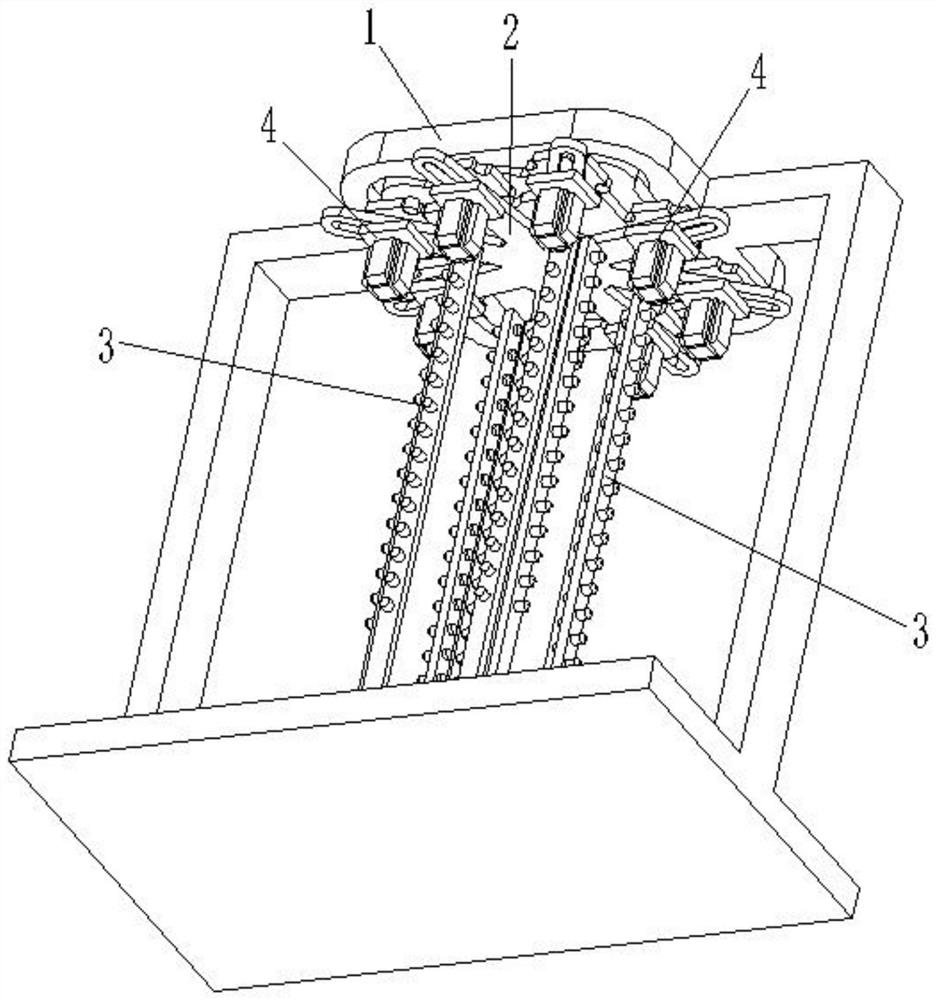

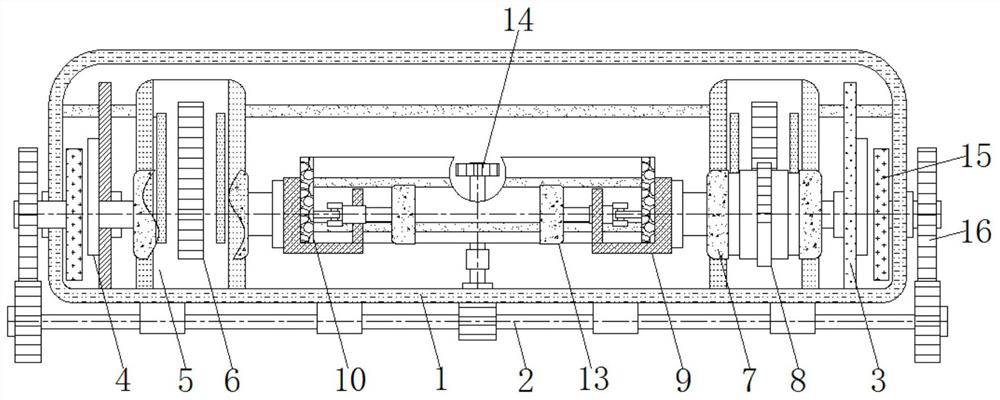

The invention relates to a machining method of a plastic-steel profile, in particular to a machining auxiliary spraying device for the plastic steel profile. The machining auxiliary spraying device comprises a base, a clamping driving mechanism, inner supporting side clamping rotating mechanisms and bearing conveying mechanisms; the clamping driving mechanism is arranged on the base, the inner supporting side clamp rotating mechanisms are correspondingly assembled on two moving platforms, the two inner supporting side clamp rotating mechanisms are oppositely arranged in a mirror image mode, the bearing conveying mechanisms are correspondingly assembled on the two moving platforms, and the two bearing conveying mechanisms are located between the two inner supporting side clamp rotating mechanisms. The device involved in the method can be matched with the spraying machining process of the circular pipe plastic steel profile to conduct spraying operation, streamlined spraying machining operation can be achieved, the machining efficiency is greatly improved, and in addition, the spraying uniformity and the spraying quality are improved in a rotary spraying mode.

