Adjustable garment fabric spraying and drying device

A drying device and adjustable technology, applied in the field of garment processing, can solve the problems of low efficiency, trouble, adjustment, etc., and achieve the effects of labor-saving adjustment, easy operation, and highly synchronous change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

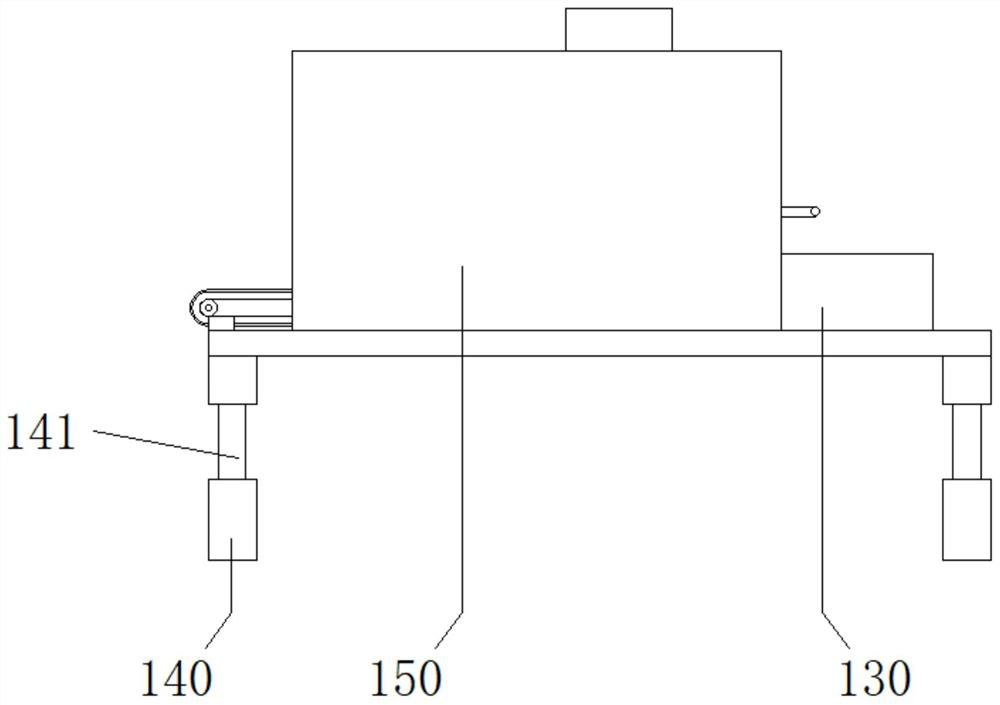

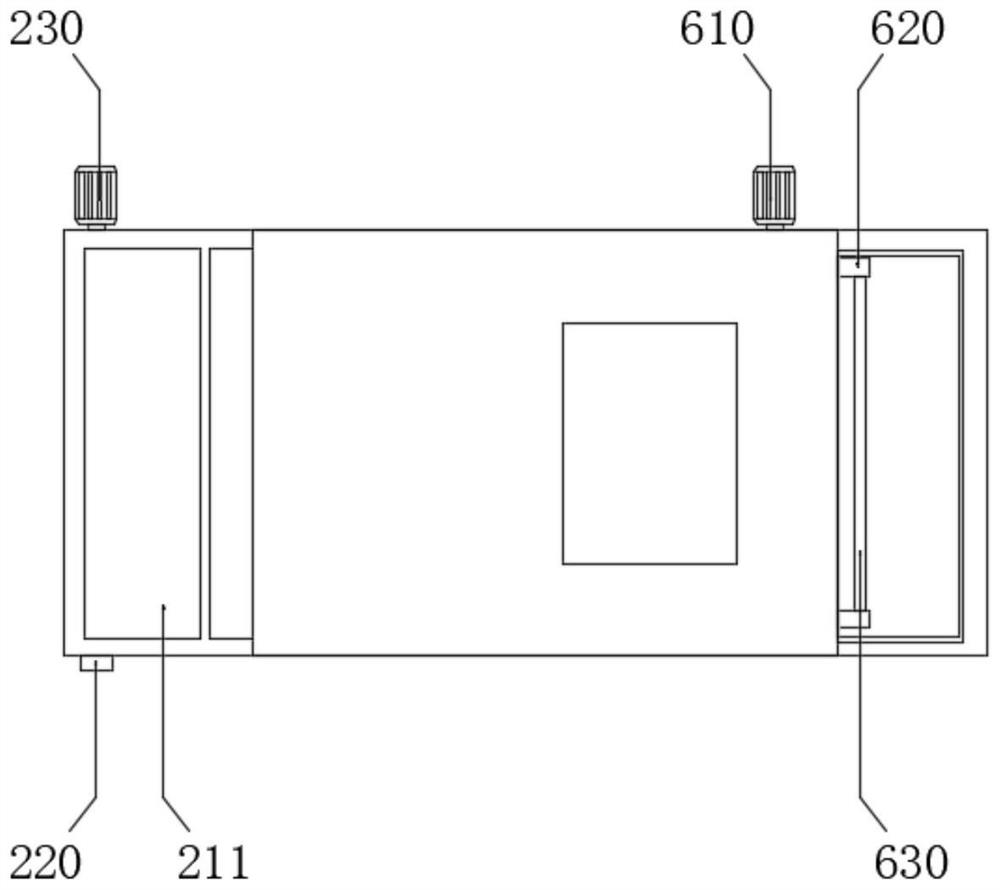

[0032] see Figure 1-5 , the present invention provides a technical solution: an adjustable spraying and drying device for clothing fabrics, including a device main body 100 , a conveyor 200 , a spraying mechanism 300 and a drying mechanism 500 .

[0033] Among them, the conveyor 200, the spraying mechanism 300 and the drying mechanism 500 are all fixedly installed on the upper part of the device main body 100, the spraying mechanism 300 and the drying mechanism 500 are all located on the upper part of the conveyor 200, and the conveyor 200 is used to transport fabrics for various processes. The spraying mechanism 300 is used to design and spray different patterns on the fabric, and the drying mechanism 500 is used to dry the fabric that has just been sprayed.

[0034] see Figure 1-2 and Figure 6 , the device main body 100 includes a workbench 120 and a protective cover 150, the protective cover 150 is fixedly installed on the upper part of the workbench 120, the protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com