Owner:西卡(广东)新型材料有限公司

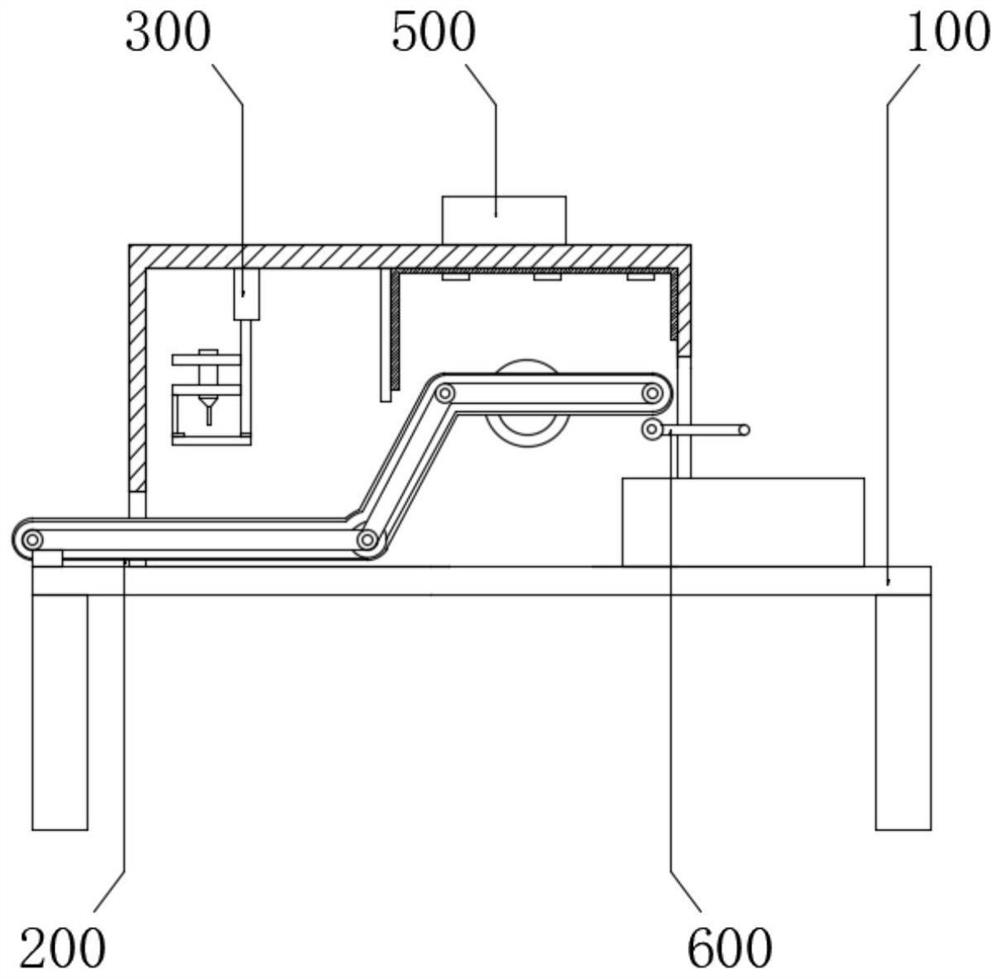

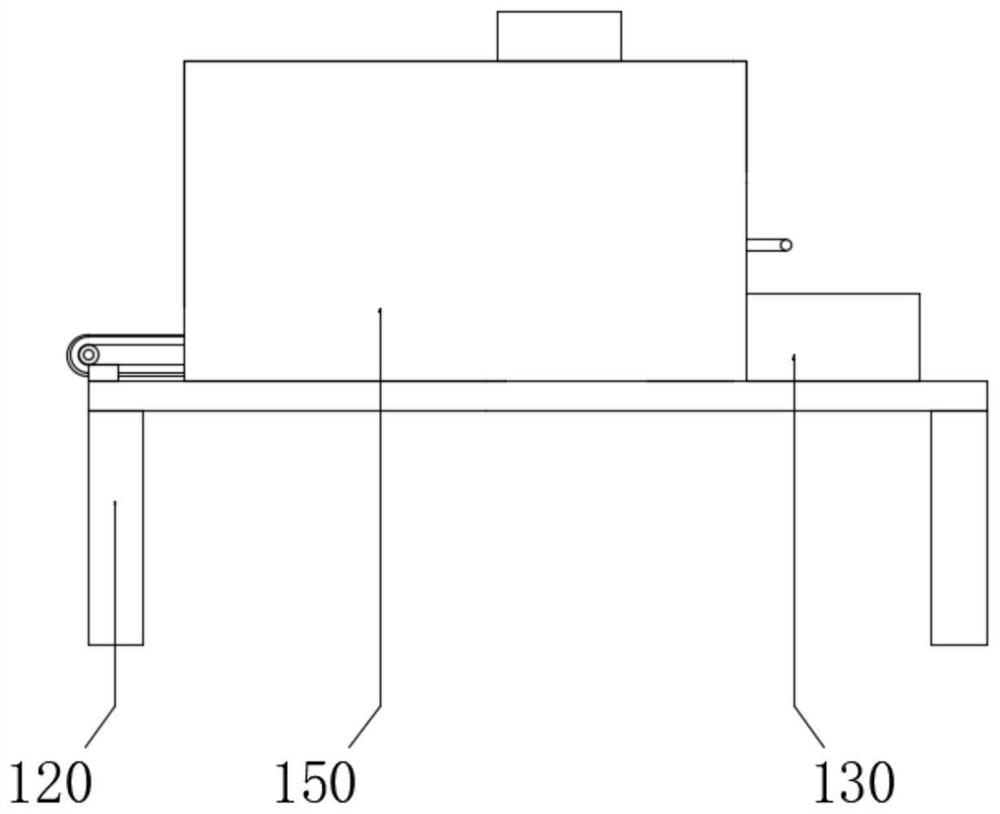

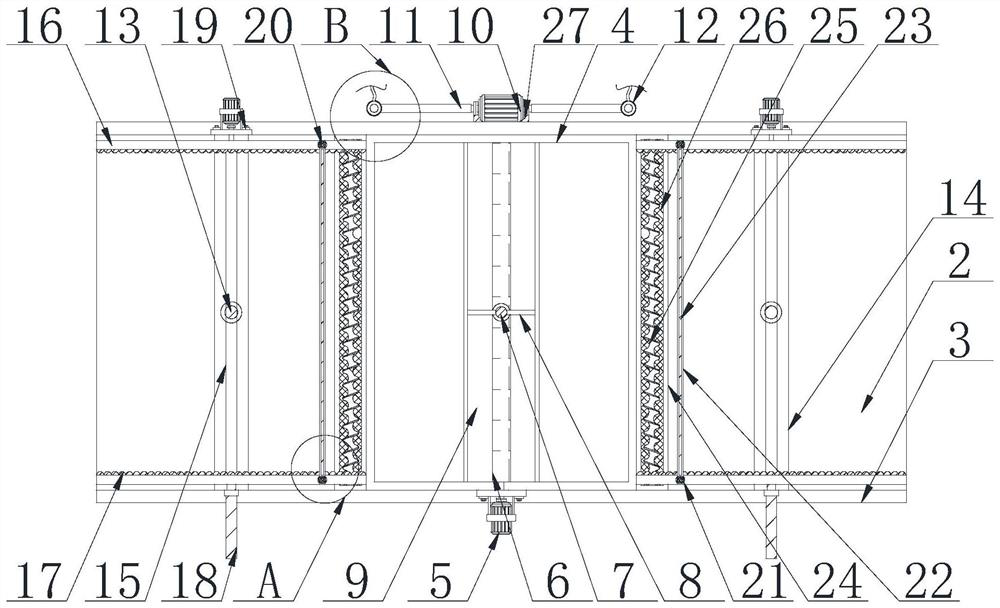

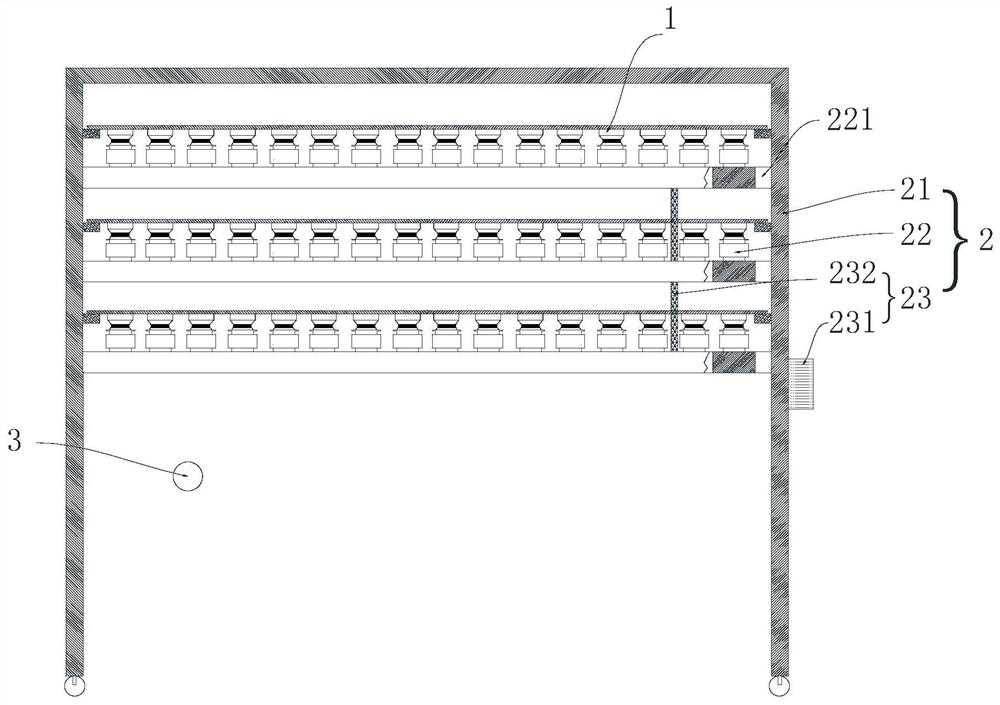

Garment fabric spraying and drying device and drying method

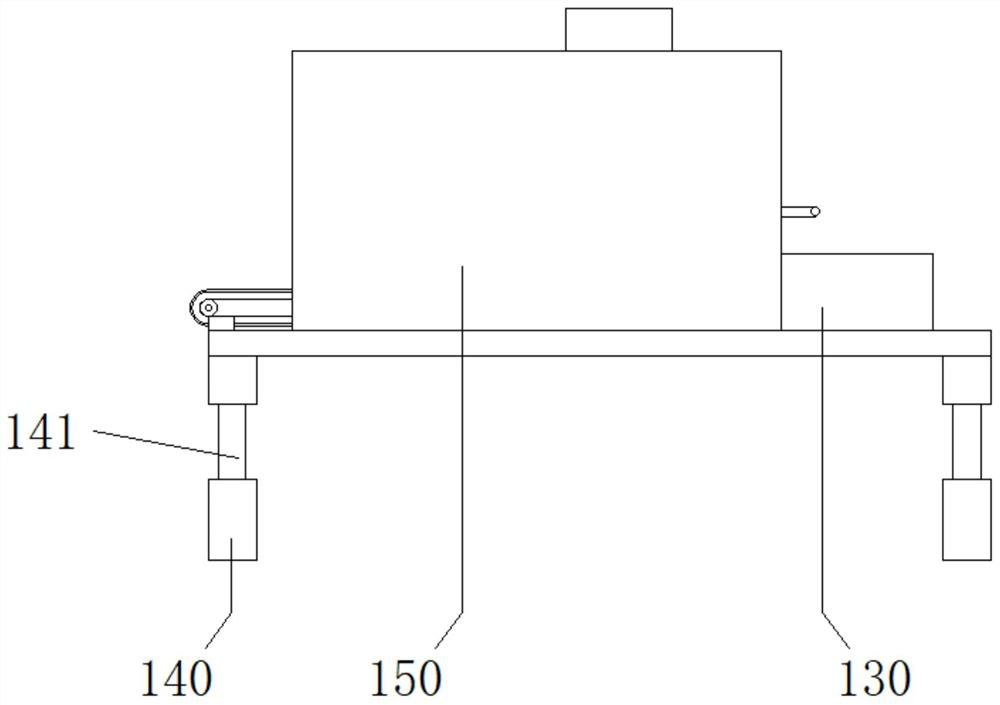

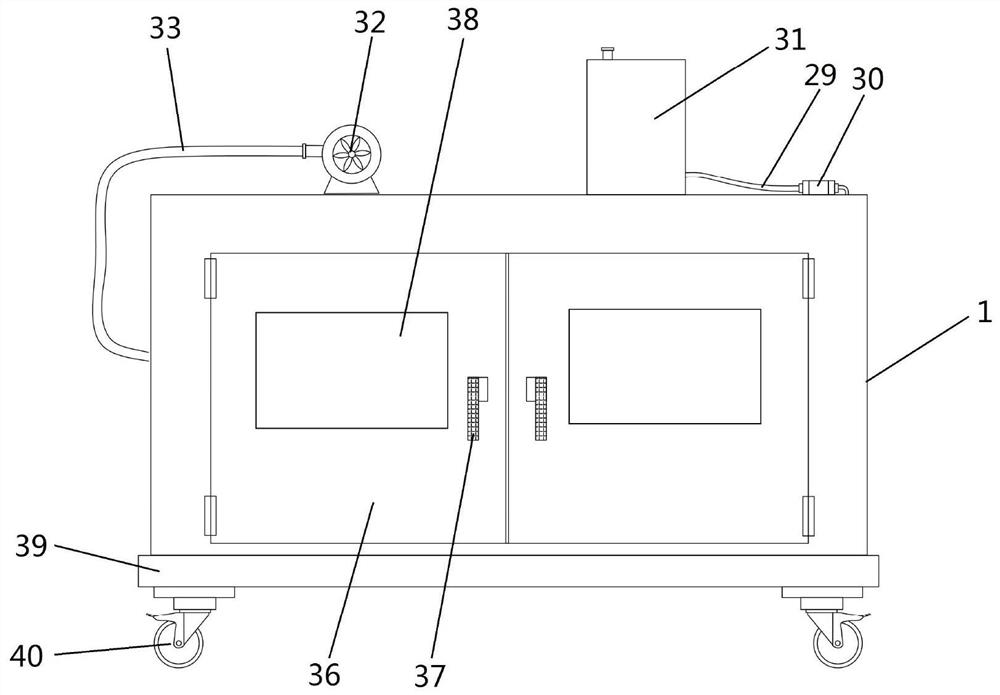

InactiveCN112718337ASimple and fast operationImprove spray processing efficiencyPretreated surfacesCoatingsIndustrial engineeringAutomatic processing

The invention provides a garment fabric spraying and drying device, and belongs to the technical field of garment processing. The garment fabric spraying and drying device comprises a rack, a conveyor, a spraying mechanism and a drying mechanism. The conveyor is located in a protective cover, the spraying mechanism comprises an electric push rod, a movable frame, a mold plate and a spray head, and the drying mechanism comprises an air heater and an air inlet pipe. During use, fabric is placed on the upper portion of the conveyor, the fabric is conveyed into the protective cover through the conveyor, the electric push rod does telescopic motion, the movable frame fixedly connected to the lower end of the electric push rod moves along with the electric push rod, the mold plate is pressed downwards to the fabric, the spray head sprays pigment, different patterns can be manufactured on the fabric through the mold plate and the spray head, then drying operation is conducted, the air heater blows hot air into the protective cover through the air inlet pipe, and coating on the fabric is dried. According to the device, operation of personnel is simple and convenient, the spraying processing efficiency is improved, and automatic processing is convenient.

Owner:周利剑

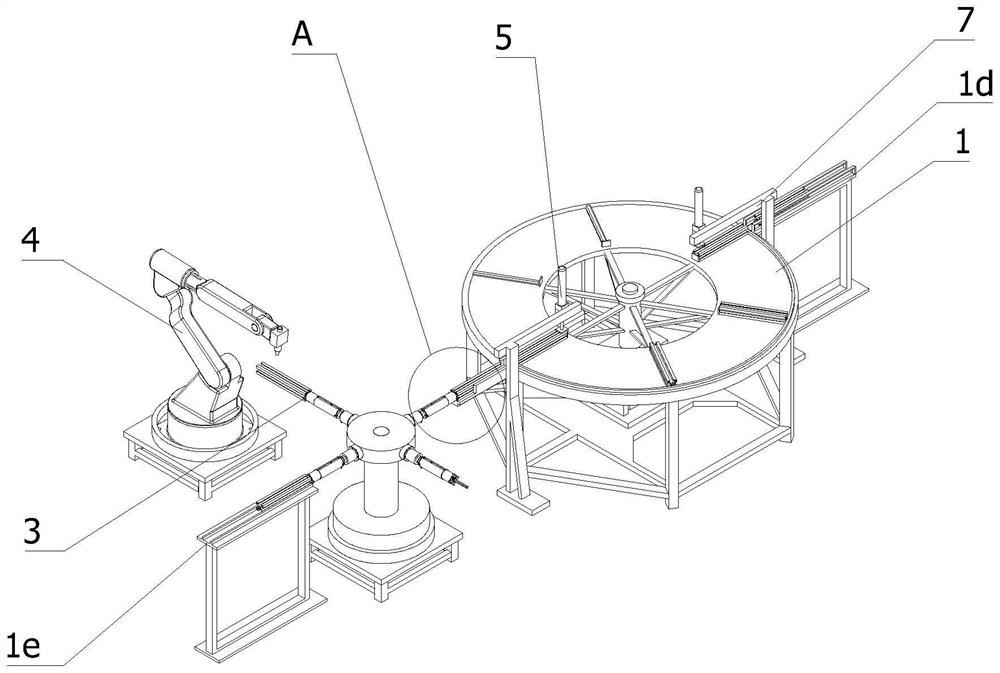

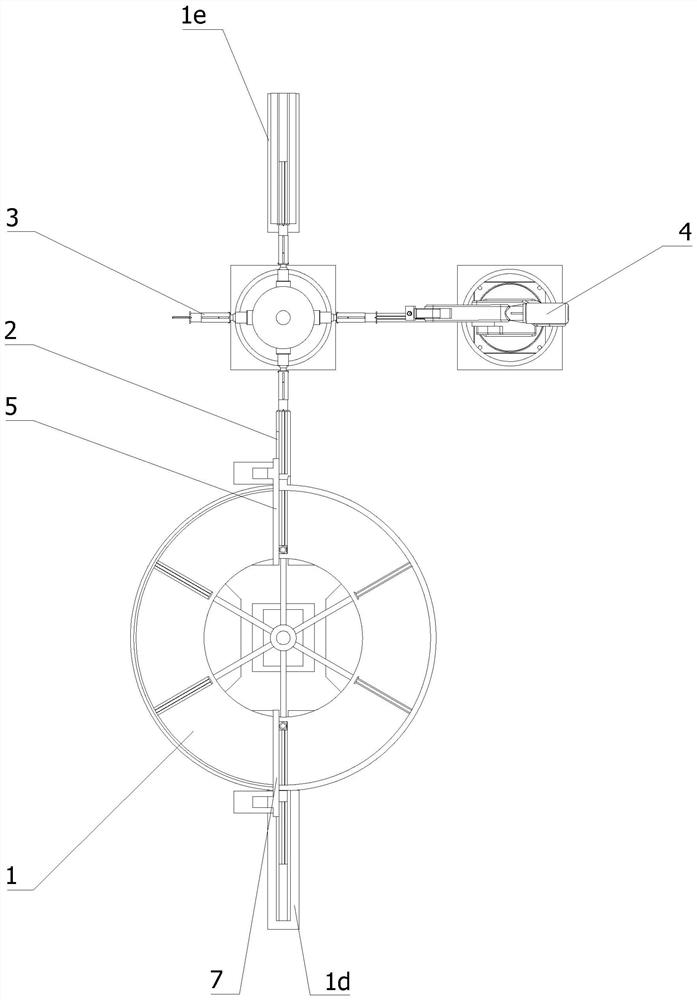

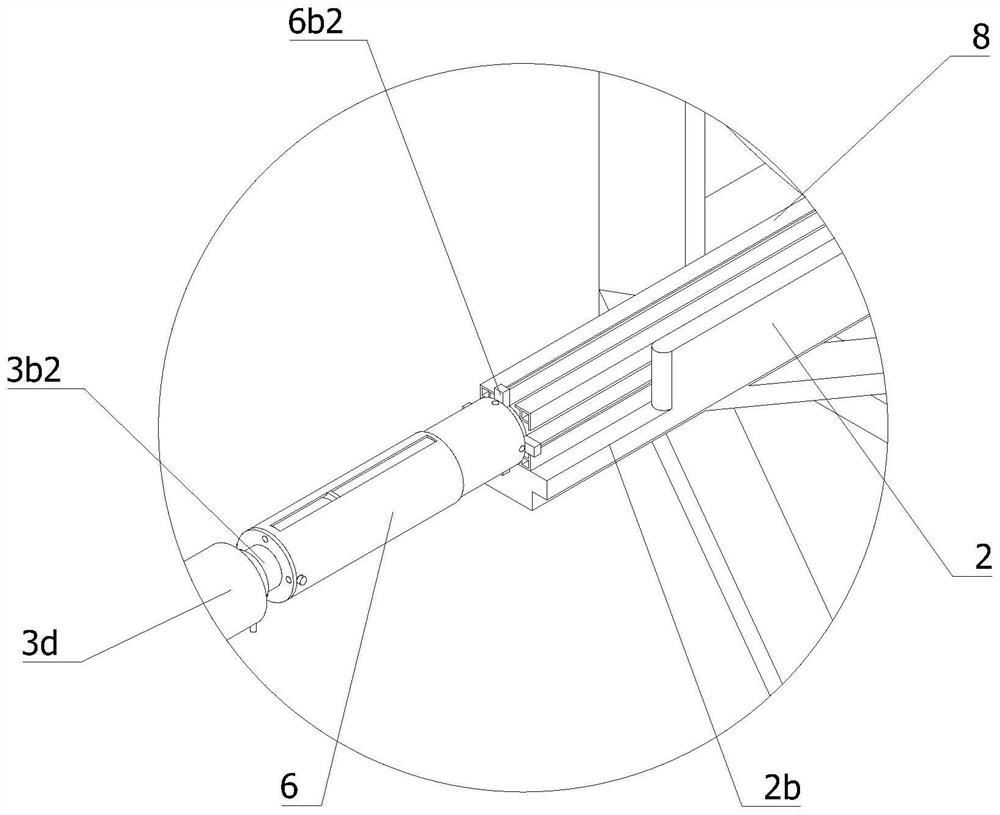

Aluminum profile spraying production line

PendingCN114558722AAchieve sprayingQuality improvementSpraying apparatusCircular discManufacturing line

The invention relates to the field of aluminum profile spraying, in particular to an aluminum profile spraying production line which comprises a rotating disc type conveying table, a pre-clamping track, a spraying robot and an auxiliary spraying device. The auxiliary spraying device comprises a disc and flexible clamping mechanisms, the flexible clamping mechanisms are arranged on the periphery of the disc and can be inserted into a through opening formed in the aluminum profile so as to fix the aluminum profile, and each flexible clamping mechanism can rotate on the disc. A rotary driver used for driving the flexible clamping mechanisms to rotate is further arranged on the disc and located at the position of each flexible clamping mechanism, each rotary driver is fixed to the disc through a machine shell, and the disc can be further rotationally arranged on a rotary table. According to the aluminum profile spraying device, the flexible clamping mechanism is inserted into an aluminum profile through opening to fix the aluminum profile, so that the surface of the clamped aluminum profile can still be completely sprayed, and the spraying quality of the aluminum profile is improved.

Owner:孟庆松

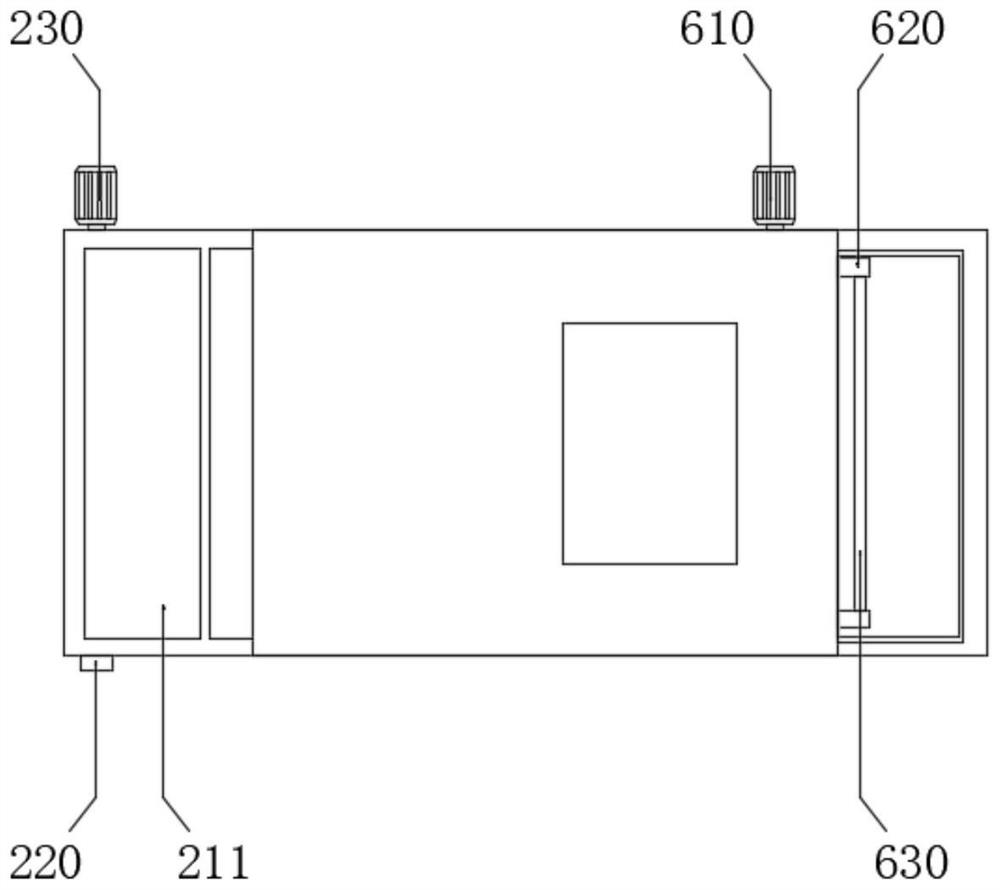

Spraying device for packaging box production and working method thereof

InactiveCN113210170AImprove spray processing efficiencyStable positionPretreated surfacesCoatingsPackaging CaseSupport plane

The invention discloses a spraying device for packaging box production and a working method thereof. The spraying device comprises a machine body shell, a feeding port and a discharging port are formed in the two ends of the machine body shell correspondingly, a supporting frame is fixedly connected to the bottom of the inner wall of the machine body shell, and a packaging box conveying belt is fixedly installed at the top of the supporting frame. The middle of one side of the inner wall of the machine body shell is fixedly provided with a conversion spraying unit, and one end of the inner wall of the machine body shell is fixedly provided with a drying and shaping mechanism. According to the spraying device for packaging box production and the working method thereof, A U-shaped spraying frame is arranged and a plurality of first spraying pieces with adjustable positions, so that the device can conduct spraying operation on multiple different point positions of a packaging box at a time, the front spraying unit and the rear spraying unit are arranged separately and driven to operate synchronously, spraying operation on the whole side wall of the packaging box is achieved, and the spraying processing efficiency is greatly improved.

Owner:霍山县雁江印务有限公司

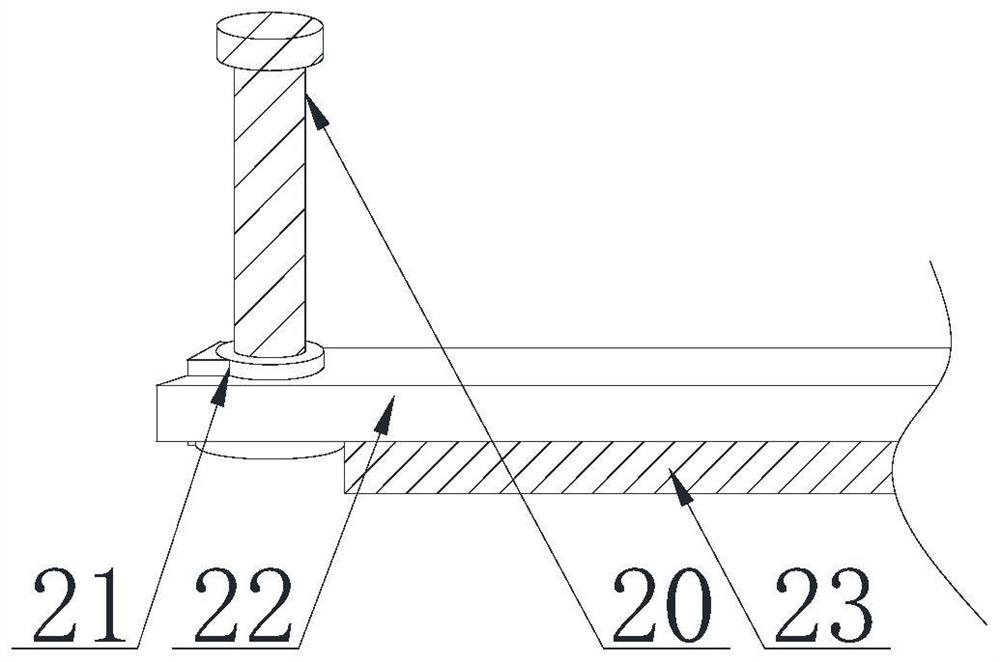

Adjustable garment fabric spraying and drying device

InactiveCN112156920ASimple and fast operationImprove spray processing efficiencyPretreated surfacesCoatingsWorking environmentEngineering

The invention belongs to the technical field of garment processing, and particularly relates to an adjustable garment fabric spraying and drying device. The device comprises a device body, a conveyor,a spraying mechanism and a drying mechanism. The device body comprises a workbench and a protective cover, wherein the protective cover is fixedly installed on the top of the workbench. Four supporting frames which are symmetrically distributed are arranged at the bottom of the workbench, hydraulic rods which are used for adjusting the heights of the supporting frames are arranged in the middlesof the supporting frames, adjusting rods which are used for adjusting the hydraulic rods to stretch out and draw back are arranged at the adjusting ends of the hydraulic rods, and connecting rods which are fixedly connected are arranged between the supporting frames. Adjusting plates capable of moving up and down are arranged in the middles of the connecting rods, the two ends of the bottom of each adjusting plate are movably connected with the corresponding adjusting rods, adjusting belts which are fixedly connected are arranged on the adjusting plates, and reset springs which are connected with the adjusting plates and the connecting rods are arranged between the adjusting plates and the connecting rods. The hydraulic rods can be utilized to drive the supporting frames to conduct heightadjustment, and the requirements of different working environments can be met as required.

Owner:周利剑

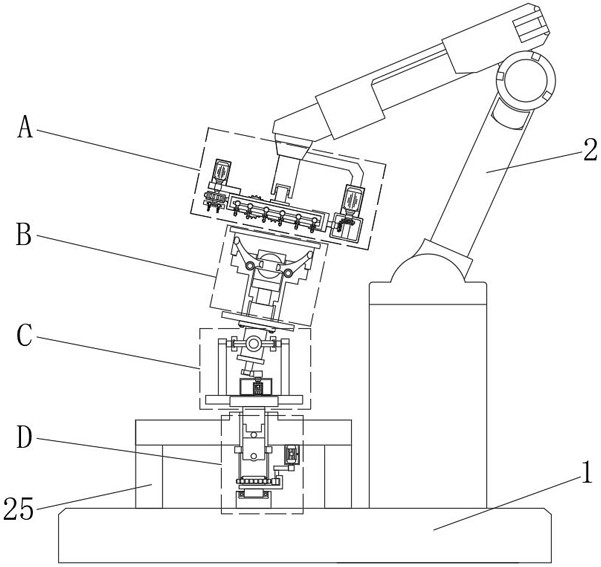

Two-dimensional code spraying device for building component

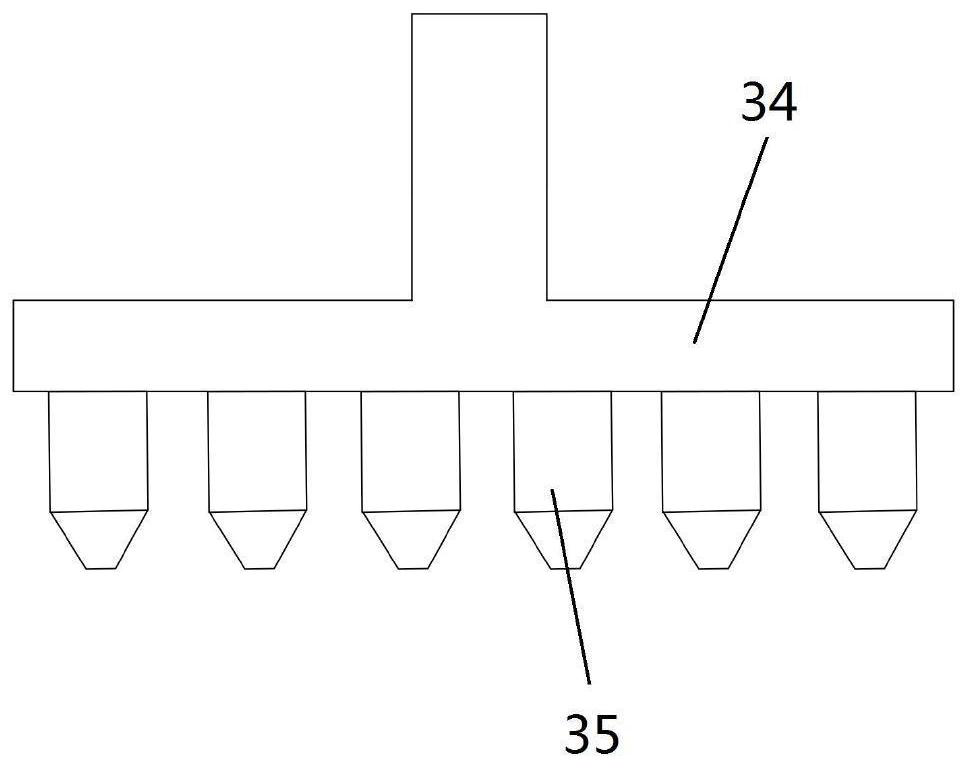

InactiveCN114083906AReduce processing timeImprove spray processing efficiencyTypewritersRobot handSprayer

The invention relates to a two-dimensional code spraying device for a building component, which comprises a base, a polygonal rotary drum and a two-dimensional code sprayer fixedly mounted on a base plate, two third supports are fixedly connected to the edge of one side of the base in the vertical direction, and the polygonal rotary drum is rotatably connected to the tops of the two third supports. a plurality of component clamping pieces are annularly distributed on the polygonal rotary drum, a storage box is fixed to the edge of the other side of the base, a two-dimensional code sprayer on the base plate sprays components in the component clamping pieces in the horizontal direction, and clamping mechanical arms are installed on the portions, located on the two sides of the two-dimensional code sprayer, of a base plate. A component to be sprayed with a two-dimensional code is installed in the polygonal rotary drum, the whole spraying and transferring operation process is completely automated, labor force is thoroughly liberated, and meanwhile the spraying machining efficiency of the component is improved.

Owner:CHINA RAILWAY CONSTR GROUP

Aluminum profile spraying system and aluminum profile spraying method

ActiveCN113171903AImprove spray qualityImprove spraying effectLiquid surface applicatorsSpraying apparatusEngineeringMaterials science

The invention belongs to the technical field of aluminum profile preparation, and discloses an aluminum profile spraying system and a spraying method. The aluminum profile spraying system comprises a supporting frame, a rotating disc, spraying head assemblies and connecting assemblies; the rotating disc is rotationally connected with the supporting frame; the connecting assemblies are connected with the rotating disc and can rotate relative to the supporting frame along with the rotating disc; the spraying head assemblies are fixedly connected with the supporting frame and rotate relative to the rotating disc in the circumferential direction; and to-be-sprayed profiles are detachably and fixedly connected with the connecting assemblies, and the surfaces, connected with the connecting assemblies, of the to-be-sprayed profiles are parallel to spraying faces formed by spraying heads in the spraying head assemblies. When aluminum profile spraying treatment is conducted by adopting the aluminum profile spraying system, the positions of the aluminum profiles in the spraying process can be adjusted, so that coatings with uniform thickness on the surfaces of the aluminum profiles are achieved, and the spraying quality and effect are improved.

Owner:广西西铝铝业有限公司

A spraying device for anti-corrosion coating on the outer layer of chemical pipelines

The invention discloses a spraying device for anti-corrosion coating on the outer layer of chemical pipelines, which can flexibly adjust the distance between the first support plate and the second support plate according to the length of the pipeline to be sprayed with anti-corrosion coating, thereby improving the ability of the spraying device to spray the pipeline It can evenly and effectively spray paint on the pipeline; through the cooperation of the telescopic bellows and the drying device, it can not only effectively protect the pipeline, but also quickly and effectively heat the paint on the surface of the pipeline to accelerate the curing of the paint , and there is no need to transfer the pipeline to the drying room for the second time, avoiding the collision and scratching of the pipeline coated with paint during the second transfer to the drying room, ensuring the integrity of the anti-corrosion coating layer on the outer surface of the pipeline, and improving the anti-corrosion coating layer of the pipeline Spraying processing efficiency; the spraying device of the present invention has a simple and reasonable structural design, high feasibility of preparation and implementation, and strong practicability.

Owner:江苏晨光涂料有限公司 +1

Auxiliary disassembly-free fixed adjustment device for wheel hub spraying based on intelligent manufacturing

ActiveCN113019749AGood fixed effectEasy to change sidesSpraying apparatusAutomotive engineeringElectric bicycle

The invention relates to the technical field of electric bicycles, and discloses an auxiliary disassembly-free fixed adjustment device for wheel hub spraying based on intelligent manufacturing. The auxiliary disassembly-free fixed adjustment device comprises a machine body, a transmission shaft is arranged on the lower surface of the machine body, a supporting plate is arranged inside the machine body, a push plate is slidably connected to the surface of the supporting plate, a side plate is arranged inside the machine body, a toothed plate is arranged on the surface of the side plate, a rotary drum is arranged on the side surface of the side plate, and a gear ring is arranged on the surface of the rotary drum. According to the auxiliary disassembly-free fixed adjustment device for wheel hub spraying based on intelligent manufacturing, through the matched use of a transmission gear and a first gear, the matched use of a rotary disc and the push plate, the matched use of the push plate and the rotary drum, the matched use of the gear ring and the toothed plate and the matched use of a shaft seat and a rotary ring, the dismounting-free surface-changing adjusting operation can be carried out on wheel hubs of an electric bicycle, the surface-changing operation of the wheel hubs is simple, the surface-changing adjusting efficiency is high, and the surface spraying processing efficiency of the wheel hubs can be effectively improved.

Owner:临海市巨丰机械有限公司

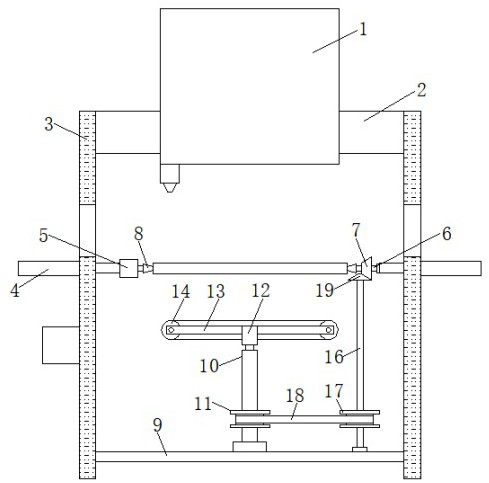

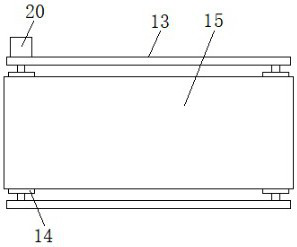

Workpiece spraying device

PendingCN114054270AImprove spray processing efficiencySpray evenlyPretreated surfacesCoatingsEngineeringPhysics

The invention discloses a workpiece spraying device which comprises a shell, a supporting frame body is arranged at the bottom in the shell, a supporting plate is installed at the top of the supporting frame body, a rotary driving mechanism is arranged at the top of the supporting plate, a spraying platform is arranged on the rotary driving mechanism, and the rotary driving mechanism can drive the spraying platform to rotate on the horizontal plane. A first clamping assembly and a second clamping assembly which are used for clamping and fixing the two ends of a workpiece are arranged on the two opposite sides of the top of the spraying platform correspondingly, the first clamping assembly can drive the clamped workpiece to turn over and rotate along the axis under the action of a turn-over mechanism, and a transmission box is installed in the middle of the top in the shell. A transmission mechanism is arranged in the transmission box, an electric telescopic rod is arranged on the transmission mechanism, the transmission mechanism can drive the electric telescopic rod to move transversely, the bottom of the electric telescopic rod penetrates through the bottom of the transmission box and is connected with a liquid spraying pipe located below the transmission box, a plurality of spraying heads are evenly installed at the bottom of the liquid spraying pipe, and an air blowing mechanism is arranged on the inner side wall of the shell.

Owner:苏州奥梦电器股份有限公司

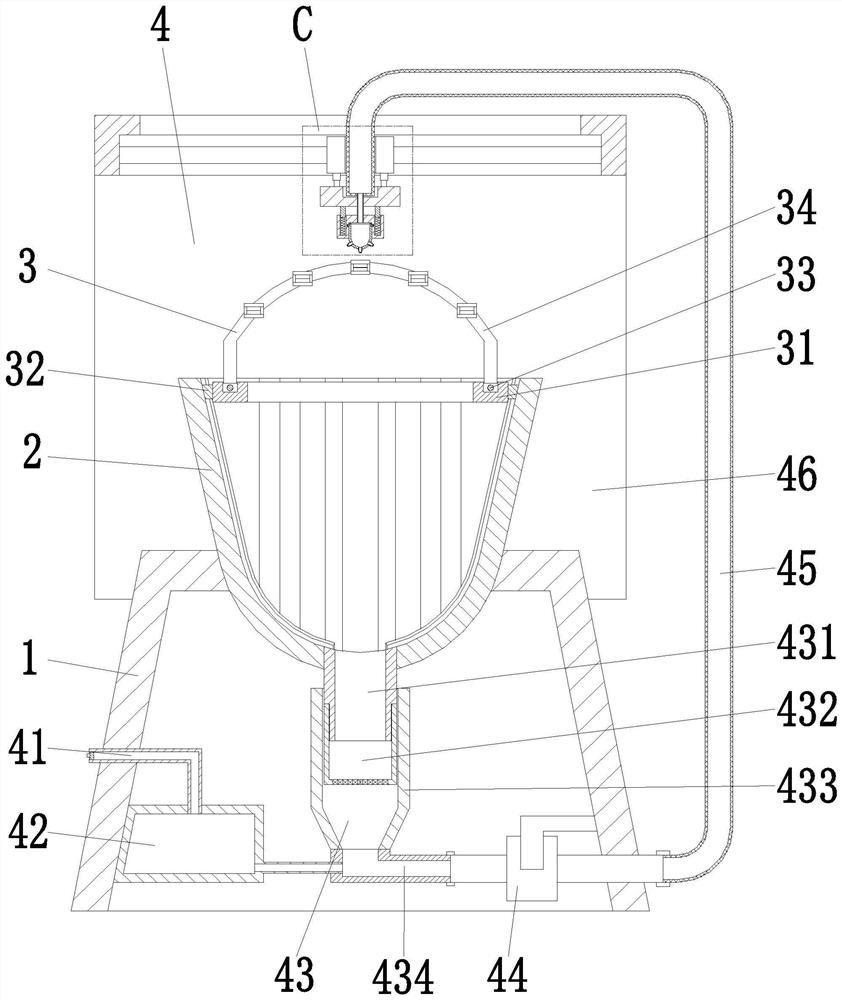

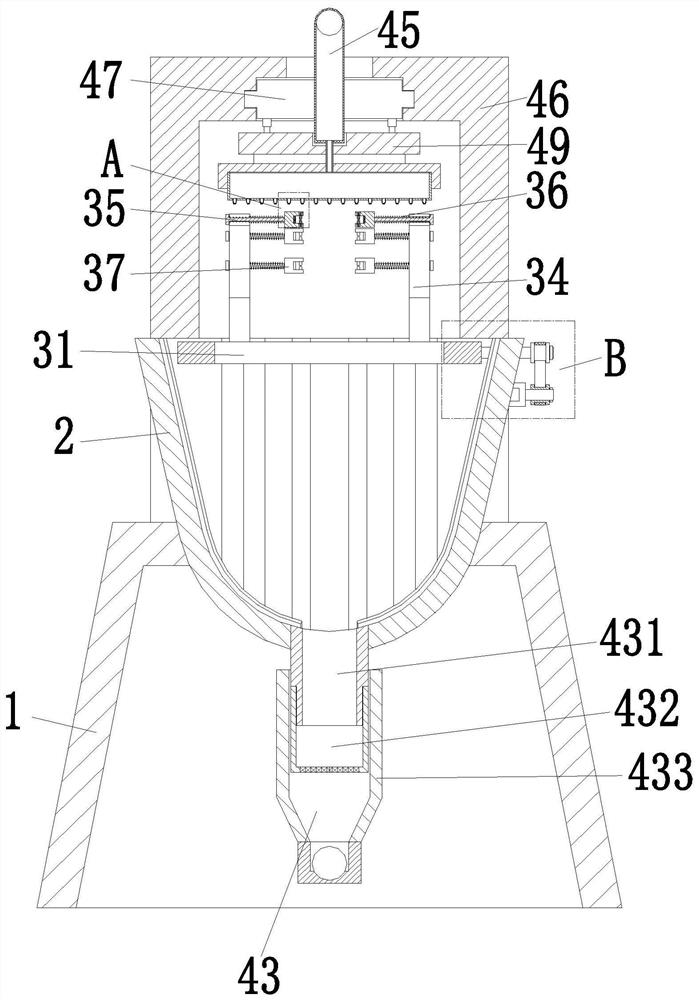

A semi-enclosed space coating equipment for building industrialization

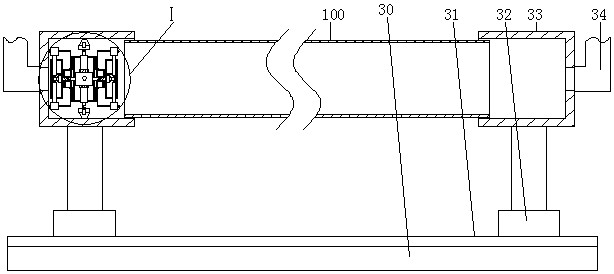

ActiveCN113477447BSmooth painted surfaceNot easy to fall offGrinding carriagesRevolution surface grinding machinesArchitectural engineeringStructural engineering

A semi-enclosed space coating equipment for construction industrialization, including a pipe clamping device, a pipeline internal walking device and a pipe inner wall coating device, the pipe clamping device can clamp and loosen the pipe, and the pipe inner wall coating device includes pipe inner wall grinding Department, pipeline inner wall spraying department, while the pipeline internal walking device reciprocates inside the pipeline, the pipe inner wall coating device can sequentially polish and spray the inner wall of the pipeline. In the present invention, the pipe is clamped by the pipe clamping device. The internal walking device of the pipe and the pipe inner wall coating device are located on the inner side of the pipe. Through the use of the present invention, the steps of first polishing and then spraying make the painting surface of the pipe inner wall smoother. The coating layer is not easy to fall off, has a longer service life, better anti-rust and anti-corrosion effects, and does not need the internal running device of the pipeline to return to its original position before processing the replaced pipe, which improves the spraying processing efficiency.

Owner:浙江中垚建设有限公司

A device for spraying the surface of medical knives

ActiveCN113414034BRealize automatic sprayingImprove spray processing efficiencySpray boothsElectric machineryEngineering

The invention discloses a medical knife surface spraying device, which comprises a support frame. A through hole is opened on the side wall of the support frame, and a double-head motor is fixedly connected in the through hole. One end of the double-head motor is provided with a A fixture for holding a medical tool, a spraying mold is provided at the end of the double-headed motor away from the fixture, and a spraying assembly is provided at the upper end of the support frame. In the present invention, by setting up the spraying assembly, when spraying medical knives of different specifications and sizes, the linear motor is used to drive the cross bar to move back and forth, and the control assembly and the spray gun are driven to move on the fixture and mold that need to be sprayed respectively. When it reaches the mould, the spray gun is sprayed synchronously, and different spraying molds can be replaced according to the tools that need to be sprayed, so as to realize automatic spraying of different types of medical knives and improve the spraying processing efficiency of medical knives.

Owner:江苏优创生物医学科技有限公司

A protection device based on sand blowing and spraying on the mounting edge of the casing

ActiveCN110496727BEasy loading and unloadingEasy clampingSpraying apparatusAbrasive machine appurtenancesRotational axisElectric machine

Owner:永嘉县纳海川科技有限公司

Surface spraying device and spraying method for wooden door production

InactiveCN114798247AConvenient spray processingEasy to paint multiple timesPretreated surfacesCleaning using toolsSynchronous motorStructural engineering

The invention discloses a surface spraying device for wooden door production and a spraying method.The surface spraying device comprises four supporting columns, a bottom plate, a bidirectional synchronous motor, a connecting frame and a spraying pipe, a fixing frame is fixedly connected to the middle of the interior of the bottom plate, a fixing frame is rotatably connected to the middle of the interior of the fixing frame, and limiting frames are slidably connected to the two sides of the fixing frame; a second servo motor operates and is matched with an electric telescopic rod and a second hydraulic rod to operate at the same time, so that rotation adjustment of the wooden door at the two ends of the bottom plate is achieved, spraying machining on the two sides of the wooden door is facilitated, the spraying machining effect is improved, meanwhile, the two sides of the wooden door are conveniently matched to be subjected to back-and-forth and circulating multiple times of paint spraying machining, and the spraying machining efficiency is improved. The spraying processing efficiency is greatly improved; and meanwhile, an electric heating wire fixedly connected to the middle of the interior of the protection frame is matched with a filter screen, so that the paint-sprayed face is aired and assisted by being matched with rotation adjustment of the wooden door, the wooden door is conveniently matched to be painted for multiple times, and the overall spraying efficiency of the wooden door is greatly improved.

Owner:安徽智扬门业股份有限公司

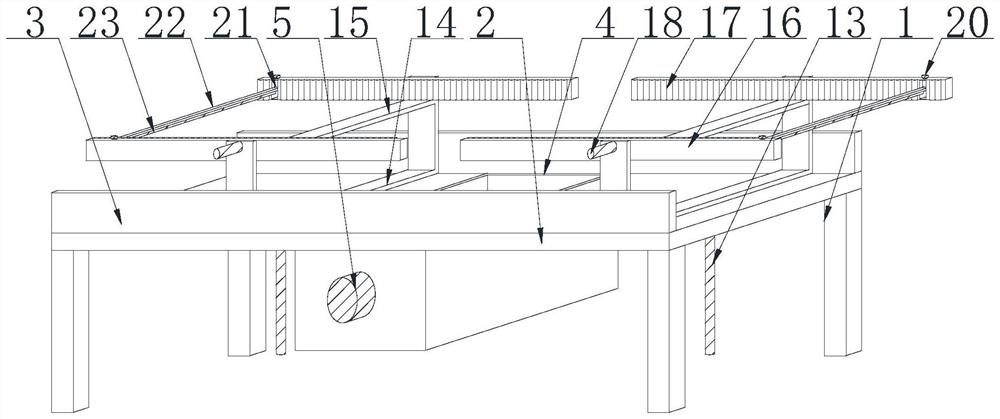

a protective device

ActiveCN106607299BIncrease the tilt angleHigh degree of automationLiquid surface applicatorsCoatingsBall screwDriving mode

The invention relates to a protective device. The protective device comprises a base. Trays are arranged above the base and connected with rotating shafts. Belt wheels A are connected with the upper portions of the rotating shafts, and a driving belt A is connected between the belt wheels A in a driving mode. A gear A is connected with the lower portion of the rotating shaft located on the front side, and meshed with a gear B. The gear B is connected with a motor and coaxially connected with a belt wheel B. A ball screw is arranged on the right side of the motor, a belt wheel B is connected with the lower portion of the ball screw, and a driving belt B is connected between the two belt wheels B in a driving mode. An L-shaped driving frame is connected with the upper portion of the ball screw in a threaded mode and connected with a guide rod in a sliding mode. Spray guns are arranged on the rear side of the L-shaped driving frame, a U-shaped groove is formed in the spray gun close to the front side, and the left ends of the spray guns are installed on the base in a hinged mode. According to the protective device, the inclination angle of each spray gun can be increased through lead screw driving so as to achieve the effect that protective liquid is automatically poured to conduct spraying protection, the degree of automation is high, control is easy, and the spraying processing efficiency is high.

Owner:ANHUI GUANGMING GRAIN & OIL IND

A kind of wheel hub spray-assisted non-disassembly fixing adjustment device based on intelligent manufacturing

The invention relates to the technical field of electric bicycles, and discloses a wheel hub spraying auxiliary disassembly-free fixing adjustment device based on intelligent manufacturing, which includes a body, a transmission shaft is arranged on the lower surface of the body, and a support plate is arranged inside the body. The surface of the support plate is slidably connected with a push plate, the inside of the body is provided with a side plate, the surface of the side plate is provided with a tooth plate, the side of the side plate is provided with a drum, and the surface of the drum is A ring gear is provided, and the wheel hub spraying auxiliary disassembly-free fixing adjustment device based on intelligent manufacturing is used through the cooperation of the transmission gear and gear one, the cooperation of the turntable and the push plate, the cooperation of the push plate and the drum, the cooperation of the ring gear and the tooth The combined use of the plate, the shaft seat and the swivel can be used to adjust the surface of the wheel hub of the electric bicycle without disassembly. s efficiency.

Owner:临海市巨丰机械有限公司

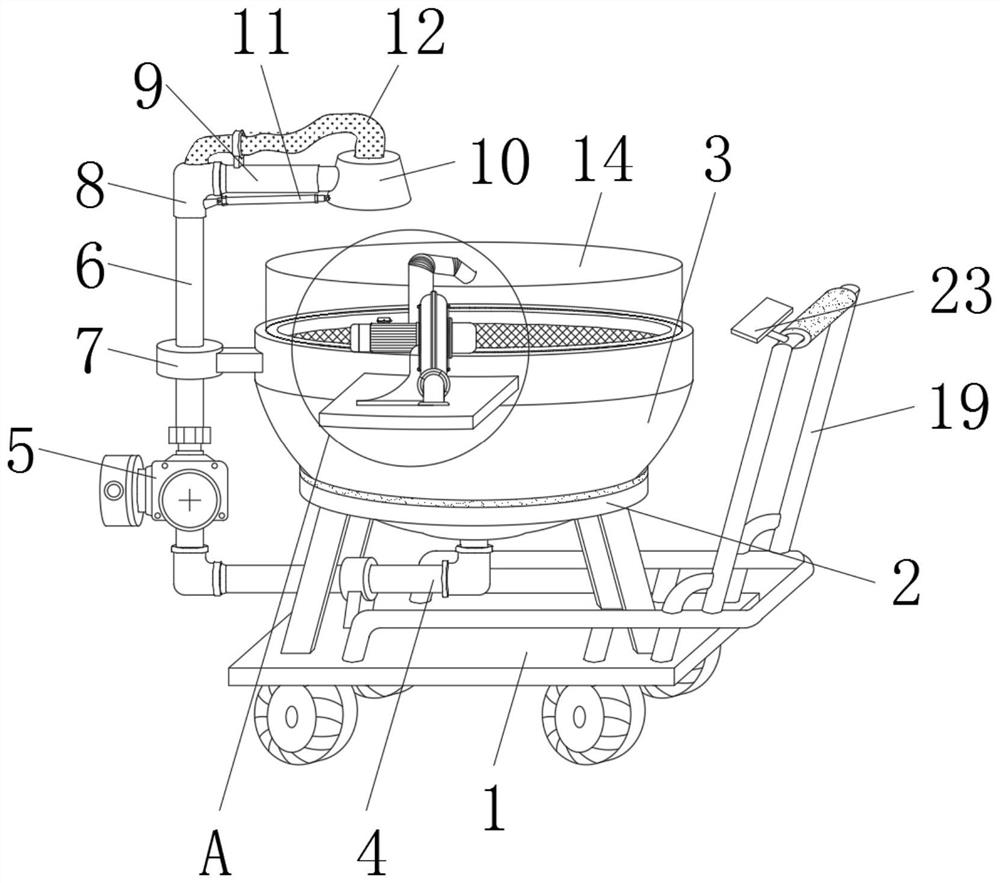

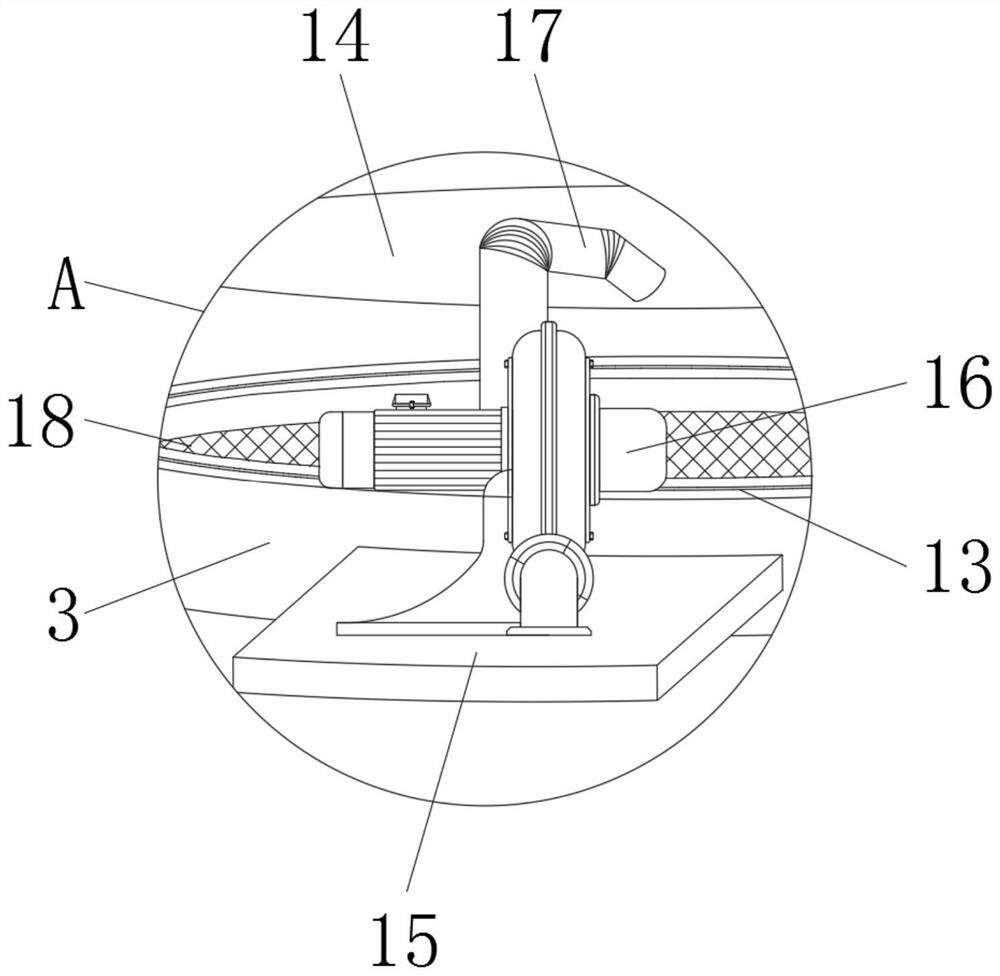

Spraying device for machining of metal parts of fitness equipment

InactiveCN113814100AImprove spray efficiency and uniformityImprove efficiencyPretreated surfacesLiquid spraying apparatusPneumatic cylinderManufacturing engineering

The invention discloses a spraying device for machining of metal parts of fitness equipment. The spraying device comprises a base, an arc-shaped bracket is mounted at the top of the base, a storage bin is arranged at the top of the arc-shaped bracket, a flow guide pipe is communicated with the middle position of the bottom of the storage bin, and a water pump is mounted at the other end of the flow guide pipe. A connecting pipe is installed at the output end of the water pump, an L-shaped rotary connecting piece is arranged at the other end of the connecting pipe, a telescopic pipe is installed at the other end of the L-shaped rotary connecting piece, and an annular cover is installed at the other end of the telescopic pipe. By arranging the connecting pipe, the L-shaped rotary connecting piece, the telescopic pipe, a rotating bead and a pneumatic cylinder, the spraying position of a spray head can be accurately adjusted through rotation and contraction of the pneumatic cylinder, concentrated spraying can be conducted on the single position, when the pneumatic cylinder stretches out and draws back in a reciprocating manner, the metal parts in a larger range can be sprayed in a reciprocating manner, and the spraying efficiency and uniformity are improved.

Owner:宁国市畅翔碾磨材料有限公司

A pedal manufacturing and processing equipment for truck brake pedal assembly

ActiveCN113499887BEasy to fixImprove spray processing efficiencySpray nozzlesLiquid spraying apparatusTruckSupport plane

Owner:JIANGSU SHUANGJU AUTOMOBILE PARTS

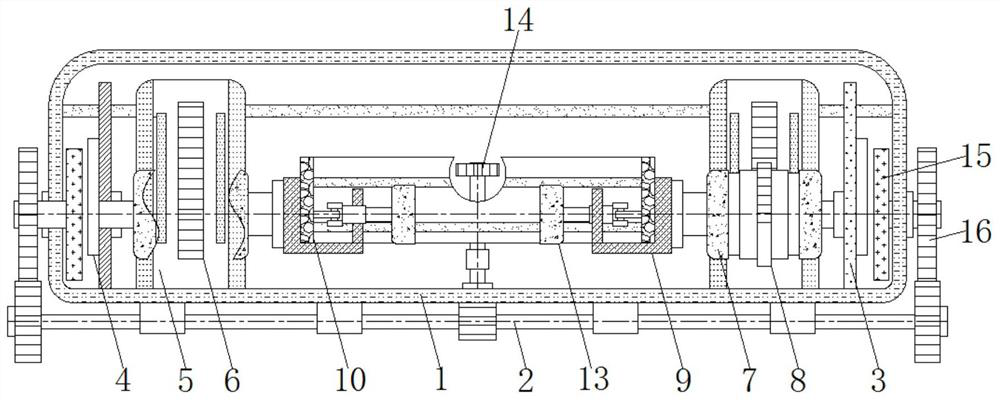

A Plasma Spraying Method Applicable to Small Diameter Ring Parts

ActiveCN110760780BIncrease heat gap timeIncrease coverageMolten spray coatingChromium carbideThermal spraying

The invention discloses a plasma spraying method suitable for small-diameter ring parts, which belongs to the field of thermal spraying processing, and comprises the following steps in sequence: using a grinding wheel to blast the surface roughness of the parts to be sprayed to 2 μm-3.5 μm, and using compressed air to Blow off the residual sand on the parts to be sprayed; clamp multiple parts to be sprayed on the spraying fixture in sequence, and only expose the area to be sprayed of the parts to be sprayed; put the nickel-chromium chromium carbide powder into the powder feeding mechanism of the plasma spray gun ; Set the spray gun to move in a "Z shape" along the vertical direction of the part's rotation axis for spraying; the invention makes the spraying flame cover more comprehensively on the part surface, improves the spraying processing efficiency, and lengthens the heating gap time of each part, and the part surface The temperature is not easy to overheat.

Owner:AECC AERO SCI & TECH CO LTD

Protective device

ActiveCN106607299AIncrease the tilt angleHigh degree of automationLiquid surface applicatorsCoatingsBall screwEngineering

The invention relates to a protective device. The protective device comprises a base. Trays are arranged above the base and connected with rotating shafts. Belt wheels A are connected with the upper portions of the rotating shafts, and a driving belt A is connected between the belt wheels A in a driving mode. A gear A is connected with the lower portion of the rotating shaft located on the front side, and meshed with a gear B. The gear B is connected with a motor and coaxially connected with a belt wheel B. A ball screw is arranged on the right side of the motor, a belt wheel B is connected with the lower portion of the ball screw, and a driving belt B is connected between the two belt wheels B in a driving mode. An L-shaped driving frame is connected with the upper portion of the ball screw in a threaded mode and connected with a guide rod in a sliding mode. Spray guns are arranged on the rear side of the L-shaped driving frame, a U-shaped groove is formed in the spray gun close to the front side, and the left ends of the spray guns are installed on the base in a hinged mode. According to the protective device, the inclination angle of each spray gun can be increased through lead screw driving so as to achieve the effect that protective liquid is automatically poured to conduct spraying protection, the degree of automation is high, control is easy, and the spraying processing efficiency is high.

Owner:ANHUI GUANGMING GRAIN & OIL IND

Rust-proof and corrosion-resistant electrostatic powder spraying device for refrigerator shell

PendingCN112934499AAdjust the conveying directionConvenient automatic flangingLiquid spraying plantsIceboxElectric machinery

The invention discloses an anti-rust and anti-corrosion electrostatic powder spraying device for a refrigerator shell, relates to the technical field of refrigerator shell machining, and aims to solve the problems that the efficiency is low and the labor cost is increased due to the fact that manual turnover is needed during existing electrostatic powder spraying. According to the scheme, the anti-rust and anti-corrosion electrostatic powder spraying device comprises a spraying box, supporting plates are fixedly connected to the two sides of the spraying box, clamping and overturning mechanisms are arranged on the sides, away from each other, of the two supporting plates, a carrying plate is fixedly connected to the bottom between the two supporting plates, a second push rod motor is rotationally connected to the top of the carrying plate, a conveying mechanism is fixedly connected to the top of the second push rod motor, and a transmission mechanism is arranged on the second push rod motor. According to the device, the shell can be conveniently and automatically subject to edge turning, labor is saved, and efficiency is high; the other side of the shell is sprayed and discharged through edge turning, and the spraying machining efficiency of the shell is improved.

Owner:滁州市友邦涂装有限公司

A shell processing technology for communication equipment

ActiveCN112718346BImprove spray processing efficiencyAchieve steeringPretreated surfacesCoatingsNumerical controlEngineering

The invention discloses a shell processing technology for communication equipment. The shell processing process specifically includes the following steps: Step 1: forming the main body of the communication equipment shell through injection molding or casting processing; Step 2: putting the main body of the communication equipment shell into the Grinding and drilling on the CNC machine tool to obtain the main body of the forming shell; Step 3: Put the main body of the forming shell into the spray drying equipment for spraying and drying processing, first put the main body of the forming shell on the conveying roller of the first arc frame , the main body of the molded shell is sent into the first drying and spraying box through the conveying roller on the first arc-shaped frame. The present invention automatically turns over the spraying of the shell by setting the turning assembly, and realizes the automatic turning over of the shell by using the turning and steering mechanism And turning, spraying treatment on different positions of the surface of the shell uniformly, a drying mechanism is set in the box to dry the surface after spraying in time, so as to ensure the quality of spraying while improving the processing efficiency.

Owner:ANHUI FEIKAI ELECTRONICS TECH CO LTD

Spraying equipment for spherical parts with auxiliary positioning structure for general machinery

ActiveCN112871512BEasy to limitAffect the quality of the finished productSpraying apparatusElectric machineEngineering

The invention relates to the technical field of mechanical processing, in particular to a spherical part spraying equipment with an auxiliary positioning structure for general machinery, including a base, a hydraulic telescopic rod, a first motor, a second motor, a third motor, a fourth motor, a pneumatic telescopic Rod and the fifth motor, a hydraulic telescopic rod is fixedly installed on the top side of the base, and a first connecting rod is fixedly connected to the end of the hydraulic telescopic rod away from the base. The present invention is provided with a clamping rod, and by starting the fourth motor, the fourth motor drives the oblique rotation rod to rotate, so that the oblique rotation rod drives the rocker to take the first connecting shaft as the axis, so that the bottom end and the top end of the rocker are circular The movement makes it easy for the rocker to drive the spherical parts to shake inside the limit barrel, and it is convenient to spray the surface of the clamping rod comprehensively, avoiding uneven spraying on the surface of the spherical parts and affecting the quality of the spraying, and at the same time improving the spraying efficiency of the spherical parts.

Owner:HUANGHE JIAOTONG UNIV

A processing device integrating protection, loading and unloading

ActiveCN106607300BHigh degree of automationImprove spray processing efficiencyLiquid surface applicatorsCoatingsEngineeringIn degree

Owner:ANHUI GUANGMING GRAIN & OIL IND

A method for processing plastic steel profiles

ActiveCN112718319BImprove spray processing efficiencyGuaranteed uniformitySpraying apparatusStructural engineeringMechanical engineering

The present invention relates to a method for processing plastic steel profiles, in particular to an auxiliary spraying device for processing plastic steel profiles, which includes a base, a clamping drive mechanism, an inner support side clamp rotation mechanism and a supporting conveying mechanism; the clamping drive mechanism is set on On the base, the two moving platforms are correspondingly equipped with the inner support side clamp rotation mechanism, and the two inner support side clamp rotation mechanisms are arranged opposite to each other in a mirror image, and the two mobile platforms are correspondingly assembled There is the supporting and conveying mechanism, and the two supporting and conveying mechanisms are located between the two inner support and side clip rotating mechanisms; the device involved in the method provided by the present invention can cooperate with the spraying process of the round pipe plastic-steel profile to carry out the spraying operation , can realize streamlined spraying processing operations, greatly improving the efficiency of processing, in addition, the uniformity of spraying and the quality of spraying are improved by means of rotary spraying.

Owner:西卡(广东)新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com